EPP seat foaming die and foaming technology

A foaming mold and seat technology, which is applied in the field of auto parts processing, can solve the problems of low seat edge strength, seat cover and seat misalignment, troublesome restoration, etc., to achieve simple and economical molding methods, ensure support strength, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

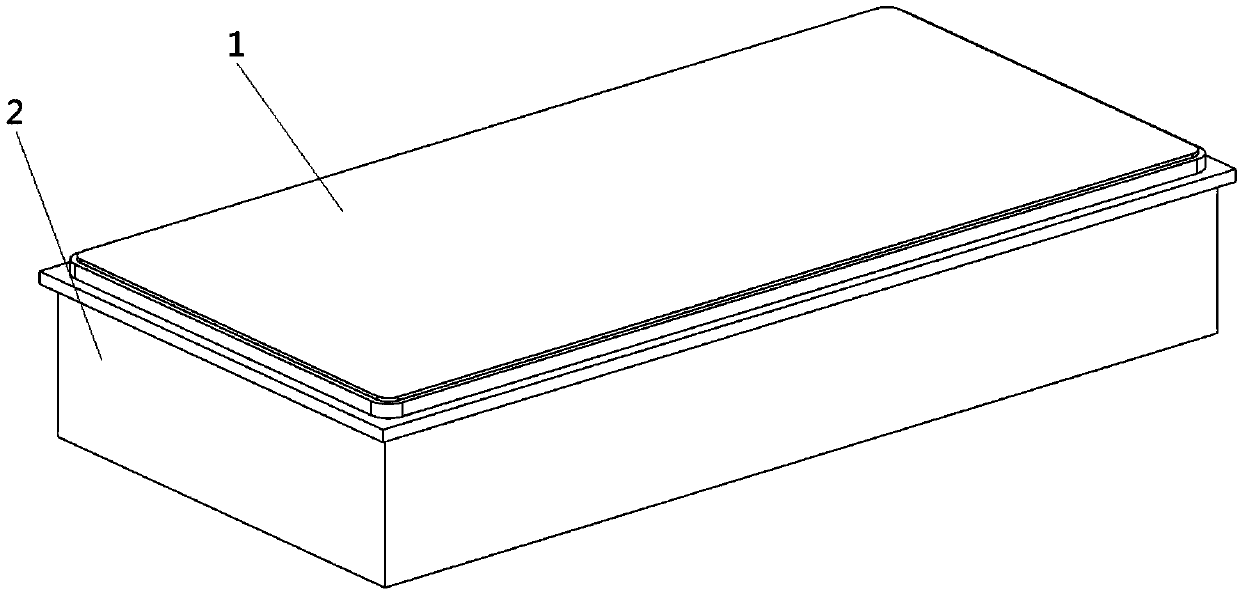

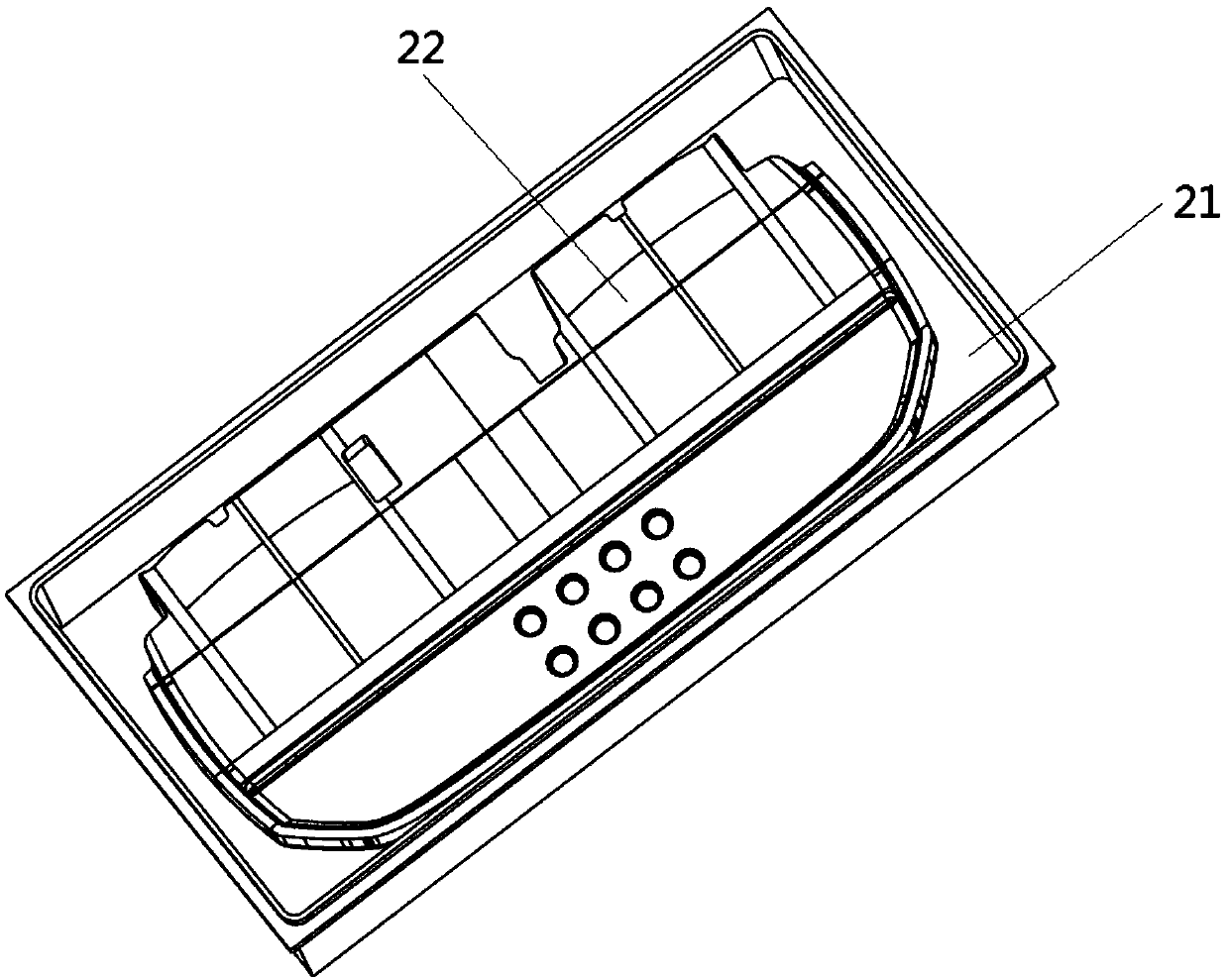

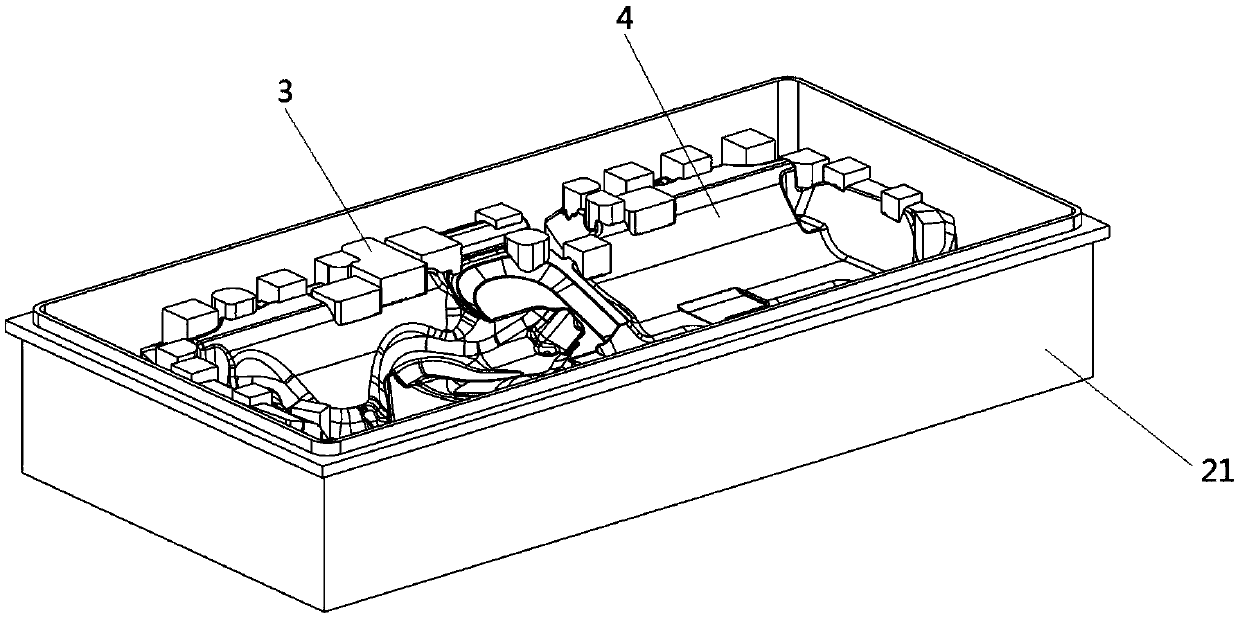

[0020] Such as Figure 1 to Figure 7 As shown, the EPP seat foam mold provided in this embodiment includes an upper template 1, a lower template 2 and a multi-section skeleton steel wire 5, and the mold composed of the upper template 1 and the lower template 2 is installed in an EPP foam molding machine for work. The upper template 1 includes an upper outer panel 11 and an upper mold core 12 arranged in the upper outer panel 11 and used for forming the seat product 4, and the lower template 2 includes a lower outer panel 21 and an upper mold core 12 arranged in the lower outer panel 21 and used for seat product 4 molding. The lower mold core 22 of chair product 4 molding. In order to integrally form the seat product 4 and the skeleton steel wire 5, a plurality of positioning blind holes are evenly processed at the edge of the lower surface of the upper mold core 12, and each positioning blind hole is embedded with a magnetic insert 3 adapted thereto. Specifically, the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com