Exhaust block structure preventing injection of die casting liquid

An exhaust block and exhaust channel technology, applied in the field of die casting, can solve the problems of obstructing gas discharge, dislocation of the exhaust block, and inaccurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

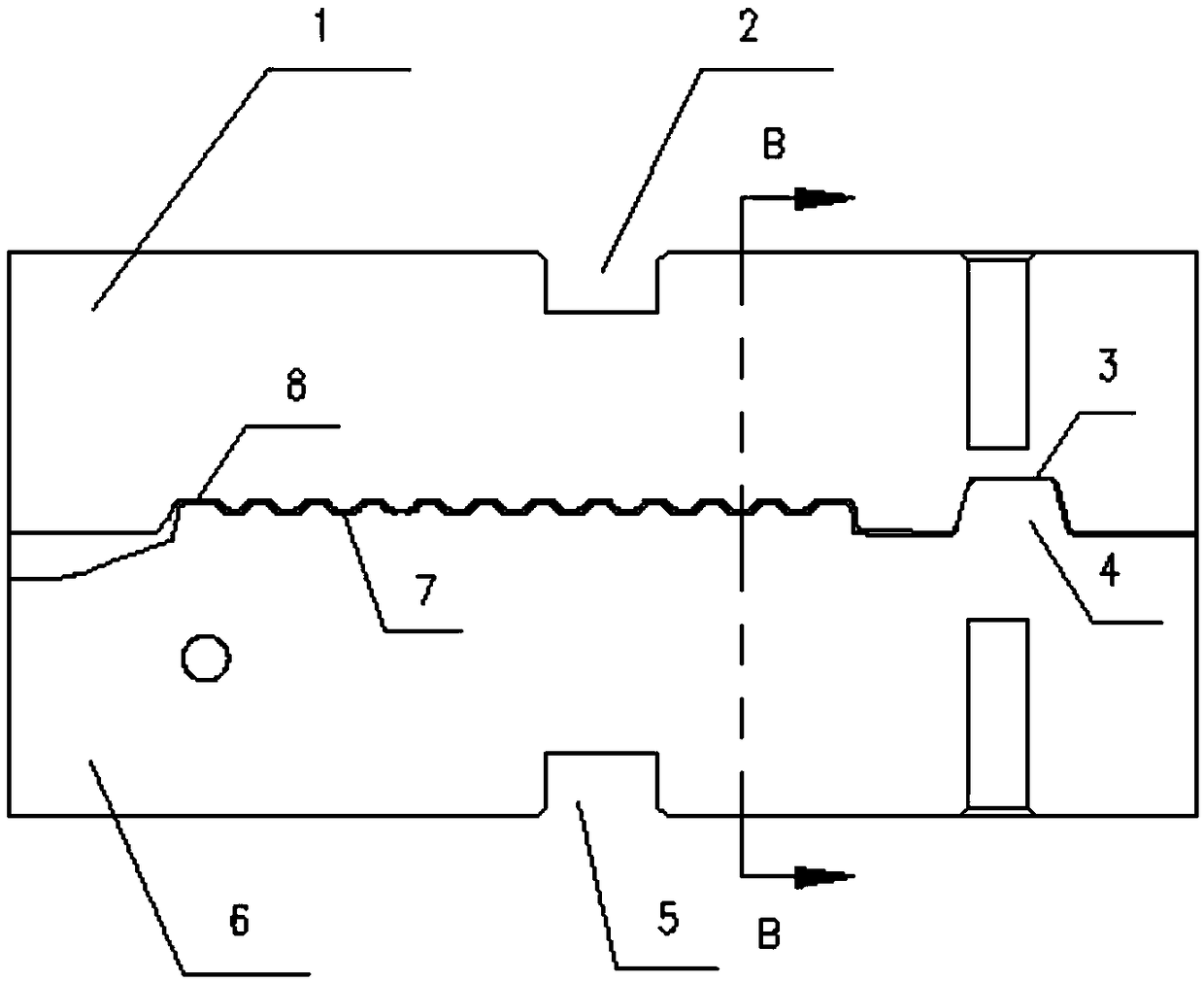

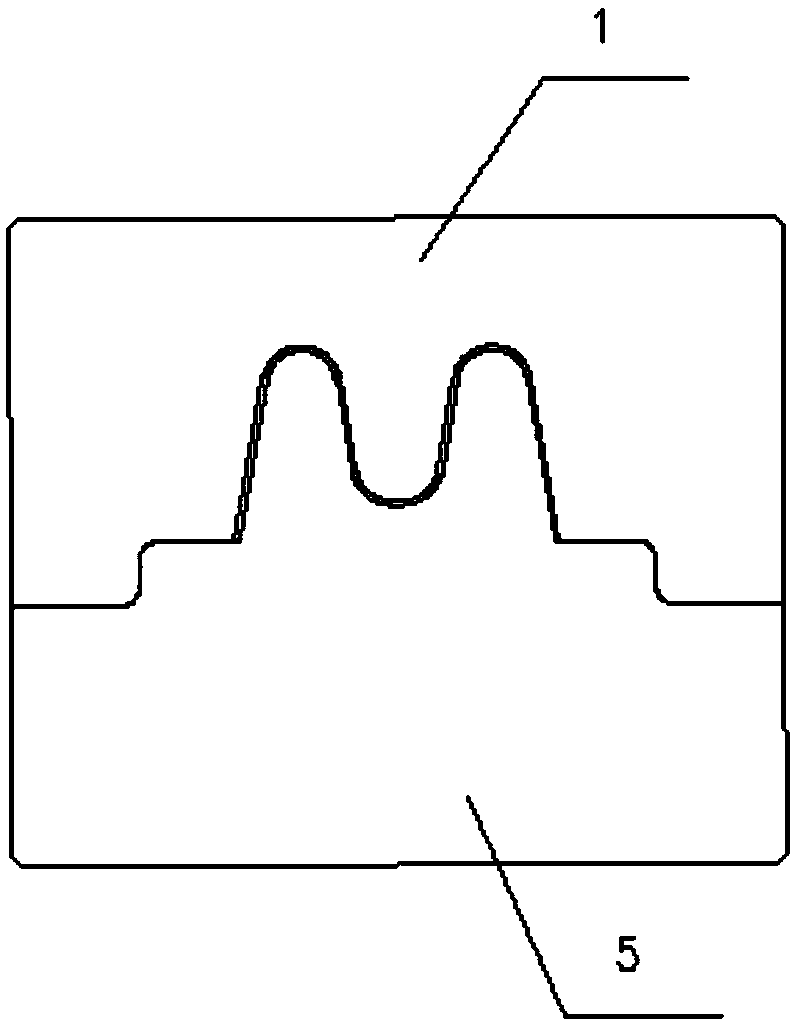

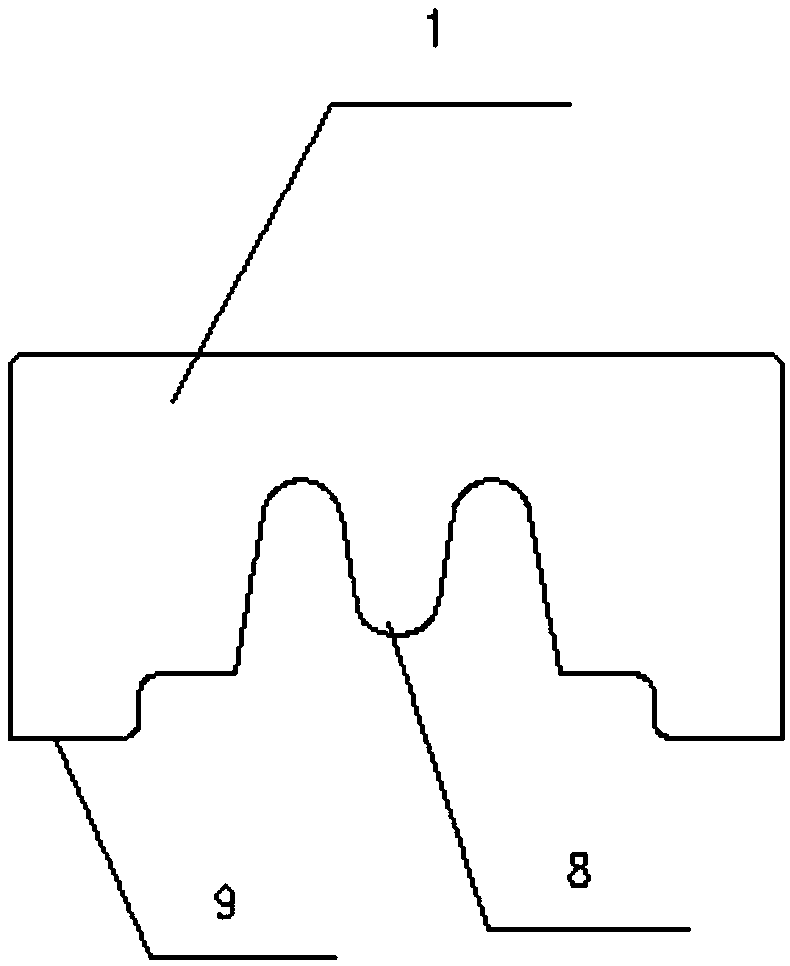

[0014] A venting block structure for preventing injection of die-casting liquid, which includes an upper venting block 1 and a lower venting block 6 that cooperate with each other, the upper venting block is a female mold, the lower venting block is a male mold, and the upper venting block The middle part is provided with a concave sinusoidal-shaped upper exhaust block exhaust channel 8 along the extension direction, and the lower exhaust block is provided with a convex lower exhaust channel 8 along the extension direction and matched with the upper exhaust block exhaust channel. block exhaust channel 7, the upper exhaust block is respectively provided with positioning protrusions 9 on both sides of the upper exhaust block exhaust channel, and the lower exhaust block is respectively provided with positioning protrusions on both sides of the lower exhaust block exhaust channel. Matching positioning depression 10, the upper exhaust block is provided with a limit groove 3 at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com