Cable core longitudinal wrapping production line and cable core longitudinal wrapping sizing die device

A technology of sizing die and production line, which is used in cable/conductor manufacturing, electrical components, circuits, etc., to achieve the effects of convenient operation, improved assembly accuracy, and guaranteed assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

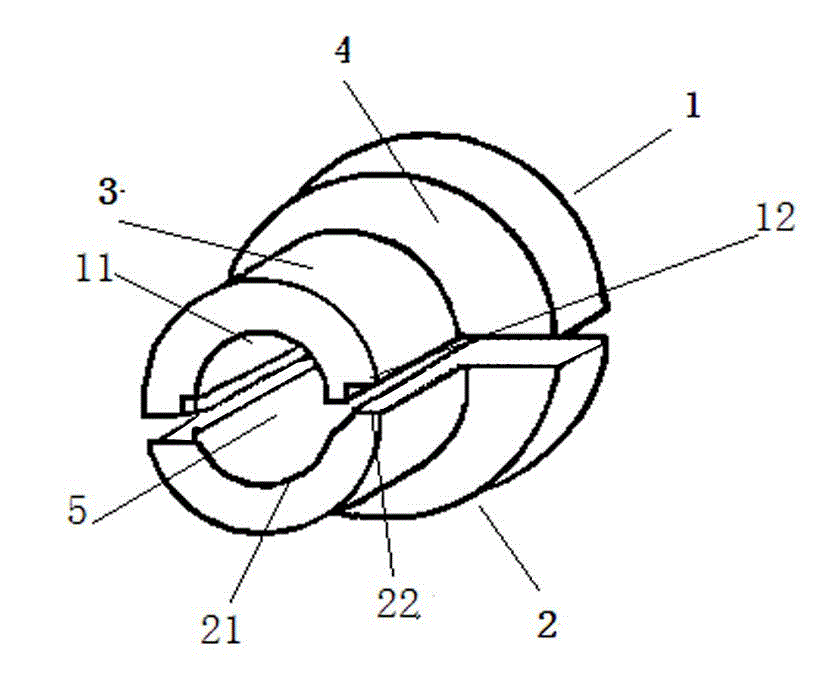

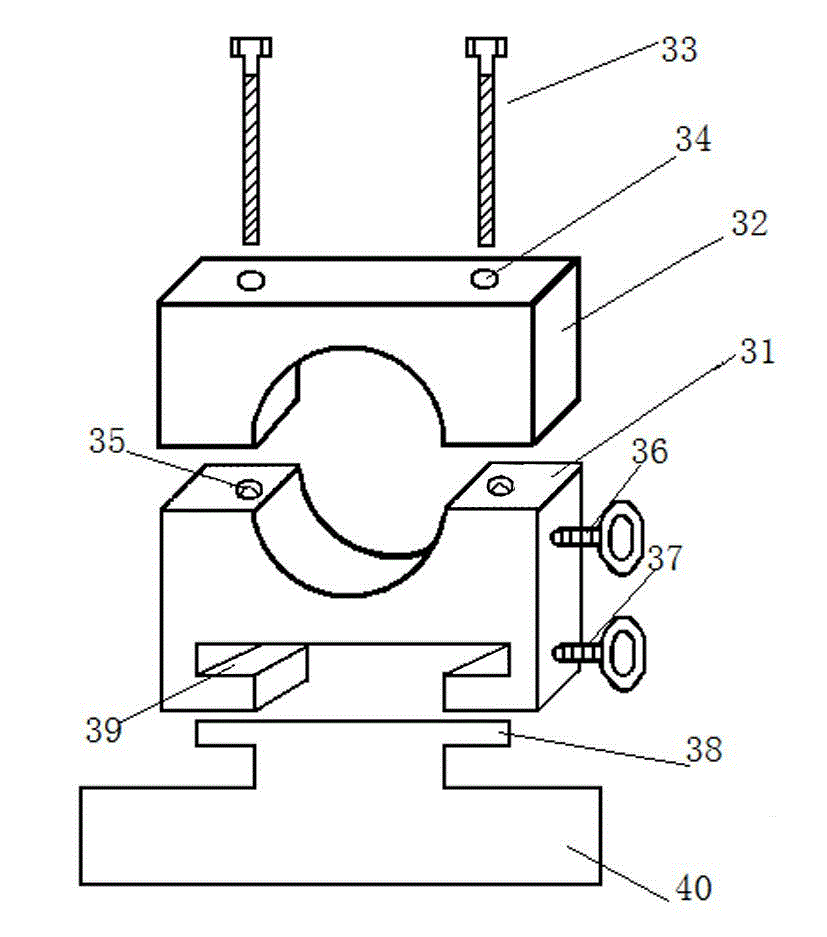

[0026] Such as Figure 2 to Figure 3 Shown, a kind of embodiment of cable core longitudinal package sizing die device, the sizing die device in this embodiment comprises sizing die, and the sizing die here comprises upper die 1 and lower die that buckle together when using The mold 2, the upper mold 1 and the lower mold 2 have opposite buckling sides, the upper mold 1 has an upper arc-shaped groove 11 on the opposite buckling side, the lower mold 2 has a lower arc-shaped groove 21 on the opposite buckling side, and the upper 1. The lower arc-shaped groove forms a sizing hole 5 for the cable core to pass through when the upper and lower molds are fastened together. And, on the opposite snapping sides of the upper and lower molds, it is used for corresponding mating to prevent the upper and lower molds from being dislocated in the horizontal radial direction. The radial limiting structure includes correspondingly arranged on the upper 1. The groove 12 and the boss 22 on the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com