Calcium cyanamide monodisperse nanoparticle preparation method

A technology of calcium cyanamide monodisperse nanoparticles, applied in the field of preparation of calcium cyanamide monodisperse nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

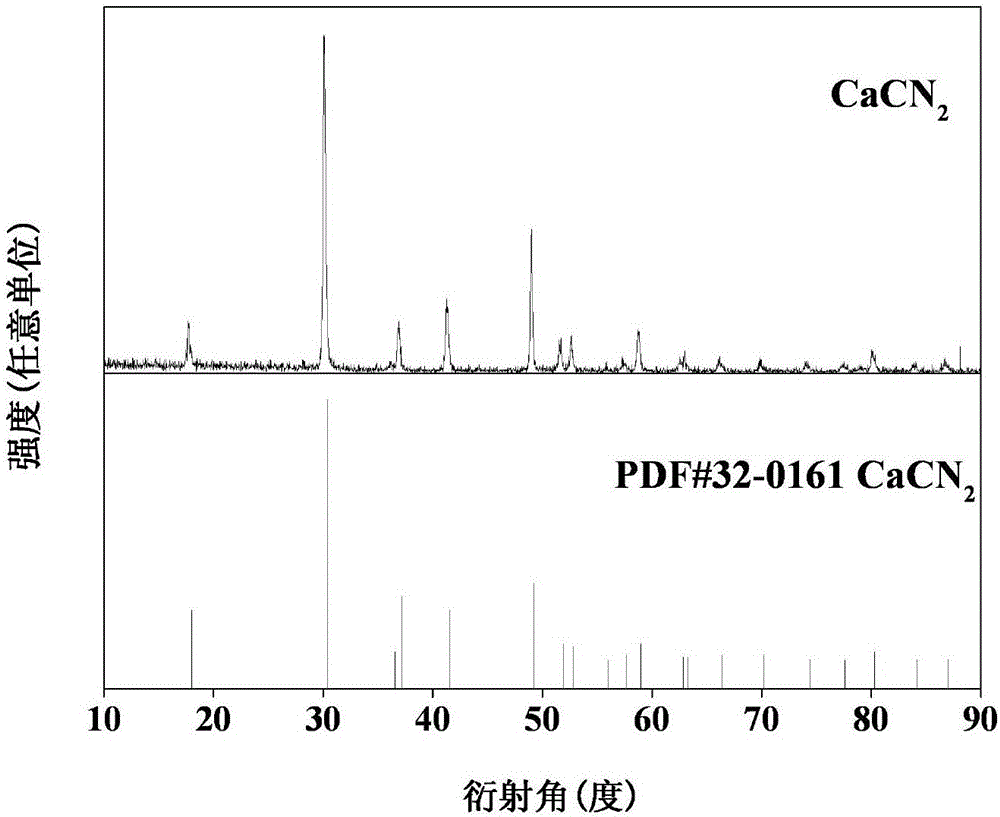

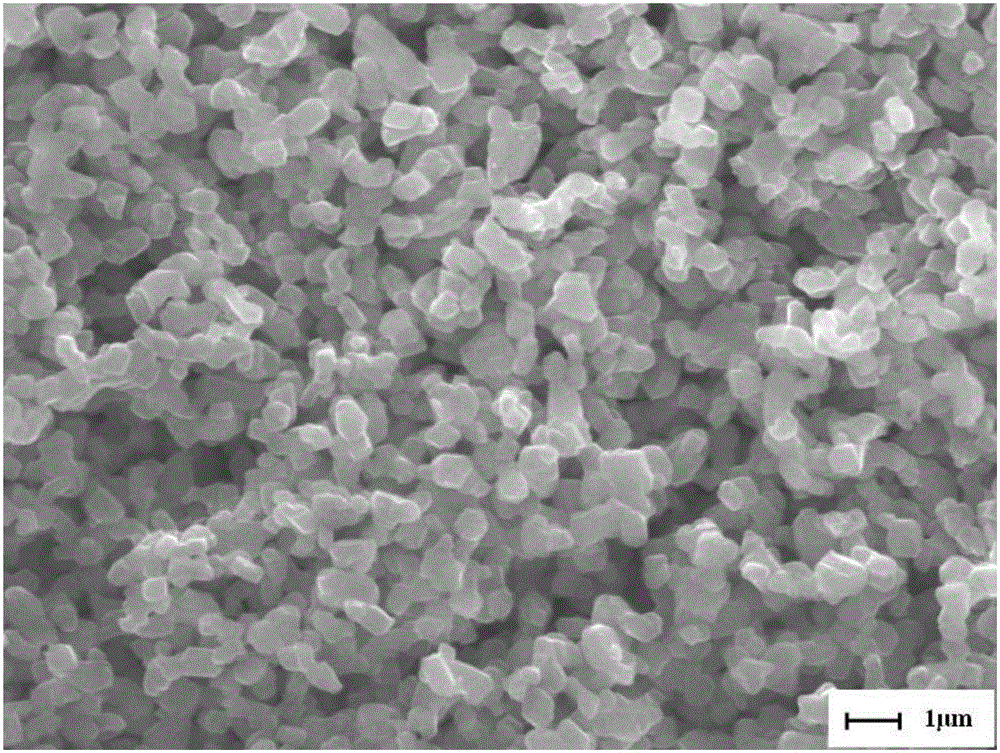

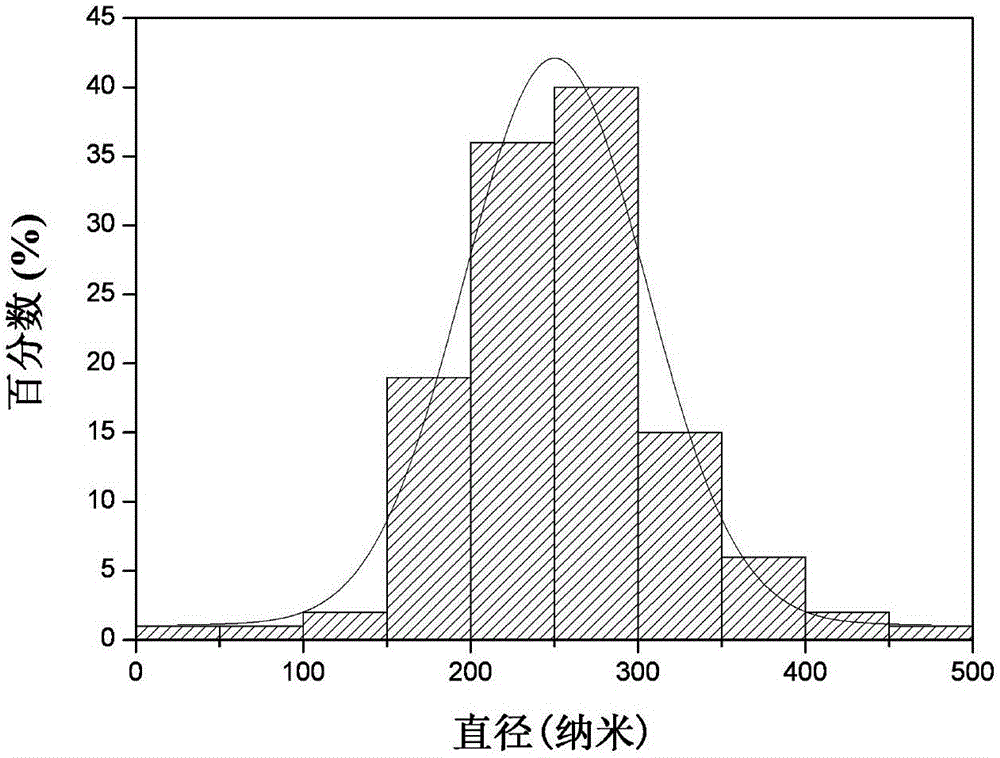

[0021] Embodiment: 1.5007g Ca(NO 3 ) 2 4H 2 O was added to 4.0174g deionized water, magnetically stirred to dissolve completely, then 7.9826g DMF was added, then 1.5016g PVP was added, and stirring was continued for 6h to obtain a colorless and transparent spinning solution; the spinning solution was injected into a 1mL plastic spray gun Into the 10mL syringe of the head, insert the graphite rod into the spinning solution, connect the graphite rod and the positive terminal of the high-voltage DC power supply with a copper wire, connect the ground wire terminal of the high-voltage DC power supply with the vertically placed barbed wire with a copper wire and ground , wire mesh is used as the receiving device for composite nanofibers, the angle between the spray gun head and the horizontal plane is 15°, the distance between the spray gun head and the wire mesh of the receiving screen is 15cm, the spinning voltage is 13kV, the indoor temperature is 20-25°C, and the relative humid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com