Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid mutual dislocation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

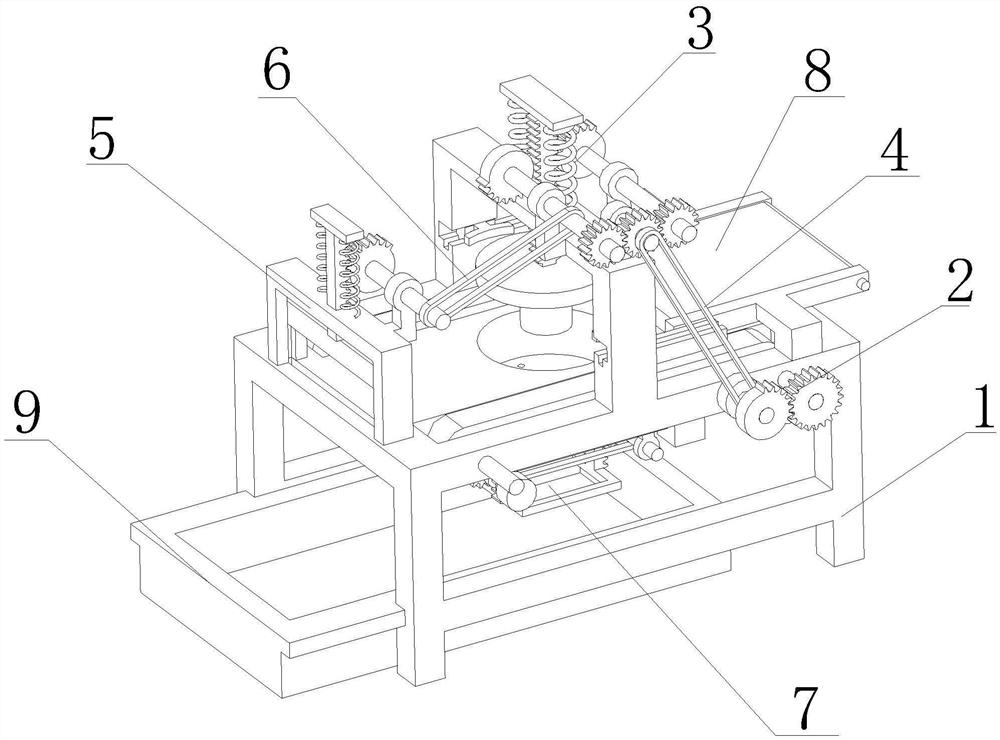

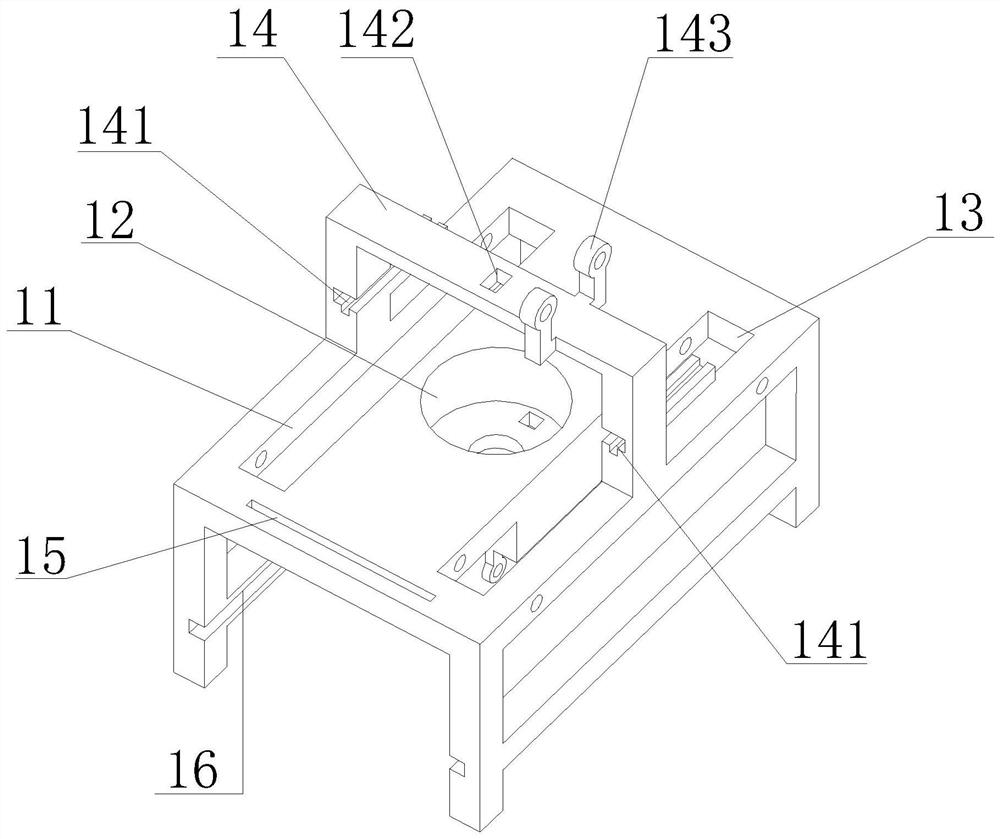

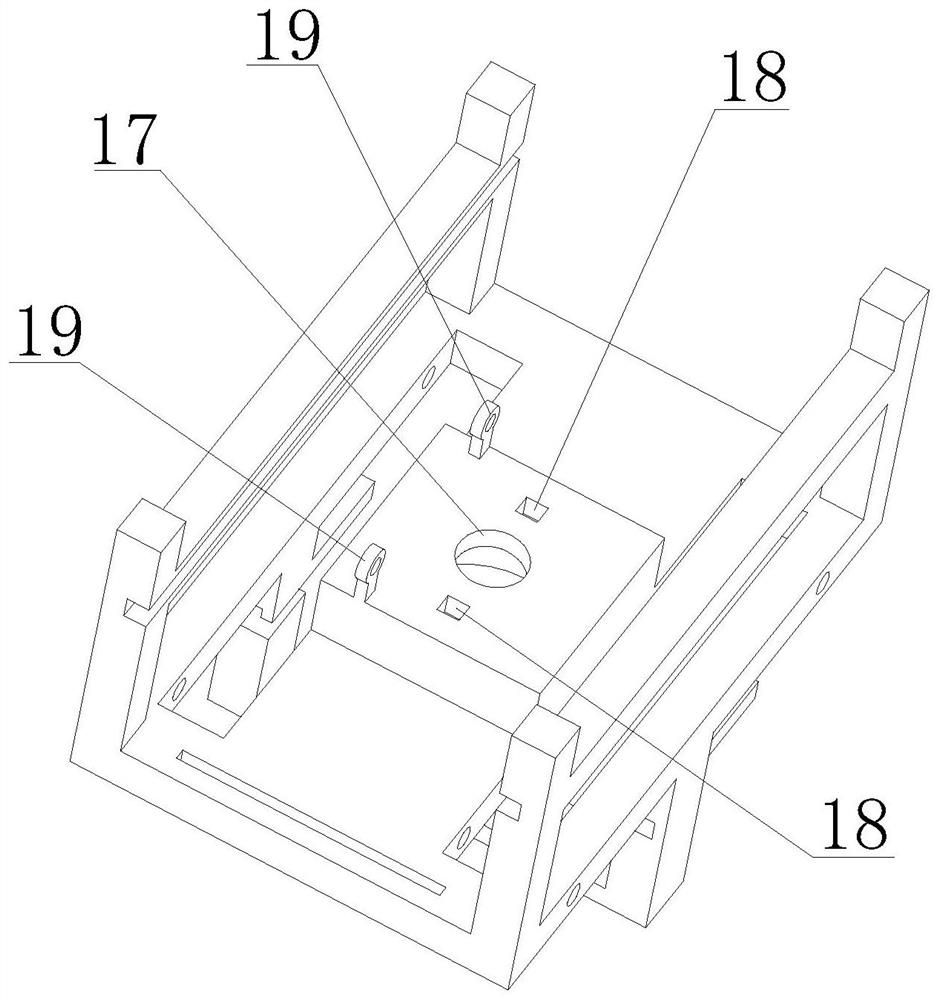

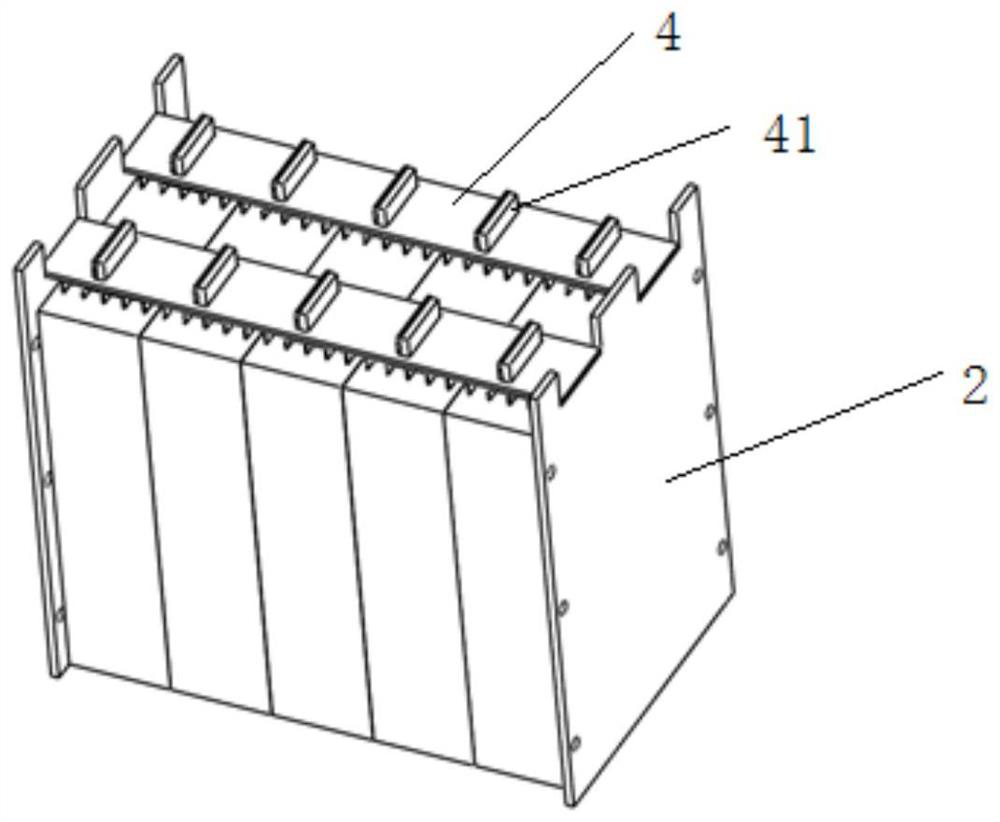

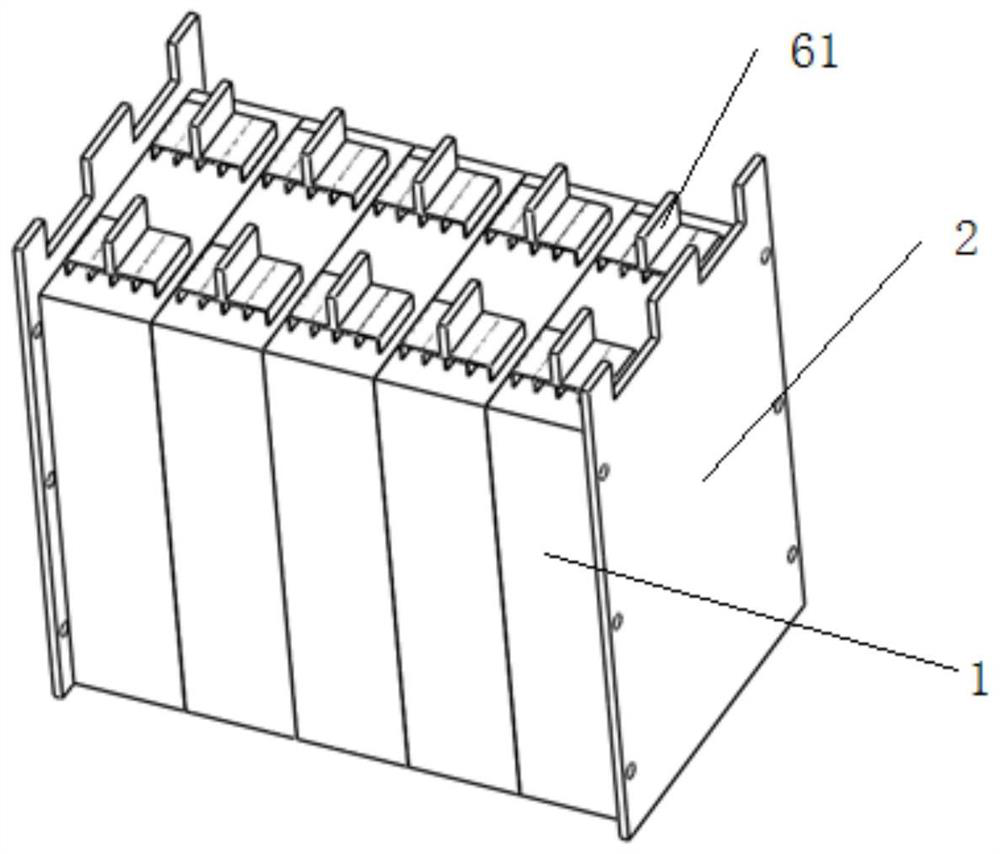

Motor iron core and machining device thereof

ActiveCN112910192AAvoid mutual dislocationGuaranteed concentricity combined with perpendicularityManufacturing stator/rotor bodiesPunchingElectric machine

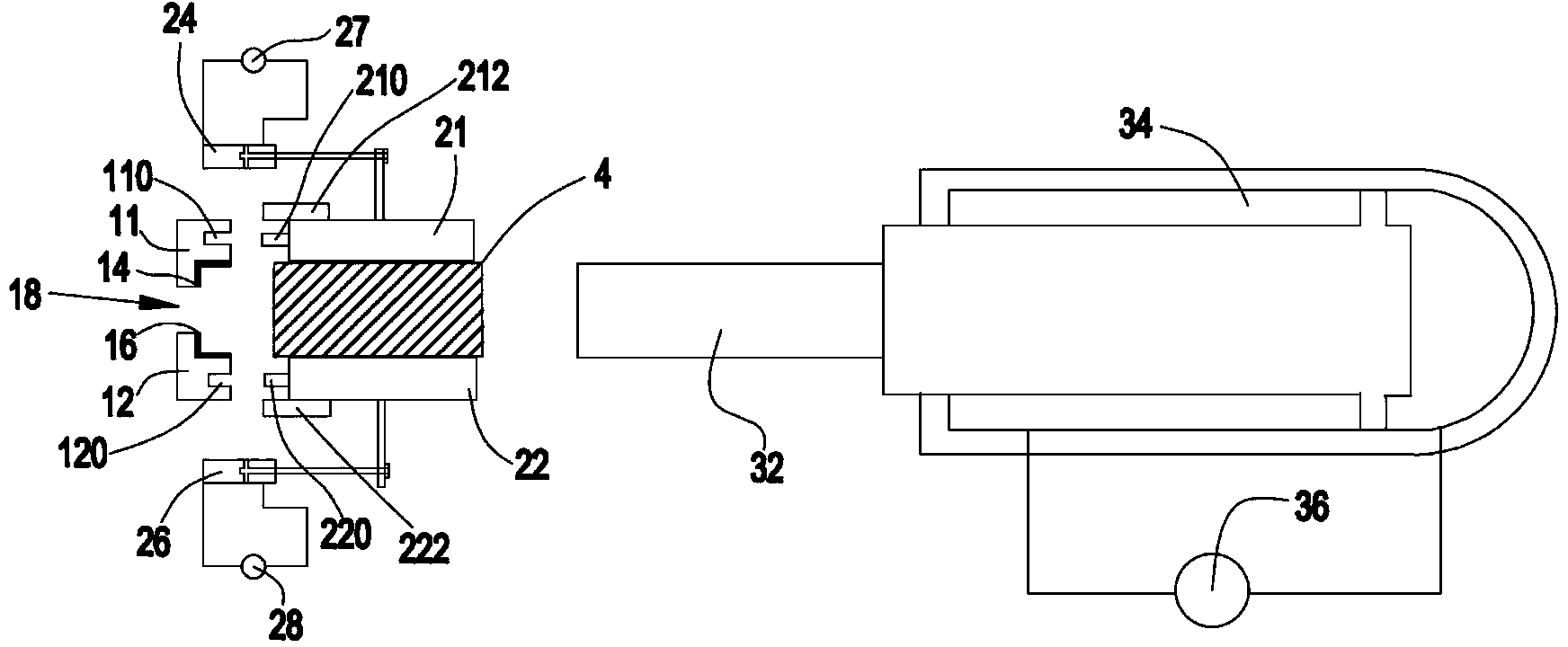

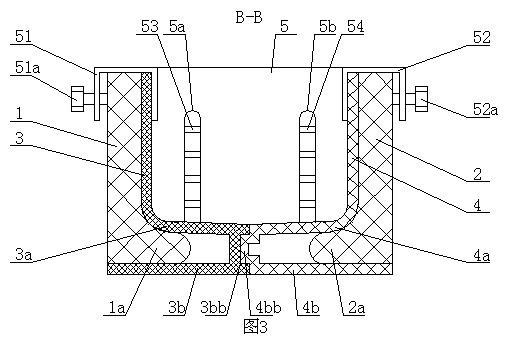

The invention discloses a motor iron core and a machining device thereof, and belongs to the field of motor iron core machining. The machining device of the motor iron core comprises a workbench, a punching mechanism, a jacking plate, positioning holes, a third punches, a cutting-off mechanism, a jacking mechanism and a discharging mechanism. The punching mechanism is installed on the workbench to achieve punching of silicon steel sheets and pre-lamination of punching sheets, the jacking plate is installed in the workbench, multiple positioning holes are formed in the jacking plate, and the positioning holes correspond to the third punches in a one-to-one mode, so that dislocation between the punching sheets is avoided, and the coaxiality and perpendicularity of iron cores are guaranteed; the cutting-off mechanism is arranged on the workbench to cut off the silicon steel sheet offcut, so that the silicon steel sheet offcut is convenient to recycle; the jacking mechanism is mounted at the lower end of the workbench, so that the iron core transplanting convenience is improved; and the discharging mechanism is arranged above the workbench, so that the iron core is transplanted.

Owner:浙江宝捷机电有限公司

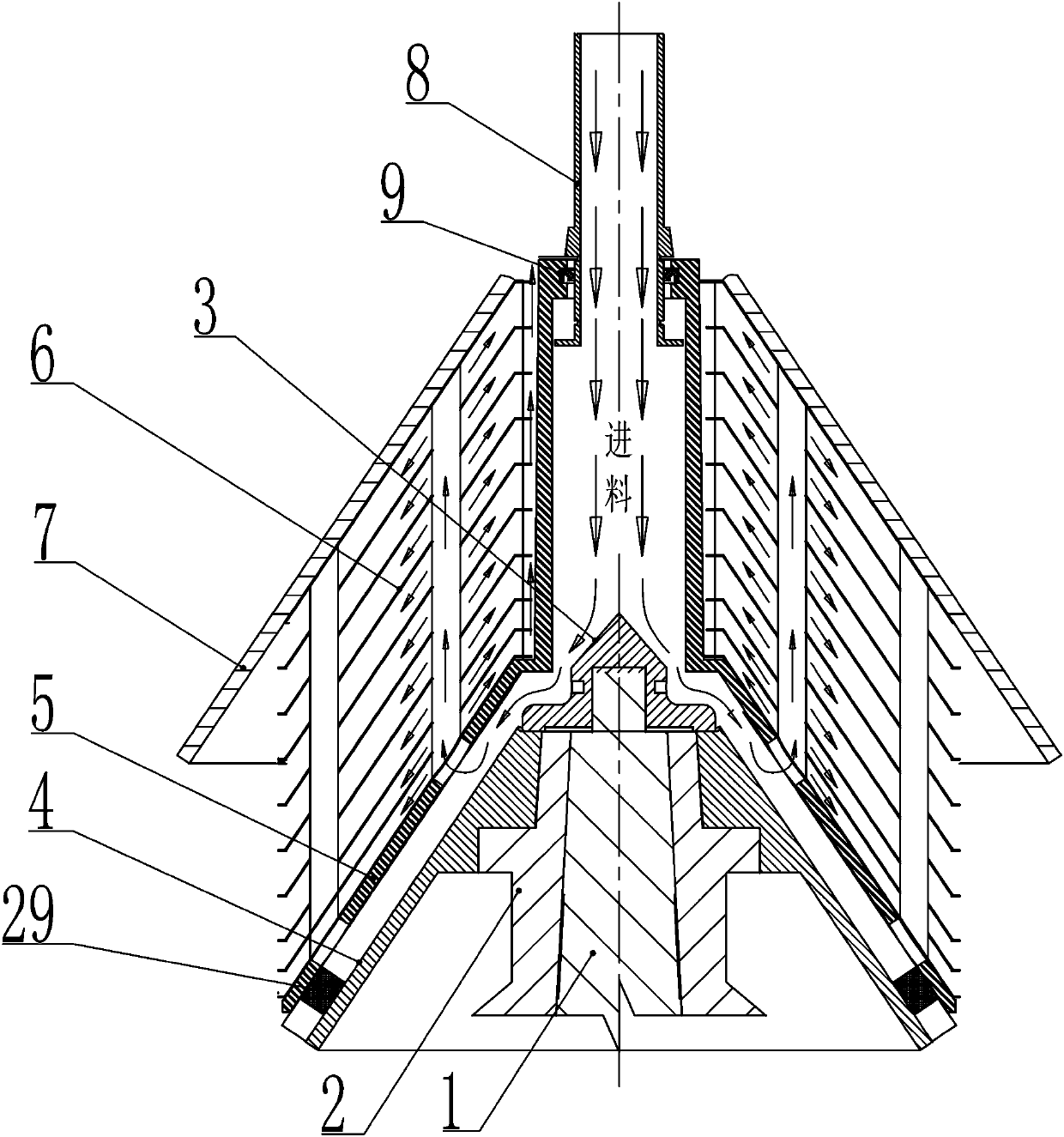

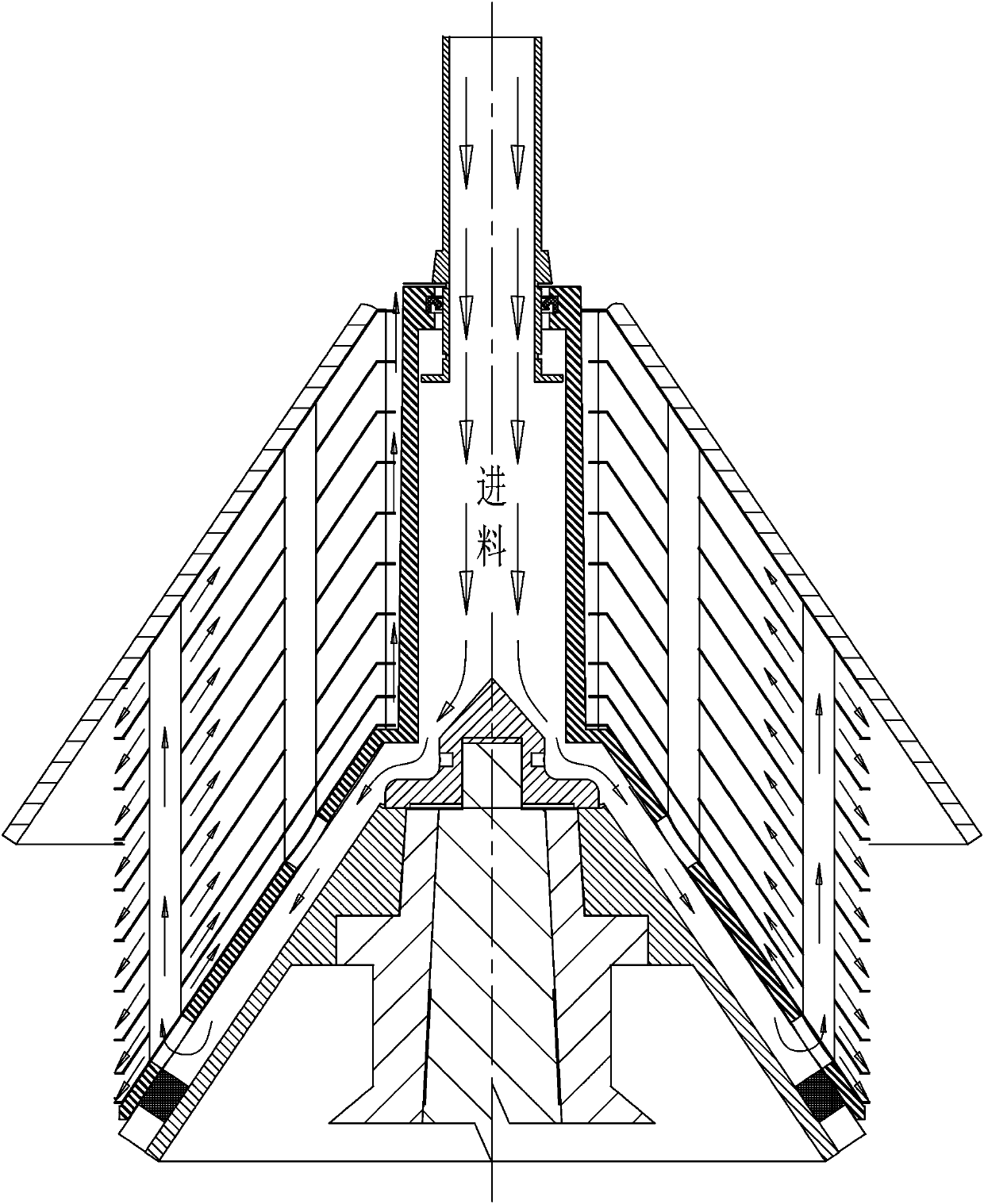

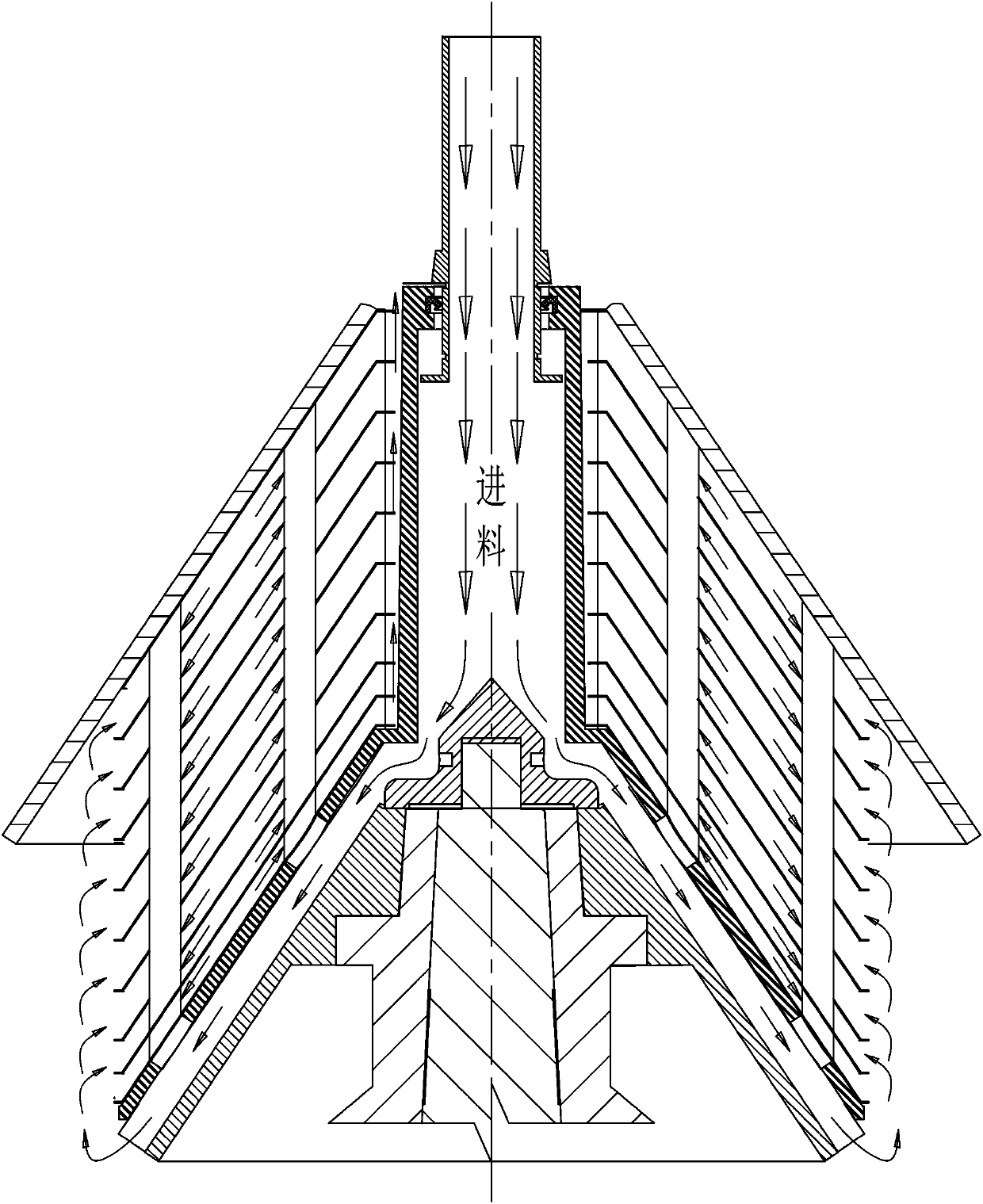

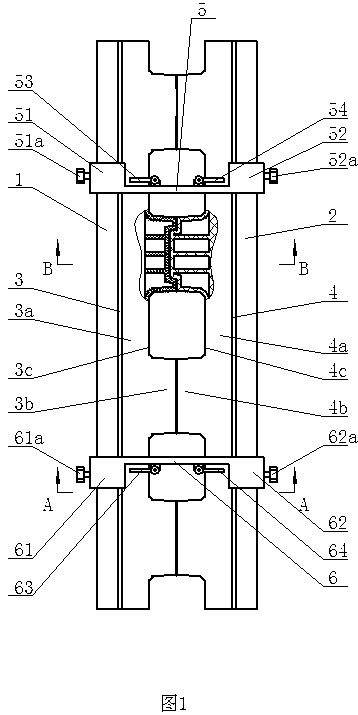

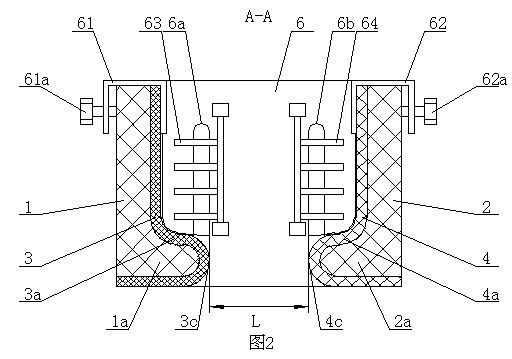

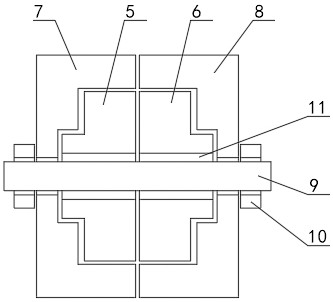

Aluminium profile extrusion device

InactiveCN103537508AAchieve mutual positioningGuaranteed extrusion effectExtrusion diesExtrusion containersExtrusionAluminium

The invention provides an aluminium profile extrusion device which comprises an extrusion rod and an aluminium profile extrusion chamber matched with the extrusion rod, wherein the aluminium profile extrusion chamber is defined by a first mould base, a second mould base, a first material liner and a second material liner together; a discharge hole for molding a product is formed between the first mould base and the second mould base; mold inserts are fixed in the first mould base and the second mould base; first matching parts are arranged on the first material liner and the second material liner; second matching parts are arranged on the first mould base and the second mould base; the first matching parts and the second matching parts are respectively formed on contact surfaces between the material liners and the mould bases. The mould bases and the material liners are respectively provided with concave parts and convex parts which are matched with each other, so that the relative location between the mould bases and the material liners can be realized, the mould bases and the material liners are prevented from being staggered from each other along the vertical direction, and furthermore, the extrusion effect of aluminium profiles and the long-term operation of the extrusion device are guaranteed.

