High-methanol gasoline additive composition for engine at low temperature and methanol gasoline of high-methanol gasoline additive composition

A gasoline additive, methanol gasoline technology, applied in the direction of fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of heavy pollution and loud noise, reduce air flow disturbance, reduce noise, reduce formaldehyde, and avoid serious pollution discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

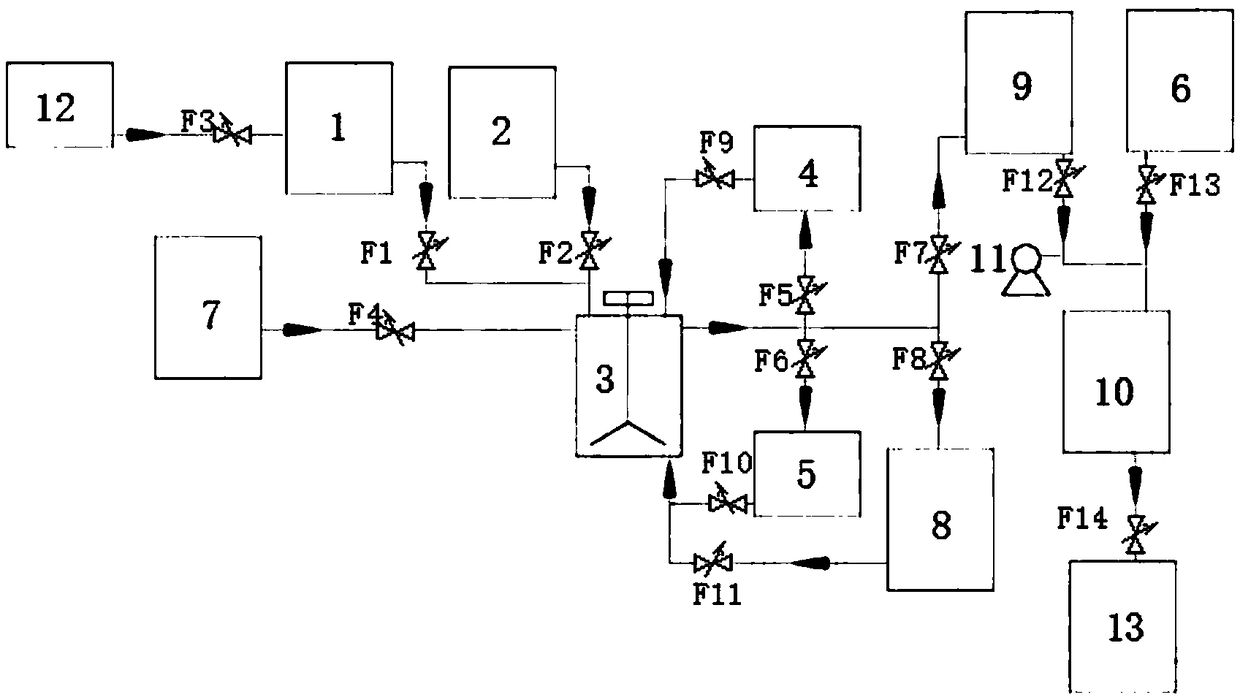

Method used

Image

Examples

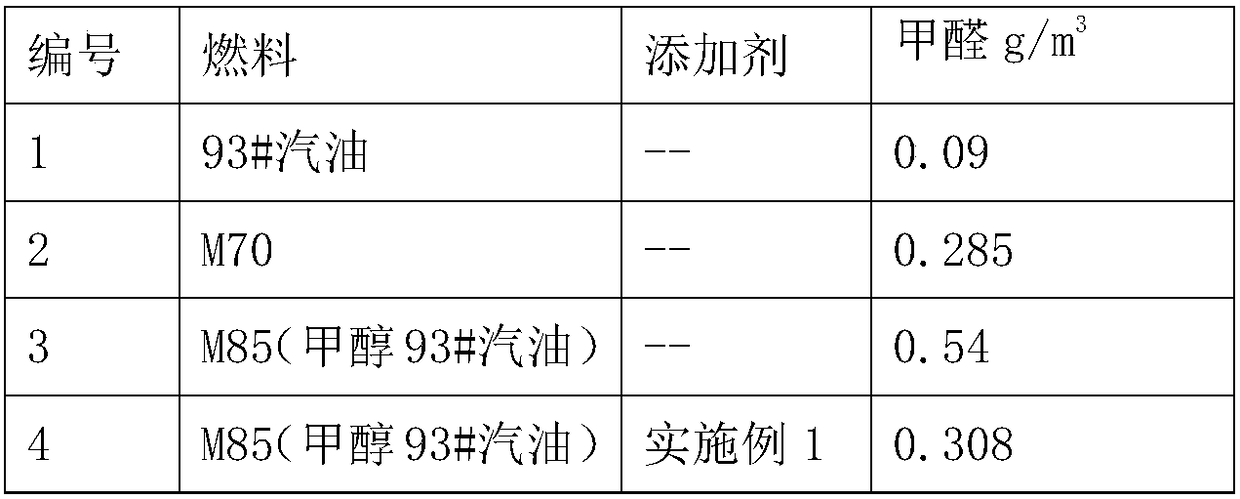

Embodiment 1

[0038] The mass percent composition of the additive composition is: 5% bis-dimethylaminoethyl ether, 25% n-decanol, 4% anhydrous hydrazine, 28% isodecyl alcohol, and the balance is acetone. The mass percentage of the additive composition in methanol gasoline is 6%. Take 2.4kg of additive composition, 40kg of methanol gasoline, and described methanol gasoline (methanol and 93# gasoline blending) is M85.

