Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164 results about "Microheater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microheaters are small high-power heaters, with precise control, that can offer temperatures in excess of 1000C, even up to 1900C. Microheaters provide for accurate high temperature control, for example in electron microscopes, pressure-anvil cells or for enhancing fiberheaters. Generally speaking, the heating method for microheaters involves conversion of electrical work to high density heat. With the increase in the temperature demanded, microheater heating materials change from metallic (non-brittle GAXP) to metal-ceramic like materials (MoSi2) which tend to be brittle. With an increase in usable temperature, microheaters need to be supported or enclosed with very high thermal-resistant ceramic materials often made from small grain, high purity aluminum oxide.

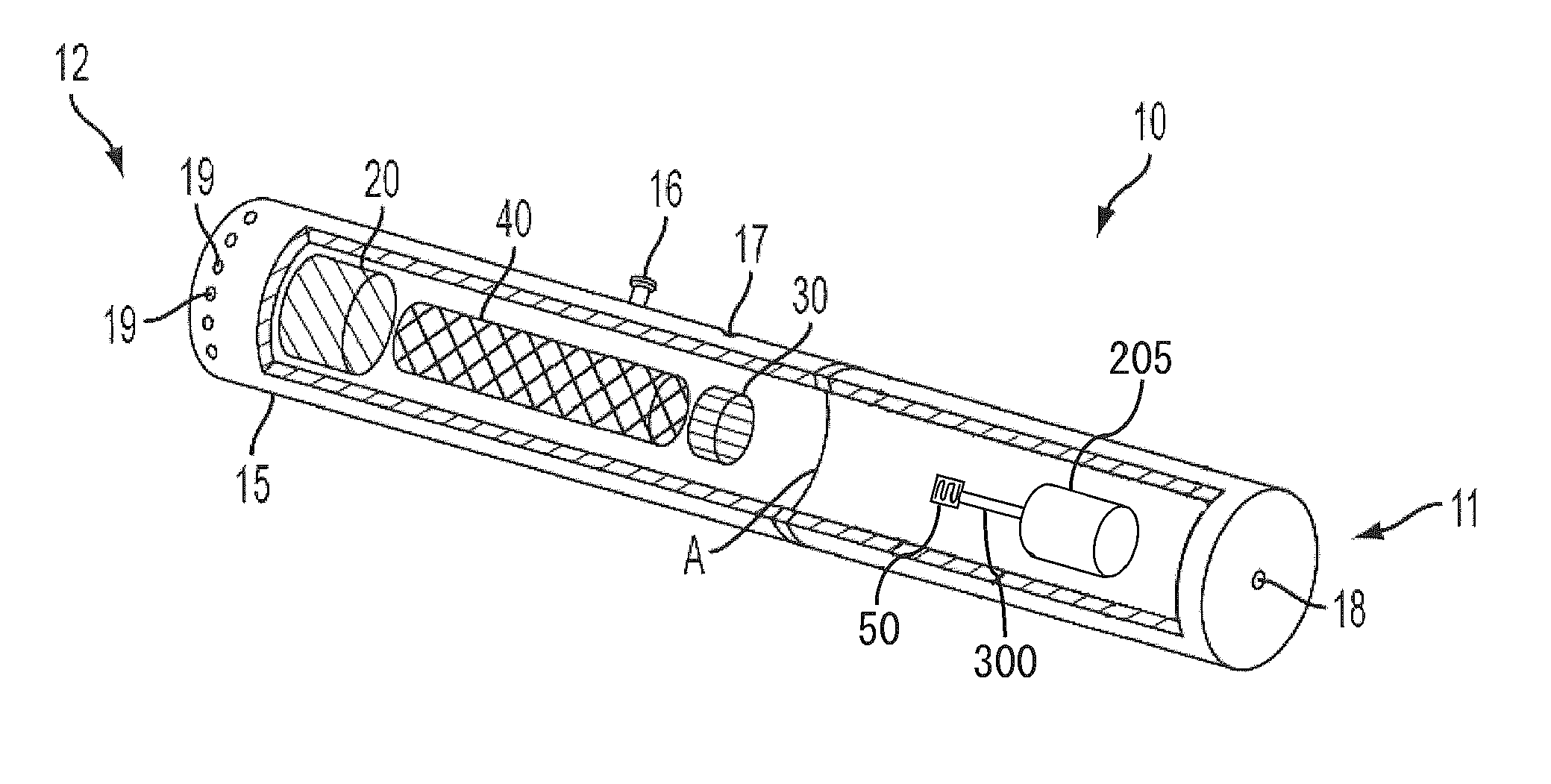

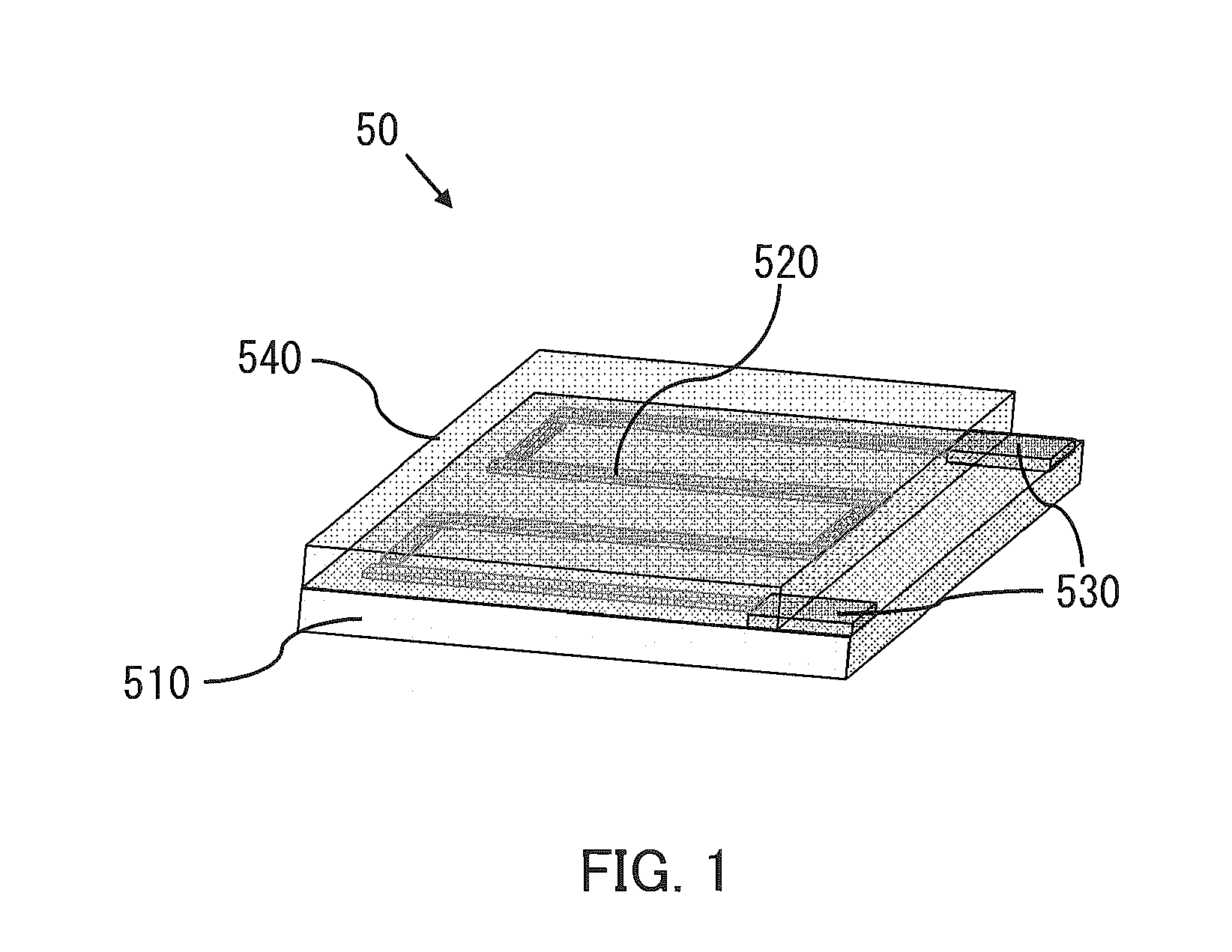

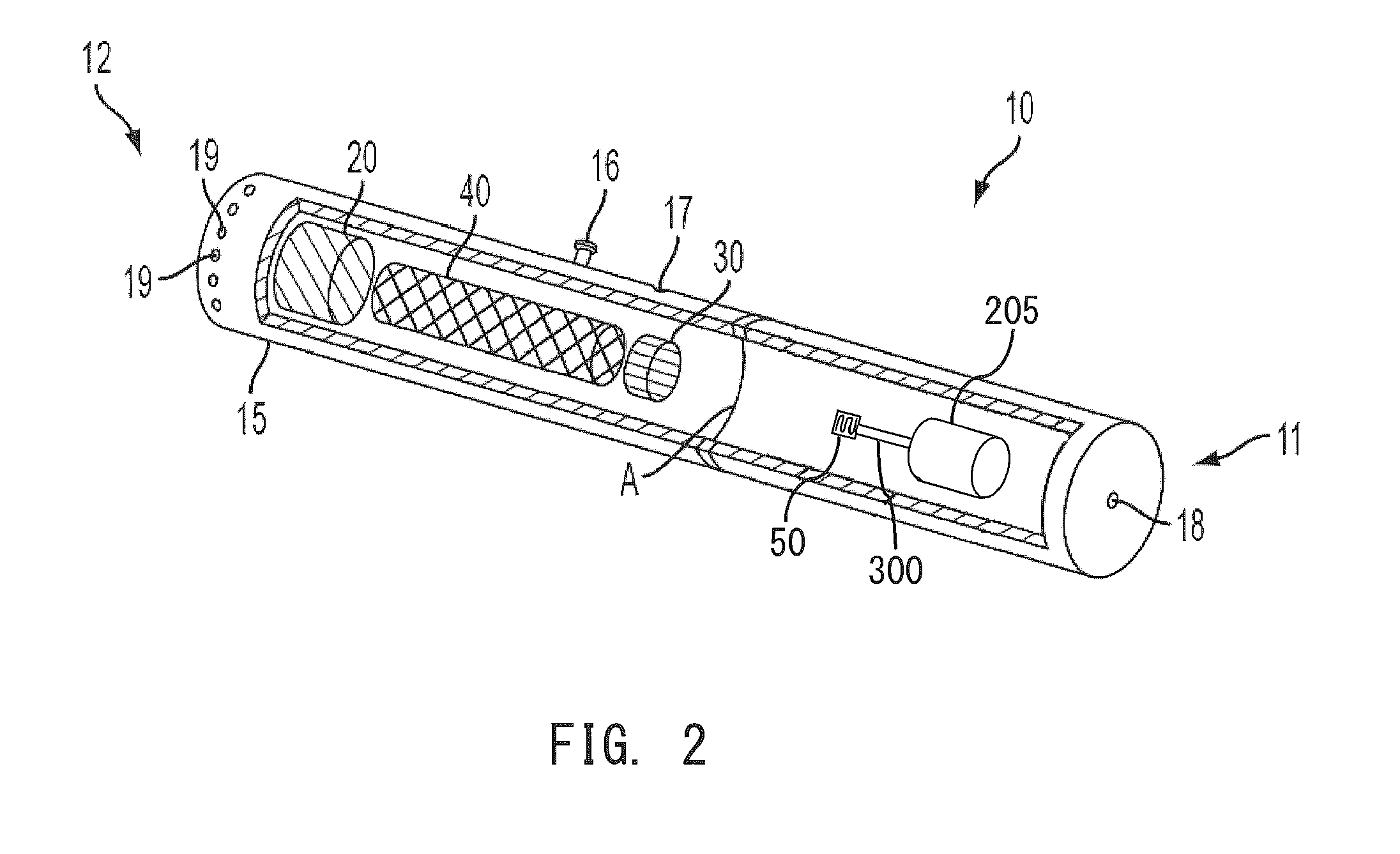

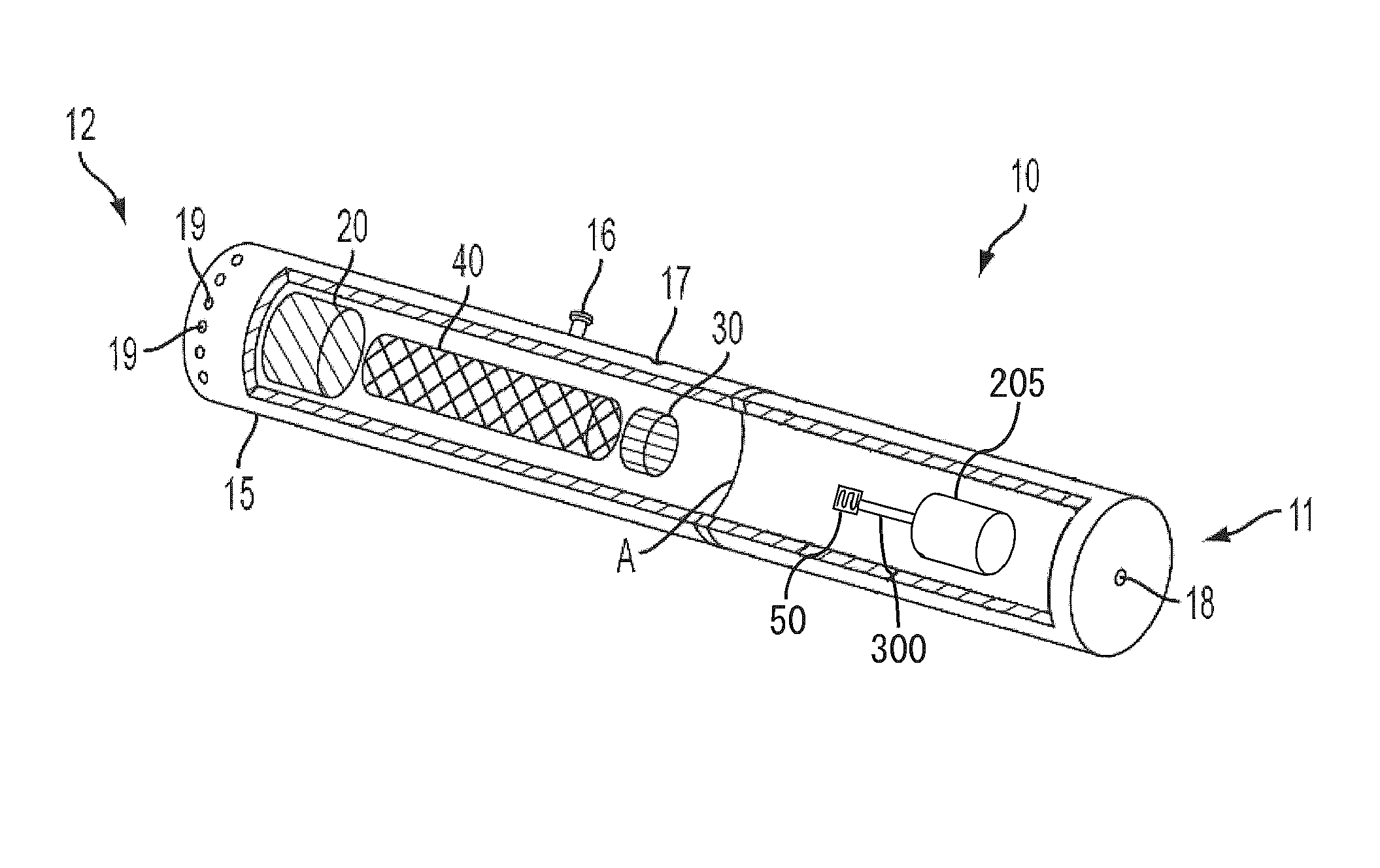

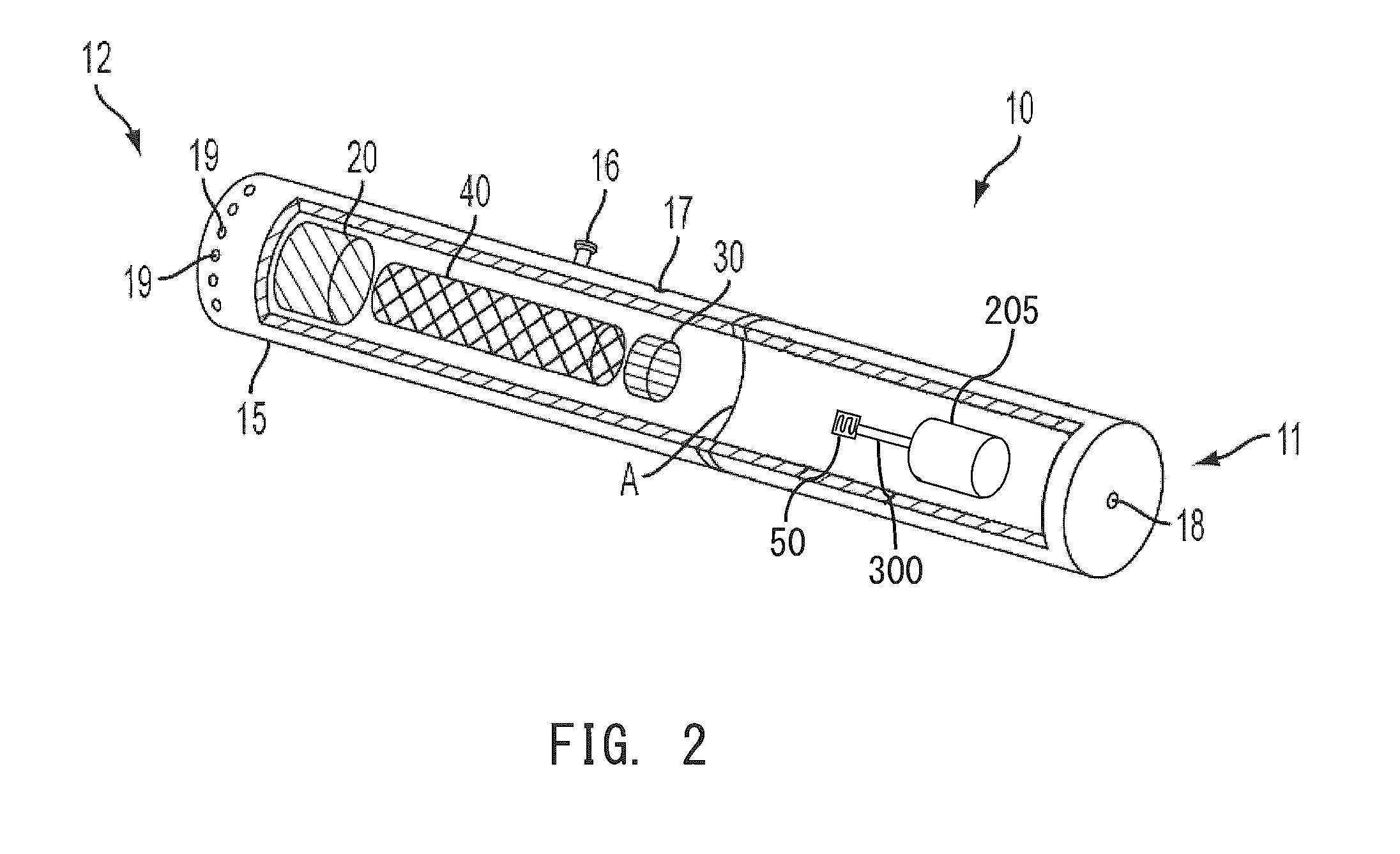

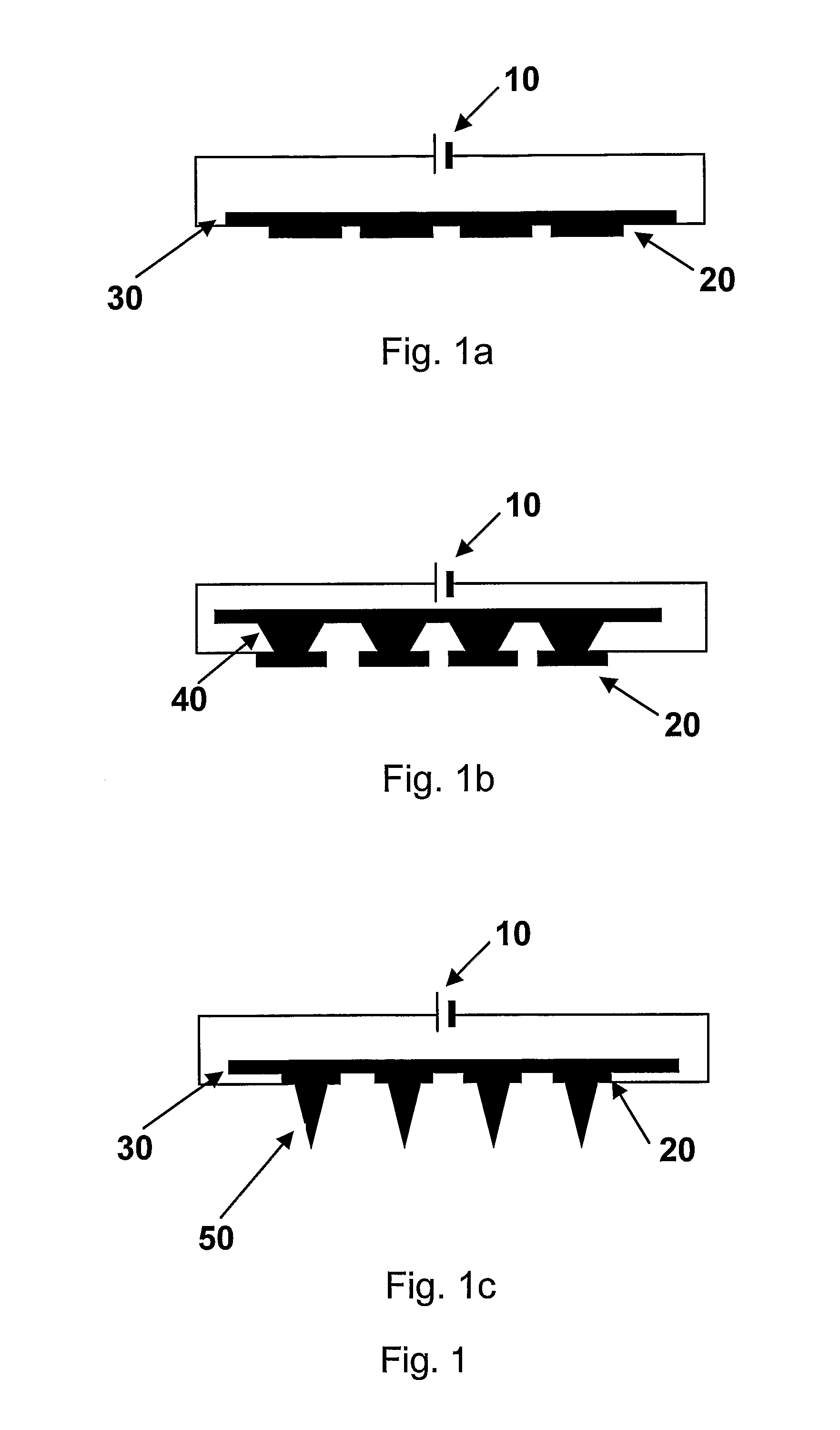

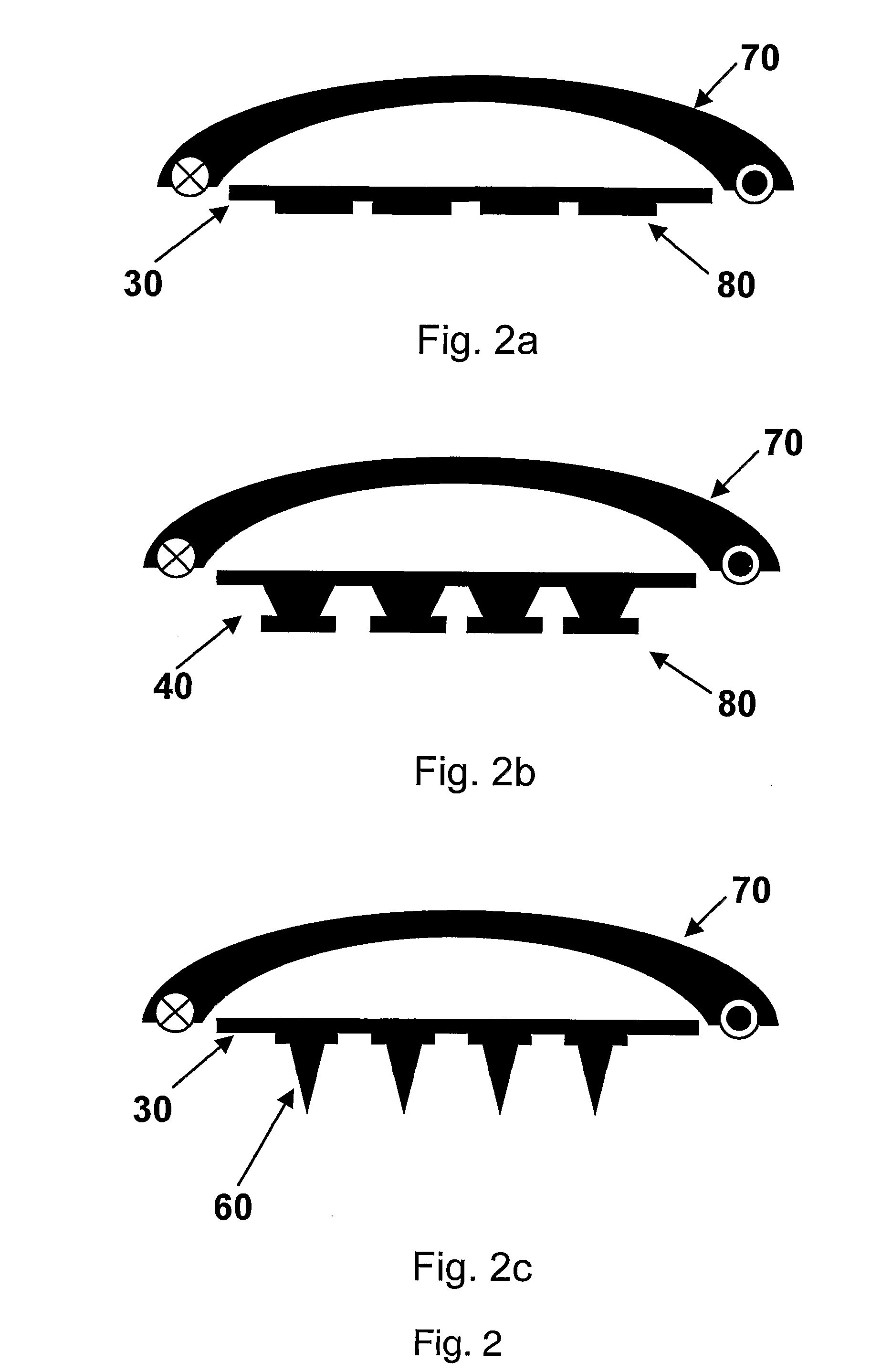

Electronic smoking article comprising one or more microheaters

The present disclosure relates to an electronic smoking article that provides for improved aerosol delivery. Particularly, the article comprises one or more microheaters. In various embodiments, the microheaters provide for improved control of vaporization of an aerosol precursor composition and provide for reduced power requirements to achieve consistent aerosolization. The present disclosure further relates to methods of forming an aerosol in a smoking article.

Owner:RAI STRATEGIC HLDG INC

Electronic smoking article comprising one or more microheaters

The present disclosure relates to an electronic smoking article that provides for improved aerosol delivery. Particularly, the article comprises one or more microheaters. In various embodiments, the microheaters provide for improved control of vaporization of an aerosol precursor composition and provide for reduced power requirements to achieve consistent aerosolization. The present disclosure further relates to methods of forming an aerosol in a smoking article.

