Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about "Cyanamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

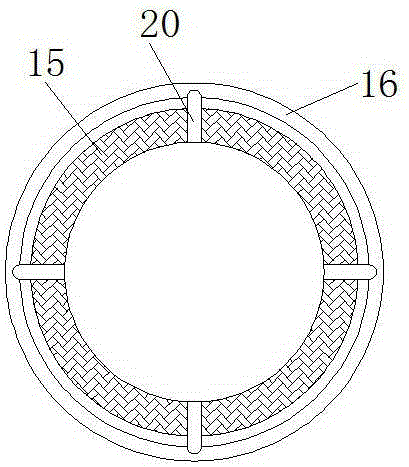

Method for efficiently preparing monocyanamide solution

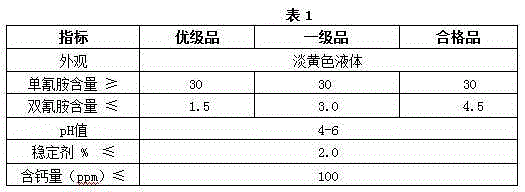

InactiveCN104445276AFill evenly and effectivelyLow concentration requirementCyanamideO-Phosphoric AcidIon exchange

The invention discloses a method for efficiently preparing a monocyanamide solution, and is used for solving the problems of high equipment investment, high energy consumption, long production period, high production cost, high requirement on concentration of carbon dioxide, high content of calcium ions and incomplete filtration of cyanamide waste residue of an existing production process of the 50% monocyanamide solution. The method comprises the steps of performing a hydrolytic decalcification process step, adding phosphoric acid to regulate pH value, and performing microporous filtration, and evaporation concentration to obtain a monocyanamide product. The monocyanamide solution is prepared by improving a gas inlet way of kiln gas and applying a microporous filtration method, an ion exchange resin decalcification technology and a rotary thin film scraper steam method. Compared with a domestic traditional process, by adopting the method, the requirement of the traditional process on the concentration of carbon dioxide is reduced, the content of the calcium ions in the monocyanamide product is strictly controlled, the product quality is improved, the production period is shortened, the energy consumption is reduced, and the production cost is reduced, so that the method is suitable for industrial large-scale production and has good social and economic benefits.

Owner:GULANG XINHUI CHEM

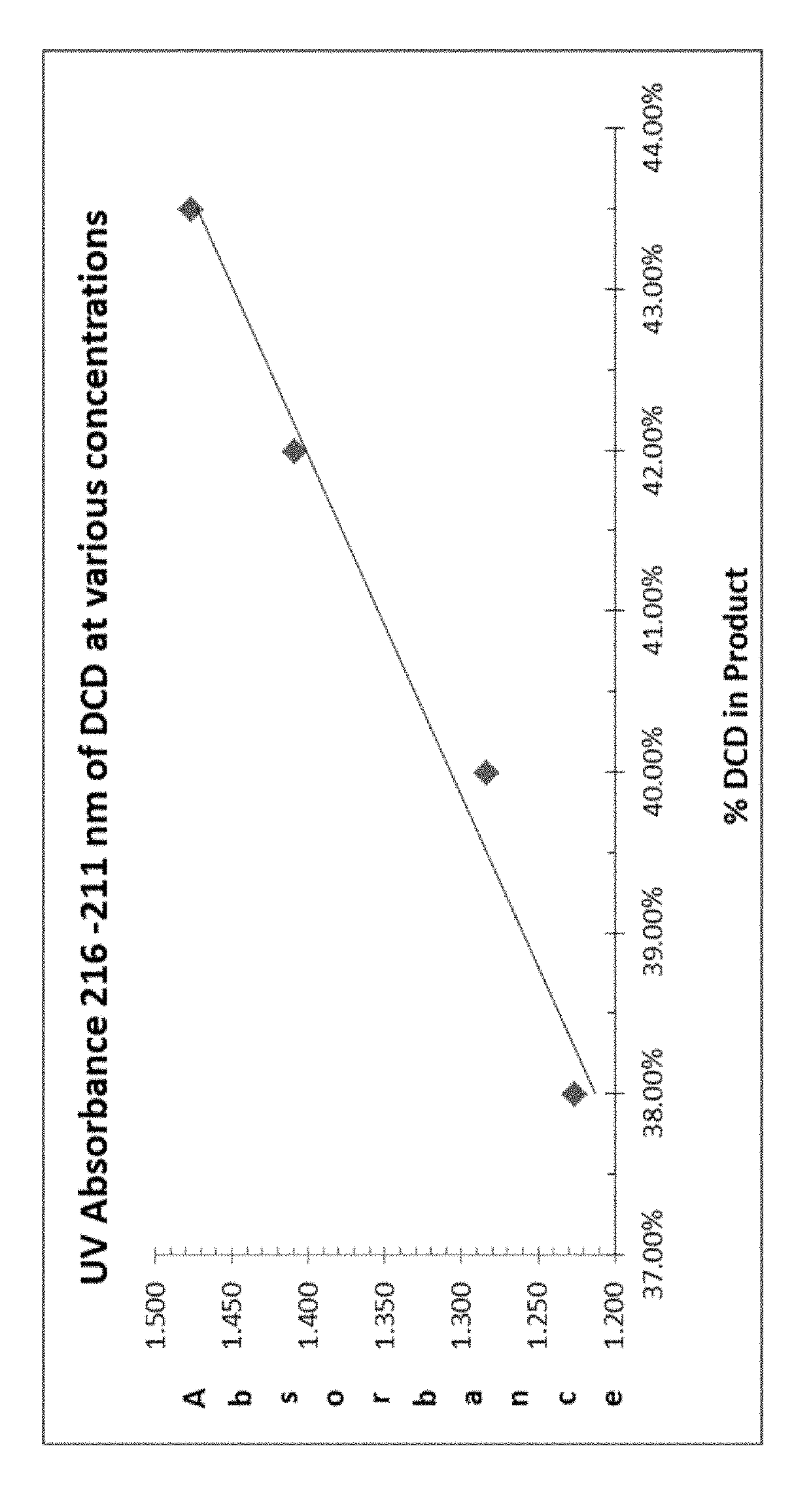

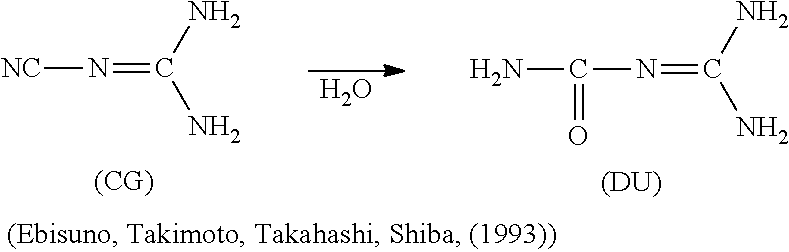

Process to conserve cyano-function and improve performance of low molecular weight nitrification inhibitors to improve fertilizer efficiency

InactiveUS10273194B2Inhibition of dissolutionImprove fertilizer efficiencyBio-organic fraction processingOrganic chemistryThiolOligomer

Disclosed are compositions and methods of making a liquid fertilizer additive of biodegradable polymers and / or oligomers comprised of utilizing a non-aqueous polar, aprotic organo liquid (NAPAOL) as the reaction medium for the reaction of aldehyde(s) with cyano-containing nitrification inhibitors that have one or more groups that react with the aldehyde(s) wherein said reactive groups are selected from the group consisting of a) primary and secondary amines, b) amides, c) thiols, d) hydroxyls and e) phenol.

