Rotary engine of oval cylinder

A rotary engine, oval technology, used in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of short life, engine wear, and can not be widely used, so as to improve life, solve oil leakage and sewage. Severe, torque-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

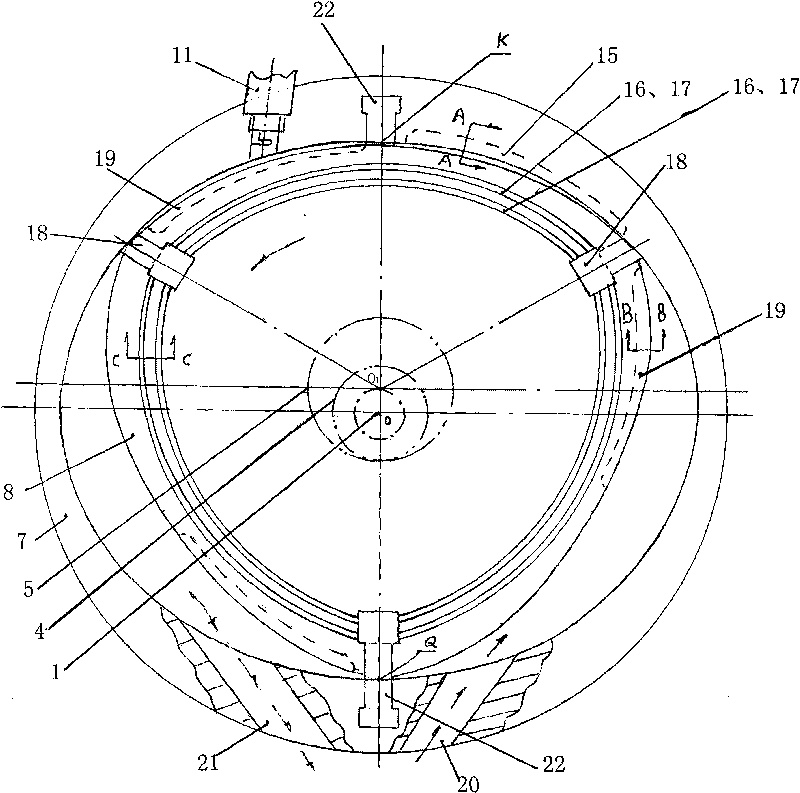

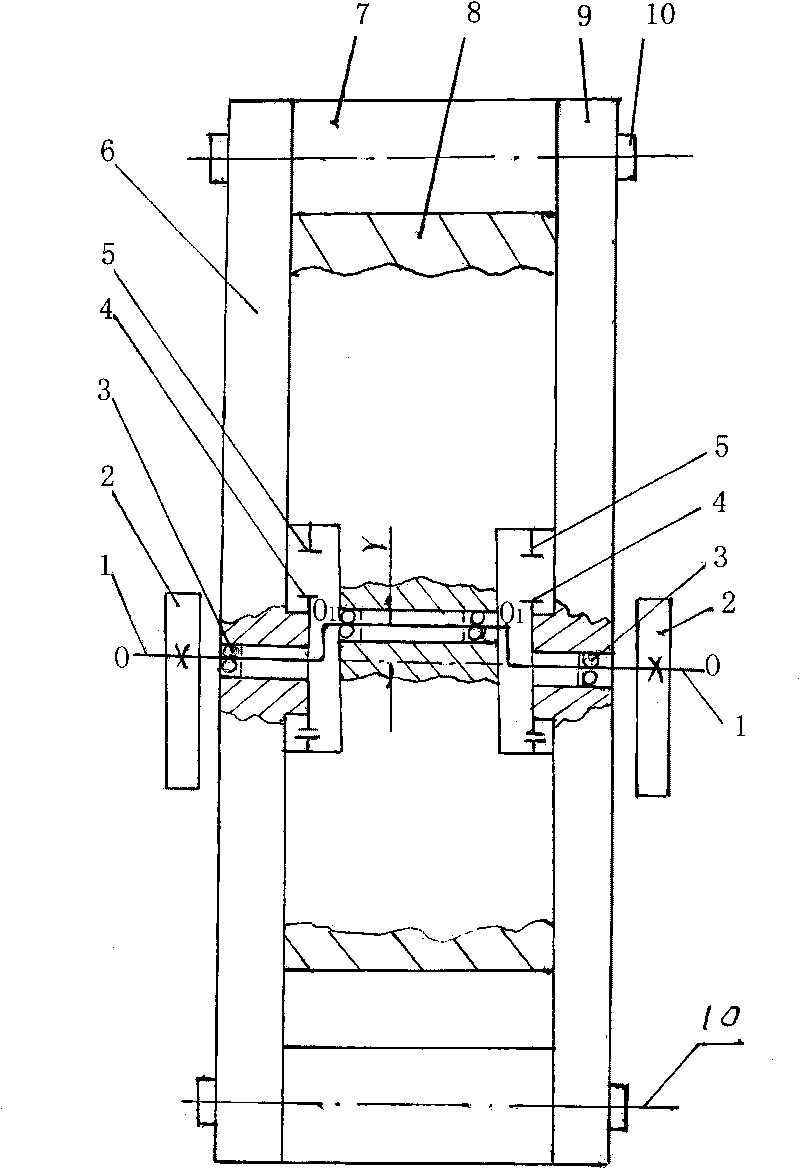

[0025] A rotor engine with an oval cylinder. The main shaft 1 is provided with a flywheel 2 and a bearing 3. The main shaft 1 is fixedly connected with the external gear 4. The external gear 4 meshes with the fixed internal gear 5 of the convex triangular rotor 8. The left cylinder plate 6 and the right The cylinder plate 9 and the cylinder 7 are fixed by the fixed shaft 10, the convex triangular rotor 8 is arranged in the cylinder 7, the inner surface of the cylinder 7 is oval, and the center of the convex triangular rotor 8 is O 1 The point is in the cylinder 7 and the center O point of the cylinder 7 performs circular motion, and the convex triangular rotor 8 performs planetary motion in the cylinder 7, and the arc track of any two vertices among the three vertices of the convex triangular rotor 8 is the planetary track. An elastic sealing door 22 is arranged at the tangent point K between the cylinder 7 and the convex triangular rotor 8 .

[0026] One side of the cylinder ...

Embodiment 2

[0031] The point of tangency among the embodiment 1 is point Q, and one side of the point of tangency Q is provided with an air inlet 20, and the other side is provided with an air outlet 21, and the cylinder 7 with an angle of 180 degrees with the point of tangency Q is point K; A spark plug 11 is provided on the front cylinder 7 of K, and a dark passage 15 is provided on the rear cylinder 7 .

