Dicyandiamide preparation method

A technology of dicyandiamide and cyanamide, applied in the field of dicyandiamide preparation, can solve the problems of large equipment investment, high production cost, and long process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

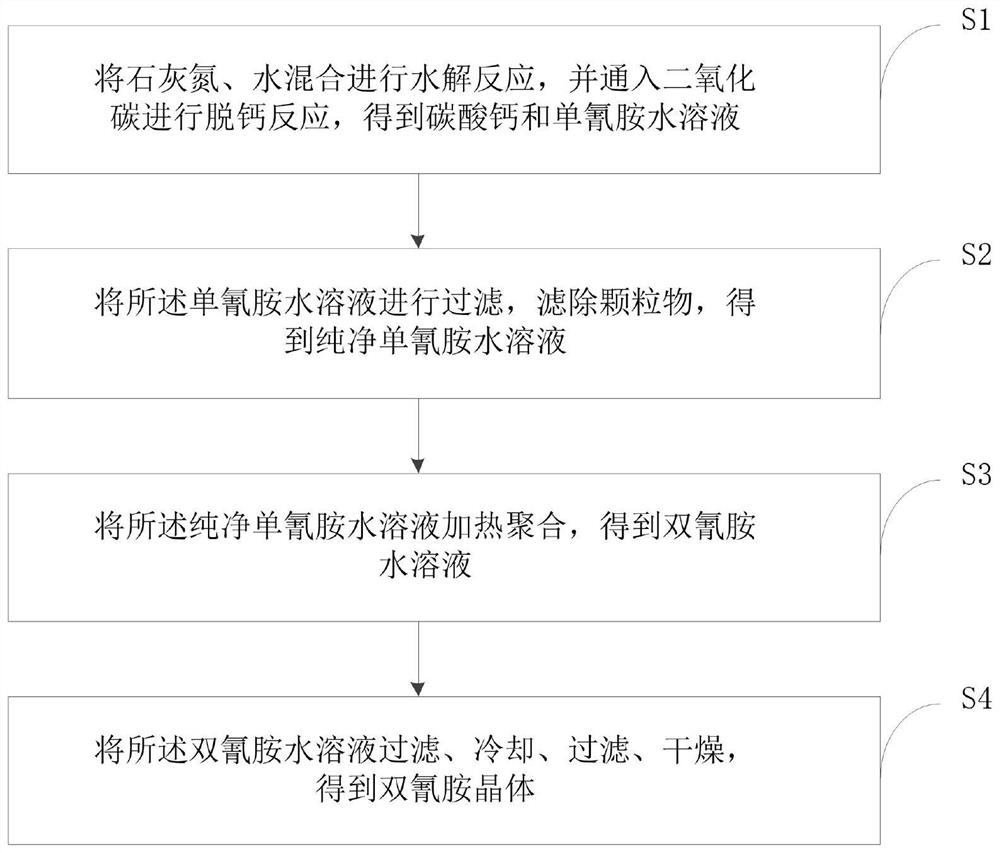

[0023] A kind of preparation method of dicyandiamide is characterized in that, comprises:

[0024] Step S11: mixing lime nitrogen and water for hydrolysis reaction, and introducing carbon dioxide for decalcification reaction to obtain an aqueous solution of calcium carbonate and cyanamide;

[0025] Step S12: Filter the cyanamide aqueous solution to remove particulate matter to obtain a pure cyanamide aqueous solution;

[0026] Step S13: heating and polymerizing the pure aqueous solution of cyanamide to obtain an aqueous solution of dicyandiamide;

[0027] Step S14: filtering, cooling, filtering and drying the dicyandiamide aqueous solution to obtain dicyandiamide crystals.

Embodiment 2

[0029] Step S21: mixing lime nitrogen and water for hydrolysis reaction, and introducing carbon dioxide for decalcification reaction to obtain an aqueous solution of calcium carbonate and cyanamide;

[0030] Step S22: Use a filter cloth to filter out particles with a particle size greater than 0.1 mm in the cyanamide aqueous solution, and then use a diatomaceous earth filter to filter particles with a particle size greater than 0.01 mm in the cyanamide aqueous solution under a pressure of 1 kg. Particles are filtered out to obtain pure cyanamide aqueous solution;

[0031] Step S23: heating and polymerizing the pure aqueous solution of cyanamide to obtain an aqueous solution of dicyandiamide;

[0032] Step S24: filtering, cooling, filtering and drying the dicyandiamide aqueous solution to obtain dicyandiamide crystals.

Embodiment 3

[0034] Step S31: mixing lime nitrogen and water for hydrolysis reaction, and introducing carbon dioxide for decalcification reaction to obtain an aqueous solution of calcium carbonate and cyanamide;

[0035] Step S32: Use a filter cloth to filter out particles with a particle size larger than 0.1 mm in the cyanamide aqueous solution, and then use a diatomaceous earth filter to filter the particles with a particle size larger than 0.01 mm in the cyanamide aqueous solution under a pressure of 1 kg. Particles are filtered out to obtain pure cyanamide aqueous solution;

[0036] Step S33: Under the condition of pH value of 8 and temperature of 30°C, heating and polymerizing the pure cyanamide aqueous solution to obtain dicyandiamide aqueous solution;

[0037] Step S34: filtering, cooling, filtering and drying the dicyandiamide aqueous solution to obtain dicyandiamide crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com