Owner:SOILGENIC TECH LLC

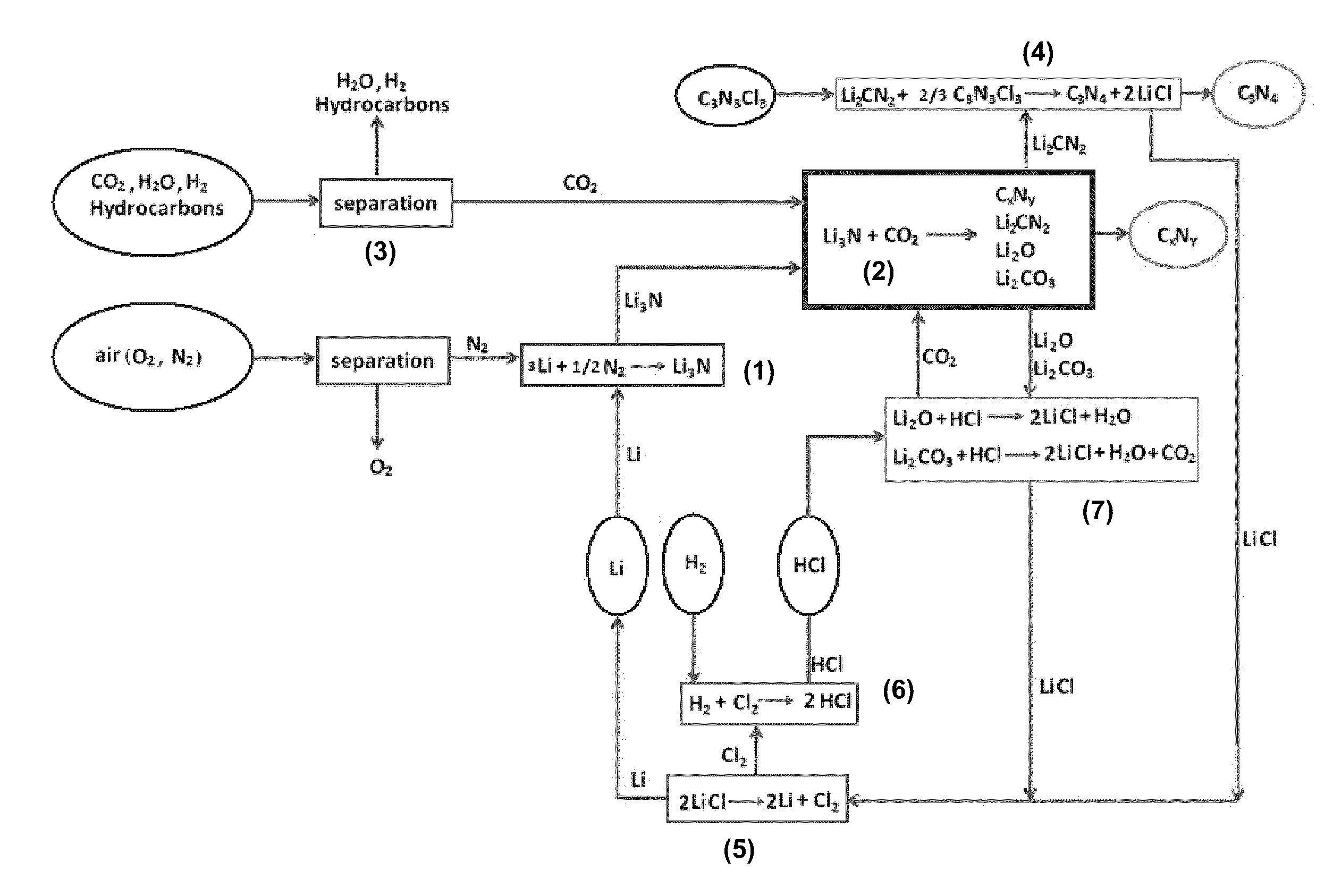

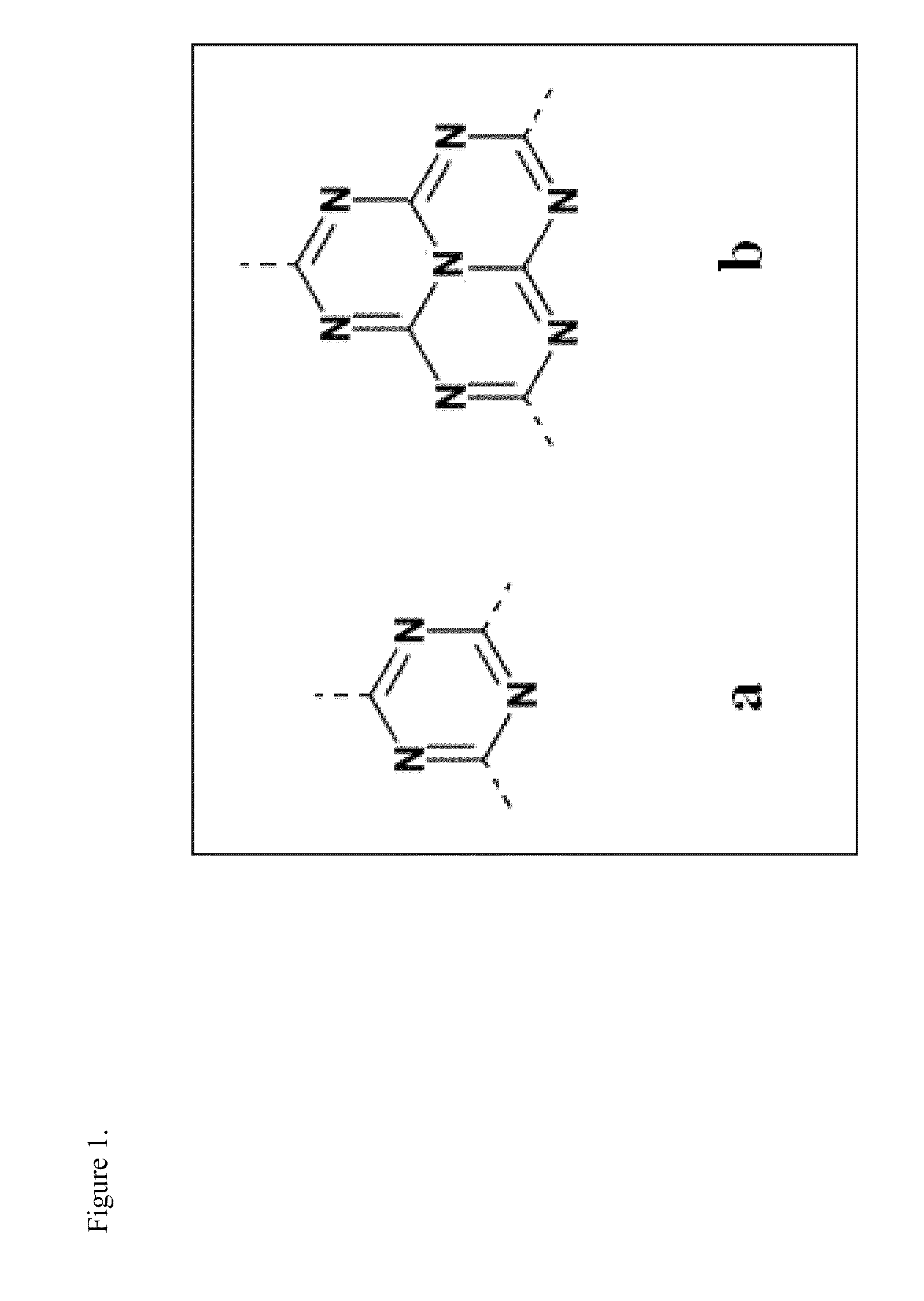

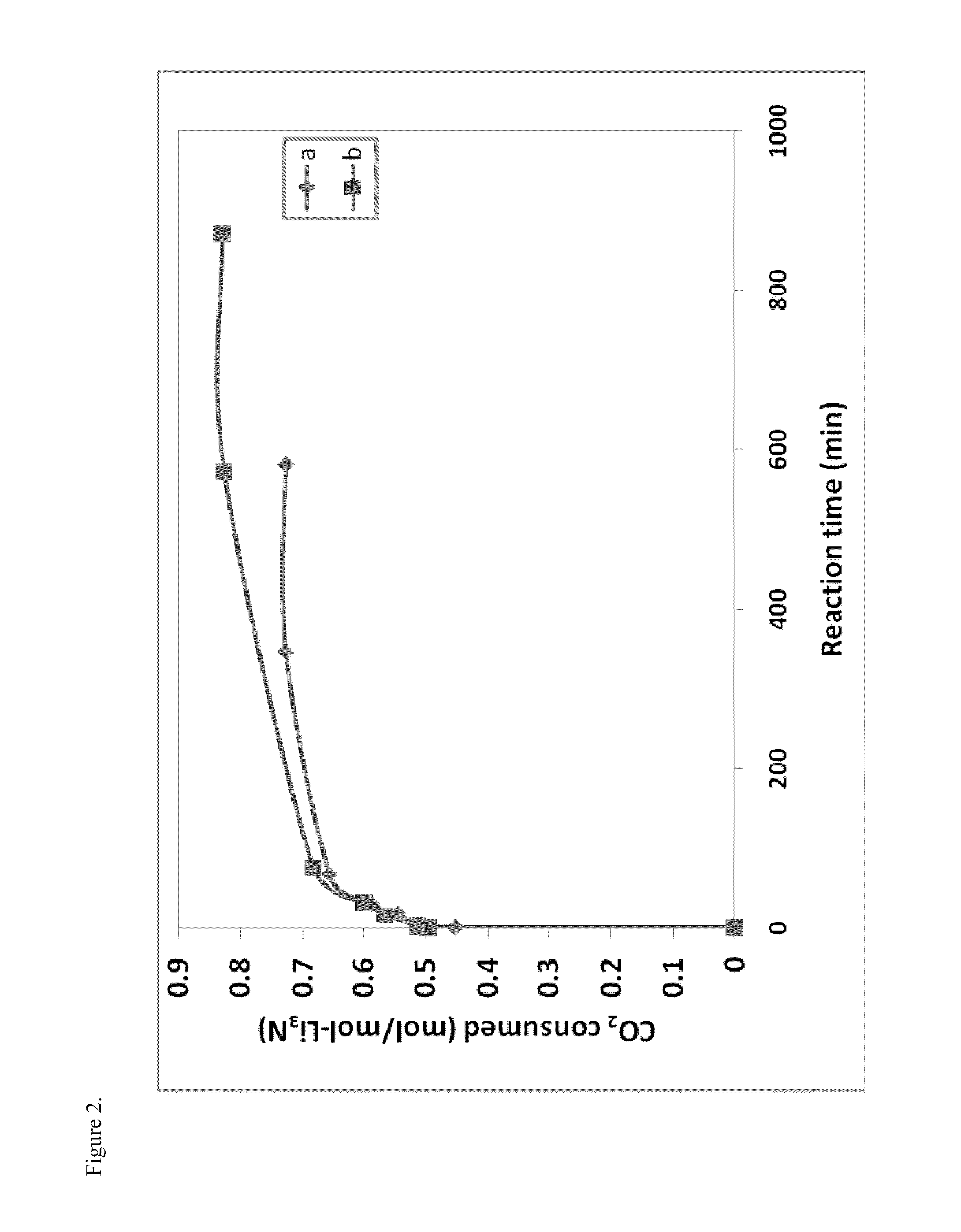

Synthesis of carbon nitrides from carbon dioxide

Provided are methods of converting carbon dioxide to carbon nitrides. In a first reaction, carbon dioxide may be reacted with metal nitrides, such as Li3N, to form carbon nitrides in a fast and exothermic reaction. Also provided are methods of using product metal cyanamides from the first reaction to subsequently generate additional carbon nitrides.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

Purification method of solid cyanamide

InactiveCN101423231ASolve the problem of instability when the water content is highSolve storage problemsCyanamideOrganic solventPurification methods

The invention relates to a purification method of solid cyanamide, and the purification process is as follows: the solid cyanamide to be purified is added in a container which contains an organic solvent and is provided with a stirring device under the stirring state, the temperature is kept at the temperature of 20-40 DEG C, the solid cyanamide is filtered after full dissolution, filtrate is put in a container with cooling and stirring devices, the stirring is continuously carried out simultaneously when decreasing the temperature, when the temperature is decreased to minus 10-5 DEG C, the stirring is carried out for 20-60 minutes, then cyanamide crystals are filtered out, a finished product is obtained after drying, and the filtrate is recycled, and one part of solid cyanamide is dissolved in 0.2-1.5 parts of organic solvent. The purification method solves the problem of instability when the water content in the solid cyanamide is higher and is characterized by simple process, low production cost and good effect, thereby being applicable to large-scale industrial production and solving the problems of storage and transportation of liquid cyanamide at the natural environmental temperature, which confuse people for a long time.

Owner:宁夏大荣化工冶金有限公司

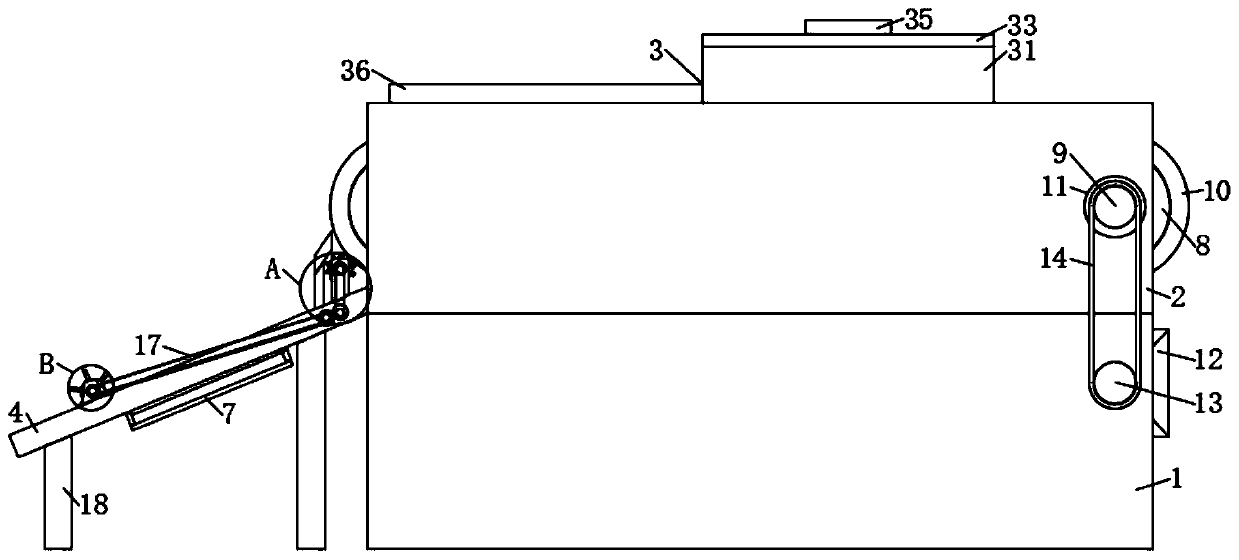

Production method and device of calcium cyanamide

InactiveCN105217655ASmall fluctuationSmall temperature fluctuationsCyanamideGranularityCalcium cyanamide

The invention relates to a production method and device of calcium cyanamide. The method comprises the steps that smashed calcium carbide, catalysts and melted calcium cyanamide are added into corresponding feed bins; the smashed calcium carbide and catalysts are ball-milled to be with required granularity according to the weight proportion and sent into the calcium carbide bin; after the melted calcium cyanamide is ball-milled to be with the granularity ranging from 0.01 mm to 30 mm, the calcium cyanamide is sent to the melted calcium cyanamide bin; the materials in the calcium carbide bin and melted calcium cyanamide bin are sent to a rotary nitriding furnace according to proportions. The device comprises the rotary nitriding furnace, a feeding device installed on the furnace end, a nitrogen input device of a furnace body reaction zone and a cooling device of a furnace body cooling zone, a feed screw conveyor is installed on the furnace end, a heating device is installed on the nitrogen input device of the furnace body reaction zone, and a cooling device is arranged on the furnace body cooling zone. The production method and device of the calcium cyanamide have the advantages that the reaction temperature in the furnace can be adjusted in time, the temperature in the furnace is small in fluctuation, and the discharging and cooling effects are good.

Owner:BEILITE CHEM CO LTD

Preparation method for lime nitrogen

The invention specifically relates to a preparation method for lime nitrogen, belonging to the field of chemical engineering. According to the preparation method, a raw material containing calcium carbonate and a raw material containing ammonia gas are used and subjected to a calcining reaction in a high-temperature reaction furnace for preparation of lime nitrogen. The lime nitrogen produced by using the method is low in energy consumption and production cost, high in the contents of active ingredients, low in impurity content and shallow in color; and calcium recovered after production of cyanamide from the lime nitrogen can be subjected to secondary development to realize valued utilization, so the target of circular economy is achieved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Method for synthesizing calcium cyanamide

InactiveCN108793195AMeet quality requirementsEasy to operateCyanamideCalcium cyanamideEnergy consumption

The invention discloses a method for synthesizing calcium cyanamide. The target product calcium cyanamide is synthesized with ammonium hydrogencarbonate and calcium oxide as raw materials under the effect of a catalyst and protected by inert gas. The method is simple in operation step, low in energy consumption, short in production cycle and high in product yield and purity, and meets the market quality requirements for the calcium cyanamide. The raw materials are easy to obtain, low in price and not subject to geographical restrictions. No waste is generated in the reaction. High environmental value is achieved, and the production cost is reduced under the premise that the product yield and quality are ensured.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Granular lime nitrogen capable of quickly releasing fertilizer effect and production technology thereof

InactiveCN105016359AEasy accessFacilitated releaseCyanamideCyanamide fertilisersPorosityDecomposition

The invention discloses granular lime nitrogen capable of quickly releasing fertilizer effect. The lime nitrogen is synthesized by adopting a drop tube furnace and prepared from nitrogen and the following drying materials including, by weight, 62-68% of calcium carbide, 18-25% of melted calcium cyanamide, 4-9% of fluorite and 8-13% of sodium chloride, wherein the gas forming amount of the nitrogen is larger than or equal to 295 L / kg, and the purity of the nitrogen is larger than or equal to 99.6 percent; the surface of the final product is provided with pores through which water can permeate, and the porosity is larger than or equal to 8 percent. The invention further provides a production technology of the granular lime nitrogen capable of quickly releasing the fertilizer effect. According to the granular lime nitrogen capable of quickly releasing the fertilizer effect and the production technology thereof, due to the fact that a synthesizing technology of the drop tube furnace is adopted, the hardness of the product is smaller than that of a product synthesized by a traditional rotary kiln; the surface porosity is high, closed pores are fewer, water can easily enter the interior of the granular lime nitrogen, the decomposition speed is high, and the fertilizer effect can be fully released; compared with the average 90-day fertilizer effect releasing time of lime nitrogen produced by the rotary kiln, the granular lime nitrogen can achieve the same effect only needing 50 days.

