Soft Sensing Method of SO_2 Emission from Power Plant Based on Variable Compression BP Neural Network

A BP neural network, SO2 technology, applied in the direction of neural learning method, biological neural network model, neural architecture, etc., can solve the problem of difficult to better control the slurry flow in the spray tower, difficult to ensure flue gas emission standards, and system nonlinearity and other problems, to achieve the effect of convenient online calculation, reliable design principle and strong nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

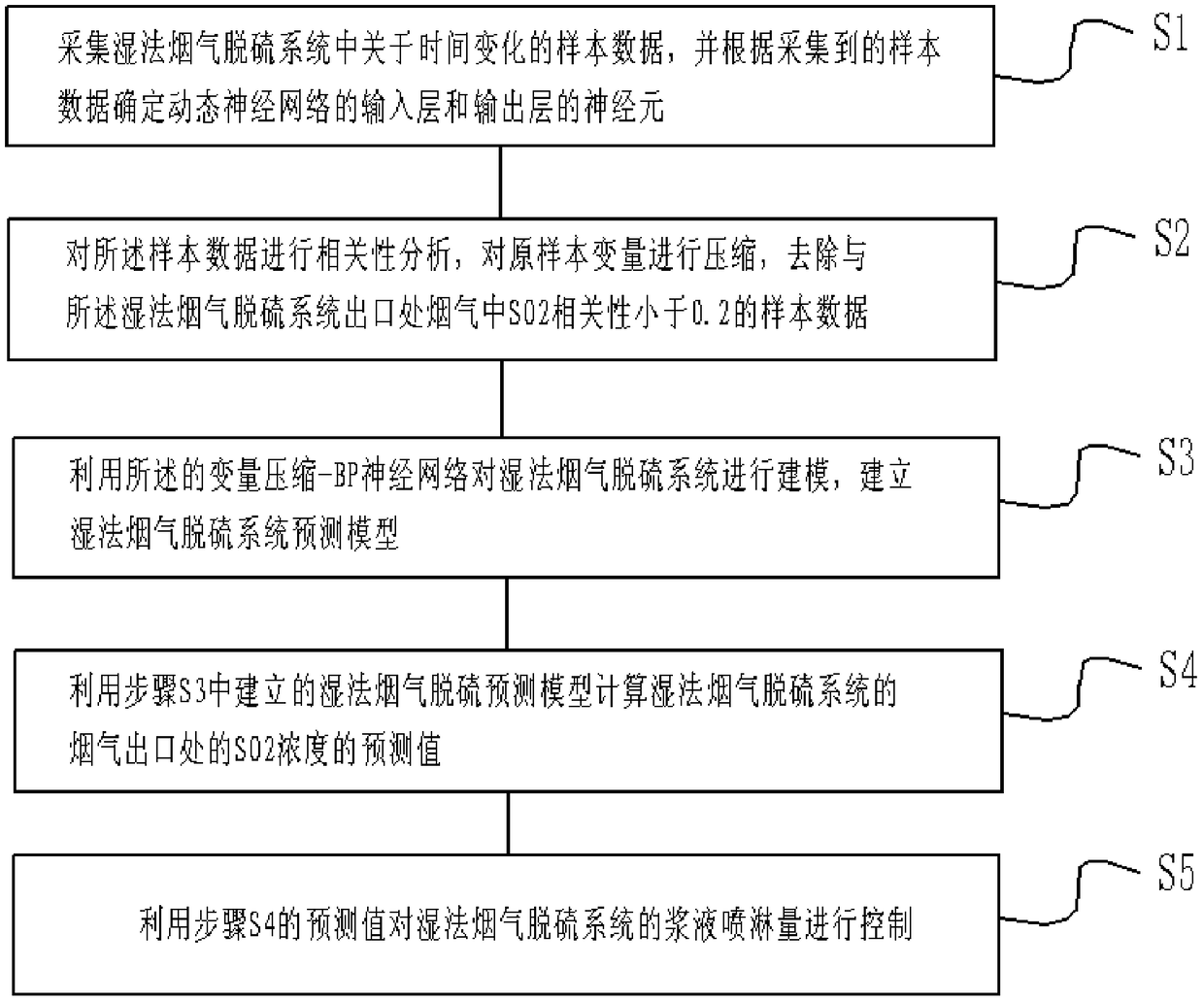

[0037] Such as figure 2 As shown, a kind of power plant SO based on variable compression BP neural network provided by this embodiment 2 The emission soft measurement method includes the following steps:

[0038] Step S1: collect sample data about time changes in the wet flue gas desulfurization system, and determine the neurons of the input layer and output layer of the dynamic neural network according to the collected sample data;

[0039] Step S2: Carry out correlation analysis on the sample data, compress the original sample variables, and remove the SO in the flue gas at the outlet of the wet flue gas desulfurization system 2 Sample data with a correlation of less than 0.2 to reduce the amount of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com