Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130 results about "Soft sensing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft-sensing modeling method and soft meter of multi-model neural network in biological fermentation process

InactiveCN101630376AResponse Growth LawRealize online measurementBioreactor/fermenter combinationsBiological substance pretreatmentsCluster algorithmNetwork model

The invention discloses a soft-sensing modeling method and a soft meter of a multi-model neural network in a biological fermentation process. The method comprises the following steps: a data preprocessing module preprocesses input variable data by a normalization and principle component analysis method; and then the data preprocessing module carries out cluster division on a preprocessed principle component variable set; through and then a BP neural network model module respectively establishes sub neural networks according to different clusters and finally establishes a soft-sensing model of the multi-model neural network. The soft-sensing model of the multi-model neural network is used for measuring biomass concentration in a fermentation process on line, and a measurement value is displayed through a biomass concentration soft-sensing value displayer. The invention introduces a core fuzzy C mean clustering algorithm based on a particle swarm algorithm and combines the mean clustering algorithm with the modeling method of the multi-model neural network, and the established model is simple, realizes the on-line measurement of the biomass concentration and has timely control, high measurement accuracy and strong capacity of resisting disturbance.

Owner:JIANGSU UNIV

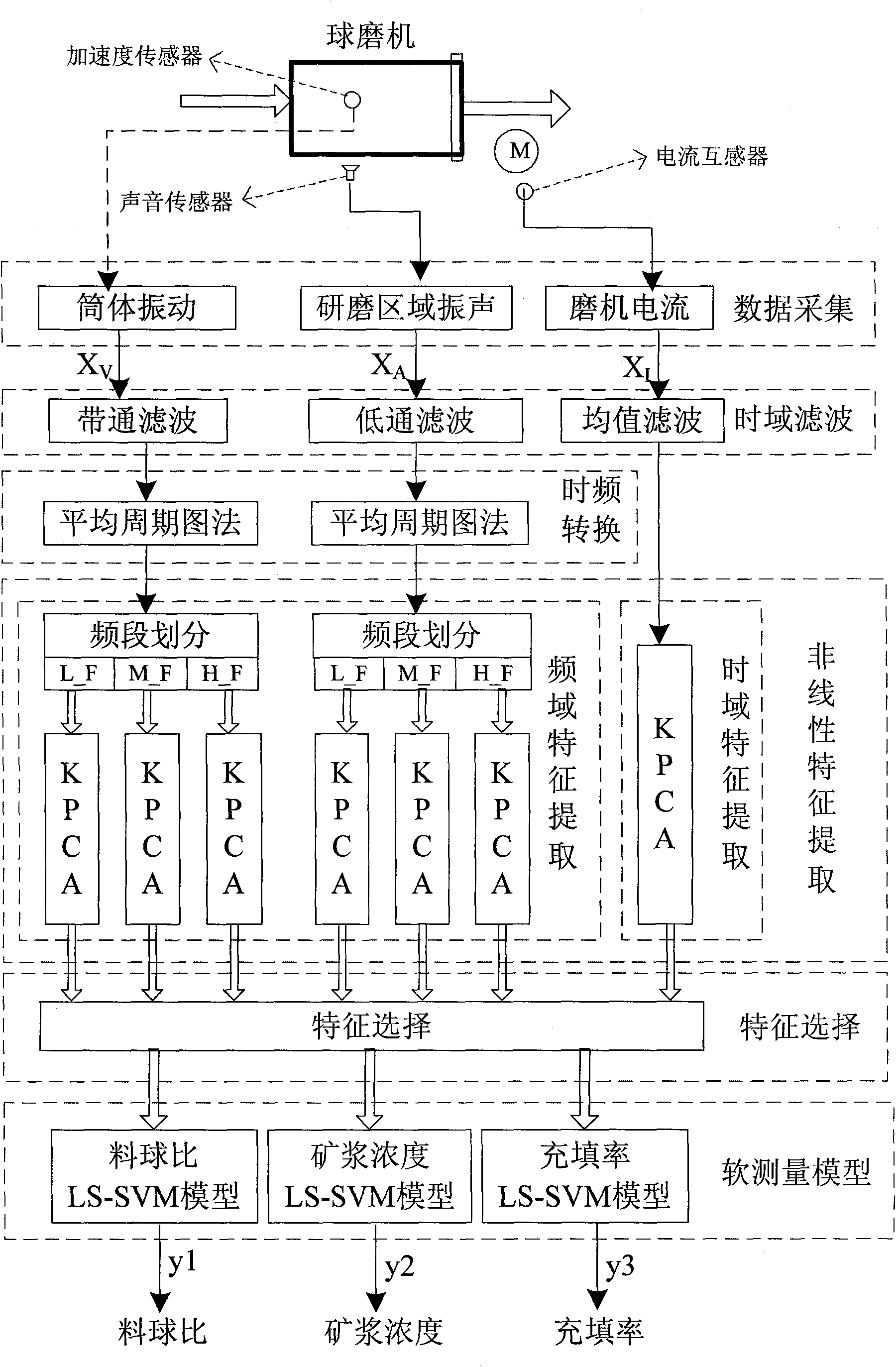

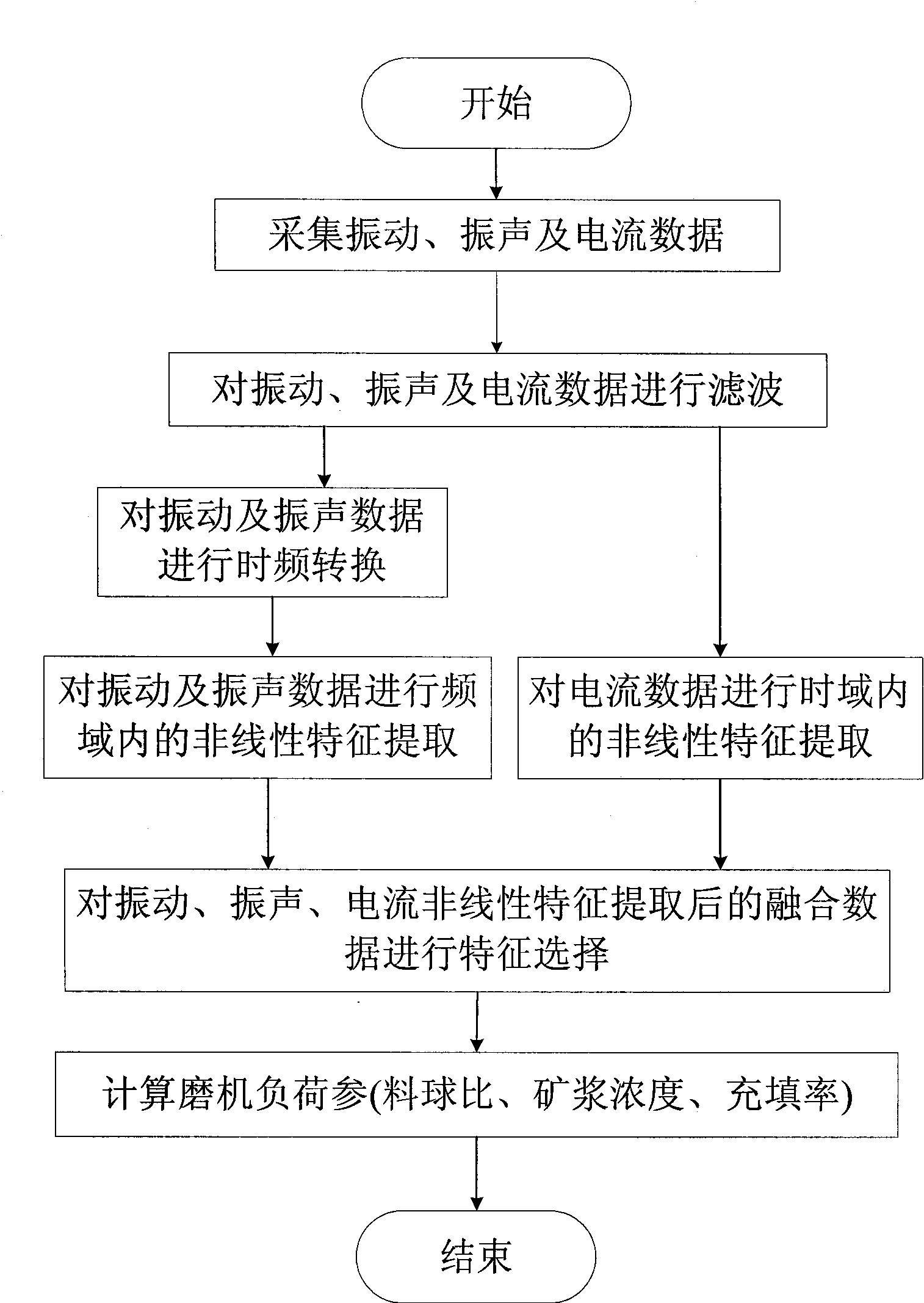

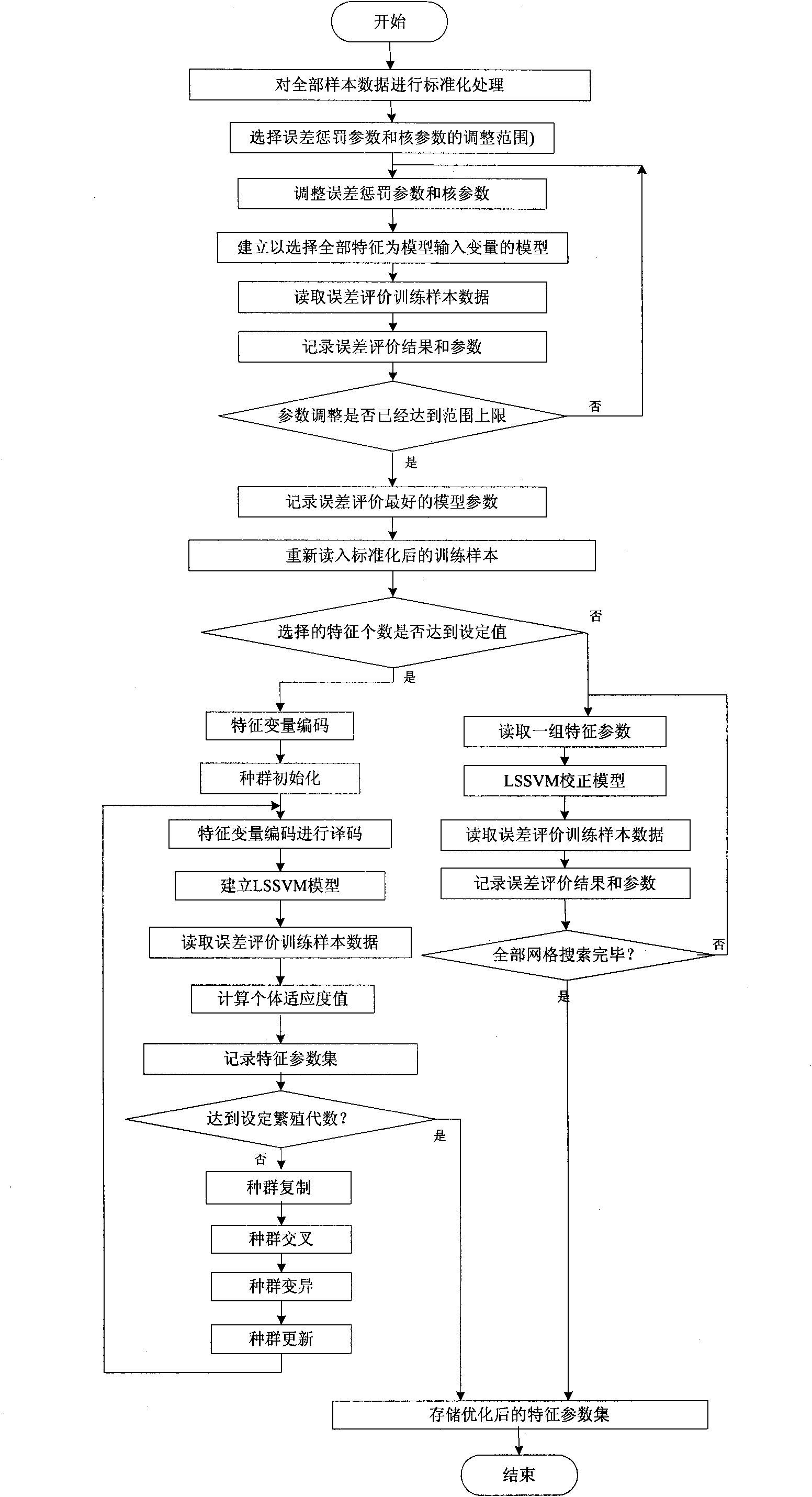

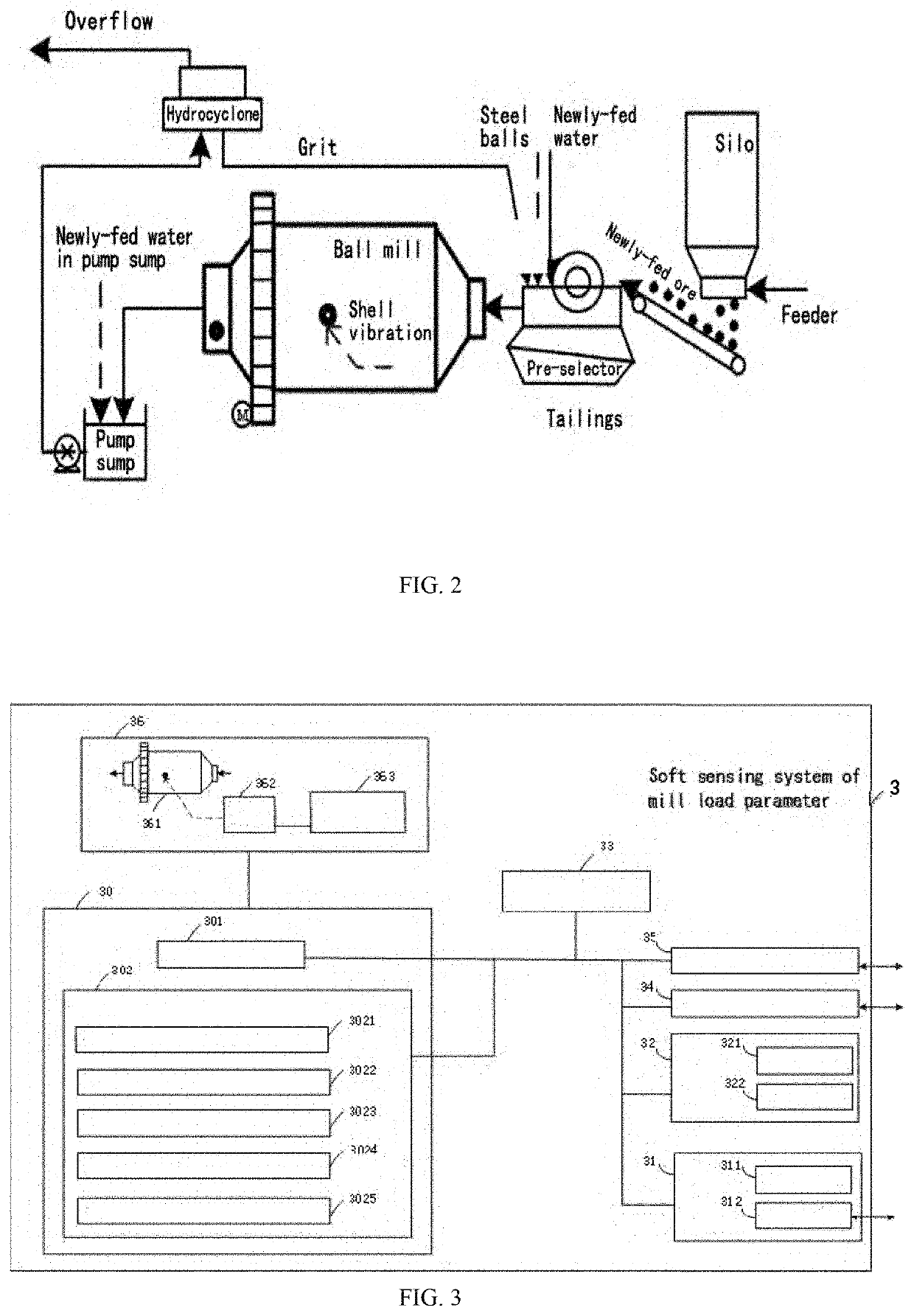

Soft sensing method for load parameter of ball mill

ActiveCN101776531AThe frequency band features are obviousObvious high frequency featuresSubsonic/sonic/ultrasonic wave measurementCurrent/voltage measurementLeast squares support vector machineEngineering

The invention relates to a soft sensing method for load parameters of a ball mill. The method is that a hardware supporting platform is used to obtain vibration signals, vibration sound signals and current signals of a ball mill cylinder to soft sense ball mill internal parameters (ratio of material to ball, pulp density and filling ratio) characterizing ball mill load. The method comprises the following steps that: the vibration, the vibration sound, the current data and the time-domain filtering of the ball mill cylinder are acquired, time frequency conversion is conducted to the vibration and the vibration sound data, kernel principal component analysis based nonlinear features of the sub band of the vibration and the vibration sound data in frequency domain are extracted, nonlinear features of the time domain current data are extracted, feature selection is conducted to the fused nonlinear feature data and a soft sensing model based on a least squares support vector machine is established. The soft sensing method of the invention has the advantages that the sensitivity is high, the sensed results are accurate, the practical value and the popularization prospect are very good, and the realization of the stability control, the optimization control, the energy saving and the consumption reduction of the grinding production process is facilitated.

Owner:NORTHEASTERN UNIV

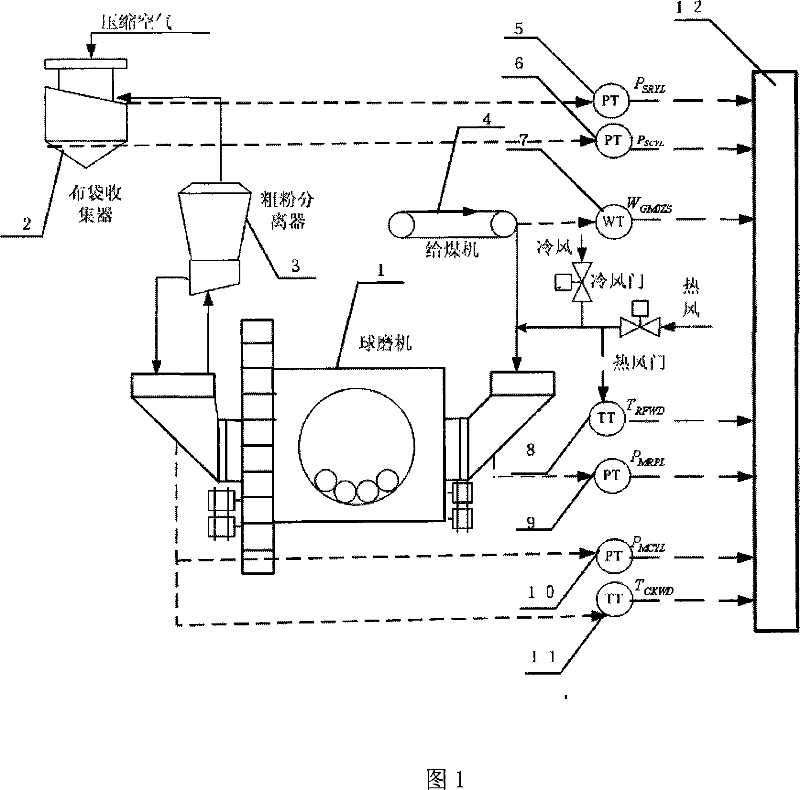

Thermal power plant ball mill load soft-sensing method

InactiveCN101126680AEffective Monitoring and GuaranteeGuaranteed monitoringSubsonic/sonic/ultrasonic wave measurementGrain treatmentsFeature extractionDifferential pressure

The utility model discloses a load soft measurement method for a coal grinding machine in the thermal power plant, which aims to solve the load detecting difficulty existing long time ago of the coal grinding machine in the thermal power plant. The utility model acquires the information attributing the grinder load by the self-adaptive feature extraction from the grinder noise, the vibration and the differential pressure signal, creates a plurality of rules to identify the condition and the fitting polynomial under the rules after the fuzzy classification of the coal grindability factor, water content of the coal, steel balls loading and the load and finally integrates the output of all the rules to get the grinder load. The utility model has the advantages of overcoming the failure to adapt to the condition changes of the prior method, acquiring good accuracy and sensitivity under various conditions and providing guarantee for effective monitor of the grinder.

Owner:XI AN JIAOTONG UNIV

Soft measurement method for coal power fineness in powdering producer

InactiveCN101038277AReduce leakageReduce workloadSpecial data processing applicationsMaterial analysisAlgorithmMeasuring instrument

A pulverized coal fineness soft-sensing method in a powder-making process based on a least squares support vector machine depends on a hardware platform, measuring instruments and a computer system used for performing a software calculation, wherein said software performs a soft-sensing through real-time process data obtained by a controlling computer of a data collector. Said method comprises the steps of selecting assistant variables, determining the structure of sample data, determining sample components, building a soft-sensing model based on the least squares support vector machine and performing the model training, parameter selection as well as the model validation and the model parameter emendation. The present invention is applied simply and easily, has a lower cost, has more accurate soft-sensing results, and helps to achieve an optimal control and an optimal operation of a pulverizing process.

