Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "N-decyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-decyl alcohol capric alcohol epal 10 antak agent 504. Identifiers ... 1-Decanol is a straight chain fatty alcohol with ten carbon atoms and the molecular formula C 10 H 21 OH. It is a colorless to light yellow viscous liquid that is insoluble in water and has an aromatic odor.

Anti-alcohol, anti-plasma, anti-static and leak-proof functional non-woven fabric

The present invention relates to a kind of functional non-woven fabric with functions of resisting alcohol, oil, plasma, static electricity and permeation. The functional non-woven fabric is produced through dipping non-woven fabric in functional assistant liquid, rolling to eliminate redundant assistant, stoving and winding. The functional assistant liquid is water solution with waterproofing agent 25í½30 g / l, antistatic agent 2í½4 g / l and seepage agent 0.5í½1.5 g / l. The waterproofing agent consists of acrylic fluoride, polymethyl acrylic acid, glycol and water in certain weight proportion; the antistatic agent consists of alkyl phosphate and water in certain ratio; and the seepage agent consists of polyglycol, sorbitan, oleic acid mixture, n-decyl alcohol and water in certain weight proportion. The roller has rolling speed of 25-35 m / min and rolling pressure of 3-5 kgf / sq cm; and the stoving temperature is 135-150 deg.c.

Owner:江阴金凤特种纺织品有限公司

Split reagent and method for ofloxacin racemic mixture

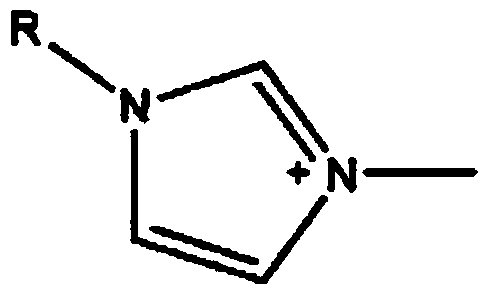

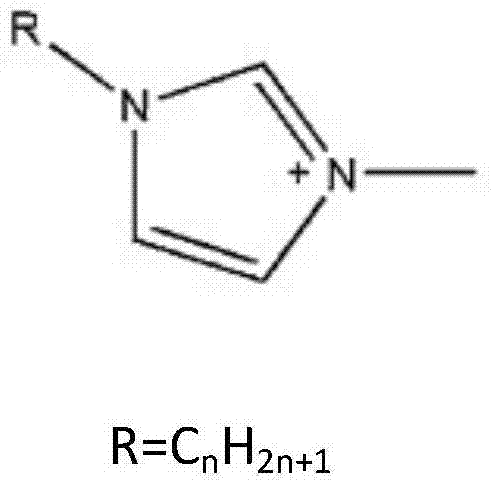

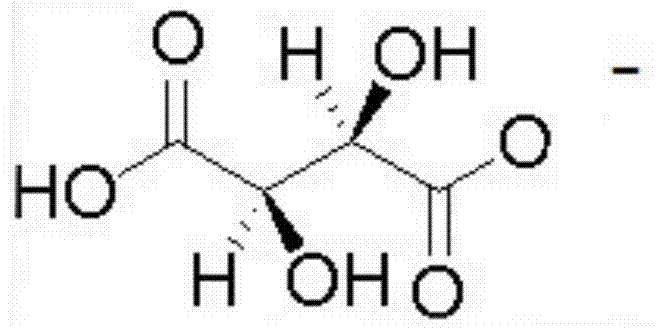

ActiveCN103664998AHigh selectivityImprove the efficiency of chiral resolutionOrganic chemistryL-ofloxacinTartrate

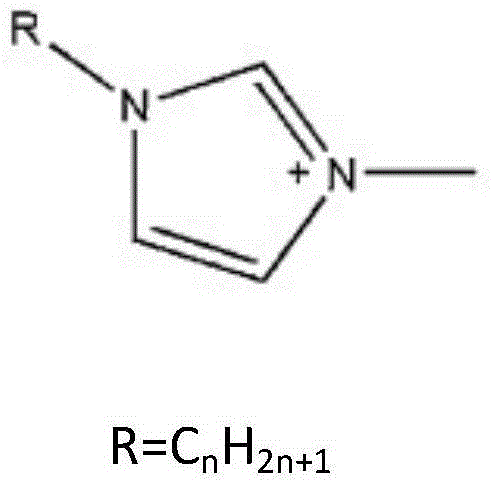

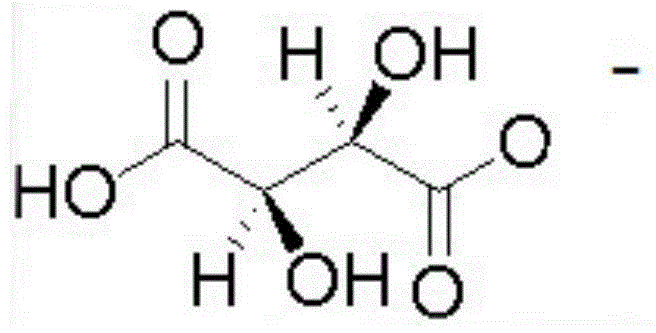

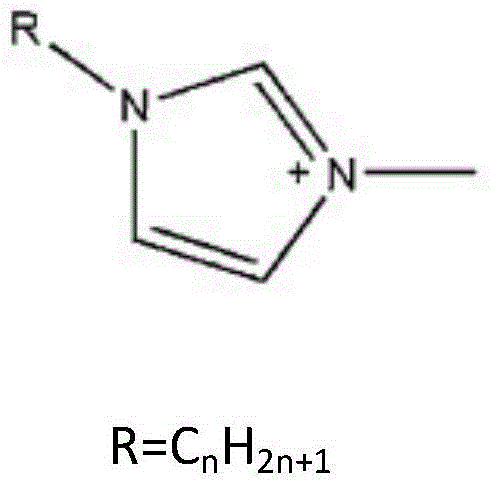

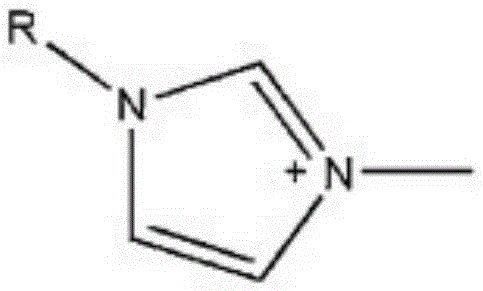

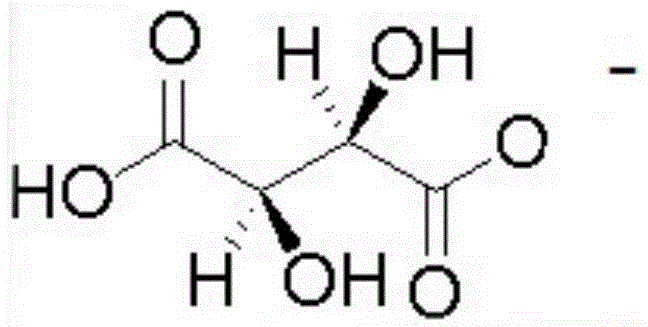

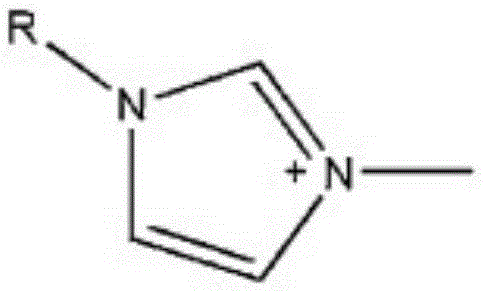

The invention discloses a split reagent and a split method for an ofloxacin racemic mixture. The method is as below: dissolving an ofloxacin racemic mixture and an alkyl imidazole L-tartaric acid salt ionic liquid in deionized water to form an aqueous phase, and at the same time dissolving D-dibenzoyl tartaric acid in n-decyl alcohol to form an organic phase; mixing the organic phase and the aqueous phase; oscillating the mixture in an oscillator and standing; detecting concentration of L-ofloxacin and D-ofloxacin in a clear aqueous phase; acquiring the concentration of L-ofloxacin and D-ofloxacin in organic phase respectively by the law of conservation of mass; respectively calculating the distribution coefficient of the L-ofloxacin and D-ofloxacin; and further calculating a separation factor. The reagent and the method have good separation effect, and is successfully in splitting. The invention uses alkyl imidazole L-tartaric acid salt ionic liquid and D-dibenzoyl tartaric acid for splitting of the ofloxacin racemic mixture, improves the splitting efficiency and reduces the reagents required by splitting; and the method has simple operation and high selectivity, and is suitable for industrial production.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

Reagents and method for separation of ofloxacin racemic mixture by utilization of ionic liquid and L-dibenzoyltartaric acid together

ActiveCN103709176AHigh selectivityImprove the efficiency of chiral resolutionOptically-active compound separationOrganic racemisationSeparation factorL-ofloxacin

The invention discloses reagents and a method for separation of ofloxacin racemic mixture by utilization of ionic liquid and L-dibenzoyltartaric acid together. Ofloxacin racemic mixture and alkyl imidazole L-tartrate ionic liquid are dissolved in deionized water and a water phase is formed. At the same time, L-dibenzoyltartaric acid is dissolved in n-decyl alcohol and an organic phase is formed. The organic phase and the water phase are mixed and placed in a vibrator for vibration, and then the mixture is permitted to stand. The concentrations of L-ofloxacin and D-ofloxacin in the water-phase clear solution are detected. The concentrations of L-ofloxacin and D-ofloxacin in the organic phase are obtained through a law of conservation of mass respectively. The distribution coefficients of L-ofloxacin and D-ofloxacin are calculated respectively, and therefore the separation factor is calculated, the separation effect is good and the separation is successful. Separation of ofloxacin racemic mixture is achieved by utilization of alkyl imidazole L-tartrate ionic liquid and L-dibenzoyltartaric acid together, the separation efficiency is raised, required reagents for separation are reduced, the operation technology is simple, the selectivity is high, and the method is suitable for industrial production.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

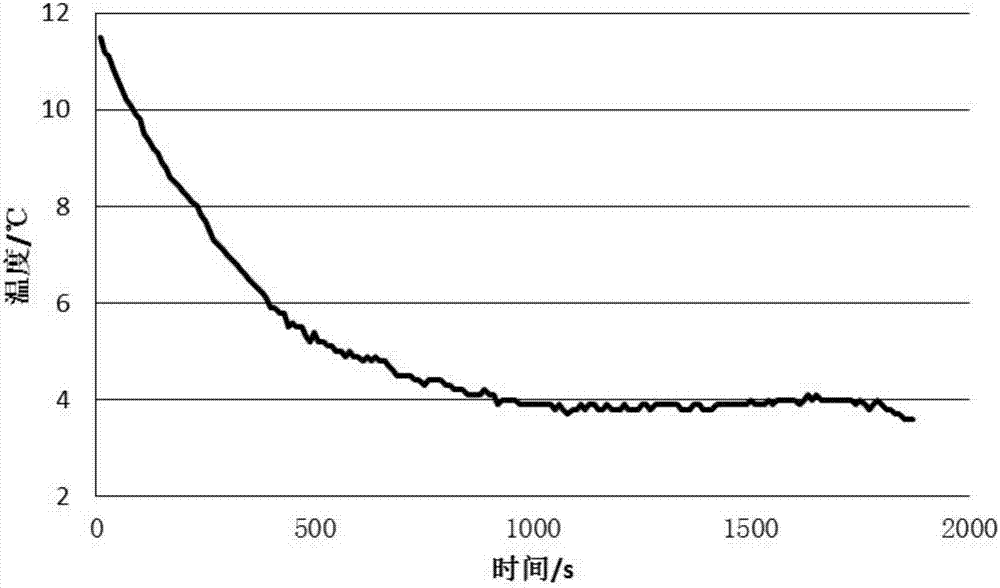

Low-temperature phase-change energy-storage material and preparation method thereof

InactiveCN105838332AImprove performanceNot corrosiveOther chemical processesHeat-exchange elementsWater bathsSnow melting

A low-temperature phase-change energy storage material and a preparation method thereof. The material is composed of n-decyl alcohol and n-stearyl alcohol in a weight ratio of 95-97:3-5. The preparation method is to firstly mix n-decyl alcohol and n-octadecanol in a weight ratio of 95-97:3-5, then heat the above mixture in a water bath at 40°C-60°C to completely melt and stir the components evenly, Finally, after cooling to room temperature, the low-temperature phase-change energy storage material can be prepared. The low-temperature phase-change energy storage material provided by the invention has stable performance, is non-toxic and non-corrosive, and can be recycled. The phase change temperature is about 5.1°C, and it can be widely used in snow and ice melting at major airports and roads in northern and plateau regions in winter. It can effectively alleviate the problems of high energy consumption, long time consumption and environmental protection. In addition, the preparation method is simple and the operation is convenient.