Owner:张家港市昊天金属科技有限公司

EPP seat foaming die and foaming technology

InactiveCN109571846AHigh strengthGuaranteed support strengthUltimate tensile strengthMechanical engineering

Owner:成都东神汽车零部件有限公司

Petroleum refining pipeline flange butt joint equipment capable of avoiding abrasion and dislocation

The invention discloses petroleum refining pipeline flange butt joint equipment capable of avoiding abrasion and dislocation in the technical field of flange mounting equipment. A bottom plate, a mounting frame, a sliding rod and sliding sleeves are included, two groups of connecting blocks are in cup joint to the outer wall of a threaded rod, the outer walls of the bottoms of the connecting blocks are fixedly connected with the outer walls of the tops of the sliding sleeves, and fixing devices are arranged on the outer walls of the bottoms of the sliding sleeves. A detection device is arranged on the outer wall of the bottom of the sliding rod, the left end and the right end of the detection device are connected with the outer walls of the sides, close to each other, of the two sets of fixing devices correspondingly, the device inclines along with dislocation of the fixing devices through a mounting rod, conductive liquid flows towards one side of a storage groove, conductive pieces inside are connected, an LED lamp is powered on to work, and the prompting effect is achieved; and a worker can know the dislocation condition of the two fixing devices in time, timely adjustment is facilitated, the phenomenon that the flange plate is damaged in the installation process due to dislocation is avoided, and the sealing performance of pipeline installation is guaranteed.

Owner:山东恩乐驰锻造有限公司

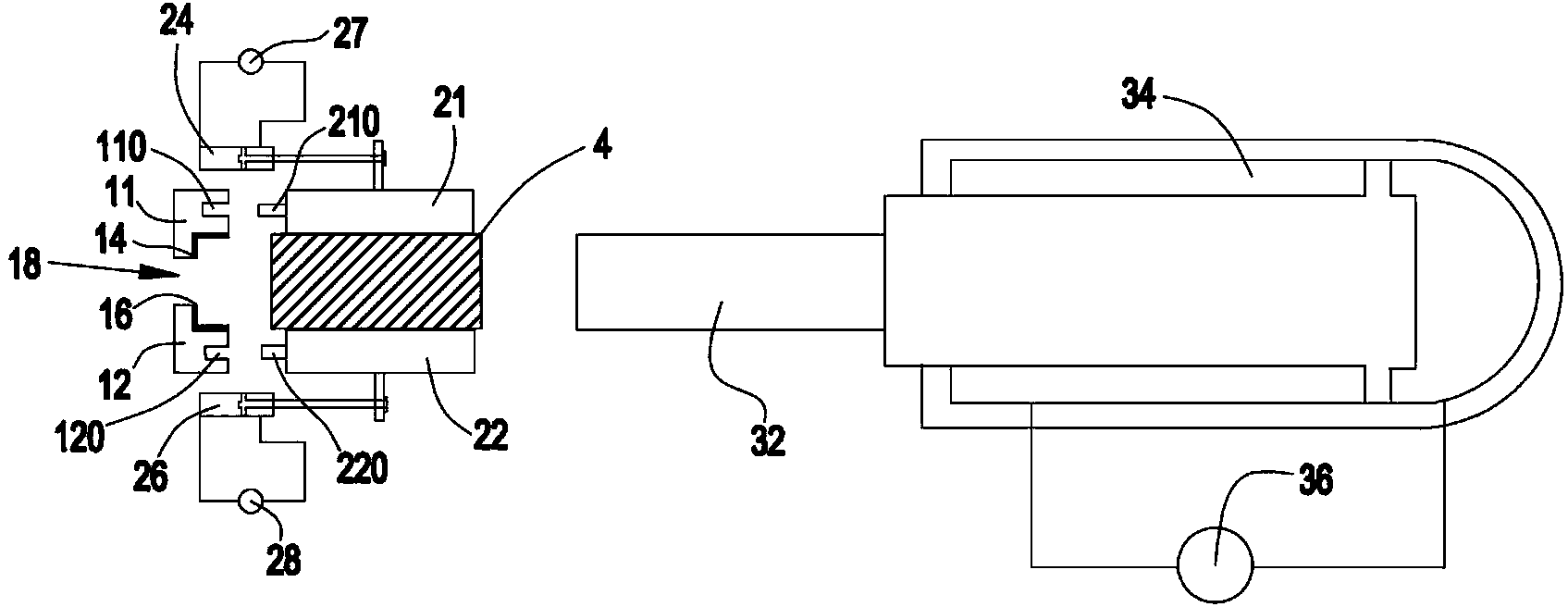

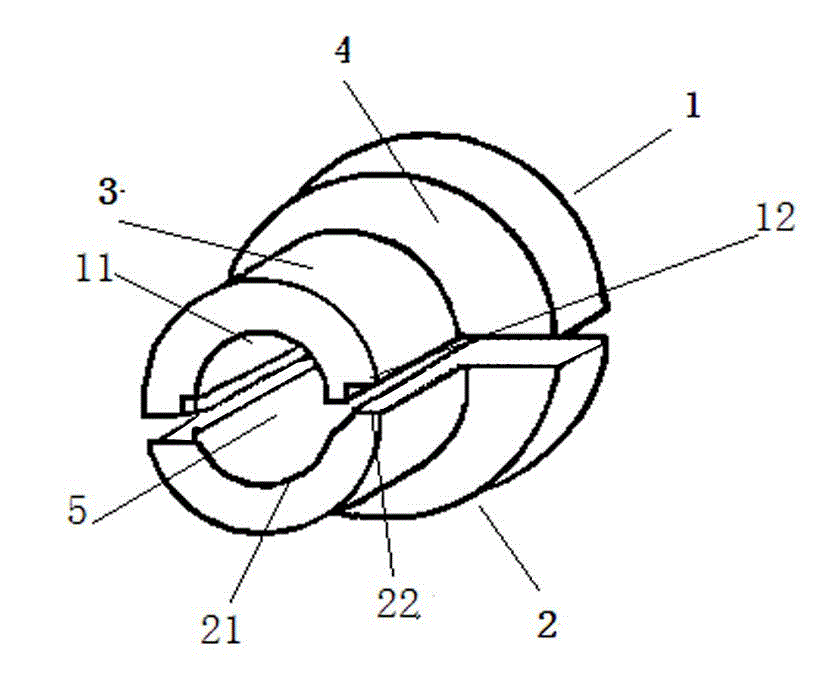

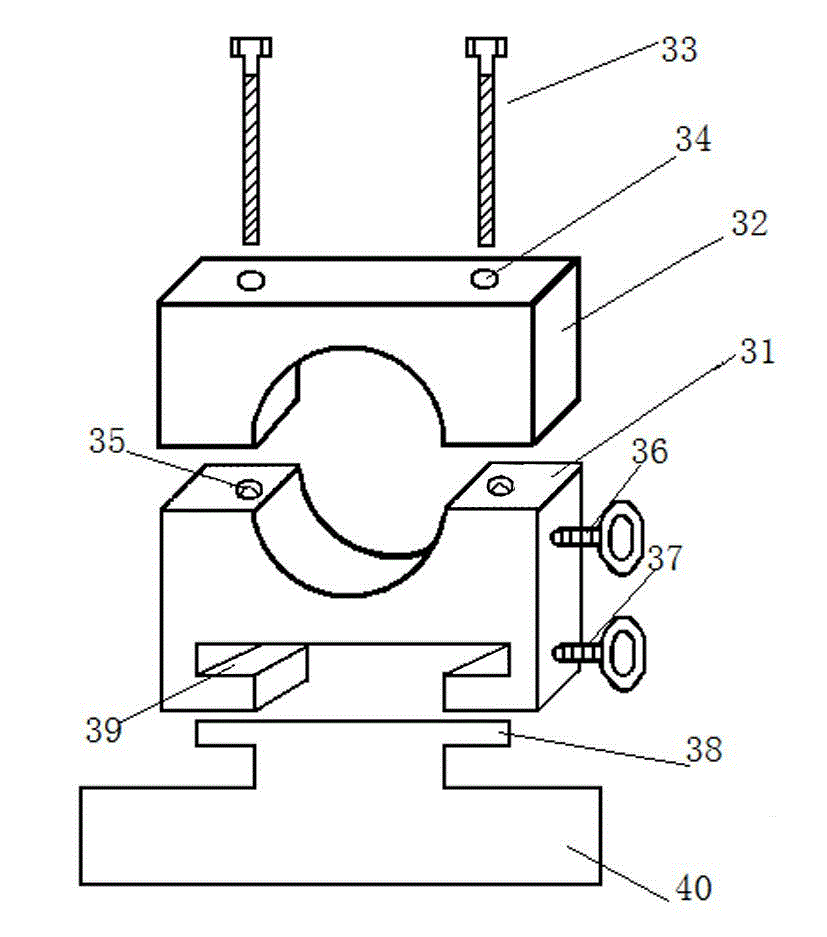

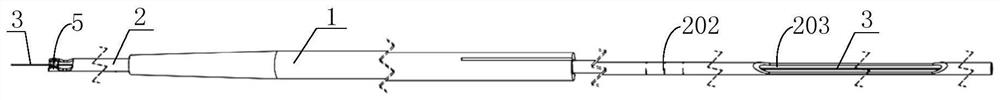

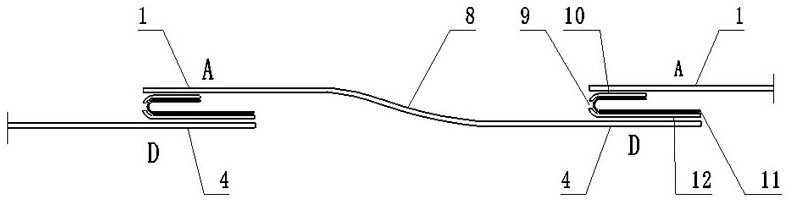

Cable core longitudinal wrapping production line and cable core longitudinal wrapping sizing die device

InactiveCN104464980AReduce maintenance costsEasy to operateCable/conductor manufactureProduction lineSizing

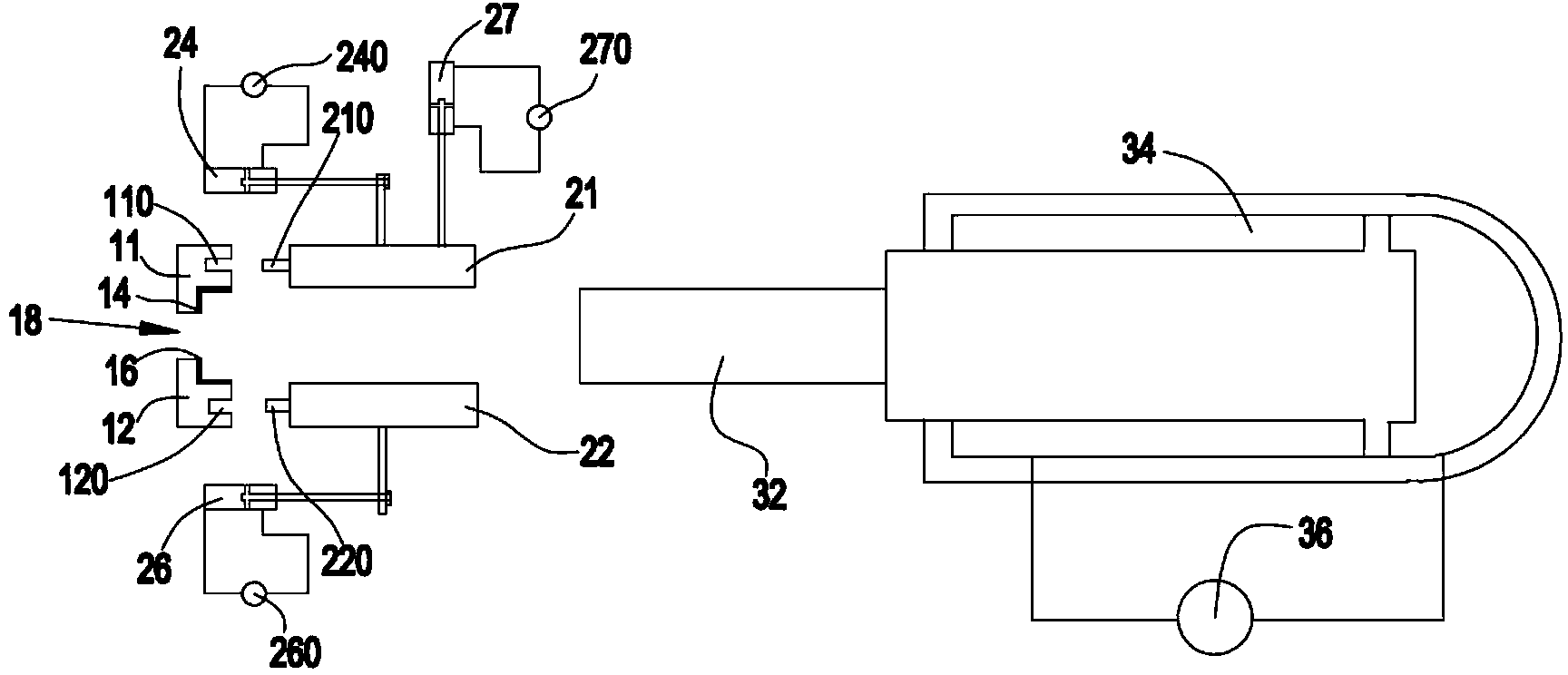

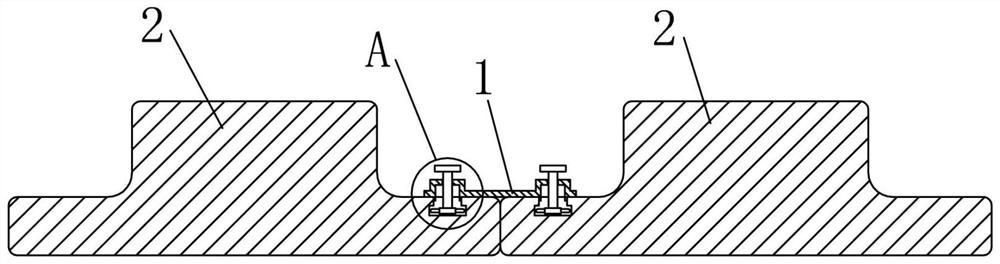

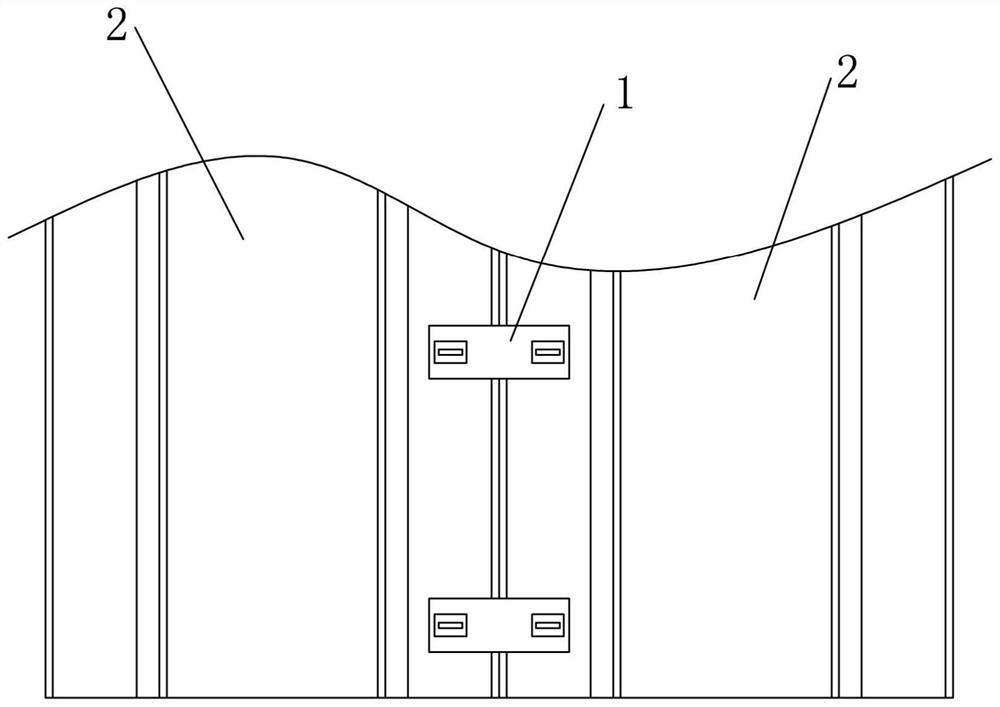

The invention provides a cable core longitudinal wrapping production line and a cable core longitudinal wrapping sizing die device. The sizing die device comprises a sizing die which comprises an upper die and a lower die, the upper die and the lower die are buckled together when used, the opposite buckling side faces of the upper die and the lower die are each provided with an arc-shaped groove, and a sizing hole through which a cable core penetrates is formed by the arc-shaped grooves when the upper die and the lower die are buckled. The sizing die device further comprises a sizing die base used for supporting the sizing die, the sizing die base comprises an upper die base body and a lower die base body, the upper die base body and the lower die base body are detachably assembled together and are close to each other in the vertical direction so as to fixedly clamp the upper die and the lower die, the opposite side faces of the upper die base body and the lower die base body are each provided with an assembling groove, and an assembling hole matched with the appearance of the sizing die in an inserted mode when the upper die base body and the lower die base body are assembled. When local damage is caused to the sizing die, the upper die or the lower die can be replaced, and maintenance cost is reduced; besides, during replacement, the upper die base body and the lower die base body can be directly disassembled, the upper die or the lower die needing to be replaced is taken out, and operation is convenient.