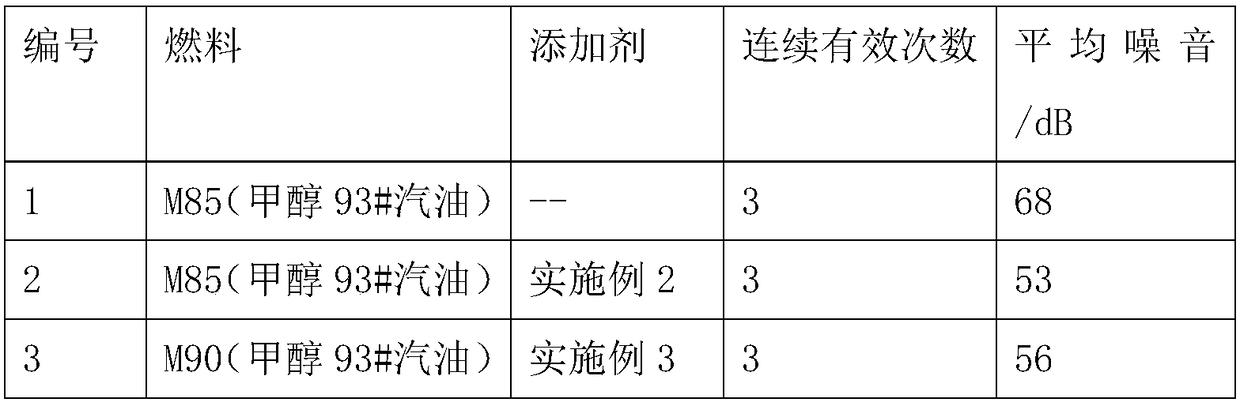

Embodiment 2

[0040] The mass percent composition of the additive composition is: 5% bis-dimethylaminoethyl ether, 25% n-decanol, 6% anhydrous hydrazine, 36% isodecyl alcohol, and the balance is acetone. The mass percentage of the additive composition in methanol gasoline is 6%. Take 2.4kg of additive composition, 40kg of methanol gasoline, and described methanol gasoline (methanol and 93# gasoline blending) is M85.

Embodiment 3

[0042] The mass percent composition of the additive composition is: 5% bis-dimethylaminoethyl ether, 25% n-decanol, 4% anhydrous hydrazine, 28% isodecyl alcohol, and the balance is acetone. The mass percentage of the additive composition in methanol gasoline is 9%. Such as taking 3.6kg of additive composition, 40kg of methanol gasoline, and described methanol gasoline (methanol is mixed with 93# gasoline) is M90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com