Owner:NORTHEASTERN UNIV

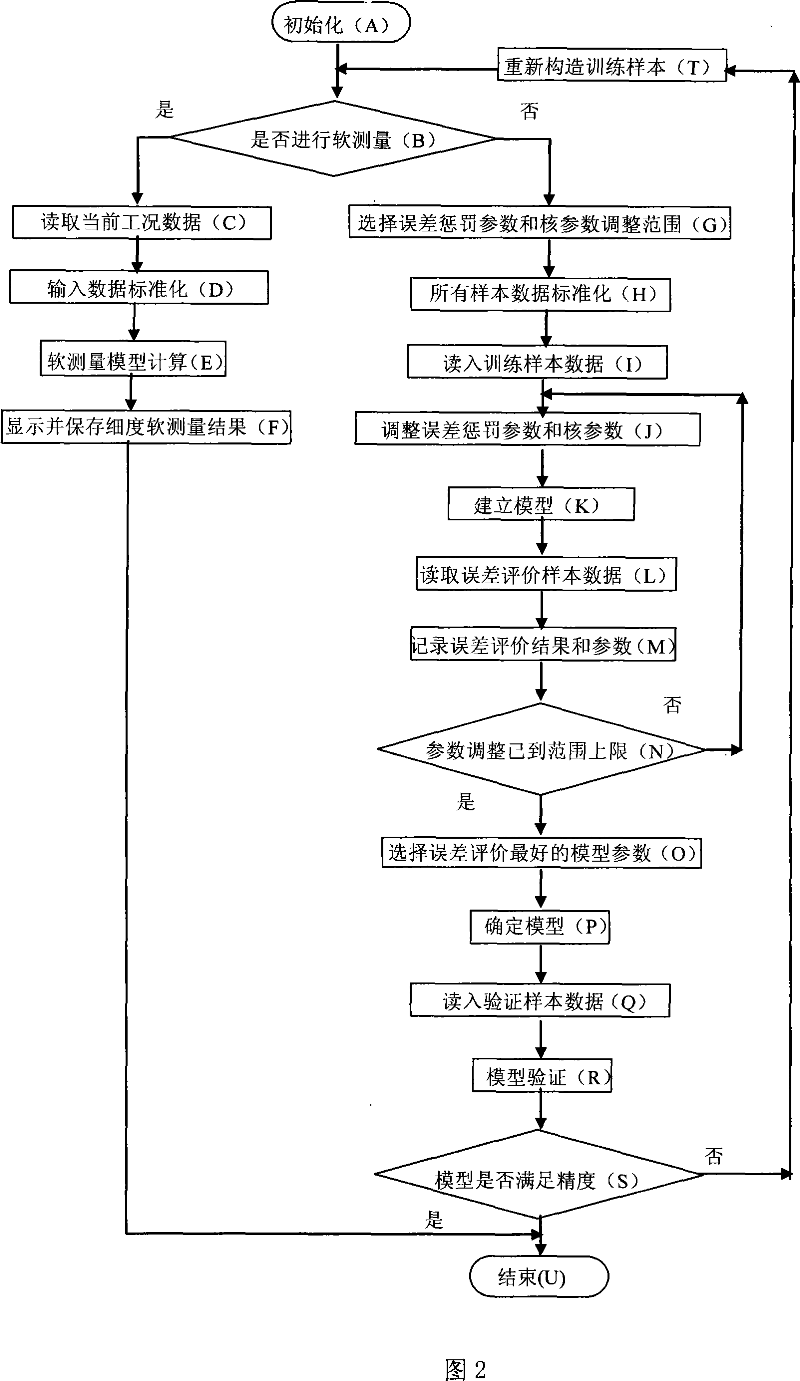

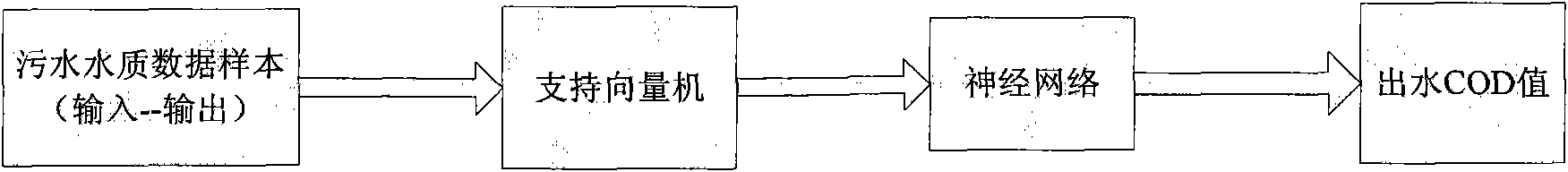

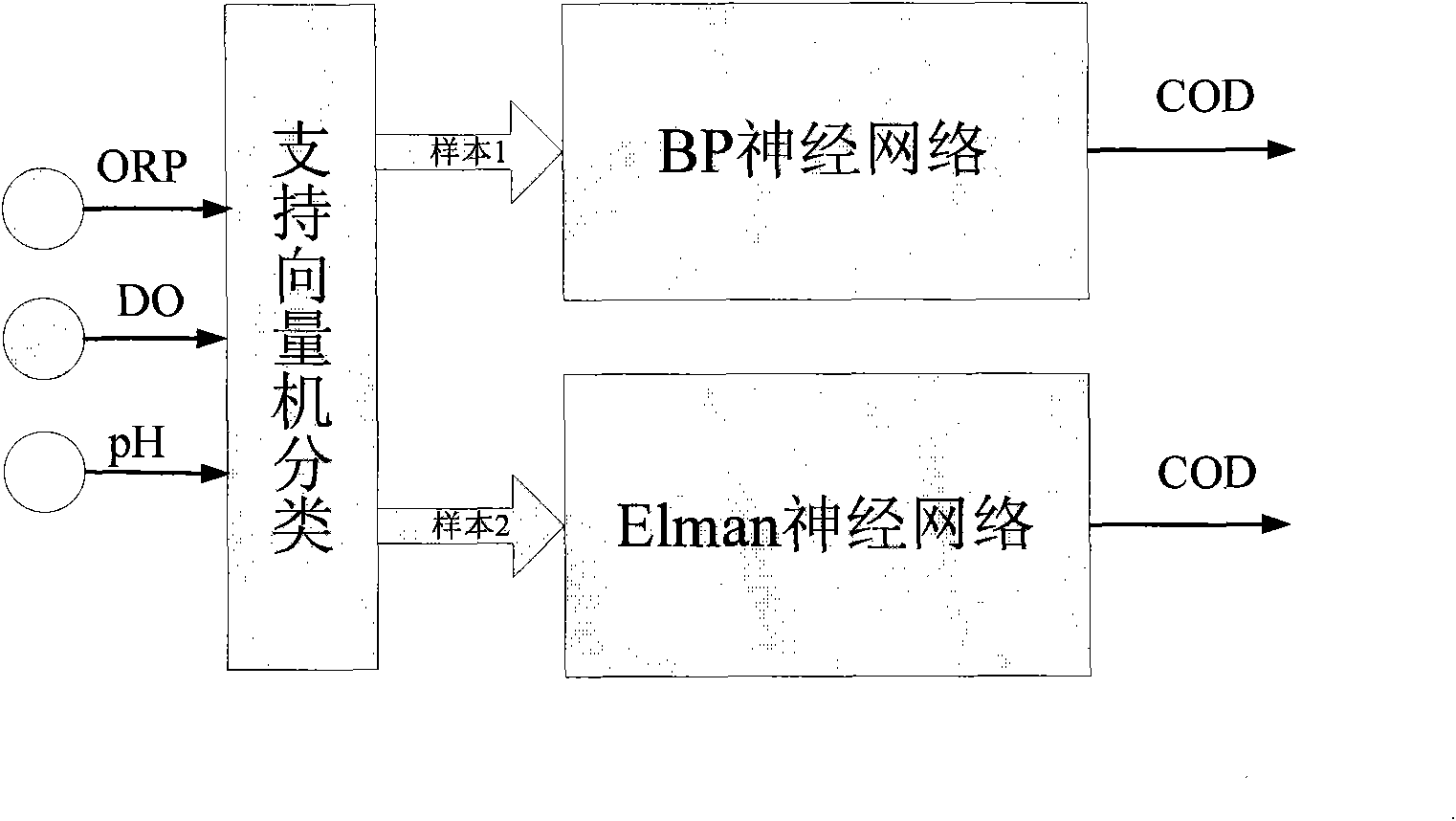

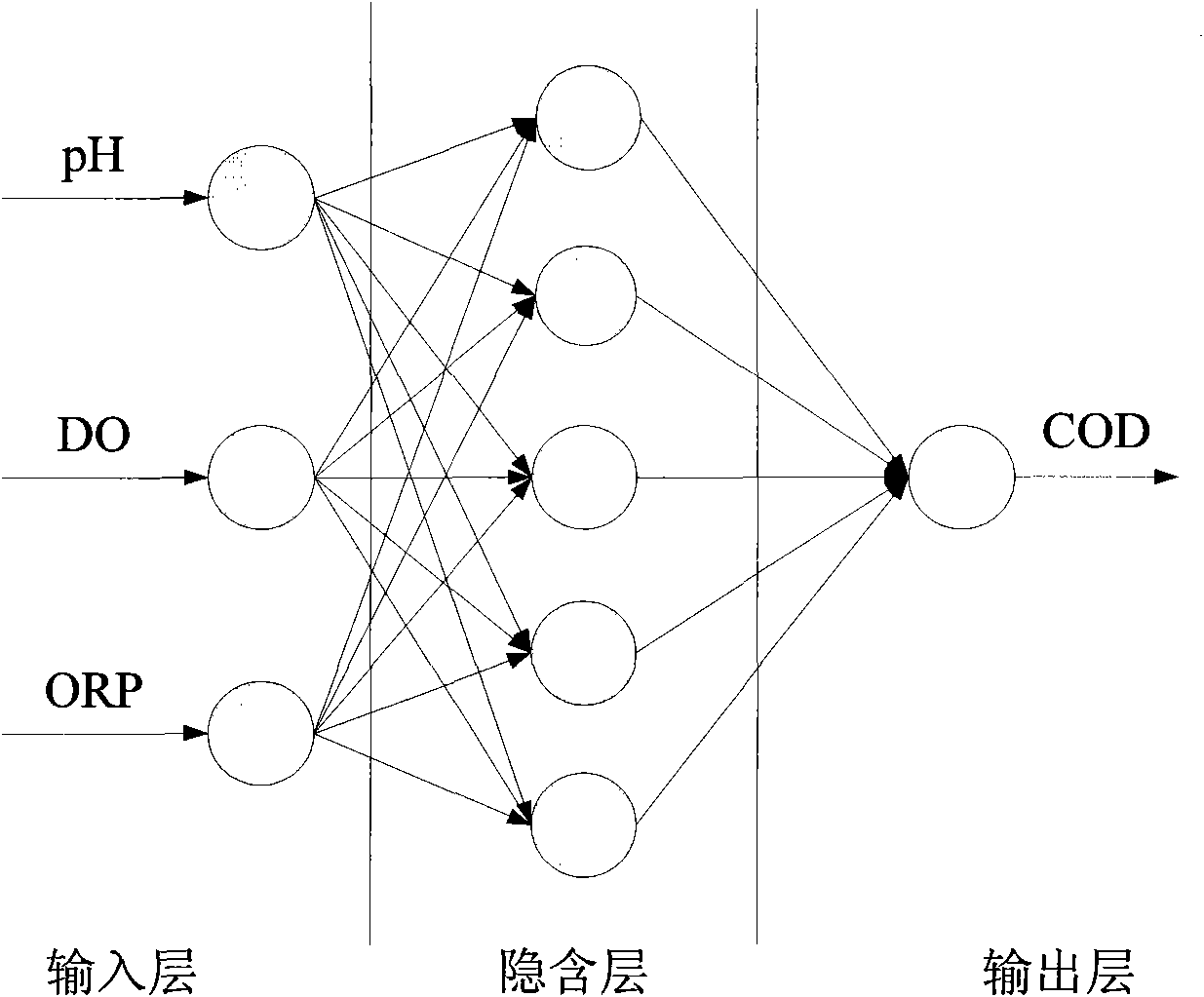

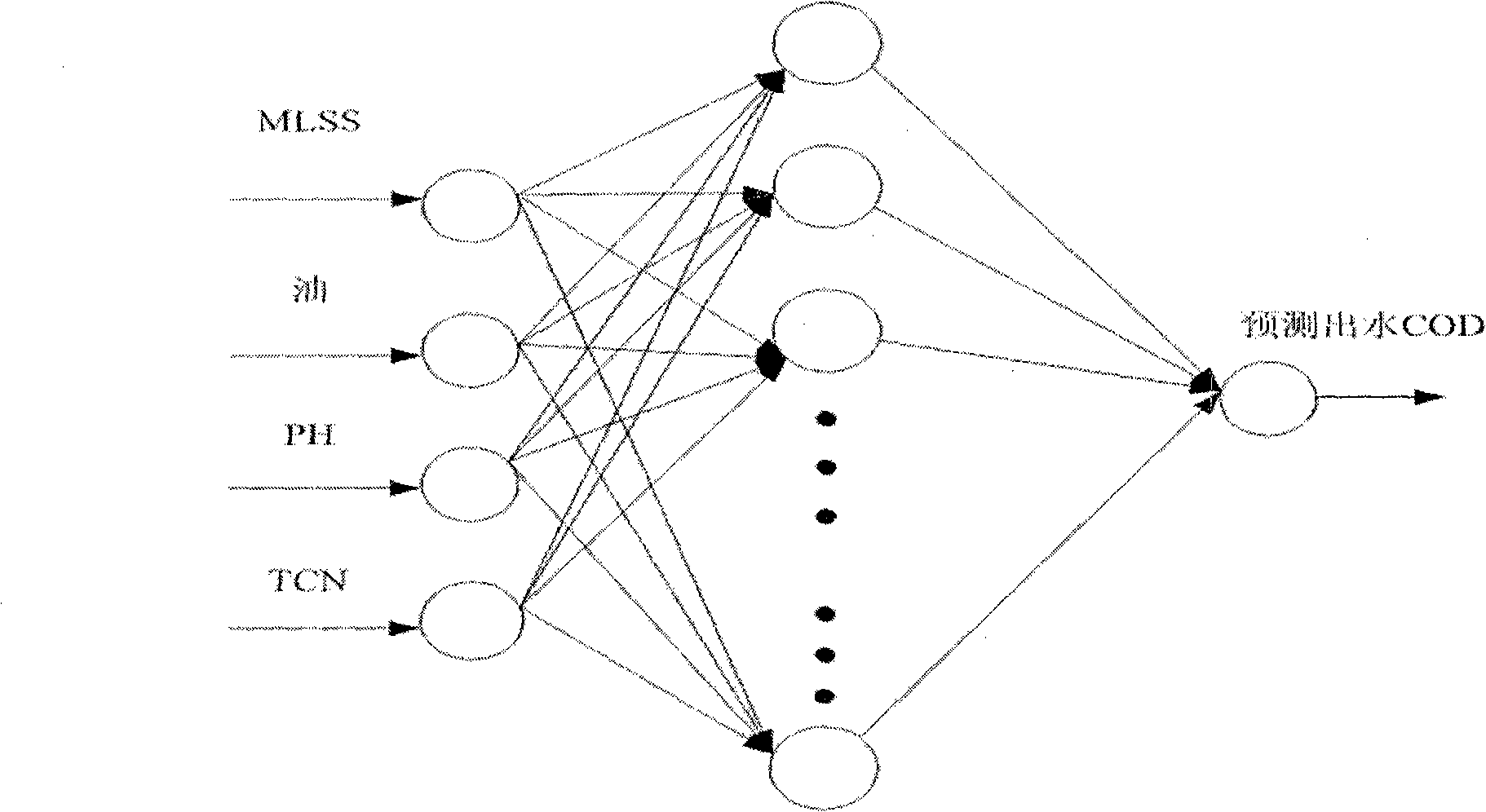

Chemical oxygen demand soft-sensing method of sewage

InactiveCN101566612AImprove estimation accuracyNeural learning methodsMaterial analysisSupport vector machineChemical oxygen demand

The invention relates to a chemical oxygen demand soft-sensing method of sewage, which comprises the steps of: (1) obtaining the water quality parameters of training samples; (2) sorting the training samples; (3) selecting a nerve network and building a nerve network model corresponding to various training samples divided in step (2); (4) training a support vector machine by using various training samples divided in step (2); (5) using various training samples divided in step (2) to train the nerve network model; and (6) estimating the chemical oxygen demand of the sewage. The chemical oxygen demand soft-sensing method of sewage uses the characteristic of better automatic sorting effect of the support vector machine and adopts the support vector machine to sort the training samples, and then respectively estimates the chemical oxygen demand of sewage through the corresponding nerve network. Compared with the prior art, the chemical oxygen demand soft-sensing method of sewage has the beneficial effects of broad range and high estimating range.

Owner:FUDAN UNIV

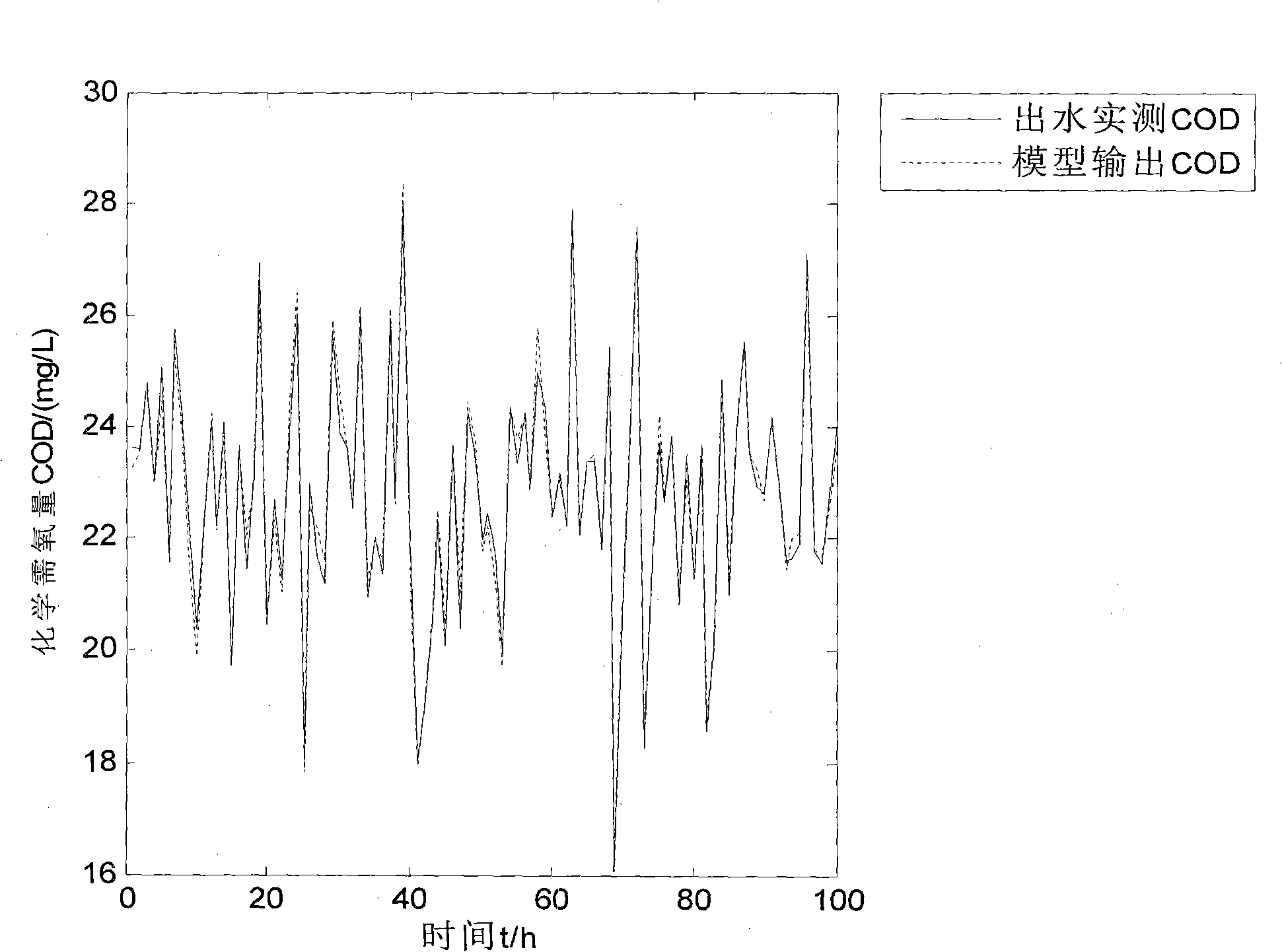

COD soft sensing process

InactiveCN101334395AReduce processing complexitySolve the problem that the initial structure is difficult to determineTesting waterSpecial data processing applicationsNetwork structureWater quality

The invention discloses a COD soft measurement method which belongs to the sewage treatment field. Water quality indicators are difficult to carry out the on-line measurement due to the non-linearity, the time-varying property and the complexity of the sewage biological treatment process, but the water quality indicators are often important for the sewage treatment. The COD soft measurement method is designed against the problem of difficult COD on-line measurement and provides the method which applies the rapid EFAST method for pruning redundant neurons, simplifying the neural network structure and carrying out the soft measurement of COD according to the characteristic of the non-linearity of the sewage treatment process. A great deal of materials matching for processing the biochemical reactions of an aeration tank are timely adjusted according to the soft measurement result, thereby facilitating the better removal of the COD and avoiding complicated projects for research and development of sensors. The method can also be expanded to carry out the research of other water quality indicators for guiding the actual production and operation.

Owner:BEIJING UNIV OF TECH

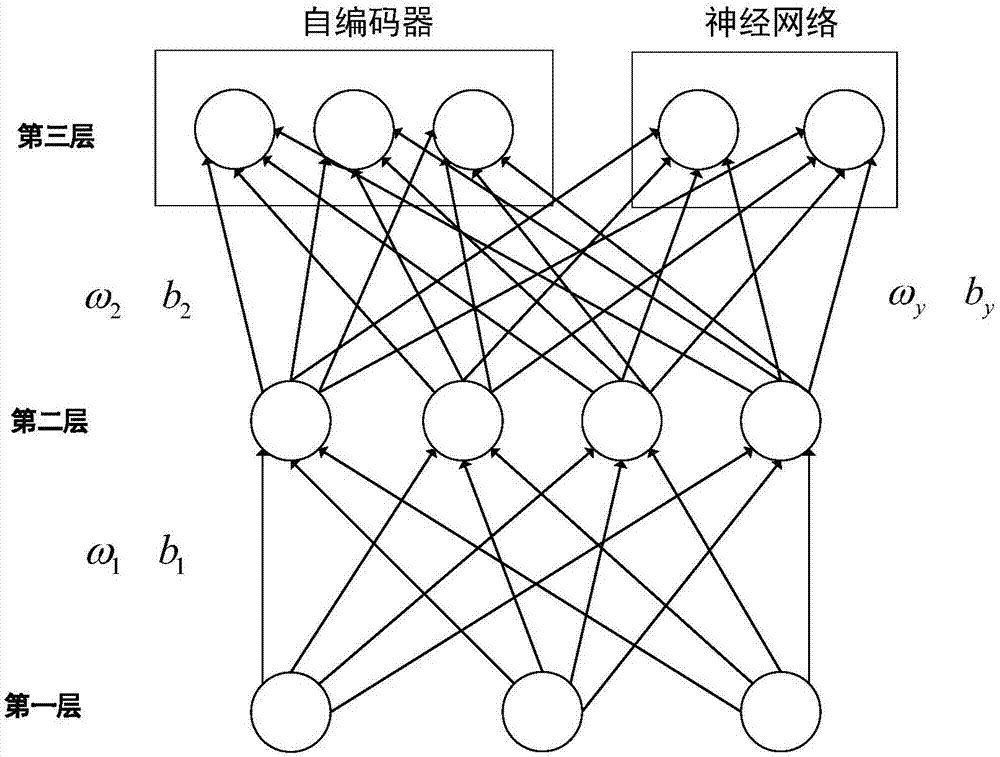

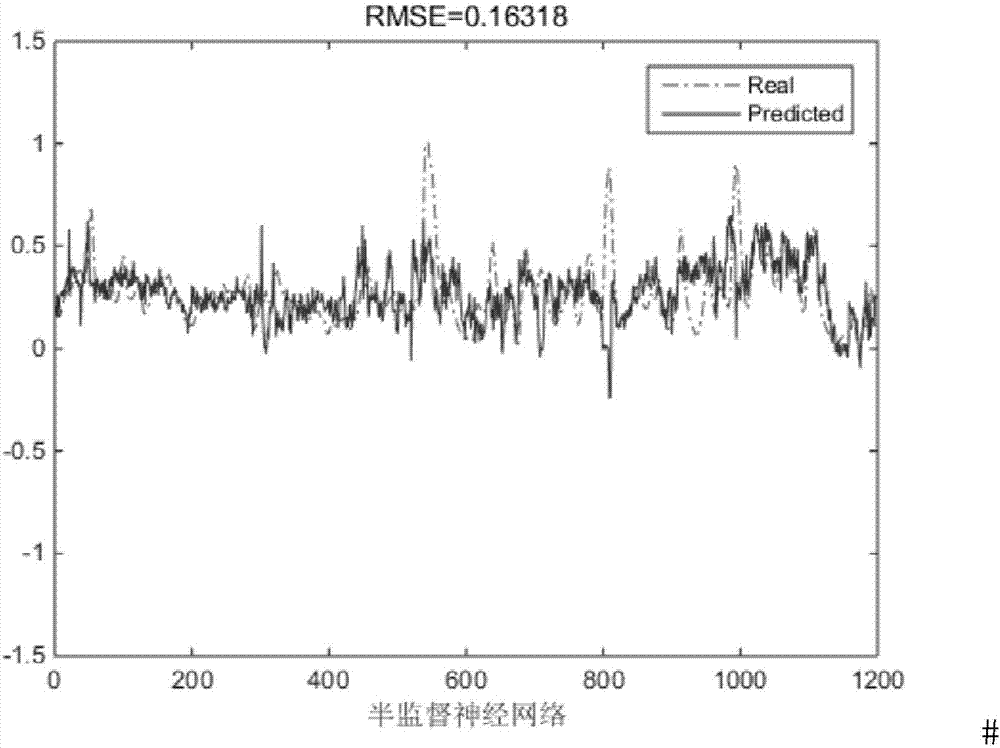

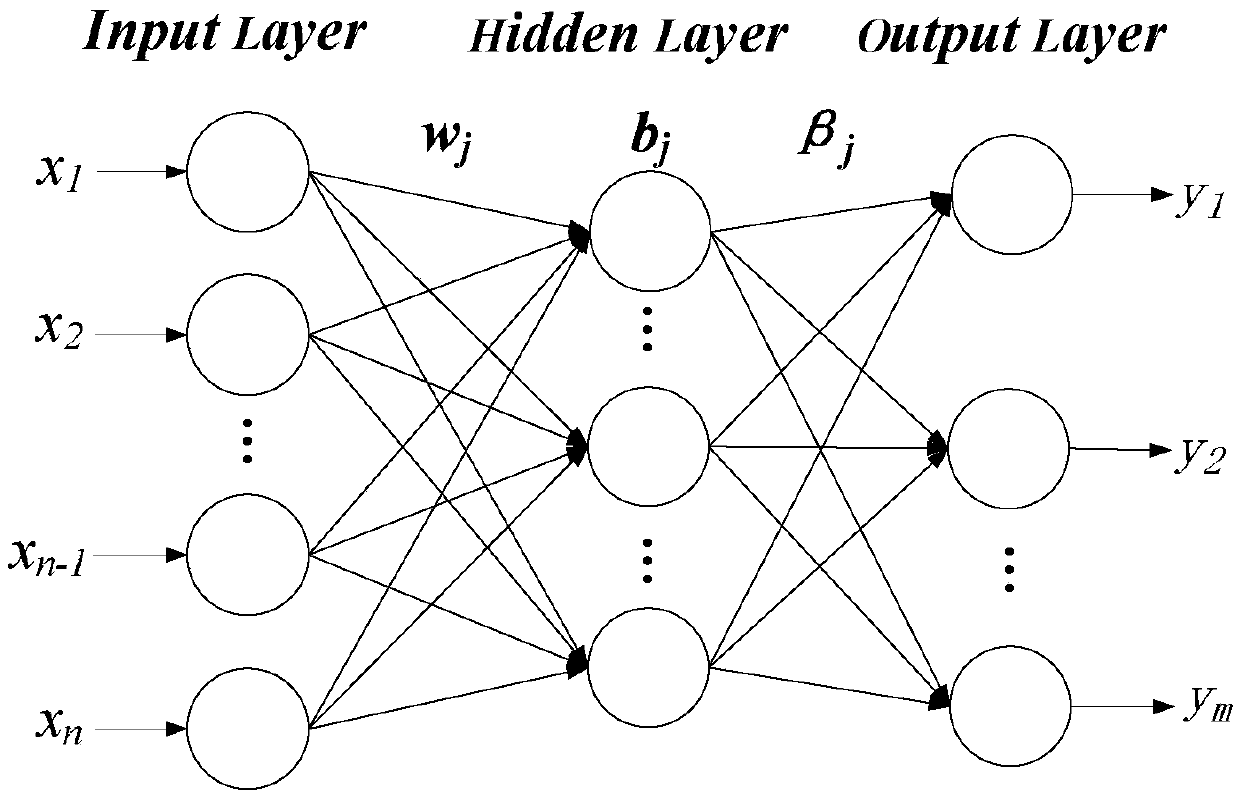

Semi-supervised neural network model and soft-sensing modeling method based on model

The present invention discloses a semi-supervised neural network model and a soft-sensing modeling method based on the model. The model is divided into three layers, wherein the first layer is an input layer, the second layer is a hidden layer, and the third layer is an output layer, wherein the output layer is divided into an auto-encoder output layer and a neural network model output layer; and a self-encoder and a neural network model share the input layer and the hidden layer. The modeling method is composed of the self-encoder and the neural network and can effectively solve the problem of inaccurate soft sensing modeling caused by the scarcity of labeled samples and abundance of unlabeled samples so as to build a more accurate semi-supervised soft-sensing model and realize process monitoring and corresponding control.