Owner:平罗县祥美化工有限公司

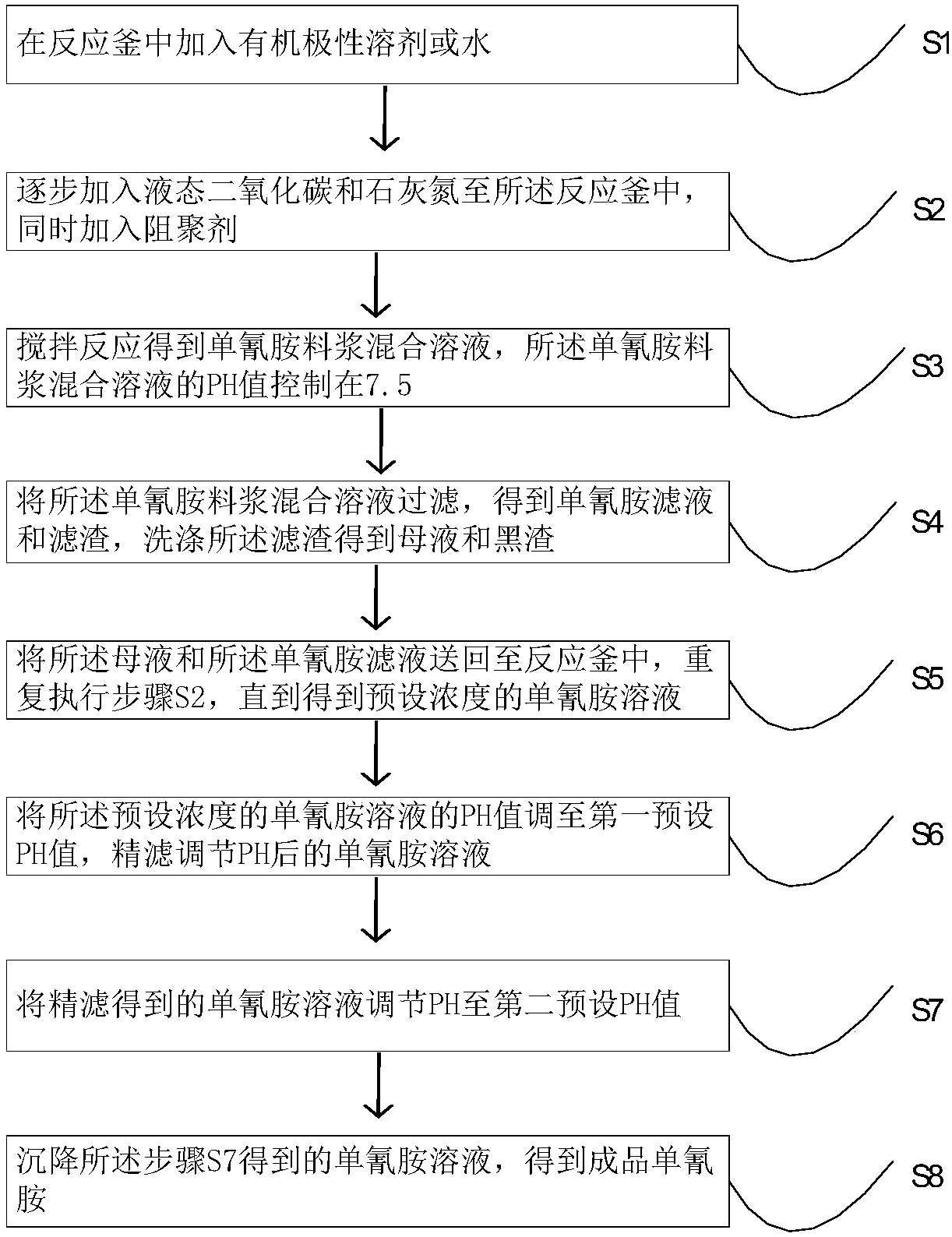

Production process of cyanamide

InactiveCN107814395AThe reaction temperature is easy to controlEasy temperature controlCyanamideFiltrationEvaporation

The invention discloses a production process of cyanamide. The production process comprises the following steps of S1, adding an organic polar solvent or water into a reaction kettle; S2, adding liquid carbon dioxide and lime nitrogen into the reaction kettle step by step, and meanwhile, adding a polymerization inhibitor; S3, carrying out agitation for reaction to obtain a cyanamide slurry mixed solution whose PH (Potential of Hydrogen) value is controlled to be 7.5; S4, filtering the cyanamide slurry mixed solution, so as to obtain cyanamide filer liquor and filter residue, and washing the filter residue to obtain mother liquor and black residue; S5, sending back the mother liquor and the cyanamide filer liquor into the reaction kettle, and repeatedly executing the step S2 until a cyanamide solution with a preset concentration is obtained; S6; regulating the PH value of a substance obtained in the step S5 to a first preset PH value, and carrying out refined filtration on the cyanamidesolution regulated in PH; S7, regulating the PH of the cyanamide solution obtained by the refined filtration to a second preset PH value; S8, settling to obtain the finished-product cyanamide. According to the embodiment of the application, an evaporation concentration process in the prior art is replaced with multiple circular reactions; the temperature is easily controlled and the phenomenon ofan explosion due to a too high reaction temperature cannot occur.

Owner:NINGXIA JIAFENG CHEMICALS CO LTD

Process for hydrolyzing lime nitrogen at one step

ActiveCN104961655AReduce consumptionReduce alkalinityCarbamic acid derivatives preparationOrganic compound preparationNitrogen gasHydrolysis

The invention provides a process for hydrolyzing lime nitrogen at one step. The process includes adding the lime nitrogen into a hydrolysis reaction kettle and simultaneously continuously filling the hydrolysis reaction kettle with mixed gas with nitrogen and carbon dioxide; dripping water and methanol liquor into the hydrolysis reaction kettle; continuously stirring the lime nitrogen, the water and the methanol liquor. The mass ratio of the water to the methanol liquor is 1-2:1. The concentration of the methanol liquor is 5-15%. An internal PH (potential of hydrogen) value of the hydrolysis reaction kettle is 6.5-6.8 when the water and the methanol liquor are dripped into the hydrolysis reaction kettle. The process has the advantages that the lime nitrogen can be hydrolyzed at one step by the aid of technologies for producing cyanamide, the dripping quantities of methyl cyanamido formate can be reduced in methyl cyanamido formate dripping procedures owing to high-quality liquid cyanamide, accordingly, consumption can be reduced, and a foundation can be laid for continuous production; the efficiency of hydrolysis kettles can be greatly improved, working hours of filter presses can be reduced, consumption of methanol can be decreased, the feasibility of hydrocyanic amine base liquor continuous production can be improved, the consumption of the methanol can be decreased by 5% at least, and the efficiency of esterification kettles can be improved by 1.5 times.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Preparation method of high-quality lime nitrogen

InactiveCN108996520AInhibition of decomposition is poorHigh temperature and pressure capability requirementsCyanamideCalcium cyanamideReaction temperature

The invention belongs to the field of chemical and particularly relates to a preparation method of high-quality lime nitrogen. Lime nitrogen is prepared from calcium oxide and urea as raw materials bycalcination, and ammonia-containing gas is introduced in the calcination process. By introducing the ammonia-containing gas in the calcination process, urea decomposition is reduced effectively, reaction temperature is reduced, yield is increased, inclusion of by products in a final product is avoided, effective content of the effective component calcium cyanamide in the product is ensured, energy consumption is lower, production cost is low, and finally, obtained lime nitrogen has high quality, broad market space and huge economic benefit.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Process to conserve cyano-function and improve performance of low molecular weight nitrification inhibitors to improve fertilizer efficiency

InactiveUS20180170818A1Inhibition of dissolutionImprove fertilizer efficiencyBio-organic fraction processingOrganic chemistryOligomerThiol

Disclosed are compositions and methods of making a liquid fertilizer additive of biodegradable polymers and / or oligomers comprised of utilizing a non-aqueous polar, aprotic organo liquid (NAPAOL) as the reaction medium for the reaction of aldehyde(s) with cyano-containing nitrification inhibitors that have one or more groups that react with the aldehyde(s) wherein said reactive groups are selected from the group consisting of a) primary and secondary amines, b) amides, c) thiols, d) hydroxyls and e) phenol.

Owner:SOILGENIC TECH LLC

Impurity separation device for lime nitrogen production

The invention discloses an impurity separation device for lime nitrogen production. The device comprises a support plate, the upper end of the support plate is fixedly connected with a mounting plate;the mounting plate is of a U-shaped structure; a shifting mechanism is mounted at the upper end of the mounting plate; third rollers are arranged on the two sides and the middle portion of the interior of the mounting plate. The third rollers are in transmission connection through a conveying belt; the third rollers are rotationally connected to the interior of the mounting plate through third rotating shafts; the beneficial effects of the device are that: the device can be used for carrying out impurity separation on lime nitrogen raw materials for multiple times. The shifting mechanism is arranged on the mounting plate; an adsorption mechanism is arranged on a sliding plate, when the device is used, a magnet rod of the shifting mechanism is used for stirring lime nitrogen raw materialson the conveying belt, the magnet rod is used for adsorbing scrap iron in the lime nitrogen raw materials, then a stirring rod of the adsorption mechanism is used for scattering the lime nitrogen falling on the sliding plate and the raw materials, meanwhile, a magnet plate is used for adsorbing remaining scrap iron in the lime nitrogen raw materials, and the separation effect is good.