Owner:CIVIL AVIATION UNIV OF CHINA

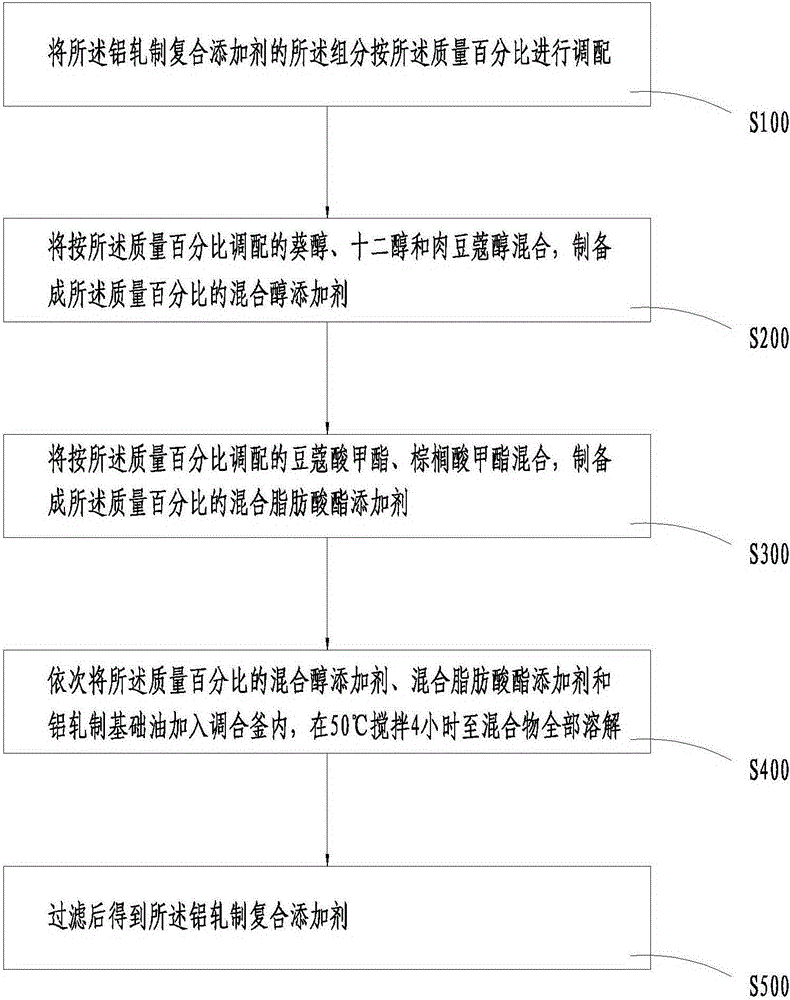

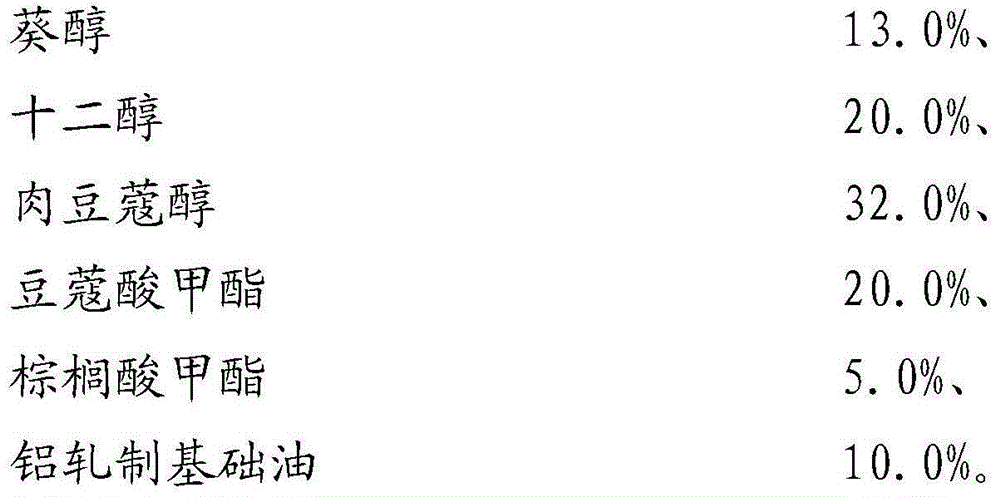

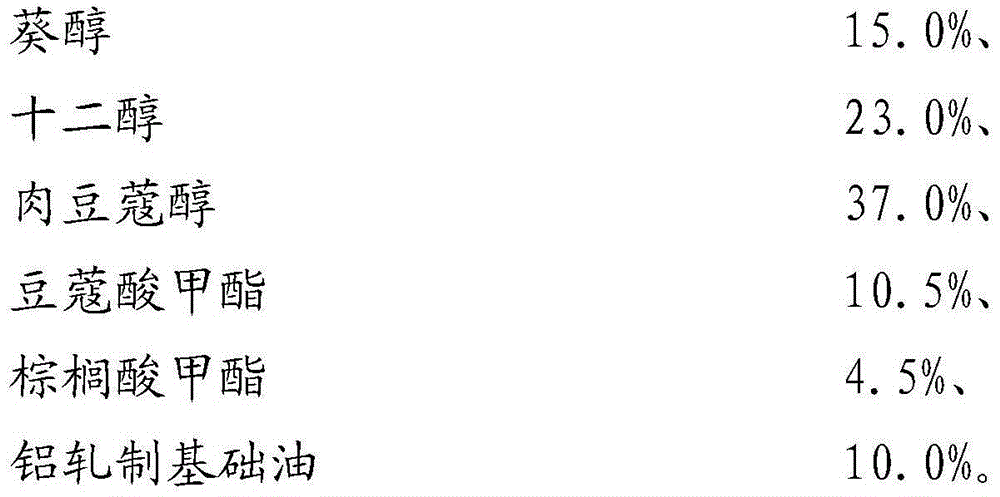

Aluminum rolling composite additive and preparation method thereof

InactiveCN105219501AGood annealing cleanlinessGuaranteed lubrication effectLubricant compositionMixed fatty acidAlcohol

The invention provides an aluminum rolling composite additive which is prepared from, by mass, 65.0-79.0% of mixed alcohol additives, 15.0-25.0% of mixed fatty alcohol acid ester additives and 6.0-12.0% of aluminum rolling base oil. The mixed alcohol additives are prepared from, by mass, 15.0-25.0% of n-decyl alcohol, 28.0-38.0% of dodecanol and 40.0-50.0% of myristyl alcohol. The mixed fatty alcohol acid ester additives are prepared from, by mass, 70.0-80.0% of tetradecanoic acid-methyl ester and 20.0-30.0% of methyl palmitate. Compared with the prior art, the aluminum rolling composite additive has the advantages of being good in annealing detergency, high in annealing product surface quality and low in annealing energy consumption.

Owner:SNTO TECH GRP

Preparation method of phase change energy storage material

InactiveCN107189764AInsufficient performance, obtained by low phase transition temperatureImprove performanceOther chemical processesHeat-exchange elementsWater bathsMass ratio

The invention discloses a preparation method of a phase change energy storage material. The preparation method comprises the following steps: weighing n-decyl alcohol and n-undecanol in a mass ratio of (90 to 92):(8 to10) respectively, and mixing the two; heating the mixture in a water bath tank at 40-60 DEG C, completely melting the components and stirring for 20-30min; finally, cooling to room temperature to obtain the low-temperature phase change energy storage material. The preparation method disclosed by the invention is simple and convenient to operate; a binary phase change material is formed by compounding; the shortcomings of various raw materials in performance are made up; a phase change material with a lower phase change temperature is obtained. The provided low-temperature phase change energy storage material has stable performance, is nontoxic and noncorrosive, and can be recycled; the phase change temperature is about 4 DEG C, and the phase change energy storage material can be widely applied to the snow melting and deicing in various large airports and roads in the northern and plateau regions in winter; the problems of high energy consumption, long time consumption, environmental unfriendliness and the like can be effectively relieved.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

High molecular polycarboxylate dispersing agent

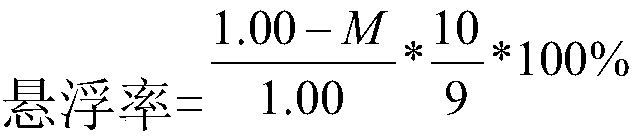

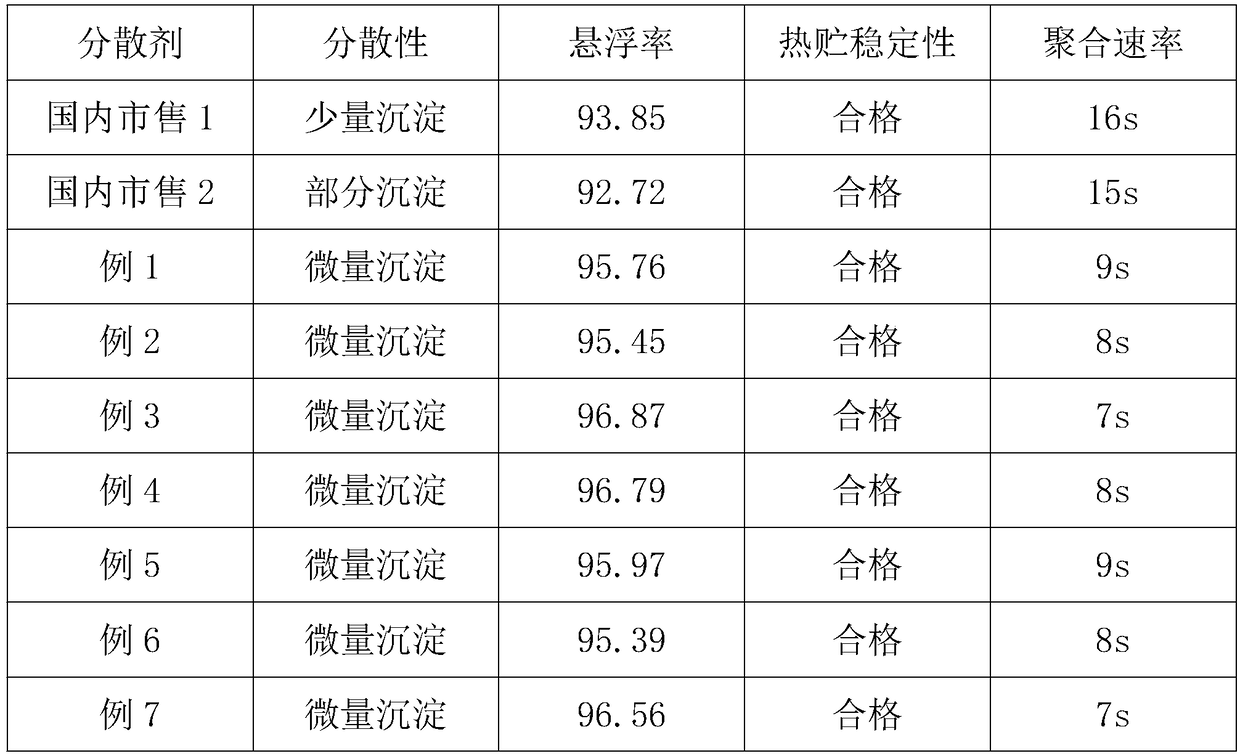

The invention discloses a high molecular polycarboxylate dispersing agent. The high molecular polycarboxylate dispersing agent contains the following raw materials in parts by weight: 100-800 parts ofitaconic acid, 10-100 parts of sodium hydrogen sulfite, 10-100 parts of n-decyl alcohol, 100-800 parts of tristyrene phenol polyoxyethylene ether, 100-500 parts of dialkyl polyoxyethylene ether methacrylate, 100-800 parts of N-oleoyl-N-methyl sodium taurate, 1000 parts of deionized water, 10-100 parts of an initiator and 10-20 parts of alkali; and the relative number average molecular weight of the high molecular polycarboxylate dispersing agent is 8000-50000. The high molecular polycarboxylate dispersing agent is synthesized by virtue of emulsion polymerization reaction, convenient to use, simple in process and suitable for being industrially produced; by virtue of a steric-hinerance effect and an electrostatic repulsion effect, a solution system is relatively stable and has a relativelygood dispersion effect, and the suspension rate of a preparation prepared from a small amount of the dispersing agent is about 96% according to National Committee On Pesticide Analysis.

Owner:南京拓际生物科技有限公司

Oregano-oil-containing antioxidant wire drawing oil

ActiveCN103992867AImprove the lubrication effectExtended service lifeLubricant compositionEpoxyBiodiesel

The invention relates to wire drawing oil, and in particular relates to oregano-oil-containing antioxidant wire drawing oil; the origanum-oil-containing antioxidant wire drawing oil comprises the following raw materials by weight: 120-140 parts of epoxy soybean oil, 45-60 parts of biodiesel, 5-8 parts of n-decyl alcohol, 1-2 parts of zinc primary-secondary alkyl sulfur phosphate, 1-2 parts of oregano oil, 10-12 parts of iso-tridecanol polyoxyethylene ether, 0.1-0.2 part of potassium stearate, 0.2-0.3 part of sodium benzoate, 1-2 parts of sulfurized isobutylene and 2-3 parts of an assistant; the oregano oil with excellent antibacterial antioxidant capacity is specially added in the formula of the oregano-oil-containing antioxidant wire drawing oil, the problem that the epoxy soybean oil in based oil is easy to oxidize and deteriorate can be effectively improved; by combination with other additives, the prepared wire drawing oil is environmentally-friendly, easy to degrade, good in thermal stability, more resistant to store, low in cost, and excellent in lubricating properties, and can meet wire drawing and drawing process of various metal wire materials.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

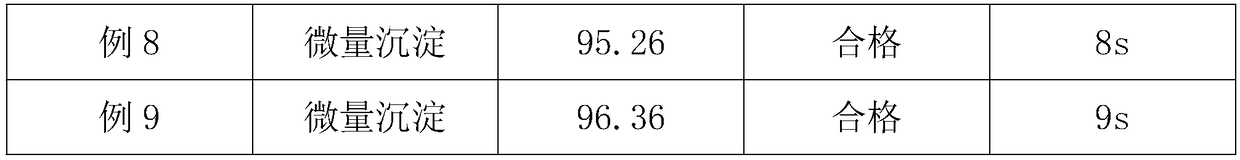

Method for synthesizing Vibativ intermediate

InactiveCN111233713ALow priceSimple oxidation conditionsCarbamic acid derivatives preparationOrganic compound preparationReaction temperatureSide reaction

The invention discloses a method for synthesizing a Vibativ intermediate. The method comprises the following steps: taking n-decanol and aminoethanol as starting materials, carrying out condensation and Fmoc-Cl amino protection, and performing oxidation to obtain N-(9-fluorenylmethoxycarbonyl)decylaminoacetaldehyde. 2, 2, 6, 6-tetramethylpiperidine oxide (TEMPO) is used as an oxidizing agent, a reaction temperature is below 0 DEG C, dichloromethane is used as a solvent, the primary alcohol is selectively controlled to be oxidized into aldehyde, materials involved in synthesis are low in price,the synthesis cost is greatly reduced, the synthesis yield is high, side reactions are few, all synthesis steps are easy to operate, follow-up treatment is simple and environmentally friendly, TEMPOoxidation conditions are mild, the pH value and the reaction temperature of a reaction liquid are controlled, aldehyde is obtained by selective oxidation, the reaction conditions are easy to control,and follow-up treatment is simple.