Owner:ZHEJIANG UNIV

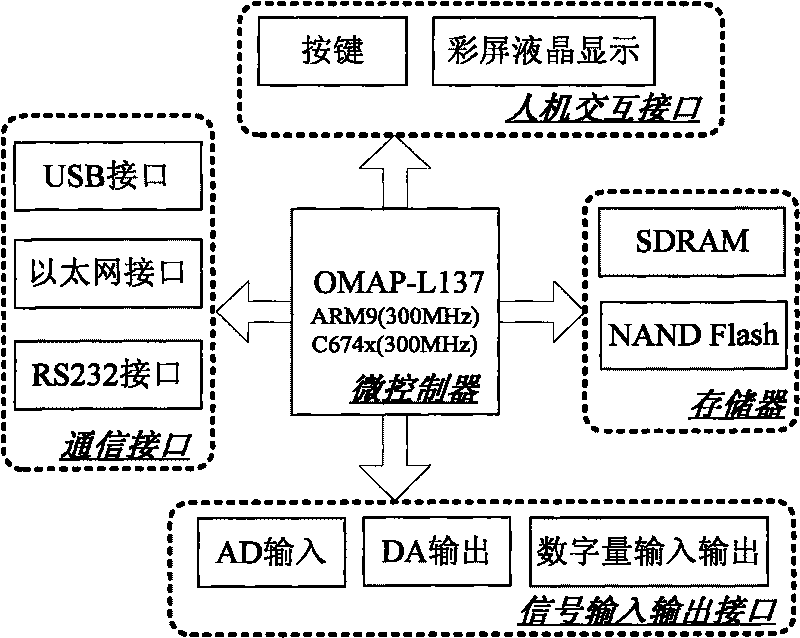

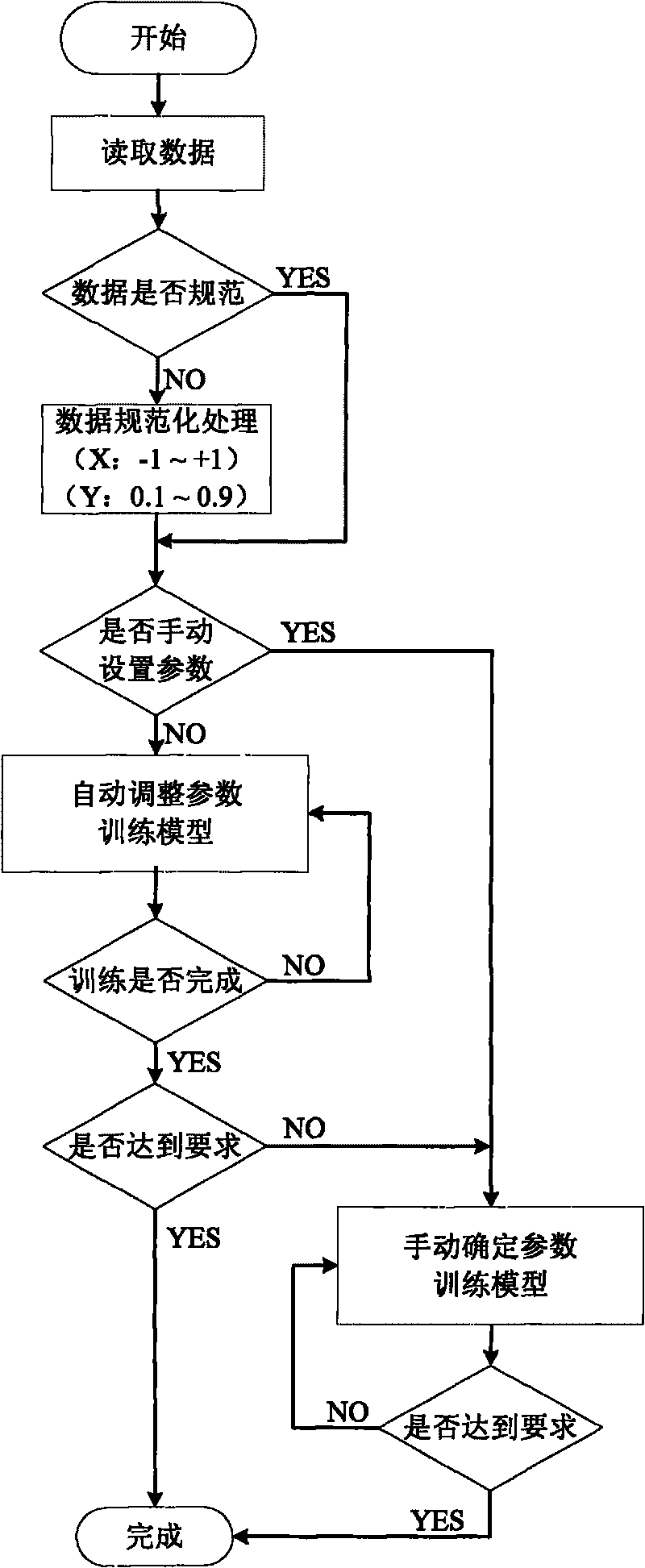

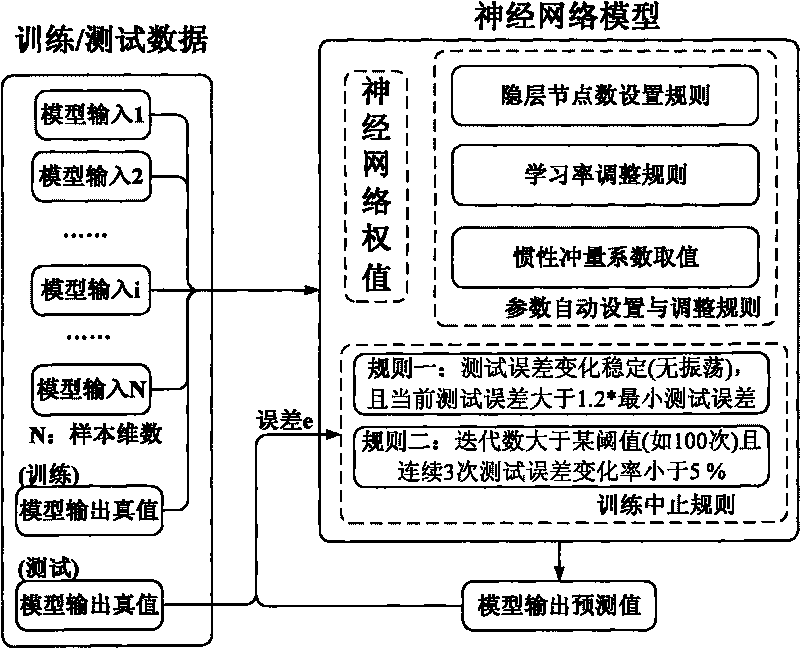

Embedded platform based neural network model online training method

InactiveCN101706882ASatisfy real-timeFulfil requirementsNeural learning methodsNerve networkMiniaturization

The invention discloses an embedded platform based neural network model online training method which can automatically set relative parameters according to the data characteristics and can set manual parameter simultaneously, thus maximally meeting the requirements of real time and intelligence. The method enables a running system to satisfy multiple functions such as portability, intelligent analysis and the like, overcomes the defect that the previous systems are hard to realize miniaturization and decide relevant training parameters and are complex in operations, and provides a low-cost, portable and high real-time solution for pattern recognition or soft sensing in the complex process of petrochemical.

Owner:ZHEJIANG UNIV

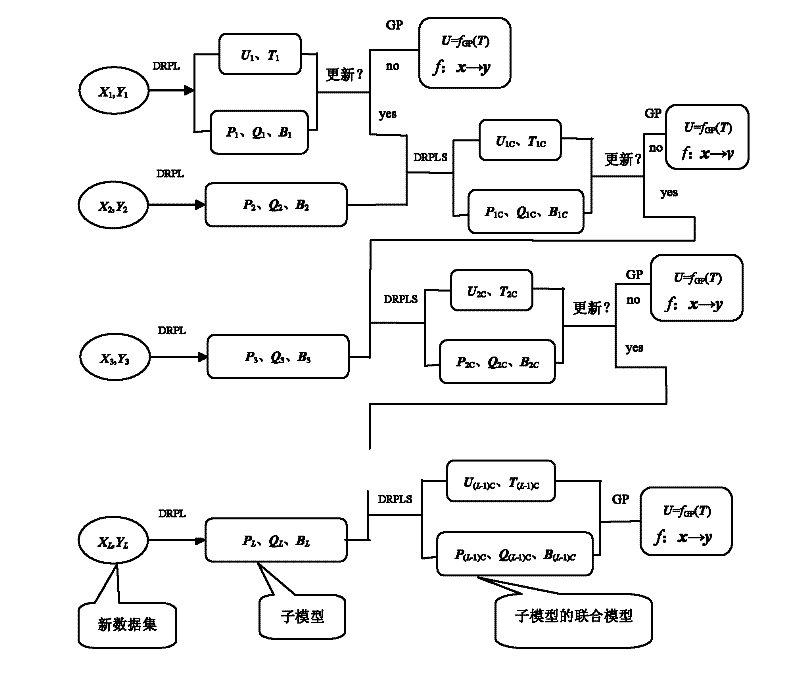

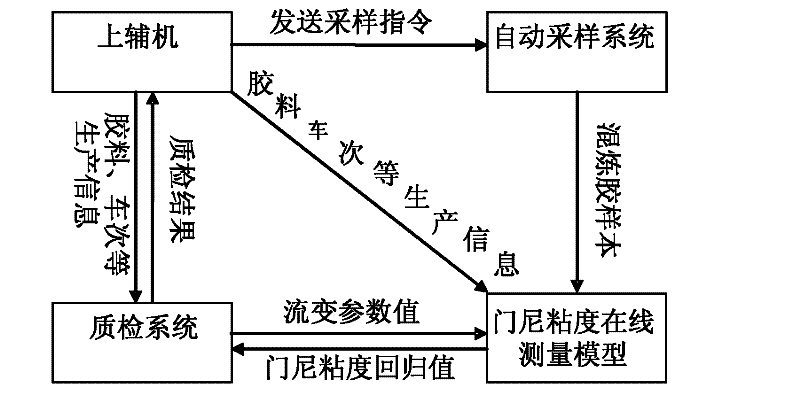

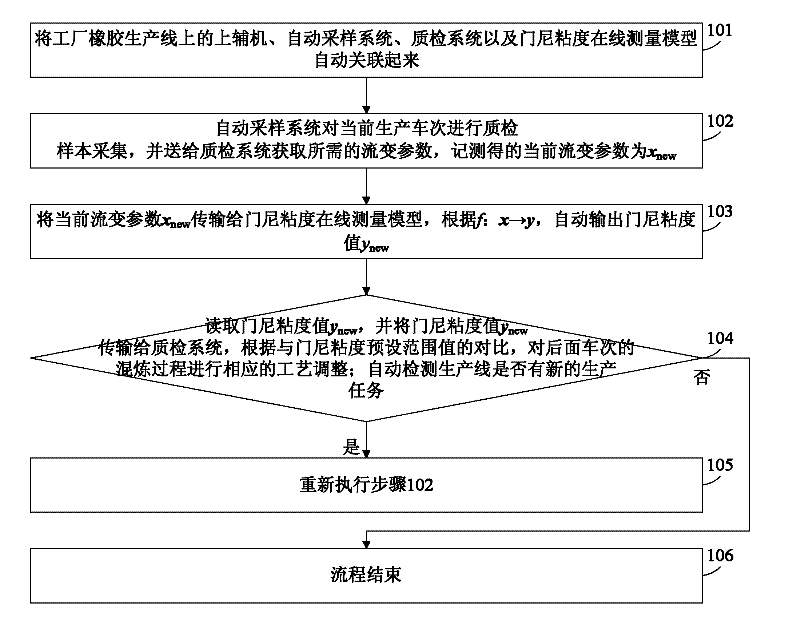

Quality monitor soft sensing method based on rubber mixing process

The invention discloses a quality monitor soft sensing method based on a rubber mixing process. An upper subsidiary engine, an automatic sampling system, a quality inspection system and a Mooney viscosity on-line automatic measurement model on a rubber mixing production line are automatically associated; the automatic sampling system carries out quality inspection sample acquisition on a current production train number and transmits the sample to the quality inspection system to obtain rheological parameters required; current rheological parameters are transmitted to the Mooney viscosity on-line automatic measurement model, and a Mooney viscosity value ynew is automatically output according to f: x->y; the Mooney viscosity value ynew is read out and transmitted to the quality inspection system, which will carry out corresponding technical adjusting on mixing process of a subsequent train number, according to contrast of the Mooney viscosity value ynew and a preset Mooney viscosity value scope, so as to automatically detect whether a new production task is for the production line. The invention saves a large amount of costs on purchasing and maintaining a Mooney viscometer and avoids huge labor and material resources required by a traditional Mooney viscometer measurement method.

Owner:XUZHOU XINLONG PIPE IND CO LTD

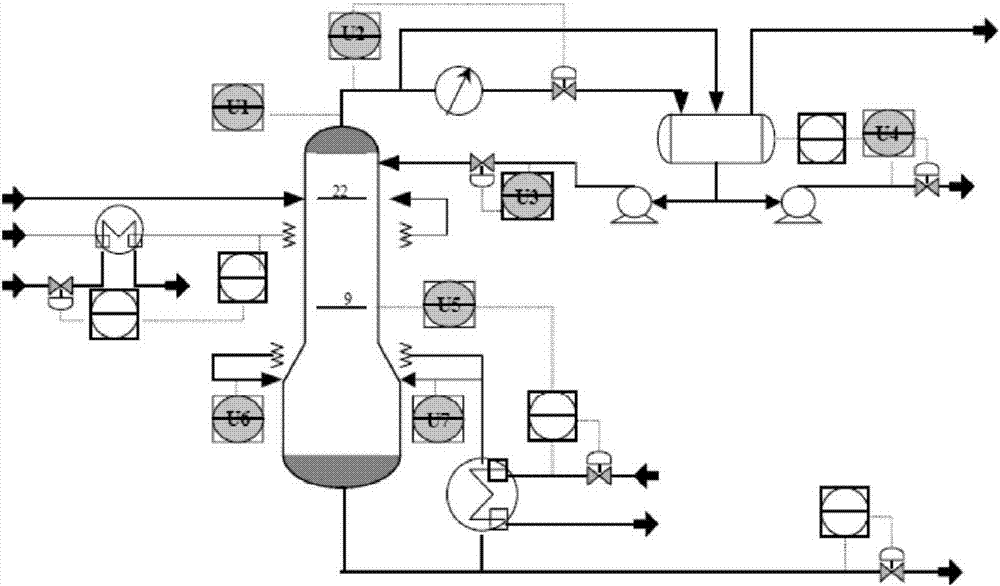

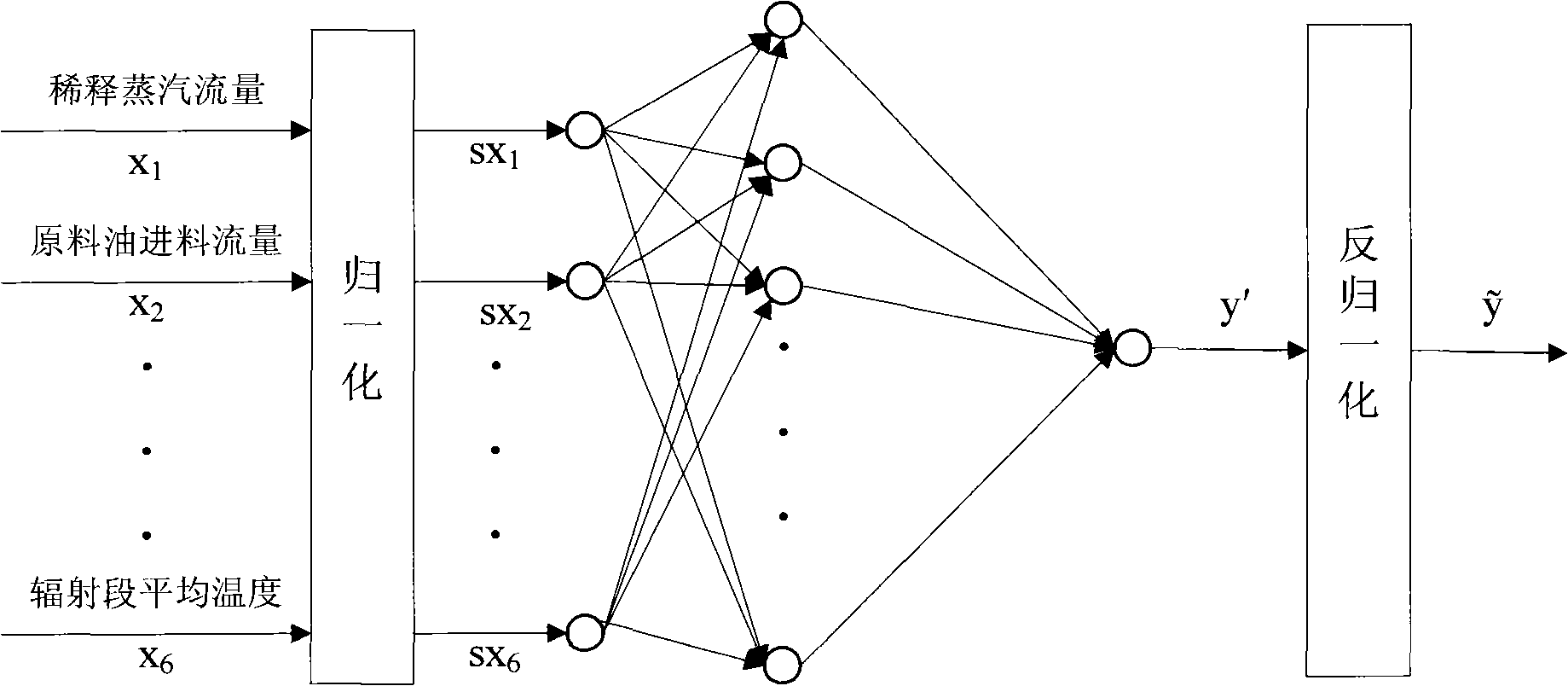

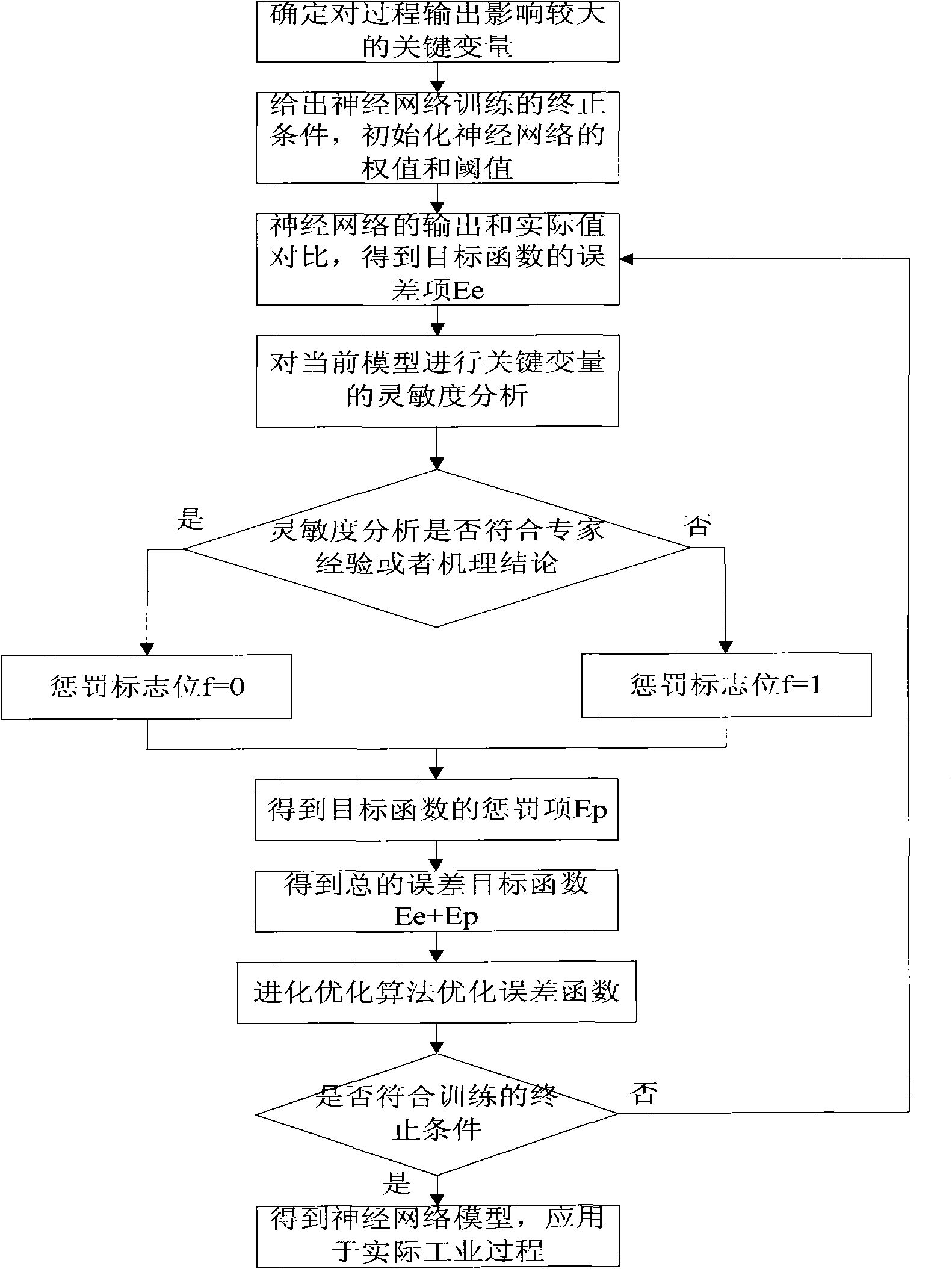

Ethylene cracking severity modeling method based on expert knowledge and neutral network

The invention relates to a modeling method for soft sensing the cracking severity of an ethylene cracking furnace based on expert knowledge and a neutral network. A model established by using the method has high prediction precision, high reliability and high extrapolation performance. The model can reflect the actual operation characteristics of the cracking furnace accurately in real time so as to instruct an operator to adjust the operation variables of the cracking process in time, and thus, the economical benefits are increased. In the invention, the expert knowledge about the ethylene cracking process is added to the network training process of ethylene cracking severity neutral network modeling, and a training sample set is formed by acquiring and preprocessing onsite production data. Meanwhile, the neutral network is optimized by using an intelligent evolutionary algorithm, and the neutral network soft sensing model of ethylene cracking severity is established.