Owner:石嘴山市鹏盛化工有限公司

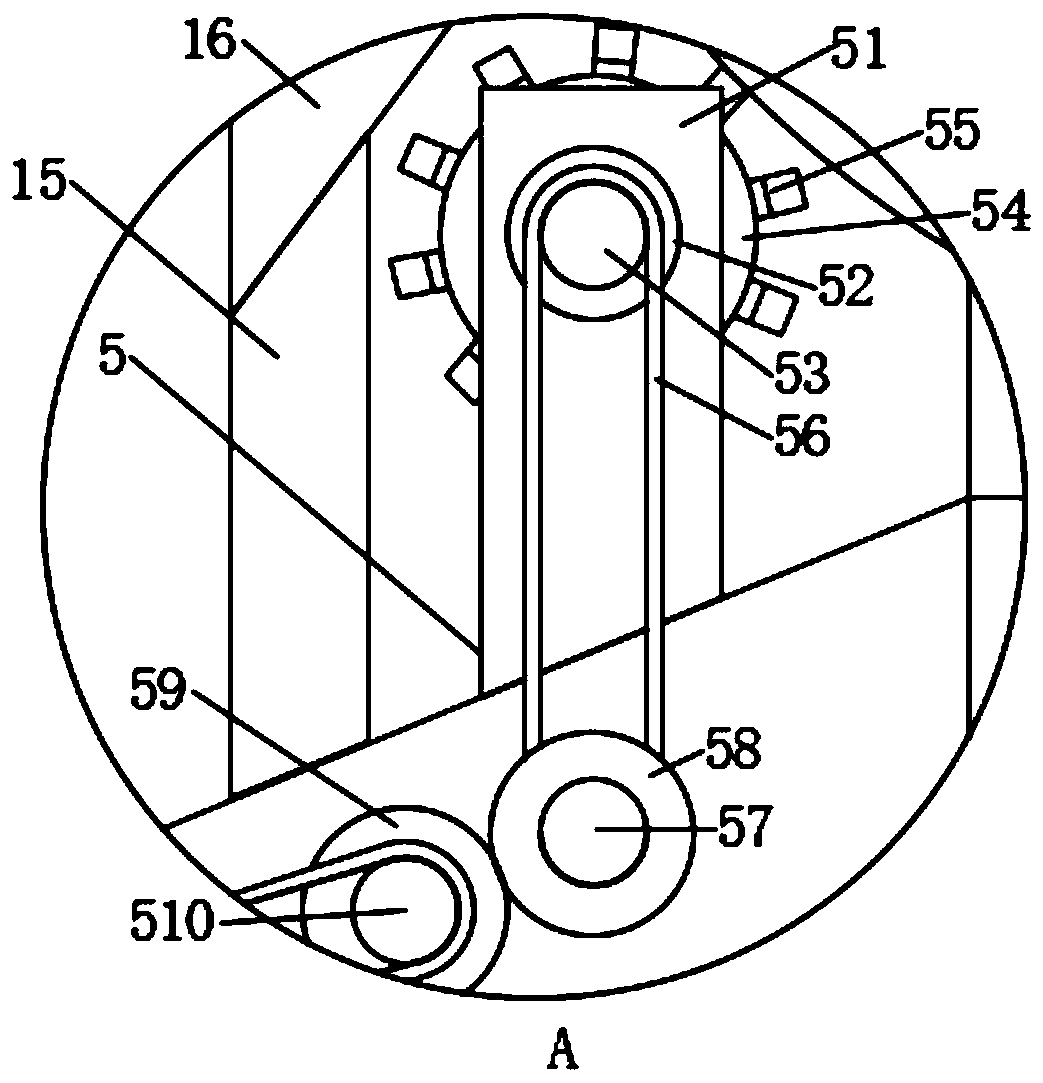

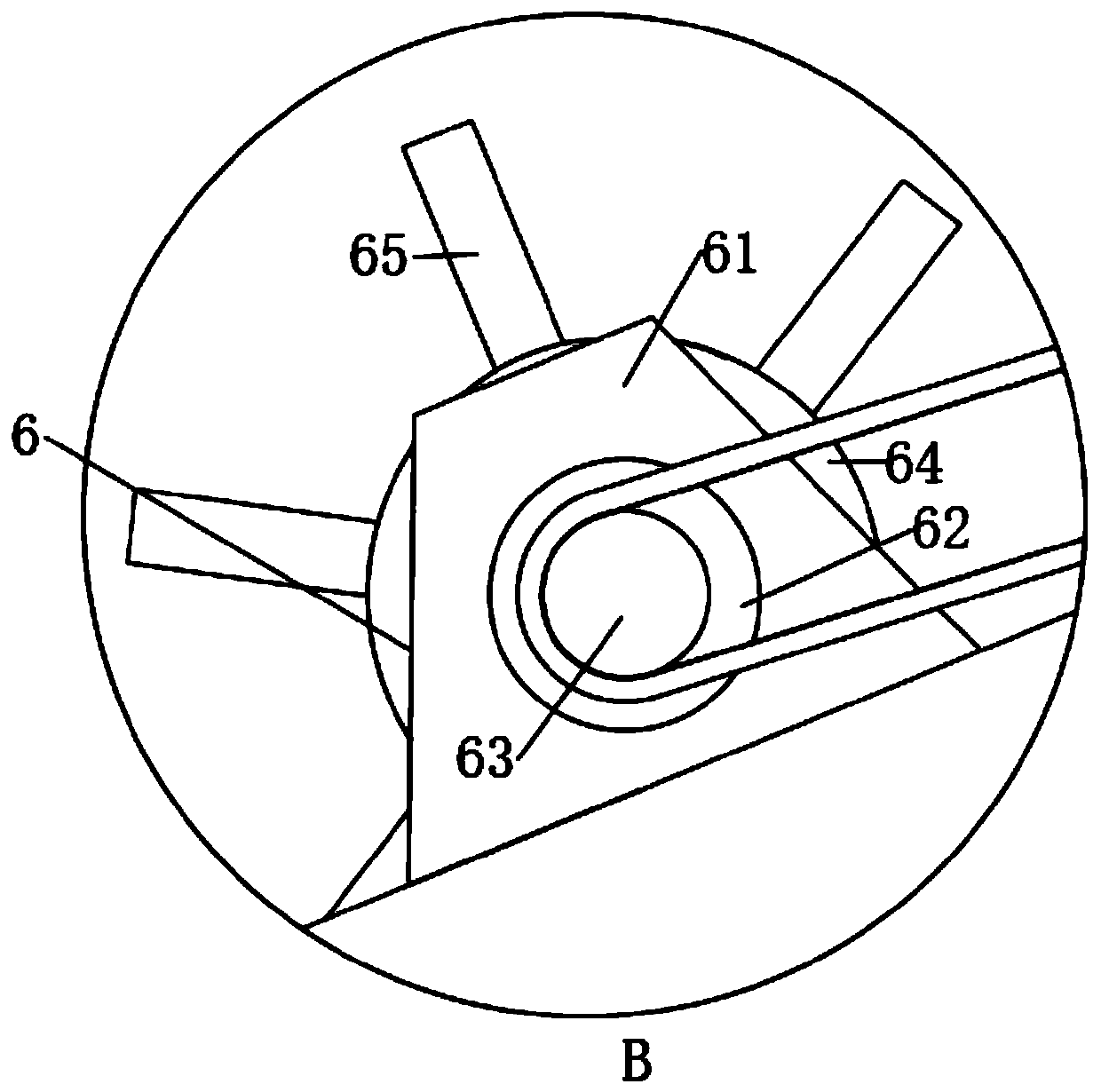

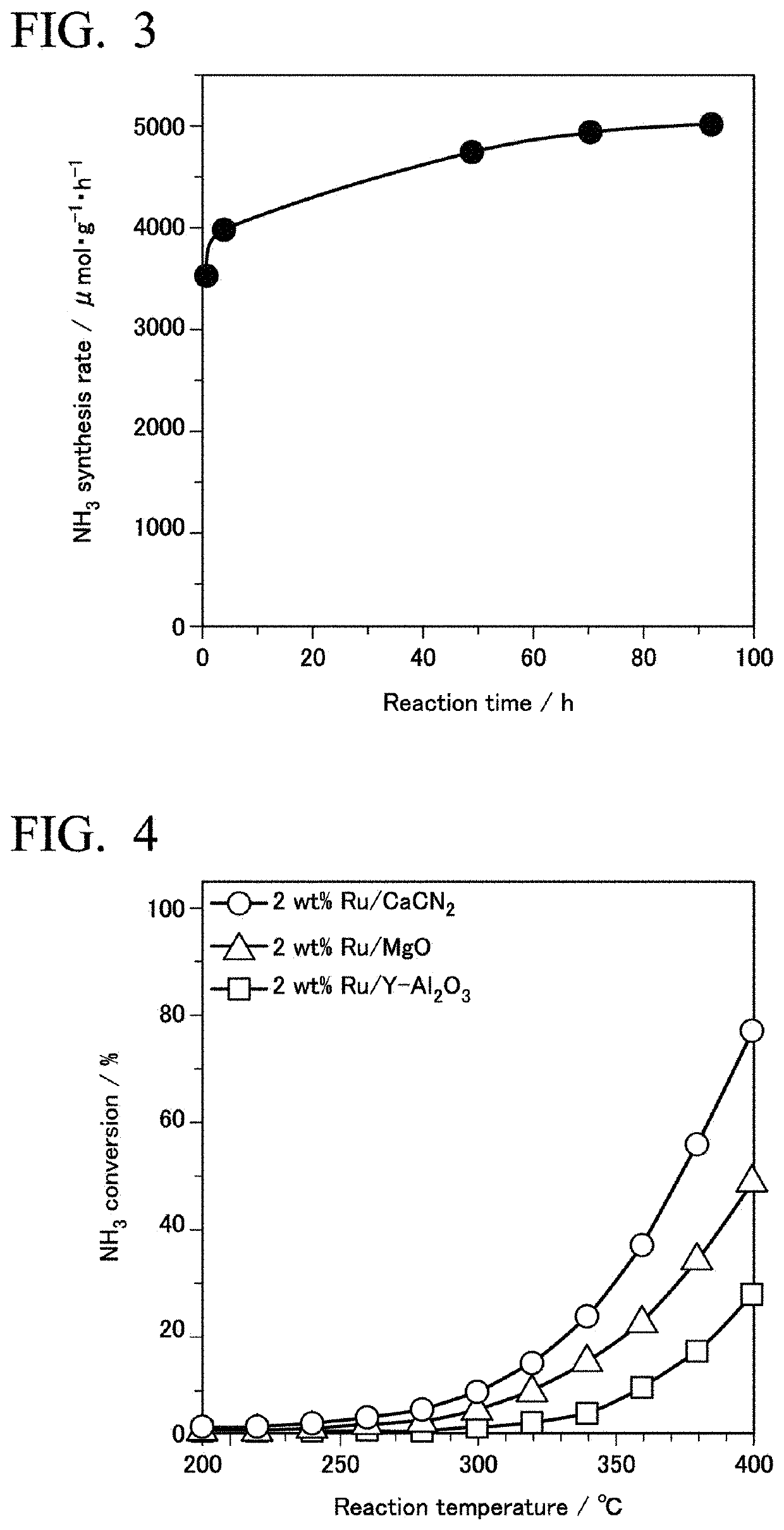

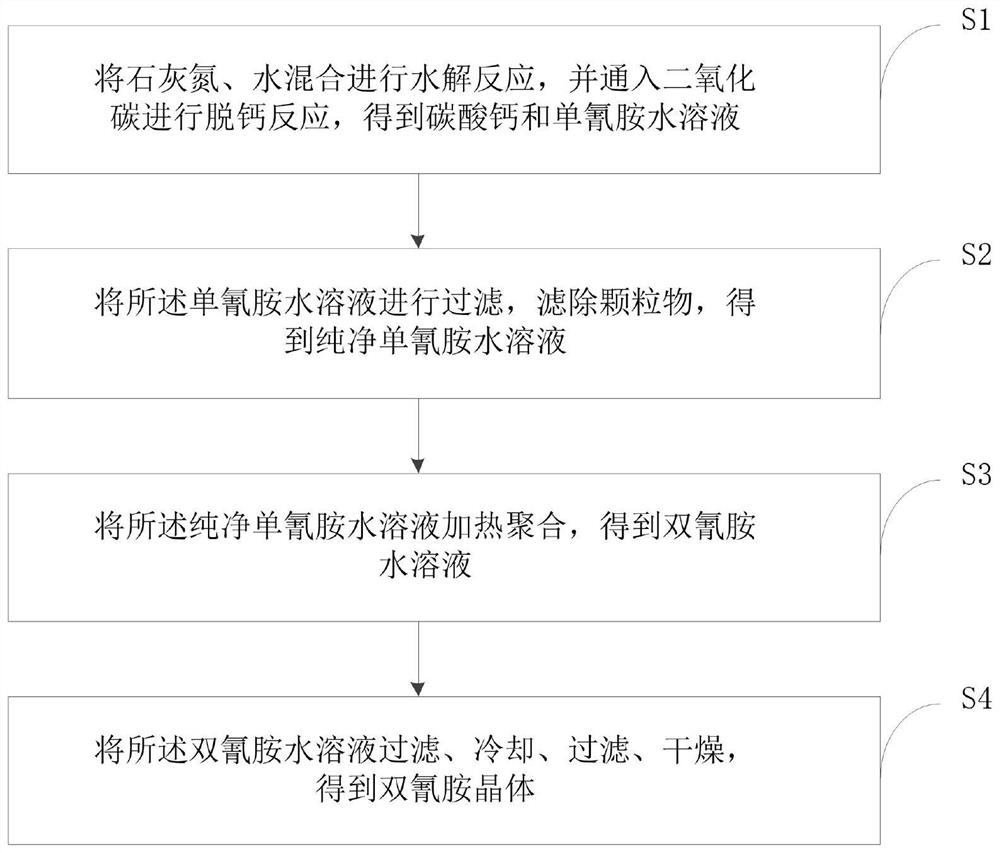

Supported metal material, supported metal catalyst, method of producing ammonia, method of producing hydrogen and method of producing cyanamide compound

PendingUS20200078771A1Low reaction pressureReduce catalytic activityCatalyst activation/preparationCyanamidePtru catalystMetal catalyst

Provided are a supported metal material showing high catalytic activity, a supported metal catalyst, a method of producing ammonia and a method of producing hydrogen using the supported metal catalyst, and a method of producing a cyanamide compound. The supported metal material of the present invention is a supported metal material in which a transition metal is supported on a support, and the support is a cyanamide compound represented by the following general formula (1); MCN2 (1), wherein M represents a group II element of the periodic table, and the specific surface area of the cyanamide compound is 1 m2g−1 or more.

