Design method of soft sensing materials for soft sensing material pressure sensor

A technology of pressure sensors and soft materials, applied in the direction of instruments, force measurement, and acceleration measurement using inertial force, etc., to reduce production costs, facilitate wide use, and simple structure

Inactive Publication Date: 2013-04-24

郭松

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There is no soft polymer material like rubber as a press

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

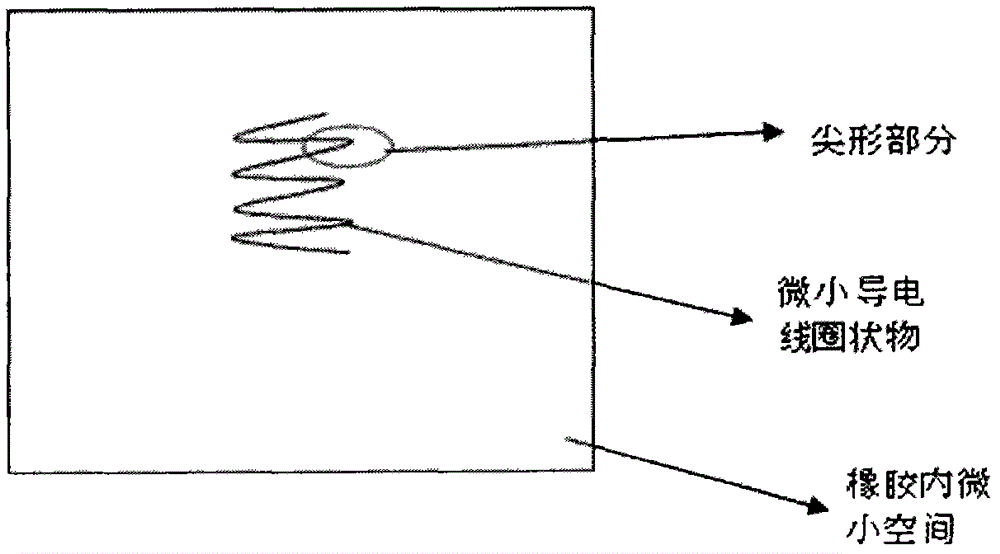

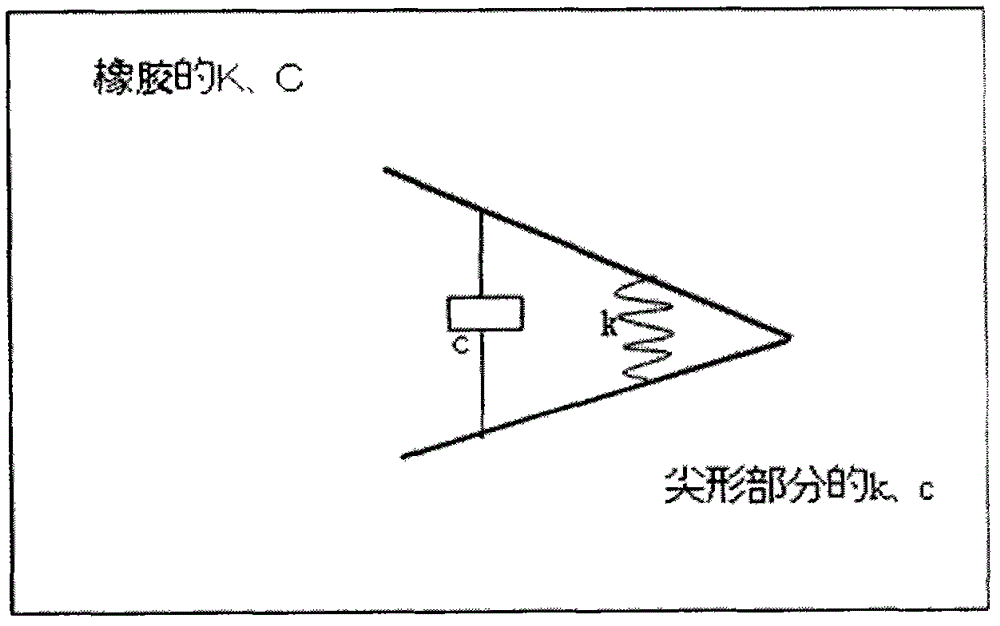

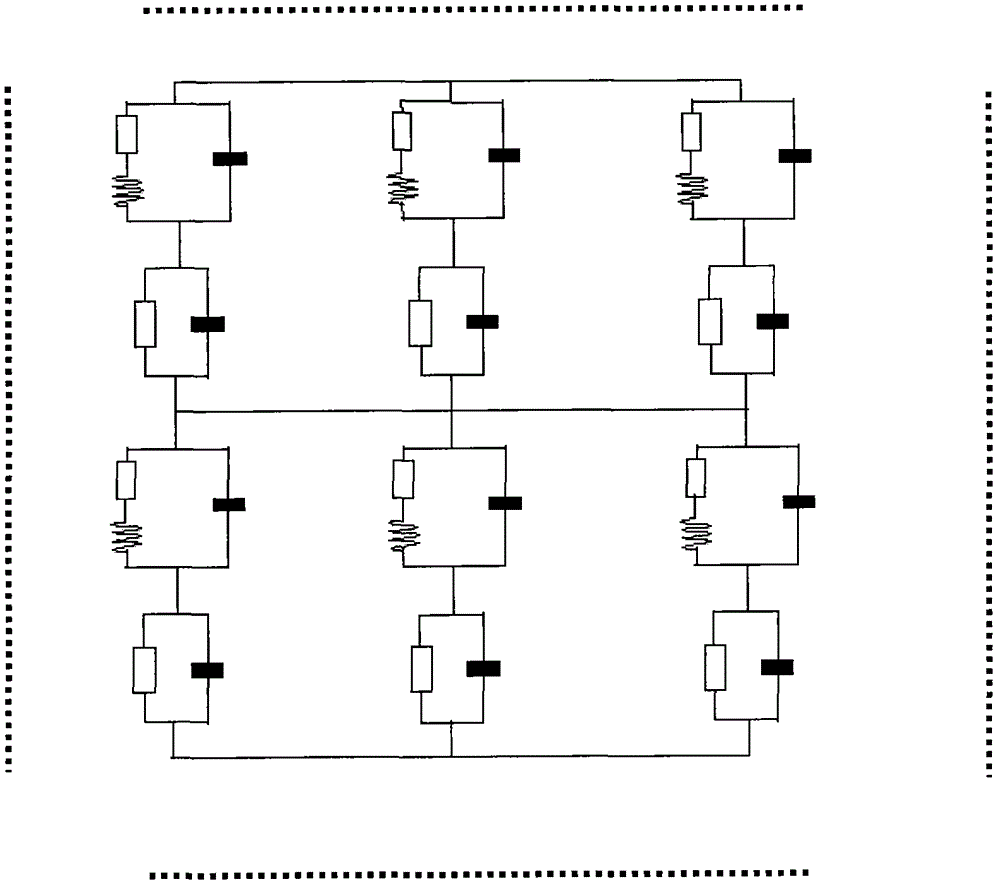

The invention relates to a design method of soft sensing materials for a soft sensing material pressure sensor. According to the design method, the soft sensing materials mixed with tiny structure bodies are deformed when being affected by the outside, the electrical characteristics are changed, the relevant electric signal variation caused by the variation of relevant positions inside a tiny space inside soft materials generated by outside effect is detected out to be used as pressure signals which cause deformation of the soft materials. According to the design method of the soft materials, the soft materials mixed with the tiny structure bodies are used as the sensing materials of the pressure sensor. Conductive tiny spiral-shaped structures are mixed in the soft rubber materials, or soft rubber materials with structure bodies of an elastic opening-closing structure are made to the soft sensing materials. When the shapes of the mixing materials are changed, the mutual positions inside the tiny space caused by changing of the shapes are changed, and the electric characteristics of the soft materials caused by the variation of stress are changed. Electrical signal variation detected by a detecting method is used as the application as the application method of the materials of pressure signals.

Description

Technical field [0001] The present invention relates to the use of a soft induction material mixed with a microstructure when it is deformed by the outside influence and its electrical characteristics change, and the relative position of the soft material in the small space inside the soft material that occurs under the external influence is changed. The related electrical signal change caused by the detection is used as the design method of the soft sensing material used in the pressure sensor that causes the deformation of the soft material. Background technique [0002] Existing pressure sensors include strain sensors that detect strain after the membrane is deformed, and are widely used in various industrial and civil fields. The above sensors are basically hard materials as materials or mechanisms for sensing speed signals. There is no flexible polymer material like rubber as a pressure signal sensing material and a simple pressure sensor. Summary of the invention [0003] ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01L1/00G01L1/20G01P15/08G01P15/12

Inventor 郭松

Owner 郭松

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com