Owner:EAST CHINA UNIV OF SCI & TECH

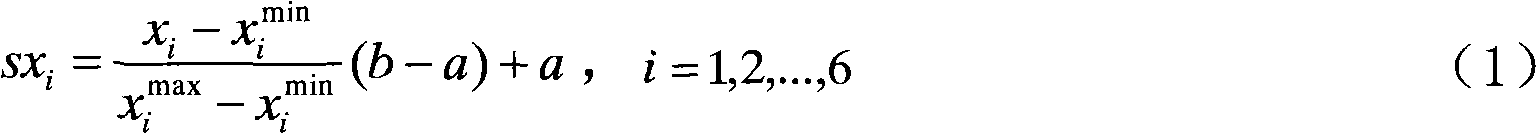

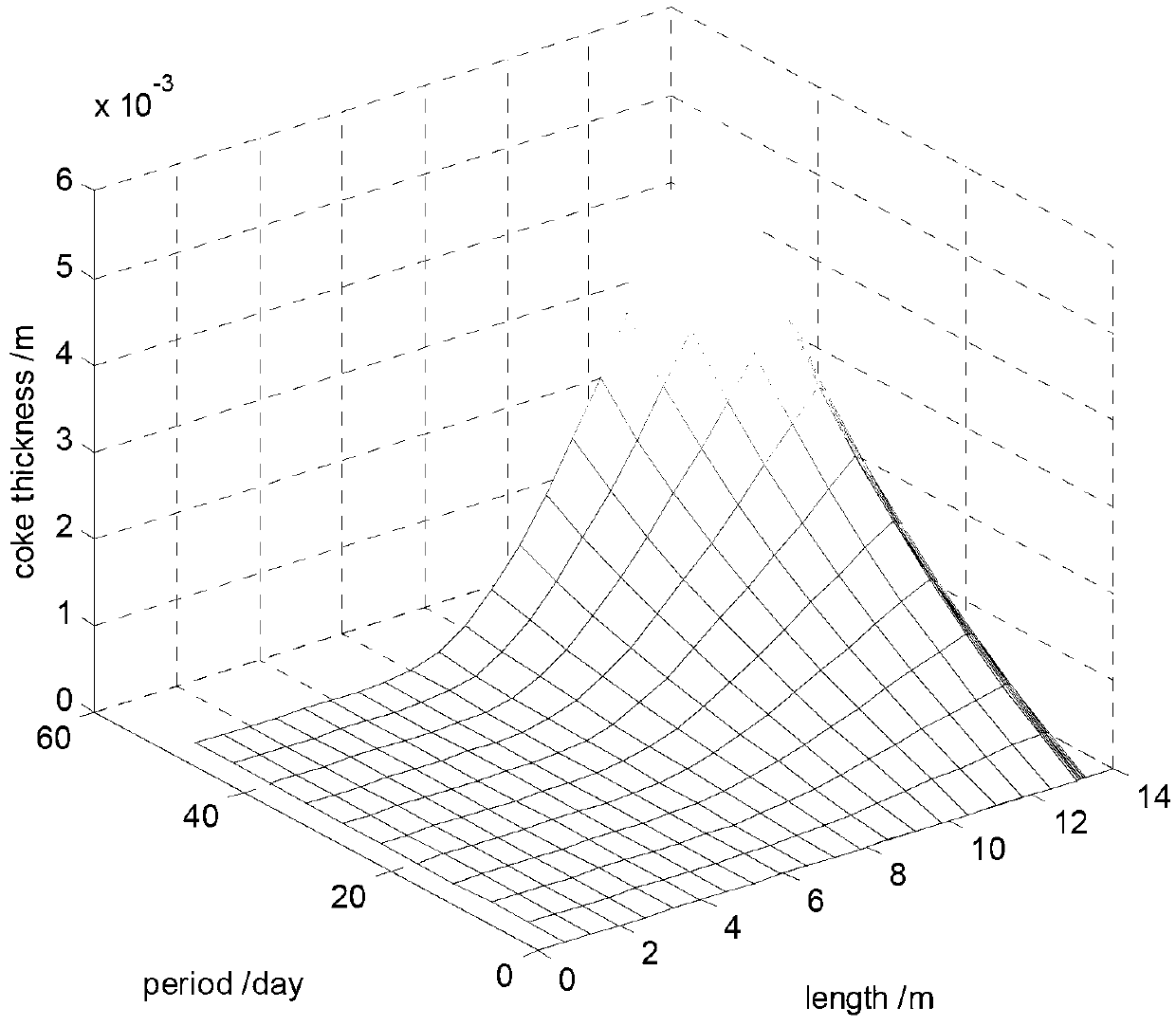

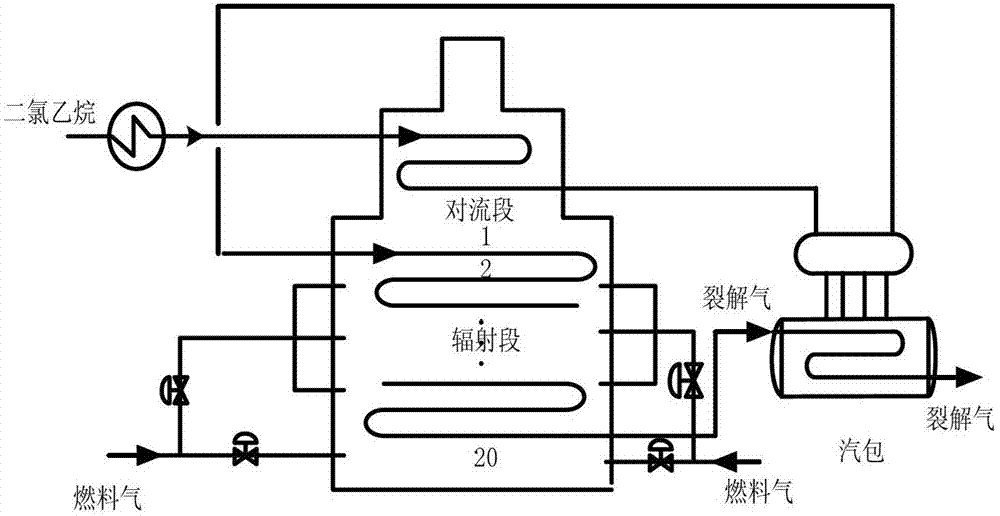

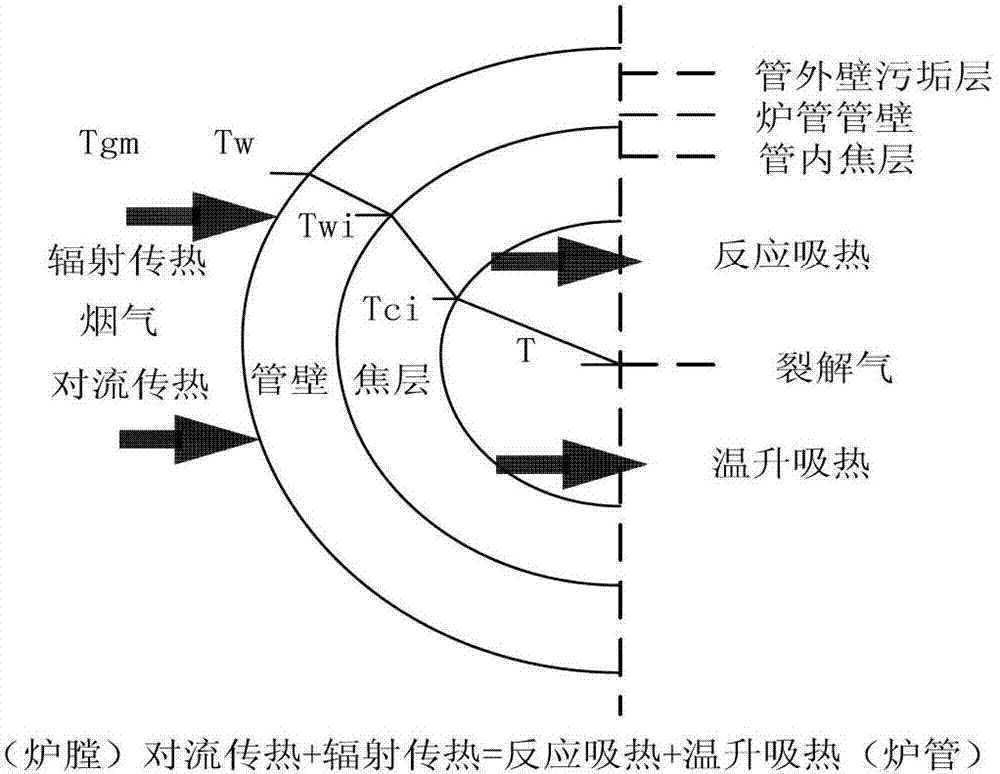

Soft sensing method for true temperature of pyrolysis mixed products at outlet of ethylene cracking furnace

ActiveCN102998013AThermometers using value differencesEnergy balance equationUnsaturated hydrocarbon

The invention relates to a soft sensing method for true temperature of pyrolysis mixed products at the outlet of an ethylene cracking furnace, comprising the following steps: firstly obtaining the furnace tube parameters of the cracking furnace; then obtaining the information of cracking raw material; then calculating the composition of pyrolysis products at the outlet of the cracking furnace; according to a cracking process model, including mass balance equation, momentum balance equation and energy balance equation, calculating the composition profiles of the pyrolysis products at the outlet of a radiant section; then calculating coking thickness in a cracking furnace tube; calculating coking thickness in a adiabatic segment furnace tube according to the contents of small molecule unsaturated hydrocarbon and aromatic hydrocarbon in the pyrolysis products and running time; and finally calculating the difference value of the temperature of a measurement and control point and the true temperature of pyrolysis mixed products so as to calculate the true temperature of pyrolysis mixed products at the outlet of the ethylene cracking furnace. Through the method, the true temperature of gas mixture of pyrolysis products at a particular moment of time can be dynamically calculated, and accurate model of the ethylene cracking furnace can be established, so that the method provides the basis for the simulation, optimization and control of cracking process.

Owner:TSINGHUA UNIV

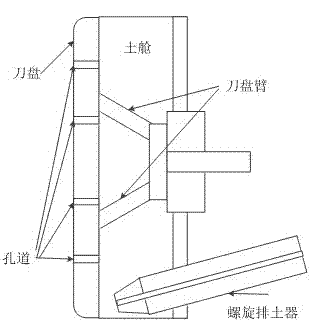

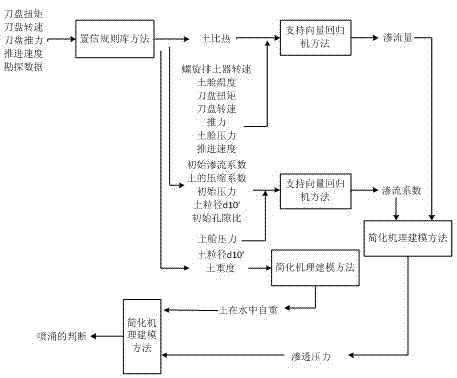

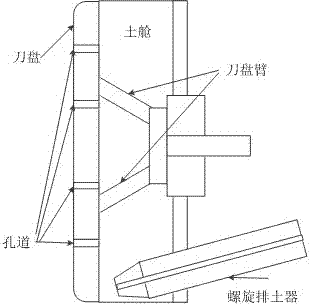

Gushing operation condition soft sensing modeling method based on hybrid multiple models in shield tunneling process

ActiveCN102243672AImprove reliabilityAdaptableSpecial data processing applicationsSupport vector machineData-driven

The invention discloses a gushing operation condition soft sensing modeling method based on hybrid multiple models in a shield tunneling process. Hybrid multiple models include the following four models: 1, a data-driven exploration information and construction data-based soil texture soft sensing model established by using a belief rule base method; 2, a data-driven seepage flow soft sensing model established by using a support vector machine method; 3, a data-driven permeability coefficient model established by using the support vector machine method; and 4, a gushing operation condition soft sensing model established by using a simplification mechanism. The soil texture soft sensing model, the seepage flow soft sensing model and the permeability coefficient model are input of the gushing operation condition soft sensing model. The modeling method disclosed by the invention has the advantages that a hybrid modeling method combining mechanism modeling and data-driven modeling is adopted, and a model modeled by using the modeling method is simple and has high interpretability, high reliability and good extrapolation.

Owner:ZHEJIANG UNIV

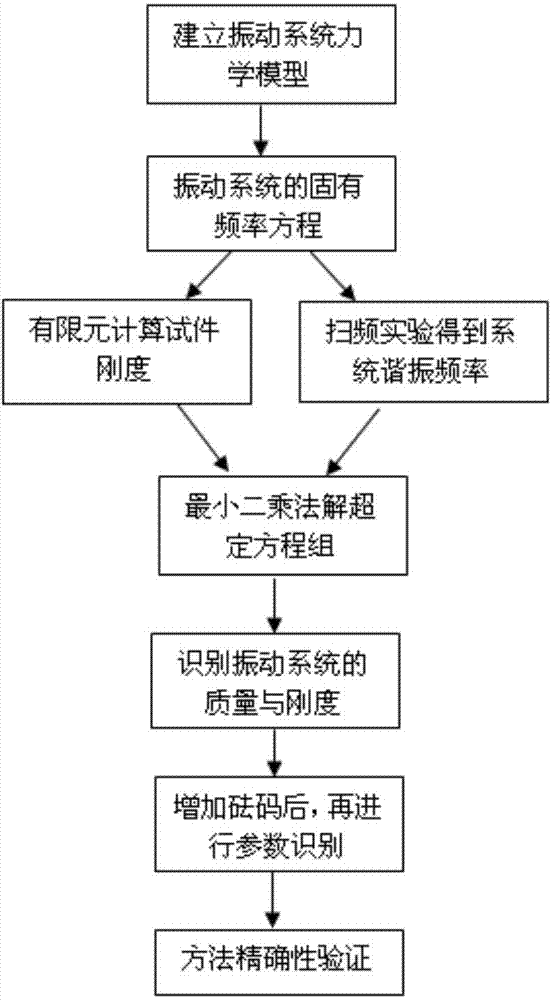

Method for identifying parameters of resonant fatigue crack propagation test vibration system based on soft sensing technology

ActiveCN104777054AStrong experimental operabilityLow cost per experimentStrength propertiesMechanical modelsThree degrees of freedom

A method for identifying parameters of a resonant fatigue crack propagation test vibration system based on a soft sensing technology comprises the following steps: 1, establishing a system three-degree-of-freedom vibration mechanical model to obtain a kinetic equation, and deriving to obtain a system frequency equation about a relationship among the system inherent frequency, the spring rigidity and the particle mass; 2, calculating according to a finite element technology to obtain the rigidity of a test piece under different crack lengths, and testing the system resonant frequency when a crack is propagated to different lengths; 3, substituting the system resonant frequency value and the corresponding test piece rigidity under different crack lengths into the system frequency equation in order to obtain overdetermined equations about the mass to be identified and unknown rigidity; 4, solving the overdetermined equations through a least squares technique to obtain nonlinear equations about the mass and rigidity; and 5, solving the nonlinear equations by using a Newton-Raphson formula, and identifying the vibration system parameters comprising the mass and the rigidity. The method has the advantages of good maneuverability, low cost and good accuracy.

Owner:ZHEJIANG UNIV OF TECH

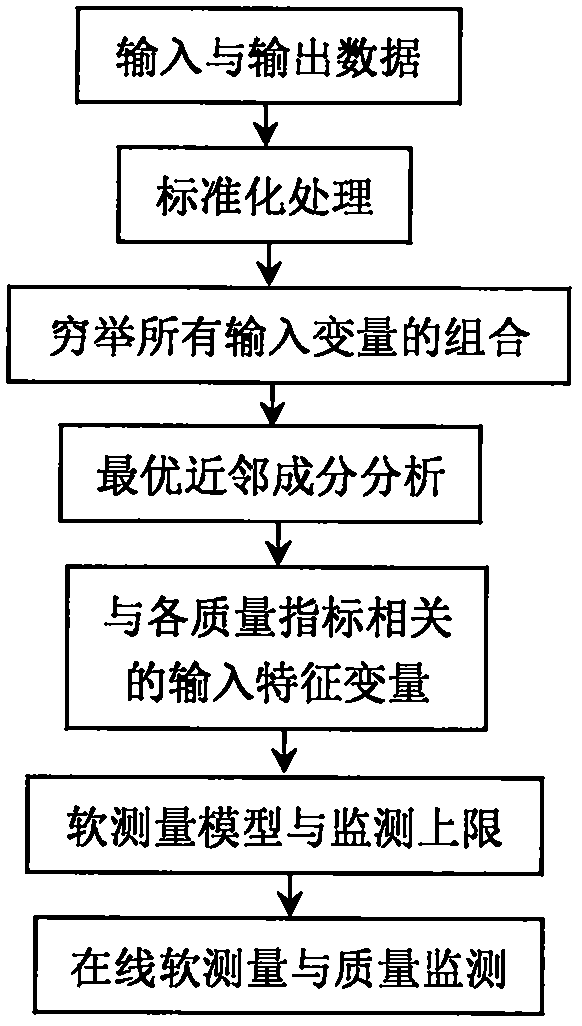

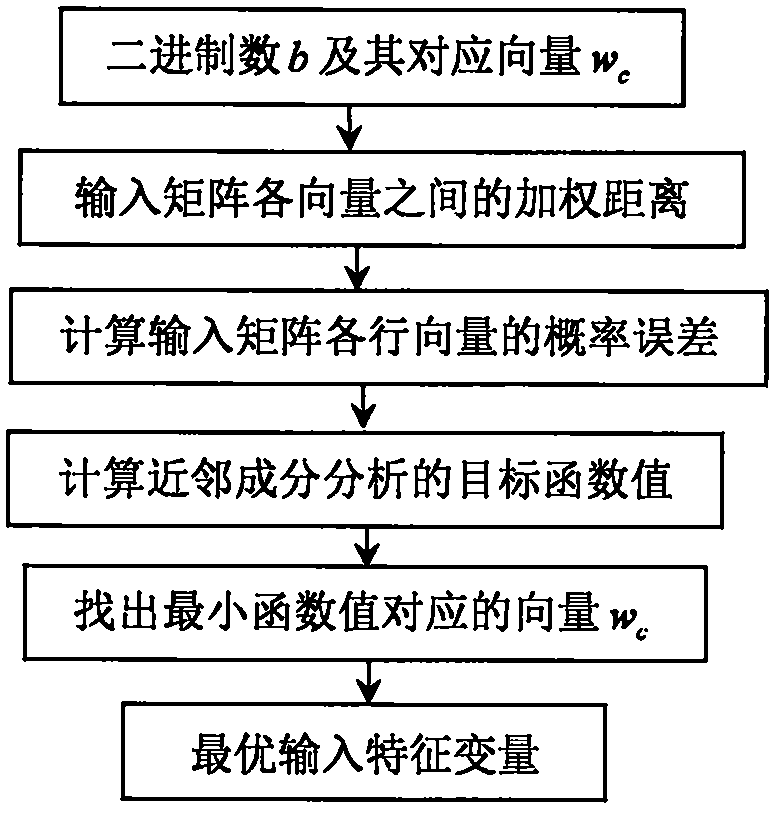

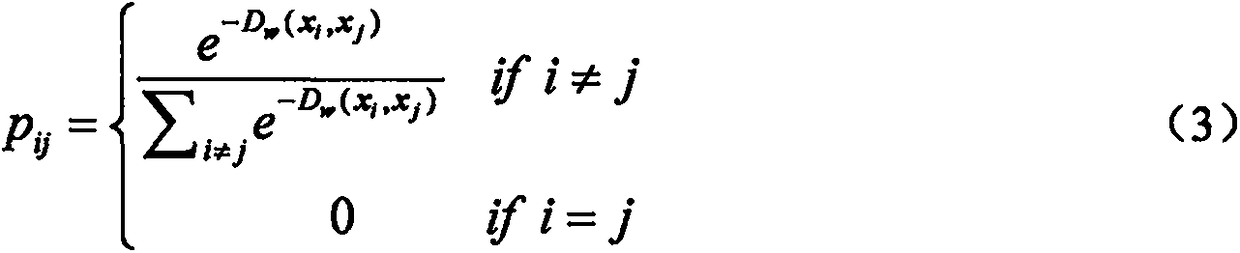

A quality soft sensing and monitoring method based on optimal nearest neighbor component analysis

ActiveCN109389314AGuaranteed global optimalityAvoid local optimaDigital data information retrievalResourcesNear neighborGlobal optimization

The invention discloses a quality soft sensing and monitoring method based on optimal nearest neighbor component analysis, aiming at solving how to optimize input characteristic variables related to each quality index from the angle of ensuring global optimization, and establishing corresponding quality index soft sensing and monitoring model based on the input characteristic variables. The methodof the invention considers the problem that each quality index corresponds to different input characteristic variables, and determines the optimal input characteristic variables corresponding to eachquality index according to the objective function value of the nearest neighbor component analysis algorithm by exhausting all possible combination forms of the input variables. The method of the invention utilizes the optimized input variable to establish the soft sensing model for each quality index, and utilizes the estimated value of the soft sensing model to monitor the status of the productquality in real time. The method of the invention can be said to be able to solve the soft sensing and monitoring problems related to the product quality.

Owner:NINGBO UNIV

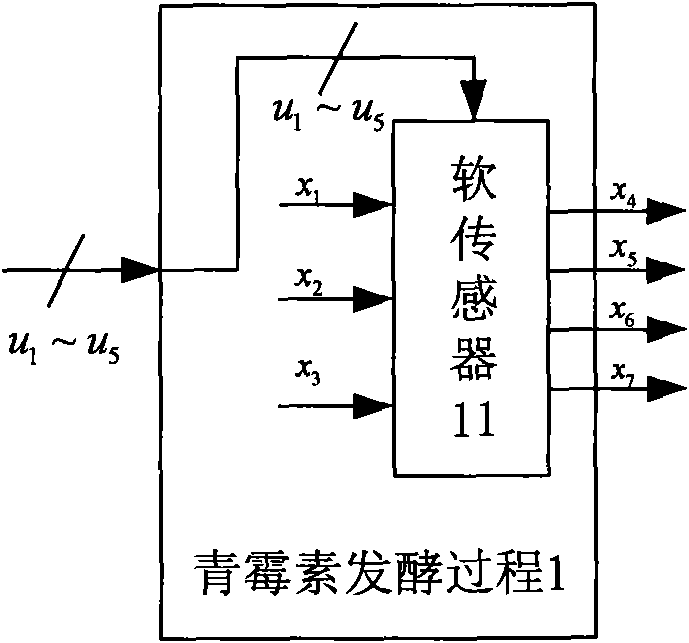

Soft-sensing method of crucial biochemical quantity in penicillin fermentation process based on fuzzy neural inverse and system structure thereof

InactiveCN101587350AHigh precisionReduce mistakesPhysical realisationTotal factory controlDifferentiatorEngineering

Soft-sensing method of crucial biochemical quantity in penicillin fermentation process based on fuzzy neural inverse and system structure thereof is a method for resloving the problem that the crucial biochemical quantity in penicillin fermentation process is difficult to be measured by physical sensor on-line and real-time. Fuzzy neural inverse soft-sensing method establishes a soft-sensor (11) model based on a kinetic equation in penicillin fermentation process (1), on this basis eatablishes an inverse model of the soft-sensor according to inverse system method, and then uses static fuzzy neural network (41) and a differentor to establish fuzzy neural inverse (4) through a free parameters determined by training the static fuzzy neural network, then the soft-sensor inverse is implemented, finally links the fuzzy neural inverse after the penicillin fermentation process to implement on-line and real-time soft-sensing of fungi concentration x[1], substrate concentration x[2] and products concentration x[3]. Specific implementation of the fuzzy neural inverse is the constructed fuzzy neural inverse system applies embedded microprocessor ARM processor.