Owner:JAPAN SCI & TECH CORP +1

Method for preparing lime nitrogen through hydrogen cyanamide production waste residues

InactiveCN108862320AAchieve recyclingSolve environmental problemsCyanamideCyanamide fertilisersHydrogenNitrogen

The invention belongs to the field of chemical production. A method for preparing lime nitrogen through hydrogen cyanamide production waste residues comprises the steps of adopting the hydrogen cyanamide production waste residues as raw materials, drying, grinding, mixing with an accessory ingredient, and calcining with an ammonia gas under the atmosphere of the ammonia gas so as to obtain the lime nitrogen. By adopting the method provided by the invention, hydrogen cyanamide residues can be value-based developed and are recycled, so that an economic and effective way is provided for recyclingthe hydrogen cyanamide residues and preparing the lime nitrogen. The lime nitrogen can be continuously used for hydrogen cyanamide production, the recycling of the hydrogen cyanamide production wasteresidues is realized, and the environmental matter brought by the solid waste residues is solved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Clean preparation method of aqueous cyanamide solution

The invention belongs to the field of chemical industry, and particularly relates to a clean preparation method of an aqueous cyanamide solution. Calcium carbonate solid waste produced in the industrial production of cyanamide is used as a raw material, and reacts with urea at a high temperature to prepare lime nitrogen, the aqueous cyanamide solution is prepared from the lime nitrogen under the action of water and carbon dioxide, and the recovery, recycling and reuse of calcium carbonate are realized. The production method of the aqueous cyanamide solution, designed in the invention, has theadvantages of high yield, low cost, and no production of three wastes in the production process, and is a green way with economic environmental benefits.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

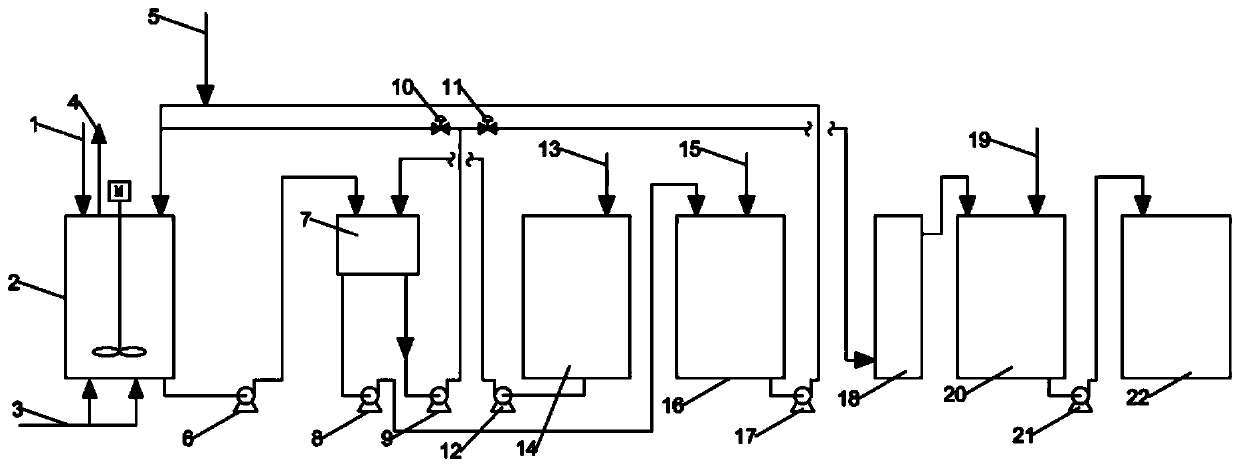

Dicyandiamide preparation method

InactiveCN112209857AQuality improvementOrganic chemistryOrganic compound preparationCalcium hydroxideAqueous solution

The invention provides a dicyandiamide preparation method, which comprises: mixing lime nitrogen and water to carry out a hydrolysis reaction, and introducing carbon dioxide to carry out a decalcification reaction to obtain calcium carbonate and a cyanamide aqueous solution; filtering the cyanamide aqueous solution, and filtering out particles to obtain a pure cyanamide aqueous solution; heating and polymerizing the pure cyanamide aqueous solution to obtain a dicyandiamide aqueous solution; and filtering, cooling, filtering and drying the dicyandiamide aqueous solution to obtain dicyandiamidecrystals. By adopting the method, impurities such as calcium oxide, calcium hydroxide and calcium carbonate in dicyandiamide are removed, and the quality of a dicyandiamide product is improved.

Owner:宁夏蓝白黑循环科技有限公司

Method for continuously producing cyanamide

The invention provides a method for continuously producing cyanamide, which comprises the following steps: a) continuously injecting mother liquor and a stabilizer into a synthesis kettle, and introducing carbon dioxide from the bottom of the synthesis kettle under stirring, meanwhile, feeding lime nitrogen for reaction to obtain a cyanamide feed liquid, wherein the reaction temperature is less than or equal to 30 DEG C, and the pH value is less than or equal to 8.5; b) continuously filtering the cyanamide feed liquid obtained in the step a) through a filter to respectively obtain filtrate andfilter residues, wherein the filtrate is circulated to the synthesis kettle for continuous reaction; c) when the content of cyanamide in the filtrate reaches a preset value, outputting the filtrate,and controlling the ratio of the circulation volume to the delivery volume of the filtrate to be (2-5):1, meanwhile, adjusting the amount of the mother liquor and the stabilizer continuously injectedinto the synthesis kettle, thereby keeping the amount of the liquid in the synthesis kettle unchanged; and d) sequentially carrying out precision filtration treatment and acidification on the outputted cyanamide to obtain a cyanamide product. By adopting the method, continuous production can be realized, and the product loss and explosion risk caused by cyanamide polymerization can be reduced.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

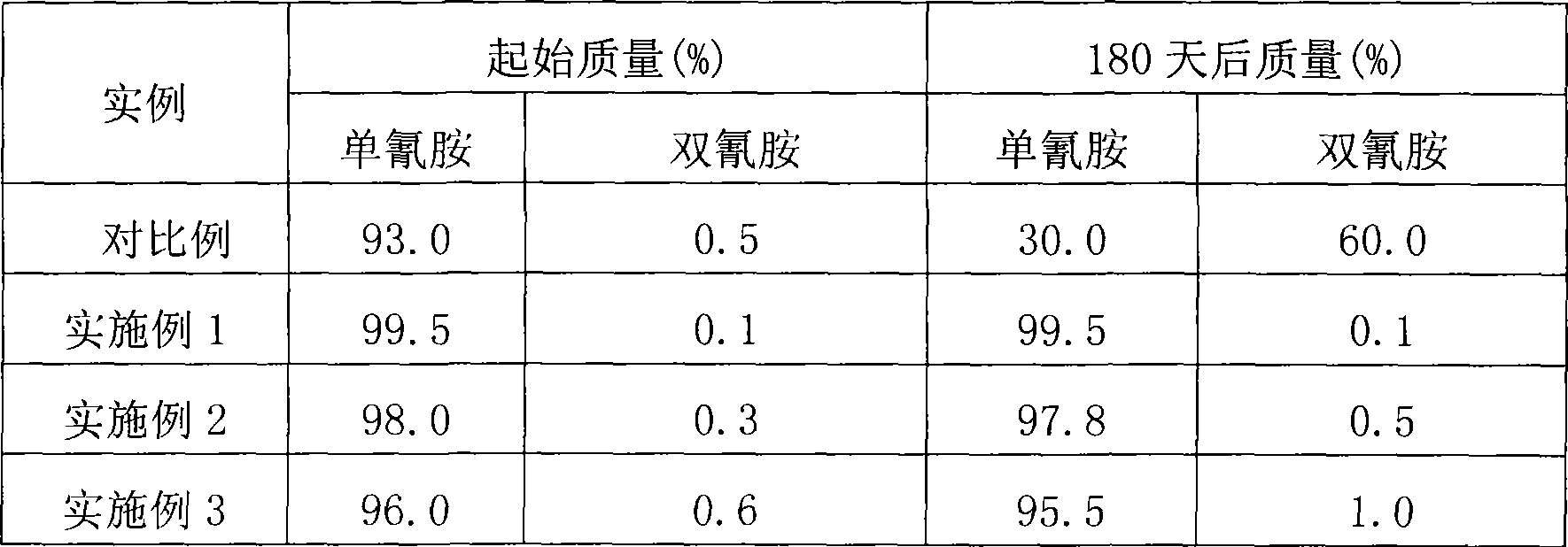

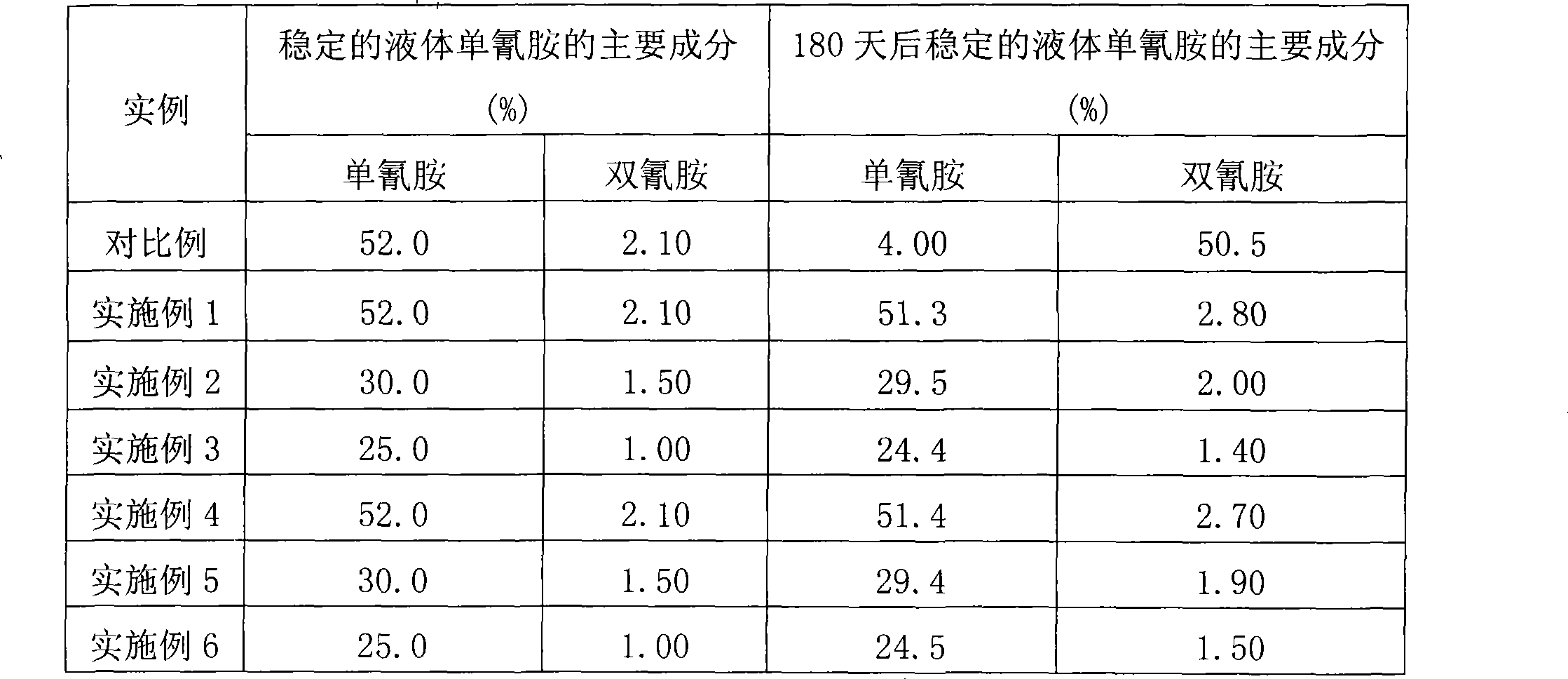

Stabilizing agent of liquid single-cyandiamide and method for producing stable liquid single-cyandiamide

InactiveCN101428821AMaintain physical and chemical propertiesSolve storage problemsCyanamideAcetic acidStable state

The invention belongs to the field of chemical engineering, and particularly relates to a stabilizer for liquid cyanamide and a method for preparing stable liquid cyanamide. The stabilizer for liquid cyanamide can be acetic acid or metacetonic acid. The method for preparing stable liquid cyanamide comprises steps as follows: liquid cyanamide is put into a container with a stirring device; the stabilizer with the liquid cyanamide weight 0.01-5.0% is added slowly in stirring; the temperature of the liquid cyanamide in the container is controlled to be the natural environmental temperature; and the liquid cyanamide with stable performance is obtained. A large amount of experiments show that proper acetic acid or metacetonic acid is added into liquid cyanamide to be the stabilizer, so that liquid cyanamide can be in a very stable state at the natural environmental temperature, all of the physicochemical properties of liquid cyanamide are kept, and the long-term problems of storage and transportation of liquid cyanamide at the natural environmental temperature are solved.

