Industrial unit dichloroethane cracking furnace coupled modeling method and application

A technology of dichloroethane and industrial equipment, which is applied in the field of coupled modeling of dichloroethane cracking furnaces in industrial equipment, and can solve problems such as the inability to accurately describe dichloroethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

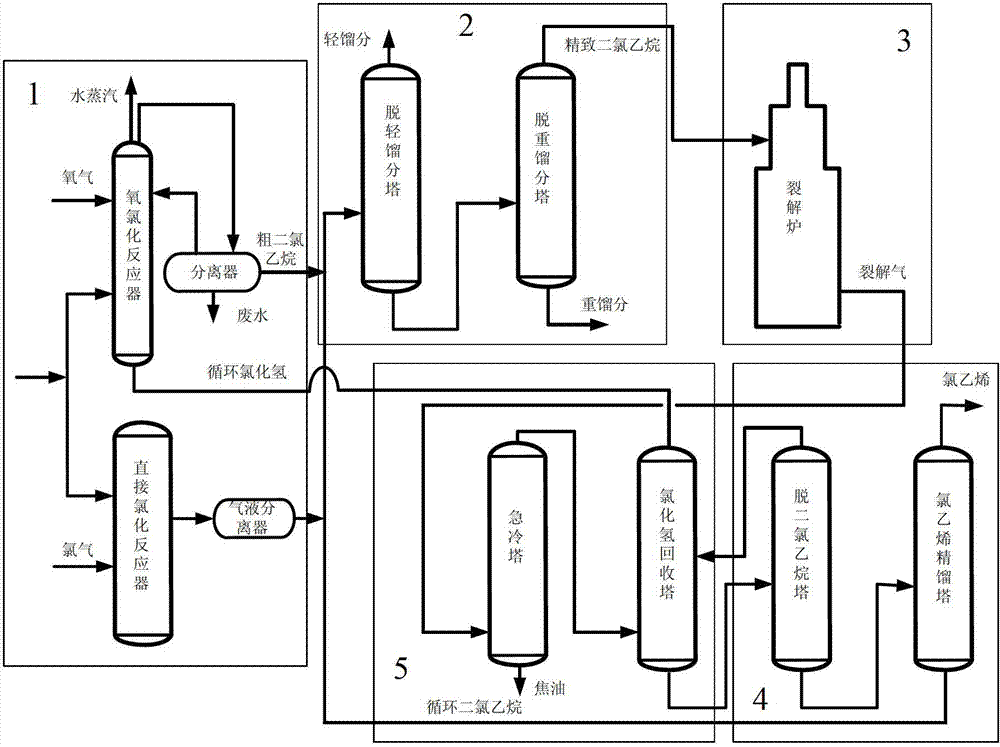

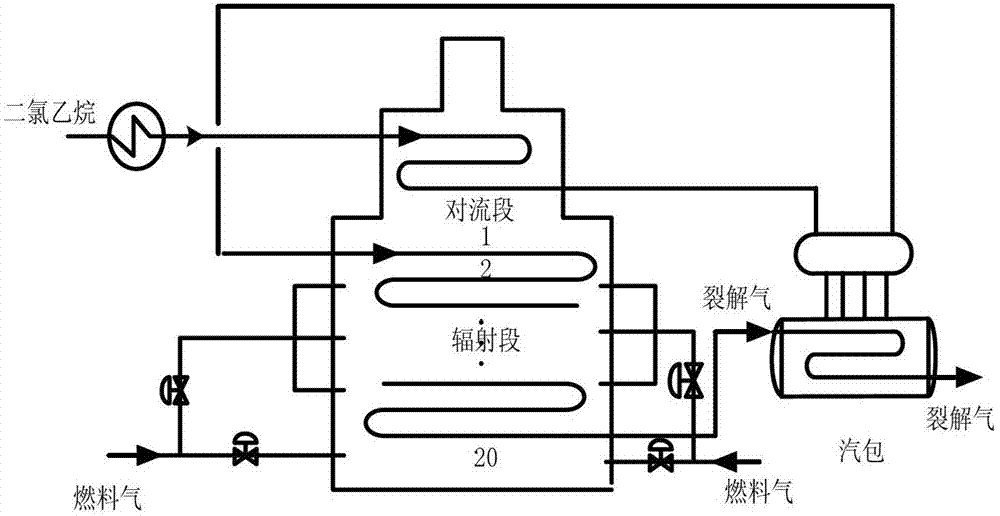

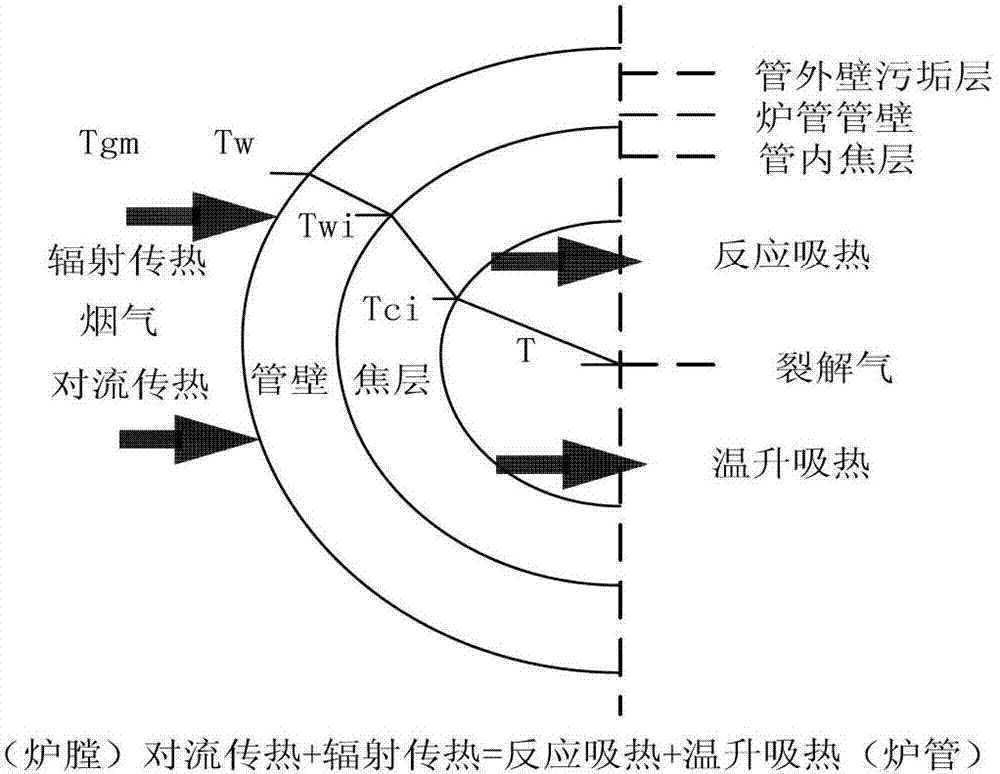

[0040] Accurate and reliable dichloroethane cracking furnace simulation is not only the basis for advanced control and real-time optimization of dichloroethane cracking furnace, but also plays an important role in production operation guidance and cracking furnace design optimization. The modeling of dichloroethane can be divided from the structure: it can be divided into reactor tube modeling and furnace modeling, but the two are not isolated from each other, but have close thermal coupling, and the modeling is more complicated. The furnace of the cracking furnace has the greatest influence on the furnace tube in the radiant section of the furnace, and the cracking reaction in the dichloroethane tube is carried out in the radiant section. Therefore, the simulation of the dichloroethane cracking furnace is modeled separately for the furnace and furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com