High molecular polycarboxylate dispersing agent

A polycarboxylate and dispersant technology, which is applied in biocides, animal repellents, plant growth regulators, etc., can solve the problems of low molecular weight, slow polymerization rate, unsatisfactory dispersion performance and stability, etc., to achieve The effect of high product molecular weight, fast polymerization rate, excellent dispersion performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add the emulsifiers tristyrene phenol polyoxyethylene ether and dialkyl polyoxyethylene ether methacrylate to the reaction flask, and the mass ratio is tristyrene phenol polyoxyethylene ether: dialkyl polyoxyethylene ether methacrylic acid Ester=1.2:1, then add 800 parts of deionized water to make the solid content in the system 25%, heat to 120°C, the reaction time is 3 hours; then add 500 parts of itaconic acid and 200 parts of N-oleoyl -N-Methyl taurate sodium and 60 parts of initiator solution, emulsion polymerization reaction occurs at 100°C, and the reaction is kept for 5 hours; 50 parts of sodium bisulfite and 50 parts of n-decyl alcohol are added to the reaction flask, and the mixture is fully stirred Add an appropriate amount of alkali to adjust the pH of the system to 7.2; spray-dry the prepared copolymer solution to obtain a polycarboxylate dispersant.

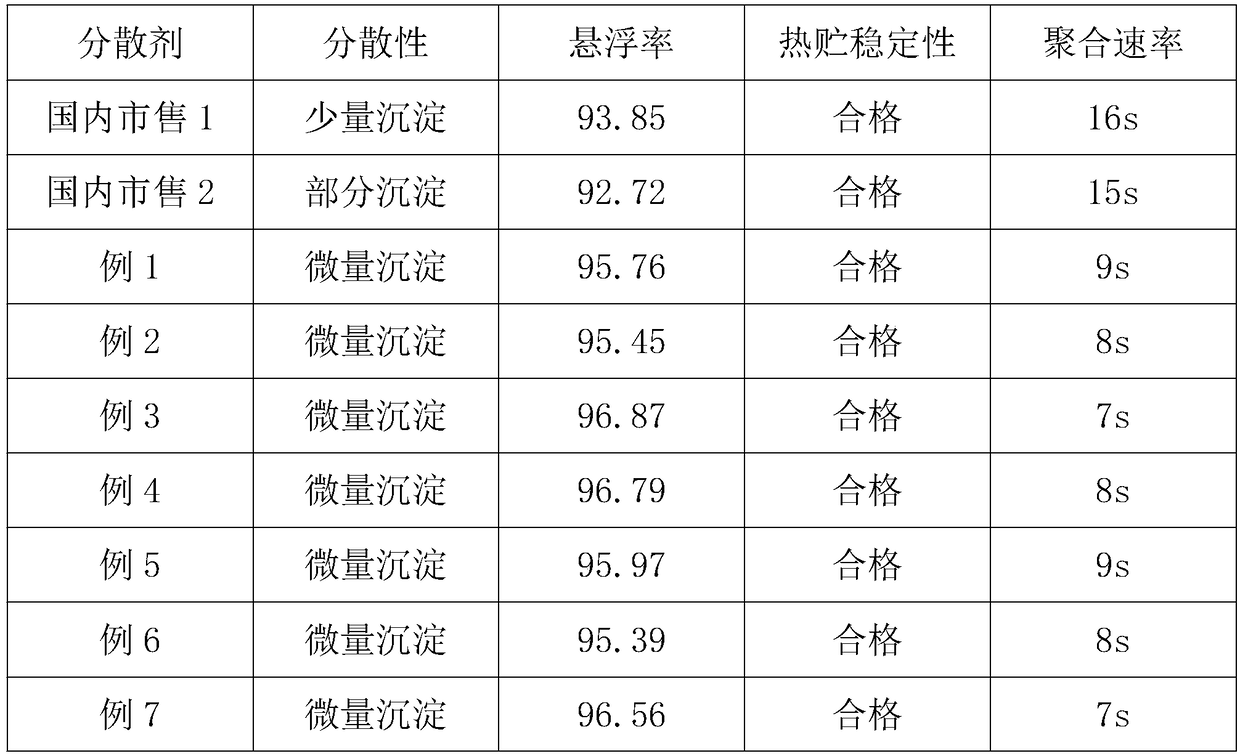

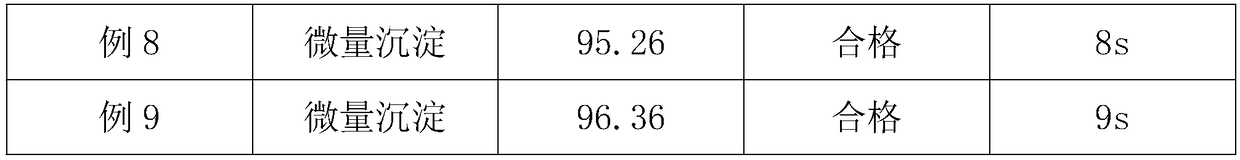

[0021] Use the polycarboxylate dispersant prepared by the above synthesis to prepare 35% imidacloprid SC for ...

Embodiment 2

[0032] Add the emulsifiers tristyrene phenol polyoxyethylene ether and dialkyl polyoxyethylene ether methacrylate to the reaction flask, and the mass ratio is tristyrene phenol polyoxyethylene ether: dialkyl polyoxyethylene ether methacrylic acid Ester=1.3:1, then add 900 parts of deionized water to make the solid content in the system 20%, heat to 120°C, the reaction time is 3 hours; then add 500 parts of itaconic acid and 200 parts of N-oleoyl -N-Methyl taurate sodium and 60 parts of initiator solution, emulsion polymerization reaction occurs at 100°C, and the reaction is kept for 5 hours; 50 parts of sodium bisulfite and 50 parts of n-decyl alcohol are added to the reaction flask, and the mixture is fully stirred , Adding an appropriate amount of alkali to adjust the pH value of the system to 6.8; spray drying the prepared copolymer solution to obtain a polycarboxylate dispersant.

[0033] According to the test method of Example 1, the dispersant prepared by this formula prepa...

Embodiment 3

[0035] Add the emulsifiers tristyrene phenol polyoxyethylene ether and dialkyl polyoxyethylene ether methacrylate to the reaction flask, and the mass ratio is tristyrene phenol polyoxyethylene ether: dialkyl polyoxyethylene ether methacrylic acid Ester=1.5:1, then add 600 parts of deionized water to make the solid content in the system 29%, heat to 120°C, the reaction time is 3 hours; then add 500 parts of itaconic acid and 200 parts of N-oleoyl -N-Methyl taurate sodium and 60 parts of initiator solution, emulsion polymerization reaction occurs at 100°C, and the reaction is kept for 5 hours; 50 parts of sodium bisulfite and 50 parts of n-decyl alcohol are added to the reaction flask, and fully stirred Add an appropriate amount of alkali to adjust the pH of the system to 6.7; spray-dry the prepared copolymer solution to obtain a polycarboxylate dispersant.

[0036] According to the test method of Example 1, the dispersant prepared by this formula prepared 35% imidacloprid SC has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com