Owner:宁夏大荣化工冶金有限公司

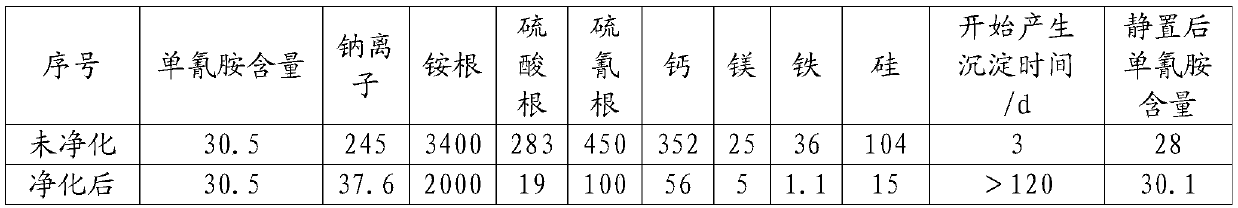

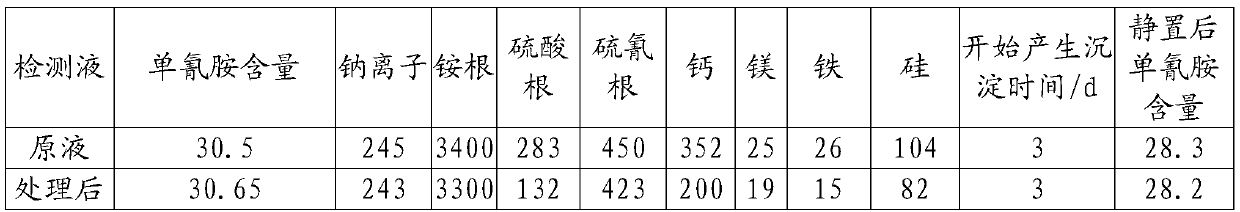

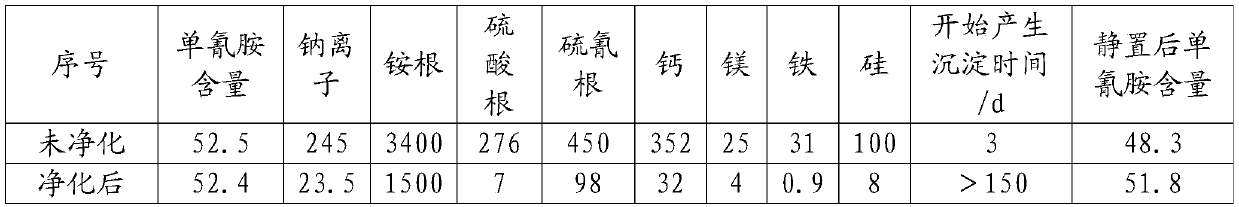

Purification method of cyanamide solution

The invention belongs to the field of chemical engineering, the invention particularly relates to a purification method of a cyanamide solution. According to the method, anion-cation exchange resin isadopted to treat cyanamide, the content of ammonium radicals, thiocyanate, iron, silicon, calcium, magnesium and other ions in the cyanamide solution is reduced, the cyanamide solution can stably exist at the natural environment temperature, insoluble substances are not separated out, the content is not reduced after the cyanamide solution is placed for a long time, and then the quality of the cyanamide is improved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

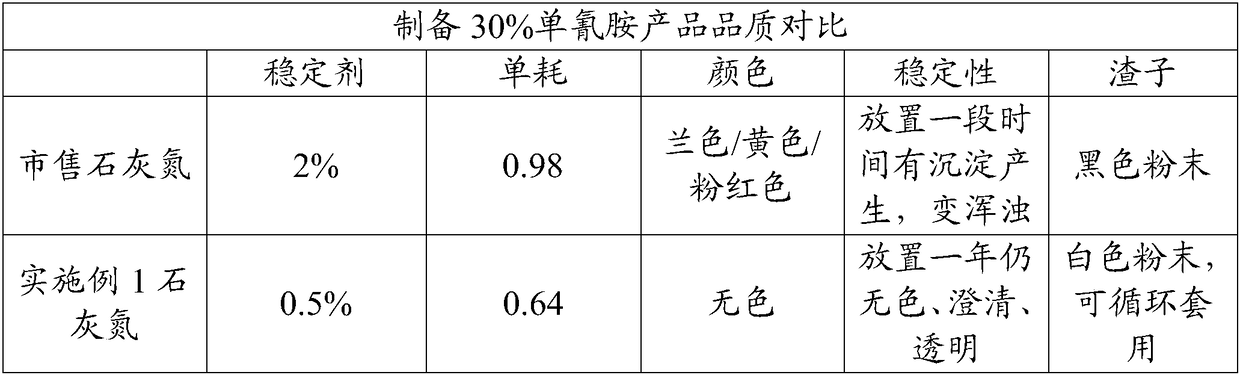

Preparation method of 30% cyanamide aqueous solution

The invention belongs to the chemical field and particularly relates to a preparation method of a 30% cyanamide aqueous solution. According to the method, solid waste produced in industrial productionof thiourea is used as a raw material and reacts with urea at high temperature to prepare lime nitrogen, a cyanamide liquid is prepared under the action of water and CO2, lime nitrogen is added to the liquid secondarily, phosphoric acid is added to control the pH of the system, filtration and separation are performed after the reaction, and the 30% cyanamide aqueous solution with the pH value inthe range of 4-5 is obtained. The designed production process of the 30% cyanamide aqueous solution can change thiourea residues into wealth and has the advantages of high yield, low cost, good product quality and the like, and an economical and effective solution is provided for reutilization of thiourea residues and preparation of 30% cyanamide.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Wet dicyandiamide pneumatic conveying device

InactiveCN111306895ASimplify the delivery processReduce labor intensityDrying solid materials with heatDrying gas arrangementsStructural engineeringProcess engineering

The invention discloses a wet dicyandiamide pneumatic conveying device which comprises a Roots blower, a heater and a quantitative stock bin, wherein an outlet silencer is arranged at the outlet of the Roots blower; an air outlet is formed in in the outlet silencer and is connected with the heater; the upper part of the quantitative stock bin is connected with a shaftless screw conveyer; a feedinghole is formed in the top of the quantitative stock bin; a pneumatic gate valve B is arranged at the lower part of the quantitative stock bin and is connected with a direct blowing rotary feeding valve arranged at the lower part; the direct blowing rotary feeding valve is connected with an exhaust pipeline below; the front end of the exhaust pipeline is connected with a hot-blast air inlet pipe;the exhaust pipeline is connected with a dissolving kettle arranged on the rear; a discharging pipe and a warehouse top reversing valve are arranged between the exhaust pipeline and the dissolving kettle; and a warehouse top exhaust pipe is arranged on the top of the dissolving kettle. During the actual using process, the wet dicyandiamide pneumatic conveying device adopts the quantitative conveying method to solve the problems about material adhesion to a wall and unsmooth discharging and to also solve the problem that the material blocks the pipeline to enable the production process to be smooth.

Owner:NINGXIA JIAFENG CHEMICALS CO LTD

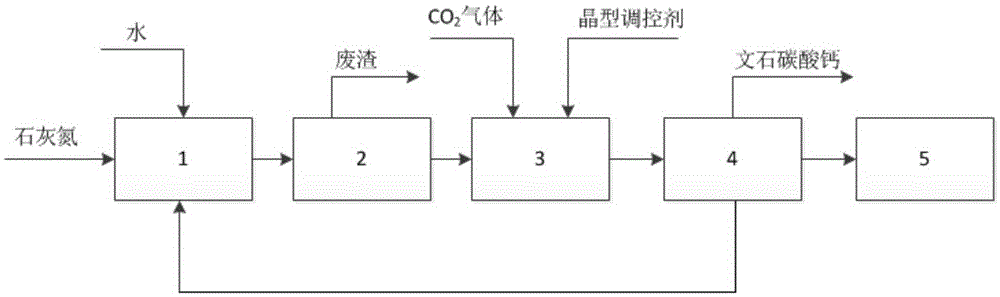

System and method for producing cyanamide and aragonite type nano calcium carbonate through lime nitrogen

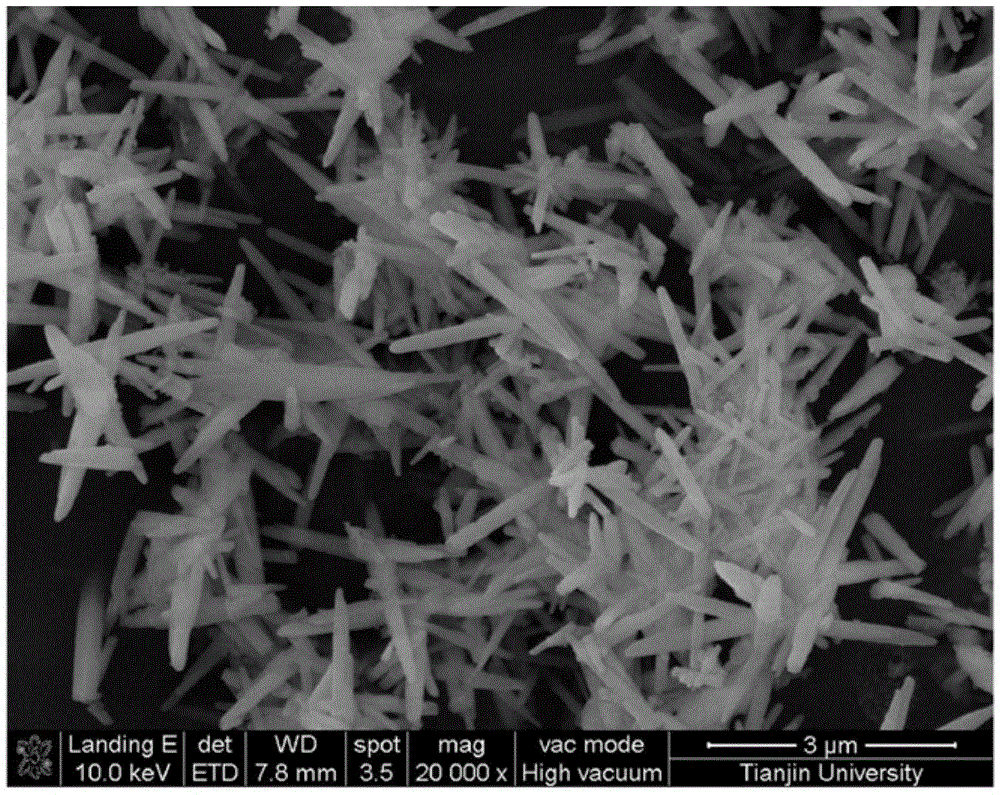

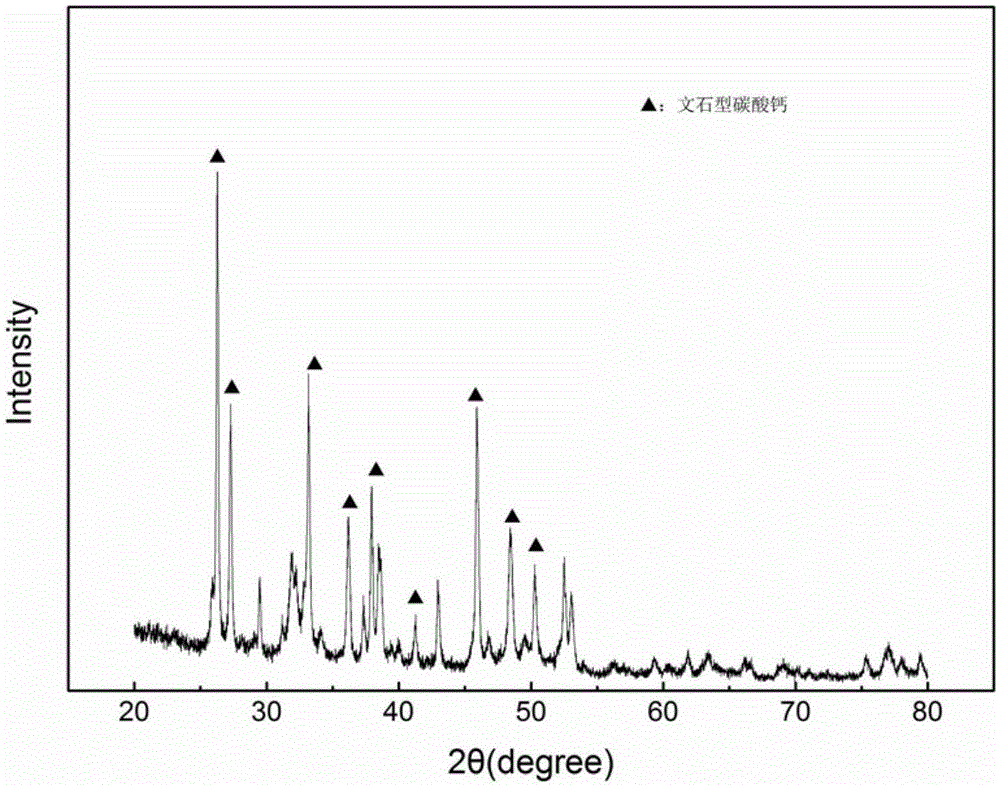

InactiveCN105347362AAvoid emissionsReduce pollutionCalcium/strontium/barium carbonatesMaterial nanotechnologyAragoniteHydrolysis

The invention discloses a system and method for producing cyanamide and aragonite type nano calcium carbonate through lime nitrogen. The system comprises a reactor. The outlet of the reactor is sequentially connected with a second filter and a cyanamide solution storage tank through pipelines. The inlet of the reactor is sequentially connected with a first filter and a hydrolysis tank. A lime nitrogen inlet and a water inlet are formed in the hydrolysis tank. A waste residue outlet is formed in the first filter. A carbon dioxide gas inlet and a crystal form regulating agent inlet are formed in the reactor. An aragonite type nano calcium carbonate outlet is formed in the second filter. The second filter is connected with the hydrolysis tank through a pipeline. Aragonite type nano calcium carbonate can be obtained while cyanamide is produced through lime nitrogen, it is avoided that in the existing production process, solid containing calcium carbonate is used as waste residues to be discharged, pollution to the environment is reduced, production benefits are increased, and quality of produced aragonite type nano calcium carbonate is equivalent to quality of aragonite type nano calcium carbonate produced with calcium oxide as the raw material.