Owner:HENAN COMM CABLE

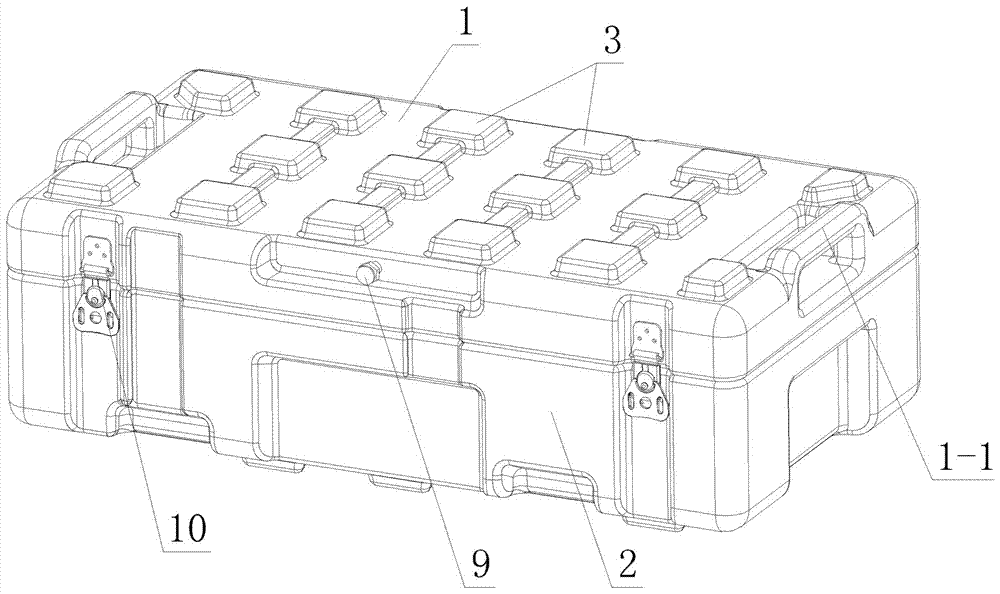

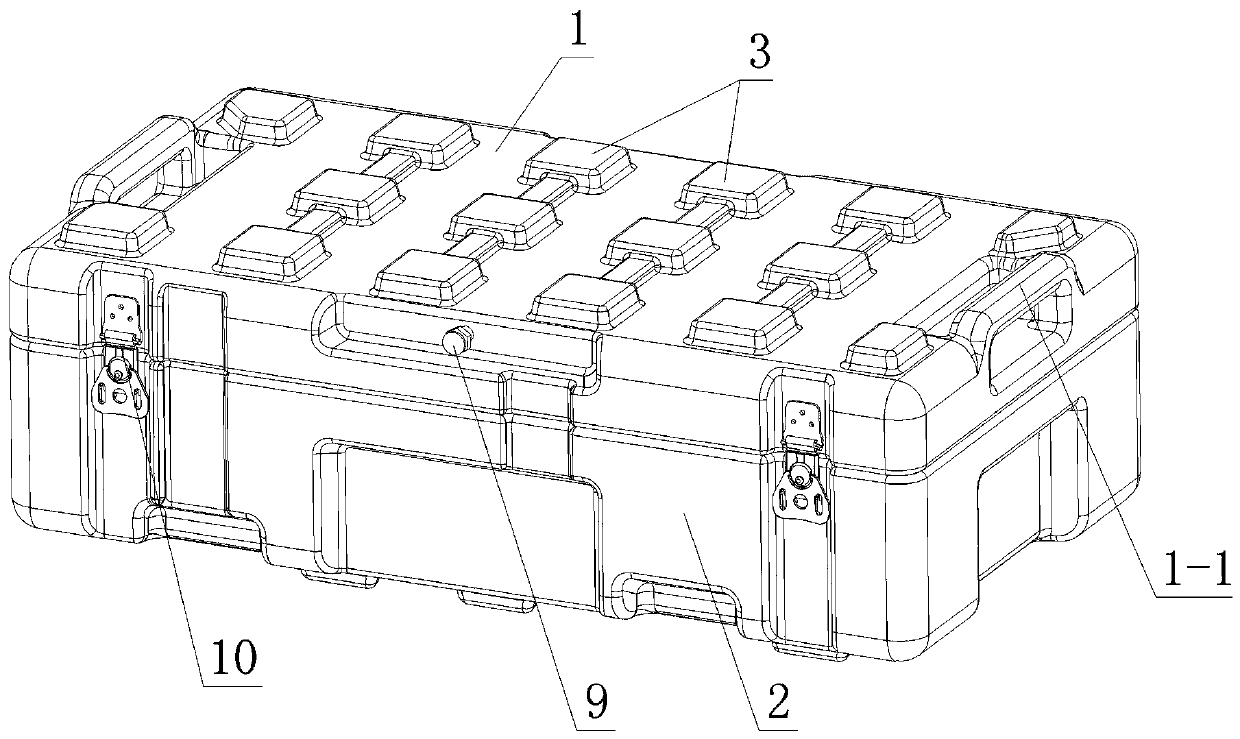

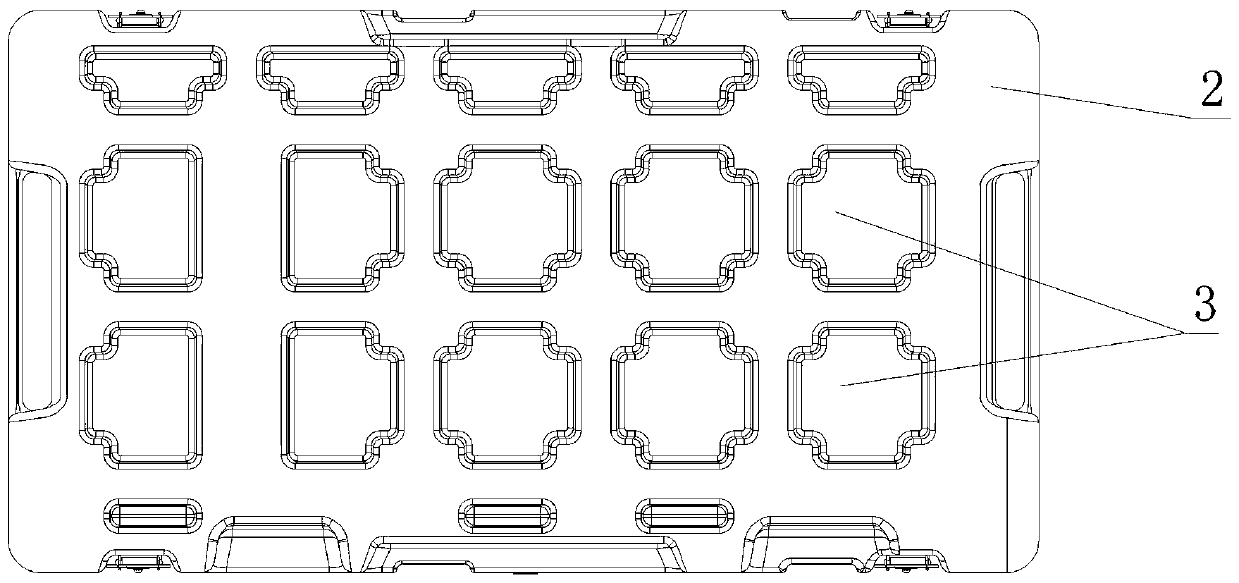

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

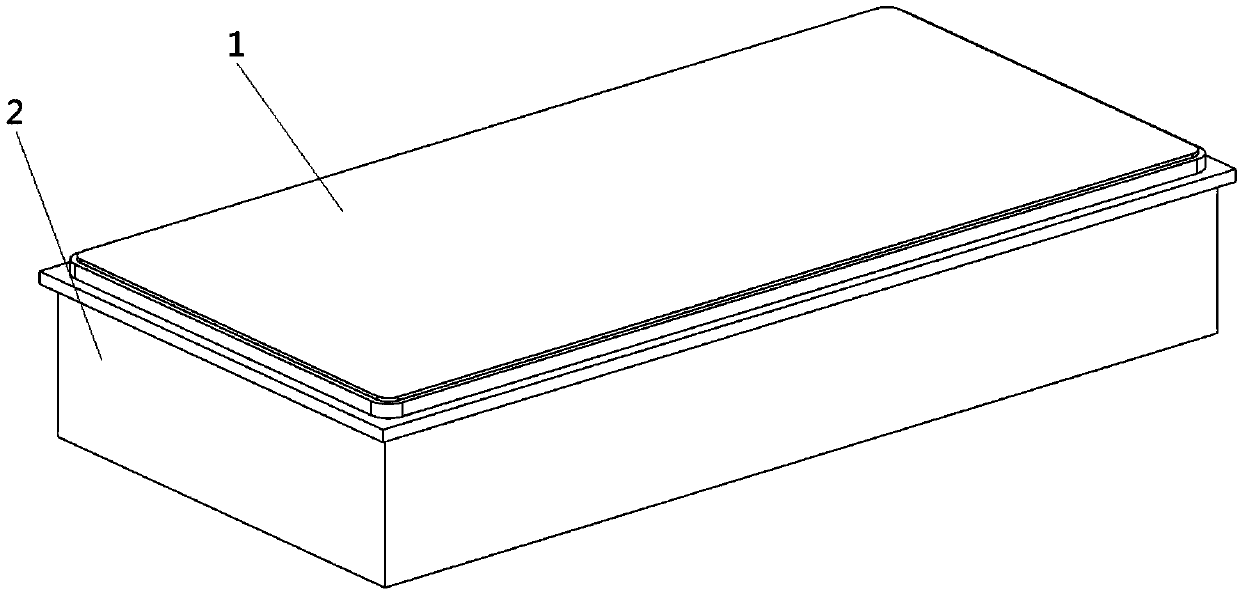

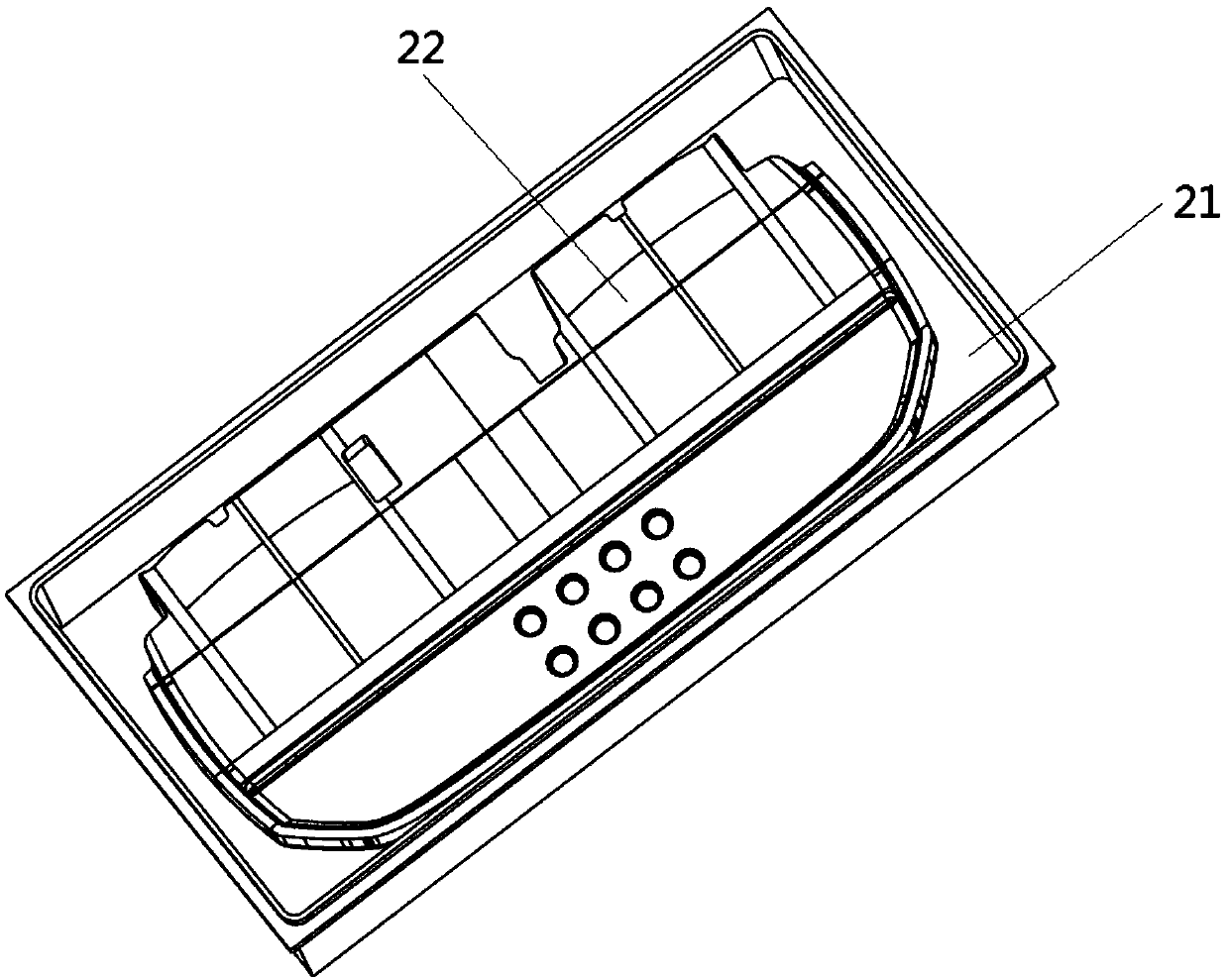

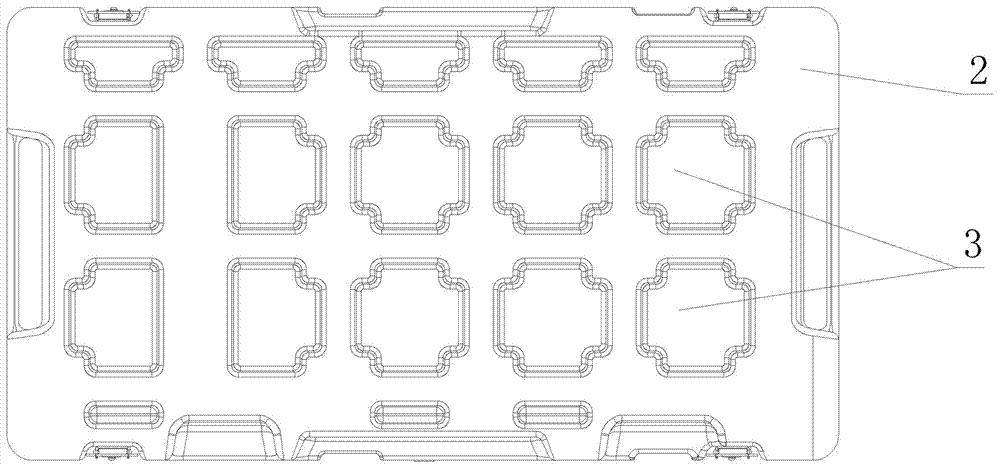

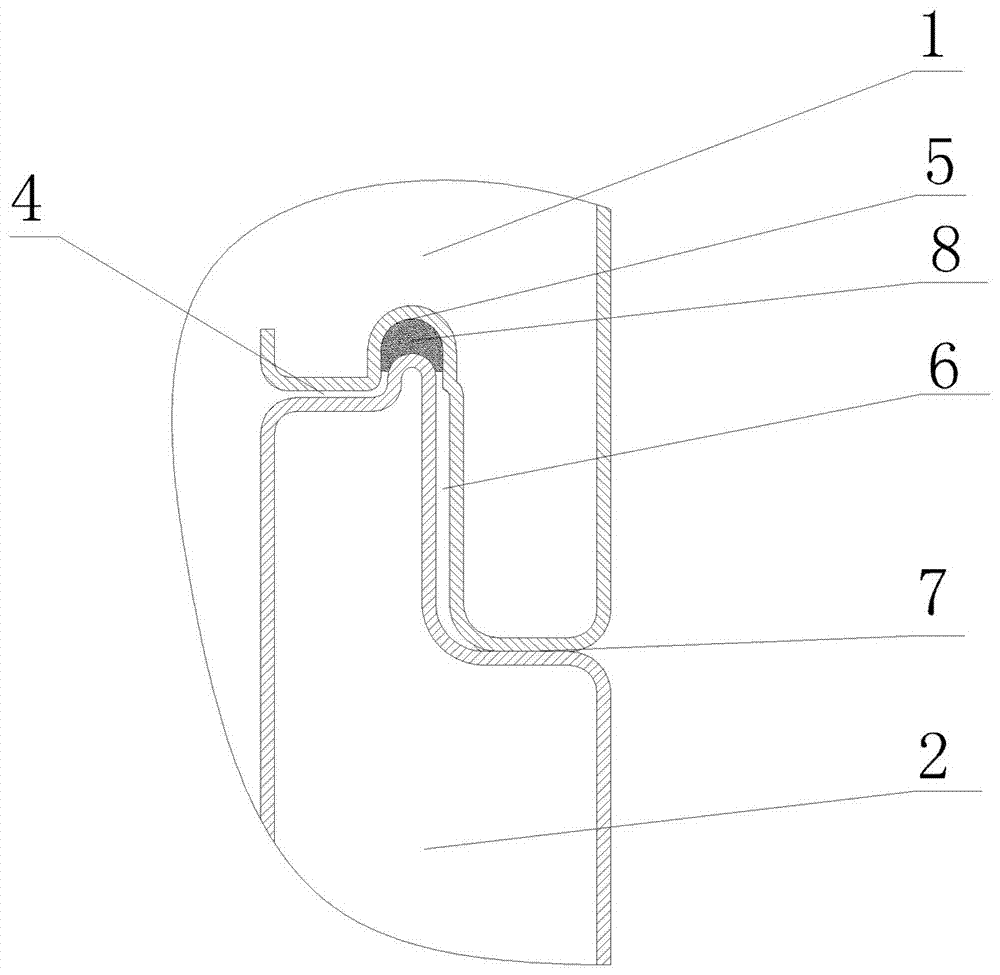

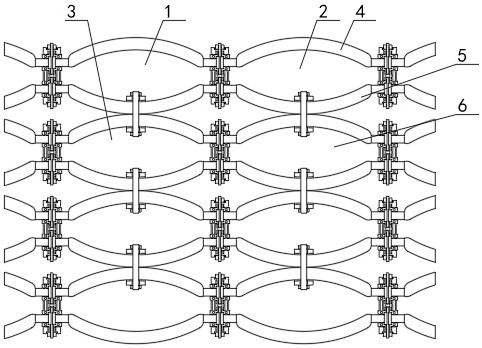

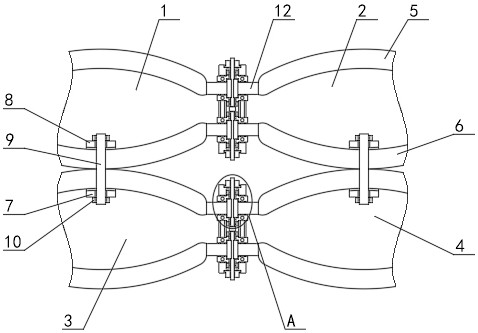

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

Changeable flow channel structure of multifunctional disc type separator capable of changing multiple flow channels

The invention relates to a changeable flow channel structure of a multifunctional disc type separator capable of changing multiple flow channels. A locking screw cap is positioned at the upper end ofa disc bracket base, is screwed on the external threads at the top of a center shaft, and is pressed on the disc bracket base; the disc bracket base is pressed on the outer conical surface of the lower body of a rotating drum in a sleeving manner; the lower body of the rotating drum is pressed on the outer conical surface of the top of the central shaft in the sleeving manner; the upper side of the disc bracket base is matched with a disc bracket; a plurality of flow channels are enclosed between the disc bracket base and the disc bracket; a detachable plug is fixed to the lower end of each flow channel; a plurality of layers of discs with gaps therebetween are arranged on the disc bracket in a sleeving manner; the discs are compressed through a disc pressing cap on the uppermost side; thedisc bracket is provided with double rows of lower cone through holes; and each disc is provided with a single row of upper through holes or a single row of lower through holes which communicate withthe lower cone through holes of the disc bracket or is not provided with the through holes. According to the changeable flow channel structure of the multifunctional disc type separator capable of changing the multiple flow channels, a variety of flow channels can be realized.

Owner:SHENYANG POLYTECHNIC UNIV

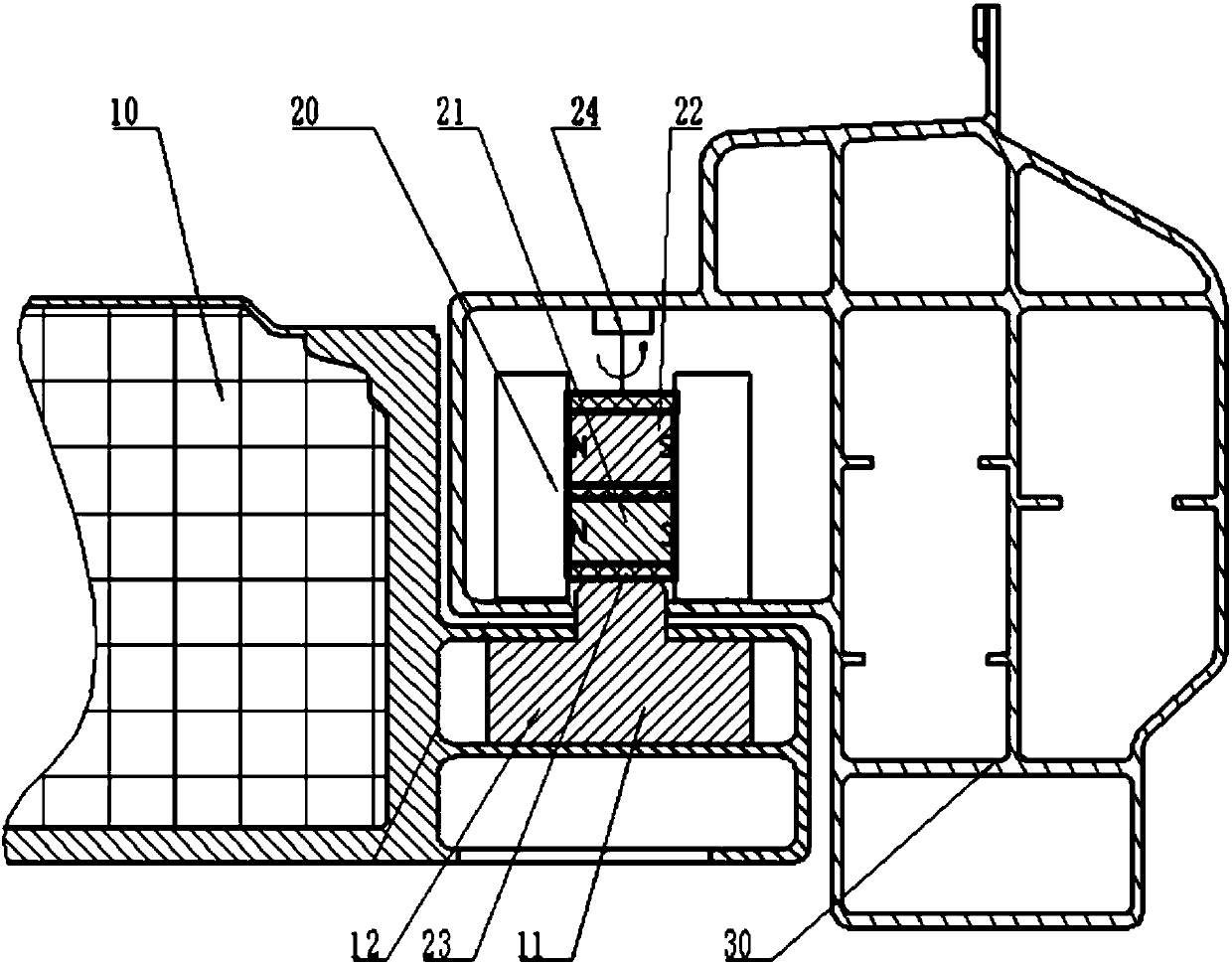

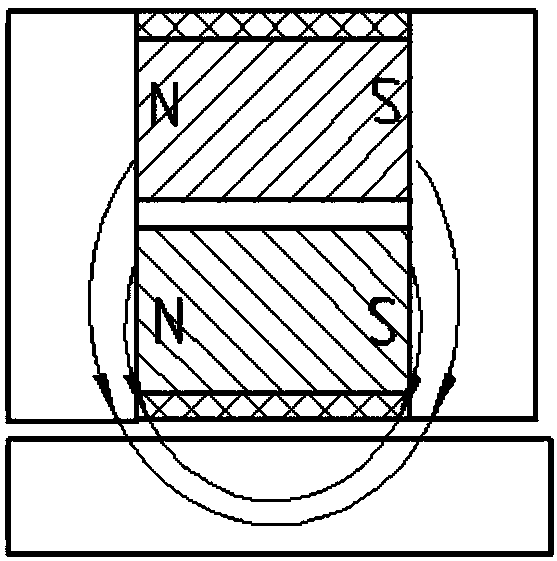

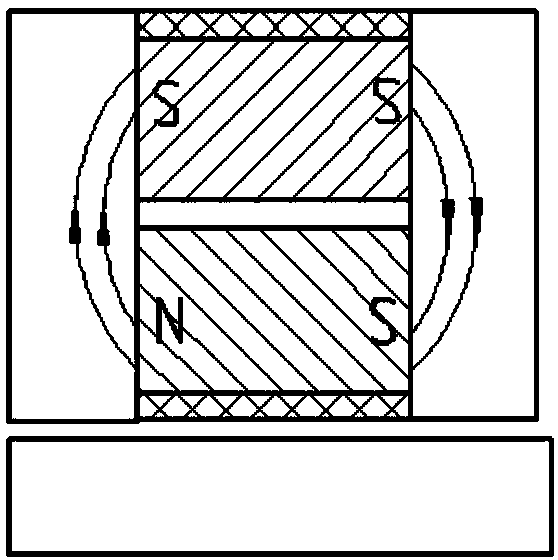

Vehicle body component, battery pack and vehicle provided with battery

PendingCN109878315AEasy to disassembleEasy to installCharging stationsElectric propulsion mountingElectrical batteryBattery pack

The invention relates to a vehicle body component, a battery pack and a vehicle provided with a battery; the vehicle provided with the battery comprises a magnetic force device; the magnetic force device has magnetism in one state and can attract a magnetic object, the magnetic force device has no magnetism in the other state, and an installation positioning device is arranged between the magneticforce device and the magnetic object. According to the vehicle battery quick-changing device, the problem that an existing battery is not easy to assemble and disassemble is solved; the battery can be assembled and disassembled more conveniently and quickly; when the battery breaks down, the battery can be disassembled quickly, and dangers of the vehicle and people in the vehicle are avoided.

Owner:NIO ANHUI HLDG CO LTD

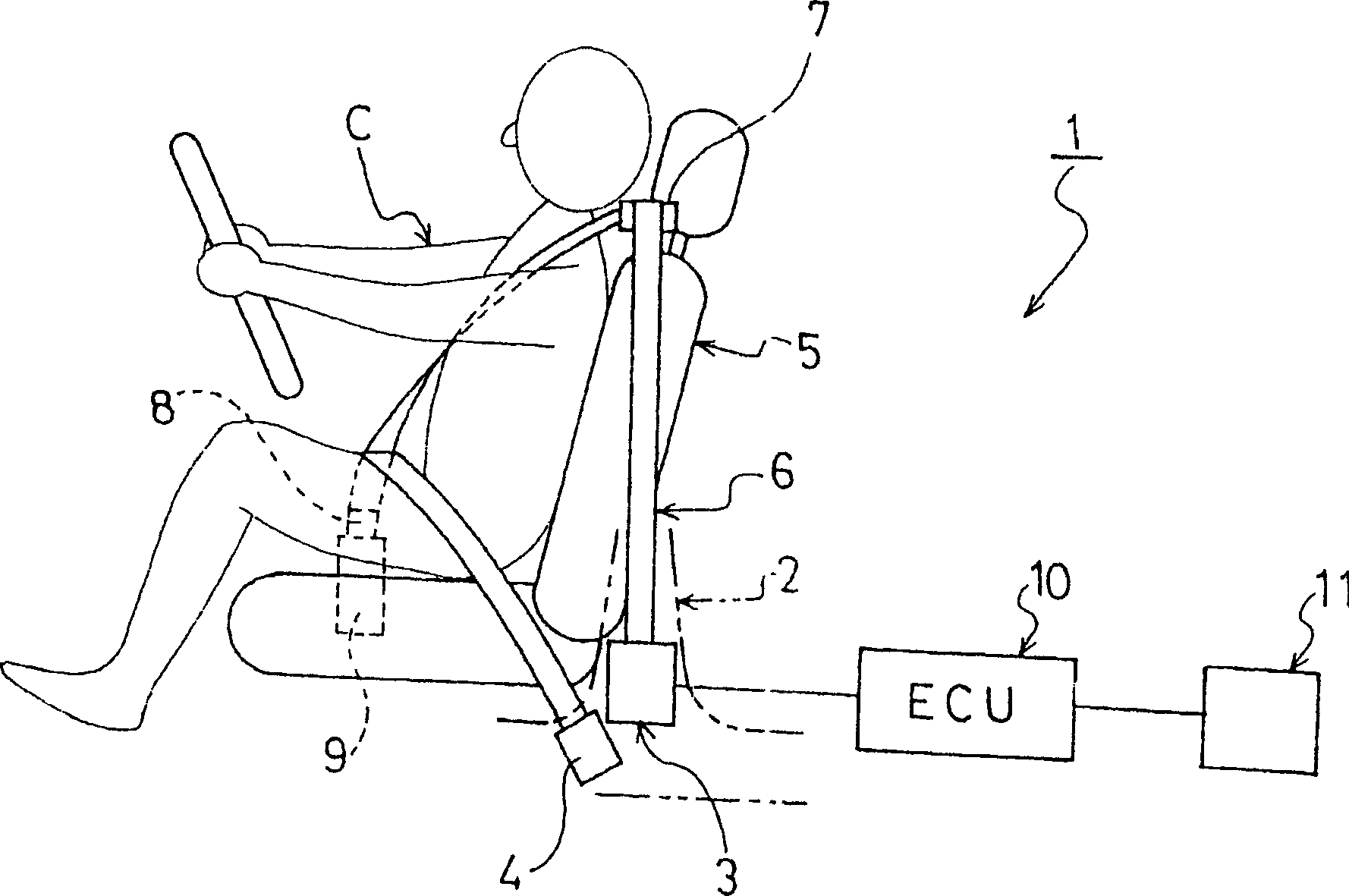

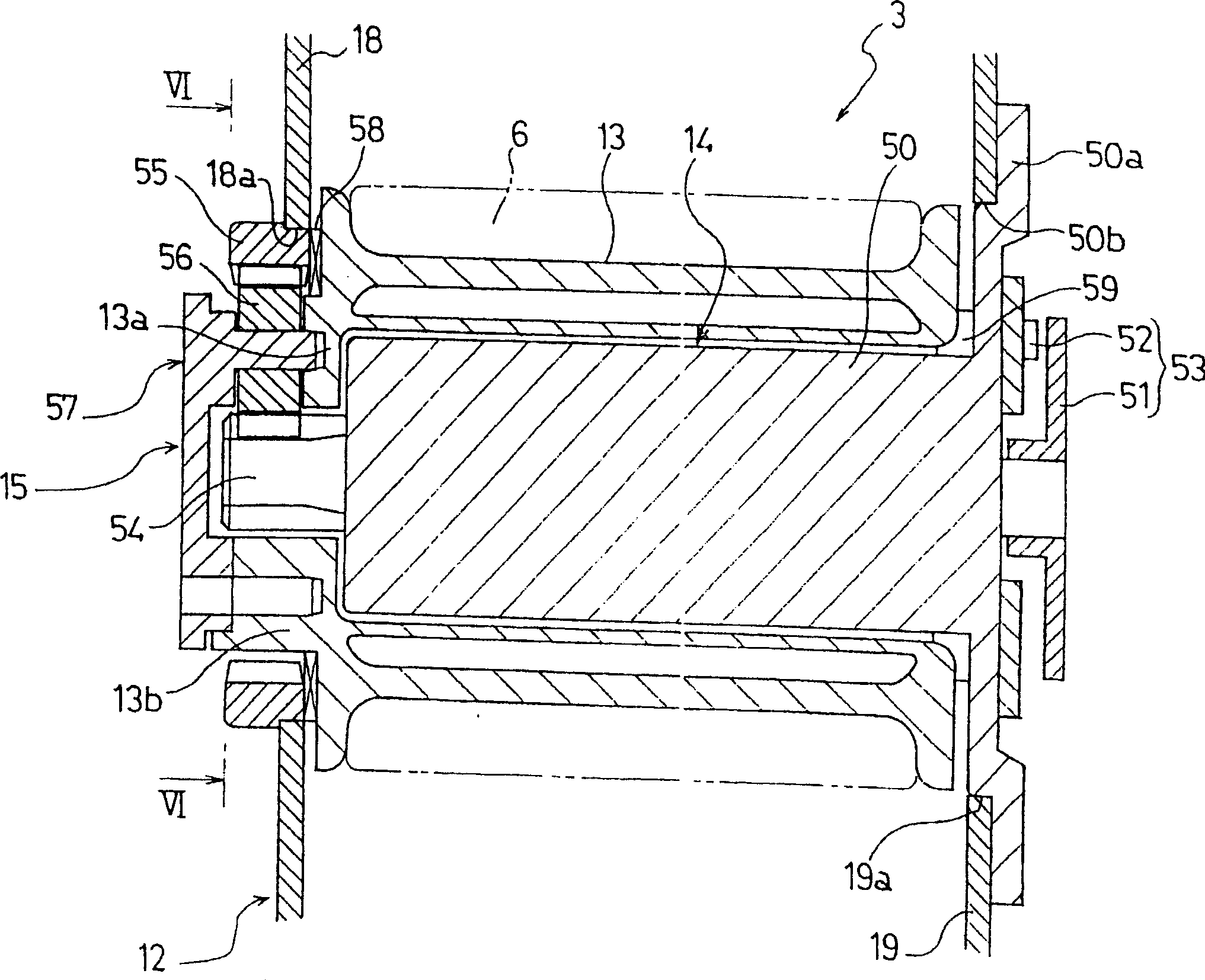

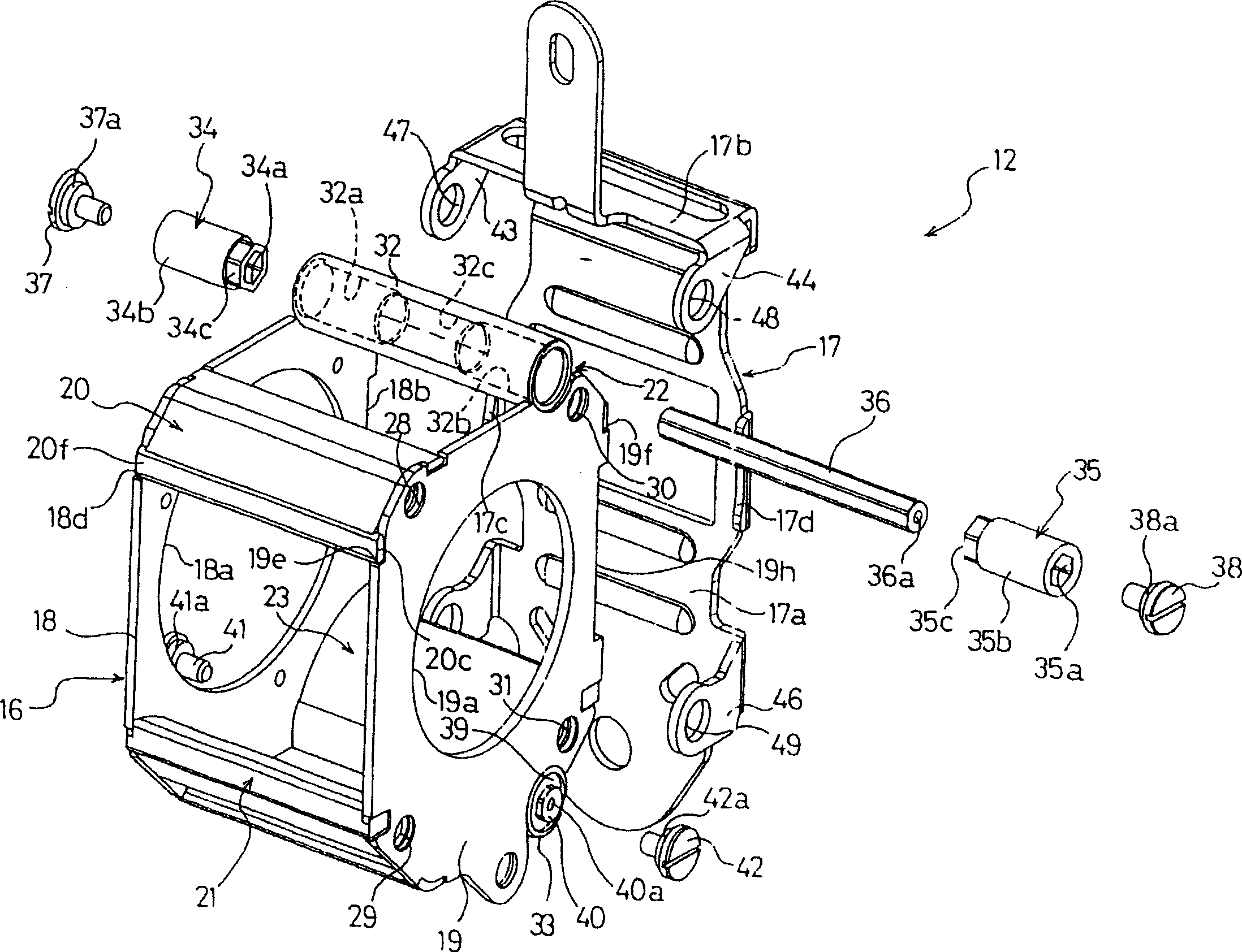

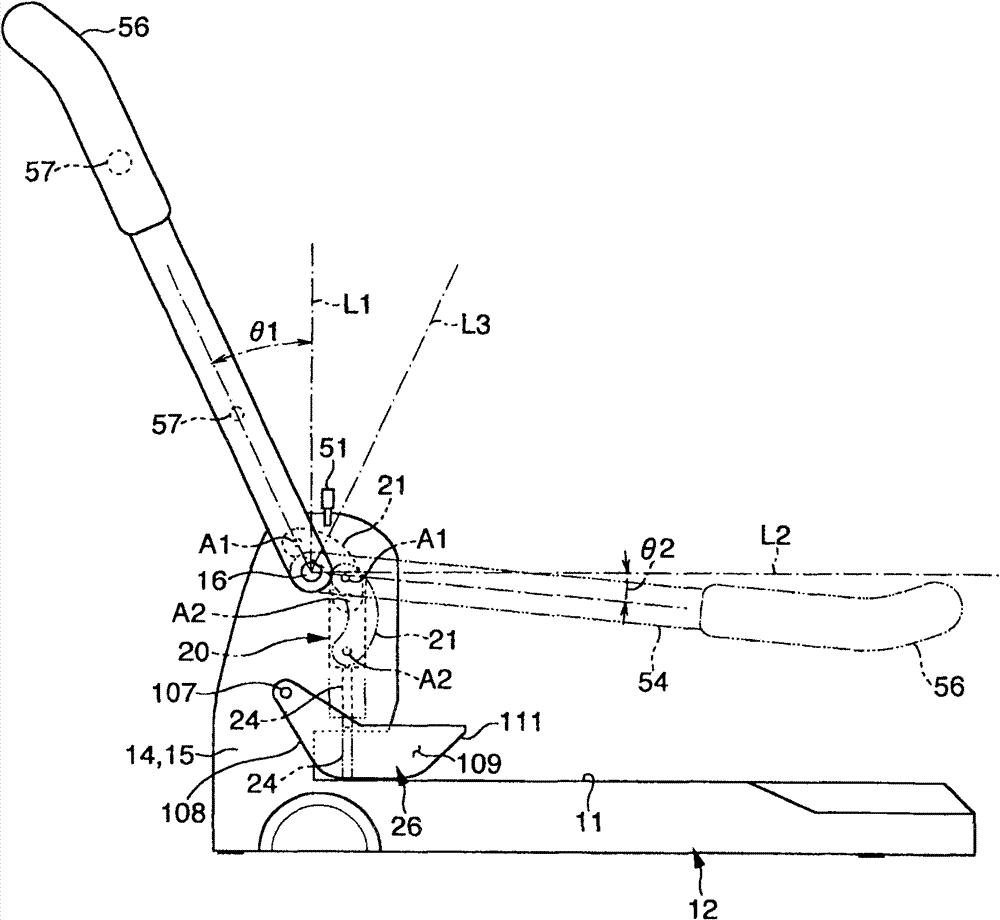

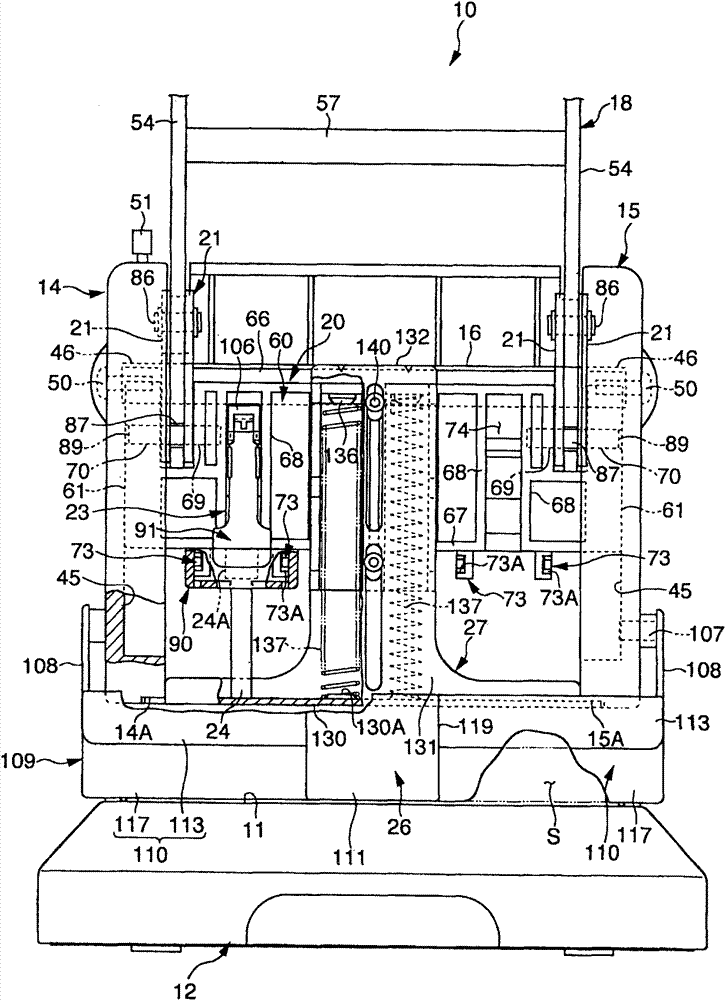

Seatbelt retractor and a seatbelt apparatus having the same

InactiveCN1843812AGuaranteed parallelismImprove assembly accuracyBelt retractorsEngineeringMechanical engineering

This invention provides a seatbelt retractor capable of effectively suppressing occurrence of a vibration and a noise, a base frame (12) is composed of a first frame (16) for rotatably supporting a spool, and a second frame (17) to be attached to a motor vehicle body. The first frame (16) is composed of a pair of flat plate-shaped first and second supporting members (18 and 19), and spacing members (20, 21, 22, and 23) that couple the pair of the first and second supporting members (18 and 19). Further, the degree of the parallelization of the pair of the first and second supporting members (18 and 19) is obtained with high accuracy by the spacing member. Accordingly, an assembling accuracy for a spool can be improved and, thereby, a vibration and a noise caused by a rotation of the spool can be suppressed.