Owner:福建康鸿生物科技有限公司

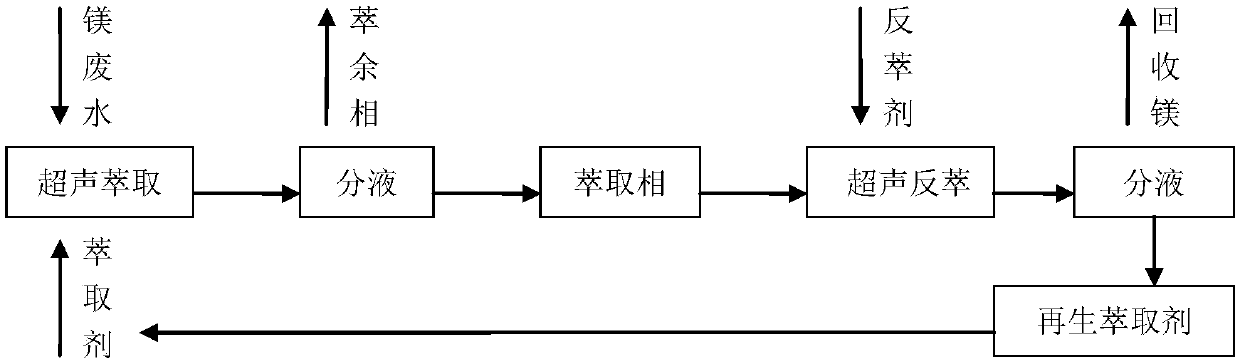

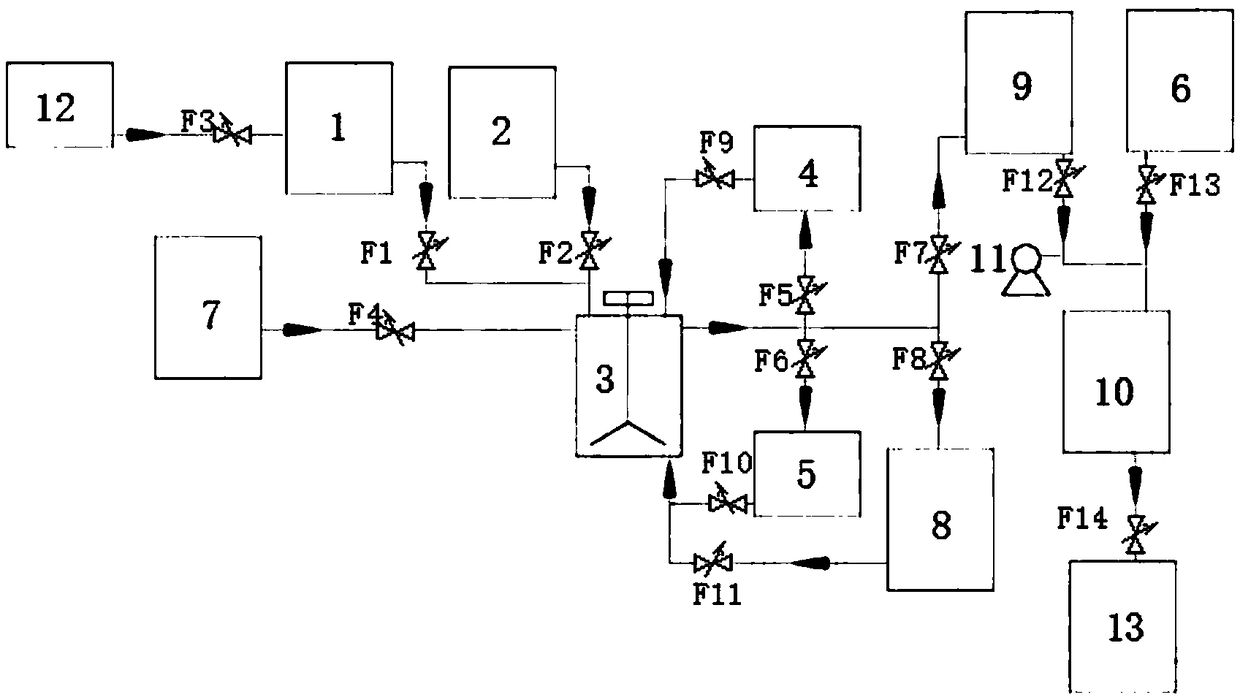

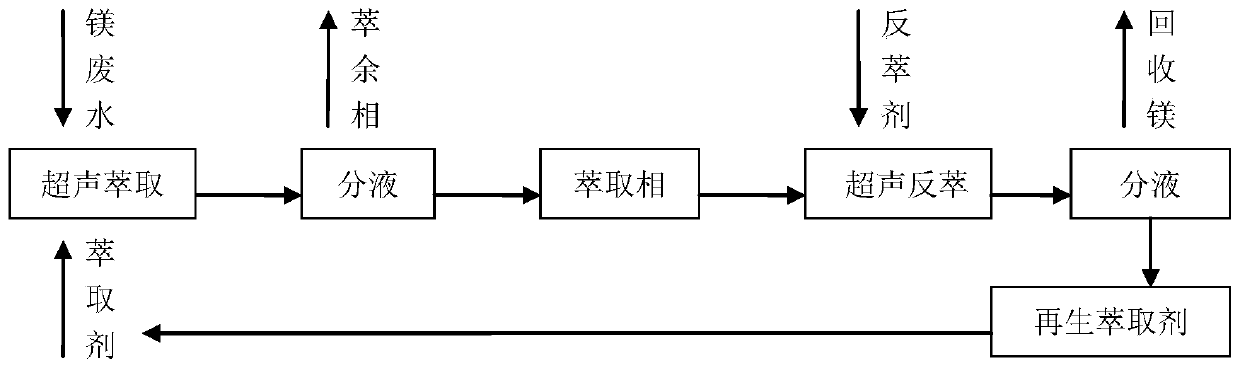

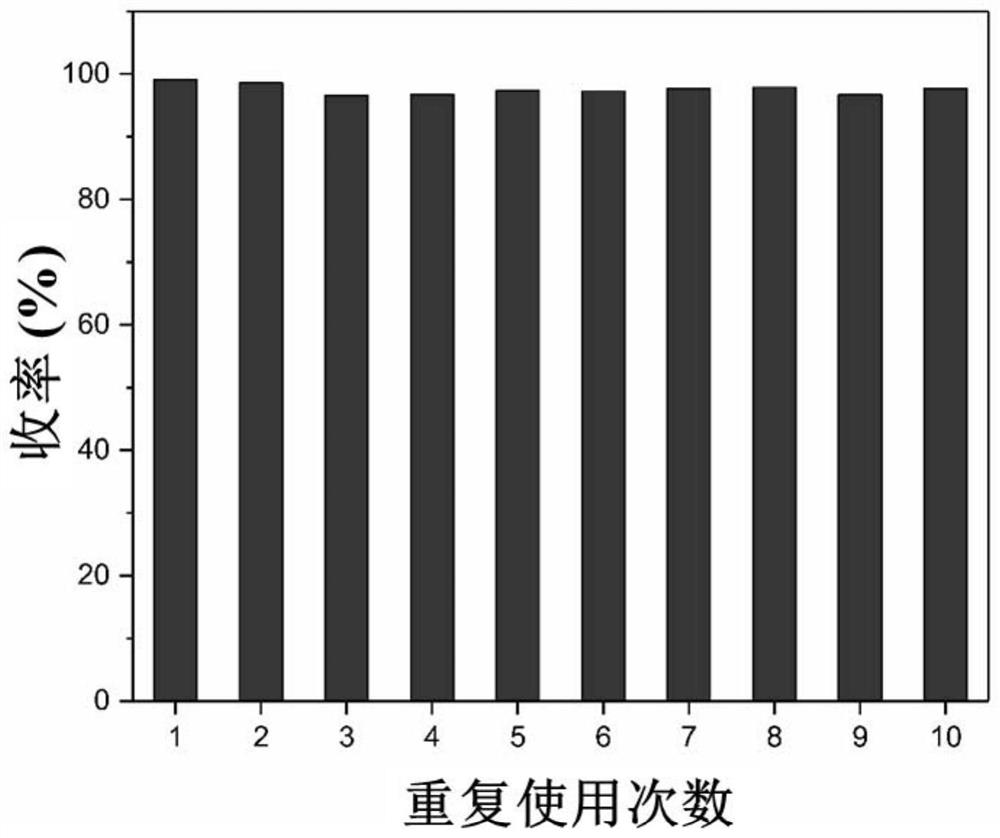

Method for extracting magnesium from metallurgical waste water

ActiveCN107585822AHigh single-stage extraction rateProduction environmental protectionWaste water treatment from metallurgical processLiquid solutions solvent extractionSingle stageKerosene

The invention discloses a method for extracting magnesium from metallurgical waste water. According to the method, magnesium is prepared by the steps of performing an extracting process and performinga back-extracting process respectively by taking sulphonated kerosene as a diluting solvent, taking dinonyl naphthalene sulphonic acid, di(2-ethylhexyl)phosphate and n-decyl alcohol as composite extracting solvents and taking sulphuric acid as a back extracting agent; the method for extracting the magnesium from the metallurgical waste water disclosed by the invention has the characteristics thatthe production process is green, environmentally friendly and production-free, the production and operation cost is low and large-scale production is facilitated. The method for extracting the magnesium from the metallurgical waste water disclosed by the invention has the advantages that high extracting speed and short extracting and back-extracting time are achieved; the extracting process and the back-extracting process can be completed within 2 to 3 minutes respectively; the liquid separating time is short and only requires 3 to 5 minutes after the extracting and the back-extracting are ended; as the method disclosed by the invention has the advantages of high extracting speed and short time consumption, a continuous feeding extracting process can be realized; moreover, the single-stage extracting rate of the extracting process and the single-stage extracting rate of the back-extracting process of the method are high, and can be up to 86.59 percent and 96.31 percent respectively; aproduction process is simple and feasible, and popularization and application are facilitated.