Owner:JIANGSU UNIV

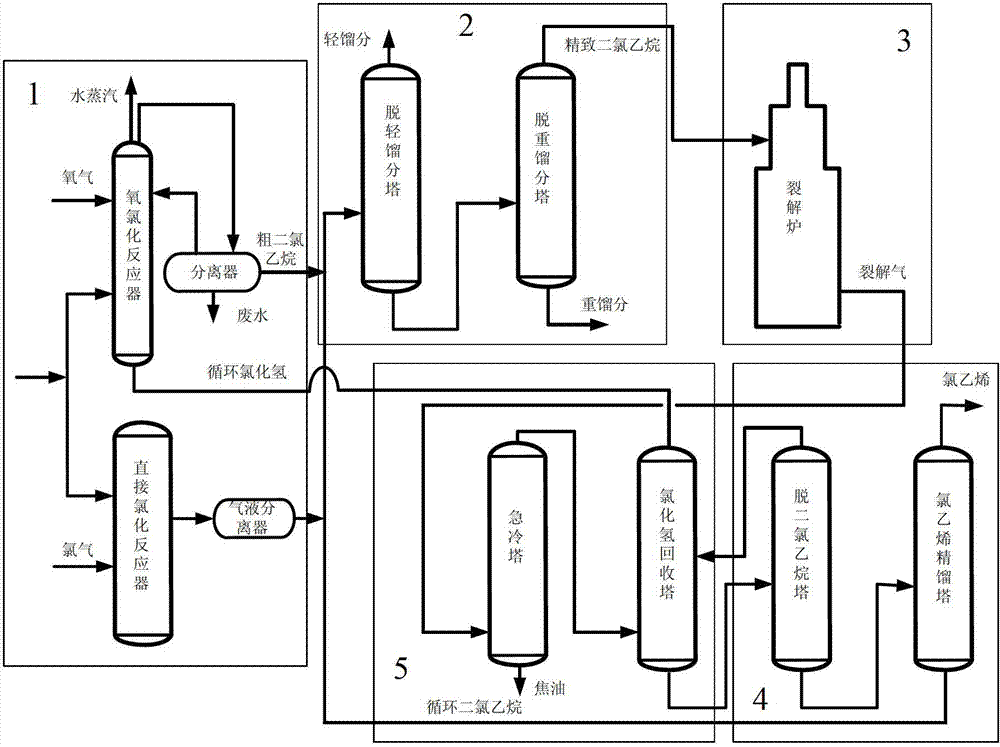

Industrial unit dichloroethane cracking furnace coupled modeling method and application

ActiveCN102779203APreparation by hydrogen halide split-offSpecial data processing applicationsAbsorption capacityReal-time data

The invention relates to an industrial unit dichloroethane cracking furnace coupled modeling method and application. In the method, during modeling, a dichloroethane cracking furnace is divided into a hearth model and a furnace tube model, a one-dimensional partition method in combination with method is used for the hearth, the smoke temperature distribution condition of the hearth is solved by a heat balance equation, for the furnace tube model, the furnace tube is partitioned according to the amount of straight tube sections of a radiant section, and the reaction and the heat absorption capacity in the tube are calculated section by section. The hearth model and the furnace tube model are mutually iterated through a quasi-newton method according to the calculated smoke temperature and heat transfer rate information, until meeting the convergence precision and the model precision. The model is based on the dynamical model and the energy conservation relation, and is corrected by real-time data so as to further measure the relevant parameters of the cracking furnace in a soft sensing manner. The accurate model is the basis of optimization, provides reliable model basis for optimization of field important economic indicators, such as the outlet temperature of the furnace tube of the cracking furnace, the dichloroethane cracking conversion rate, the selectivity, the unit consumption and so on, and realizes real-time soft sensing of relevant parameters.

Owner:EAST CHINA UNIV OF SCI & TECH

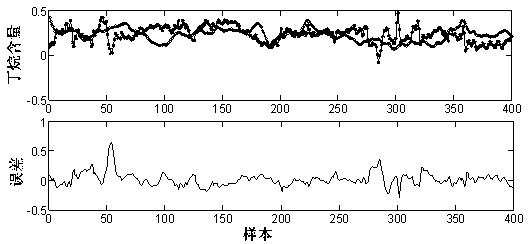

Probabilistic principal component regression model-based method for soft sensing of butane content of debutanizer

InactiveCN103389360ARealize online estimationMaterial analysisComplete dataPrincipal component regression

The invention discloses a soft sensing method based on a probabilistic principal component regression model for online detection of butane content of a debutanizer. Principal component regression model is a common modeling approach for soft sensing. However, as noise information of process data is not taken into consideration well, the principal component regression model fails in many real processes. The method introduces a probabilistic modeling approach which converts the conventional principal component regression model into a probabilistic form, which is a soft-sensing model based on probabilistic principal component regression. Compared to the conventional principal component regression model, the probabilistic principal component regression model allows modeling on the process data and the noise information at the same time and provides more complete data information, so that the soft sensing results are more reliable.

Owner:ZHEJIANG UNIV

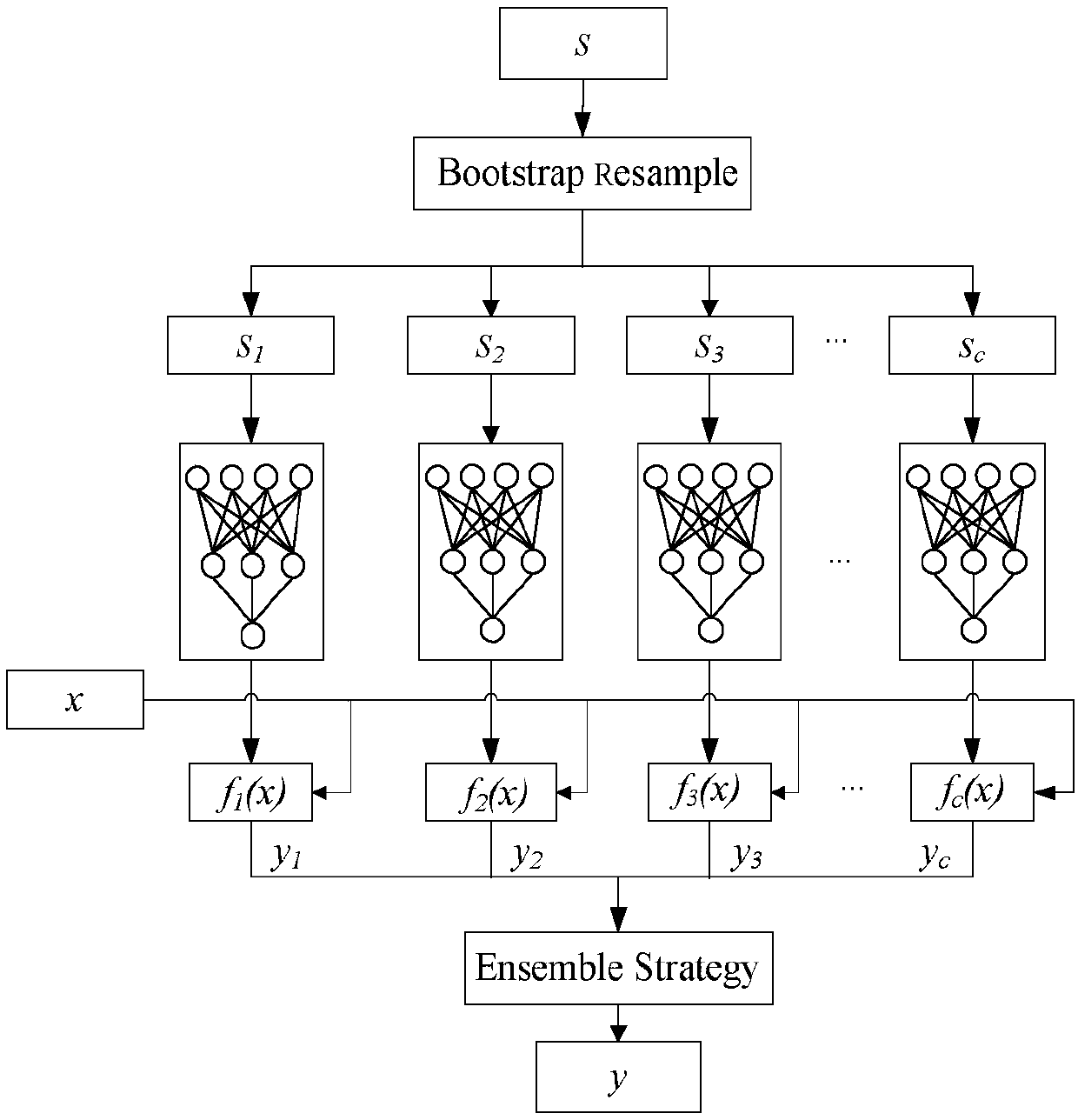

A PM2.5 measurement method based on image features and integrated neural network

The invention relates to a soft sensing method for PM2.5 of air fine particles based on image features and an integrated neural network, which belongs to the field of both environmental engineering and detection technology. An atmospheric environmental system has many variables, nonlinear and complicated internal mechanism. Compared with single neural network, an ensemble neural network has betterability to deal with highly nonlinear and seriously uncertain system, and the real-time and high efficiency of PM2.5 prediction can be improved effectively by using image features as input variables.The invention aims at the problem that PM2.5 is difficult to predict with high precision and real-time. Firstly, the image features related to PM2.5 are extracted based on the feature extraction method. Secondly, the soft sensor model between PM2.5 and the image features is established by using the ensemble neural network based on the simple average method. Finally, the PM2.5 is predicted with the established soft sensor model and good results are obtained. The output results of the soft sensor model can provide timely and accurate information of atmospheric environment quality for environmental management decision-makers and the masses, which is conducive to strengthening the control of atmospheric pollution and preventing serious pollution.

Owner:BEIJING UNIV OF TECH

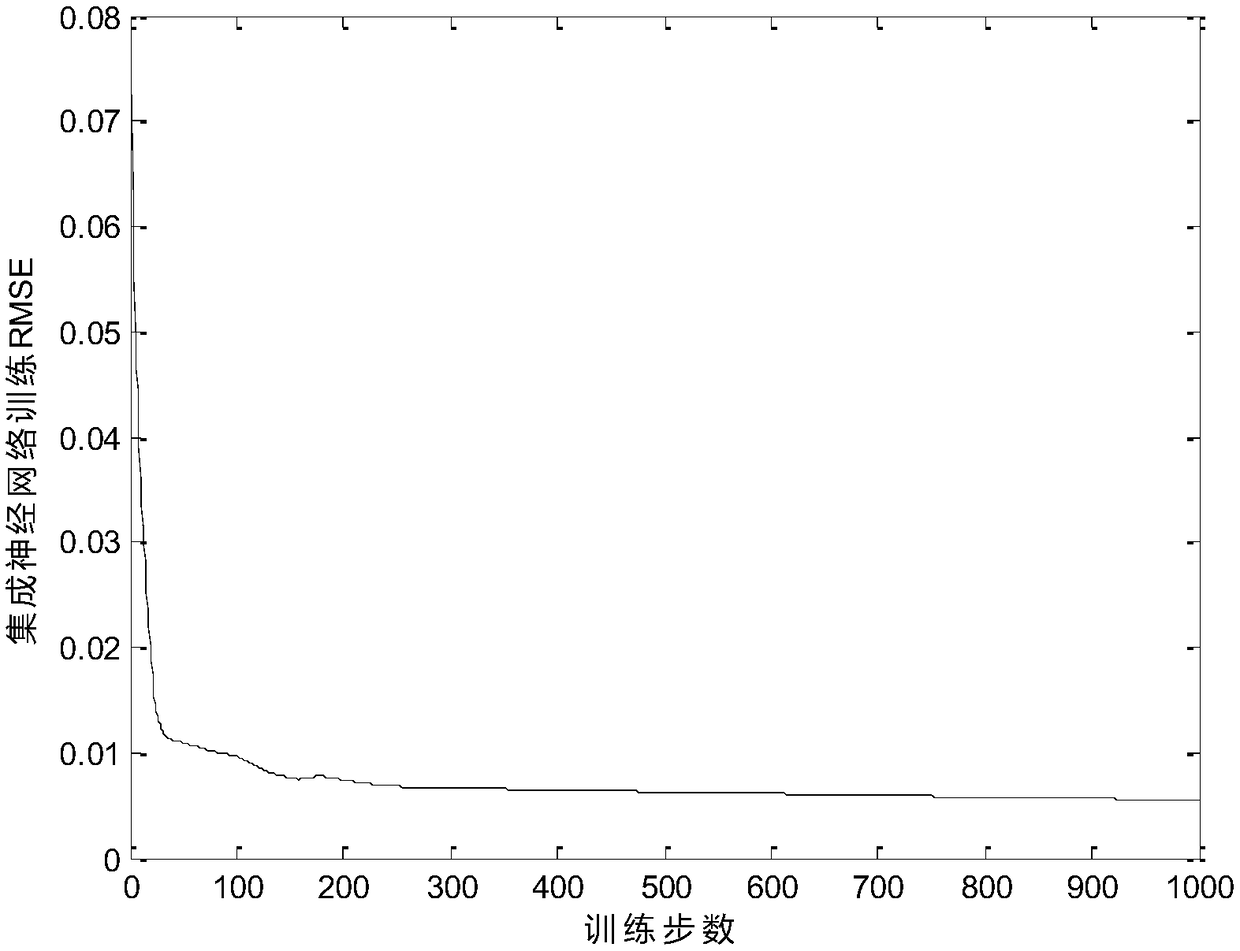

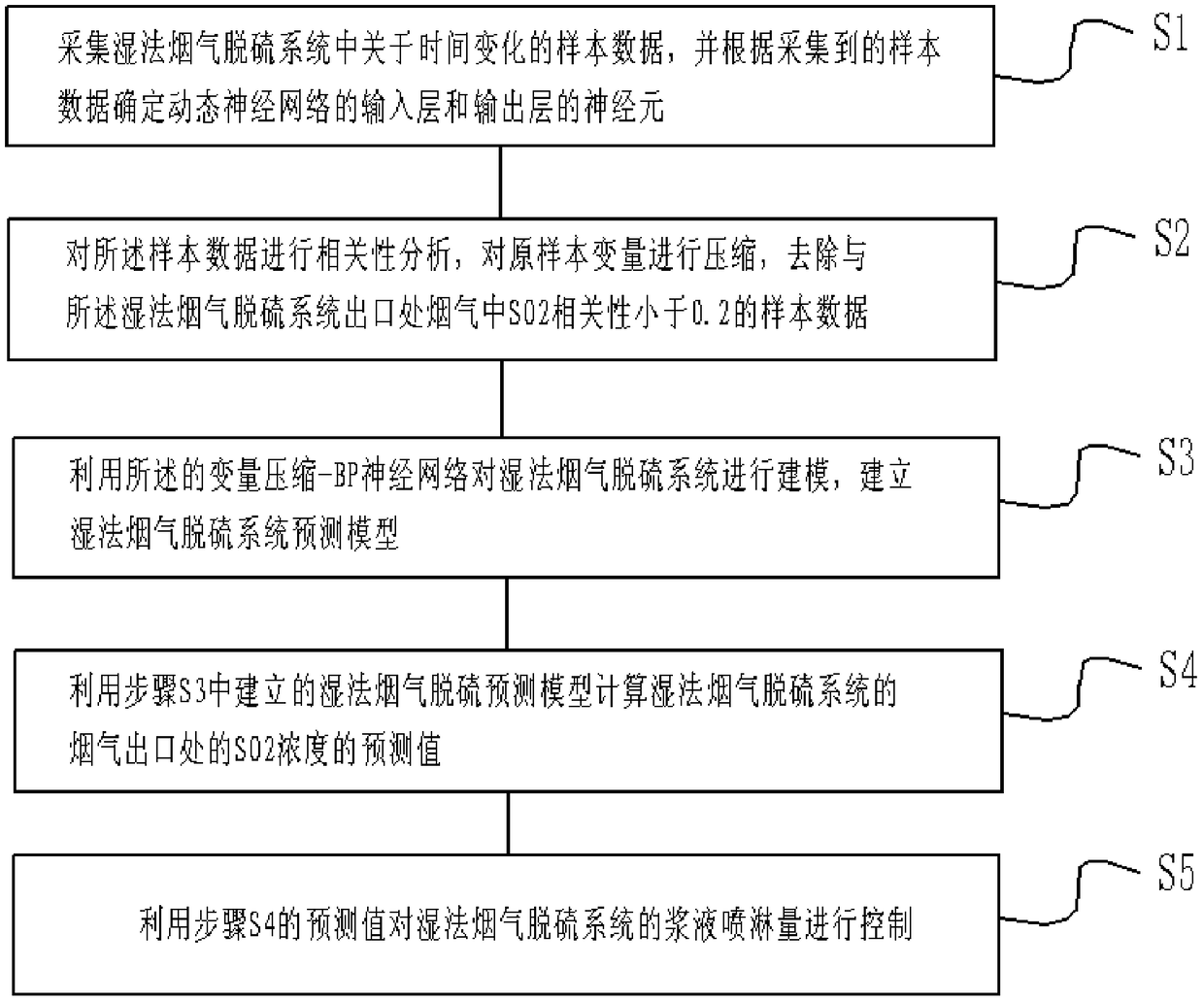

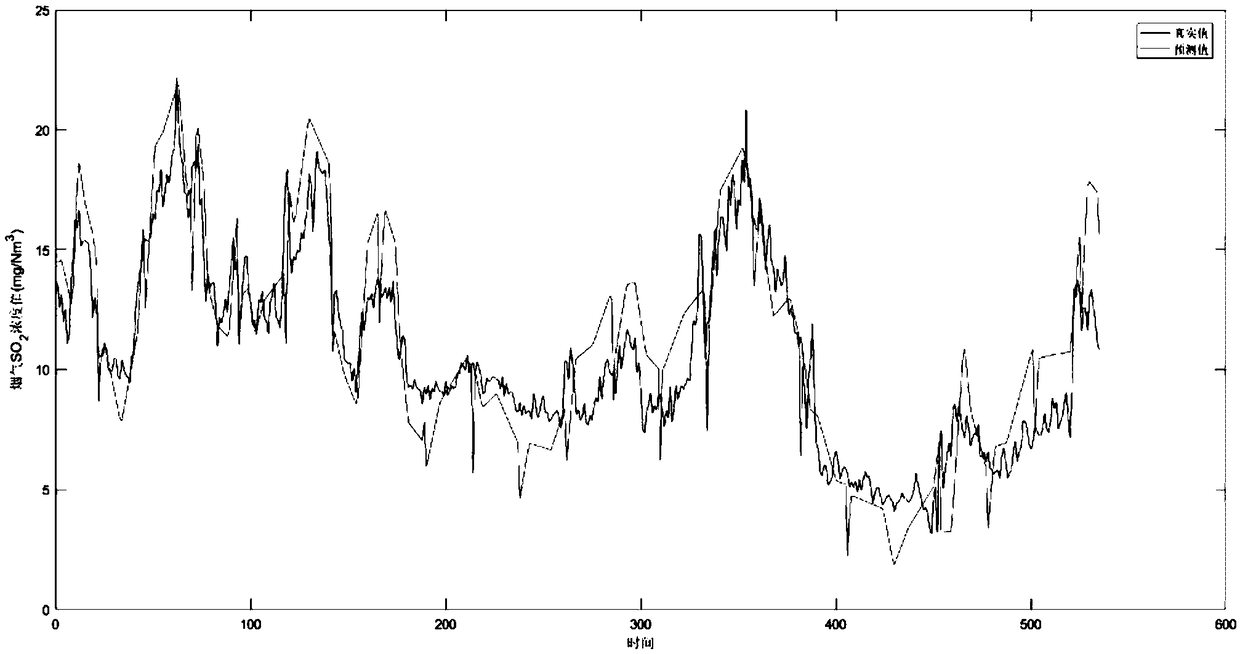

Soft Sensing Method of SO_2 Emission from Power Plant Based on Variable Compression BP Neural Network

InactiveCN109508832ADenseIncrease disturbanceForecastingNeural architecturesDynamic neural networkFlue gas

The invention relates to a soft sensing method for SO2 emission of a power plant based on variable compression BP neural network, comprising the steps of S1, collecting sample data about time variation in a wet flue gas desulfurization system, and determining neurons of an input layer and an output layer of the dynamic neural network according to the collected sample data; 2, performing correlation analysis on that sample data, compressing the original sample variable to remove sample data whose correlation with SO2 in the flue gas at the outlet of the wet flue gas desulfurization system is less than 0.2; Step S3: Compressing by using the variable-BP neural network model wet flue gas desulfurization system, establish wet flue gas desulfurization system prediction model; Step S4, calculating the predicted value of SO2 concentration at the flue gas outlet of the wet flue gas desulfurization system by using the wet flue gas desulfurization prediction model established in the step S3; StepS5: controlling The slurry spraying amount of the wet flue gas desulfurization system by using the predicted value of step S4.

Owner:李东峰

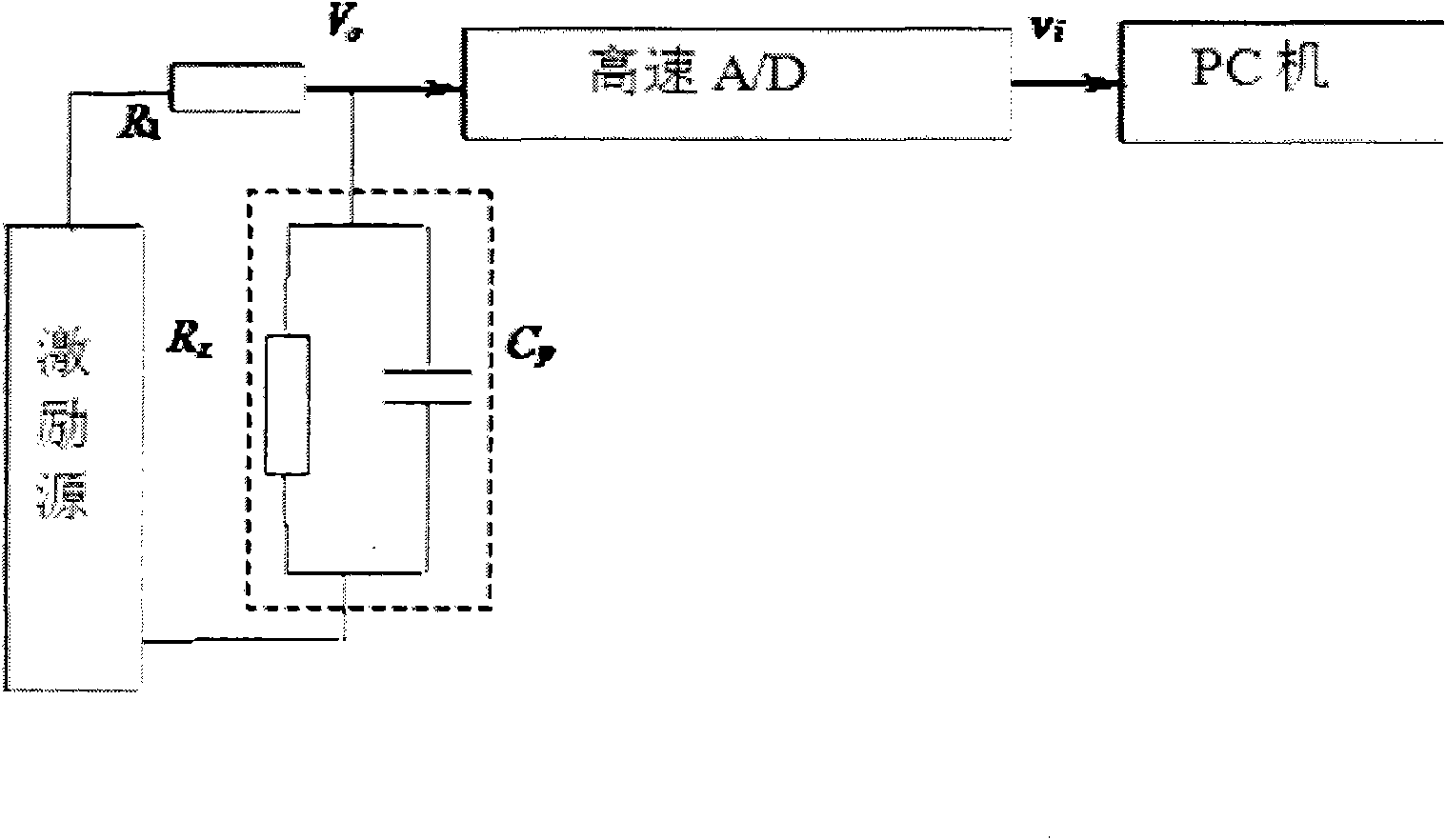

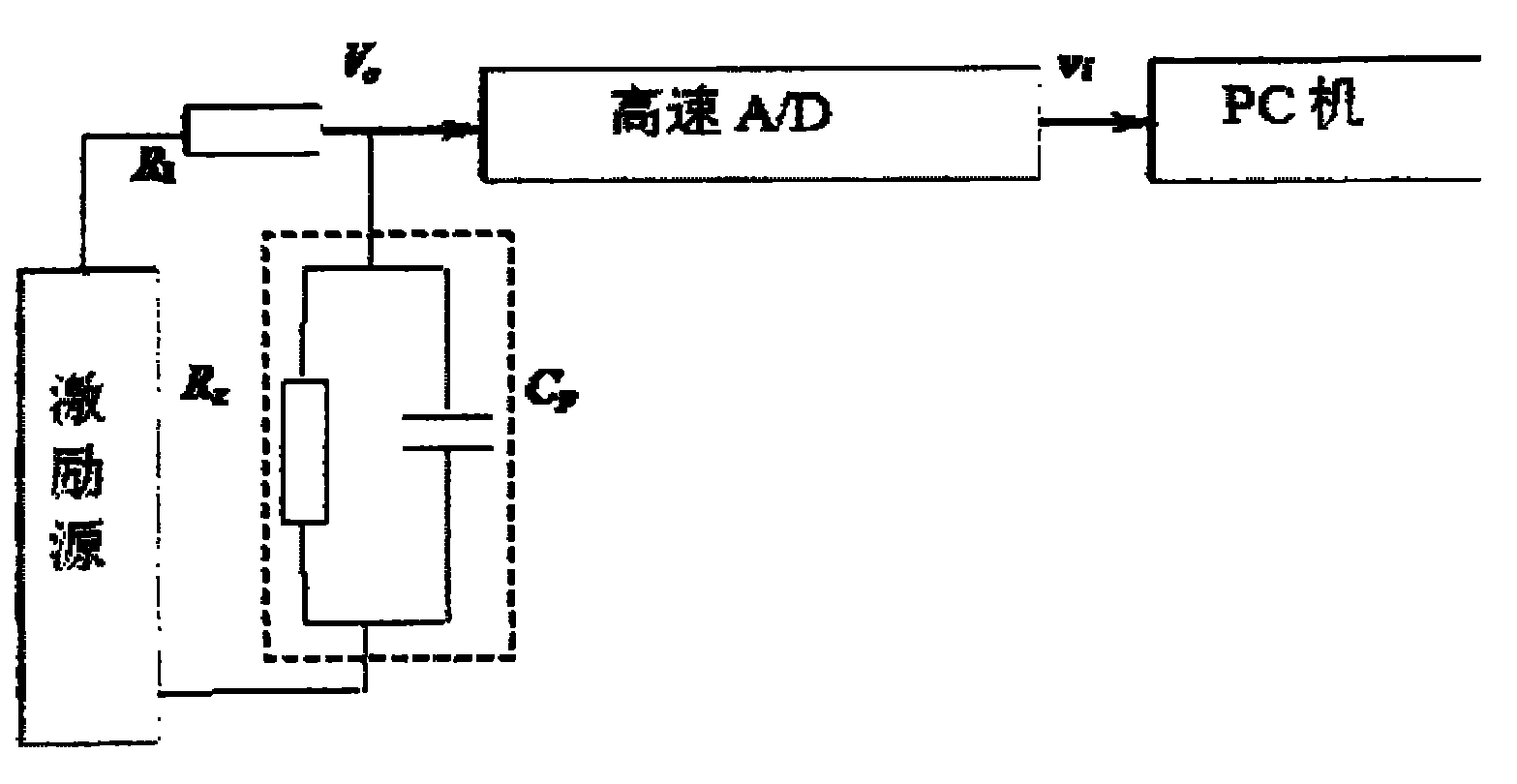

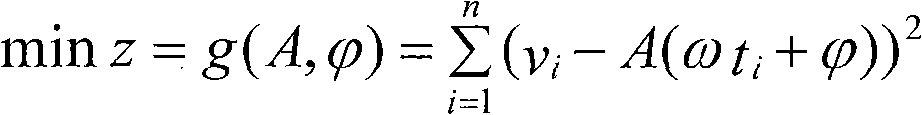

Resistor-capacitor decoupling soft sensing method based on magnitude-phase characteristics

InactiveCN101839946AAccurately obtain amplitude and phase characteristicsHigh measurement accuracyFluid resistance measurementsSteep descentElectrical resistance and conductance

The invention relates to a resistor-capacitor decoupling soft sensing method based on magnitude-phase characteristics, belonging to the technical field of the soft sensing technology of solution conductivity. The method is characterized in that the conductivity measurement in a conductivity cell is changed to the measurement of electrical property equivalent resistance-capacitance network of the conductivity cell, and the magnitude-phase characteristics of the resistance-capacitance network is estimated to obtain the resistance-capacitance parameter, wherein the resistance parameter is the resistance of the solution to be measured. Sine wave is used to excite the resistance-capacitance network; the steepest descent method is adopted for optimization and calculation based on the non-linear principle of least square; and multi-sampling of response signals is utilized to fit system function form and further obtain magnitude-phase characteristic parameter of the system. Then the magnitude-phase characteristics and the function relationship of the resistance-capacitance network are used to obtain the resistance-capacitance parameter. The invention has the effects and benefits of higher measurement accuracy and less iterations. In addition, the invention also provides a method for accurately obtaining the magnitude-phase characteristics of the linear system.