Owner:TAKATA CORPORATION

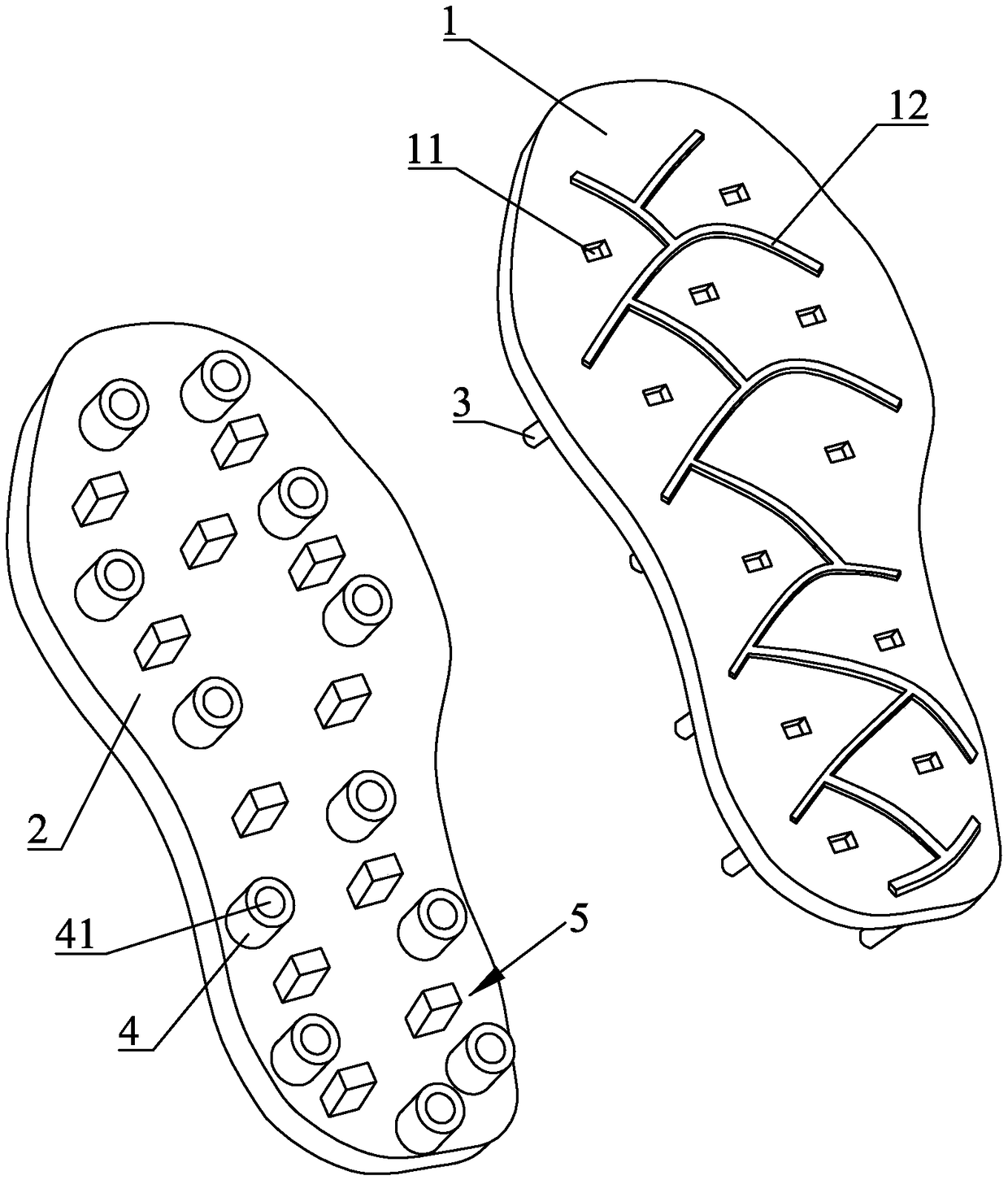

Shock-absorbing insole with health care function

The invention discloses a shock-absorbing insole with a health care function, comprising an upper pad body and a lower pad body, wherein a plurality of cylindrical support columns are arranged on thelower surface of the upper pad body; the upper surface of the lower pad body is provided with the same numb of support seats as the support columns; a limiting hole with an inner diameter correspond to the outer diameter of the support columns is arranged inside the support seats; the support columns are slidably arranged in the limiting hole, and a first spring for supporting the support columnsis arranged between the support columns and the bottom of the limiting hole; the upper pad body is provided with a plurality of ventilation holes, and the upper surface of the lower pad body below theventilation holes is provided with a health care component capable of volatilizing health care drugs; and the health care component opens with the descending of the upper pad body and closes with theascending of the upper pad body. The invention has the characteristics of good shock absorbing effect and health care to the sole of the foot, and can reduce the waste of health care medicine when noone uses it.

Owner:福建省华志新材料科技有限公司

Chemical Vapor Deposition Furnace

ActiveCN104342631BAvoid mutual dislocationEasy to operateChemical vapor deposition coatingWater coolingChemical vapor deposition

Owner:威科赛乐微电子股份有限公司

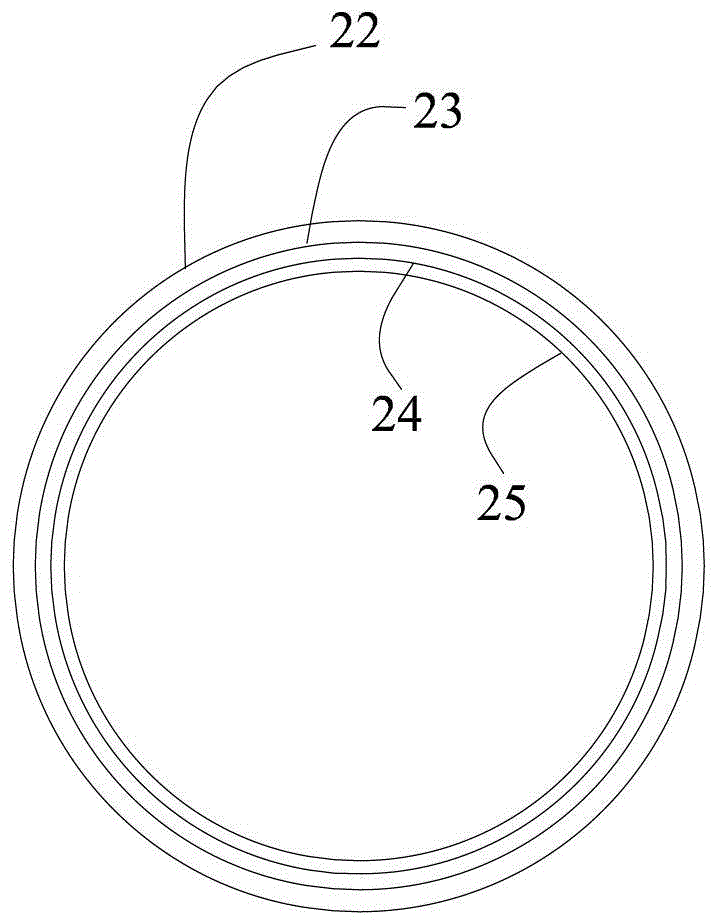

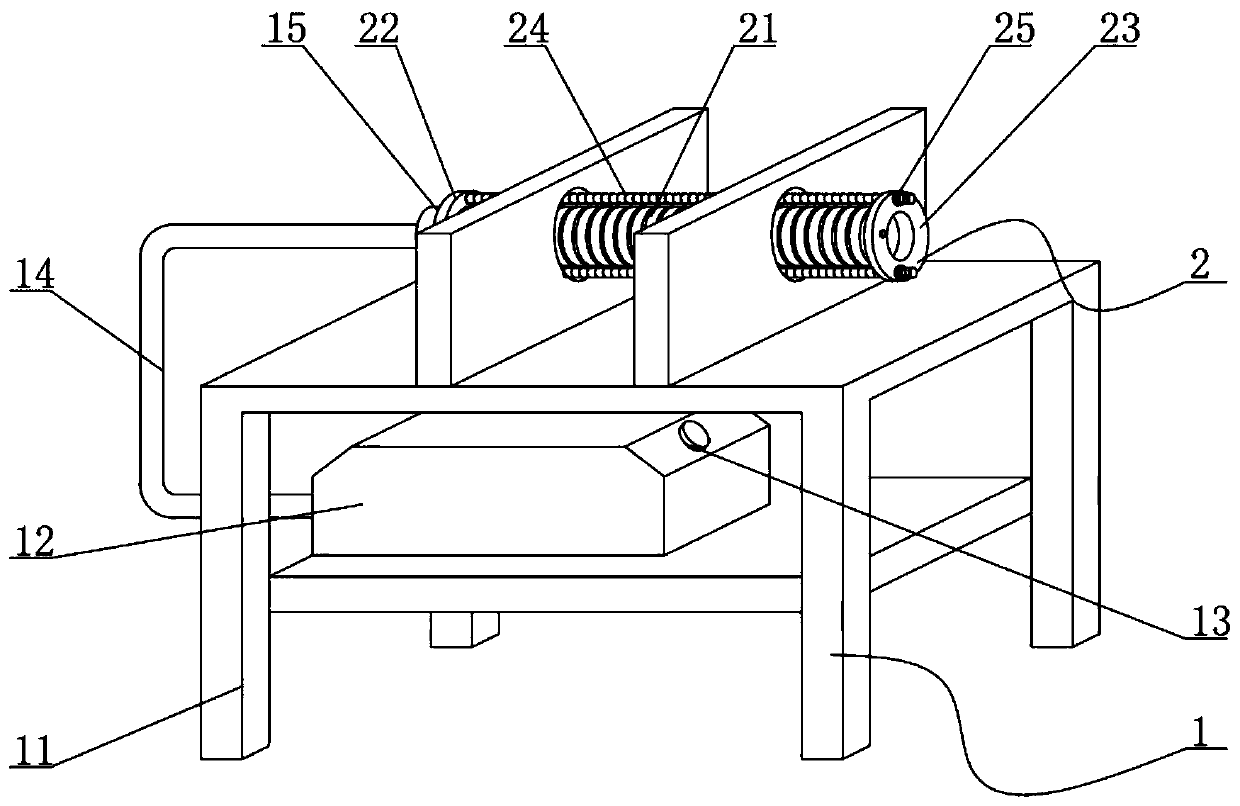

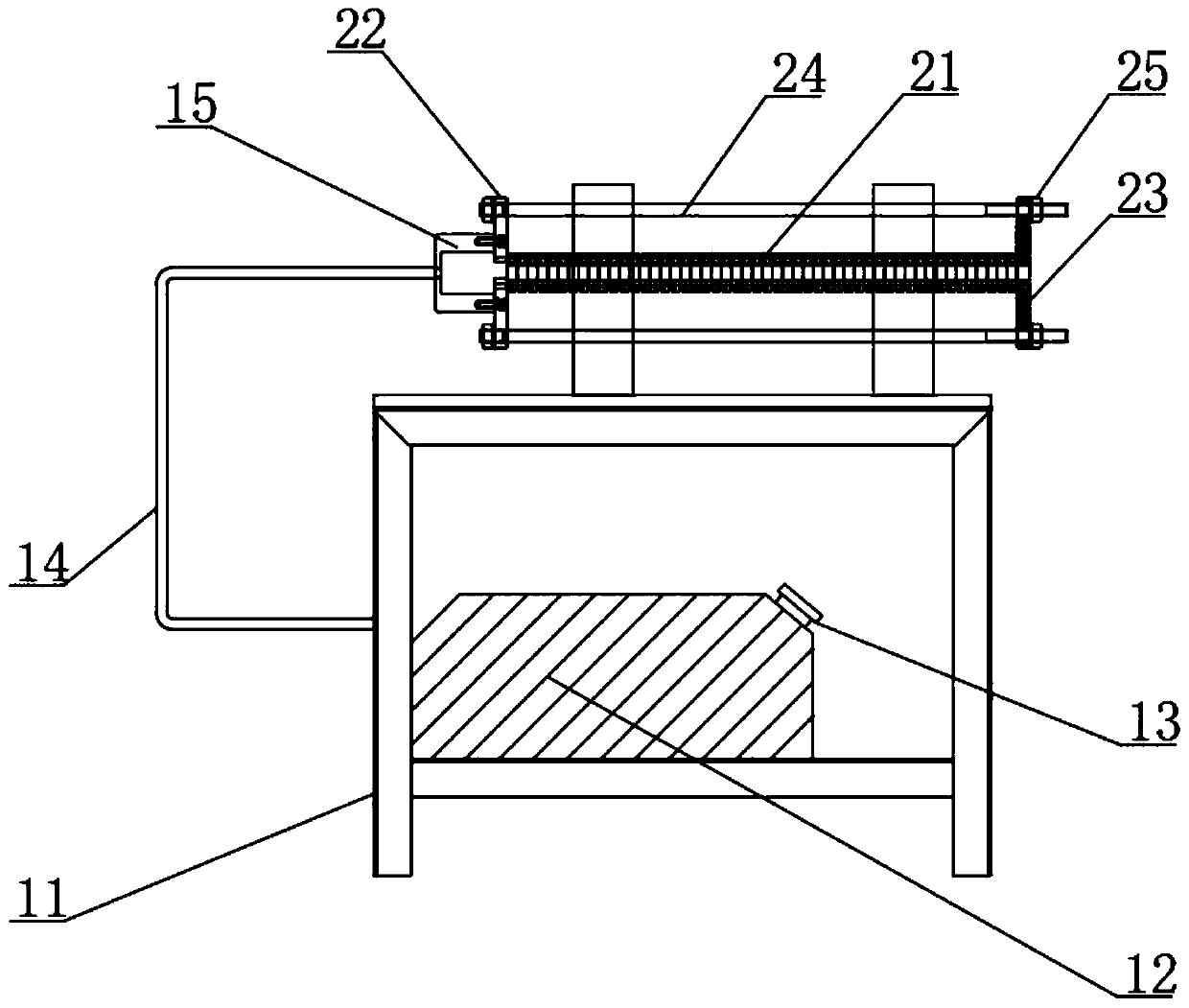

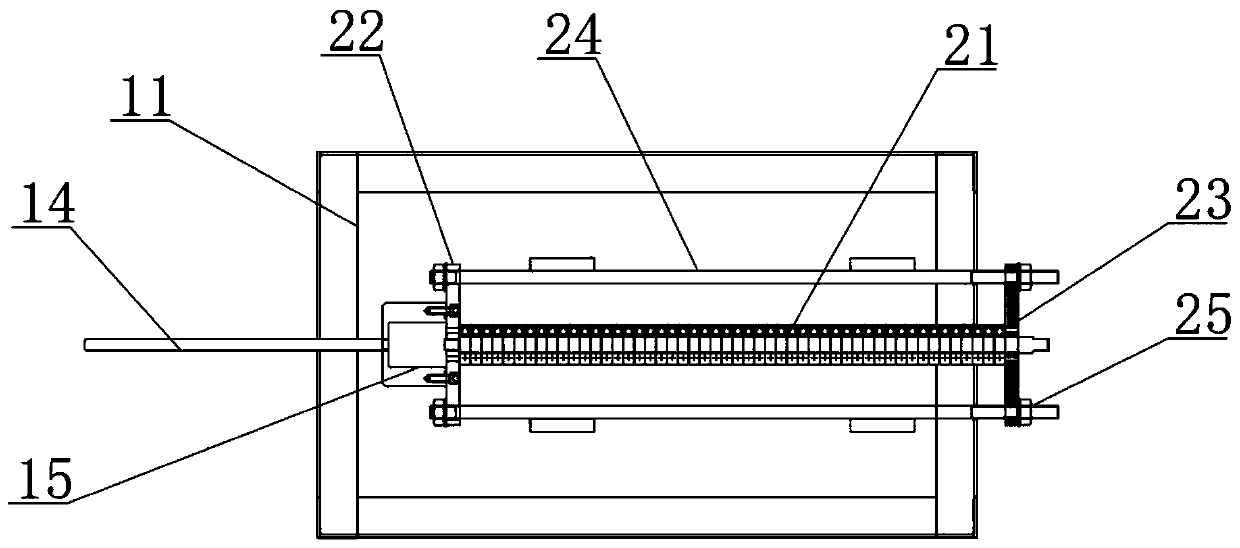

Automatic grease-adding machine for bearings

PendingCN110274147AAvoid mutual dislocationCompactLubricant transferBearing componentsButt jointScrew joint

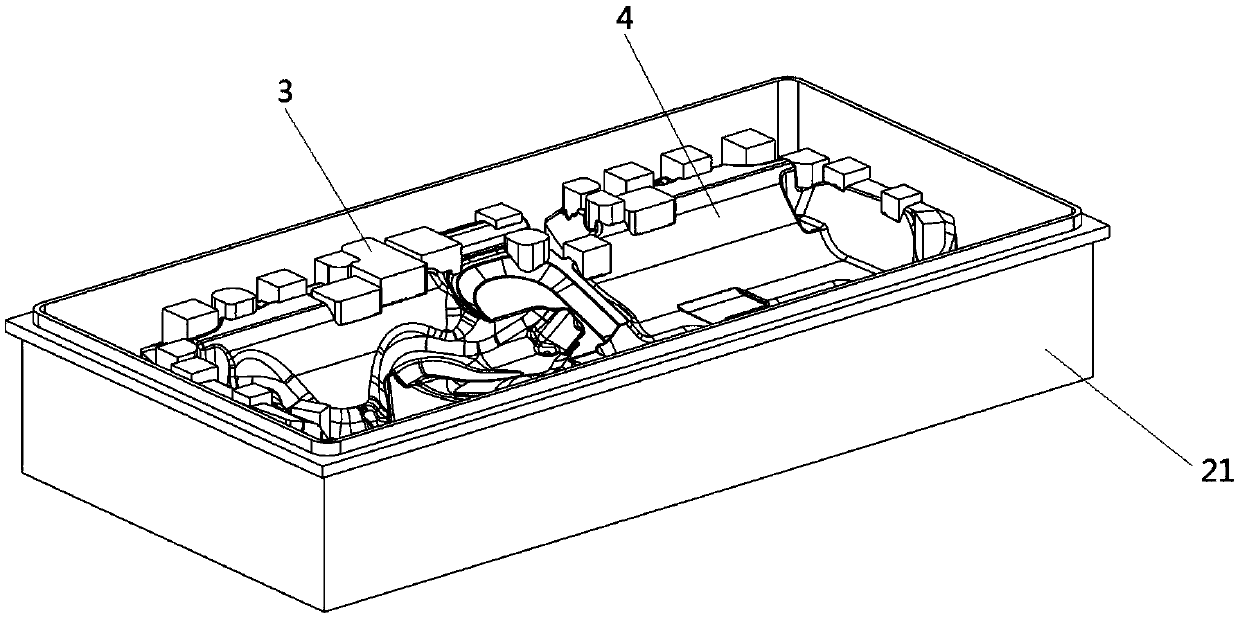

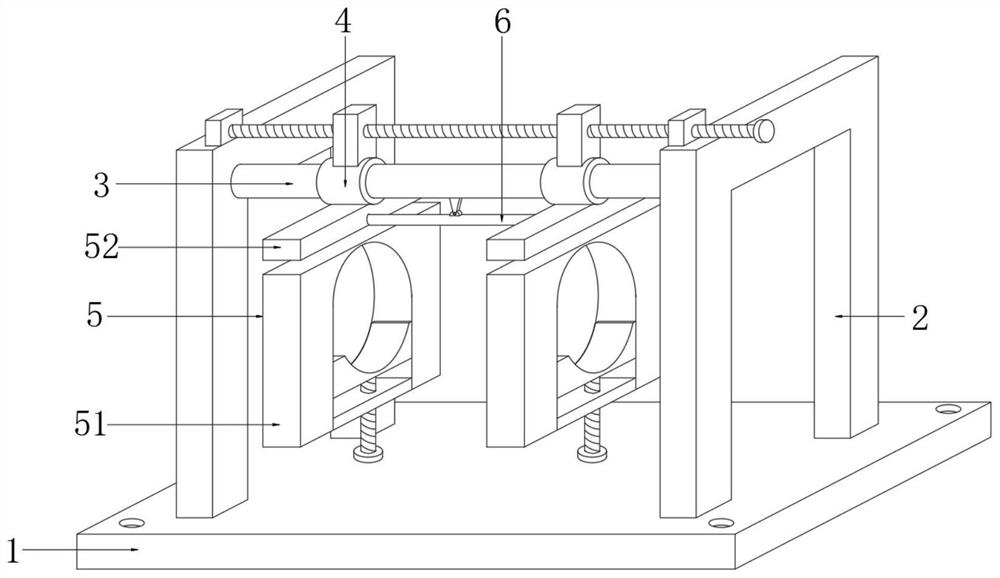

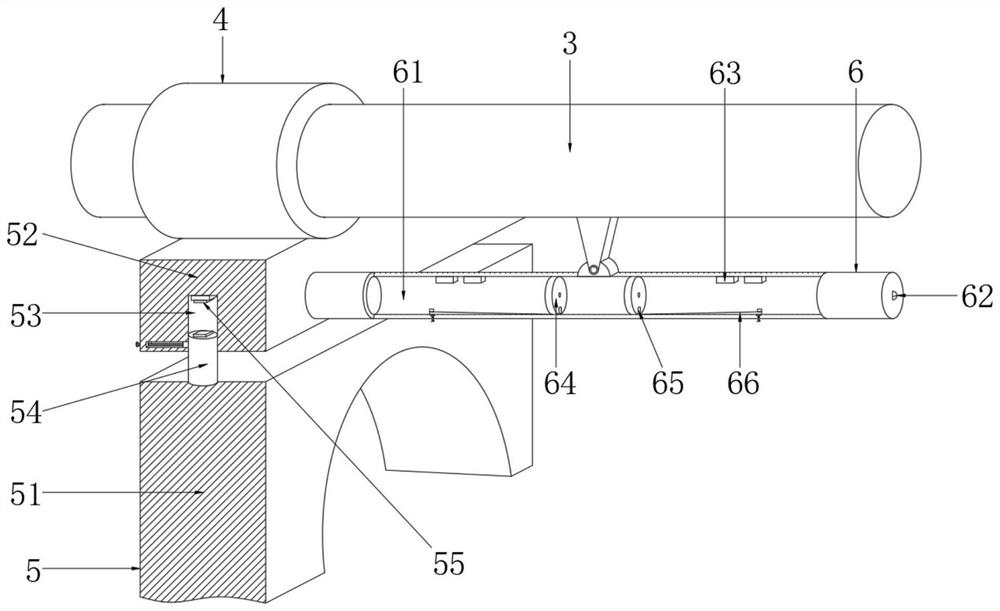

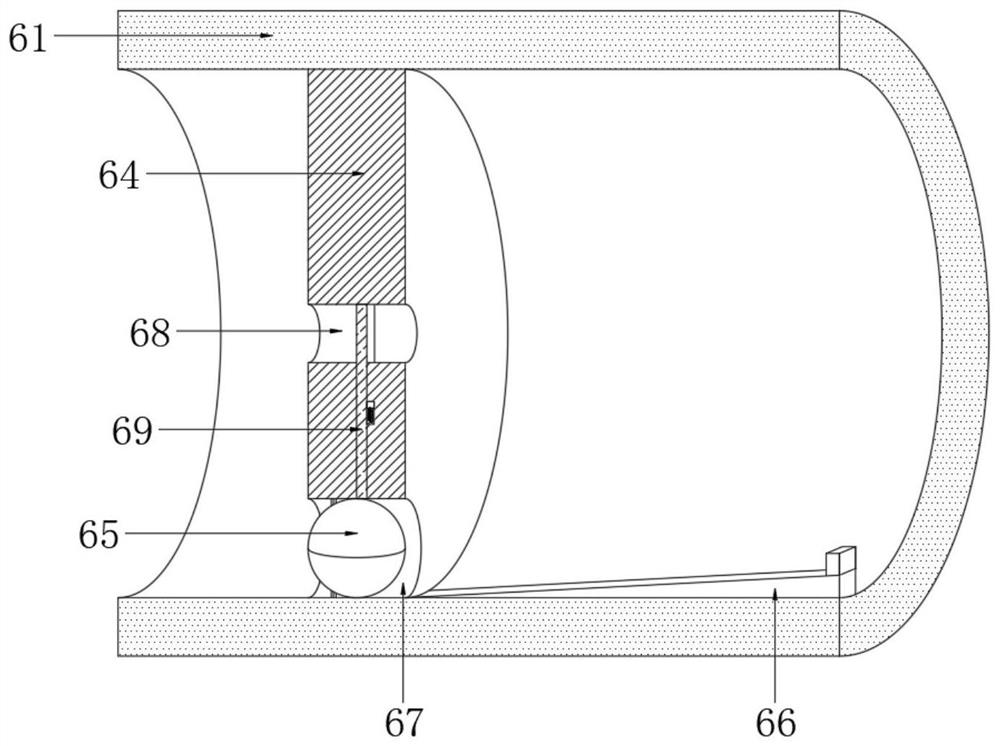

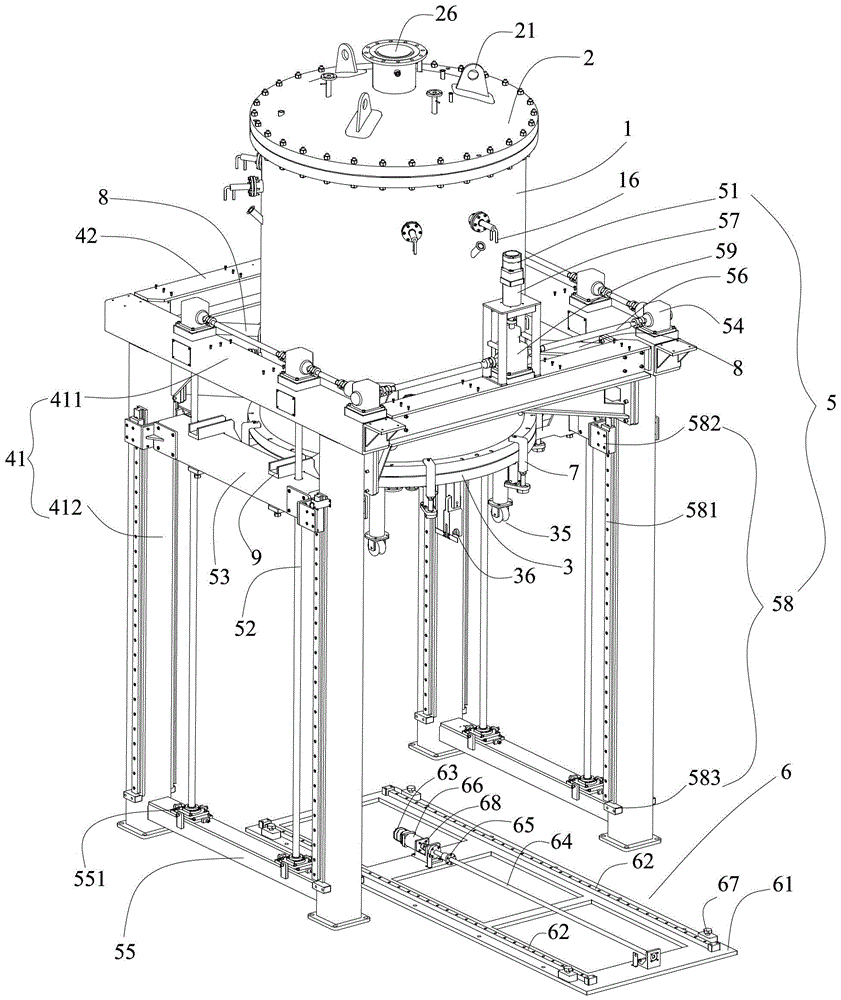

The invention belongs to the technical field of bearing processing and provides an automatic grease-adding machine for bearings. The automatic grease-adding machine comprises a grease-adding assembly and a fixing assembly. The grease-adding assembly comprises a worktable, a grease-adding box for accommodating a grease-adding pump is mounted in the worktable, and one end of a pipeline is connected to the grease-adding pump in the grease-adding box; a plurality of bearings are penetrated through a straight bar, so that the bearings are kept on a same straight line, and the bearings are prevented from being staggered. Meanwhile, a front end plate and a back end plate are arranged at two ends of a bearing row and are in screw joint through a threaded rod, and the front end plate and the back end plate extrude the middle bearings from left and right ends to the middle, so that the whole bearing row is compact integrally, and a phenomenon of omission as a result of gaps among the bearings is avoided. A butt joint is mounted on the front end plate. Bearing lubricating grease is added to the bearing row through the grease-adding box. As the lubricating grease is added automatically, the condition of fatigue as a result of frequent manual operations is avoided.