Owner:SHANGHAI FLUKO TECH DEV

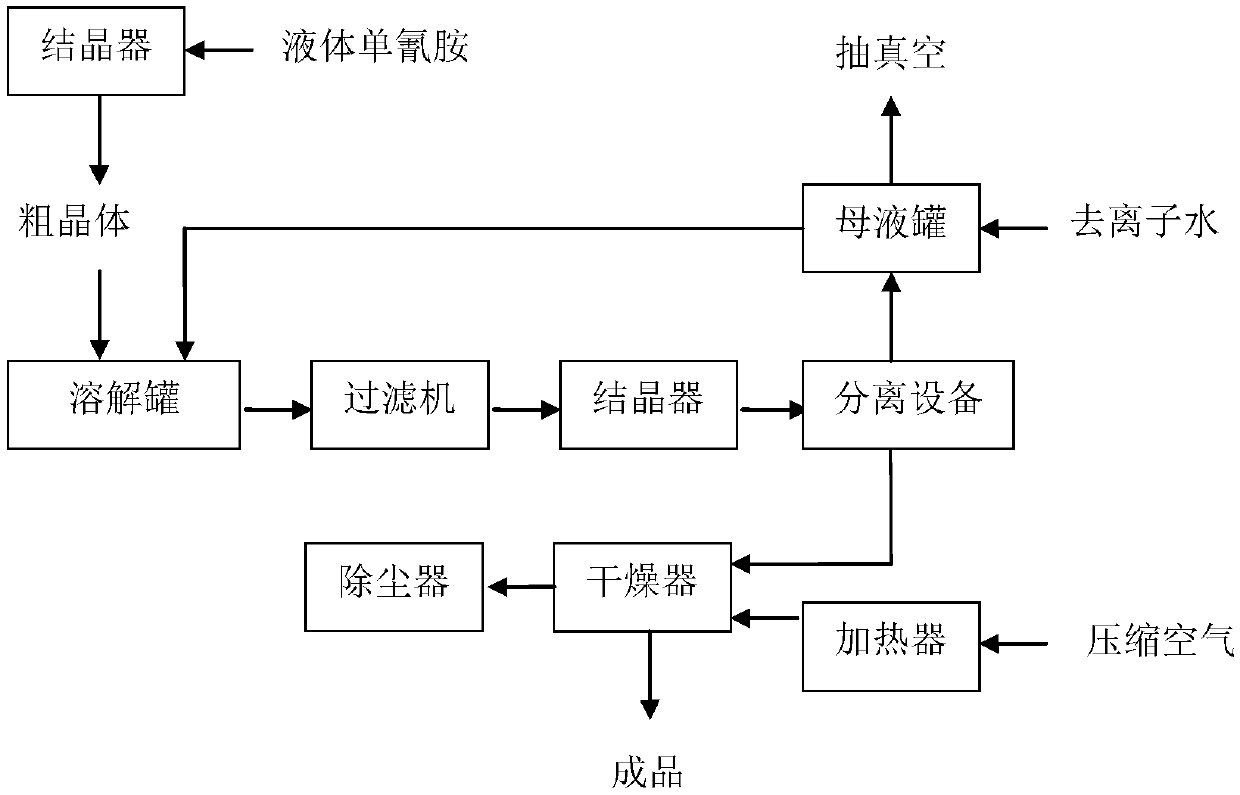

Preparation method of higher safety for solid cyanamide

The invention discloses a preparation method of higher safety for solid cyanamide. The method comprises the following steps that liquid cyanamide is driven into a crystallizer, after freezing and cooling, coarse cyanamide crystals are obtained, and the coarse cyanamide crystals are spin-dried by a centrifugal machine and then dissolved in water; after the crystals are dissolved completely, impurities in the crystals are removed by filtering equipment, filtered liquid is frozen and cooled to obtain crystals, and the crystals are separated out and dried at the low temperature to obtain the high-purity solid cyanamide; the filtered liquid flows into a dissolution kettle again for dissolving the coarse crystals and can be repeatedly used. The preparation method for the solid cyanamide has theadvantages that the technology is simple, the yield is high, the cost is low, the obtained cyanamide crystals are high in purity, and solves the problem that the solid cyanamide produced by adopting an alcohol separation method is difficult to store and transport, water as a solvent for recrystallization, and the hidden safety danger and pollution on air in the production process adopting dangerous chemicals of alcohol and the like as the solvent are eliminated.

Owner:宁夏大荣化工冶金有限公司

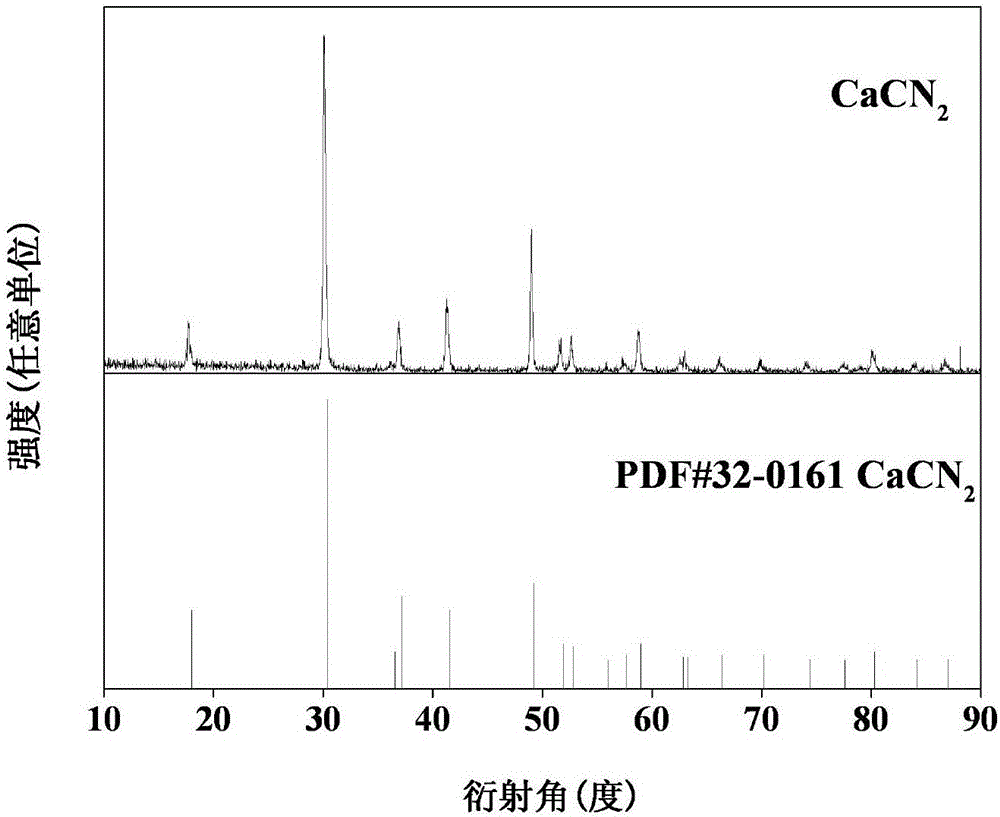

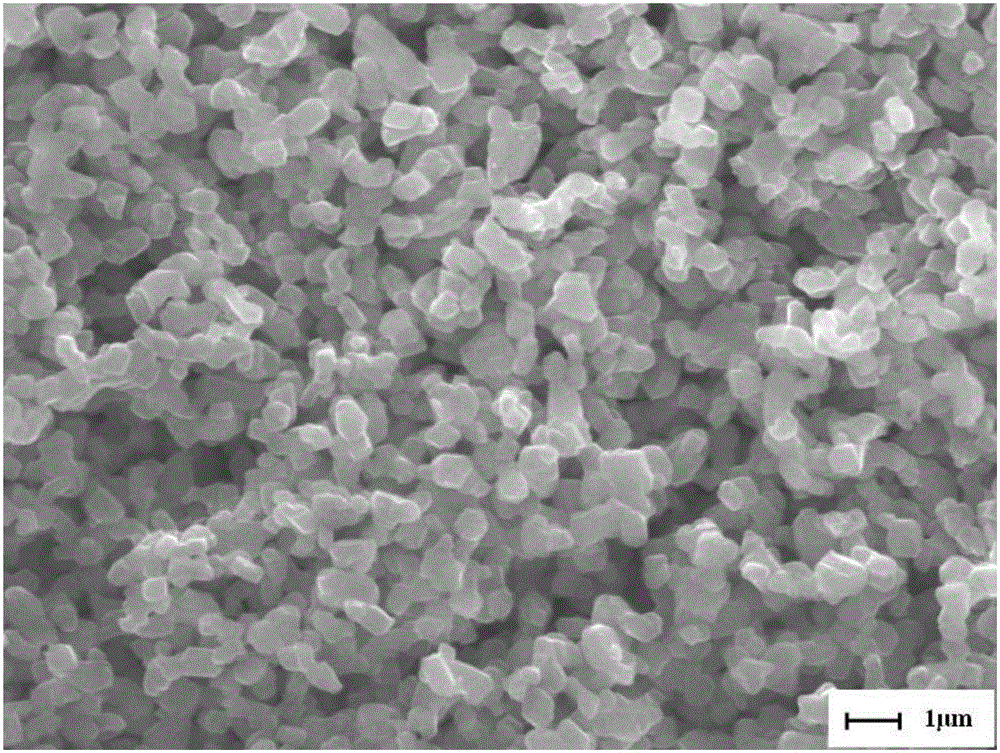

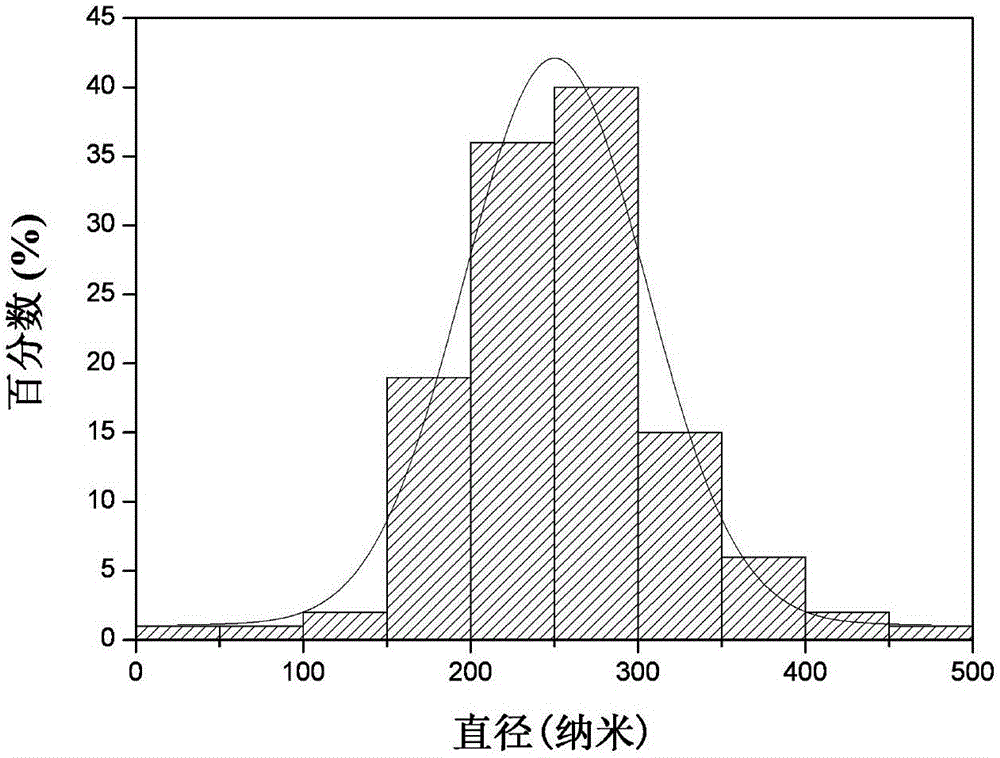

Calcium cyanamide monodisperse nanoparticle preparation method

The present invention relates to a calcium cyanamide monodisperse nanoparticle preparation method, and belongs to the technical field of nanometer material preparation, wherein CaCN2 monodisperse nanoparticles are prepared by combining an electrospinning technology and a cyanogen ammoniation method. The preparation method comprises: (1) preparing a spinning liquid; (2) preparing PVP / Ca(NO3)2 composite nano-fibers by using an electrostatic spinning technology; (3) carrying out high temperature heat treatment on the PVP / Ca(NO3)2 composite nano-fibers to obtain CaCO3 nano-fibers; and (4) carrying out cyanogen ammoniation on the CaCO3 nano-fibers by using graphite boat and ammonia gas to obtain the CaCN2 monodisperse nanoparticles, wherein the obtained CaCN2 monodisperse nanoparticles have good crystallinity, belong to a trigonal system, and have the diameter of 250+ / -0.27 nm. According to the present invention, the preparation method is simple and easy to perform, is suitable for batch production, and has broad application prospect.