Owner:DALIAN UNIV OF TECH

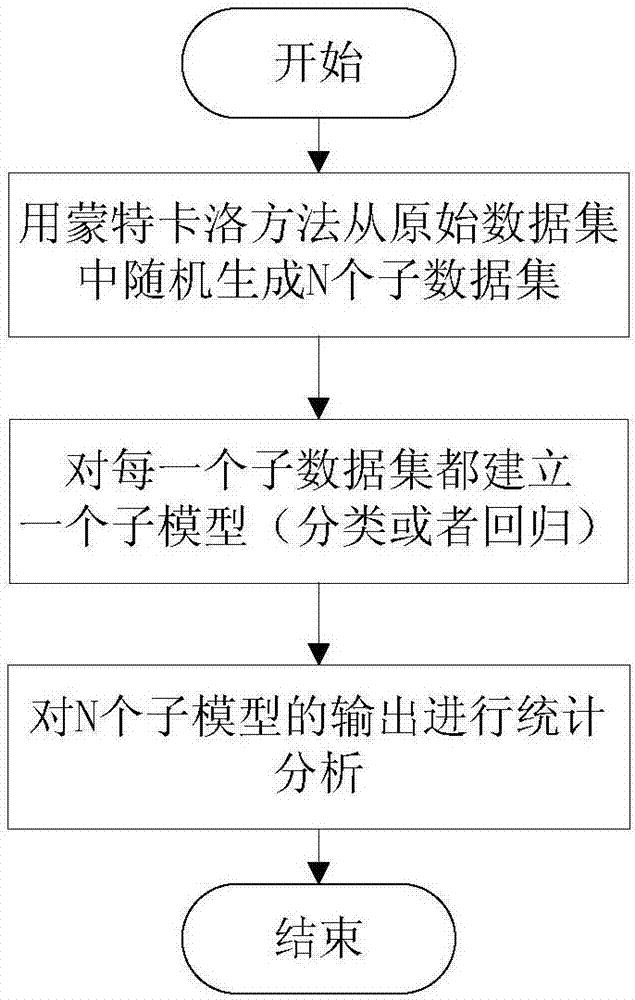

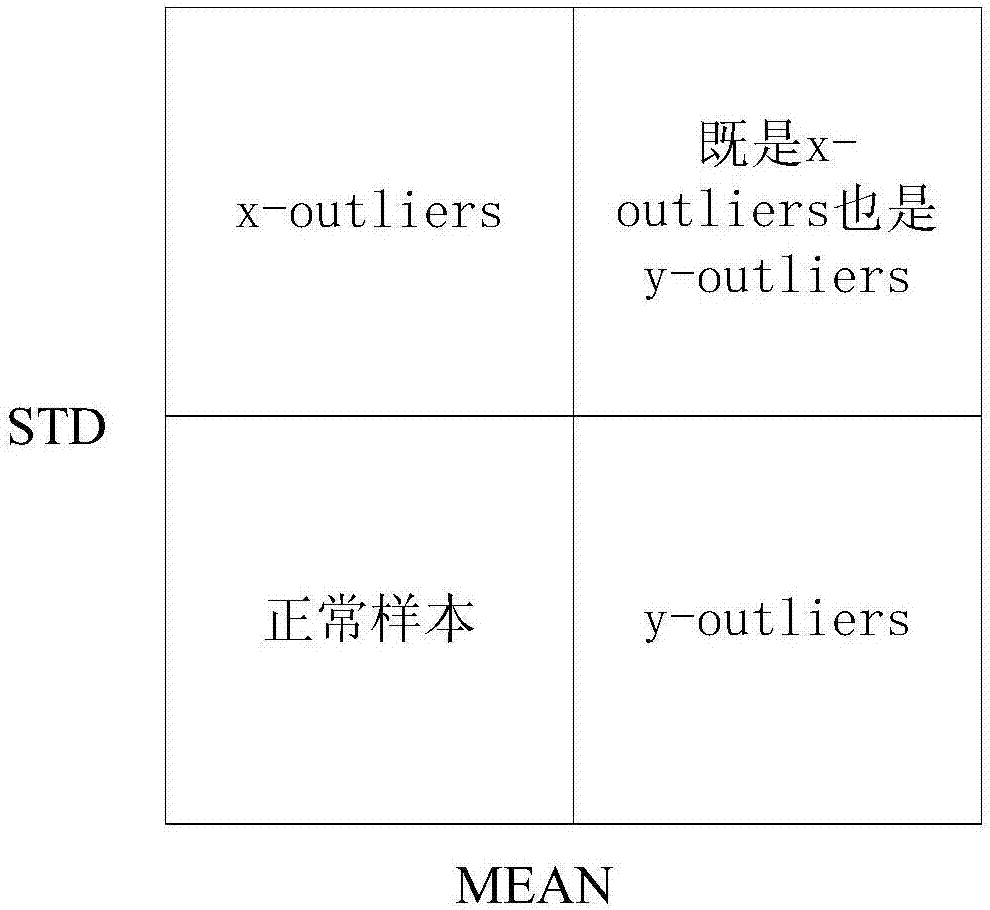

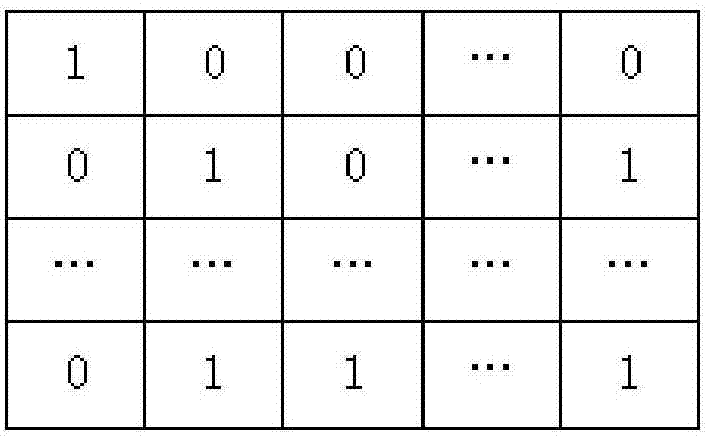

Monte Carlo cross verification-based multiple-soft sensing algorithm cluster modeling method

The invention discloses a Monte Carlo cross verification-based multiple-soft sensing algorithm cluster modeling method. According to the method, the model evaluation and outlier search of a model cluster analysis method are systematically applied. The invention tries to construct an ensemble learning system under the framework of the model cluster analysis method. In the outlier search, a model cluster analysis method-based Monte Carlo cross validation algorithm is adopted; after outliers are removed, a variety of soft-sensing algorithms are selected to model industrial processes; and the prediction results of the soft-sensing algorithms are integrated. In the model evaluation, a large number of training clusters are generated, so that influence on a model evaluation result caused by the selection of the training clusters can be eliminated, and therefore, the diversity of data is improved. Compared with existing other methods, the method of the invention can improve the accuracy of prediction by removing the outliers and analyze the change of the overall prediction effects of the algorithms before and after removing the outliers from the perspective of statistics.

Owner:ZHEJIANG UNIV

Integral soft sensing element with pressure and non-contact gap measuring functions

InactiveCN103743504AAchieve pressureEnables non-contact gap measurementForce measurementUsing electrical meansSoft sensingCopper foil

The invention relates to an integral soft sensing element with pressure and non-contact gap measuring functions, and belongs to the technical field of sensors. The integral soft sensing element comprises an insulation encapsulation film, a pressure-sensitive film and a plane type eddy current coil film, wherein the insulation encapsulation film is made of polyimide, the pressure-sensitive film layer is made of conducting polymer composite materials, the plane type eddy current coil film consists of a polyimide film and a copper foil coil compounded on the polyimide film, the conducting polymer composite materials are directly vulcanized on the naked copper foil coil to form an integral structure, and the pressure and non-contact gap measurement is realized through obtaining the impedance of the integral structure. The integral sensing element developed by the invention has the advantages that the softness is good, the thickness is small, the process is simple, the cost is low, the pressure measurement and the non-contact gap measurement can be realized only through one set of sensing system, the integral soft sensing element is applicable to the interlayer pressure and gap measurement of narrow and small curved surfaces of industrial equipment, and the key technology can also be applied to the development of multifunction electronic skin.

Owner:NORTHEASTERN UNIV

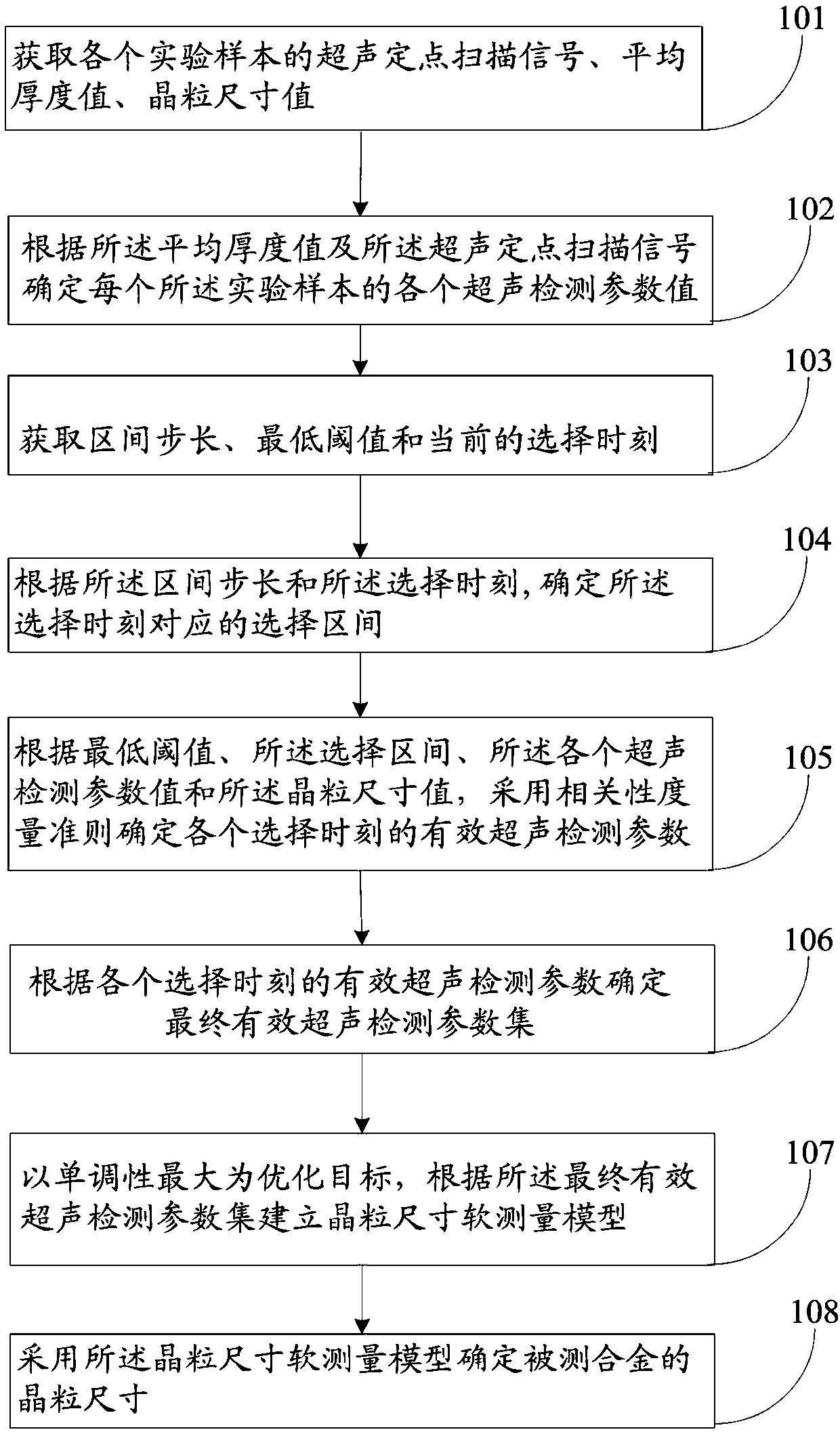

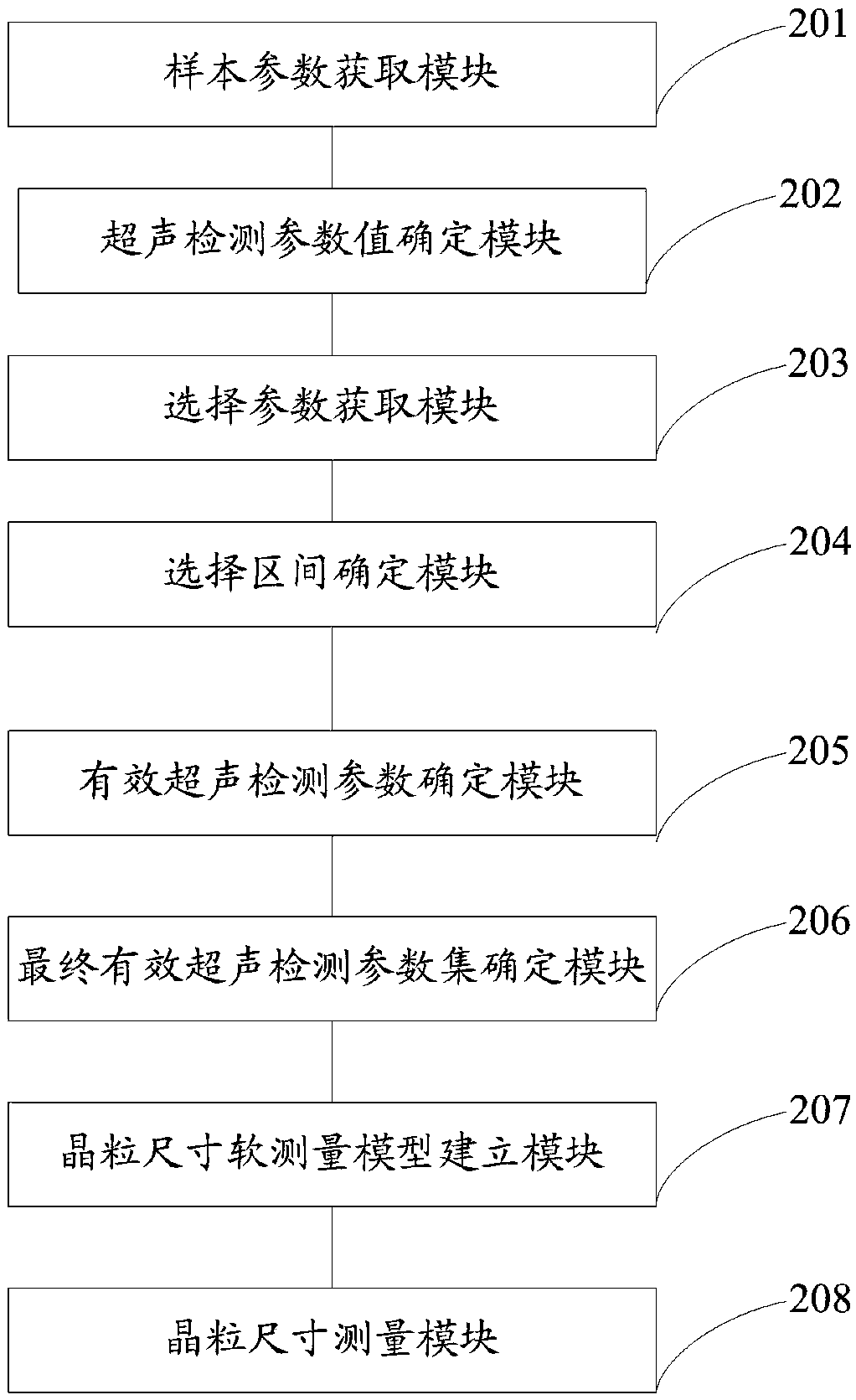

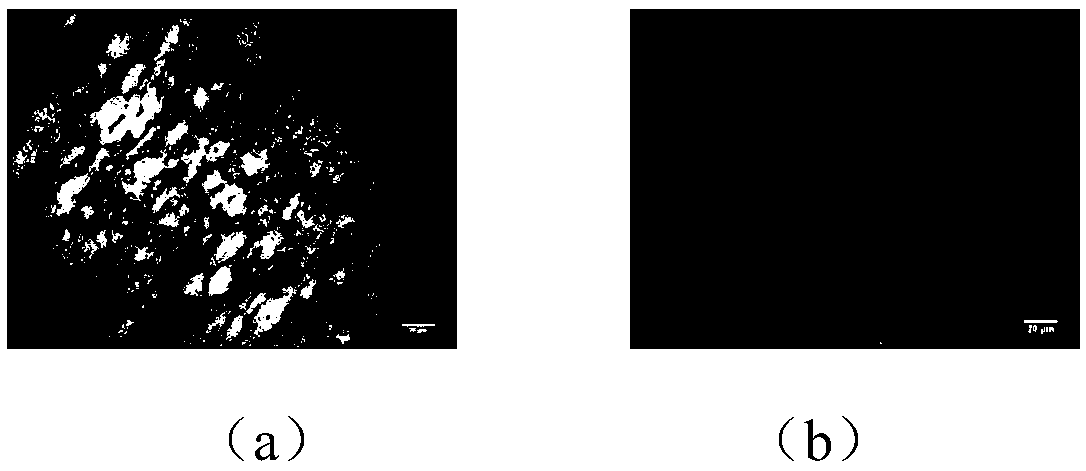

Method and system for determining grain size of alloy based on mapping monotonicity

ActiveCN109033586AImprove monotonicityHigh measurement accuracyDesign optimisation/simulationSpecial data processing applicationsUltrasonic testingAlloy

The invention discloses a method and a system for determining the grain size of alloy based on mapping monotonicity. The invention adopts correlation measurement criterion to screen effective ultrasonic detection parameters step by step, and then with the monotonicity maximization objective, according to the final set of effective ultrasonic testing parameters, a soft-sensing model of grain size is established, which not only keeps the form of monotonous increasing or decreasing, but also realizes the validity of off-set testing of samples under the condition of ordered arrangement of grain size. Therefo0re, the soft sensing model of grain size established by the determination method and the determination system provided by the invention has the advantages of high measurement accuracy, good monotonicity, small error, intuitive and complete result diagram of the model and stable evaluation effect.