Owner:江苏阆达机械有限公司

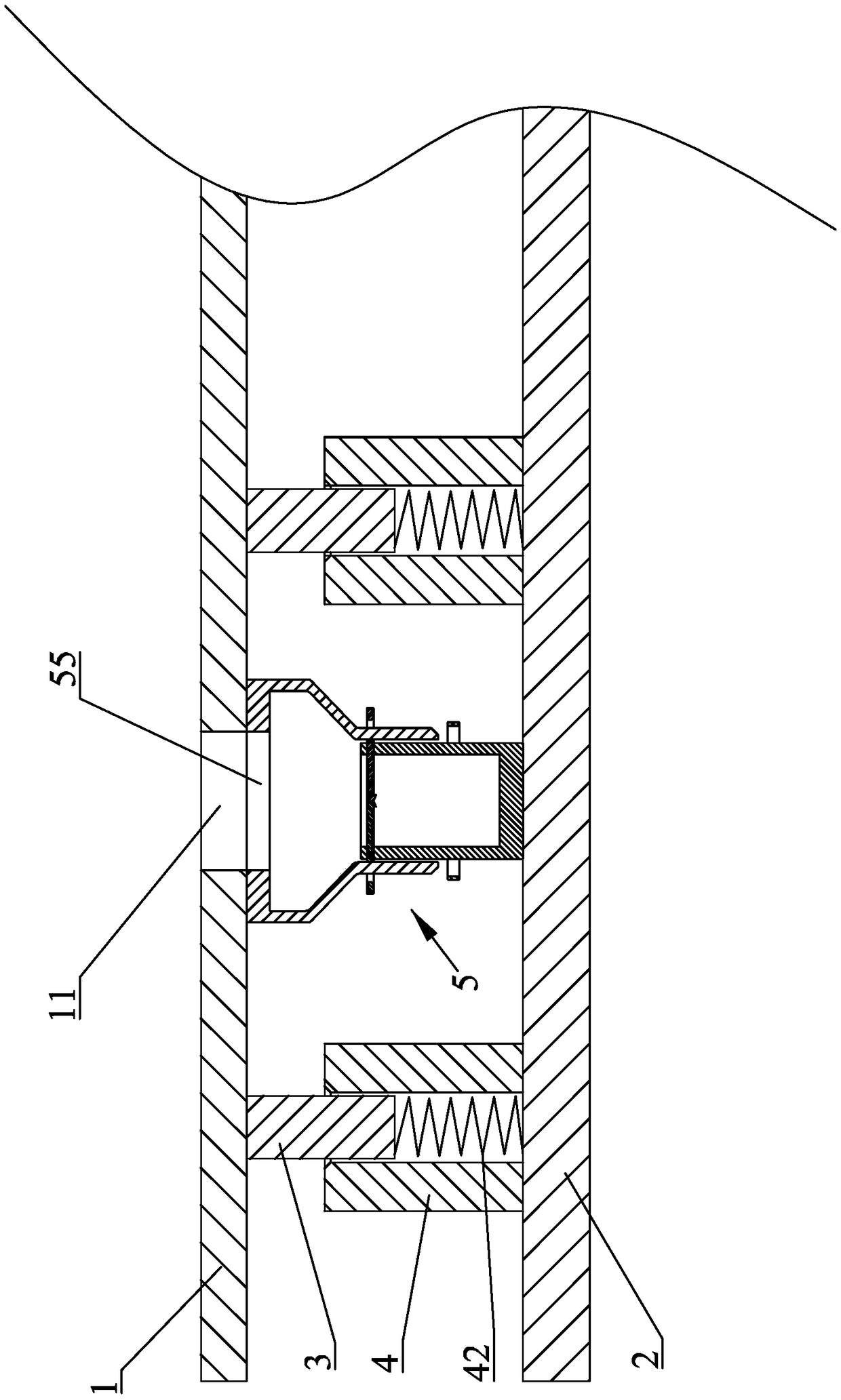

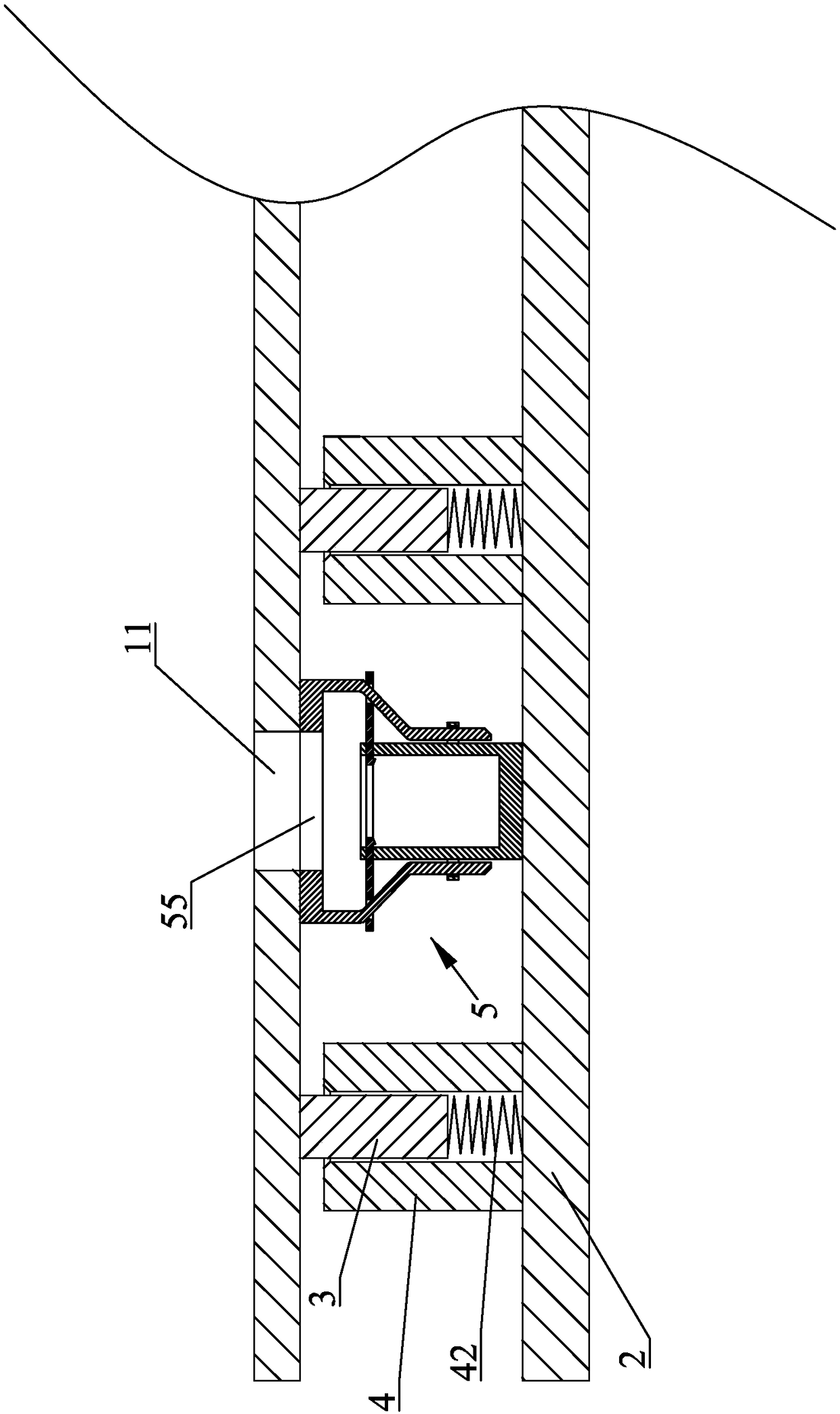

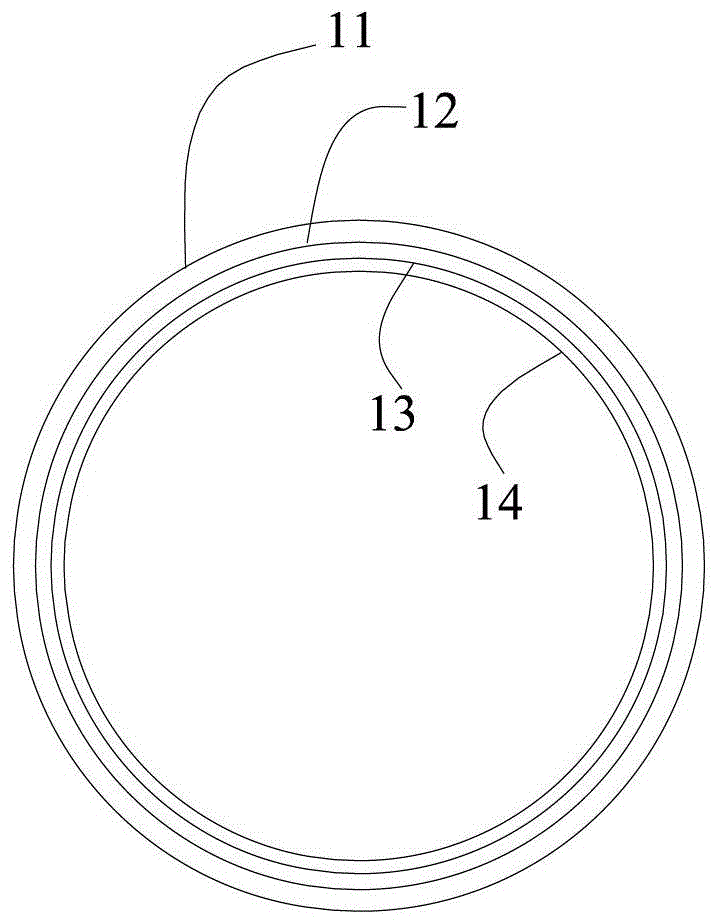

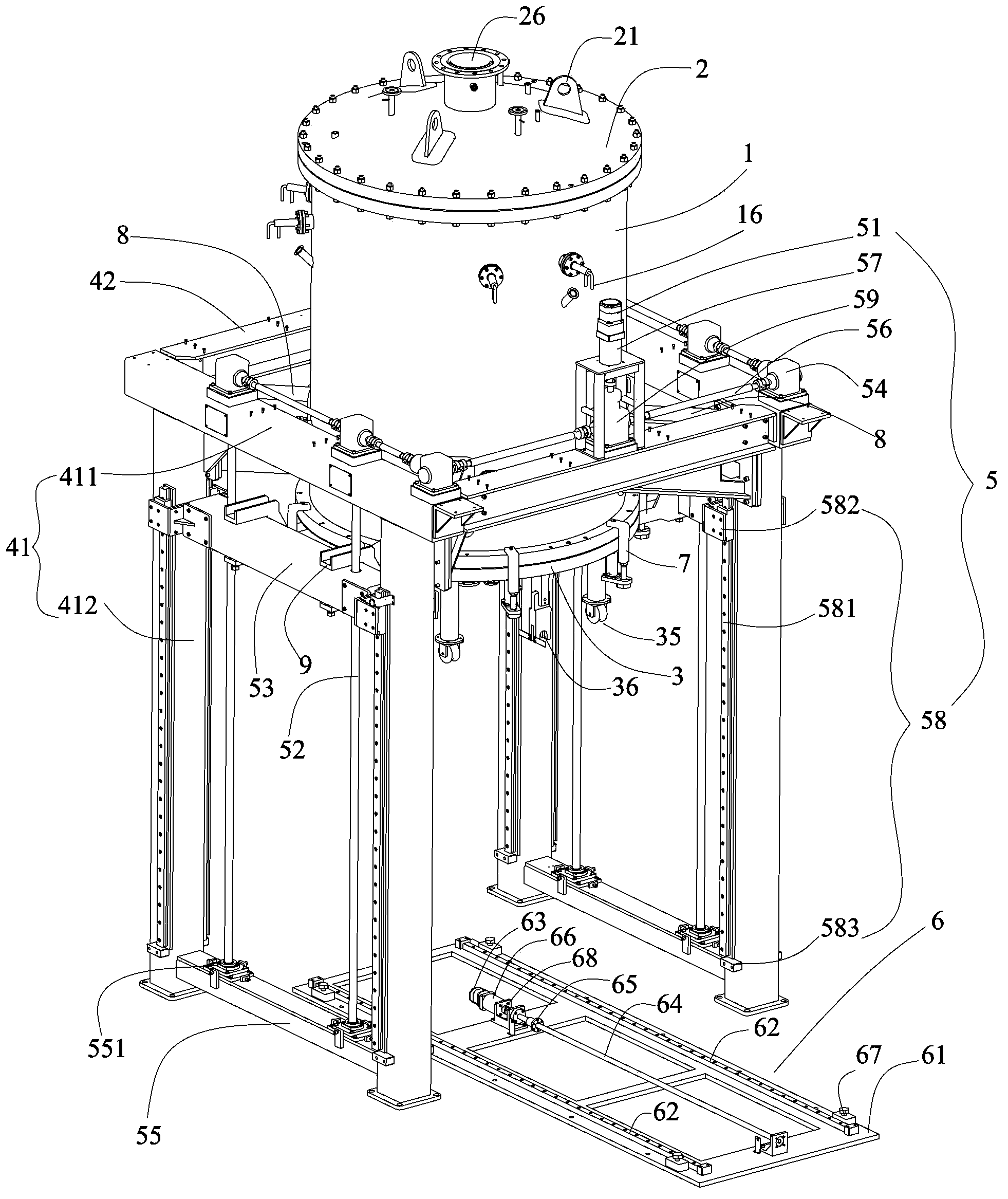

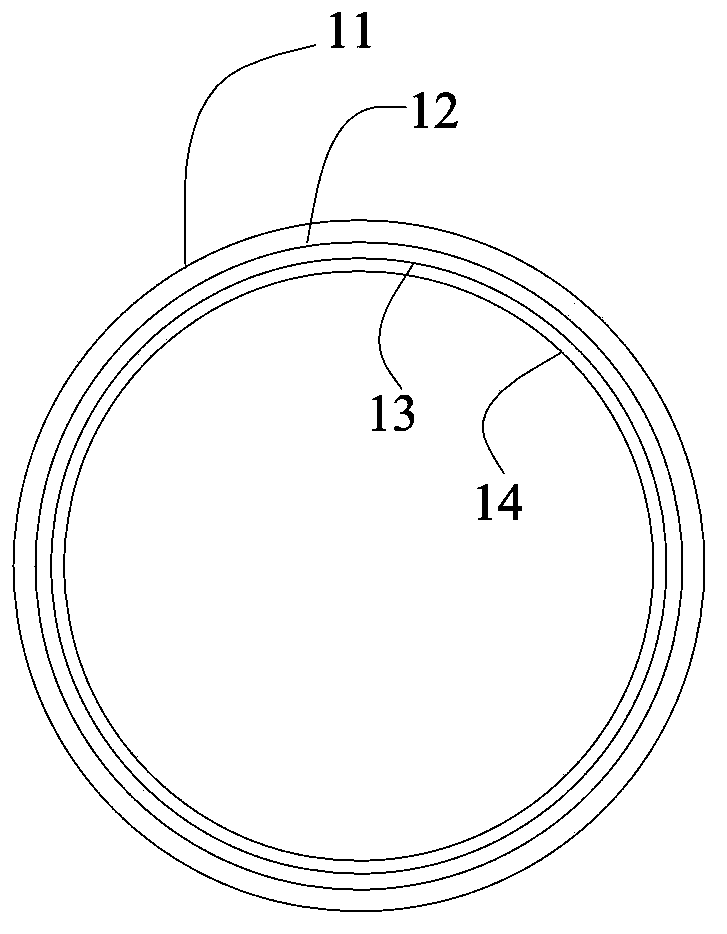

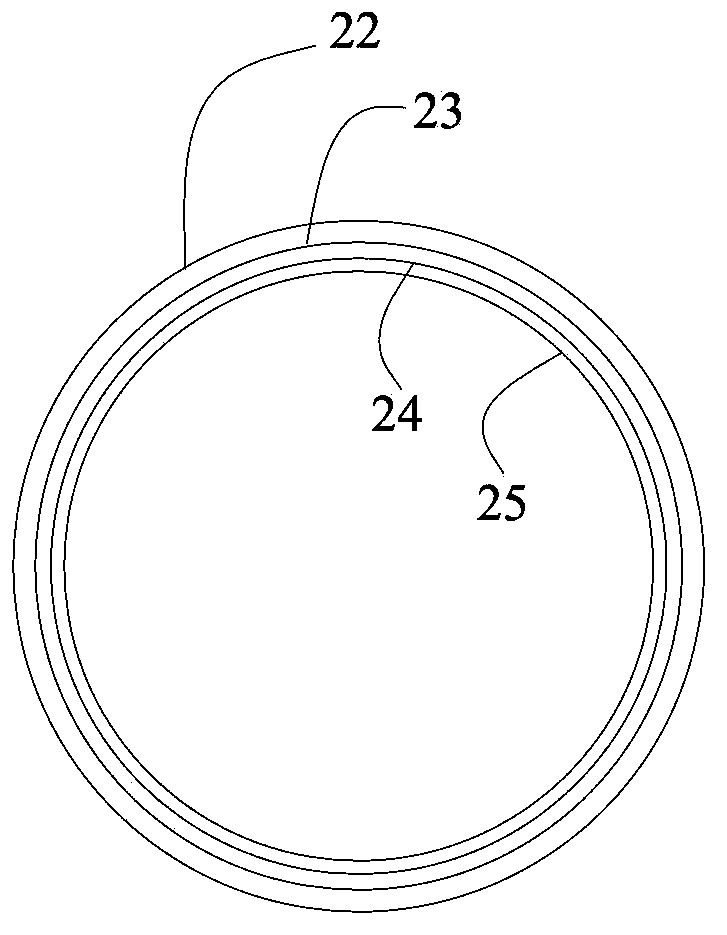

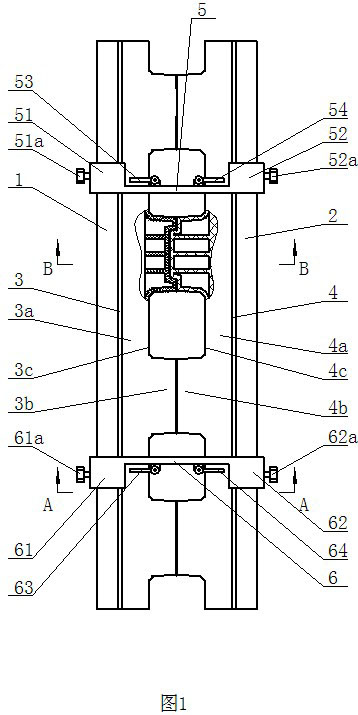

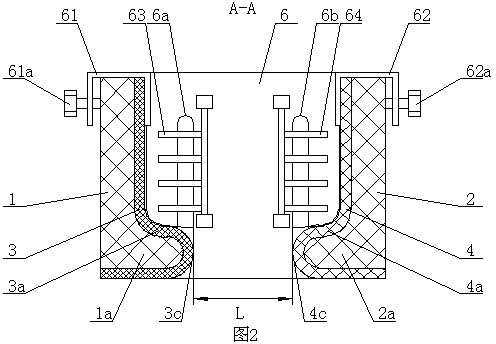

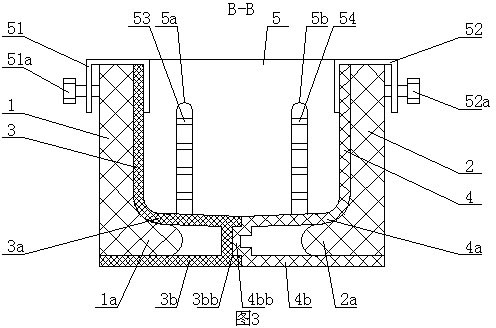

Chemical vapor deposition furnace

ActiveCN104342631AAvoid mutual dislocationEasy to operateChemical vapor deposition coatingWater coolingChemical vapor deposition

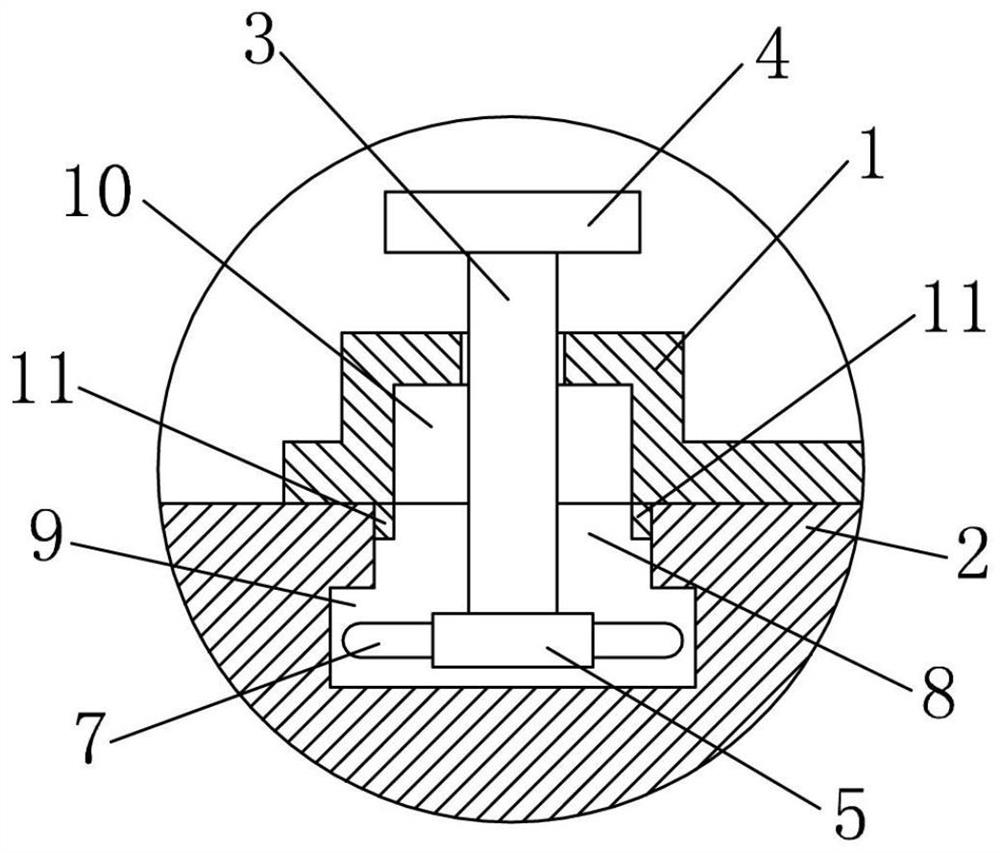

The invention provides a chemical vapor deposition furnace. The furnace comprises a furnace body; an upper furnace cover which is arranged at the upper portion of the furnace body and is detachably fixedly connected with the furnace body in a sealing manner; a lower furnace cover arranged at the lower portion of the furnace body and in sealed detachable fixed connection with the furnace body; and a lower furnace cover elevating mechanism fixedly connected with the lower furnace cover to make the lower furnace body removed from the fixed furnace body drive the lower furnace cover to fall in order to discharge and drive the lower furnace cover after discharge to rise to be combined with the furnace body. The chemical vapor deposition furnace also comprises a forward / backward pushing mechanism arranged just below the lower furnace cover, and the forward / backward pushing mechanism makes the lower furnace cover elevating mechanism drive the falling lower furnace cover to fall on the forward / backward pushing mechanism and forward / backward move to the periphery in order to carry out discharging and charging. The furnace body, the upper furnace cover and the lower furnace cover adopts a water cooling interlayer and a heat insulating layer respectively. The mutual dislocation of the furnace body in the repeated dismounting process is avoided; the discharging and the charging are safe and reliable, and are convenient to operate; and the stability of the thermal field in the furnace is stable, and the high temperature work safety is improved.

Owner:威科赛乐微电子股份有限公司

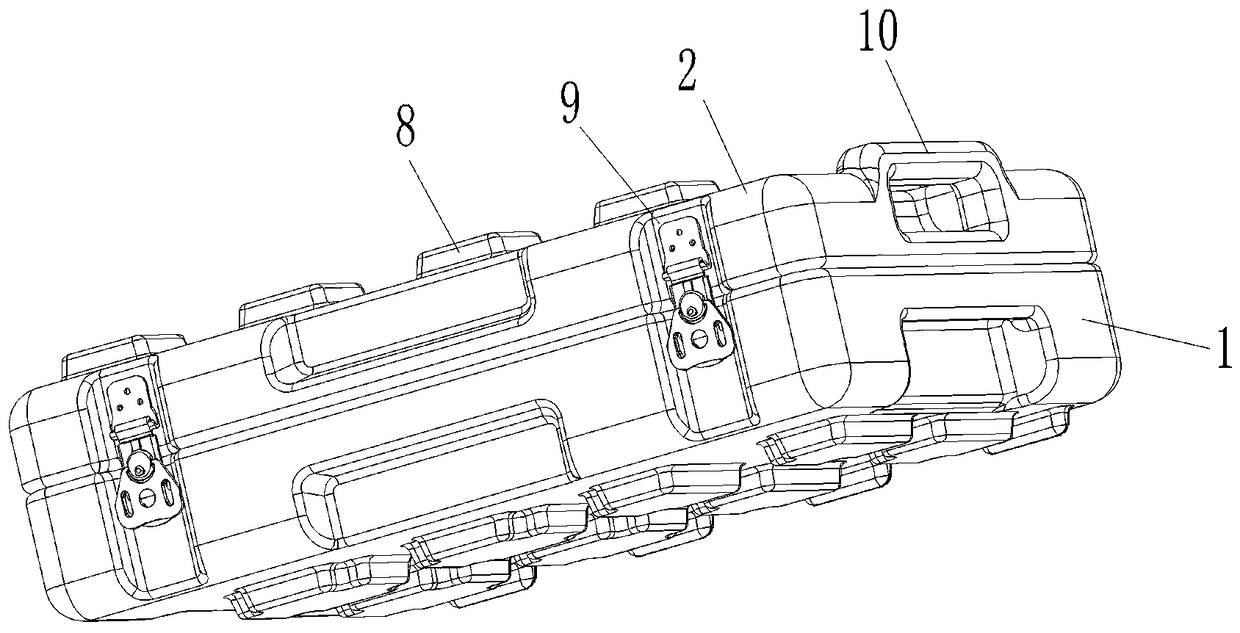

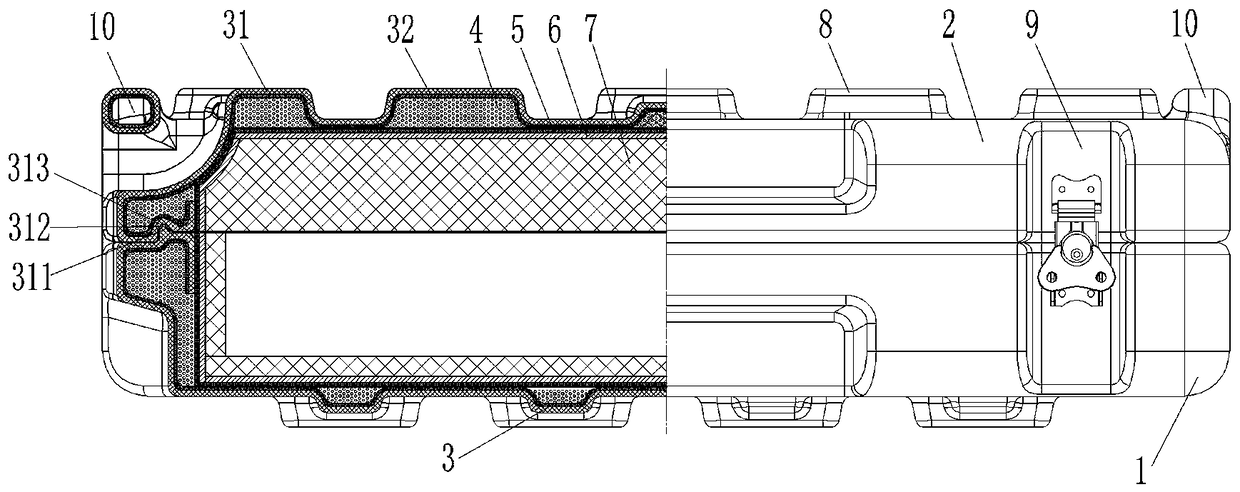

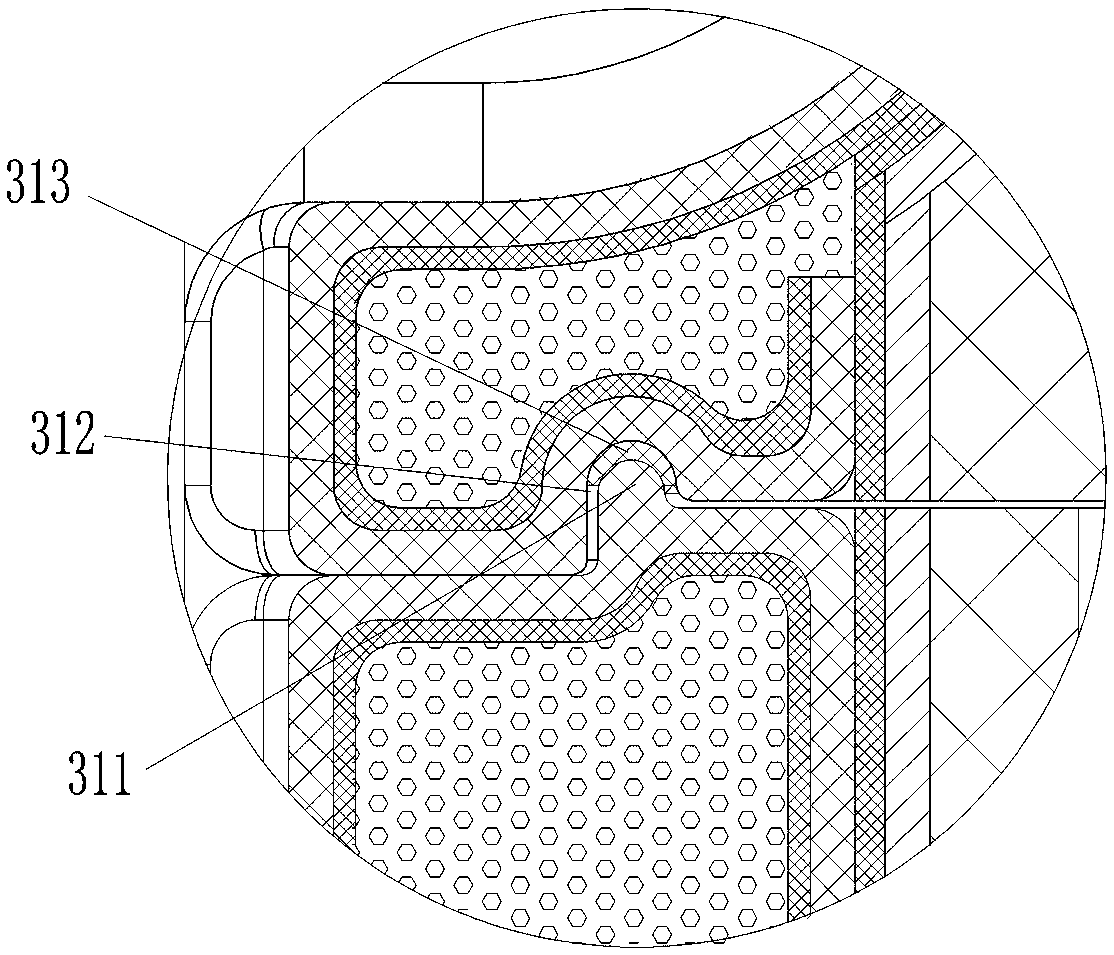

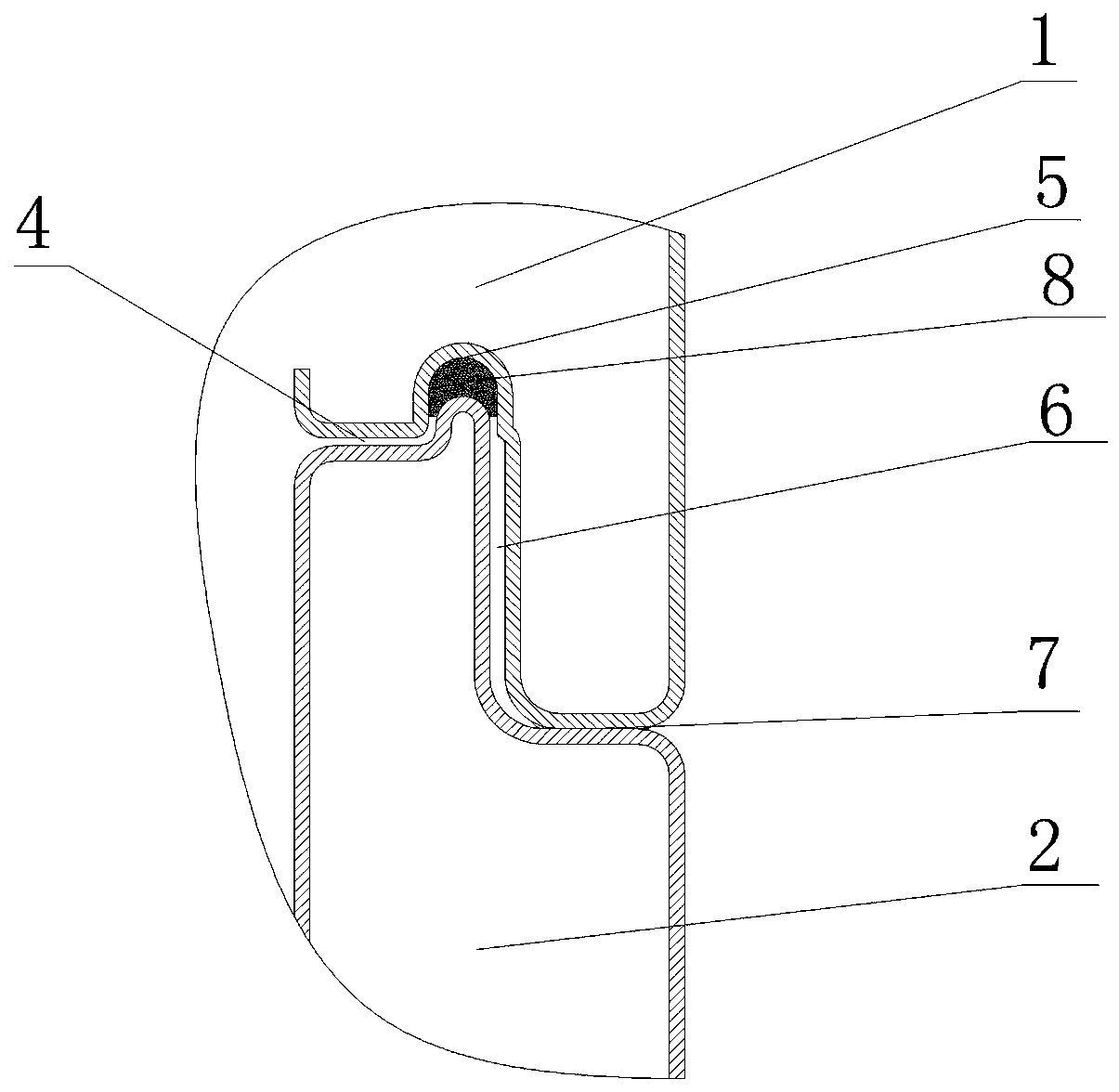

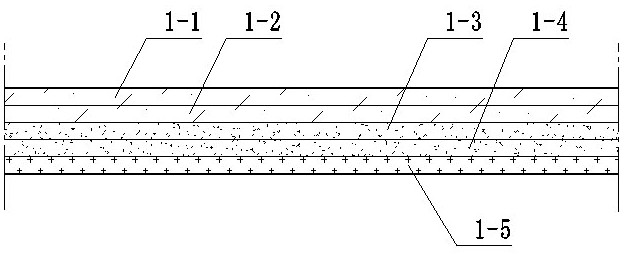

Flame-retardant and explosion-proof ammunition box

PendingCN108426491AAvoid mutual dislocationAvoid unstable placementAmmunition storageDislocationExplosion protection

The invention relates to a flame-retardant and explosion-proof ammunition box, and belongs to the field of packaging of flammable and explosive materials. The flame-retardant and explosion-proof ammunition box comprises a sealing cavity defined by a box body and a box cover fastened on the box body, and the box body and the box cover both comprise a rotational moulding outer shell, a heat insulating filling layer, a heat insulating felt or plate layer and a metal foam explosion-proof inner shell from outside to inside; a containing cavity defined by the metal foam explosion-proof inner shell of the box body is internally provided with a vibration reduction mold shell matched with ammunition in shape and specification, the rotational moulding outer shells on the box body and the box cover form a stepped limit sealing structure of snap fastening by relying on matched protrusions and notches, the metal foam explosion-proof inner shells are surrounded by the heat insulating felt or plate layers, a heat insulating felt or plate on the box cover is lower than the corresponding metal foam explosion-proof inner shell, a heat insulating felt or plate on the box body is correspondingly higher than the corresponding metal foam explosion-proof inner shell, a double-layer dislocation fastening sealing structure is formed, and the heat insulating filling layers are heat preservation materials filling gaps between the rotational moulding outer shells and the heat insulating felt or plate layers. The packaging box has multiple protection functions of flame retardance, heat insulation, vibration and shock resistance and explosion protection.