Owner:RAI STRATEGIC HLDG INC

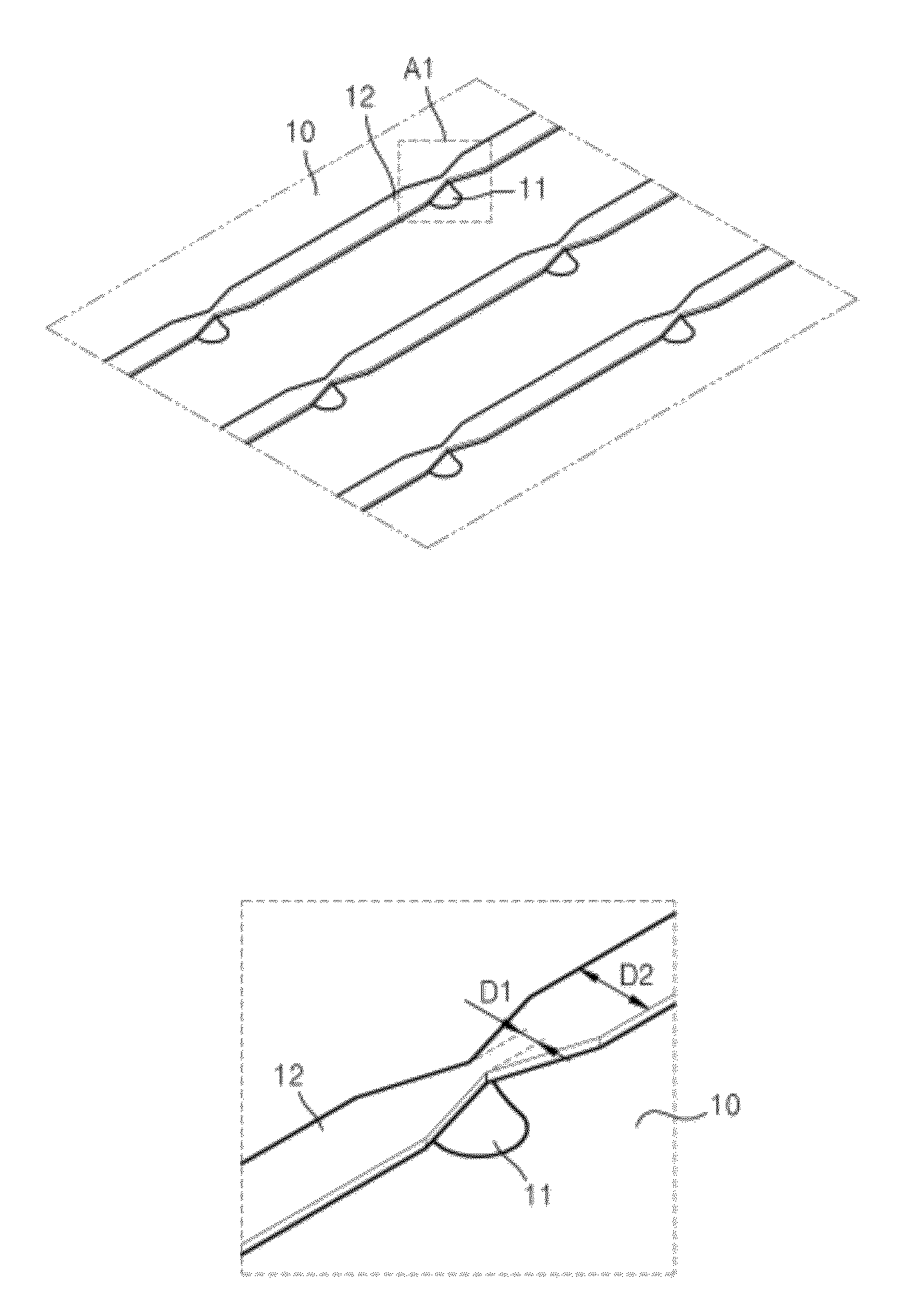

