Method and system for determining grain size of alloy based on mapping monotonicity

A technology of grain size and determination method, used in manufacturing computing systems, instruments, design optimization/simulation, etc., can solve the problems of low evaluation accuracy, loss of evaluation effect, lack of accuracy of evaluation models, etc., and achieve small errors and measurement accuracy. High, good monotonicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

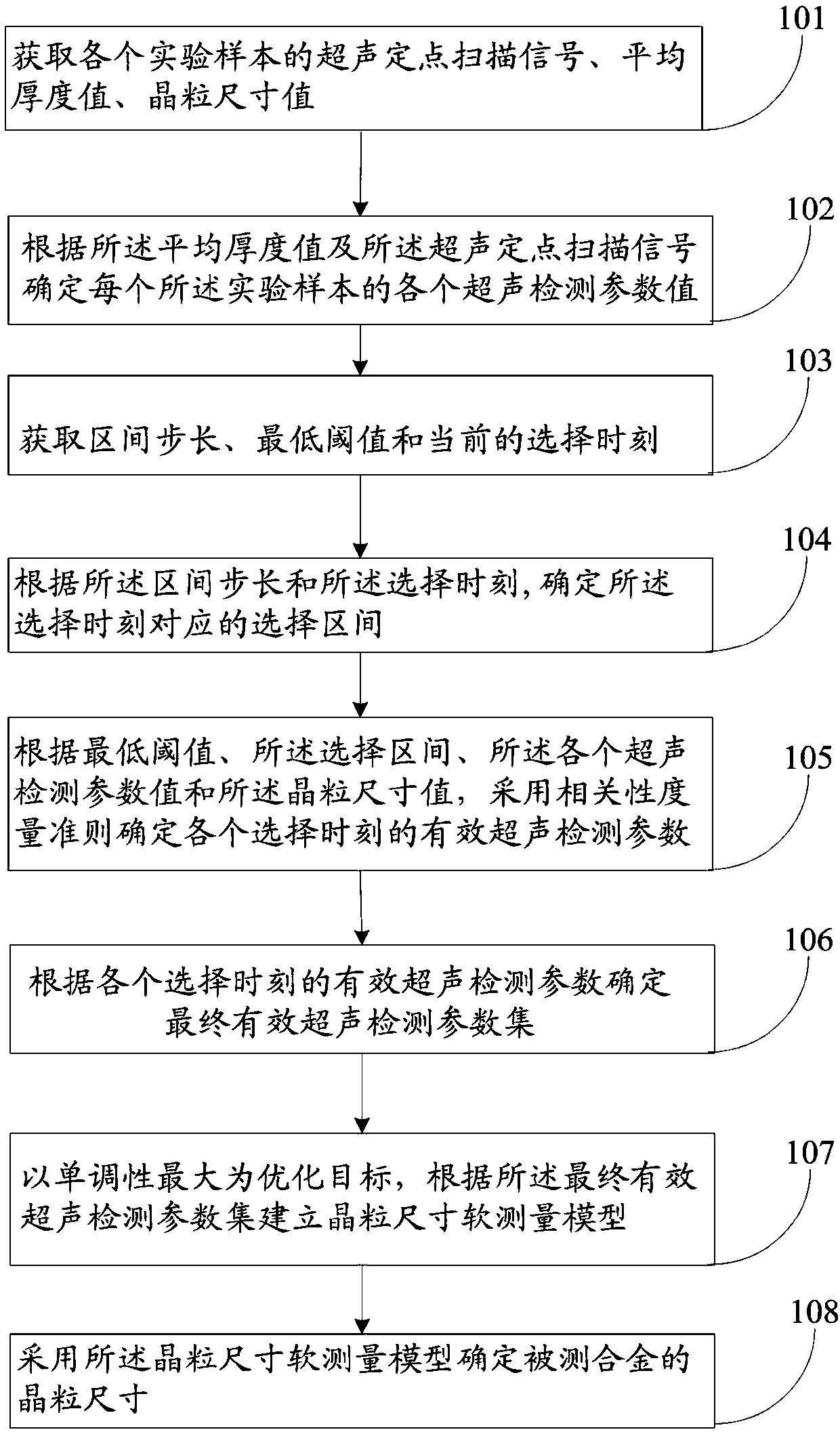

[0075] figure 1 It is a flowchart of a method for determining alloy grain size based on mapping monotonicity provided by Embodiment 1 of the present invention. Such as figure 1 Shown, a kind of determination method based on the alloy grain size of mapping monotonicity, described determination method comprises:

[0076] Step 101: Obtain the ultrasonic fixed-point scanning signal, average thickness value, and grain size value of each experimental sample;

[0077] Step 102: Determine each ultrasonic detection parameter value of each experimental sample according to the average thickness value and the ultrasonic fixed-point scanning signal;

[0078] Step 103: Acquire interval step size, minimum threshold and current selection moment;

[0079] Step 104: According to the interval step size and the selection time, adopt the formula: determining the selection interval corresponding to the selection moment, where t represents the selection moment, Indicates the interval step siz...

