Probabilistic principal component regression model-based method for soft sensing of butane content of debutanizer

A technology of butane and principal element regression in a butane tower is applied in the field of soft sensing modeling and on-line detection of butane content in a butane tower, which can solve the problem of not well considering process data noise information, model failure performance, degradation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

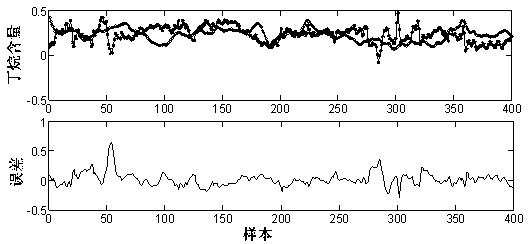

[0014] Aiming at the problem of detecting the butane content in the debutanizer, the invention uses variables that are easy to measure in the process and uses a probability principal component regression analysis model to perform on-line soft measurement of the butane content in the process.

[0015] The main steps of the technical solution adopted in the present invention are respectively as follows:

[0016] Step 1: Collect the data of each process variable in debutanizer through distributed control system and real-time database system: X={x i ∈R m} i=1,2,…,n . Among them, n is the number of samples, and m is the number of process variables. Store these data in the historical database respectively, and select some data as samples for modeling;

[0017] Step 2: Obtain the butane content value corresponding to the sample used for modeling in the historical database through on-site extraction and offline laboratory analysis, and use it as the output y∈R of the soft sensor m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com