Owner:NANCHANG HANGKONG UNIVERSITY

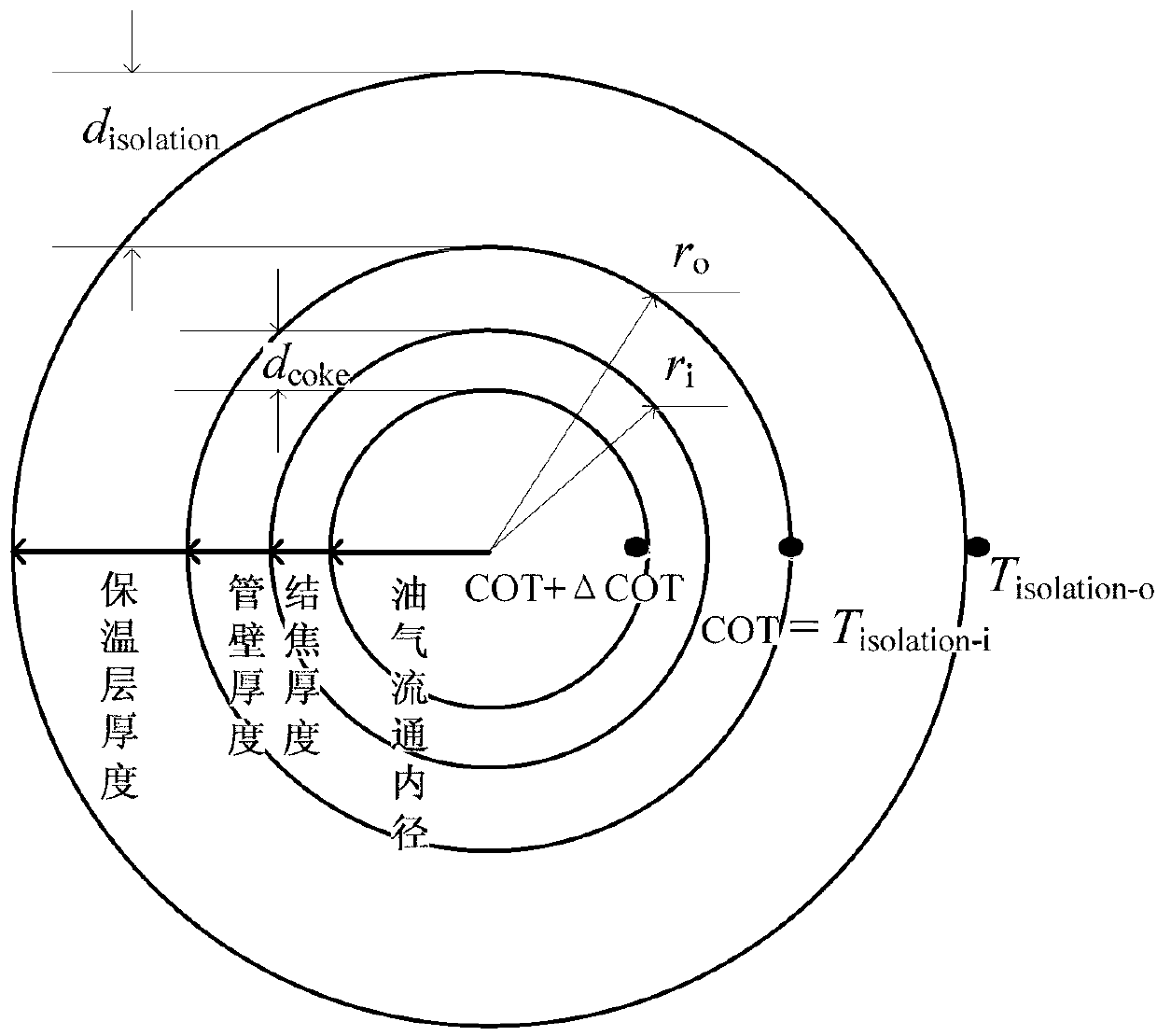

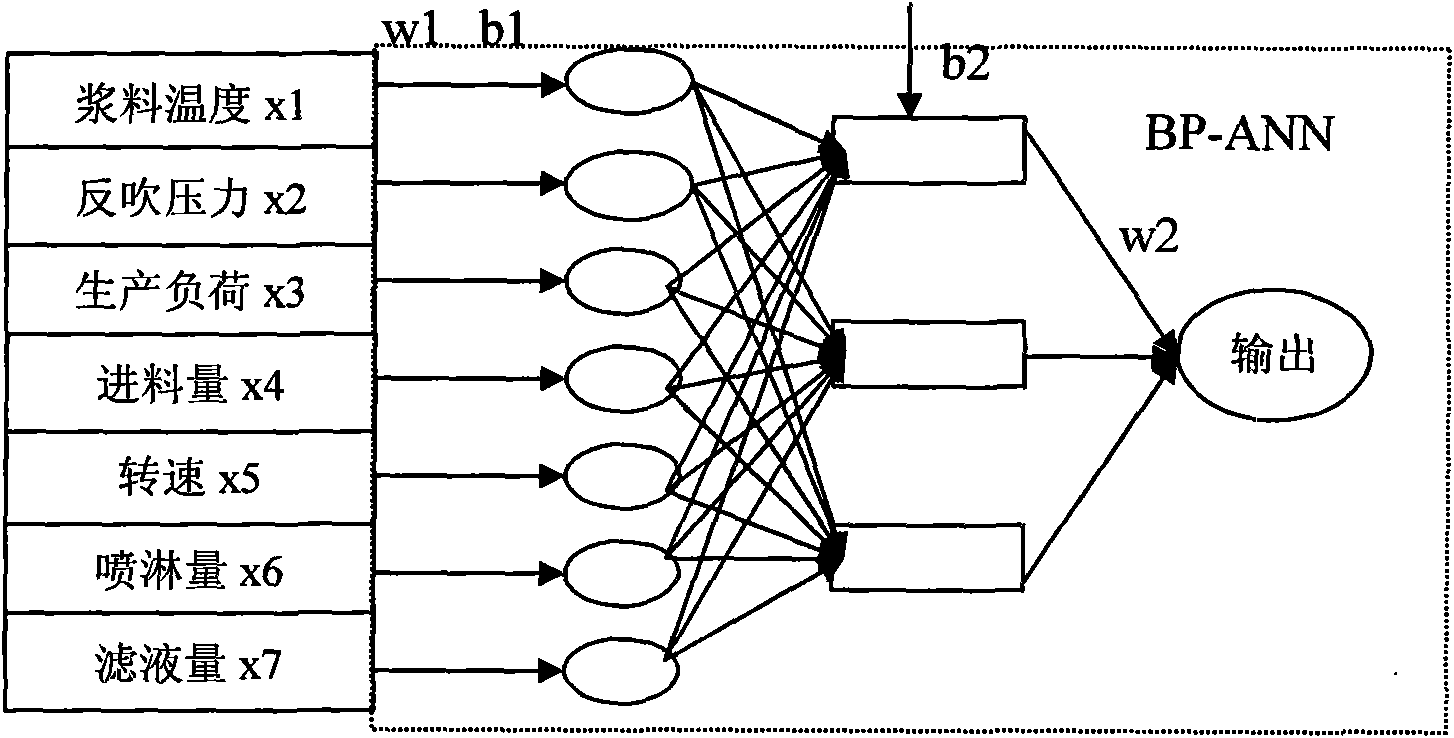

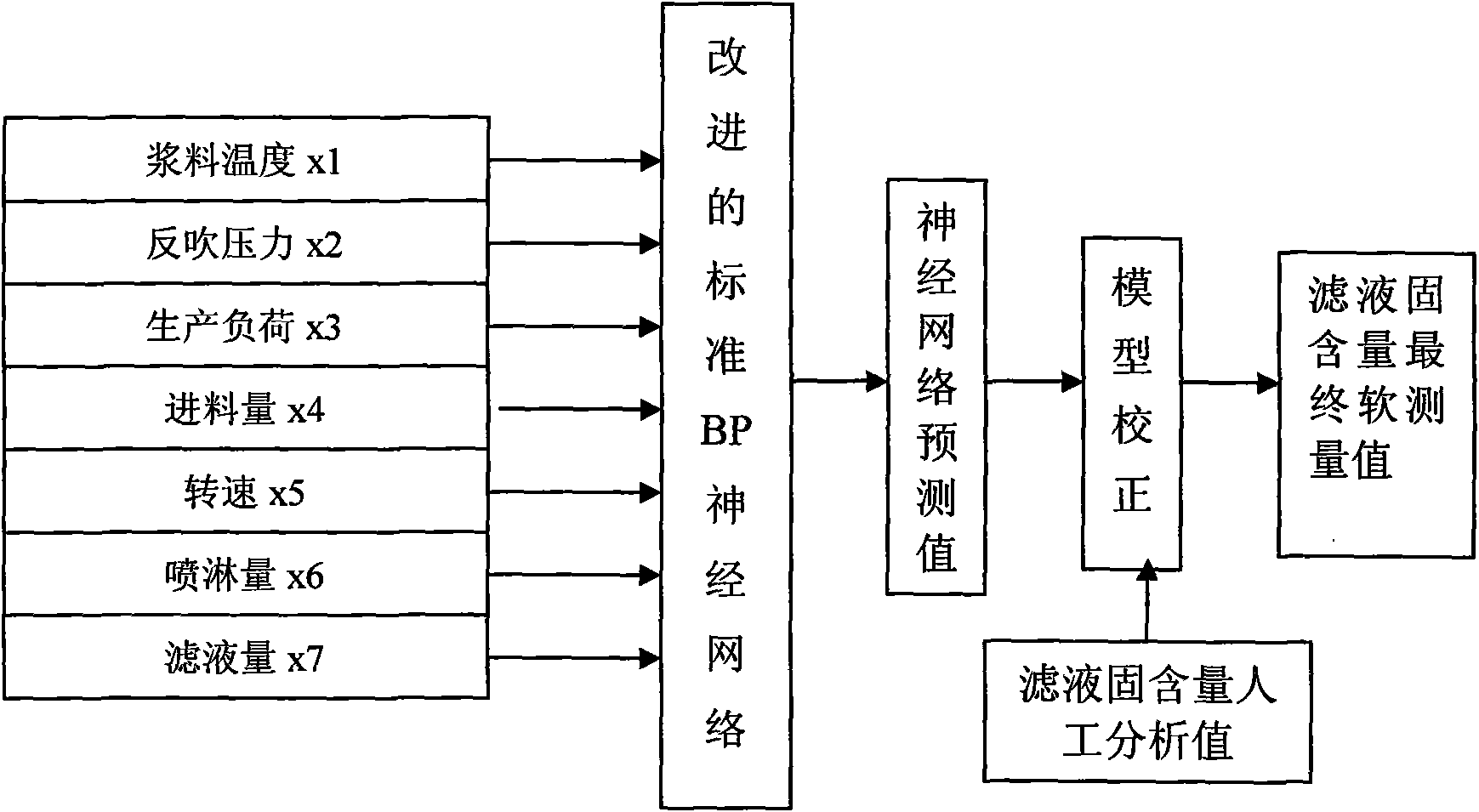

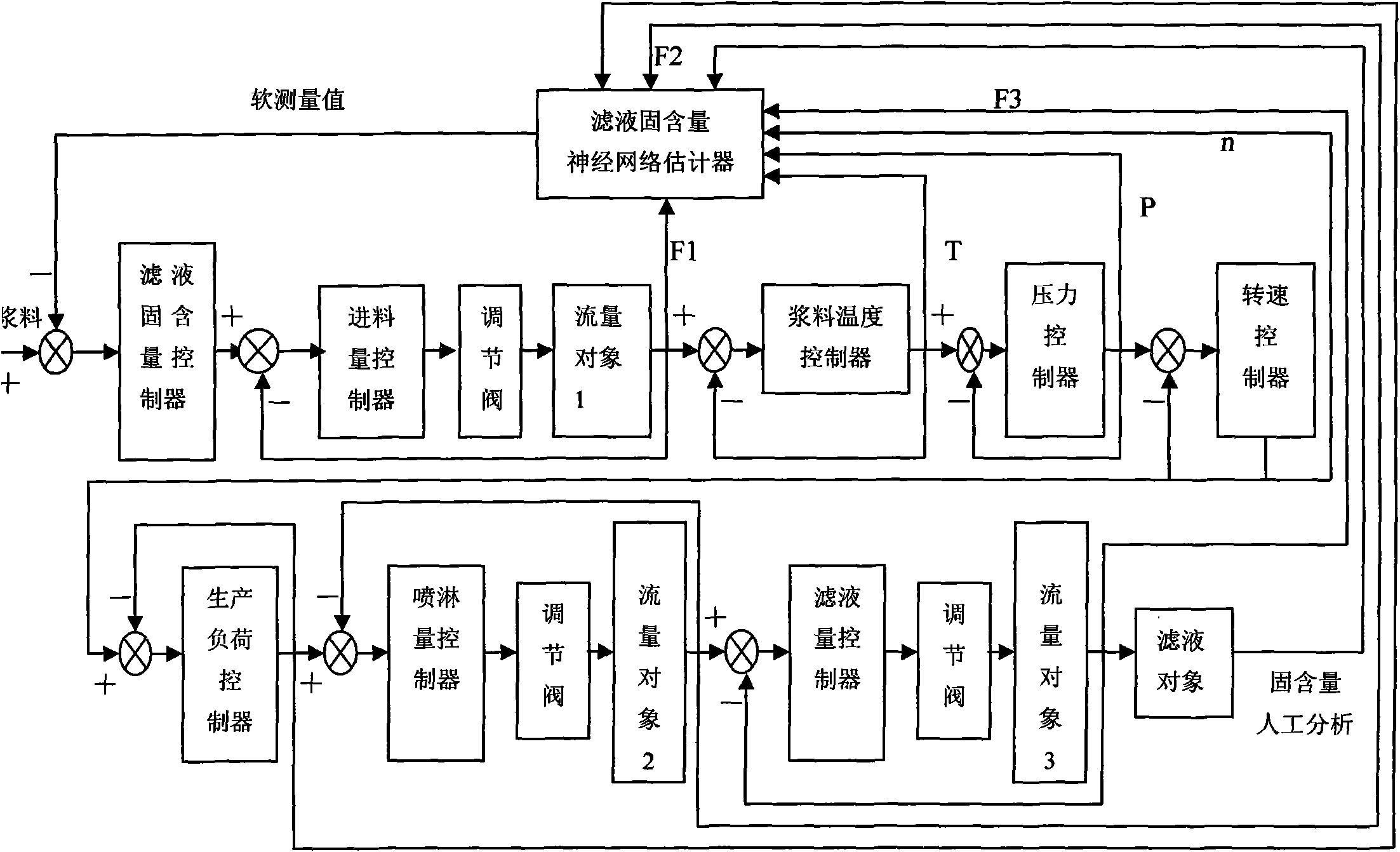

On-line control method for oxidation mother liquor filter process in purified terephthalic acid production

InactiveCN101963785AHigh recovery rateLow solid contentAdaptive controlProcess engineeringSoft sensing

The invention relates to an on-line control method for an oxidation mother liquor filter process in purified terephthalic acid production. The method comprises the following steps: normalizing technological operation parameters which influence the solid content in the filtrate in the filter process; carrying out analog computation by utilizing an improved standard BP neural network to establish a filter process model, and optimizing the filter operation parameters by using the model; after de-normalizing the real-time output value of the module, correcting by using the manual analysis value of the filtrate solid content in an on-line mode to obtain the soft sensing value of the filtrate solid content; and finally, carrying out real-time deduction control on the filter process according to the soft sensing value and the optimized filter operation parameters. When being used for intelligently controlling the filter operation parameters of the oxidation mother liquor in purified terephthalic acid production, the method can stabilize the filter operation, reduce the solid content of the mother liquor after the filter operation and increase the recovery rate of terephthalic acid.

Owner:NANJING UNIV OF TECH

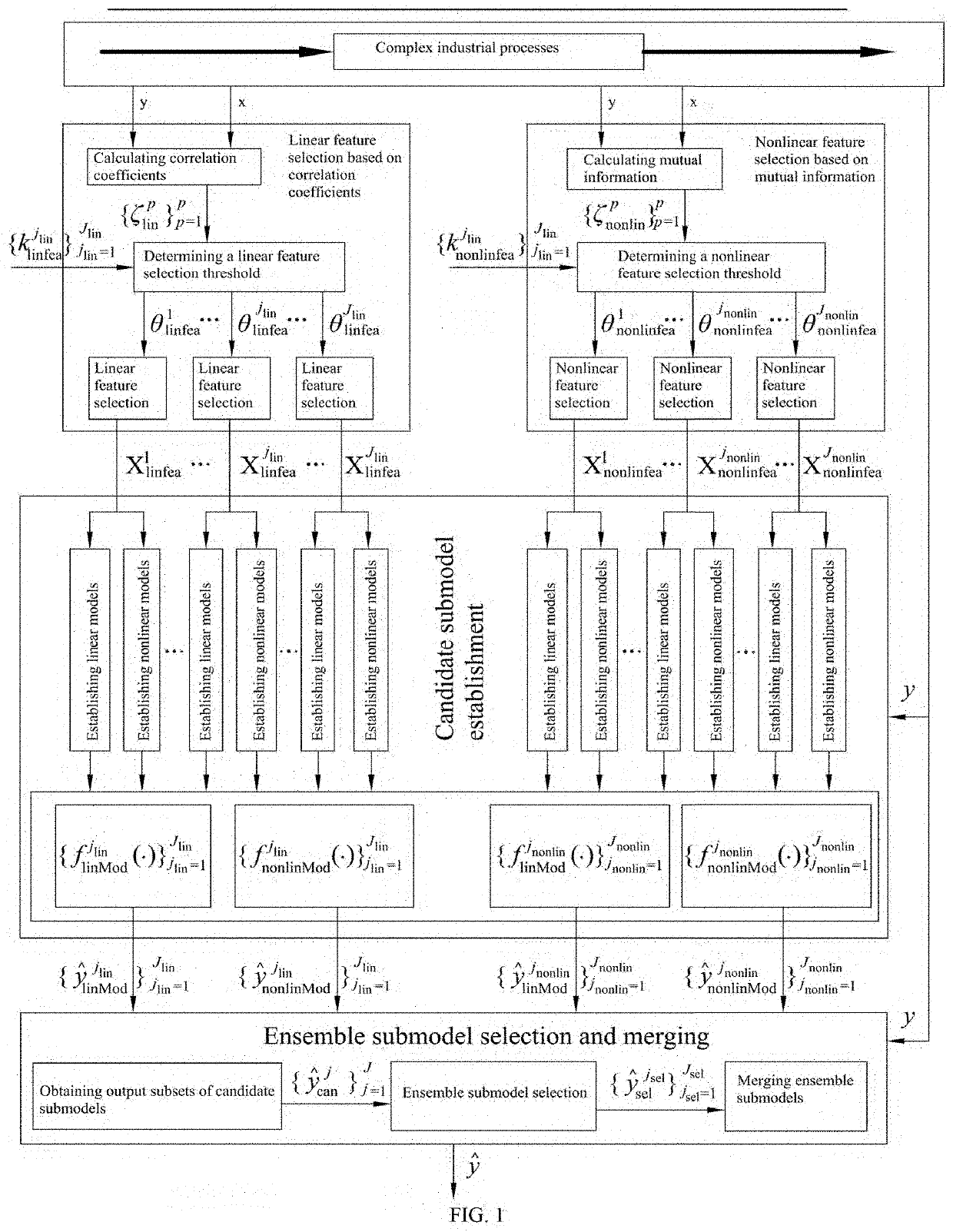

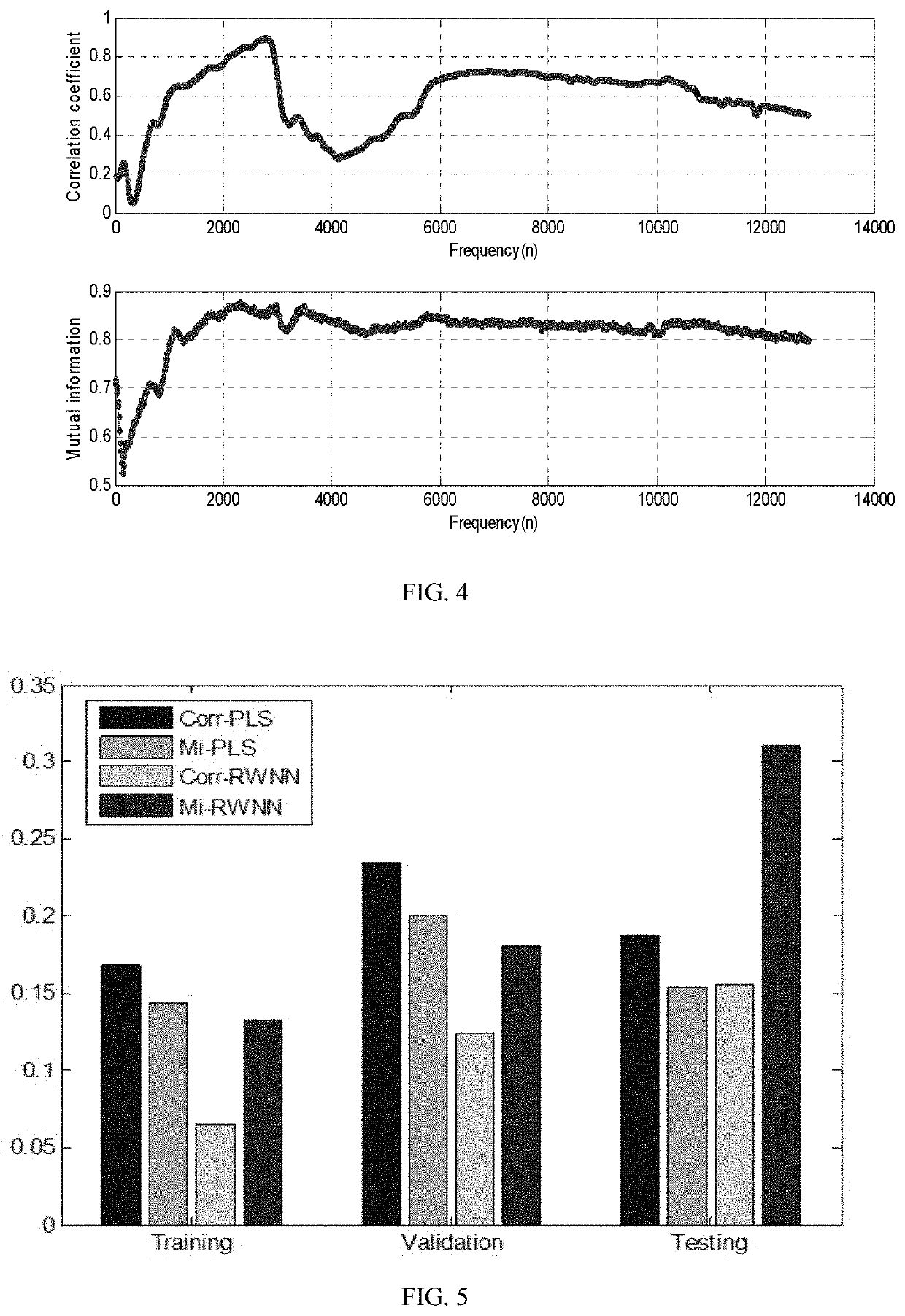

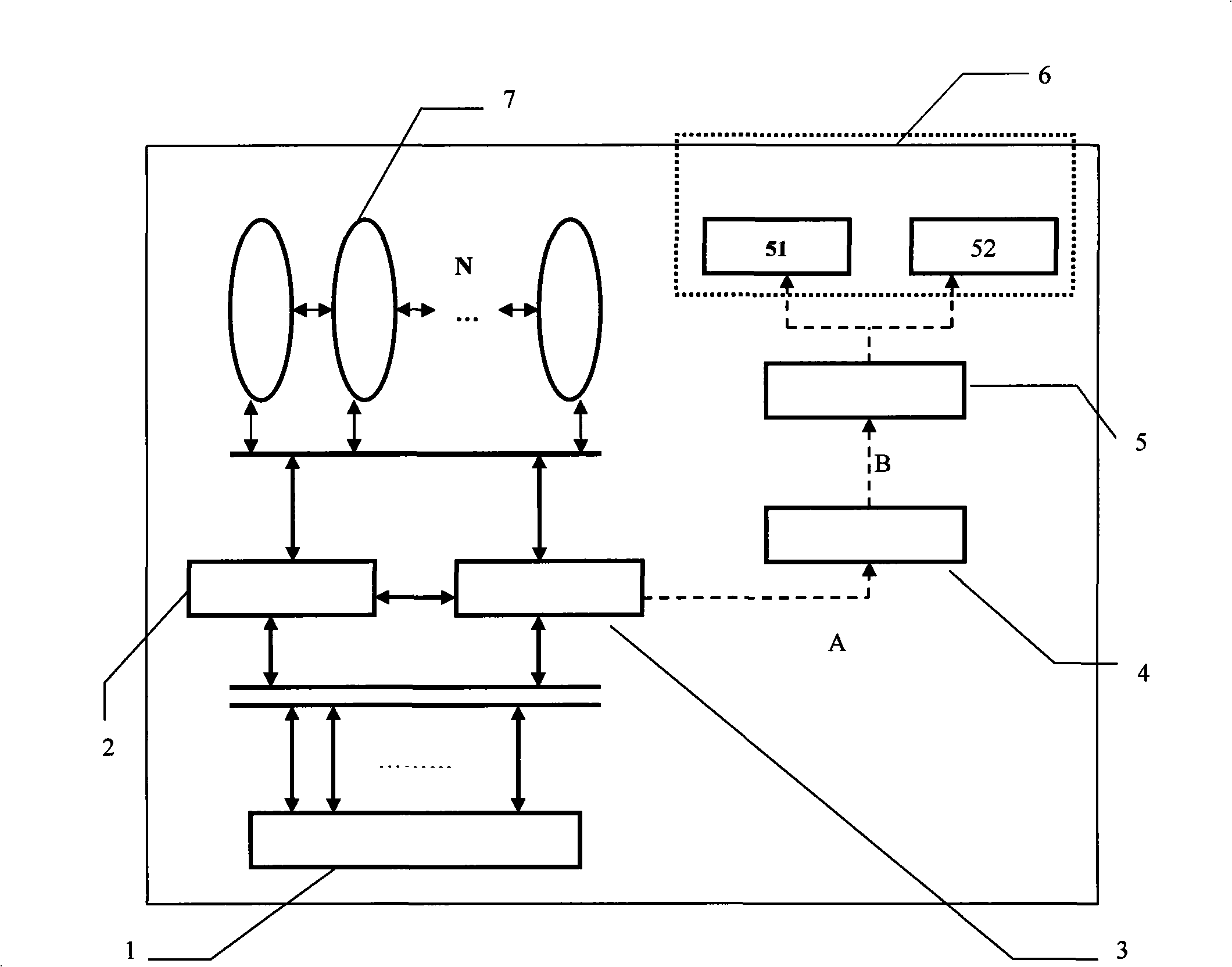

Soft sensing method and system for difficult-to-measure parameters in complex industrial processes

Disclosed is a soft sensing method for difficult-to-measure parameters in complex industrial processes. A linear selection of high-dimensional original features is performed using correlation coefficients, and several linear feature subsets are obtained based on a preset set of linear feature selection coefficients. A nonlinear selection of the original features is performed using mutual information, and several nonlinear feature subsets are obtained based on a preset set of nonlinear feature selection coefficients. Linear and nonlinear submodels are established based on the linear and nonlinear feature subsets, respectively, resulting in 4 submodel subsets including a linear submodel of linear features, a nonlinear submodel of linear features, a linear submodel of nonlinear features and a nonlinear submodel of nonlinear features. A SEN soft sensing model for difficult-to-measure parameters with better generalization performance is obtained by selecting and merging the candidate submodels based on an optimization selection and a weighting algorithm.

Owner:BEIJING UNIV OF TECH

Copper matte air refining procedure parameter soft sensing instrument and its soft sensing method

InactiveCN101285816AImprove control accuracyImprove accuracyTesting metalsSpecial data processing applicationsFurnace temperatureCurve fitting

The invention discloses a soft measuring apparatus for procedure parameters of copper-matte converting and a soft measuring method using the same, relating to a measuring apparatus, in particular to a soft measuring apparatus for procedure parameters of copper-matte converting and a measuring method using the same based on neural network curve fitting and mechanism analysis. The invention provides the soft measuring apparatus for the following procedure parameters of the copper-matte converting in copper-matte converting process: phase composition, elementary composition and the copper-matte converting of furnace temperature and the soft measuring method using the same. The soft measuring apparatus is provided with an intelligent apparatus, a data storage device and an upper computer, wherein the intelligent apparatus is provided with a sensor, a server, a replicating machine, an on-line display and at least one workstation; the data storage device connected with the intelligent apparatus is provided with a database and a replicating machine; and the upper computer is a soft measuring processor, which is connected with the intelligent instrument and the data storage device.