Owner:CHONGQING THREE GORGES UNIV

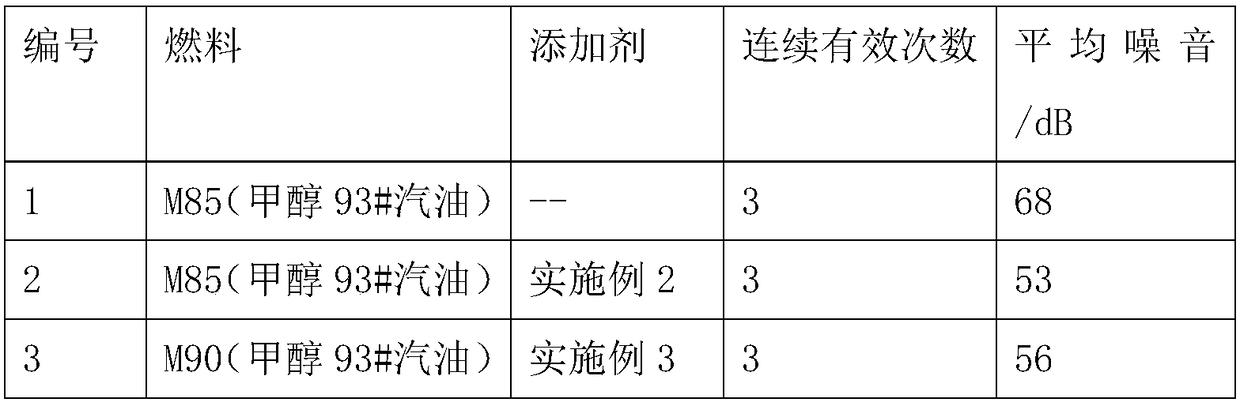

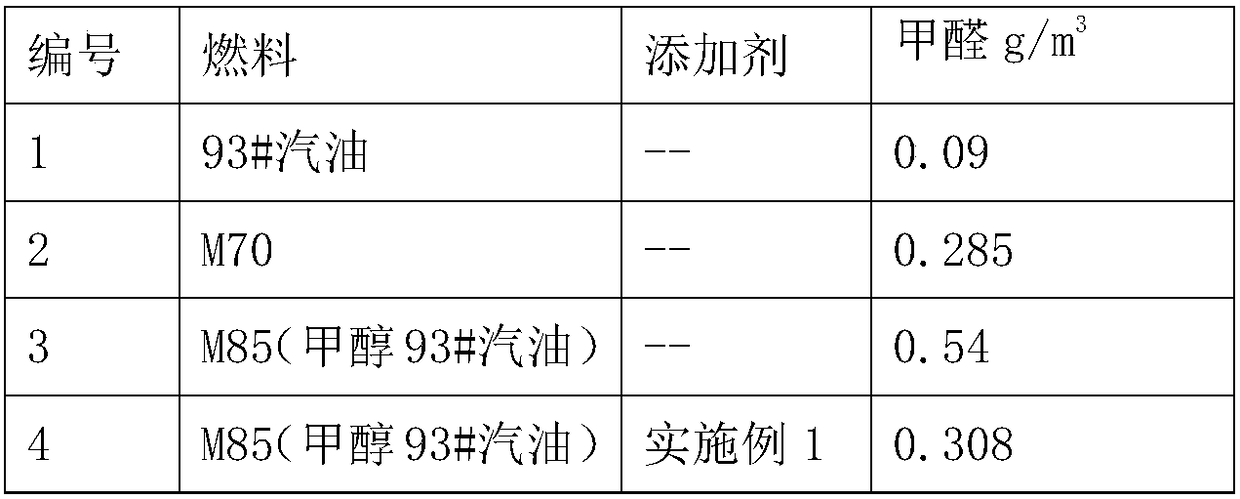

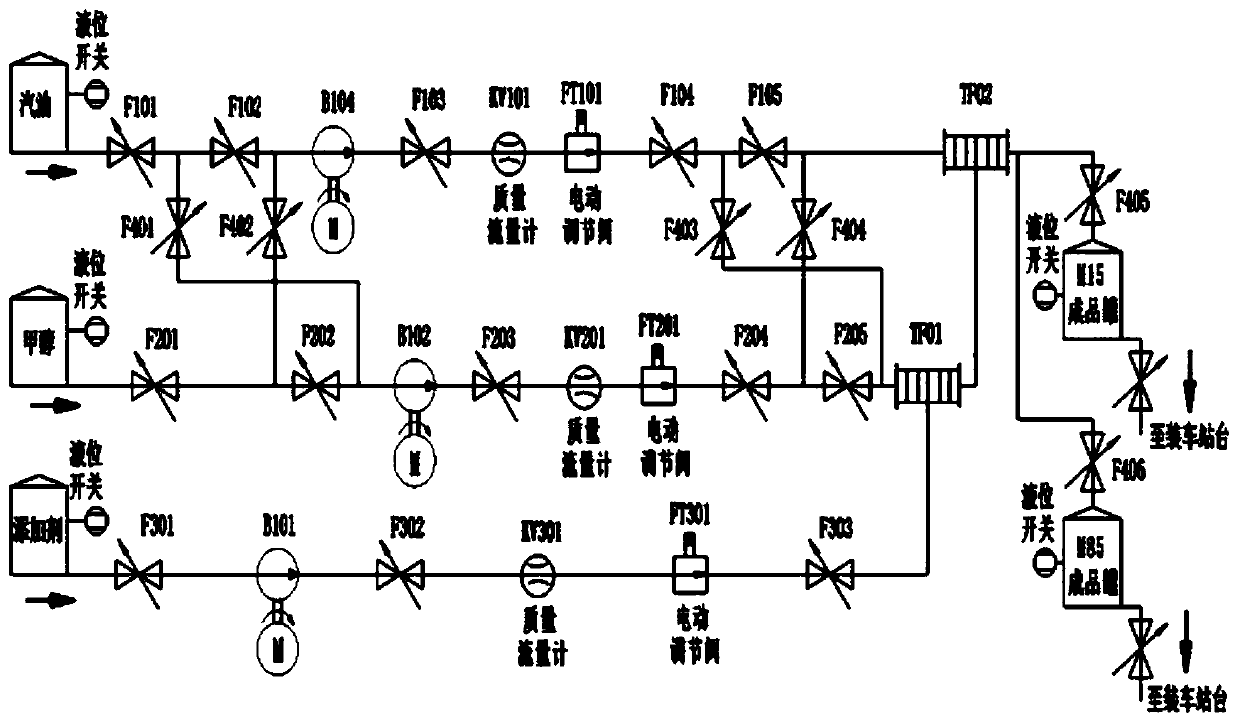

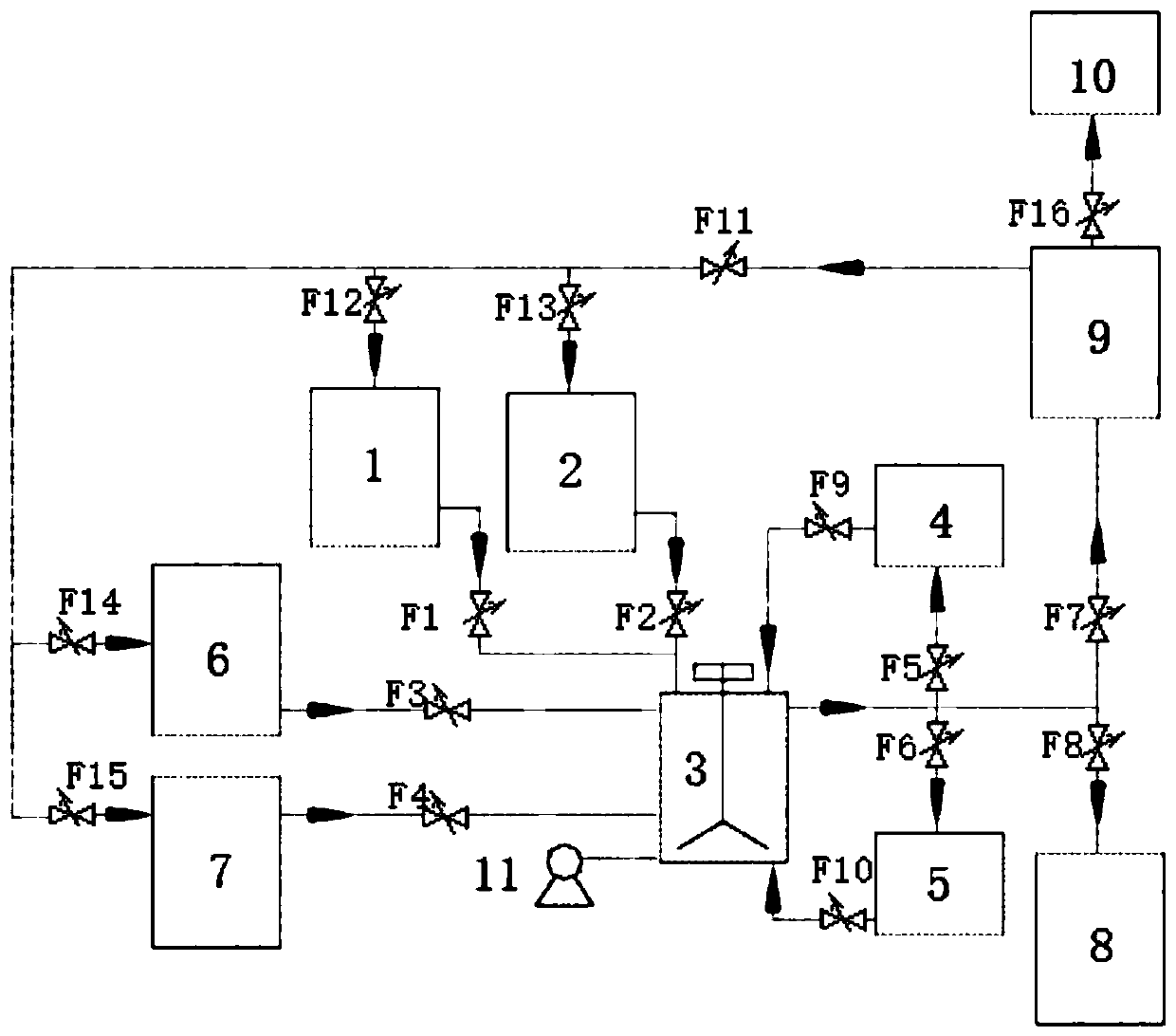

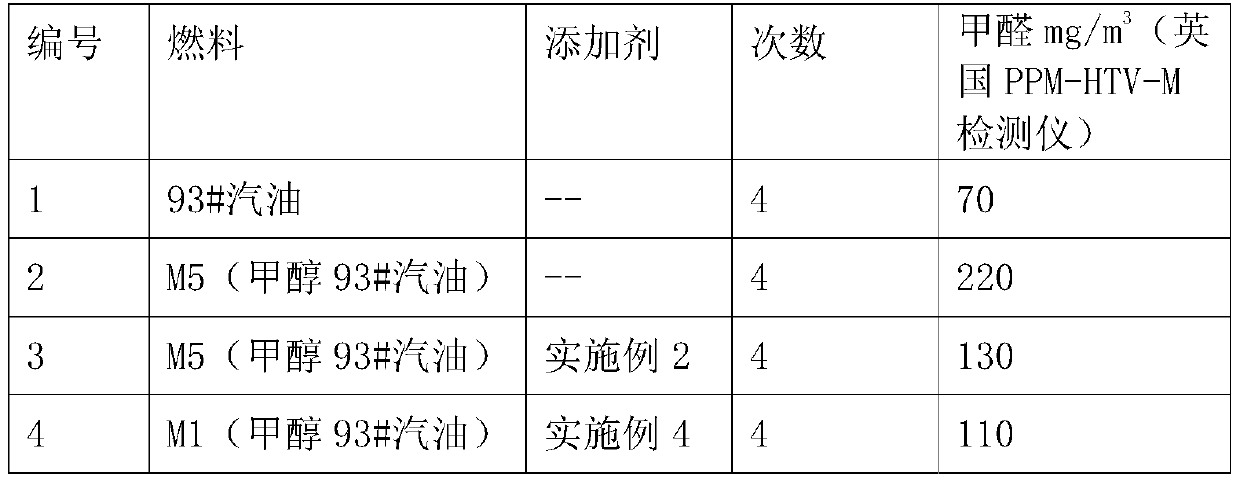

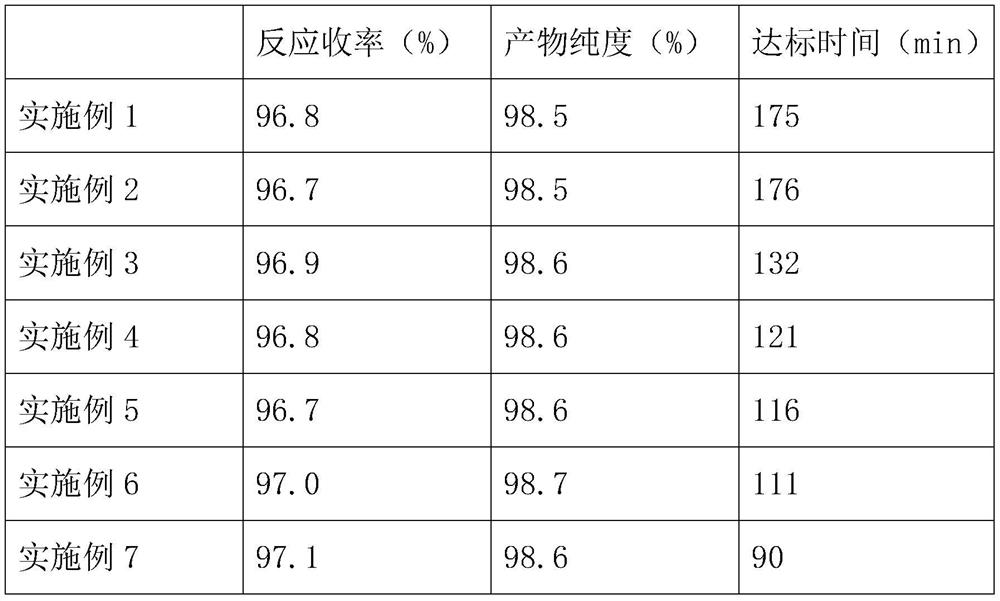

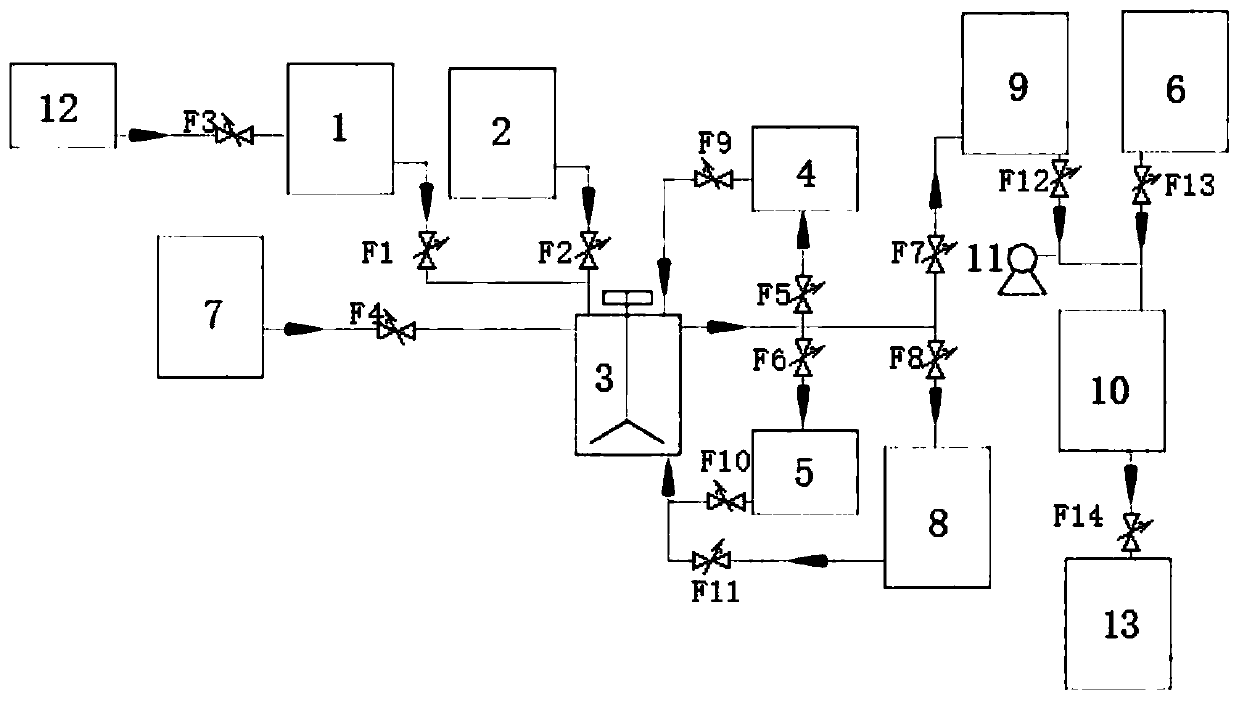

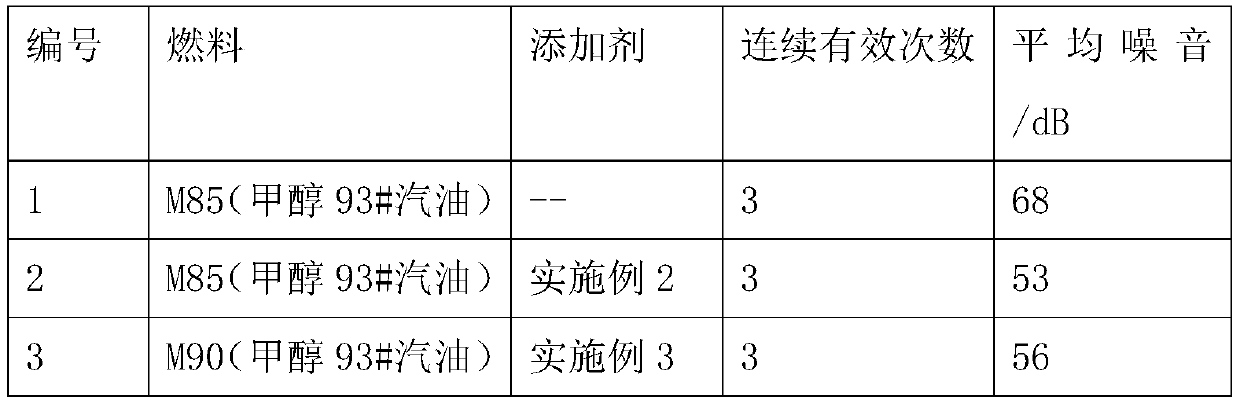

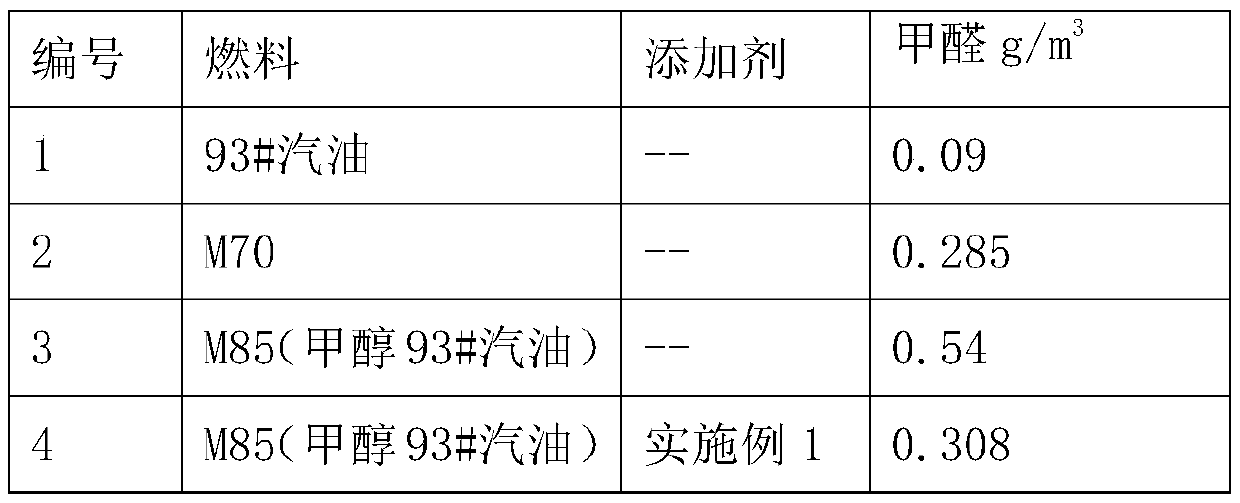

High-methanol gasoline additive composition for engine at low temperature and methanol gasoline of high-methanol gasoline additive composition

InactiveCN109321292AAvoid serious pollutionReduce generationLiquid carbonaceous fuelsFuel additivesGasolineOil additive

The invention belongs to the field of high-methanol gasoline at a low temperature and particularly relates to a high-methanol gasoline additive composition for an engine at the low temperature and methanol gasoline of the high-methanol gasoline additive composition. The high-methanol gasoline additive composition is characterized by being prepared from the following components in percentage by mass: 30 percent of a modifier A, 32-42 percent of a modifier B and the balance of acetone and being prepared by the following special steps of 1) after heating a stirring tank, adding n-decyl alcohol, mixing bis(2-dimethylaminoethyl) ether in the n-decyl alcohol, and performing centrifugal stirring for 8-20 min to obtain the modifier A, wherein the number of revolutions for centrifugal stirring is 1500 r / min, and the mass ratio of the bis(2-dimethylaminoethyl) ether to the n-decyl alcohol is 1 to 5; 2) after heating the stirring tank, adding isodecanol, mixing anhydrous hydrazine in the isodecanol, and performing stirring for 8-20 min to obtain the modifier B, wherein the mass ratio of the anhydrous hydrazine to the isodecanol is (1 to 7)-(1 to 6); and 3) mixing the modifier A, the modifierB and the acetone to obtain the additive composition. The additive at the low temperature and the methanol gasoline thereof are clean and environmentally friendly and are low in noise and less in yield of formaldehyde.