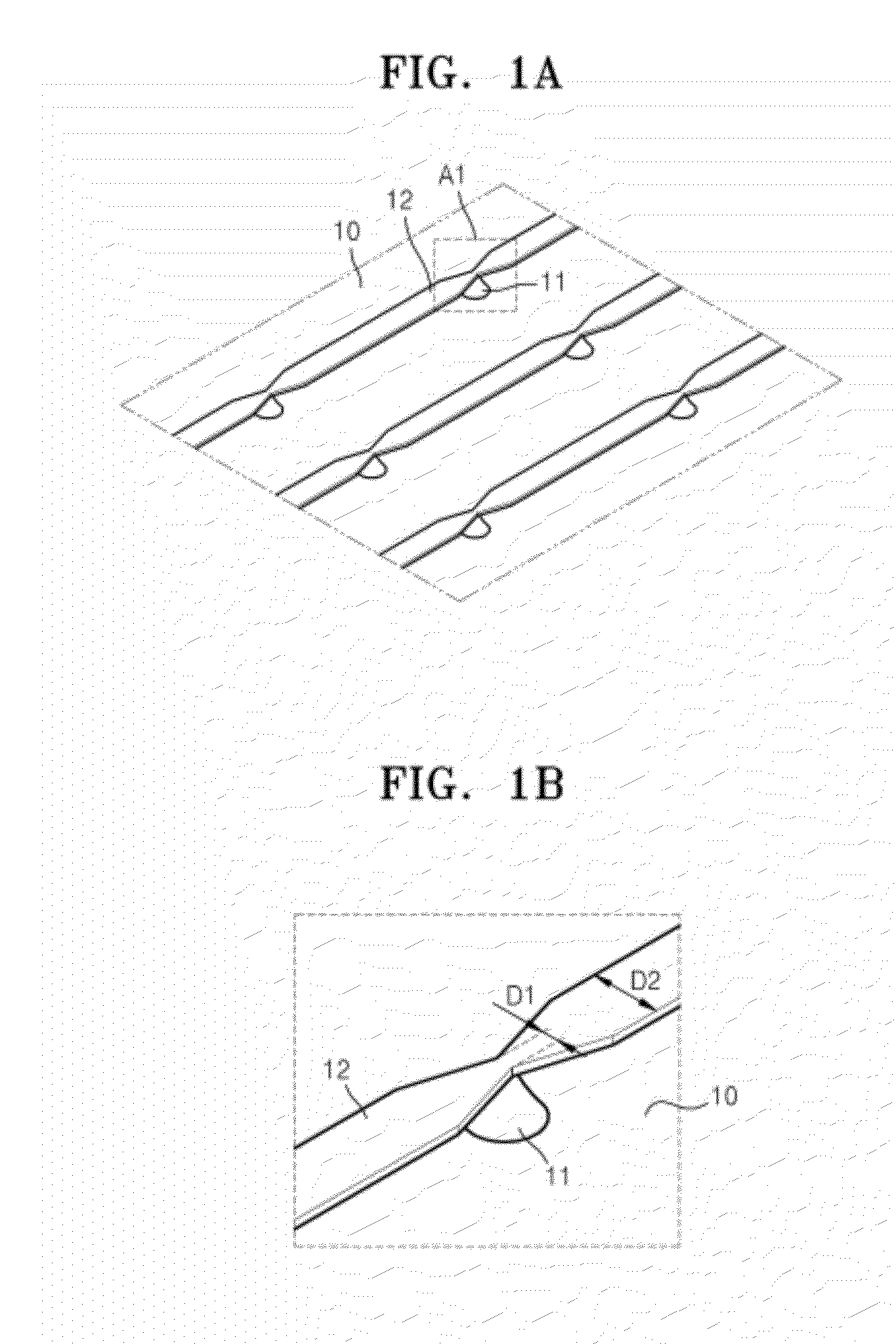

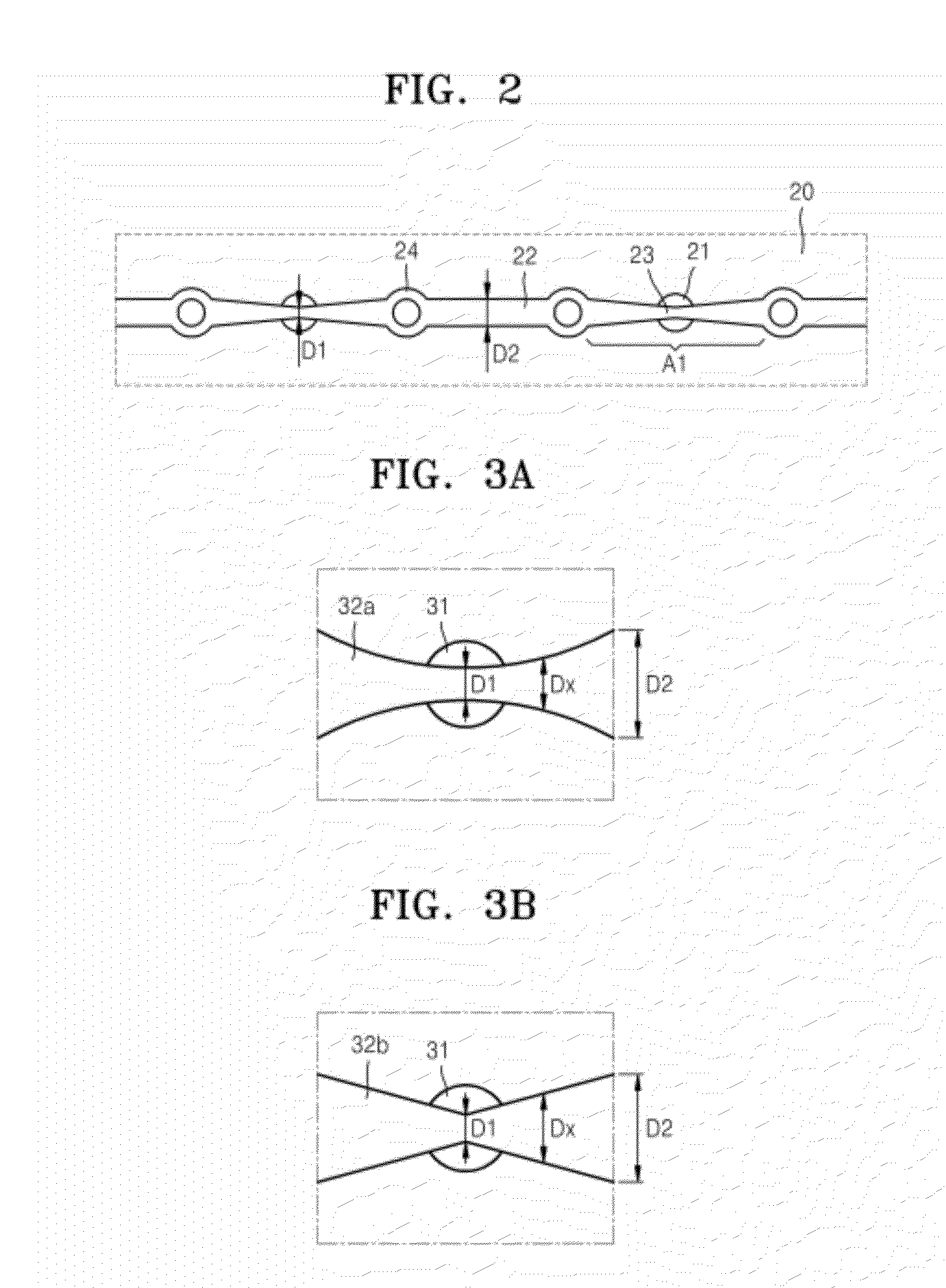