Owner:XIAMEN UNIV

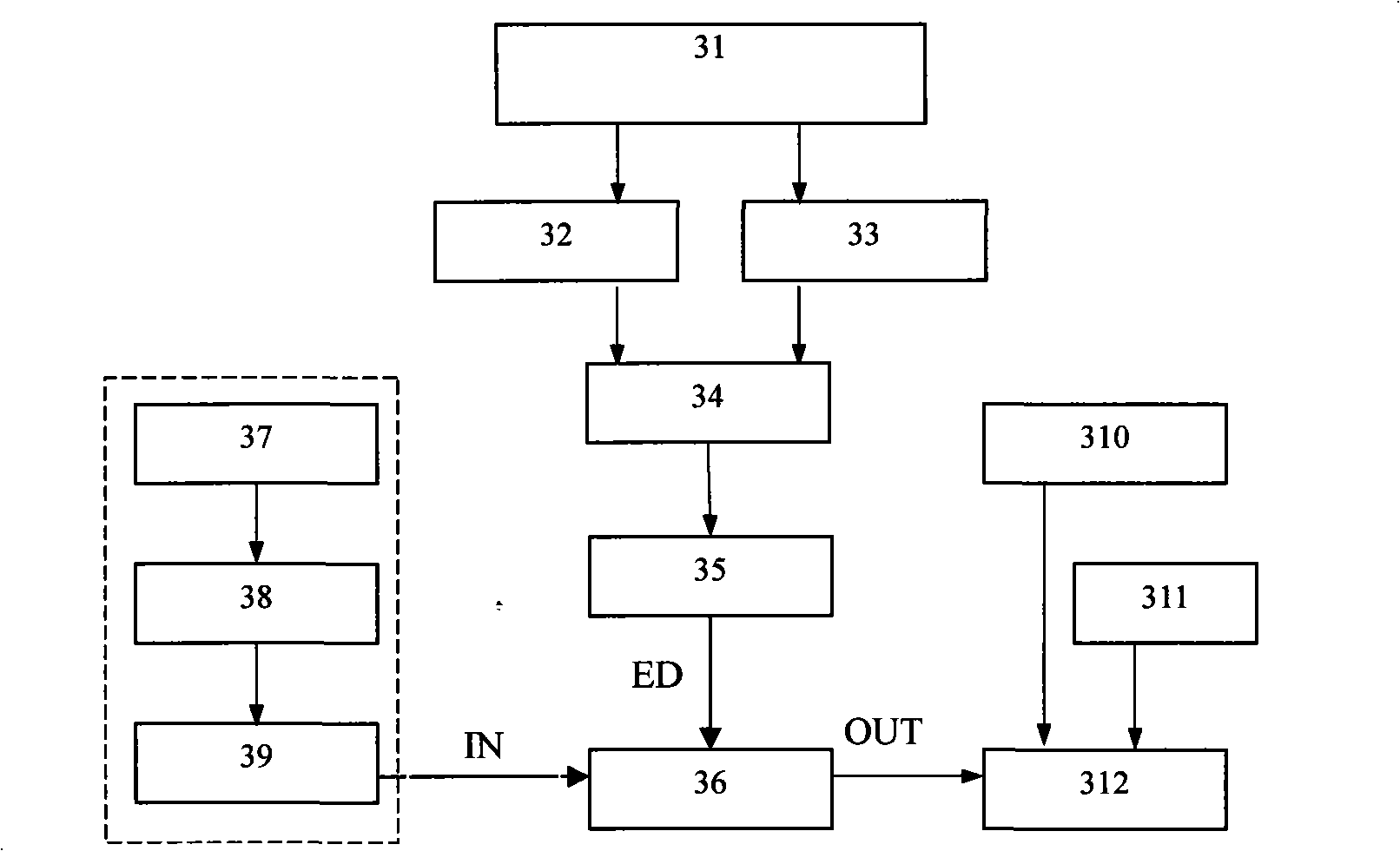

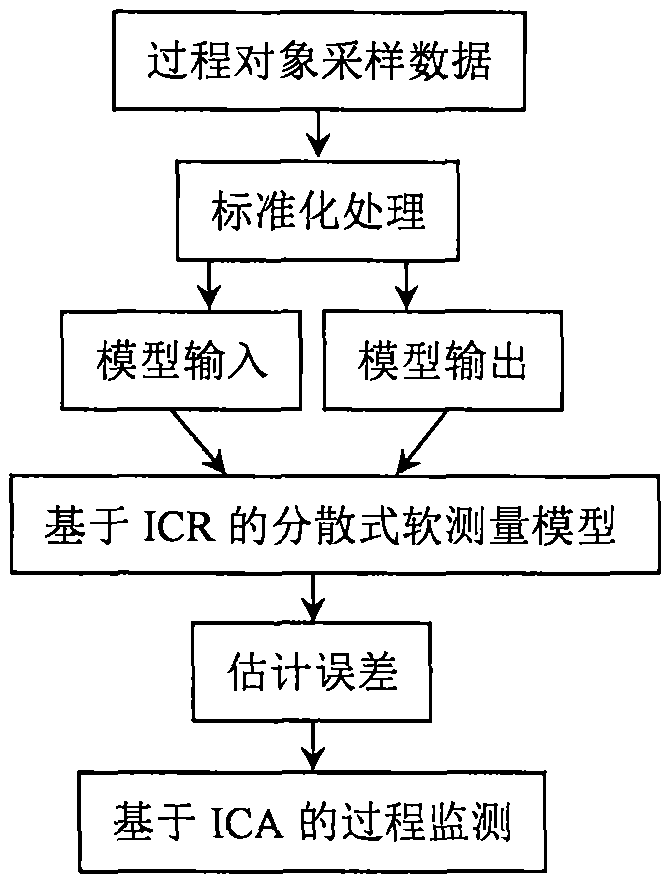

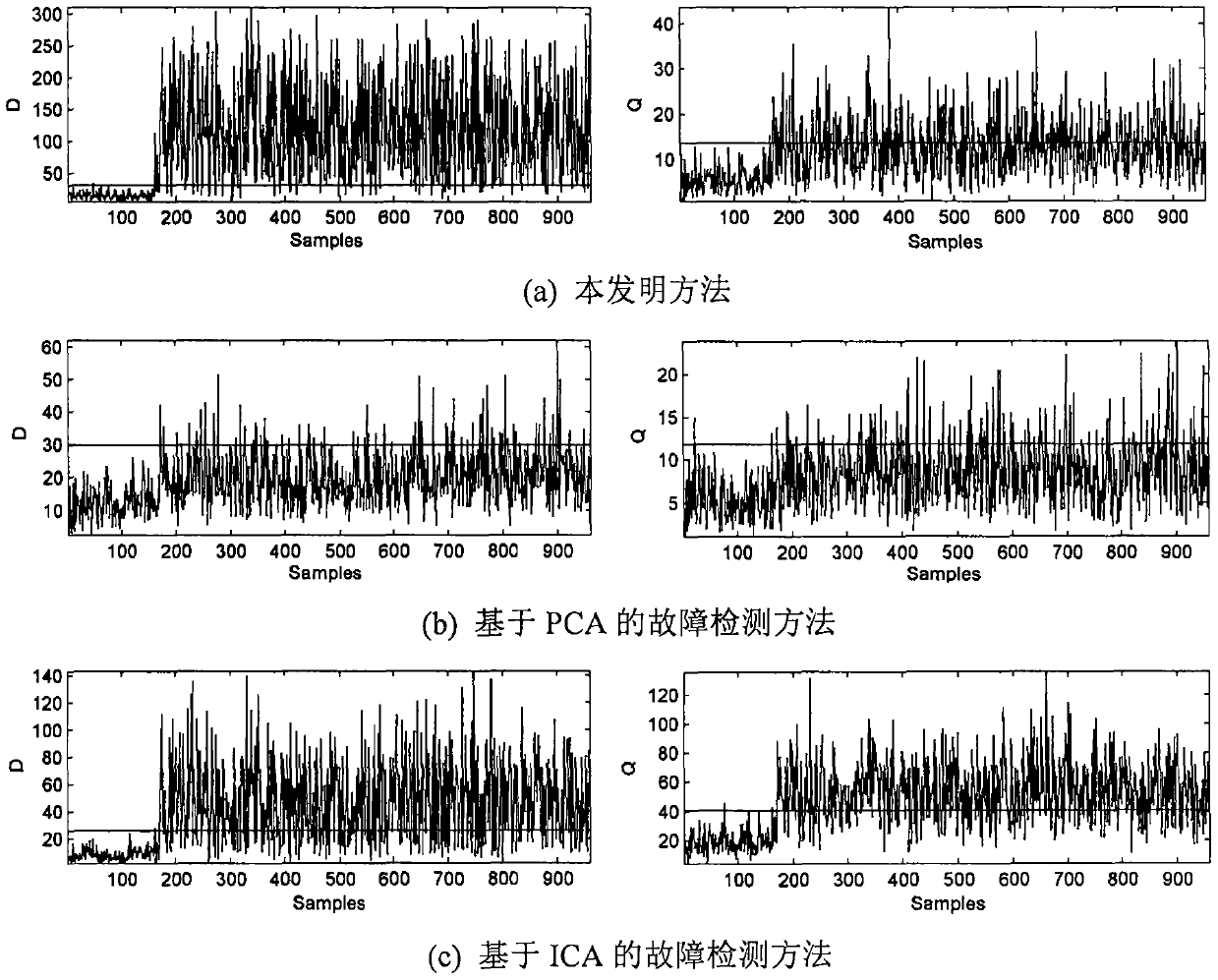

Non-Gaussian process monitoring method based on distributed ICR model

ActiveCN108445867AEasy fault detectionProgramme controlElectric testing/monitoringData modelingIndependent component analysis

The invention discloses a non-Gaussian process monitoring method based on distributed ICR (Independent Component Regression) models, aiming at solving the problem of how to use a non-Gaussian data modeling algorithm to convert sampling data into errors through a data model and the problem of implementing non-Gaussian process monitoring by taking errors as monitored objects. Specifically, the method of the invention includes the following steps: firstly, establishing a soft sensing model between each variable and other variables using an independent component regression (ICR) algorithm for eachmeasured variable; and secondly, establishing a process monitoring model based on independent component analysis (ICA) to implement non-Gaussian process monitoring using estimation errors of a soft sensor model as monitored objects. It can be seen that the method of the invention utilizes the advantages of distributed modeling and adopts an implementation mode combined with a plurality of non-Gaussian data analysis algorithms, so the method is a more preferred data-driven process monitoring method suitable for a non-Gaussian process.

Owner:NINGBO UNIV

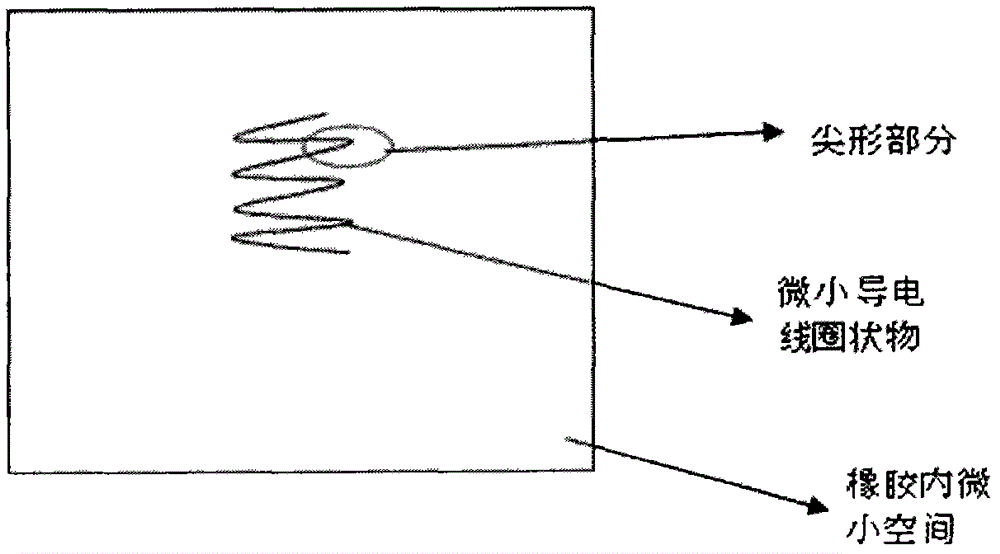

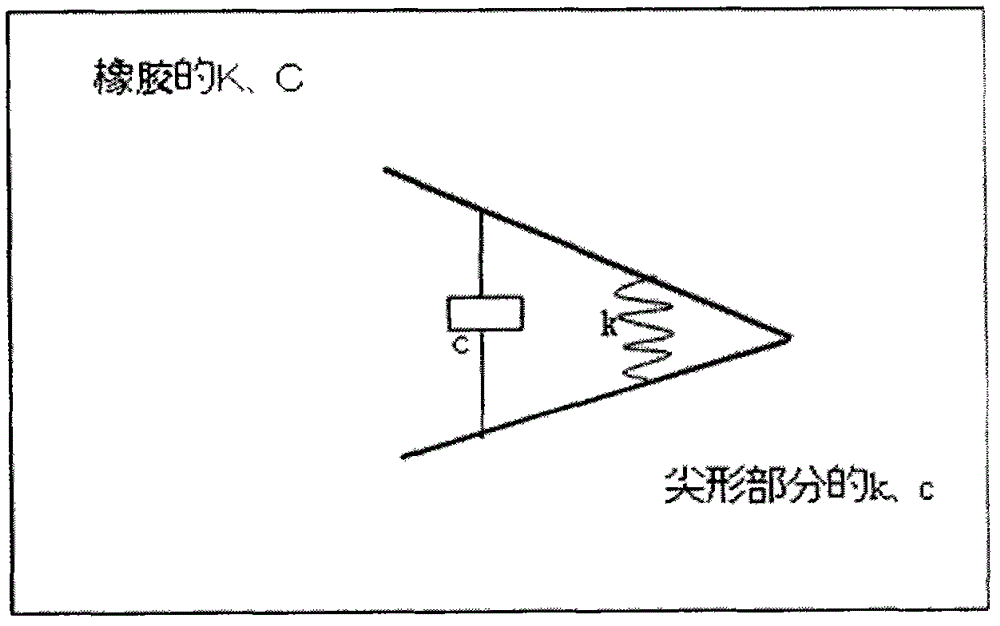

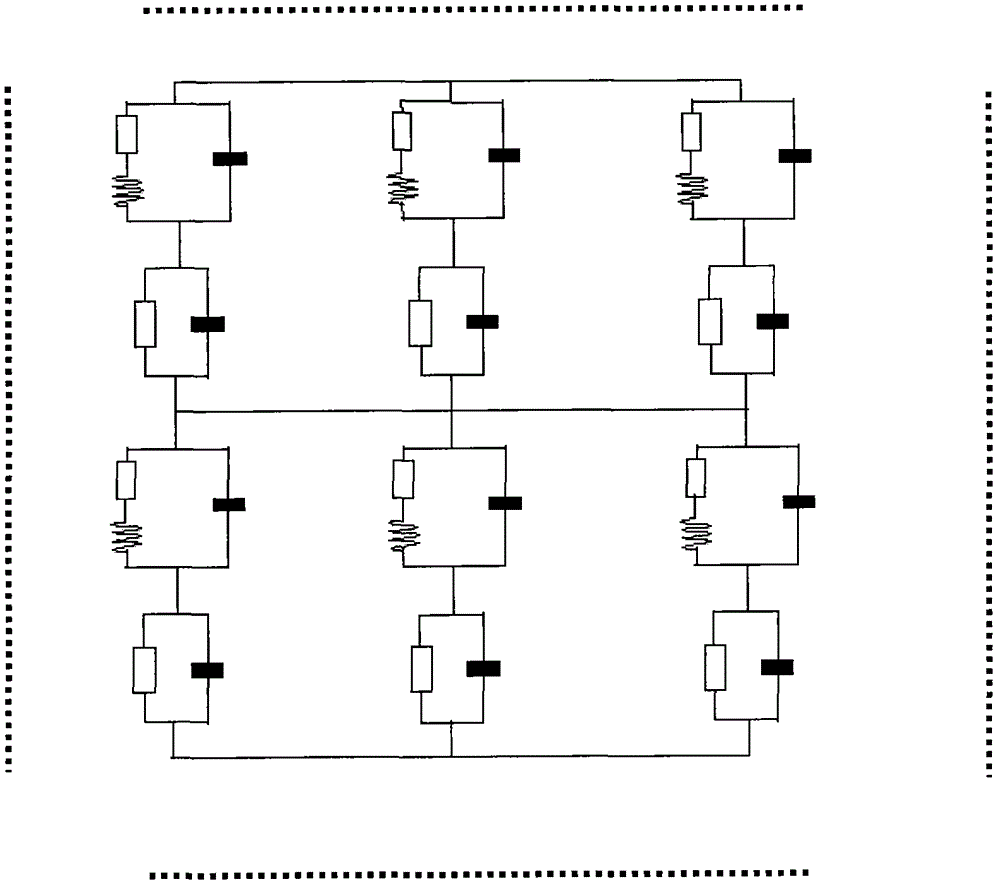

Design method of soft sensing materials for soft sensing material pressure sensor

InactiveCN103063332AReduce manufacturing costSimple structureAcceleration measurement using interia forcesForce measurementRubber materialMixed materials

Owner:郭松

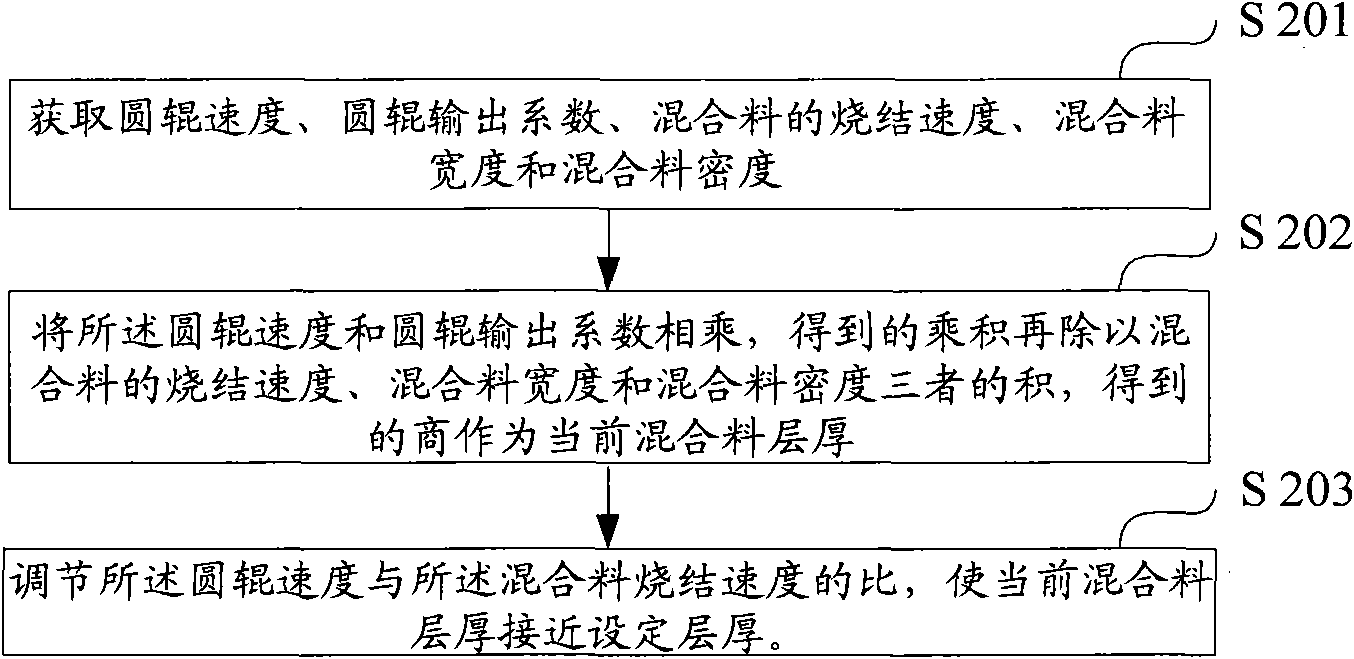

Thickness control method and control system of mixed material layer

ActiveCN101560599AReduce production and maintenance costsStable controlMaterial dimension controlControl systemVolumetric Mass Density

The invention relates to a thickness control method of a mixed material layer, comprising the following steps of: acquiring round roller speed, round roller output coefficient, speed of mixed material sintering, width of a sintering pallet and density of the mixed material; multiplying the round roller speed with the round roller output coefficient to obtain a product which is then divided by the product of the speed of the mixed material sintering, the width of the sintering pallet and the density of the mixed material to obtain a quotient which is taken as the current thickness of the mixed material layer; and regulating the ratio between the round roller speed and the speed of the mixed material sintering to cause the current thickness of the mixed material layer to be close to the set layer thickness. The invention also discloses a thickness control system of the mixed material layer. The method realizes control to the thickness of the mixed material layer by a soft-sensing mode, thus not only saving the production and maintenance cost of a manufacturer, but also having the advantages of stable and reliable control, etc.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

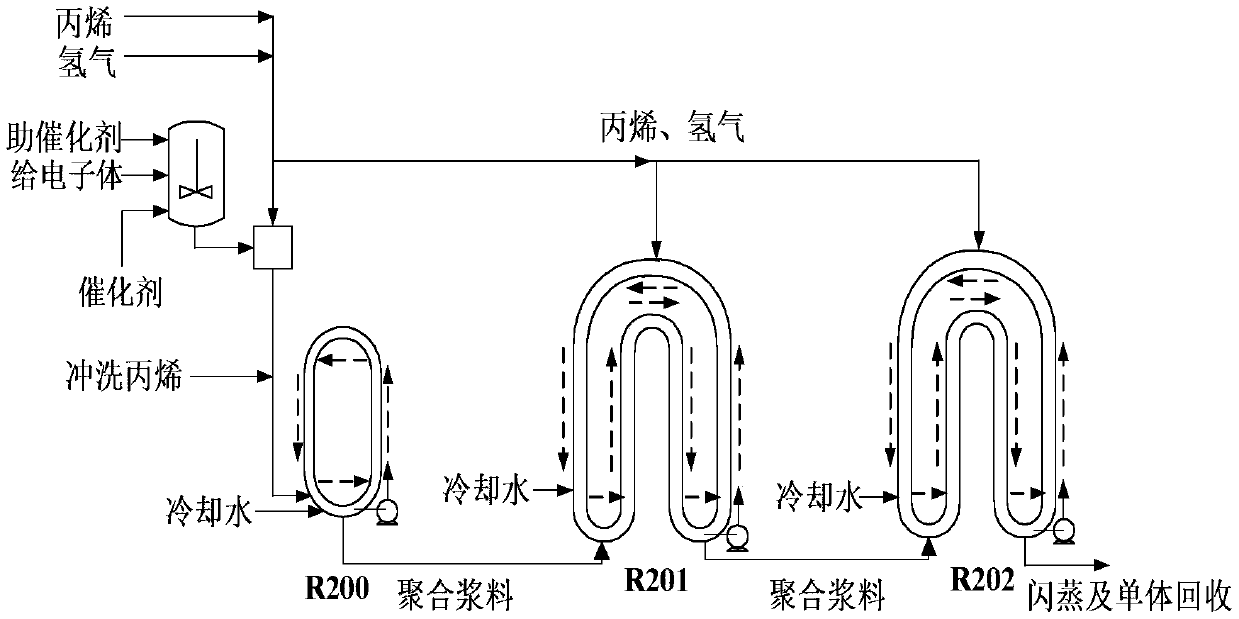

A soft sensing method for a melt index of polypropylene based on a selective integrated limit learning machine

InactiveCN108985574AImprove forecast accuracyImprove stabilityForecastingResourcesLearning machineData set

A soft sensing method for a melt index of polypropylene based on a selective integrated limit learning machine includes: firstly, an original sample data set is divided into training sample set and evaluation sample set, multiple subsets of training samples are established by random resampling method, and each subset is trained to establish the limit learning machine submodel, then the performanceof each submodel is evaluated by using the evaluation sample set, and the submodel for integration is screened, and finally, the predicted value of polypropylene melt index of each submodel is obtained by calculating the weight coefficient of each submodel. The invention has the characteristics of high prediction accuracy and high generalization ability. According to the soft sensing result obtained by the invention, the melt index change trend of the polypropylene production process can be well tracked, and effective technical support is provided for operation optimization and quality control of the polypropylene production process.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com