Owner:深圳市端致科技材料有限公司

Anti-alcohol, anti-plasma, anti-static and leak-proof functional non-woven fabric

Owner:江阴金凤特种纺织品有限公司

Synthetic method of 1, 3-didecyl glyceryl ether ethoxylate

InactiveCN104030897AImprove lipophilicityImprove surface activityEther preparation from oxiranesDrilling compositionGlycineBetaine

The invention discloses a synthetic method of 1, 3-didecyl glyceryl ether ethoxylate. According to the technical scheme, the synthetic method comprises three synthesis operations: reacting n-decyl alcohol with epoxy chloropropane to obtain decyl glycidyl ether and 1, 3-didecyl glyceryl ether; and adding ethylene oxide to the 1, 3-didecyl glyceryl ether to obtain the 1, 3-didecyl glyceryl ether ethoxylate. The method disclosed by the invention has the following effects that the ethoxylate has good lipophilicity and surface activity; the ethoxylate is compounded with a carboxyl glycine betaine ampholytic surfactant to reduce the tension of crude oil / formation water balanced interface to 10<-3>mN / m order of magnitudes without adding any alkalis, basic salts, neutral electrolytes or cosurfactants.

Owner:JIANGSU WAN QI BIOLOGICAL TECH

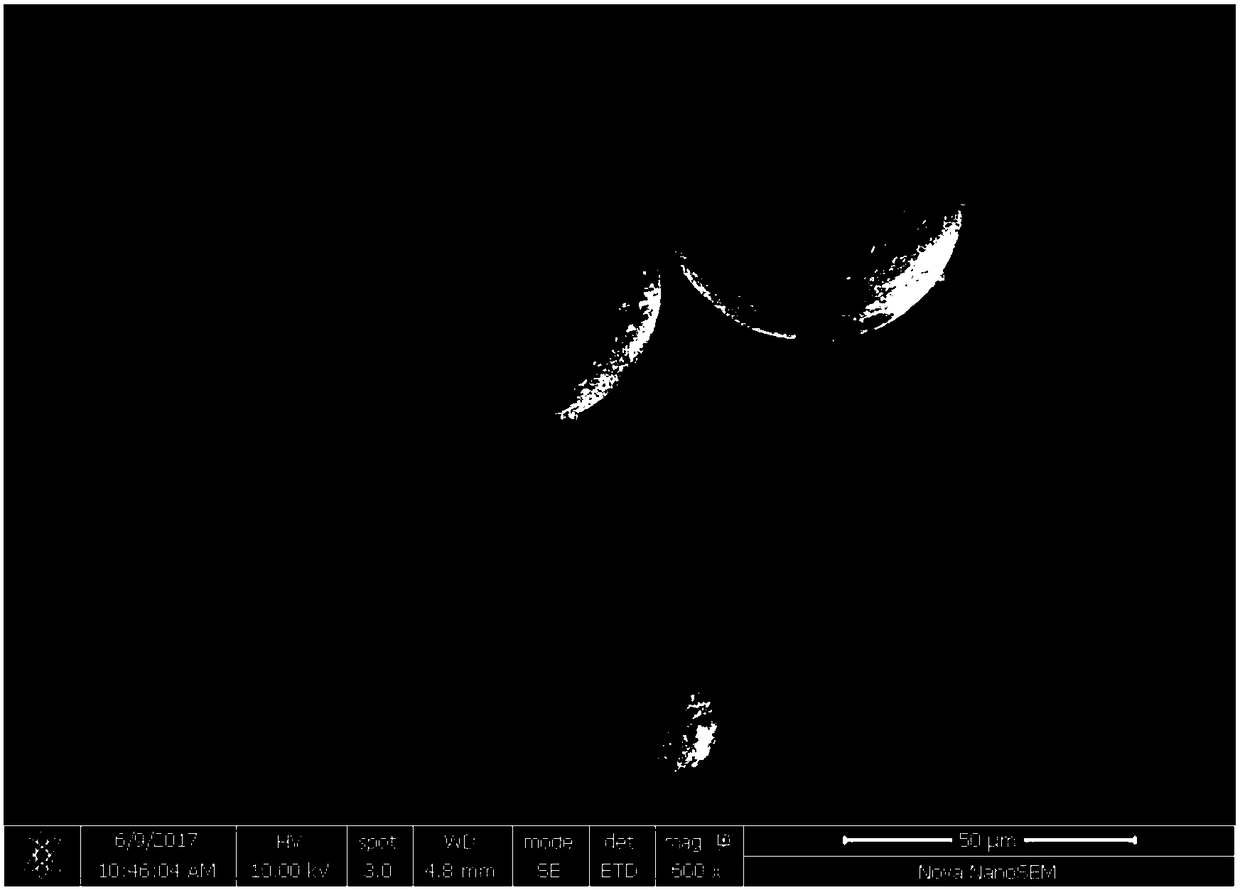

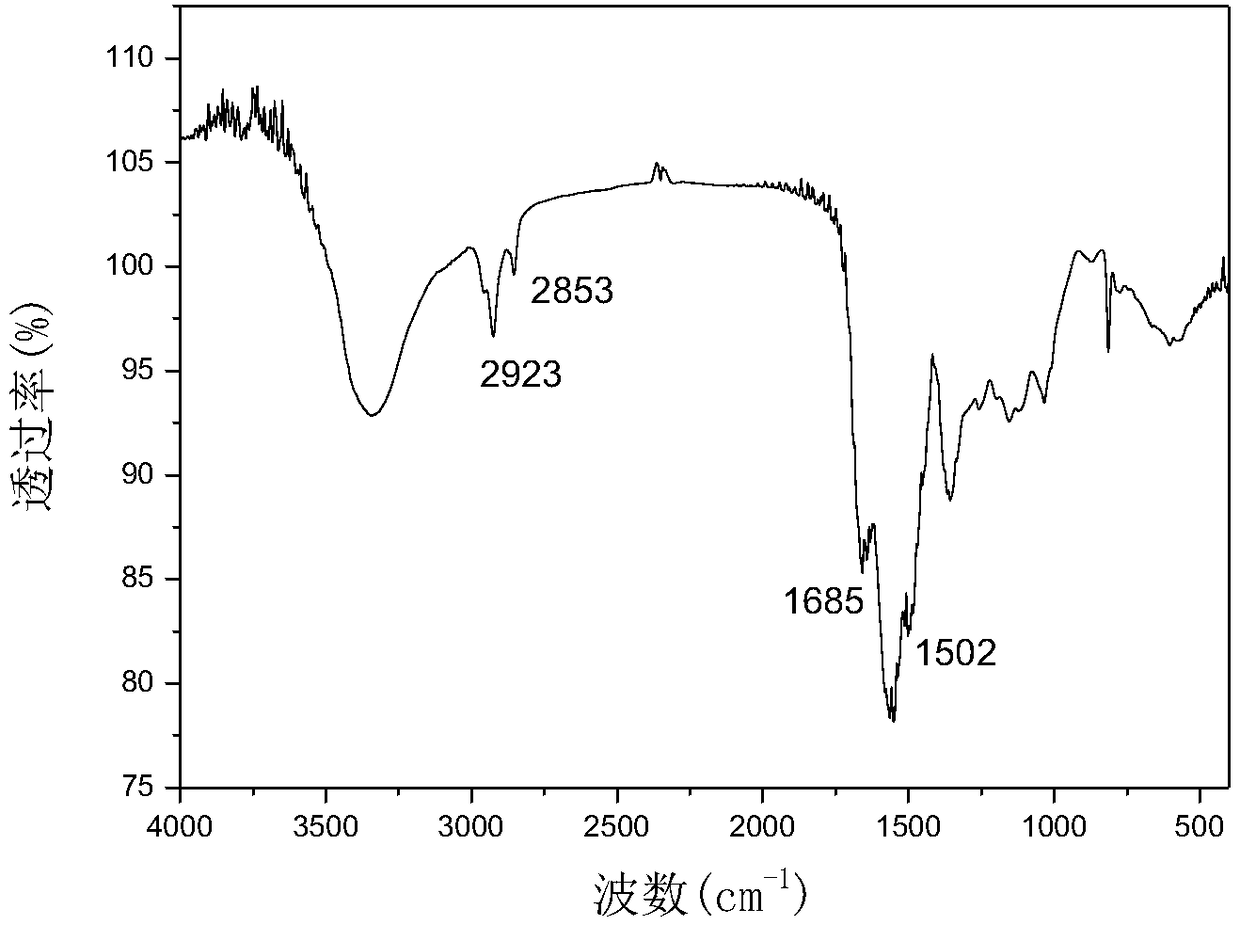

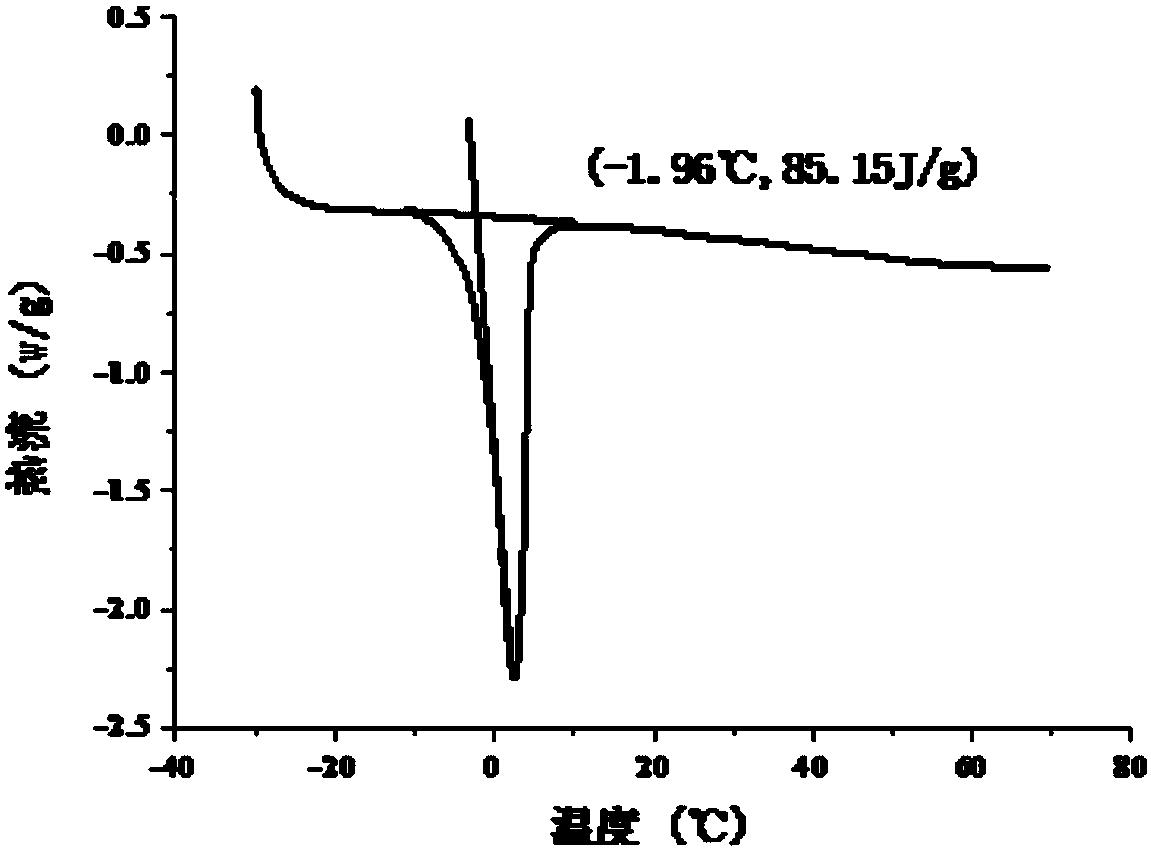

Preparation method of enhanced type self-temperature adjustment material based on n-decyl alcohol/lauric acid phase change microcapsule

InactiveCN108148557ARecyclableWith green cleaningHeat-exchange elementsMicroballoon preparationTemperature controlPhase change

The invention relates to a preparation method of a low temperature adjustment agent taking n-decyl alcohol / lauric acid / melamine modified urea formaldehyde resin / polypropylene as a temperature adjustment material. The preparation method comprises the following steps: mixing n-decyl alcohol and lauric acid in a certain proportion; coating the mixture with urea / melamine / formaldehyde resin to obtain amicrocapsule on the premise that a proper emulsifier is selected, wherein the microcapsule has a maximum endothermic peak of 85.15 J / g at -1.96 DEG C; adding the prepared microcapsule into polypropylene in a certain proportion; and performing extrusion with a double screw extruder by reasonably controlling the extrusion temperature so as to obtain a final product. The product has certain self-temperature adjustment performance, has a certain temperature control effect in a range of -20 DEG C to 10 DEG C, and reaches the maximum endothermic peak of 15.41 J / g at -4.21 DEG C. The preparation method provided by the invention has the advantages of efficient and quick preparation, reversible and recyclable temperature adjustment process, waste reduction, simple technology, low cost, greenness,environmental protection, wide application prospect and the like, and the product has certain mechanical performance.

Owner:TONGJI UNIV

A composition for engine low-alcohol gasoline additive and its preparation method

InactiveCN109456804BReduce gas explosionReduce generationLiquid carbonaceous fuelsOil additiveMaterials science

The invention belongs to the field of methanol gasoline additives, and particularly relates to a composition for low-alcohol gasoline additives for engines and a method for preparing the composition.The composition for the additives comprises, by weight, 21% of modifiers A, 36-45% of modifiers B, 3% of nanometer combustion improvers and the balance acetone. Stirring tanks are vacuumized and are heated until the temperatures of the stirring tanks reach 30-35 DEG C, then ethylene glycol monomethyl ether and glycerin are mixed with each other and are centrifugally stirred for 8-20 min to obtainthe modifiers A, the centrifugal stirring numbers of turns are 1500 r / min, and a mass ratio of the ethylene glycol monomethyl ether to the glycerin is 1:6; stirring tanks are vacuumized and are heateduntil the temperatures of the stirring tanks reach 30-35 DEG C, then bis-dimethylamino ethyl ether and n-decyl alcohol are mixed with each other and are centrifugally stirred for 8-20 min to obtain the modifiers B, the centrifugal stirring numbers of turns are 1500 r / min, and a mass ratio of the bis-dimethylamino ethyl ether to the n-decyl alcohol is 1:8-1:5. The composition and the method have the advantage that the problems of difficulty in starting under the low-temperature conditions, unclean and non-environment-friendly tail gas and high noise can be solved by the aid of the compositionand the method.