Owner:河北金后盾塑胶有限公司

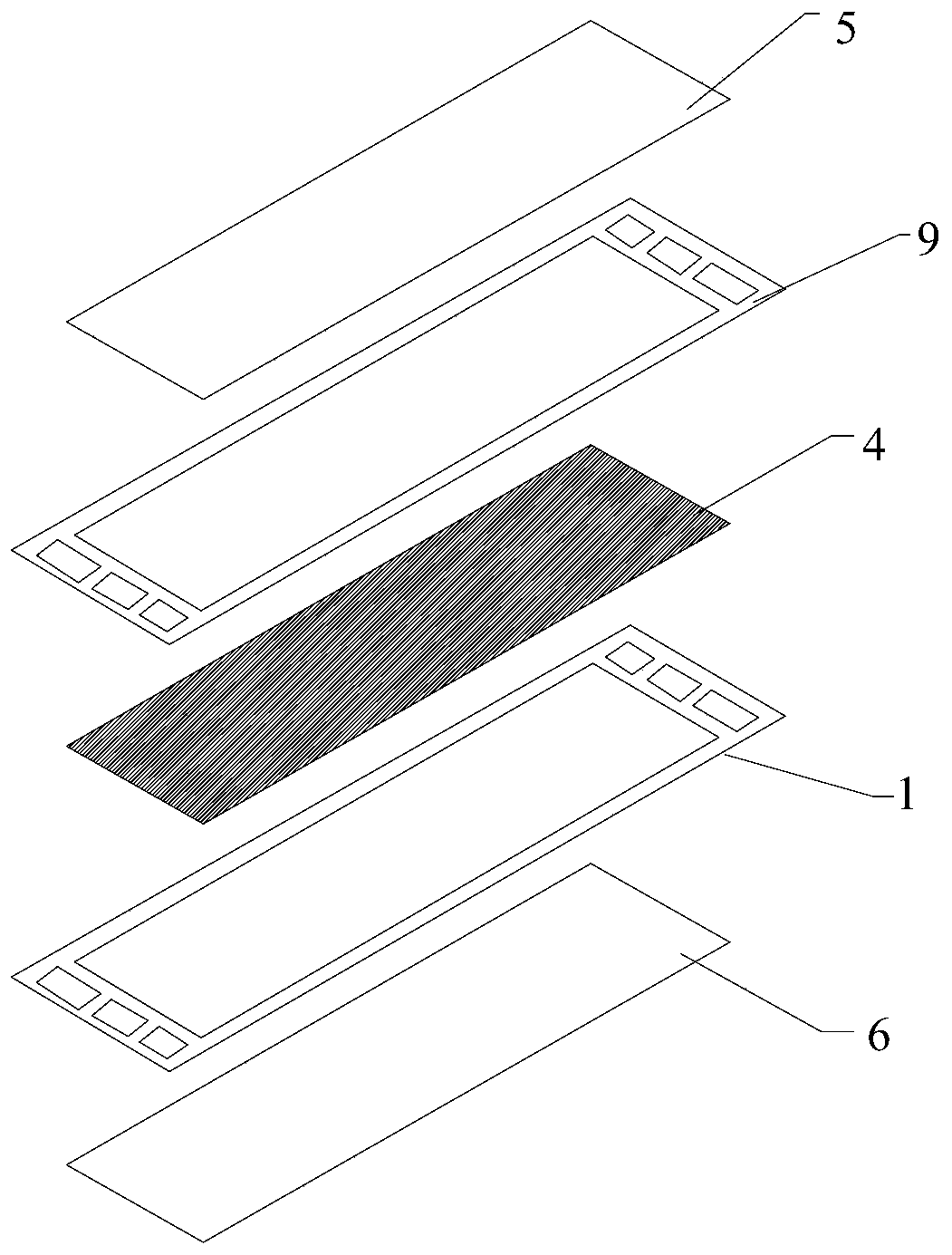

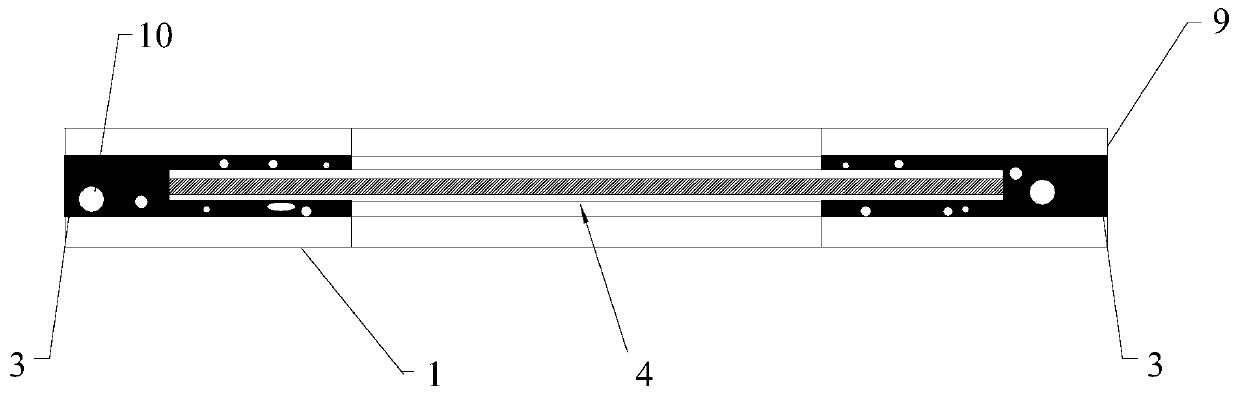

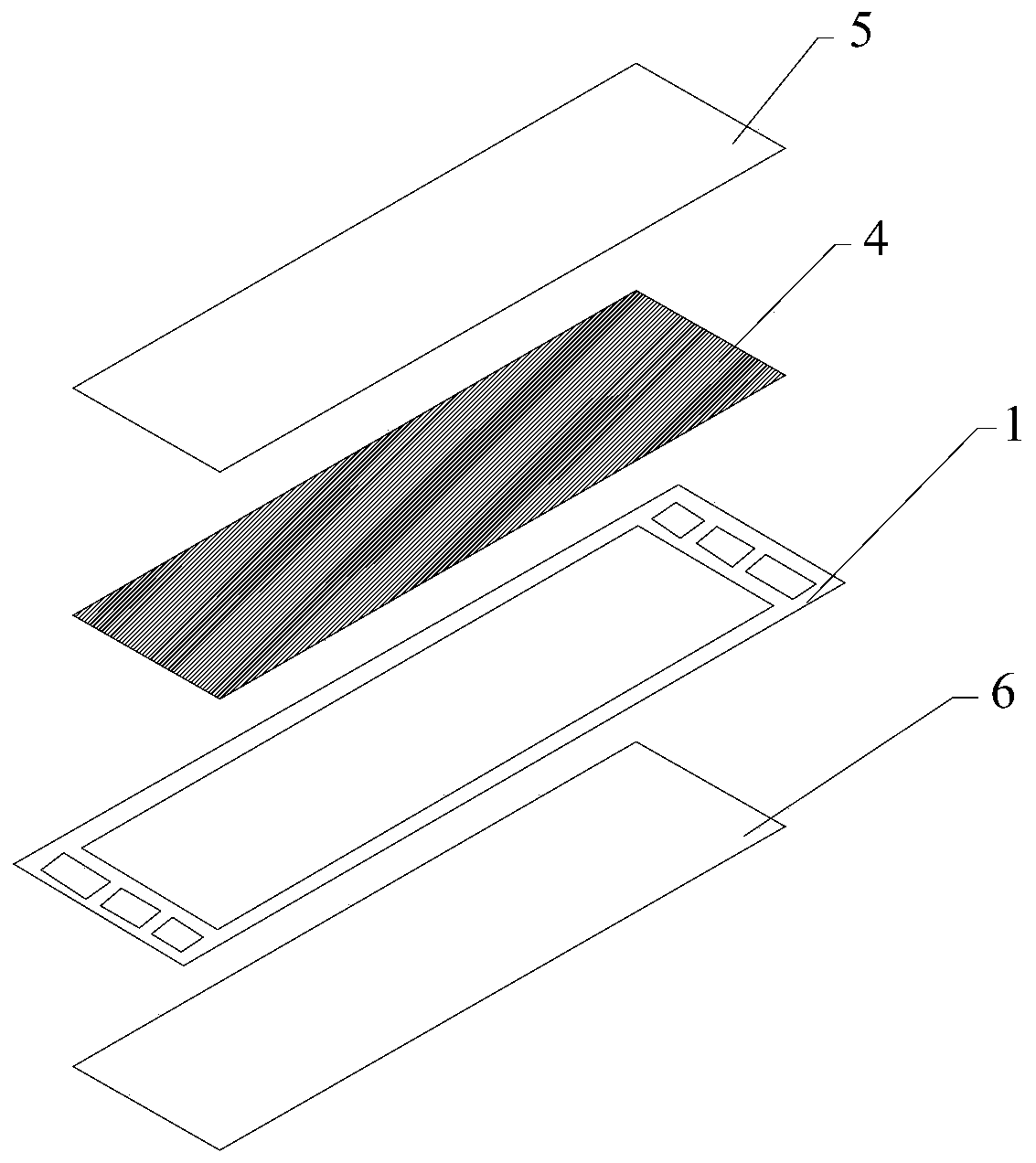

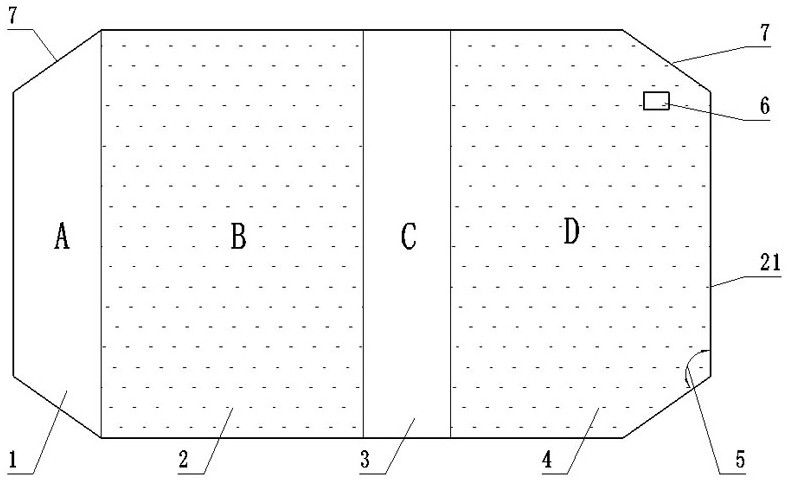

Membrane electrode packaging structure and packaging method

PendingCN111477912AAvoid mutual dislocationLow costFinal product manufactureFuel cellsFuel cellsPtru catalyst

The invention relates to the field of fuel cells, in particular to a membrane electrode packaging structure and a packaging method. The membrane electrode packaging structure comprises a top surface gas diffusion layer and a bottom surface gas diffusion layer, a frame and a catalyst coating film which are mutually stacked are clamped between the two gas diffusion layers, the catalyst coating filmis bonded and fixed on the top surface of the frame, only one frame is arranged, the part, bonded with the catalyst coating film, of the top surface of the frame is concave, the catalyst coating filmis bonded on the bottom wall of the concave part, and the inner side wall of the concave part blocks the periphery of the catalyst coating film. The packaging structure can reduce the production costand reduce the air leakage risk of the sealing area.

Owner:SINOHYKEY TECH CO LTD

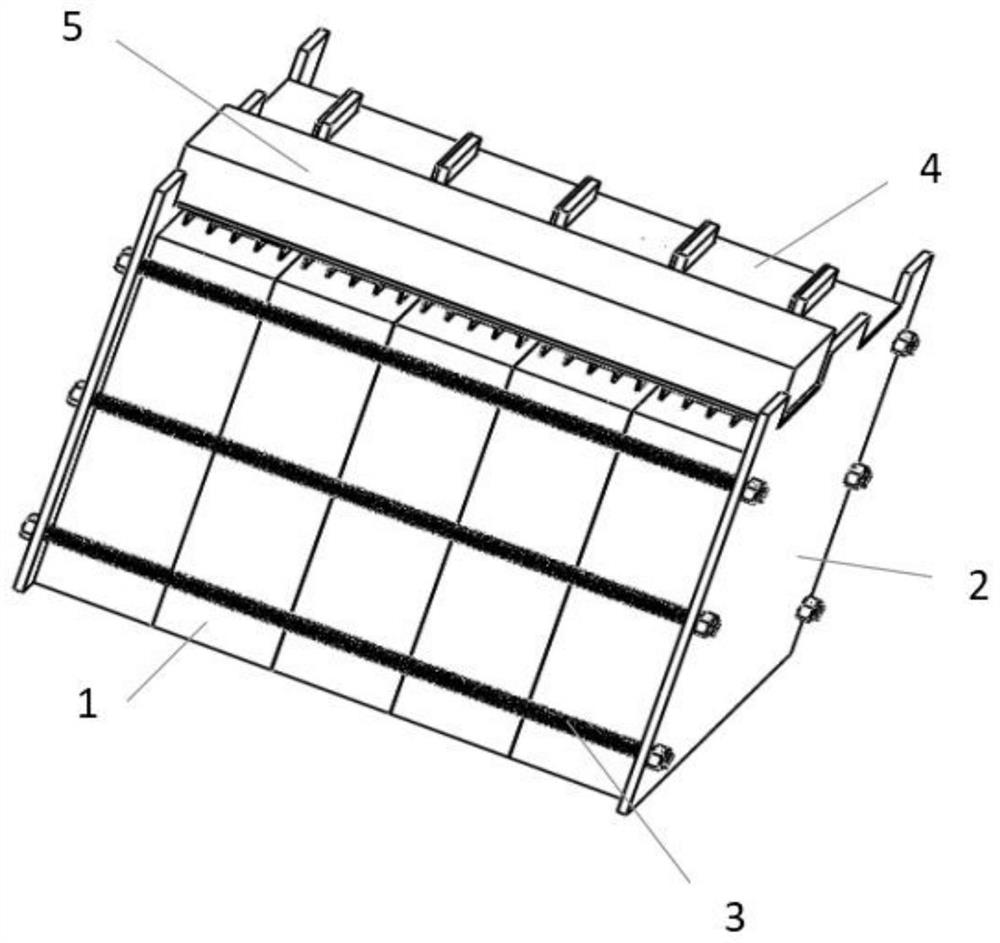

Reinforcing rib making die for ribbed superposed concrete prefabricated member

ActiveCN102303364AEasy to disengageSave manpower, material resources and working hoursMouldsEngineeringMechanical engineering

The invention discloses a reinforcing rib making die for a ribbed superposed concrete prefabricated member. The die comprises a first template and a second template which are arranged corresponding to each other; the sections of the first template and the second template respectively consist of a vertical plate body and a horizontal plate body positioned at the lower part of the vertical plate body and are L-shaped; a first elastic lining film and a second elastic lining film are respectively arranged on the inside walls of the first template and the second template; the mutually corresponding edges of the first lower lining film and the second lower lining film are respectively concave-convex; a first baffle plate and a second baffle plate are respectively arranged between the first template and the second template and are respectively in contact with the first elastic lining film and the second elastic lining film; the first baffle plate is provided with a first steel bar hole and asecond steel bar hole; and the second baffle plate is provided with a third steel bar hole and a fourth steel bar hole. The die has the remarkable characteristics of standardization, strong interchangeability, simplicity and convenience in disassembly and assembly, no need of die release treatment and capability of meeting industrialized production of concrete prefabricated members.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