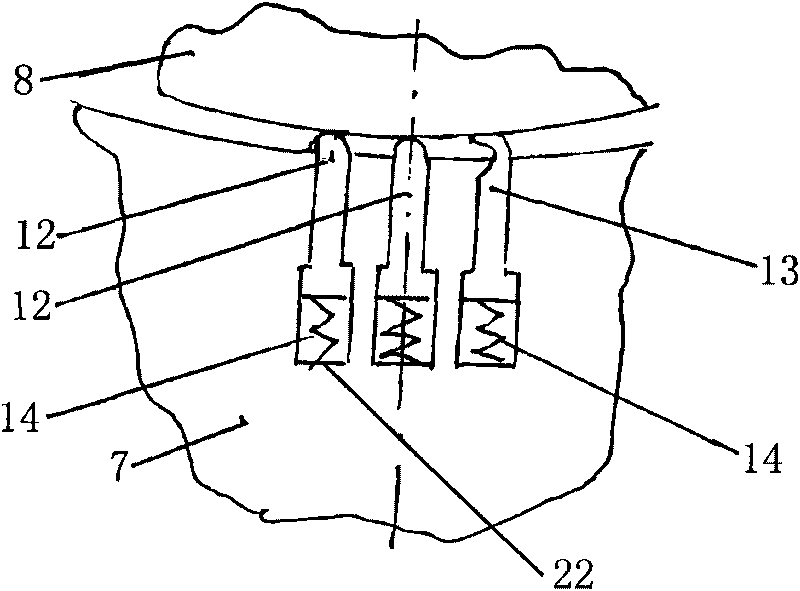

[0032] Elastic sealing door 22 is two groups, and the first group is made of sealing plate 12 and the spring 14 that is connected with sealing plate 12, and the top that sealing plate 12 contacts with convex triangular rotor 8 is arc-shaped; The mouth-shaped sealing plate 13 and the spring 14 connected with the duck-bill-shaped sealing plate 13 constitute, and the top of the duck-bill-shaped sealing plate 13 in contact with the convex triangular rotor 8 is arc-shaped, and the side connected with the top is duckbill-shaped.

[0033] The elastic seals 18 are in two groups. The first gro...

Embodiment 3

[0035] The point of tangency among the embodiment 1 is two points of Q point and K point, one side of the point of tangency Q is provided with an air inlet 20, and the other side is provided with an air outlet 21; Spark plug 11 is arranged, and backside cylinder 7 is provided with dark channel 15.

[0036] Elastic sealing door 22 is three groups, and the first group and the second group are made of sealing plate 12 and the spring 14 that is connected with sealing plate 12, and the top that sealing plate 12 contacts with convex triangular rotor 8 is arc-shaped; The group is composed of a duckbill-shaped sealing plate 13 and a spring 14 connected to the duckbill-shaped sealing plate 13, and the top of the duckbill-shaped sealing plate 13 in contact with the convex triangular rotor 8 is arc-shaped, and the side connected to the top is Duckbill.

[0037] There are three groups of elastic seals 18, the first group and the second group are composed of a sealing plate 12 and a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com