Owner:中丽石油化工(浙江自贸区)有限公司

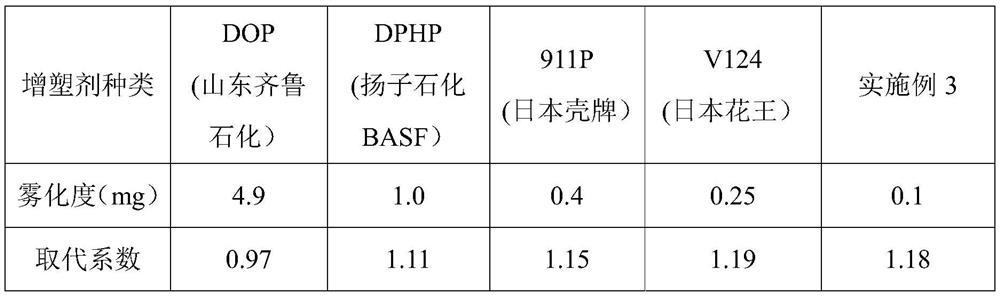

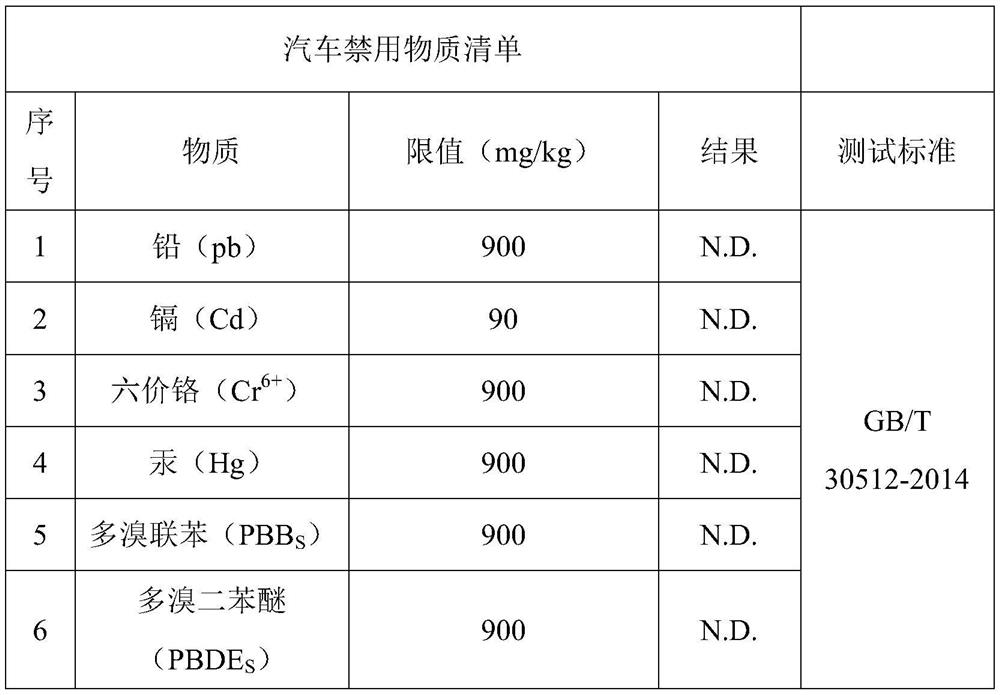

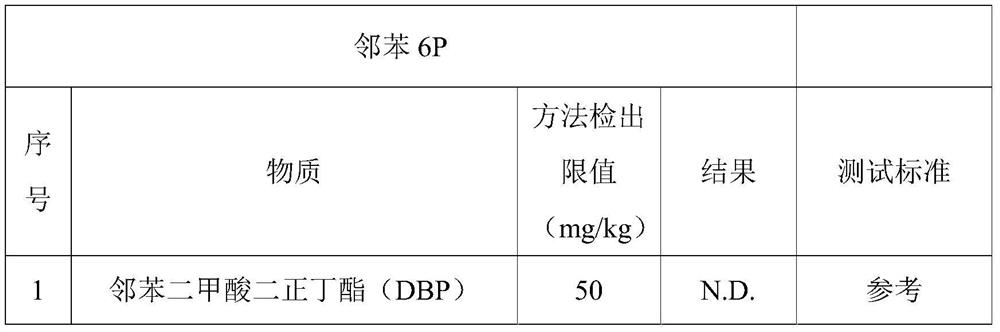

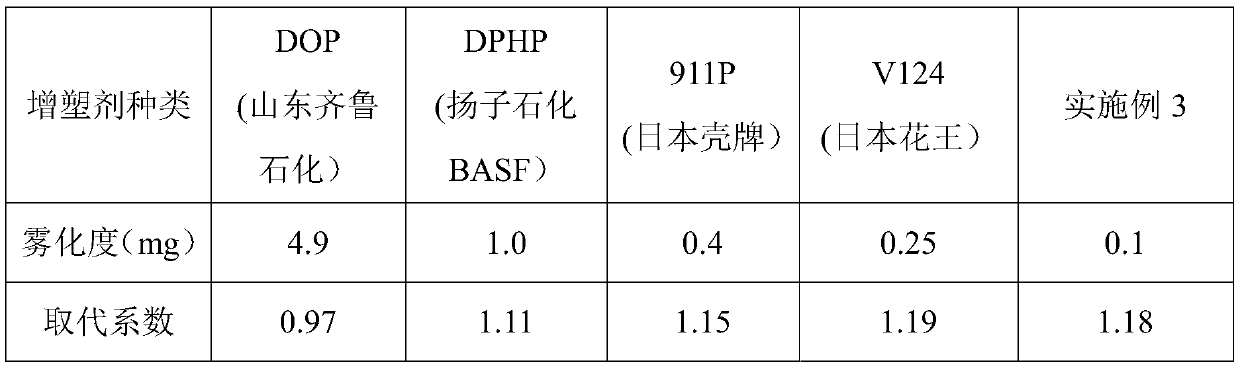

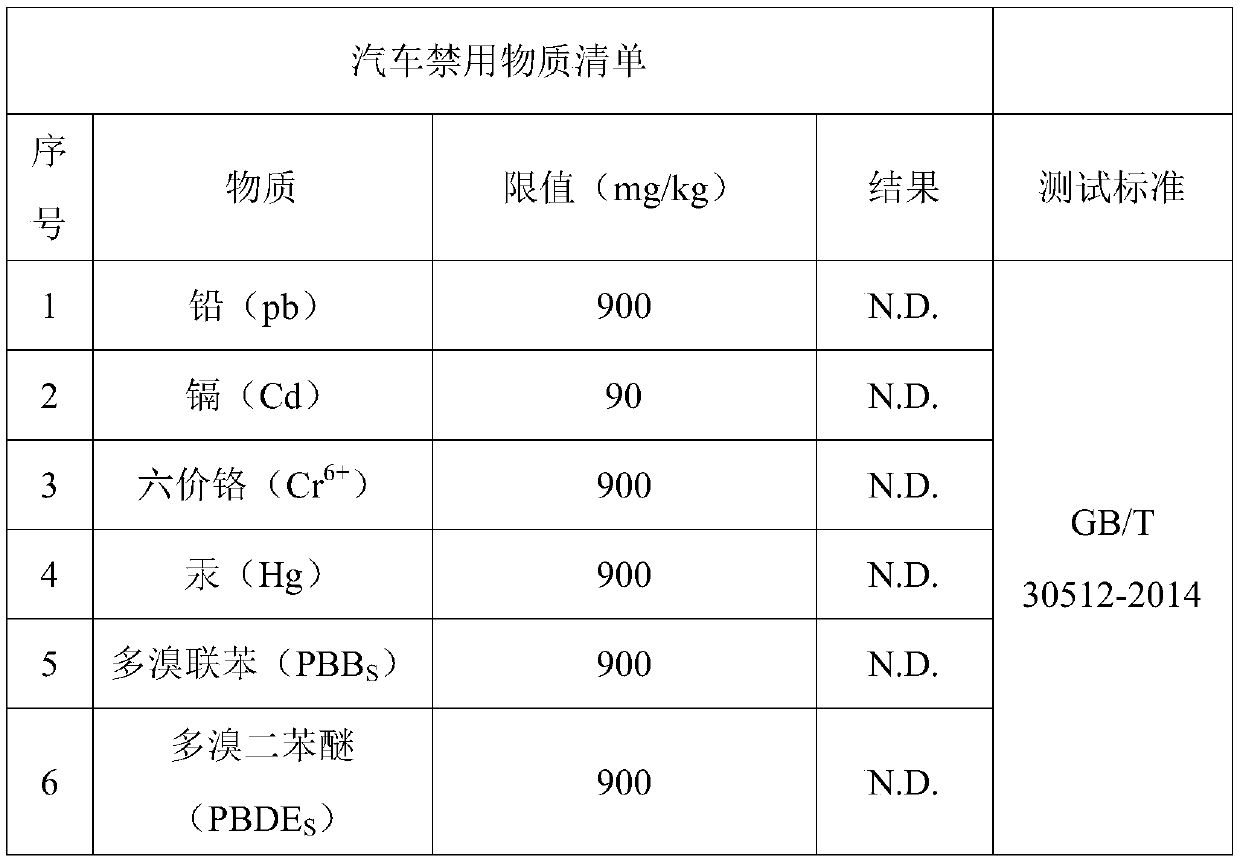

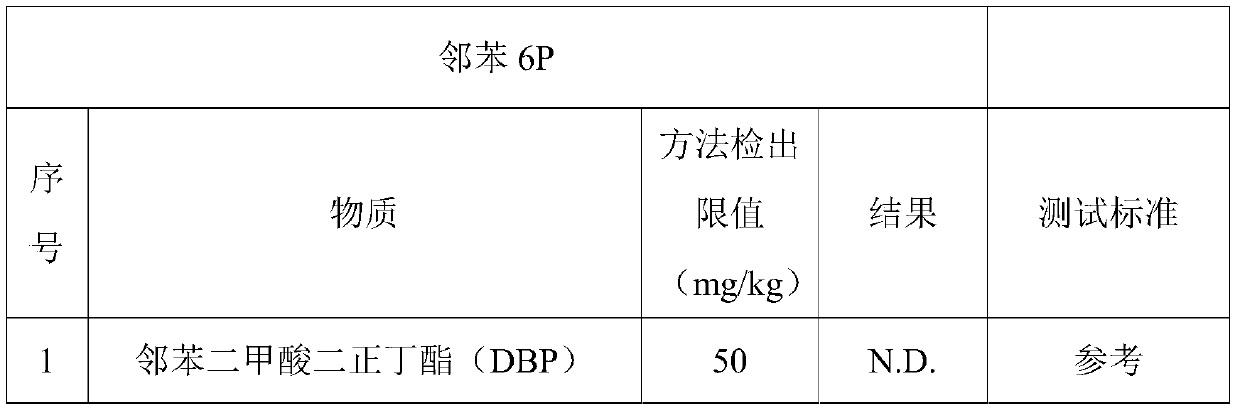

A kind of plasticizer composite, preparation method and PVC composite material containing the same

ActiveCN111499925BReduce color depthGood for multi-field useOrganic compound preparationCarboxylic acid esters separation/purificationAlkaline waterPolymer science

The present invention relates to the technical field related to plasticizers, and more particularly, the present invention provides a plasticizer compound, a preparation method and a PVC compound material containing the same. A first aspect of the present invention provides a plasticizer compound, the preparation raw materials include dianhydrides, alcohols, catalysts, alkaline water and filter aids; wherein, the alcohols include n-decanol. The invention mainly provides a light-colored plasticizer, which improves the processing performance of the plasticizer and the PVC matrix material, and simultaneously improves the temperature resistance of the product obtained by using the plasticizer, reduces the haze and the taste of the composite material, And reduce VOC gas emissions.

Owner:JIANGSU SENHE CHEM TECH CO LTD

Plasticizer compound and preparation method thereof and PVC composite material containing plasticizer compound

ActiveCN111499925AReduce color depthGood for multi-field useOrganic compound preparationCarboxylic acid esters separation/purificationAlkaline waterPolymer science

The invention relates to the technical field related to plasticizers, and particularly provides a plasticizer compound and a preparation method and a PVC composite material containing the plasticizercompound. A first aspect of the invention provides a plasticizer compound. The plasticizer compound is prepared from the following raw materials: a dianhydride substance, an alcohol substance, a catalyst, alkaline water and a filter aid, wherein the alcohol substance comprises n-decanol. The invention mainly provides a light-colored plasticizer, which improves the processability of the plasticizerand a PVC matrix material, improves the temperature resistance of a product obtained by using the plasticizer, reduces the haze and the taste of a composite material, and reduces the discharge amountof VOC gas.

Owner:JIANGSU SENHE CHEM TECH CO LTD

Reagent and method for splitting ofloxacin racemate by using ionic liquid and l-dibenzoyl tartaric acid

ActiveCN103709176BHigh selectivityImprove the efficiency of chiral resolutionOptically-active compound separationOrganic racemisationSeparation factorL-ofloxacin

The invention discloses reagents and a method for separation of ofloxacin racemic mixture by utilization of ionic liquid and L-dibenzoyltartaric acid together. Ofloxacin racemic mixture and alkyl imidazole L-tartrate ionic liquid are dissolved in deionized water and a water phase is formed. At the same time, L-dibenzoyltartaric acid is dissolved in n-decyl alcohol and an organic phase is formed. The organic phase and the water phase are mixed and placed in a vibrator for vibration, and then the mixture is permitted to stand. The concentrations of L-ofloxacin and D-ofloxacin in the water-phase clear solution are detected. The concentrations of L-ofloxacin and D-ofloxacin in the organic phase are obtained through a law of conservation of mass respectively. The distribution coefficients of L-ofloxacin and D-ofloxacin are calculated respectively, and therefore the separation factor is calculated, the separation effect is good and the separation is successful. Separation of ofloxacin racemic mixture is achieved by utilization of alkyl imidazole L-tartrate ionic liquid and L-dibenzoyltartaric acid together, the separation efficiency is raised, required reagents for separation are reduced, the operation technology is simple, the selectivity is high, and the method is suitable for industrial production.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

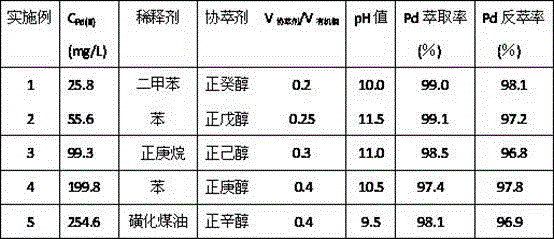

Method for extracting palladium from alkaline cyanide solution with dodecyldimethyl-2-phenoxyethyl ammonium bromide

InactiveCN104313324BFree from destructionLarge range of valuesProcess efficiency improvementKeroseneN-Heptanol

The invention relates to a method for extracting palladium from an alkaline aurocynide solution by using dodecyl dimethyl-2-phenoxyacetic ammonium bromide and belongs to noble metal hydrometallurgy. The method comprises the following steps: adjusting pH of [Pd(CN)4]2- slurry to 9.5-11.5 as an aqueous phase of an extraction system; by using dodecyl dimethyl-2-phenoxyacetic ammonium bromide (DDPB for short) as an extraction agent, one of n-amyl alcohol, hexyl alcohol, n-heptanol, n-octyl alcohol or n-decyl alcohol as a synergist and one of benzene or xylene or n-heptane or sulfonated kerosene as a diluent, mixing phases and standing to layer as the concentration of DDPB in an organic phase is 0.01-0.03mol / L; transferring [Pd(CN)4]<2-> from the aqueous phase to the organic phase, and reversely extracting palladium from a 0.1-0.3mol / LNH3SCN liquid; and the like. The solvent provided by the invention is saturated in extraction system and high in extraction capacity, easy to reversely extract, short in extraction period and low in cost, and has promotional and application prospects.