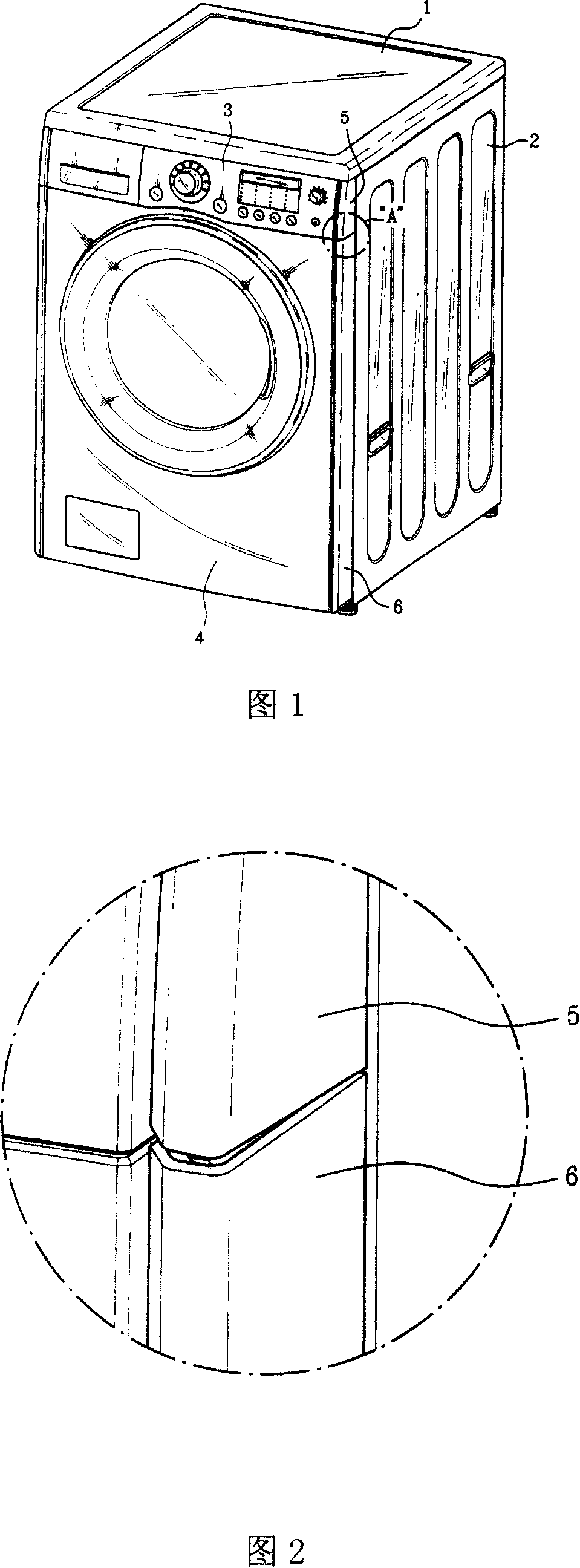

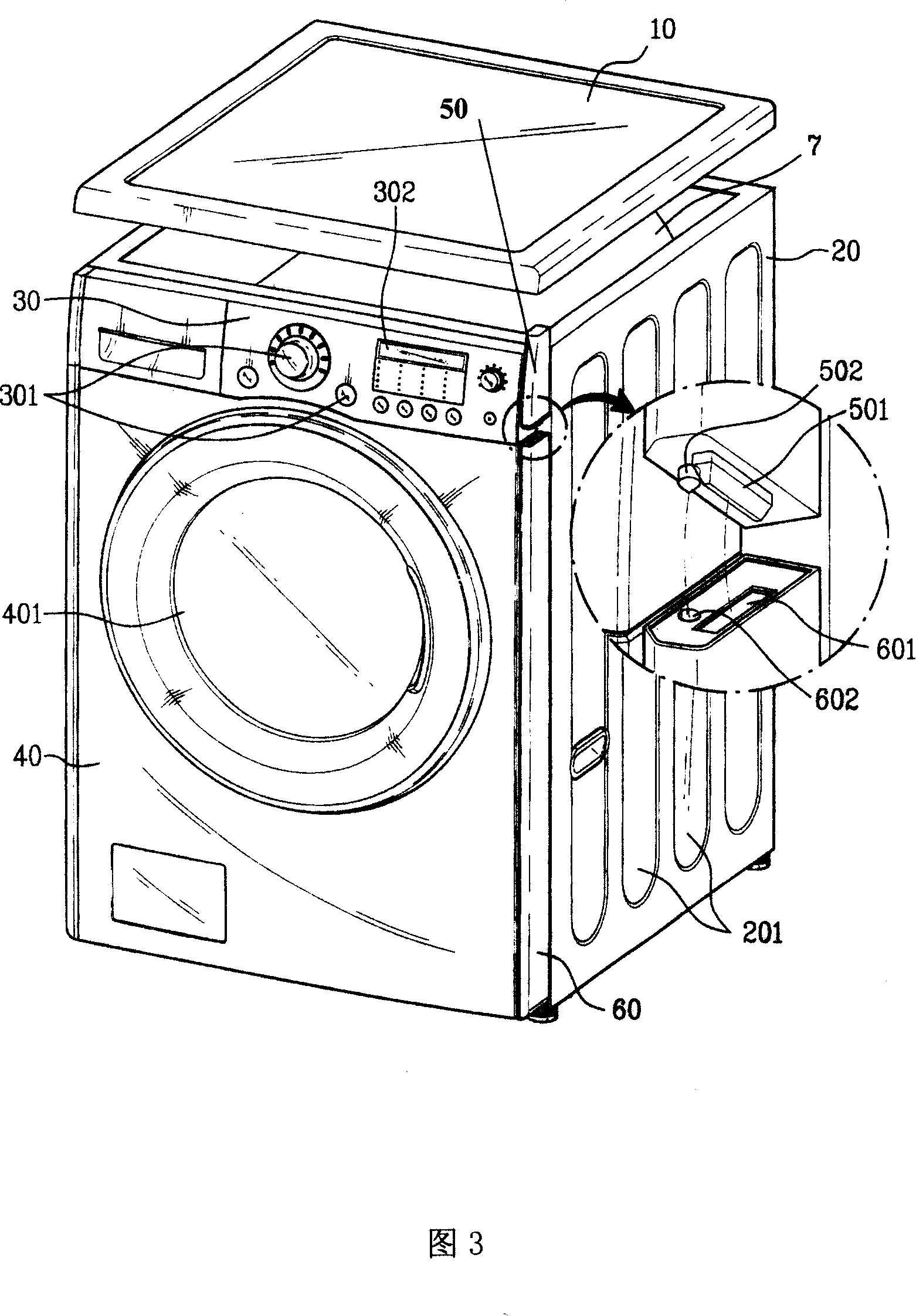

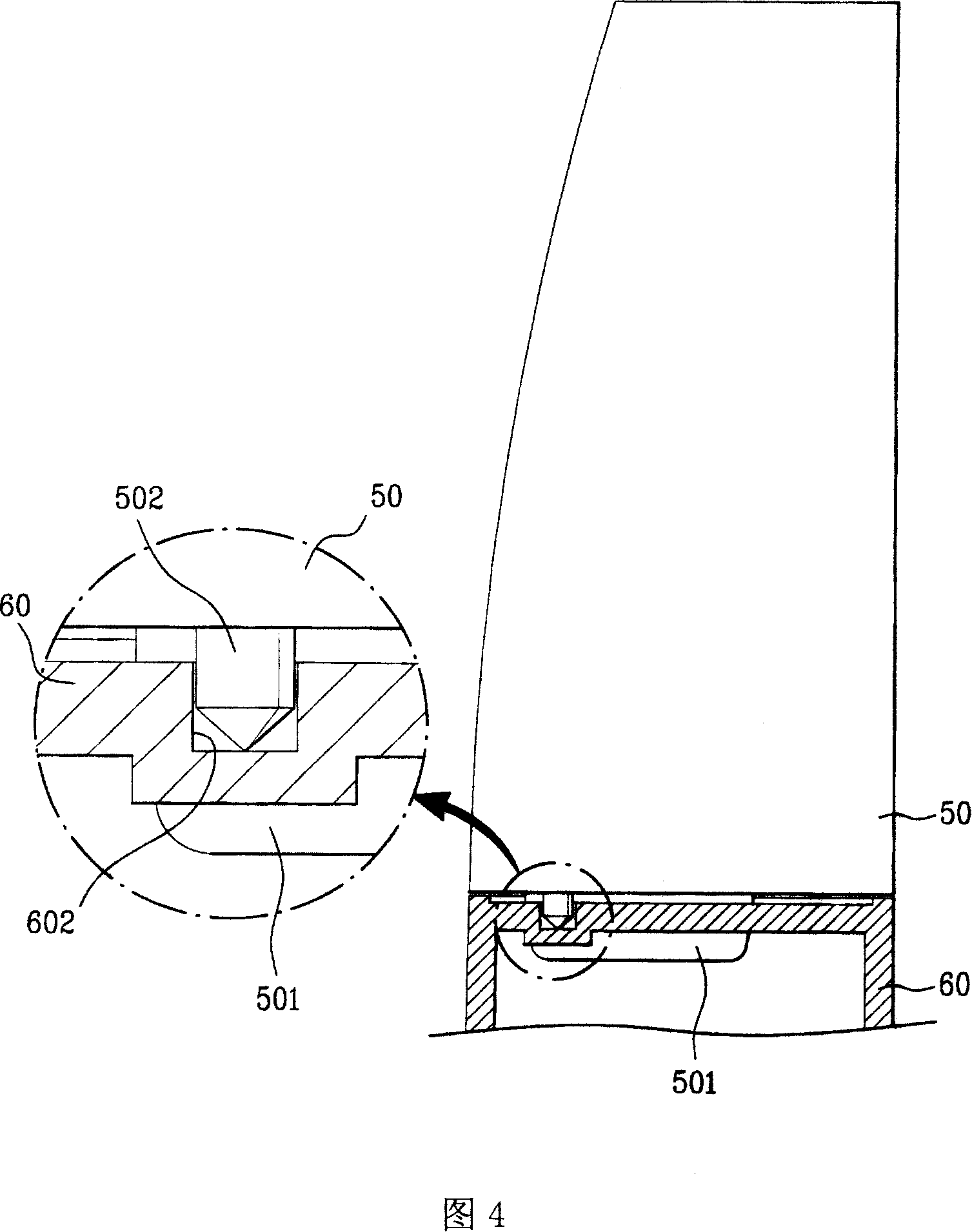

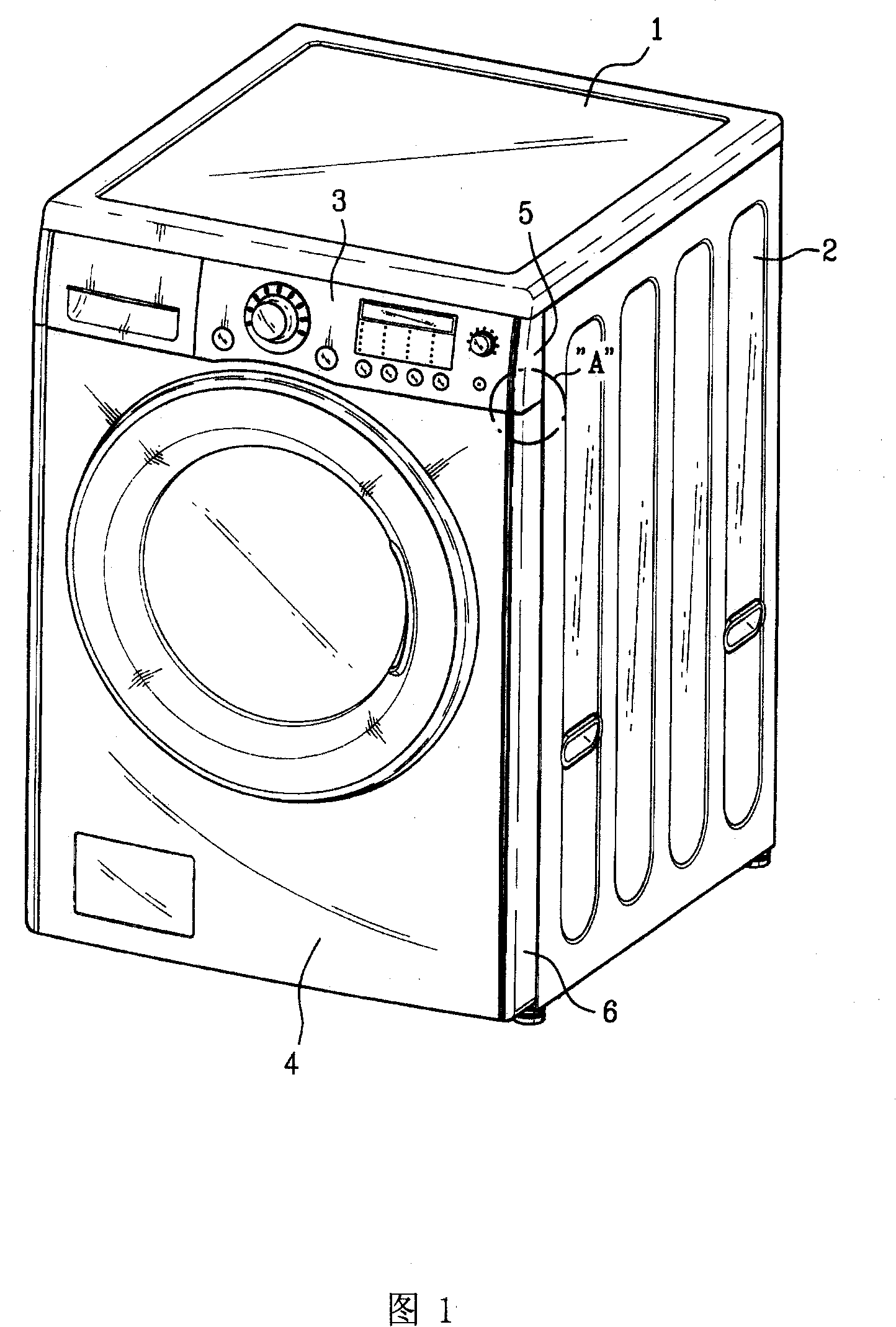

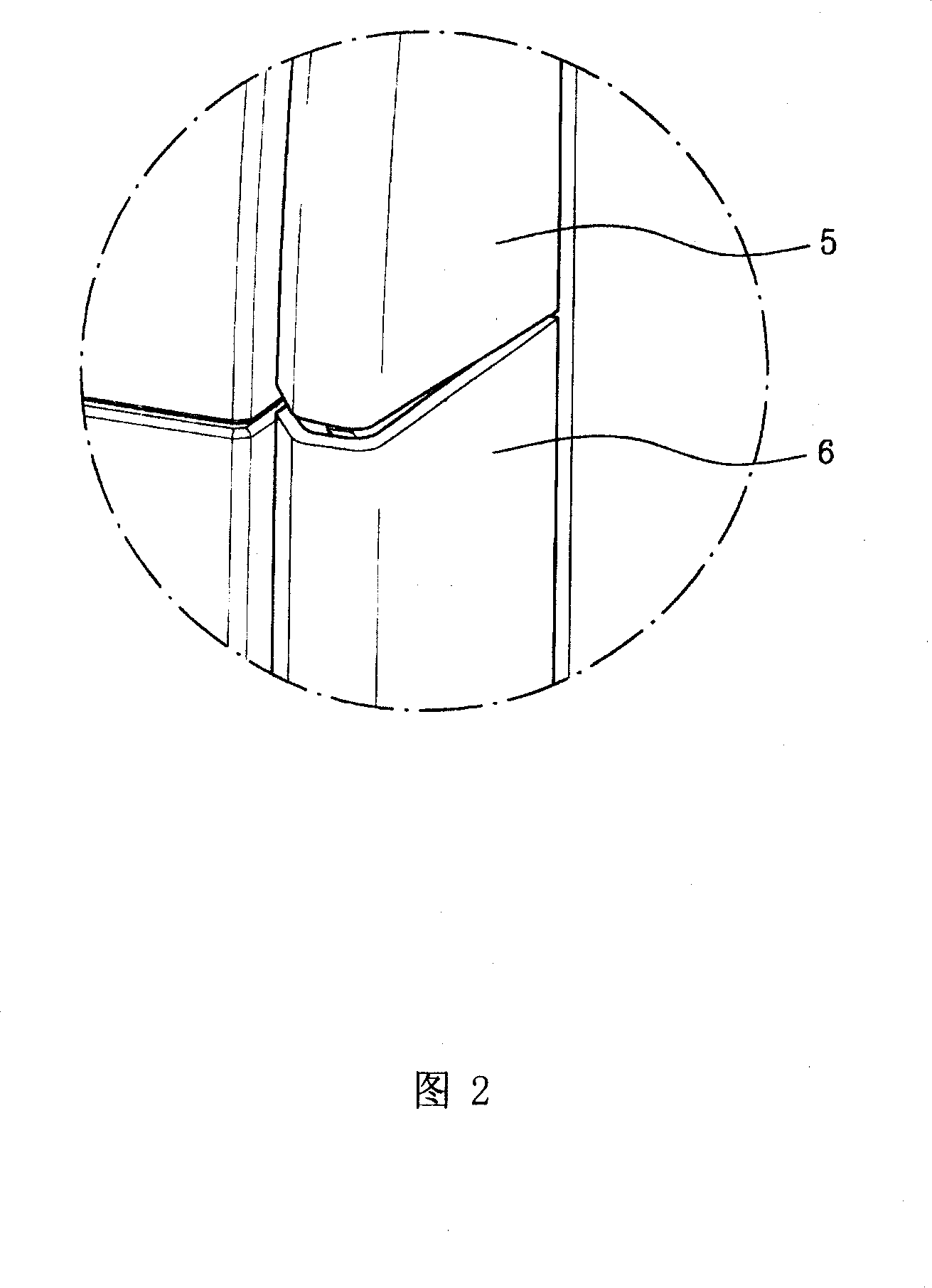

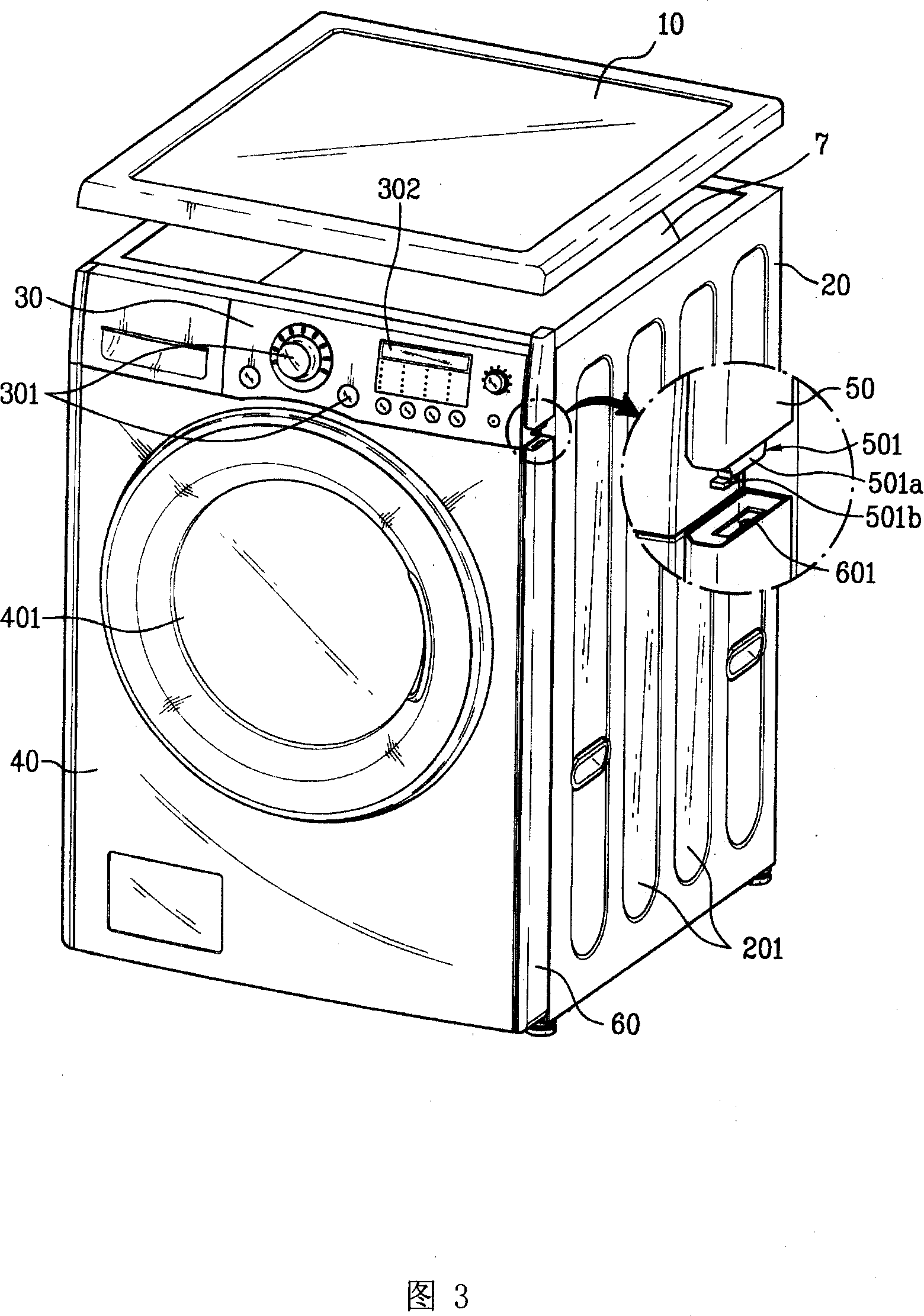

Upper decoration plate and side decoration plate combination structure of drum washing machine

InactiveCN101086120AAvoid mutual dislocationCombine accuratelyOther washing machinesTextiles and paperAgricultural engineeringDislocation

The invention discloses a combination structure of upper decorative plate and lateral decorative plate of drum washing machine, the structure mainly includes: shell of drum washing machine, top board, control panel and fore panel below the covering shell; one side of said decorative plate bottom is formed inserting part extending towards down, and another side is formed positioning pin convex down; one side of lateral decorative plate is formed inserting hole, and another side is formed pin groove. The beneficial effects of the invention are: when said decorative plate is installed on the lateral decorative plate, the positioning pin is inserted in the interior of pin groove in order to the bottom periphery of upper decorative plate is anastomotic with the upper periphery of lateral decorative plate, so the phenomenon of upper decorative plate and lateral decorative plate are in dislocation each other or floating. So the upper decorative plate and the lateral decorative plate can combine precisely, thereby the appearance looks uniform and at the same time the reliability of users to the products is increased.

Owner:NANJING LG PANDA APPLIANCES

Upper decoration plate and side decoration plate combination structure of drum washing machine

InactiveCN101086121AAvoid mutual dislocationAvoider floatOther washing machinesTextiles and paperAgricultural engineeringDislocation

The invention discloses a combined structure of upper decorative plate and lateral decorative plate of drum washing machine, it includes: the shell composing the appearance; the upper hiding shell and the top plate forming the upper plate; the control panel of drum washing machine is installed below the fore end of top plate and is equipped with various operating buttons, the drum washing machine also is equipped with upper decorative plates which are installed on two sides of control panel and bottom is extended down and formed the lock part; in order to fix the lock part of upper decorative plate, the upper of the machine is formed with lateral decorative plate equipped with fixing hole; and the fore panel is installed in the inner side of lateral decorative plate and composes the front face external appearance of drum washing machine. The lock part includes the inserting part which is formed through extending from the bottom of upper decorative plate and one side end which is formed on the inserting part, it can avoid the floating protrusion of upper decorative plate. The invention can align the bottom of upper decorative plate and the upper periphery of lateral decorative plate accurately, so it can avoid the mutual dislocation or floating between the upper decorative plate and the lateral decorative plate.

Owner:NANJING LG PANDA APPLIANCES

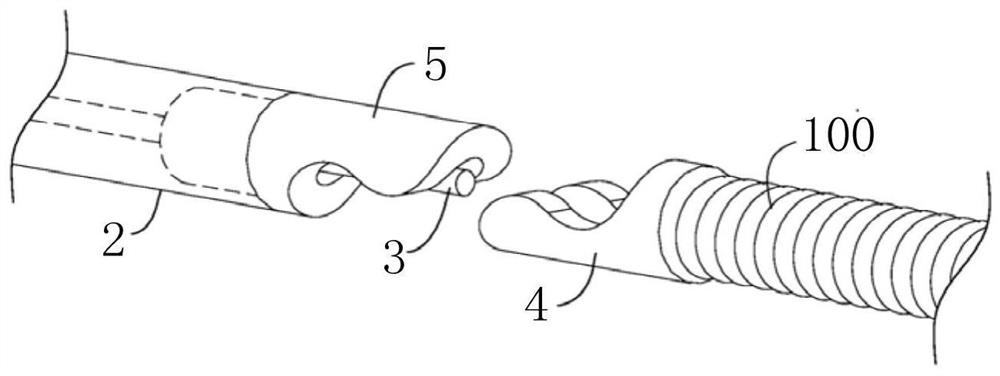

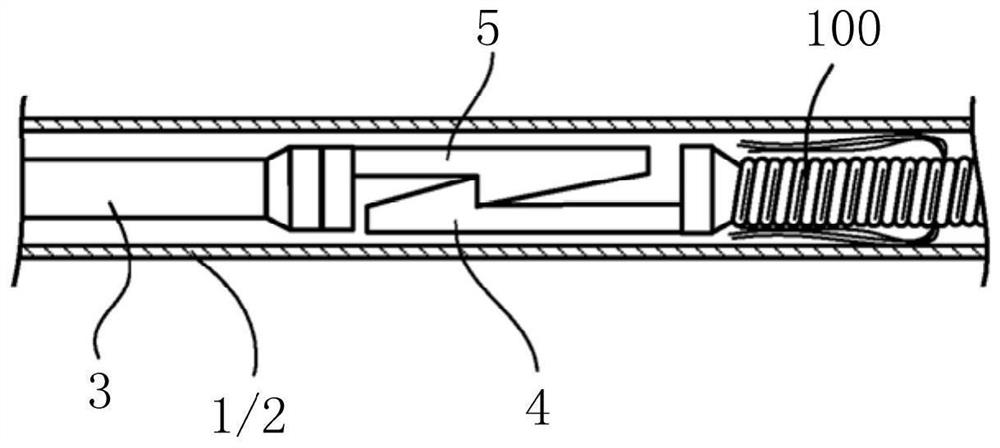

Post-release device for medical instrument implant

PendingCN112790808AImprove lock stabilityAvoid mutual dislocationOcculdersThrombusApparatus instruments

The invention provides a medical instrument implant post-release device, and relates to the field of medical instruments, a first center hole is formed in a first locking part, a first cutting groove is formed in the peripheral surface of the rear end of the first locking part, and a first curved surface is formed on the top surface of a groove body of the first cutting groove; a second center hole is formed in a second locking part and communicates with a pipe cavity of the slender pipe, a second cutting groove is formed in the circumferential surface of the front end of the second locking part, a second curved surface is formed on the top surface of a groove body of the second cutting groove, and an anti-falling limiting part is connected to the front end of the second locking part; in the locking state, the first curved surface and the second curved surface are buckled with each other, the front end of a control cable penetrates through the first center hole and the second center hole, and the anti-falling limiting part is matched with the control cable to limit the front end of the second locking part in the first cutting groove. The post-release device at least relieves the problem that in an existing post-release device capable of mechanically releasing a medical instrument implant, once the medical instrument implant is separated from a conveying pipe, the medical instrument implant cannot be withdrawn back to the conveying pipe, and consequently mistaken thrombus can be possibly caused.

Owner:BEIJING PERCUTEK THERAPEUTICS CO LTD

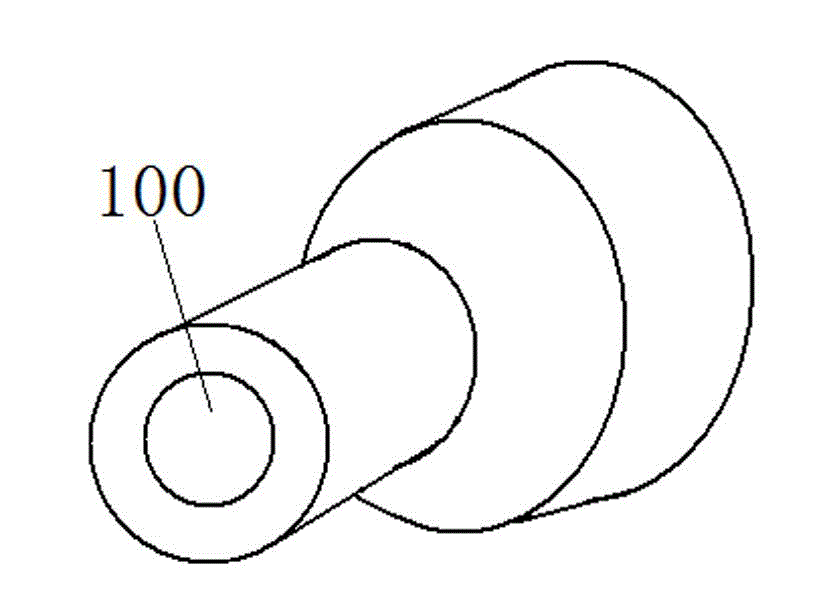

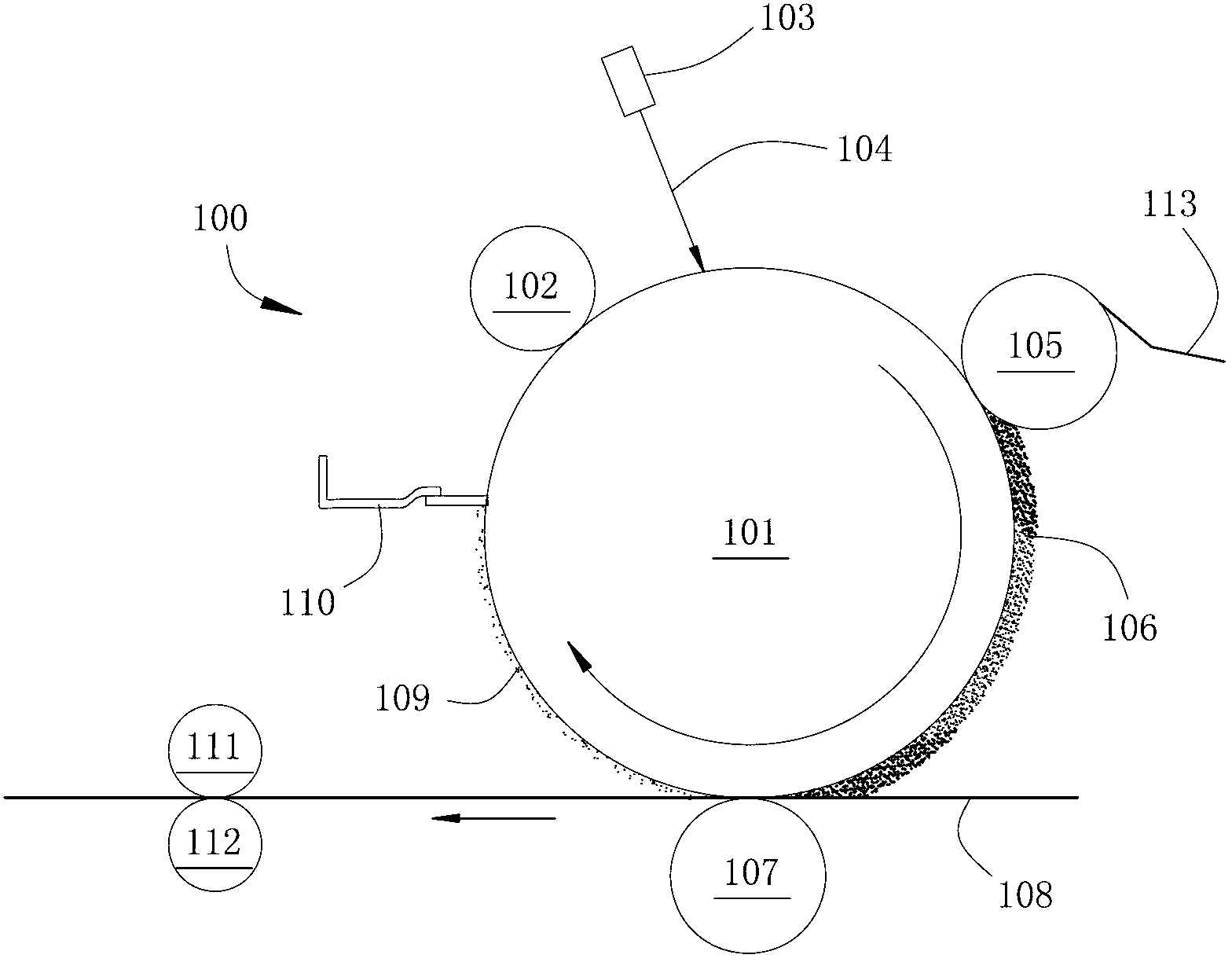

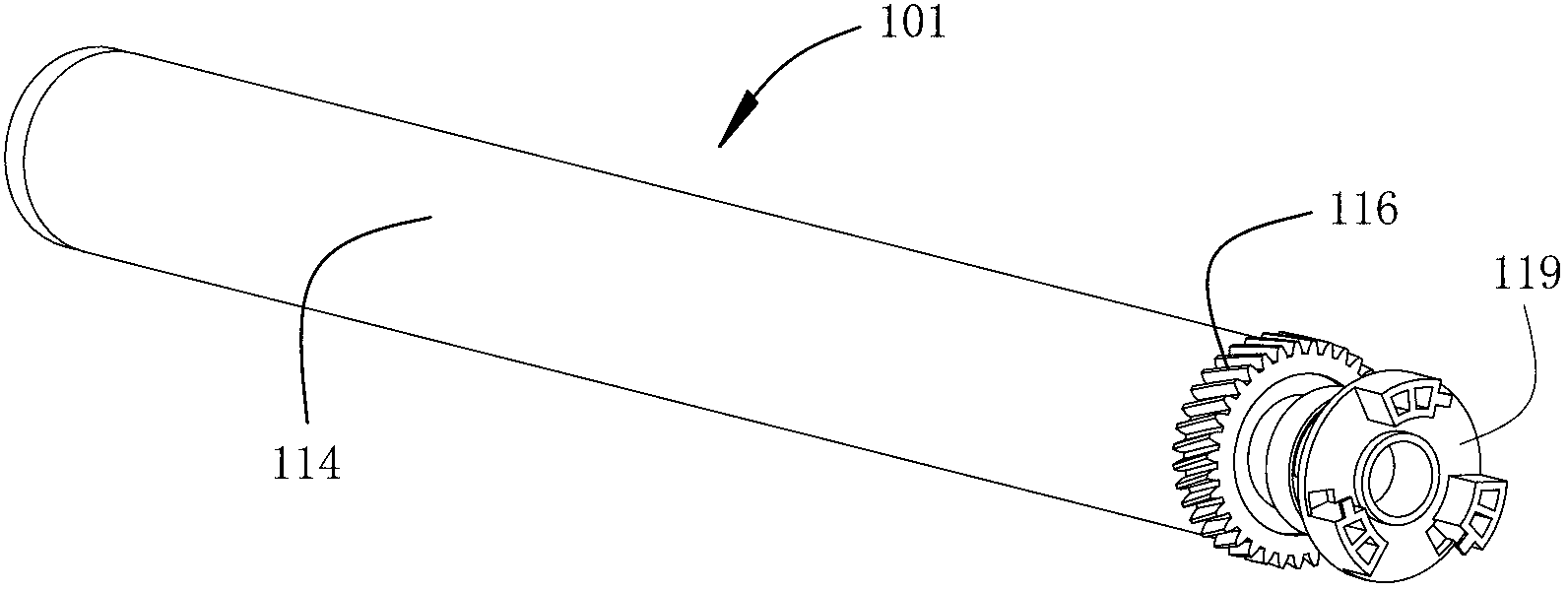

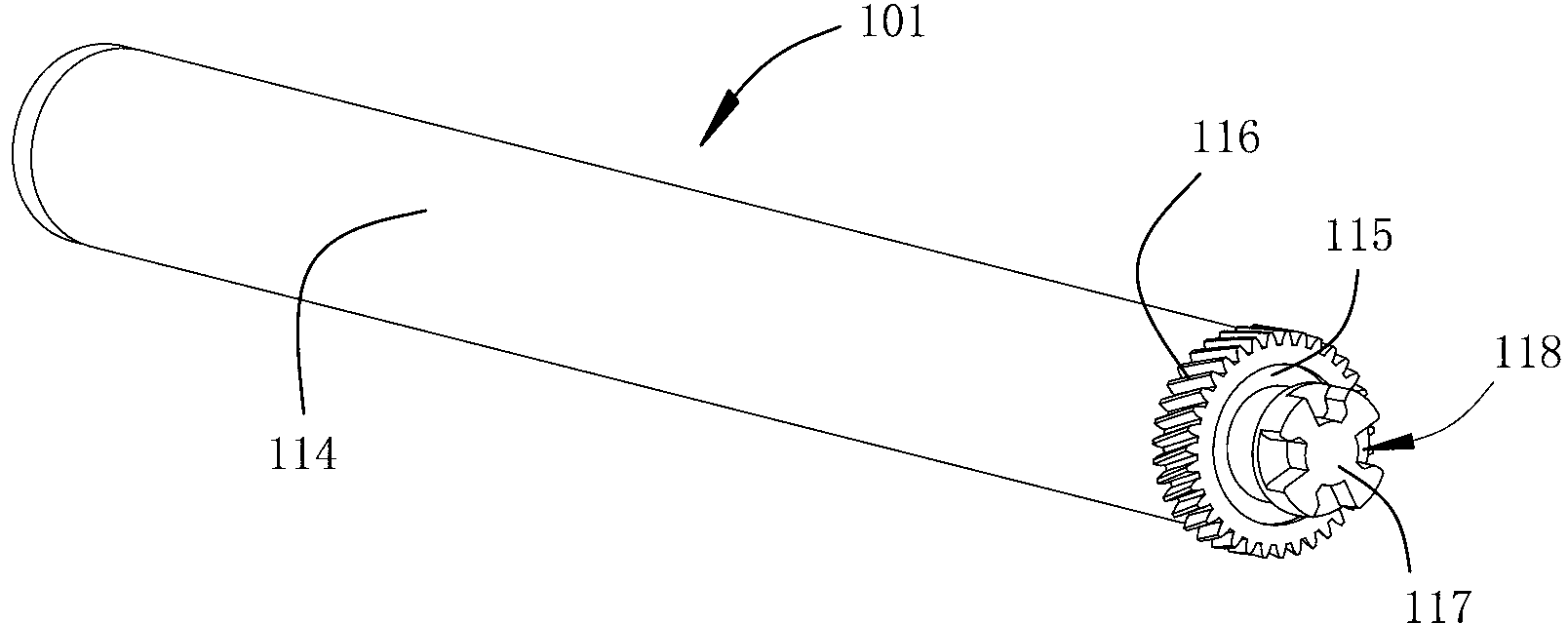

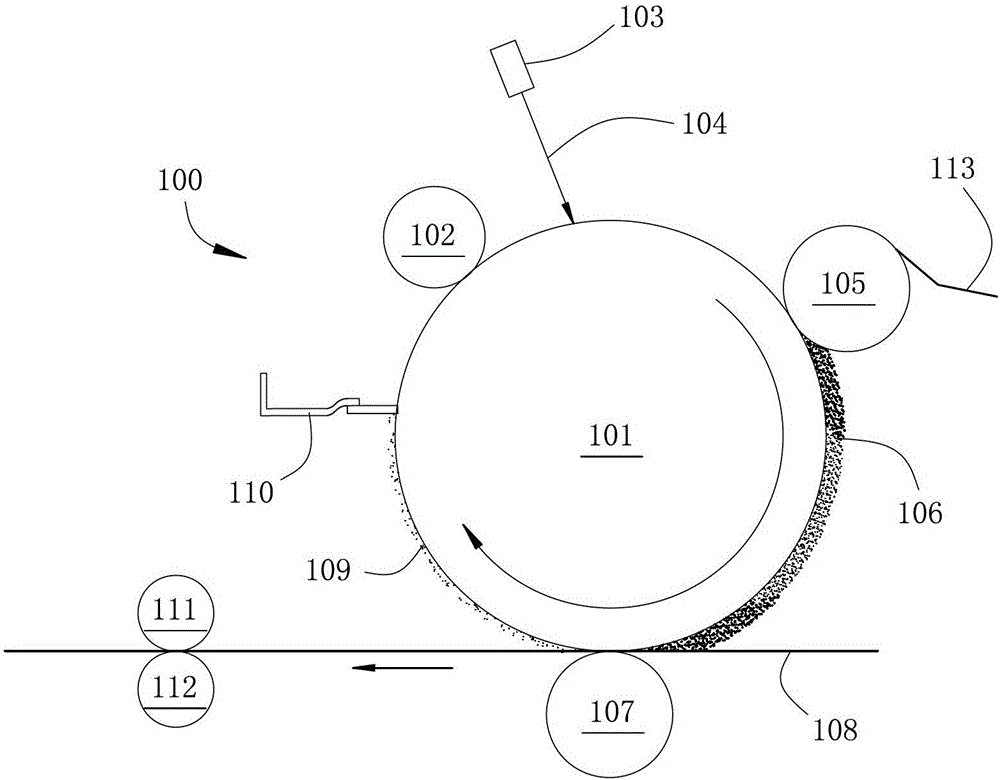

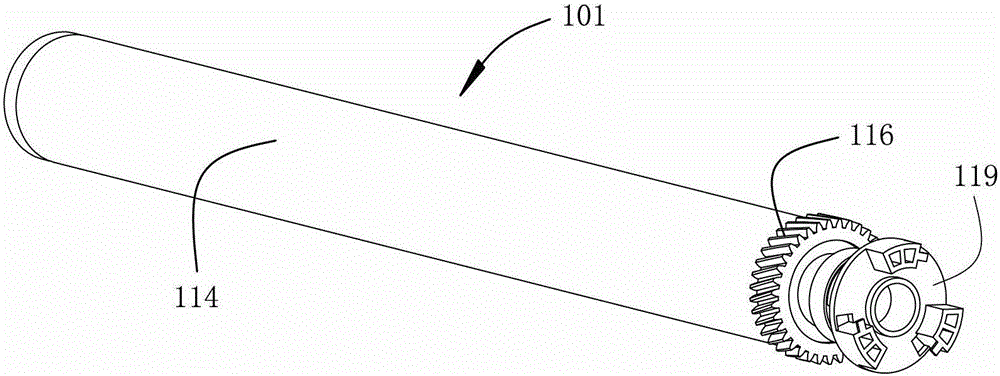

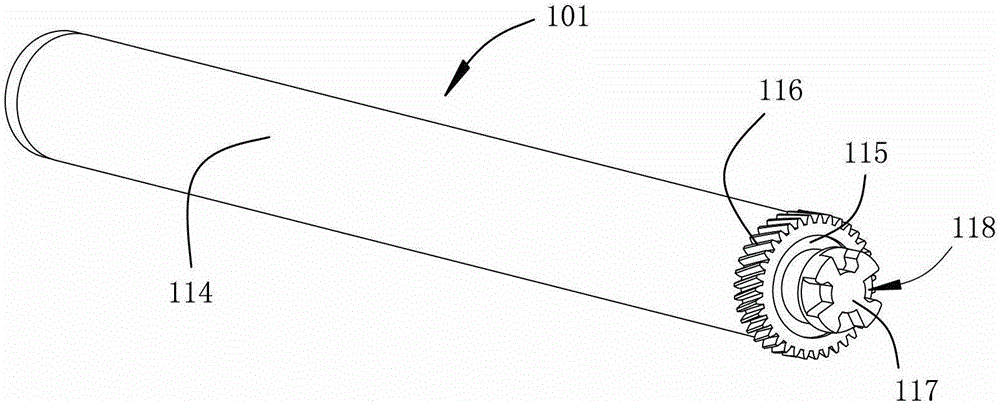

Photosensitive drum for laser printing machine

ActiveCN103309195AEfficient deliveryReduce play gapElectrographic process apparatusElectrical and Electronics engineeringLaser printing

