Method for continuously producing cyanamide

A technology for cyanamide and cyanamide material, applied in the field of continuous production of cyanamide, can solve the problems of cyanamide polymerization explosion, cyanamide loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

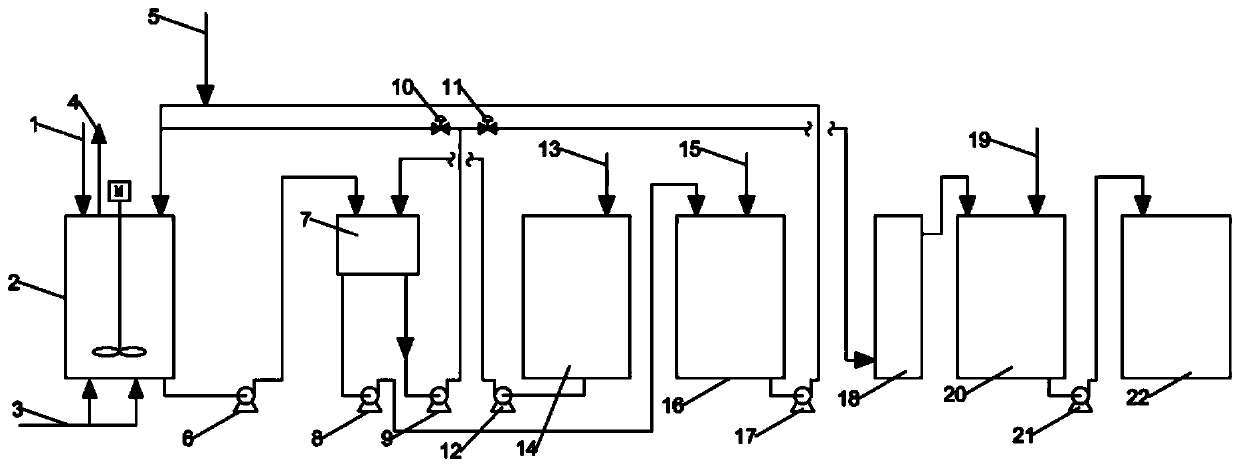

Method used

Image

Examples

Embodiment 1

[0057] (1) Continuously inject mother liquor from the mother liquor tank to the synthesis kettle with a feed rate of 20t / h, and the liquid amount in the synthesis kettle is maintained at 4m 3 Afterwards stop injecting; Simultaneously, before mother liquor is transported into synthetic kettle, in mother liquor, inject ferric trichloride continuously, the consumption of described ferric chloride is 0.01% of mother liquor mass flow rate in mother liquor pipeline; Open stirring, control rotating speed is 150r / min, and carbon dioxide is introduced from the bottom of the synthesis kettle, and the amount of carbon dioxide introduced is controlled to be 100Nm 3 / h; start to add lime nitrogen, through the metering and feeding system, control the amount of lime nitrogen added to 220kg / h; during the synthesis process, control the temperature ≤ 30 ℃, control the pH ≤ 8.5.

[0058] (2) After feeding for 2 hours, turn on the material transfer pump and control the flow rate of the material ...

Embodiment 2

[0062] (1) Continuously inject mother liquor into the synthesis kettle with a feed rate of 20t / h from the mother liquor tank, and the liquid amount in the synthesis kettle is maintained at 3m 3 Stop injecting after; Simultaneously, before mother liquor is transported into synthetic kettle, in mother liquor, inject sodium sulfide continuously, the consumption of described sodium sulfide is 0.01% of mother liquor mass flow rate in mother liquor pipeline; Open stirring, control rotating speed is 150r / min, and Introduce carbon dioxide from the bottom of the synthesis kettle, and control the amount of carbon dioxide inflow to 120Nm 3 / h; start to add lime nitrogen, through the metering and feeding system, control the amount of lime nitrogen added to 220kg / h; during the synthesis process, control the temperature ≤ 30 ℃, control the pH ≤ 8.5.

[0063] (2) After feeding for 1 hour, turn on the material transfer pump and control the flow rate of the material transfer pump to 1m 3 / h, ...

Embodiment 3

[0067] (1) Continuously inject mother liquor into the synthesis kettle with a feed rate of 20t / h from the mother liquor tank, and the liquid amount in the synthesis kettle is maintained at 4m 3 Stop injecting after; Simultaneously, before mother liquor is conveyed into synthetic kettle, in mother liquor, inject ferric trichloride continuously, the consumption of described ferric chloride is 0.02% of mother liquor mass flow rate in the mother liquor pipeline; Open stirring, control rotating speed is 200r / min, and carbon dioxide is introduced from the bottom of the synthesis kettle, and the amount of carbon dioxide introduced is controlled at 120Nm 3 / h; start to add lime nitrogen, through the metering and feeding system, control the amount of lime nitrogen added to 220kg / h; during the synthesis process, control the temperature ≤ 30 ℃, control the pH ≤ 8.5.

[0068] (2) After feeding for 1 hour, turn on the material transfer pump and control the flow rate of the material transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com