Owner:YUNNAN UNIV

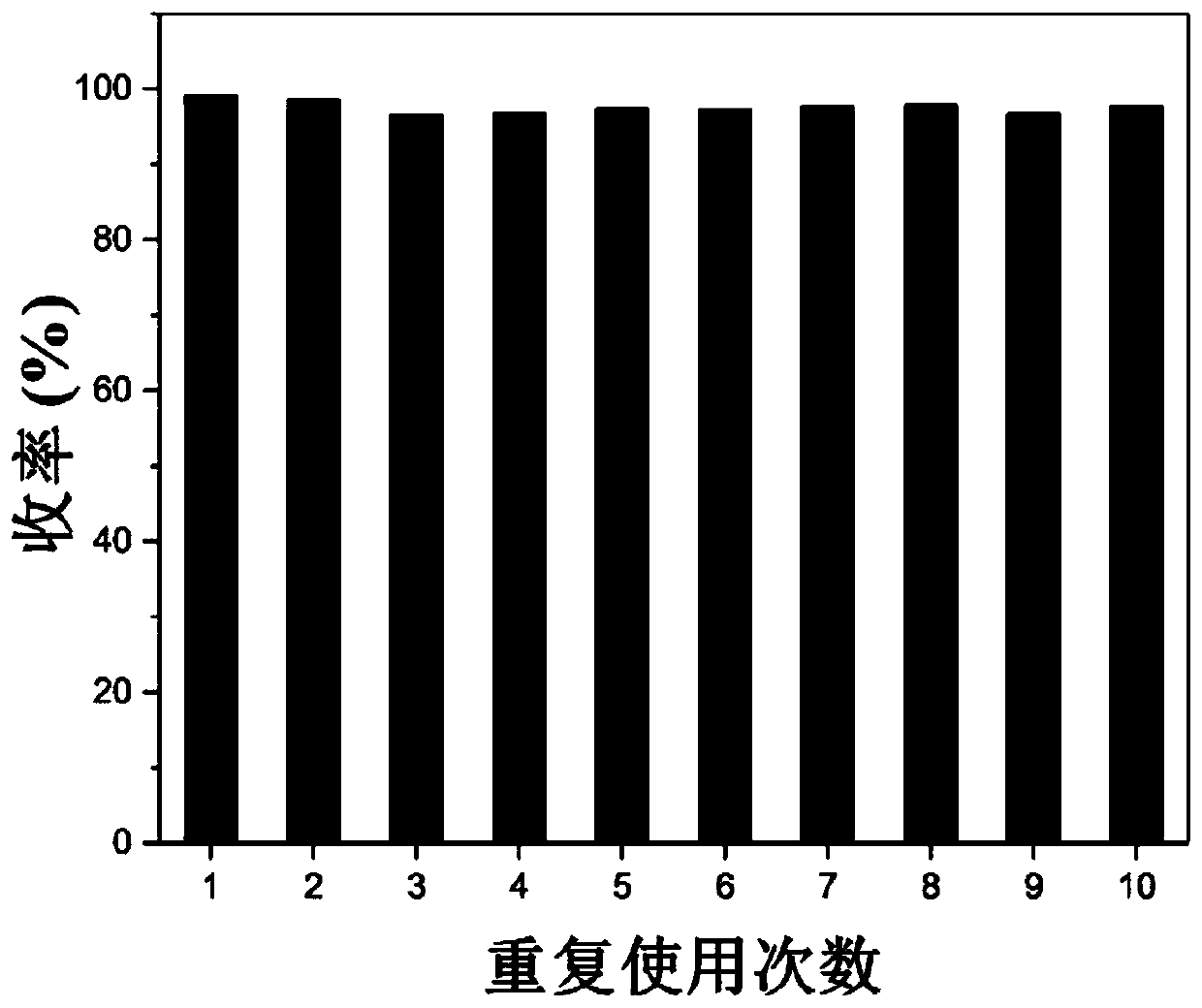

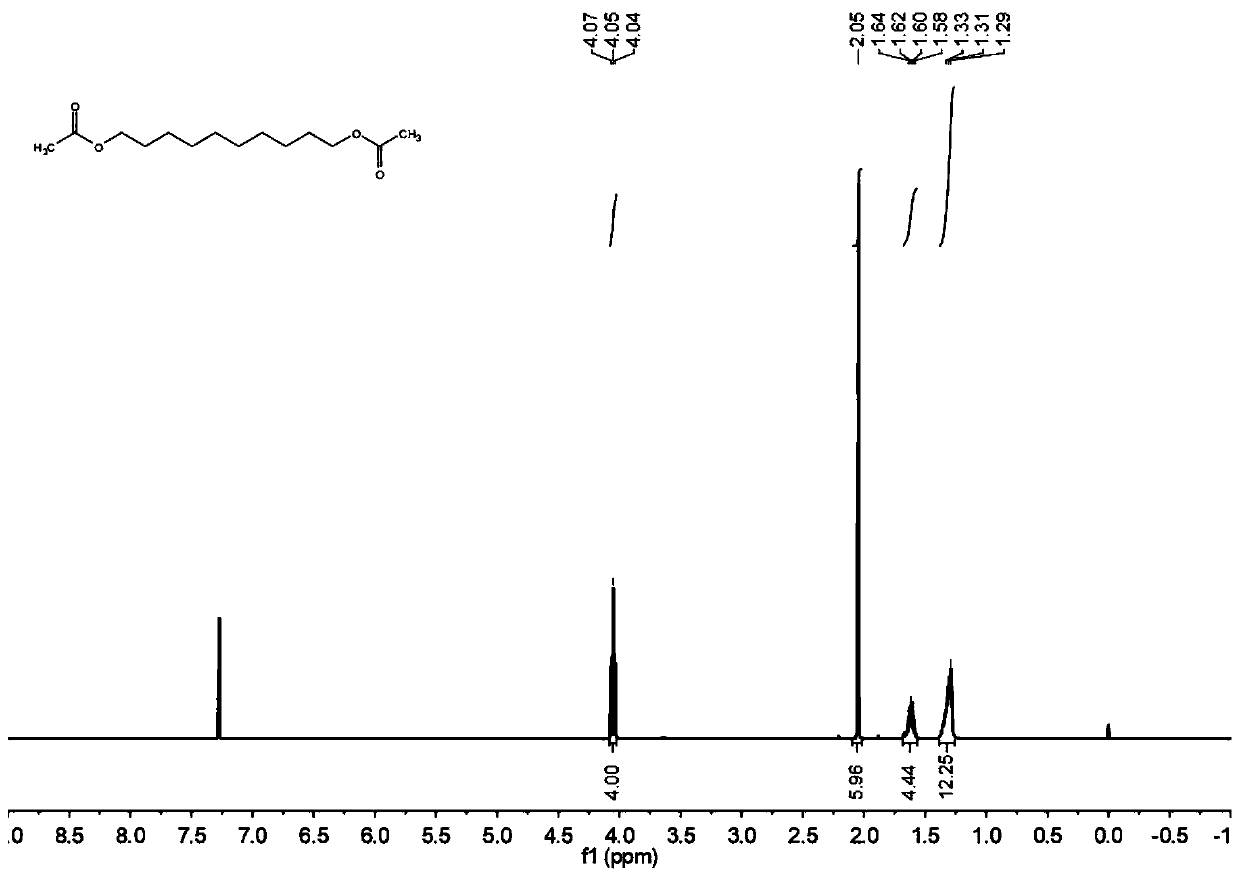

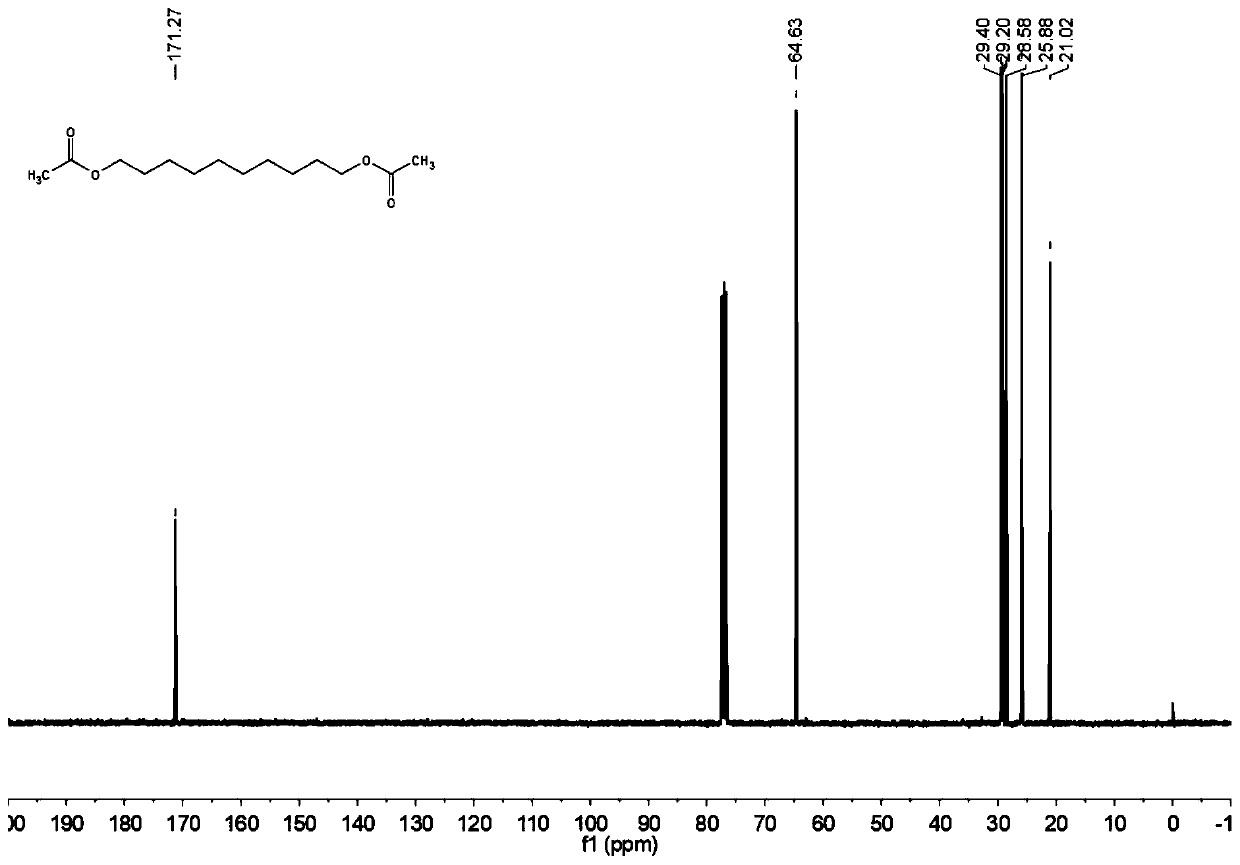

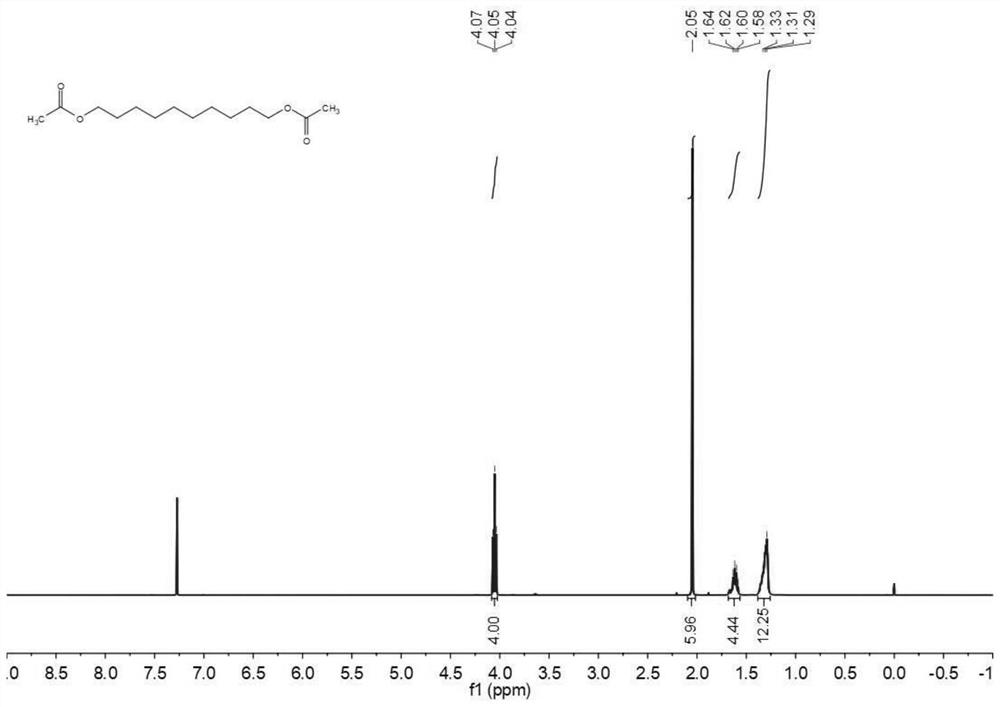

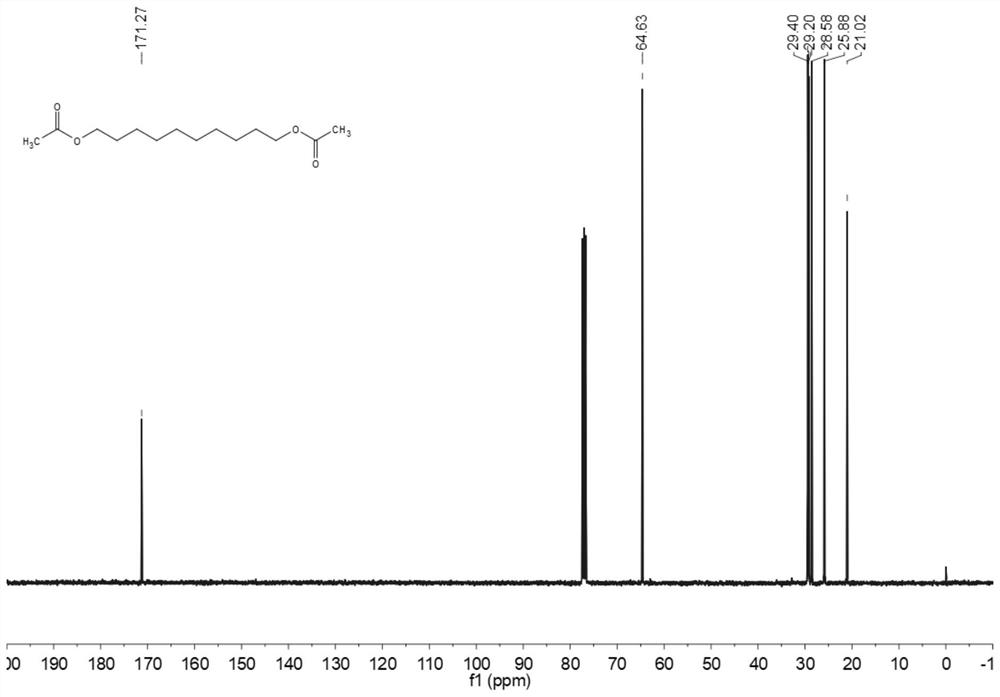

Method for preparing decanediol dicarboxylate and derivative thereof

ActiveCN111018701AGood reproducibilityHigh yieldOrganic compound preparationCarboxylic acid esters preparationPtru catalystFurfural

The invention discloses a method for preparing decanediol dicarboxylate and a derivative thereof. The furfural is used as a raw material and can be obtained by hydrolyzing hemicellulose, and the furfural is efficiently converted into decanediol dicarboxylic ester, carboxylic acid n-decyl ester and corresponding alcohol through two steps of condensation and hydrogenolysis. The method is characterized in that a compound shown as a formula (I) is used as a raw material, and under the dual action of trifluoromethanesulfonate and a hydrogenation catalyst, decanediol dicarboxylate and carboxylic acid n-decyl ester are obtained through selective hydrodeoxygenation in an acid solvent. A saponification reaction is carried out on the product to obtain 1, 10-decanediol and n-decanol. The method has the advantages of cheap and accessible raw materials, high product yield, high product purity, low environmental pollution and simple process route, and is suitable for industrial production.

