Soft measurement method for coal power fineness in powdering producer

A support vector machine and pulverized coal fineness technology, applied in measuring devices, special data processing applications, instruments, etc., can solve problems such as lack of guidance for operators, unavoidable pulverized coal, and large influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

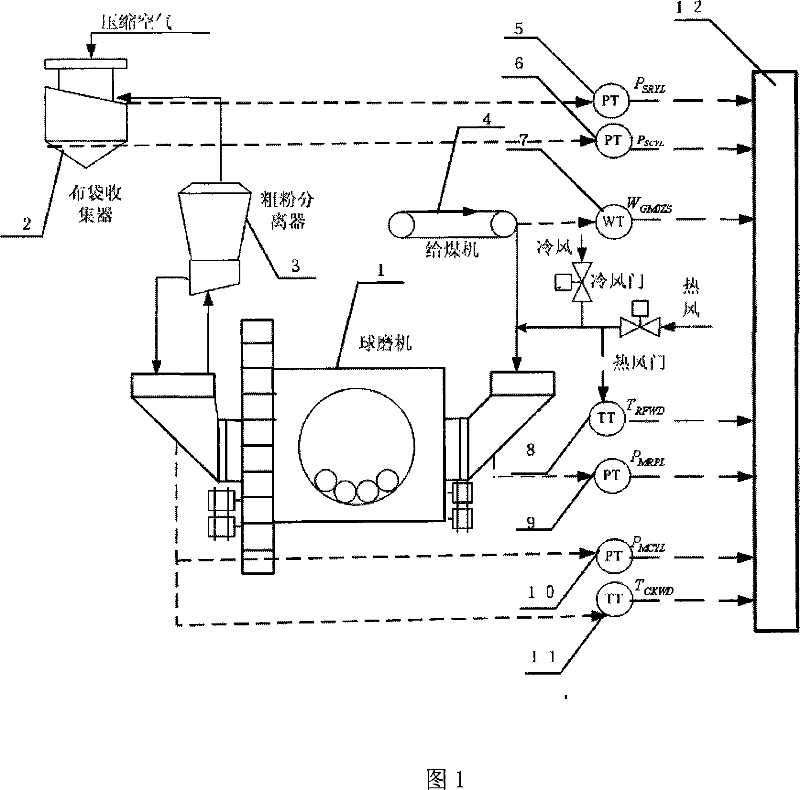

[0111] Taking the steel ball coal pulverization system used in the alumina sintering rotary kiln as an example, as shown in Figure 1, the coal pulverization process consists of a coal feeder, a coal mill, a coarse powder separator, a bag filter, and a pulverized coal bin, etc. Equipment composition. The raw coal and hot air are ground and dried in the ball mill, and the pulverized coal enters the coarse powder separator under the action of the exhaust fan, and the returned powder returns from the section warehouse to the mill to continue grinding. The powder is sent into the pulverized coal bin by the conveying device.

[0112] The specification of the coal mill is Φ3.2×9.5m, and the designed production capacity is 28t / h. The coal mill is divided into three warehouses: drying bin, ball bin and section bin; the main motor model is YR80-8 / 1180, and the rated power is 800KW.

[0113] The coal pulverizer system has the following measuring instruments installed as required by this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com