The invention relates to a photosensitive drum for a laser printing machine. The photosensitive drum comprises a photosensitive part and a transmission part, wherein the transmission part is fixed on one side of the photosensitive part along the length direction of the photosensitive part; a cylindrical stress block is arranged at one end, which is back on to the photosensitive part along the length direction of the photosensitive part, of the transmission part; four blind holes which are inwards sunken along the axial direction are formed in the outer end wall, which is back on to the photosensitive part, of the stress block along the axial direction; the blind holes are provided with continuous hole walls on the axial cross section of the stress block; on the axial cross section of the stress block, the four blind holes are symmetrically distributed relative to the radial center of the stress block; the stress block of the photosensitive drum is accurately aligned to a driving head of the laser printing machine, so that the required rotating driving force can be obtained stably from the laser printing machine.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

A kind of rotomolding packaging box for airdrop and preparation method thereof

ActiveCN107383579BNot easy to damageImprove toughnessCoatingsRigid containersLow-density polyethyleneLinear low-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

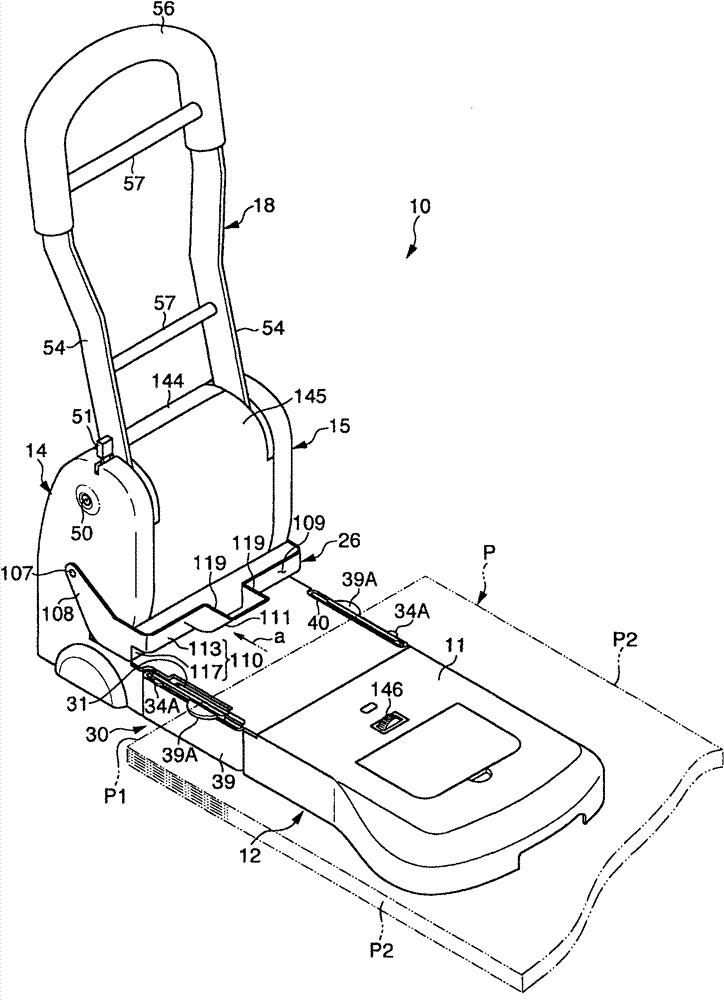

Puncher

ActiveCN101664941BAvoid mutual dislocationSecure the piercing positionMetal working apparatusPunchingEngineering

The invention provides a puncher forming punch holes more than the number of punching blades along the end edge of paper sheets and accurately specifying positions where the punch holes are to be formed. This puncher (10) comprises: a base (12) having a support surface (11) for a sheet of paper (P); the punch blades (24) for punching the sheet (P); and an operation lever (18) for vertically moving the punch blades (24). A position restraining member (31) mounted on the base (12) disappearably to the upper surface side. The position restraining member (31) restrains the position of the side end edge (P1) of the sheet (P) perpendicular to the insertion side end edge (P1) thereof so that the punch holes of two times the number of the punch blades (24) can be formed in the positions symmetrical with respect to the center of the insertion side end edge (P1). A centering member (30) is provided in the base (12), and used as an extended support surface.

Owner:KOKUYO CO LTD

Reinforcing rib making die for ribbed superposed concrete prefabricated member

ActiveCN102303364BEasy to disengageArbitrarily determine the size lengthMouldsBody positionsSteel bar

The invention discloses a reinforcing rib making die for a ribbed superposed concrete prefabricated member. The die comprises a first template and a second template which are arranged corresponding to each other; the sections of the first template and the second template respectively consist of a vertical plate body and a horizontal plate body positioned at the lower part of the vertical plate body and are L-shaped; a first elastic lining film and a second elastic lining film are respectively arranged on the inside walls of the first template and the second template; the mutually corresponding edges of the first lower lining film and the second lower lining film are respectively concave-convex; a first baffle plate and a second baffle plate are respectively arranged between the first template and the second template and are respectively in contact with the first elastic lining film and the second elastic lining film; the first baffle plate is provided with a first steel bar hole and asecond steel bar hole; and the second baffle plate is provided with a third steel bar hole and a fourth steel bar hole. The die has the remarkable characteristics of standardization, strong interchangeability, simplicity and convenience in disassembly and assembly, no need of die release treatment and capability of meeting industrialized production of concrete prefabricated members.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

Joint connecting structure of prefabricated floor slab and construction method

InactiveCN112252558AAvoid mutual dislocationImprove stabilityFloorsProtective buildings/sheltersEarthquake resistantFloor slab

The invention discloses a joint connecting structure of a prefabricated floor slab and a construction method and belongs to the technical field of floor slab connection. The structure comprises a fixed plate; the fixed plate is arranged at the joint of two adjacent prefabricated floor slabs; connecting assemblies are arranged on two sides of the fixed plate correspondingly; the two adjacent prefabricated floor slabs are connected through clamping of the connecting assemblies; each connecting assembly comprises a vertical rod, a handle and a clamping module; the handles are fixedly arranged atthe top ends of the vertical rods; the bottom ends of the vertical rods penetrate through the fixed plate and then are connected with the clamping modules; clamping grooves matched with the clamping modules are formed in the prefabricated floor slabs; and the clamping modules are connected with the clamping grooves in a clamped mode. The two adjacent prefabricated floor slabs are connected together to form a whole, so that the integrity and continuity of a whole floor are guaranteed, high stability and high anti-seismic strength are achieved, and mutual dislocation between the prefabricated floor slabs is prevented.

Owner:绍兴宝城建筑工业化制造有限公司

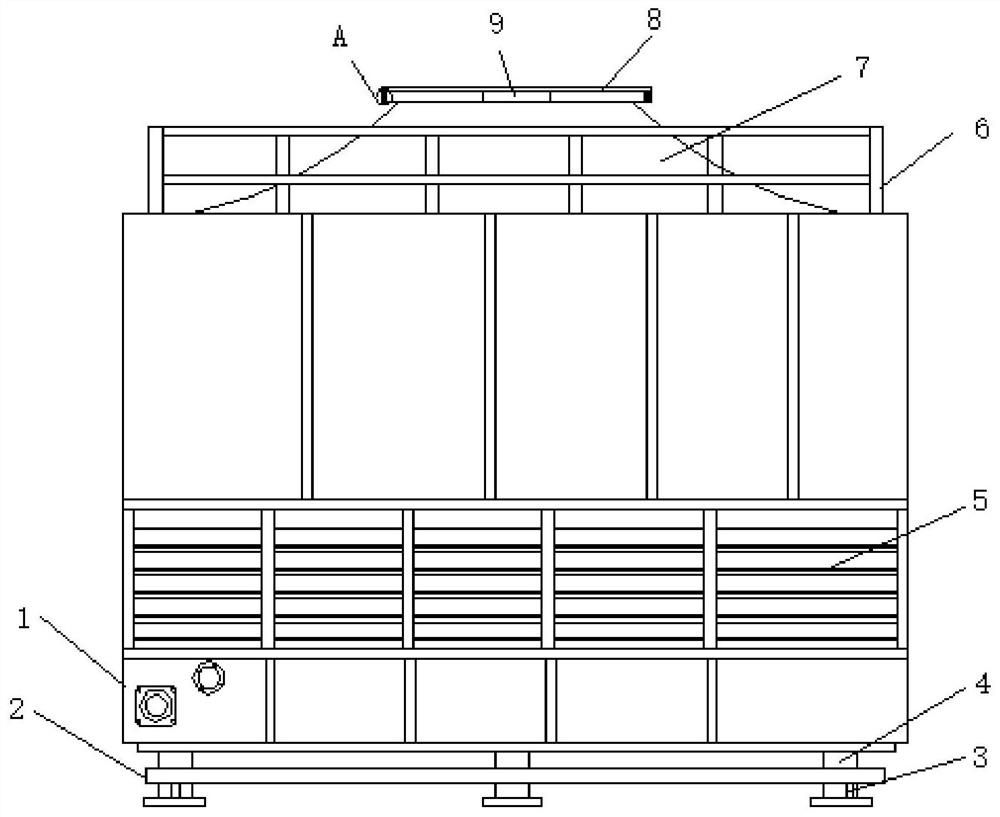

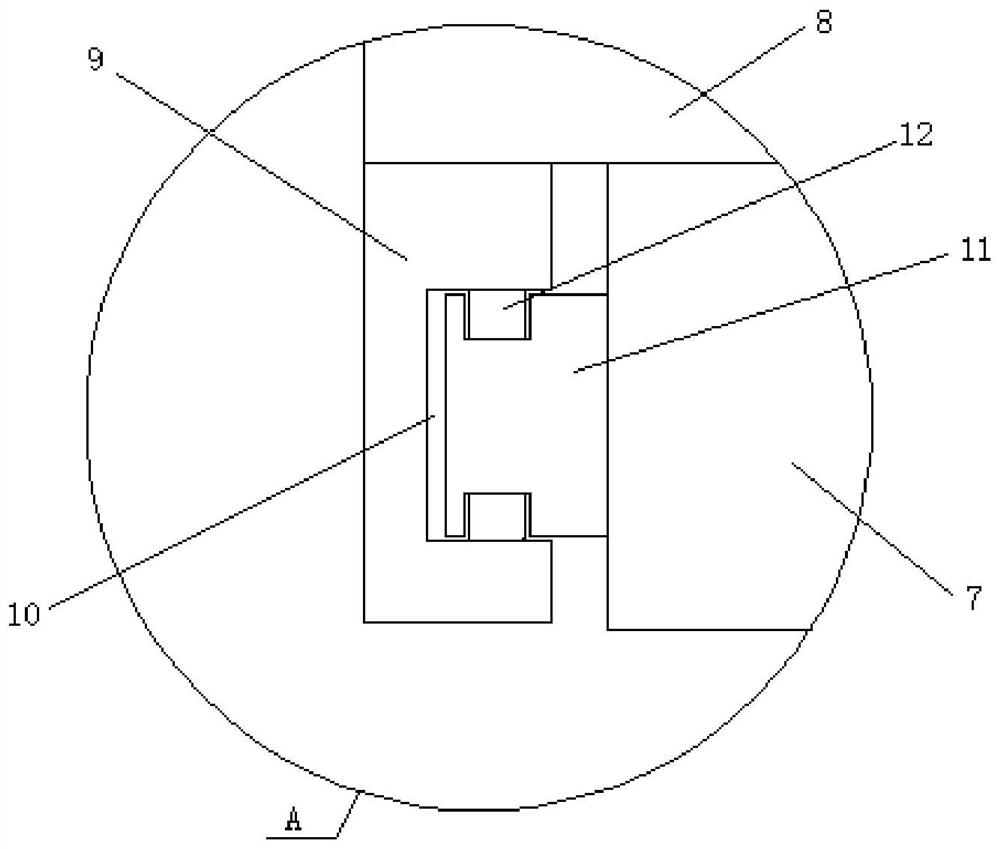

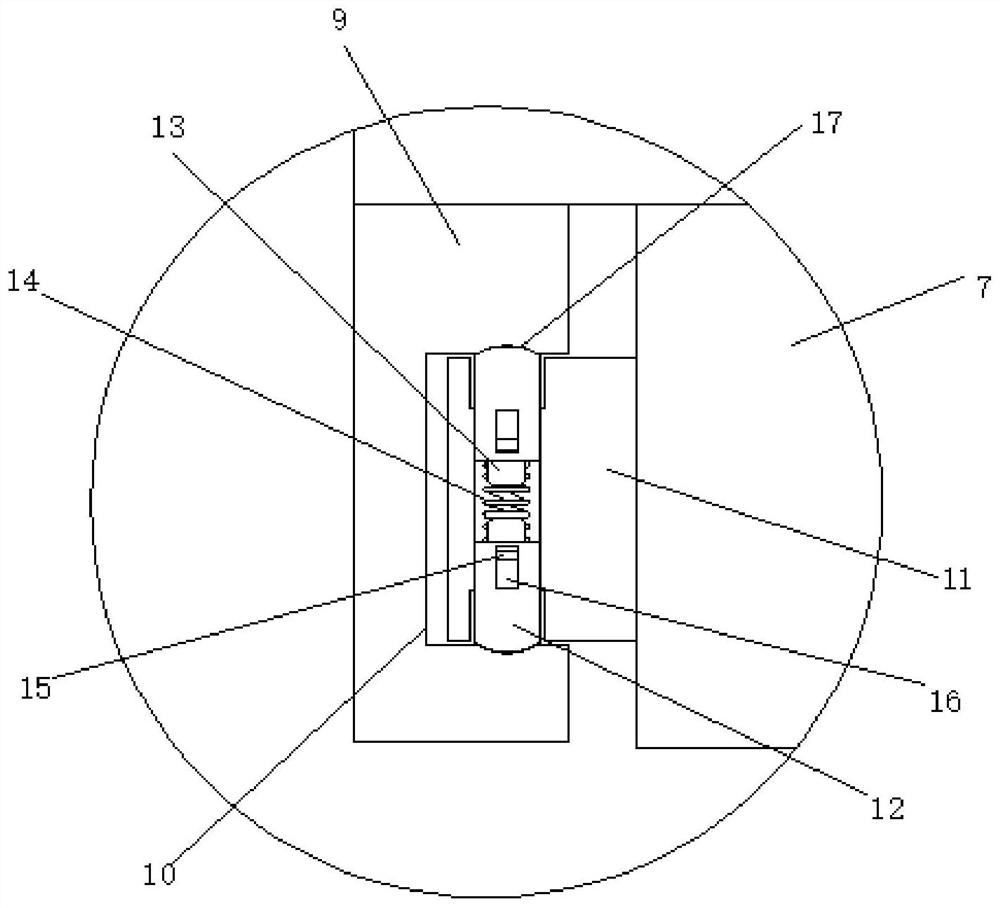

Cooling device for metallurgical furnace charge production

PendingCN112902690APlay the role of isolating impuritiesPlay a corrective roleTrickle coolersMetallurgyEngineering

The invention discloses a cooling device for metallurgical furnace charge production. The cooling device comprises a tower body, wherein an exhaust port is formed in the top of the tower body, a top frame is arranged at the top of the exhaust port, a stainless steel net plate is fixed to the inner side of the top frame, side plates are fixed to the four quadrant points of the bottom of the top frame, and mounting grooves are formed in the side faces of the side plates; and mounting plates are fixed to the four quadrant points of the side wall of the exhaust port correspondingly, and one end of each mounting plate is arranged in the corresponding mounting groove. According to the cooling device, the stainless steel net plate is designed and arranged at the top of the exhaust port, so that the effect of isolating impurities is achieved, the situation that the impurities enter the device and damage the device is avoided; and through the design of fixing columns, the fixing columns are rapidly clamped in fixing grooves, and then the top frame is subjected to limiting installation, so that the side plates and the mounting plates are prevented from being disengaged due to mutual dislocation caused by rotation of the top frame, and the cooling device is more stable in mounting.

Owner:洪江市三兴冶金炉料有限责任公司

Photosensitive Drums for Laser Printers

ActiveCN103309195BEfficient deliveryReduce play gapElectrographic process apparatusEngineeringLaser printing

A photosensitive drum (101) for a laser printer comprises a photosensitive component (114) and a transmission component (115). The transmission component (115) is fixed on one side of the photosensitive component (114) along the lengthwise direction thereof. One end of the transmission component (115) along the length direction of the photosensitive component (114) that faces away from the photosensitive component (114) is provided with a cylindrical stressed block (117). An external end wall of the stressed block (117) along the axis direction thereof that faces away from the photosensitive component (114) is provided with a blind hole (121) recessed inwardly along the axis direction thereof. The blind hole (121) is provided with a continuous hole wall on an axial cross section of the stressed block (117). The number of blind holes (121) is four. On the axial cross section of the stressed block (117), four blind holes (121) are symmetrically distributed relative to the radial centre of the stressed block (117). The stressed block (117) of the photosensitive drum (101) and a driving head (119) of the laser printer are positioned to be aligned accurately, thus stably acquiring the required rotational driving force from the laser printer.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Assembled geocell

ActiveCN113981940AAvoid mutual dislocationEasy to installSoil preservationGeocellsStructural engineering

Owner:ANHUI ZHONGLU ENG MATERIAL CO LTD

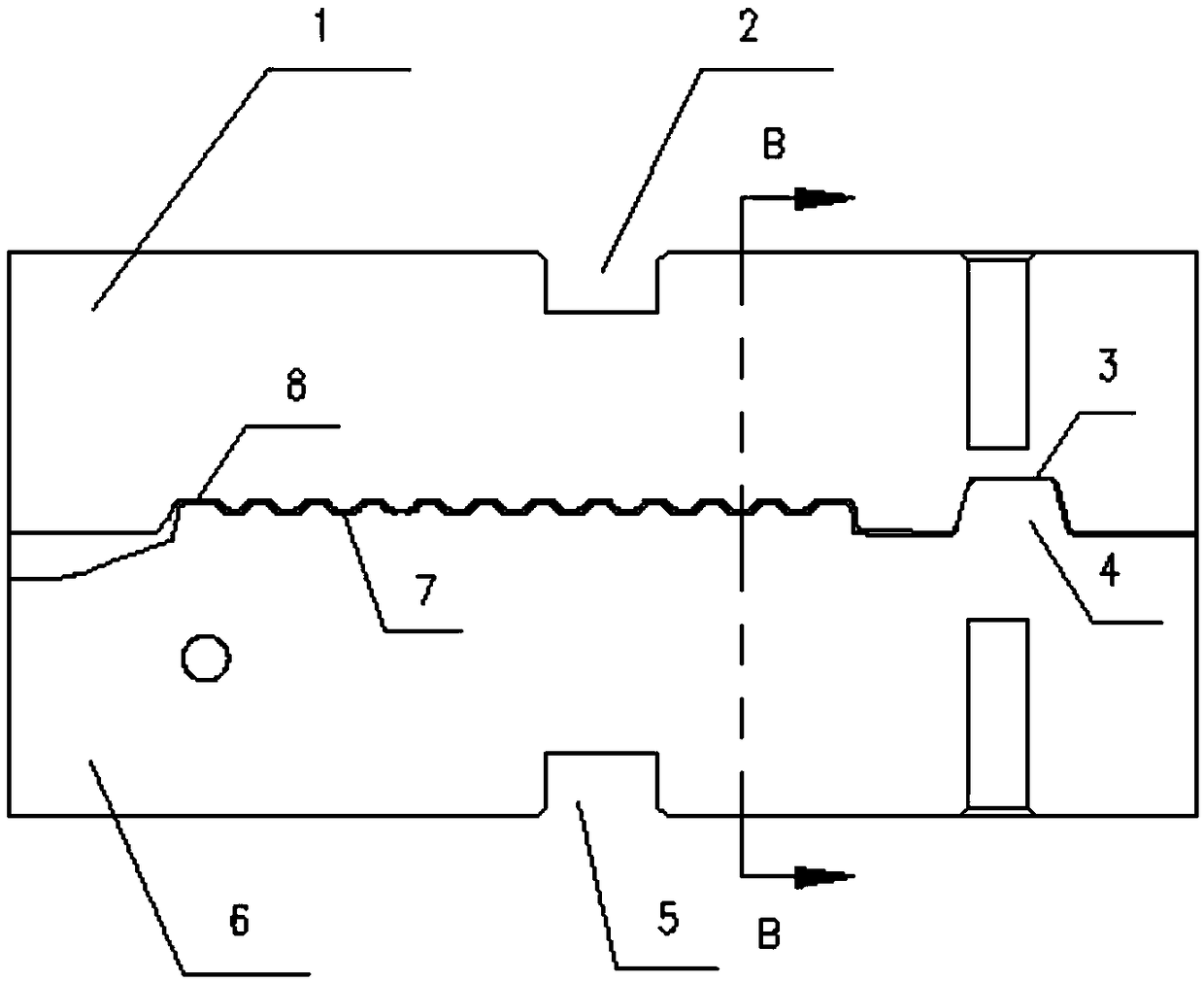

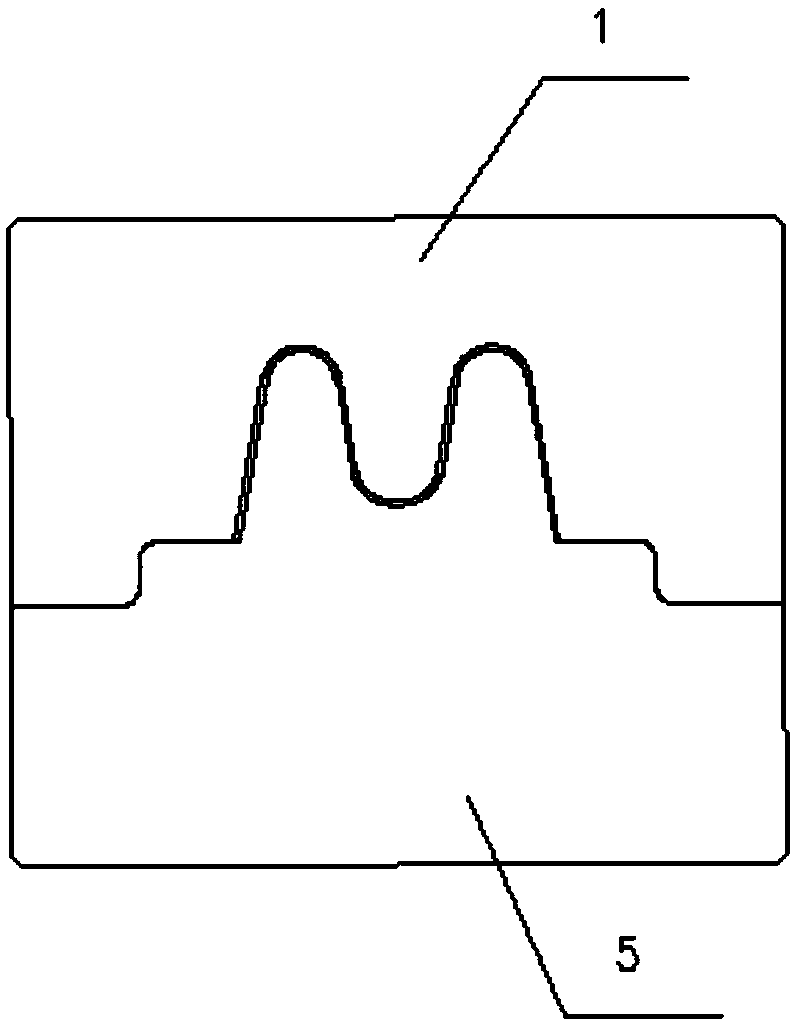

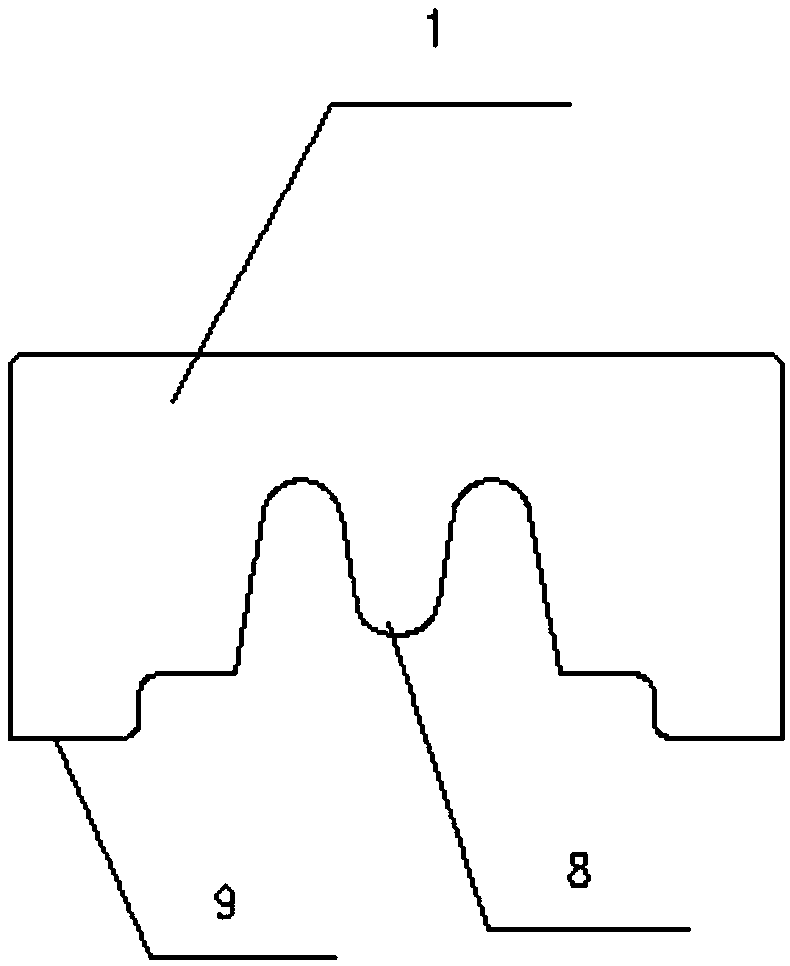

Exhaust block structure preventing injection of die casting liquid

The invention relates to the field of die casting, in particular to an exhaust block structure preventing injection of die casting liquid. The exhaust block structure comprises an upper exhaust blockand a lower exhaust block which are matched with each other. The upper exhaust block is a female die, and the lower exhaust block is a male die. A concave quasi-sinusoidal upper exhaust block exhaustpassage is formed in the middle of the upper exhaust block in the extending direction. A convex lower exhaust block exhaust passage matched with the upper exhaust block exhaust passage is formed in the middle portion of the lower exhaust block in the extending direction. Positioning protrusions are arranged on the parts, on the two sides of the upper exhaust block exhaust passage, of the upper exhaust block. Positioning depressions matched with the positioning protrusions are arranged on the parts, on the two sides of the lower exhaust block exhaust passage, of the lower exhaust block. Limiting grooves are formed in the positions, at the ends of the upper exhaust block exhaust passage, of the upper exhaust block. Limiting protrusions matched with the limiting grooves, are formed in the positions, at the ends of the lower exhaust block exhaust passage, of the lower exhaust block. The exhaust block structure provided by the invention is simple in structure and accurate in positioning andcan prevent injection of the die casting liquid.

Owner:天津市发利汽车压铸件有限公司

Material formula and production process of automatic winding packaging film

ActiveCN111761899BModerate thicknessStable antistaticFlexible coversWrappersLinear low-density polyethyleneLow-density polyethylene

The invention relates to packaging materials for agricultural harvested crops, in particular to a material formula and a production process for wrapping automatic packaging films used for harvesting and packaging operations such as cotton and silage. Winding automatic packaging film material formula, measured by mass percentage, including the following raw materials: linear low-density polyethylene, high-pressure low-density polyethylene, metallocene polyethylene, color masterbatch, anti-aging agent, ultraviolet absorber, antistatic agent; winding The production process of automatic packaging film mainly includes: material preparation; film blowing; glue coating; making roll film unit; roll film unit is connected to form a finished roll film. Utilizing the material formula, the prepared packaging film material has moderate thickness, stable anti-aging and anti-static properties, high anti-buffer strength, good retraction rate and good puncture resistance. The production process of the present invention is reasonable in process design, economical and practical, so that the sealing mouth of the material is tight and firm, and the produced packaging film can be quickly separated during the packaging process of the material.

Owner:新疆棉锦农业科技有限公司

Connection structure of flexibly-packaged high-capacity battery cell and pole

PendingCN114243224ADoes not increase internal resistanceIncrease connection areaSecondary cellsCell component detailsBusbarEngineering

The invention provides a connection structure of a soft-package high-capacity battery cell and a pole, and belongs to the technical field of energy storage batteries, the connection structure comprises a soft-package battery cell and a busbar, the busbar is provided with a through hole, a connection plate is arranged at the through hole, the soft-package battery cell is connected with a tab, and the tab penetrates through the through hole in the busbar and is attached to the connection plate. According to the invention, the through hole is formed in the busbar, and no hole is formed in the tab, so that the internal resistance of the tab is not increased; and meanwhile, the tabs are attached to the connecting plates, so that the connecting area of the tabs and the busbars is increased, namely, the overcurrent area of the tabs and the busbars is increased, and pseudo soldering can be effectively prevented.

Owner:SHAANXI OLYMPUS POWER ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com