Embodiment 2

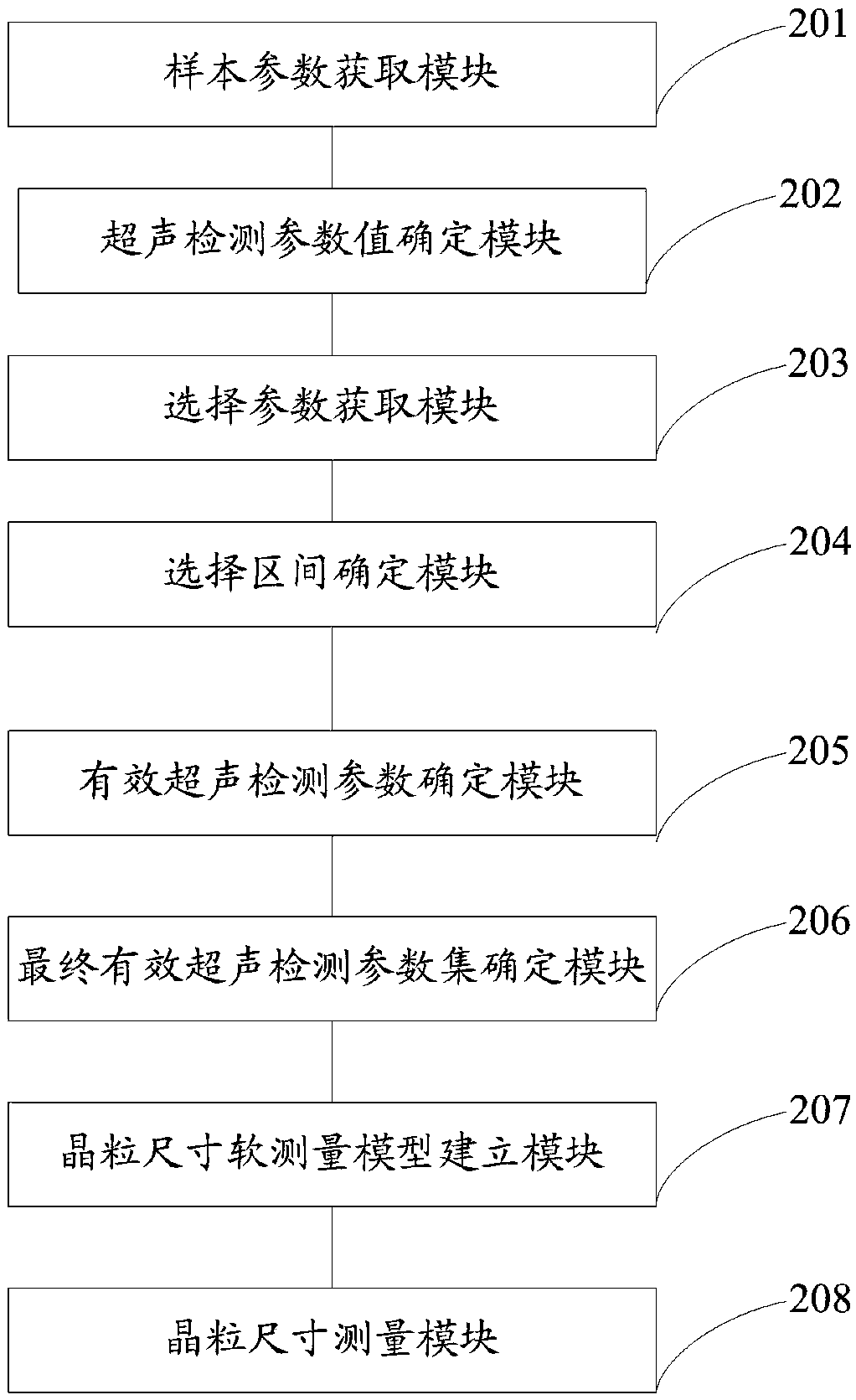

[0102] figure 2A structural block diagram of a system for determining alloy grain size based on mapping monotonicity provided by Embodiment 2 of the present invention. Such as figure 2 Shown, a kind of determination system of alloy grain size, described determination system comprises:

[0103] The sample parameter acquisition module 201 is used to acquire the ultrasonic fixed-point scanning signal, average thickness value, and grain size value of each experimental sample;

[0104] An ultrasonic detection parameter value determination module 202, configured to determine each ultrasonic detection parameter value of each experimental sample according to the average thickness value and the ultrasonic fixed-point scanning signal;

[0105] Selection parameter acquisition module 203, used to acquire interval step size, minimum threshold and current selection moment;

[0106] Select the interval determination module 204, for according to the formula: determining the selection i...

Embodiment 3

[0128] In this embodiment, the influence of monotonic performance is taken as a strategy, and multiple ultrasonic detection parameters are preferably reduced to single-dimensional parameters and normalized, and the grain size of the primary α phase is fitted through a one-time item and the monotonicity (reduced to single-dimensional ultrasonic parameters) is formulated. The maximum sequence difference of detection parameter sample points (both positive or negative) is the optimization goal, and the self-adaptive differential evolution algorithm (self-adaptive differential evolution, SADE) algorithm is used to determine the optimization problem to optimize the goal, and the corresponding mapping function and fitting function are obtained by solving The undetermined coefficient of , so as to establish an ultrasonic evaluation method for the grain size of TC4 primary α phase that maps monotonicity.

[0129] Step 1: Conduct an experiment to obtain the ultrasonic fixed-point scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com