Owner:JILIN NORMAL UNIV

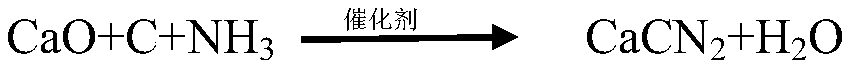

Synthesis method of calcium cyanamide

Belonging to the technical field of fine chemicals, the invention in particular relates to a synthesis method of calcium cyanamide. The method adopts calcium oxide, carbon powder and ammonia gas as the raw materials to synthesize the target product calcium cyanamide under the action of a catalyst, and the catalyst is one or more of calcium fluoride, calcium chloride and zinc oxide. The method provided by the invention has the advantages of simple operation steps, low energy consumption, short production cycle, high product yield and purity, and meets the quality requirements of the market forcalcium cyanamide; the raw materials are easily available and cheap, and have no geographical limitation; the reaction does not generate waste, and has high environmental protection value. The methodgreatly lowers the production cost, improves the product yield and quality, and is suitable for industrial production.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Method for purifying cyanamide

ActiveCN109879298AInhibit aggregationAvoid decompositionCyanamidePurification methodsOrganic solvent

The invention relates to a method for purifying cyanamide, which comprises the following steps: with a cyanamide crude product as a raw material, carrying out reduced-pressure distillation in a reaction kettle under the conditions that the vacuum degree is 0.07-0.09 MPa and the temperature is 30-50 DEG C for 2-4 hours; taking a residual product in the reaction kettle after distillation, and conducting recrystallizing with an organic solvent and a stabilizer under the condition that the temperature is -8 DEG C to -20 DEG C; and filtering the crystal obtained by recrystallization, and conductingdrying to remove the organic solvent, so as to obtain the cyanamide crystal with a purity of 99.0% or above. By adopting the method, most of water in the raw material is removed by utilizing a reduced-pressure distillation method, and the polymerization and decomposition of the cyanamide can be prevented by controlling the temperature within 50 DEG C; residual water in the product can be removedat a low temperature by using an organic solvent capable of being mixed with water, and the organic solvent can be recycled; and by adding the stabilizer, polymerization and decomposition reactions ofthe cyanamide in the purification process can be inhibited, and the purity of the cyanamide is effectively improved.

Owner:ZHEJIANG LONGYOU DONGFANG ANASAKE CROP TECHCO

A kind of method for efficiently preparing cyanamide solution

InactiveCN104445276BFill evenly and effectivelyLow concentration requirementCyanamideHigh energyFiltration

The invention discloses a method for efficiently preparing a monocyanamide solution, and is used for solving the problems of high equipment investment, high energy consumption, long production period, high production cost, high requirement on concentration of carbon dioxide, high content of calcium ions and incomplete filtration of cyanamide waste residue of an existing production process of the 50% monocyanamide solution. The method comprises the steps of performing a hydrolytic decalcification process step, adding phosphoric acid to regulate pH value, and performing microporous filtration, and evaporation concentration to obtain a monocyanamide product. The monocyanamide solution is prepared by improving a gas inlet way of kiln gas and applying a microporous filtration method, an ion exchange resin decalcification technology and a rotary thin film scraper steam method. Compared with a domestic traditional process, by adopting the method, the requirement of the traditional process on the concentration of carbon dioxide is reduced, the content of the calcium ions in the monocyanamide product is strictly controlled, the product quality is improved, the production period is shortened, the energy consumption is reduced, and the production cost is reduced, so that the method is suitable for industrial large-scale production and has good social and economic benefits.

Owner:GULANG XINHUI CHEM

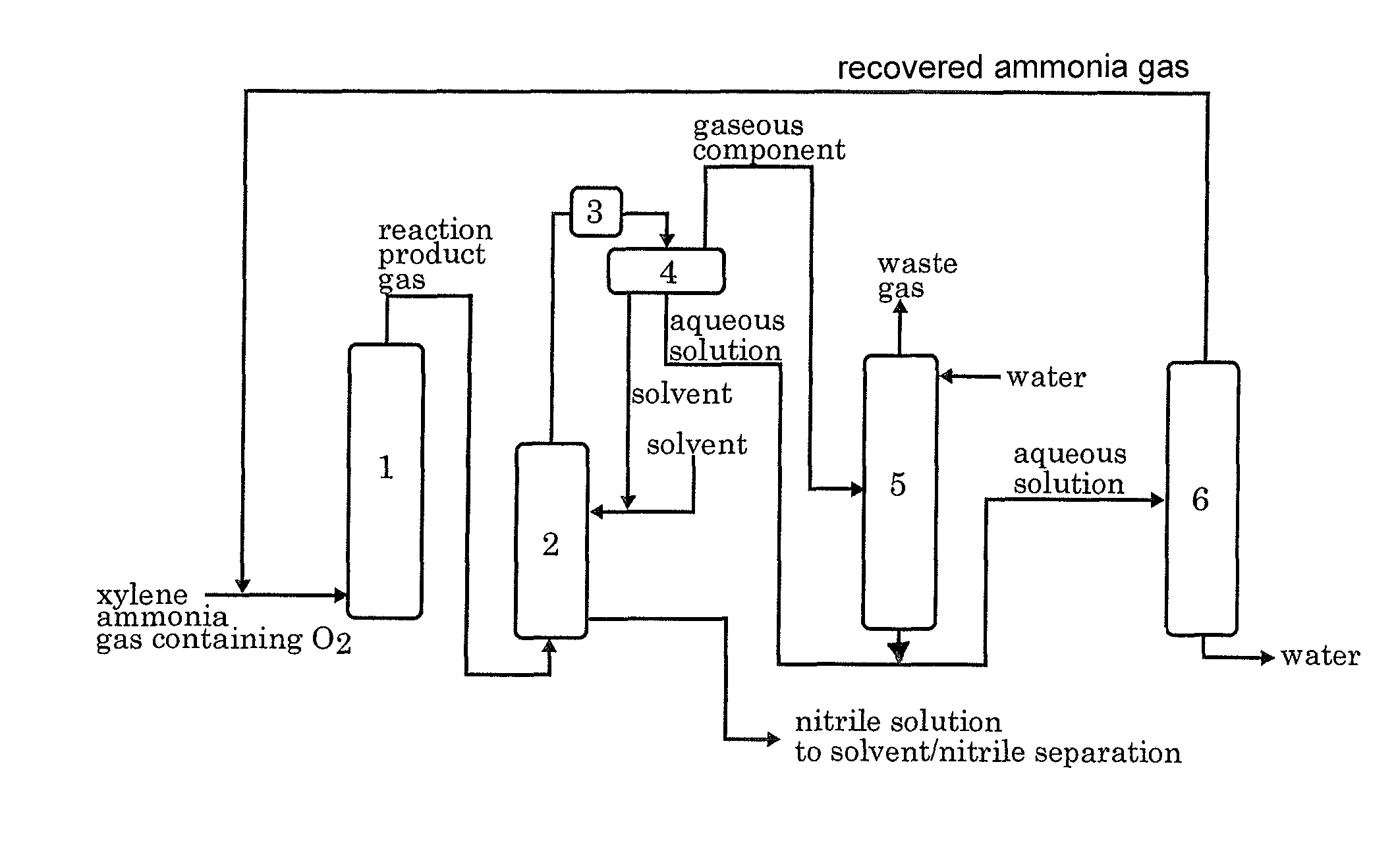

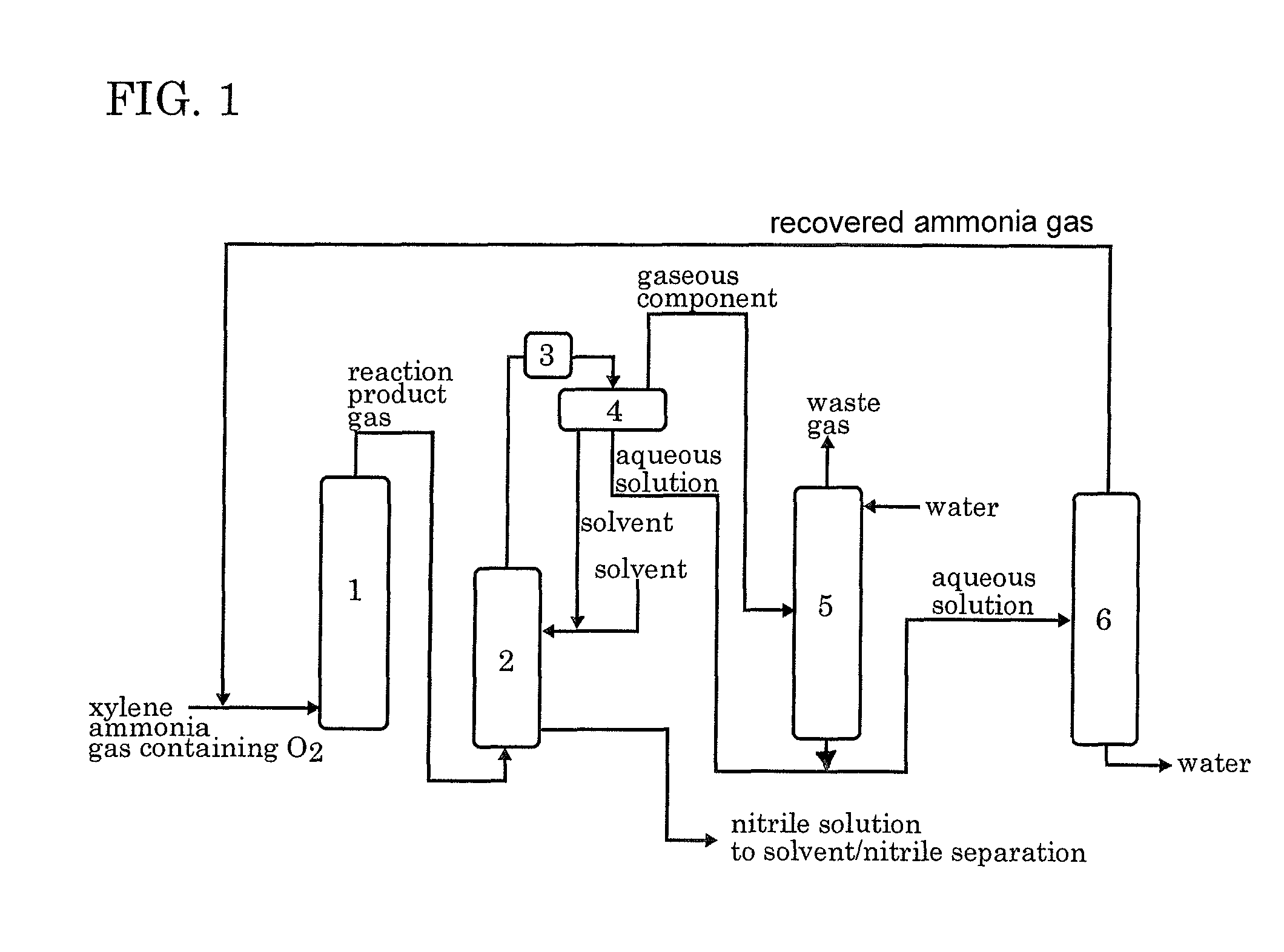

Method of recovering ammonia

ActiveUS7785556B2Isocyanic acid derivatives preparationOrganic compound preparationDistillationAlloy

A method of recovering ammonia by the distillation of an aqueous solution containing ammonia, carbon dioxide and hydrogen cyanide. The distillation is conducted using a distillation apparatus having at least its portion which comes into contact with the aqueous solution made of an alloy 1 or alloy 2. The alloy 1 contains 3% by weight or more of molybdenum, 15% by weight or more of nickel and 15% by weight or more of chromium. The alloy 2 contains 1% by weight or more of molybdenum, 9% by weight or less of nickel and 20% by weight or more of chromium. The use of the alloy 1 or alloy 2 prevents the corrosion of the distillation apparatus and enables the stable recovery of ammonia for a long period of time.

Owner:MITSUBISHI GAS CHEM CO INC

Method for preparing lime nitrogen by using thiourea production waste residues

The invention belongs to the field of chemical production, and particularly relates to a method for preparing lime nitrogen by using thiourea production waste residues. The method includes using the thiourea production waste residues as a raw material, conducting carbonization, desulfurization, filtration, drying and grinding treatment and burning with ammonia gas in the ammonia atmosphere for reaction to obtain the lime nitrogen. According to the method, the value of the thiourea residues can be developed and turned into wealth, and a cost-effective way for the reuse of the thiourea residuesand the preparation of the lime nitrogen is provided. At the same time, the refinery plant waste gas carbon dioxide can be effectively utilized to reduce emission of the carbon dioxide of a plant. Thefinally obtained lime nitrogen can be used in the production of the thiourea continuously, the recycling of the thiourea wastes can be achieved, and the environmental protection problem caused by solid waste residues can be solved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com