The preparation method of decyl oleate

A technology of decyl oleate and oleic acid, applied in the field of preparation of decyl oleate, can solve the problem that the stability of the new crown vaccine cannot be improved, the preparation method of decyl oleate is not found, the purity of decyl oleate is difficult to guarantee, etc. problems, to achieve the effect of inhibiting side reactions and reverse reactions, shortening reaction time, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

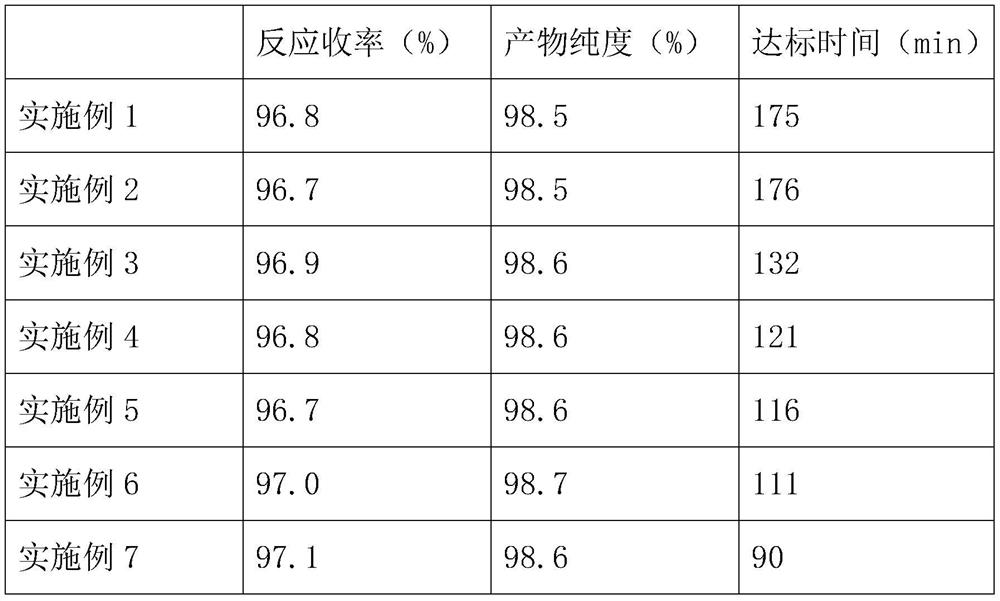

Examples

Embodiment 1

[0042] A preparation method for decyl oleate, comprising the following steps:

[0043] In step (1), add 1 kg of oleic acid and 1 kg of n-decyl alcohol into a four-neck flask, and mix evenly to form a premix.

[0044] Step (2), continue to add 0.22kg SO in the four-necked flask 4 2- / Fe 2 o 3 Solid superacid, mix well to form a mixture.

[0045]Step (3), the four-necked flask that mixture is housed is put into oil bath, and installs condensing pipe so that the water vapor in the reaction system is discharged at one of the openings of four-necked flask, while condensing pipe is away from four-necked flask Place an Erlenmeyer flask at one end to collect the water formed by the condensation of water vapor, and seal the other opening of the four-neck flask with a rubber stopper, then heat the oil bath to 160°C, react for 12 hours, and cool to room temperature to obtain decyl oleate ester.

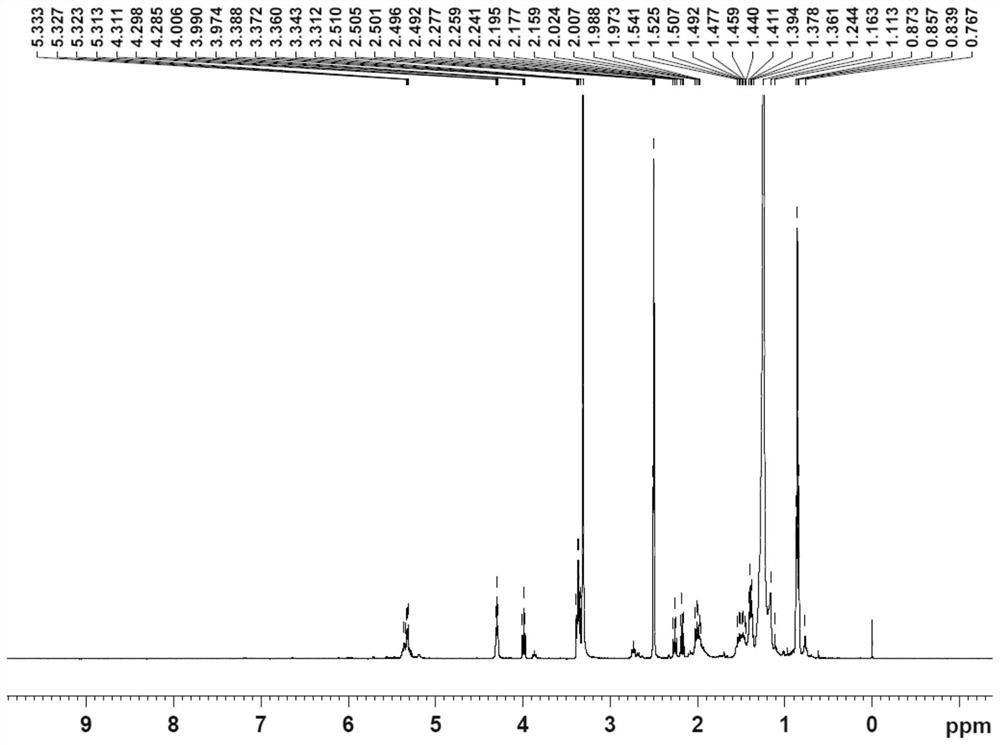

[0046] see figure 1 , for the decyl oleate prepared in this example 1 HNMR spectrum,...

Embodiment 2

[0048] The difference from Example 1 is that the reaction temperature in step (3) is 280°C, and the reaction time is 5h.

Embodiment 3

[0050] The difference with Example 1 is: the reaction temperature in step (3) is 220°C, and the reaction time is 4h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com