Owner:UNIV OF SCI & TECH OF CHINA

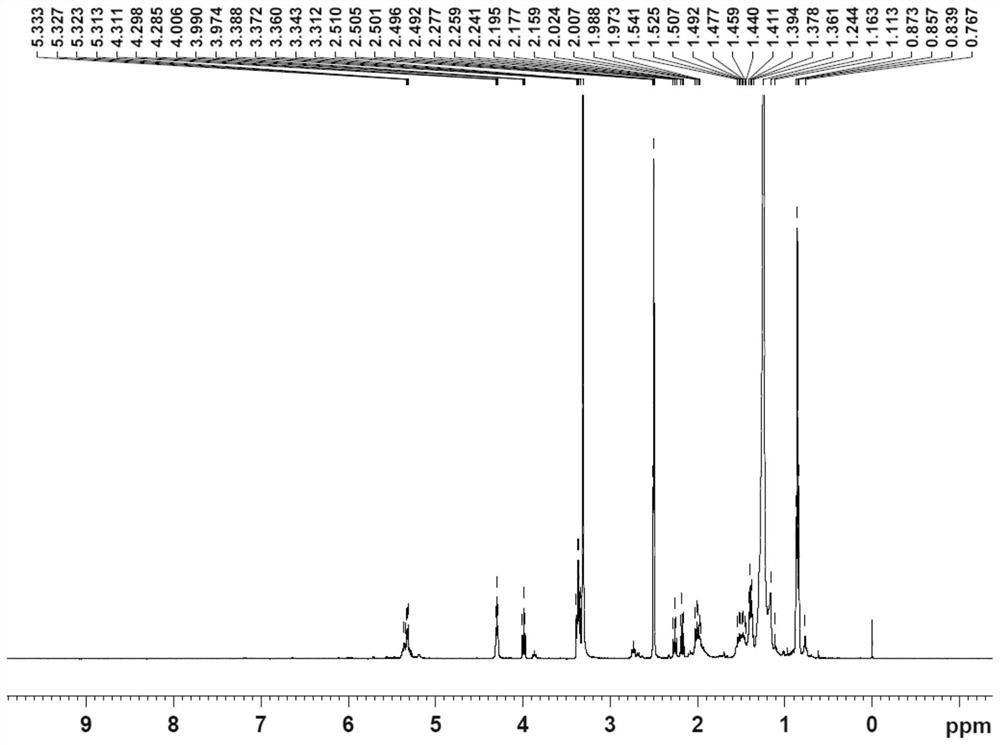

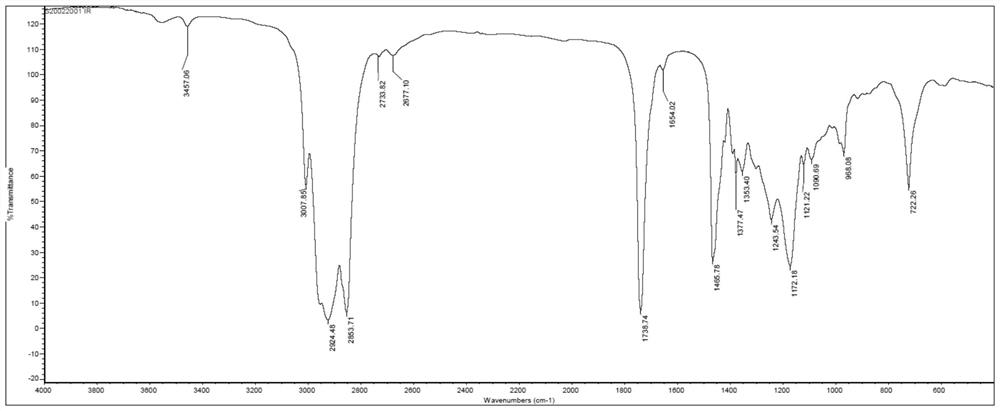

The preparation method of decyl oleate

ActiveCN111423328BImprove conversion rateHigh purityOrganic compound preparationCarboxylic acid esters preparationPtru catalystReaction rate

The present invention relates to the technical field of compound synthesis. Aiming at the problem that there is no preparation method of decyl oleate in the prior art, a preparation method of decyl oleate is provided, which includes the following steps: step (1), mixed oil Acid and n-decyl alcohol form a premix; step (2), add catalyst to the premix to form a mixture; step (3), heat the mixture to 160°C-280°C, react for 2-12h, take the reacted mixture to obtain decyl oleate. The invention has the effects of accelerating the reaction rate, improving the yield of the reaction and the purity of the product.

Owner:广州隽沐生物科技股份有限公司

A kind of high-alcohol gasoline additive composition and its methanol gasoline for engine at low temperature

InactiveCN109321292BAvoid serious pollutionReduce generationLiquid carbonaceous fuelsFuel additivesOil additiveGasoline

The invention belongs to the field of high-methanol gasoline at a low temperature and particularly relates to a high-methanol gasoline additive composition for an engine at the low temperature and methanol gasoline of the high-methanol gasoline additive composition. The high-methanol gasoline additive composition is characterized by being prepared from the following components in percentage by mass: 30 percent of a modifier A, 32-42 percent of a modifier B and the balance of acetone and being prepared by the following special steps of 1) after heating a stirring tank, adding n-decyl alcohol, mixing bis(2-dimethylaminoethyl) ether in the n-decyl alcohol, and performing centrifugal stirring for 8-20 min to obtain the modifier A, wherein the number of revolutions for centrifugal stirring is 1500 r / min, and the mass ratio of the bis(2-dimethylaminoethyl) ether to the n-decyl alcohol is 1 to 5; 2) after heating the stirring tank, adding isodecanol, mixing anhydrous hydrazine in the isodecanol, and performing stirring for 8-20 min to obtain the modifier B, wherein the mass ratio of the anhydrous hydrazine to the isodecanol is (1 to 7)-(1 to 6); and 3) mixing the modifier A, the modifierB and the acetone to obtain the additive composition. The additive at the low temperature and the methanol gasoline thereof are clean and environmentally friendly and are low in noise and less in yield of formaldehyde.

Owner:深圳市端致科技材料有限公司

Preparation method and application of oxidation flocculation composite water treatment agent

InactiveCN104310570AImprove conversion ratePromote oxidative decompositionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationUltrasonic oscillationPolyacrylamide

The invention provides a preparation method of an oxidation flocculation composite water treatment agent, which comprises the following concrete steps of weighing n-decyl alcohol, putting silver powder with the weight of 0.5-5.5% of n-decyl alcohol into a three-mouth flask, continuously supplying nitrogen, adding 20ml ethylene diamine tetraacetic acid, quickly performing temperature rise to 100-300 DEG C, cooling to a room temperature after reaction completion, adding 10g trinitrotoluene, heating to 40 DEG C, stirring for 30min, cooling to the room temperature, adding trimethylamine and chitosan to a solution, performing a thermostatic reaction for 5h, naturally cooling to the room temperature, adding 10g dimethyl ether, 10g humic acid and 10g polyacrylamide, loading into a sealed pressure vessel, performing a reaction for 2-4h at 1.0-2.0MPa and 150-250 DEG C, performing ultrasonic oscillation on the solution for 60-90min, and obtaining the oxidation flocculation composite water treatment agent. The oxidation flocculation composite water treatment agent prepared by the method has the advantages of less consumption, high reaction speed, good flocculation effect and the like.

Owner:HONGFEI GRP

Ethanol gasoline emulsifying agent

InactiveCN102965163AFully integratedNo damageLiquid carbonaceous fuelsPotassium nitrateSodium stearate

The invention relates to an ethanol gasoline emulsifying agent which comprises the following components by weight percent: 10-20 percent of dimethylbenzene, 1-8 percent of sodium hydroxide, 20-30 percent of n-caprylic alcohol, 15-25 percent of hexadecyl alcohol, 10-12 percent of alums, 25-35 percent of isopropyl alcohol and 25-38 percent of n-decyl alcohol. The ethanol gasoline emulsifying agent also comprises the following components by weight: 0.1-0.5 percent of potassium nitrate, 0.5-1.5 percent of sodium stearate and 0.5-1 percent of sodium nitrate. The ethanol gasoline emulsifying agent has no harm to a human body and machinery, can achieve combustion supporting and dissolving assistance, is reduced in anti-explosion index and reduced in air resistance, and ensures that ethanol gasoline is fully mixed. The ethanol gasoline emulsifying agent can ensure that deposited carbon of a combustion system in an engine is removed, so that an oil path system is cleaner, and the service life of the engine is prolonged.

Owner:JIAOZHOU FUTIAN CHEM ENG

Wear-resistant flame-retardant PVC gasket

The invention relates to a wear-resistant flame-retardant PVC gasket comprising the components of: 85 parts of polyvinyl chloride, 3 parts of magnesium chloride, 2 parts of calcium hydroxide, 9 parts of phthalate, 2 parts of molybdenum disulfide, and 2 parts of antimony trioxide. The sealing strip further comprises 7 parts of n-decyl alcohol and 1 part of paraben. The material has good wear resistance. With a coupling treatment method with a high-hardness wear-resistance modifier, the compatibility of the material with PVC is enhanced.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Reagent and method for resolution of ofloxacin racemate

ActiveCN103664998BHigh selectivityImprove the efficiency of chiral resolutionOrganic chemistryL-ofloxacinTartrate

The invention discloses a split reagent and a split method for an ofloxacin racemic mixture. The method is as below: dissolving an ofloxacin racemic mixture and an alkyl imidazole L-tartaric acid salt ionic liquid in deionized water to form an aqueous phase, and at the same time dissolving D-dibenzoyl tartaric acid in n-decyl alcohol to form an organic phase; mixing the organic phase and the aqueous phase; oscillating the mixture in an oscillator and standing; detecting concentration of L-ofloxacin and D-ofloxacin in a clear aqueous phase; acquiring the concentration of L-ofloxacin and D-ofloxacin in organic phase respectively by the law of conservation of mass; respectively calculating the distribution coefficient of the L-ofloxacin and D-ofloxacin; and further calculating a separation factor. The reagent and the method have good separation effect, and is successfully in splitting. The invention uses alkyl imidazole L-tartaric acid salt ionic liquid and D-dibenzoyl tartaric acid for splitting of the ofloxacin racemic mixture, improves the splitting efficiency and reduces the reagents required by splitting; and the method has simple operation and high selectivity, and is suitable for industrial production.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

A method for extracting magnesium from metallurgical wastewater

ActiveCN107585822BHigh single-stage extraction rateProduction environmental protectionWaste water treatment from metallurgical processLiquid solutions solvent extractionAlcoholPhosphate

Owner:CHONGQING THREE GORGES UNIV

Environment-friendly fuel oil synergist

InactiveCN109897698AReduce consumptionAvoid generatingLiquid carbonaceous fuelsCombustion chamberPhenyl Ethers

The invention relates to the technical field of industrial emulsifier, in particular to an environment-friendly fuel oil synergist. The environment-friendly fuel oil synergist is prepared from the following raw materials in parts by weight: 8-15 parts of polyethylene glycol p-isooctyl phenyl ether, 15-25 parts of dodecyl petroleum sulfonic acid, 35-45 parts of n-decyl alcohol, 10-18 parts of deionized active water and 13-16 parts of octadecylamine, wherein 12 parts of polyethylene glycol p-isooctyl phenyl ether, 20 parts of dodecyl petroleum sulfonic acid, 40 parts of n-decyl alcohol, 15 partsof deionized active water and 15 parts of octadecylamine can be used to prevent carbon from depositing on the inner surface of a combustion chamber, achieving a casual maintenance effect and having adecomposing effect on originally deposited carbon. The originally deposited carbon is discharged along with exhaust, and at the same time, consumption of fuel oil and discharge of pollutants such ascarbon monoxide, hydrocarbon and oxynitride are reduced.

Owner:CHANGZHOU WUJIN GREAT WALL TOOLS

A method for preparing decanediol dicarboxylate and derivatives thereof

ActiveCN111018701BGood reproducibilityHigh yieldOrganic compound preparationCarboxylic acid esters preparationPtru catalystFurfural

The invention discloses a method for preparing decanediol dicarboxylate and derivatives thereof. The raw material used in the present invention is furfural, which can be obtained by hydrolysis of hemicellulose, and the furfural is efficiently converted into decanediol dicarboxylate, n-decyl carboxylate and corresponding alcohols through two steps of condensation and hydrogenolysis. It is characterized in that: using the compound of formula (I) as raw material, under the double action of trifluoromethanesulfonate and hydrogenation catalyst, selectively hydrodeoxygenating in acidic solvent to obtain decanediol dicarboxylate and carboxylate N-decyl acid. The above product was saponified to obtain 1,10-decanediol and n-decyl alcohol. The raw materials used in the invention are cheap and easy to obtain, the yield of the product is high, the purity is high, the pollution to the environment is small, the process route is simple, and it is suitable for industrialized production.

Owner:UNIV OF SCI & TECH OF CHINA

An antioxidant drawing oil containing oregano oil

ActiveCN103992867BImprove the lubrication effectExtended service lifeLubricant compositionEpoxyORIGANUM OIL

The invention relates to wire drawing oil, and in particular relates to oregano-oil-containing antioxidant wire drawing oil; the origanum-oil-containing antioxidant wire drawing oil comprises the following raw materials by weight: 120-140 parts of epoxy soybean oil, 45-60 parts of biodiesel, 5-8 parts of n-decyl alcohol, 1-2 parts of zinc primary-secondary alkyl sulfur phosphate, 1-2 parts of oregano oil, 10-12 parts of iso-tridecanol polyoxyethylene ether, 0.1-0.2 part of potassium stearate, 0.2-0.3 part of sodium benzoate, 1-2 parts of sulfurized isobutylene and 2-3 parts of an assistant; the oregano oil with excellent antibacterial antioxidant capacity is specially added in the formula of the oregano-oil-containing antioxidant wire drawing oil, the problem that the epoxy soybean oil in based oil is easy to oxidize and deteriorate can be effectively improved; by combination with other additives, the prepared wire drawing oil is environmentally-friendly, easy to degrade, good in thermal stability, more resistant to store, low in cost, and excellent in lubricating properties, and can meet wire drawing and drawing process of various metal wire materials.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com