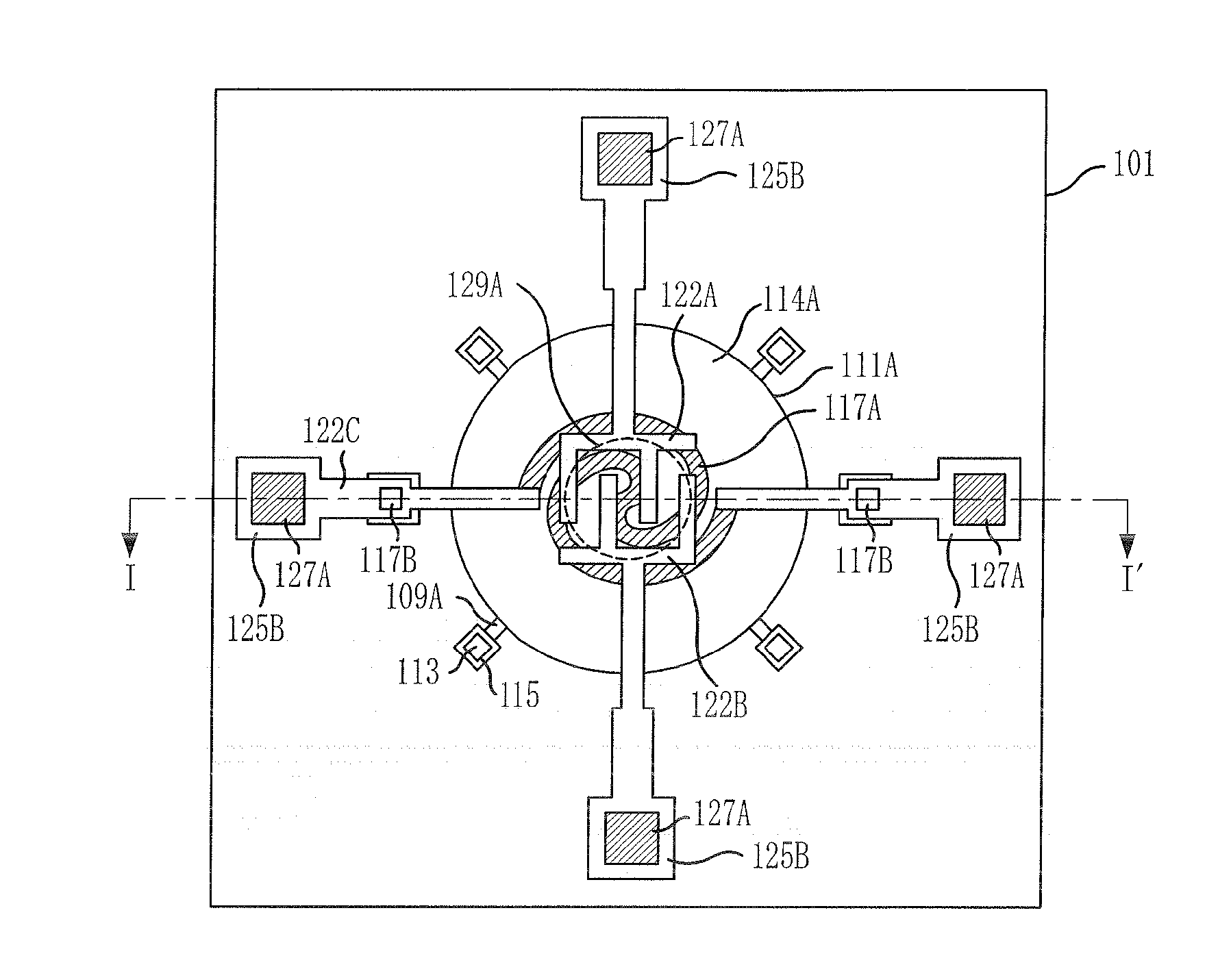

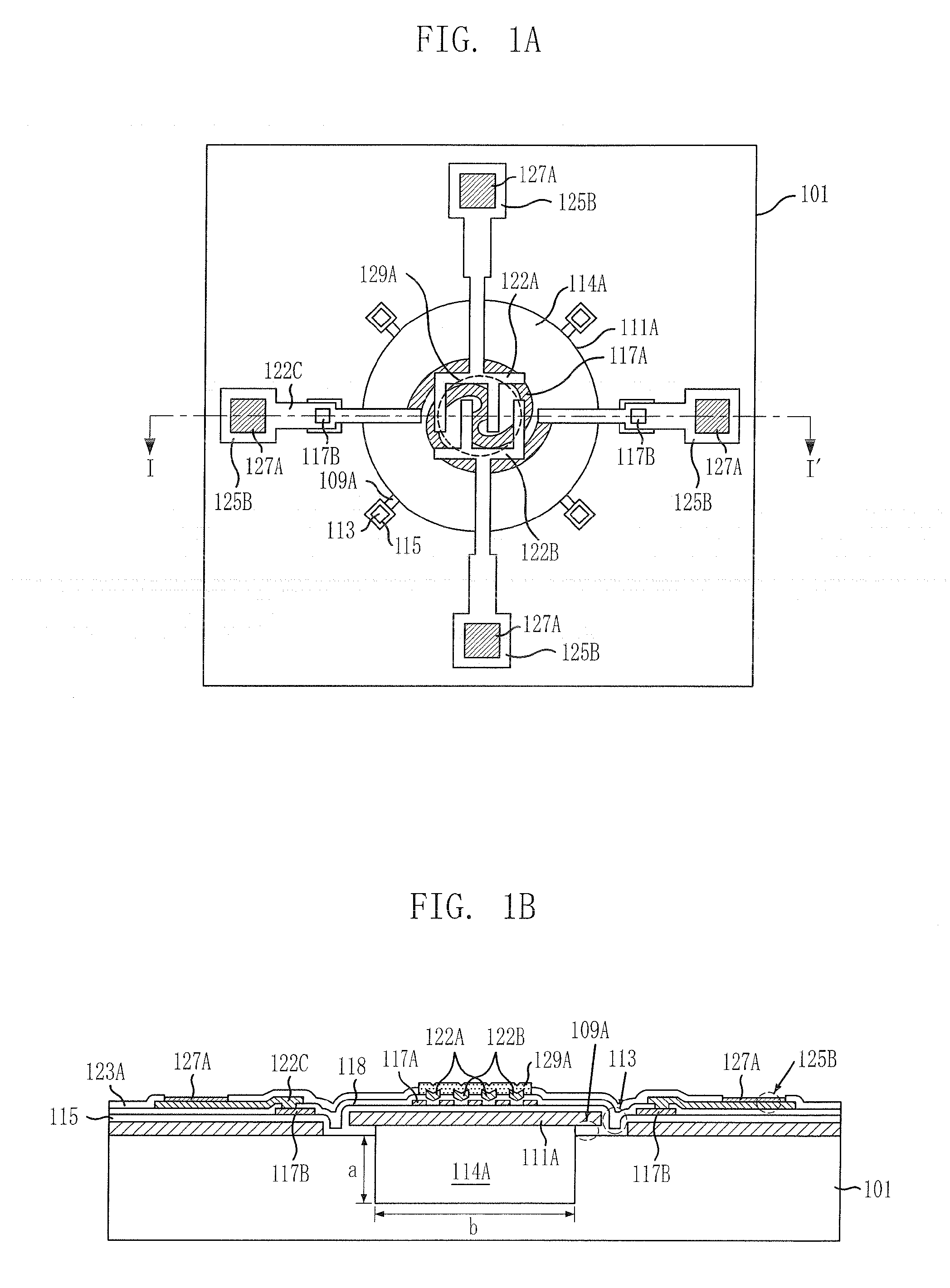

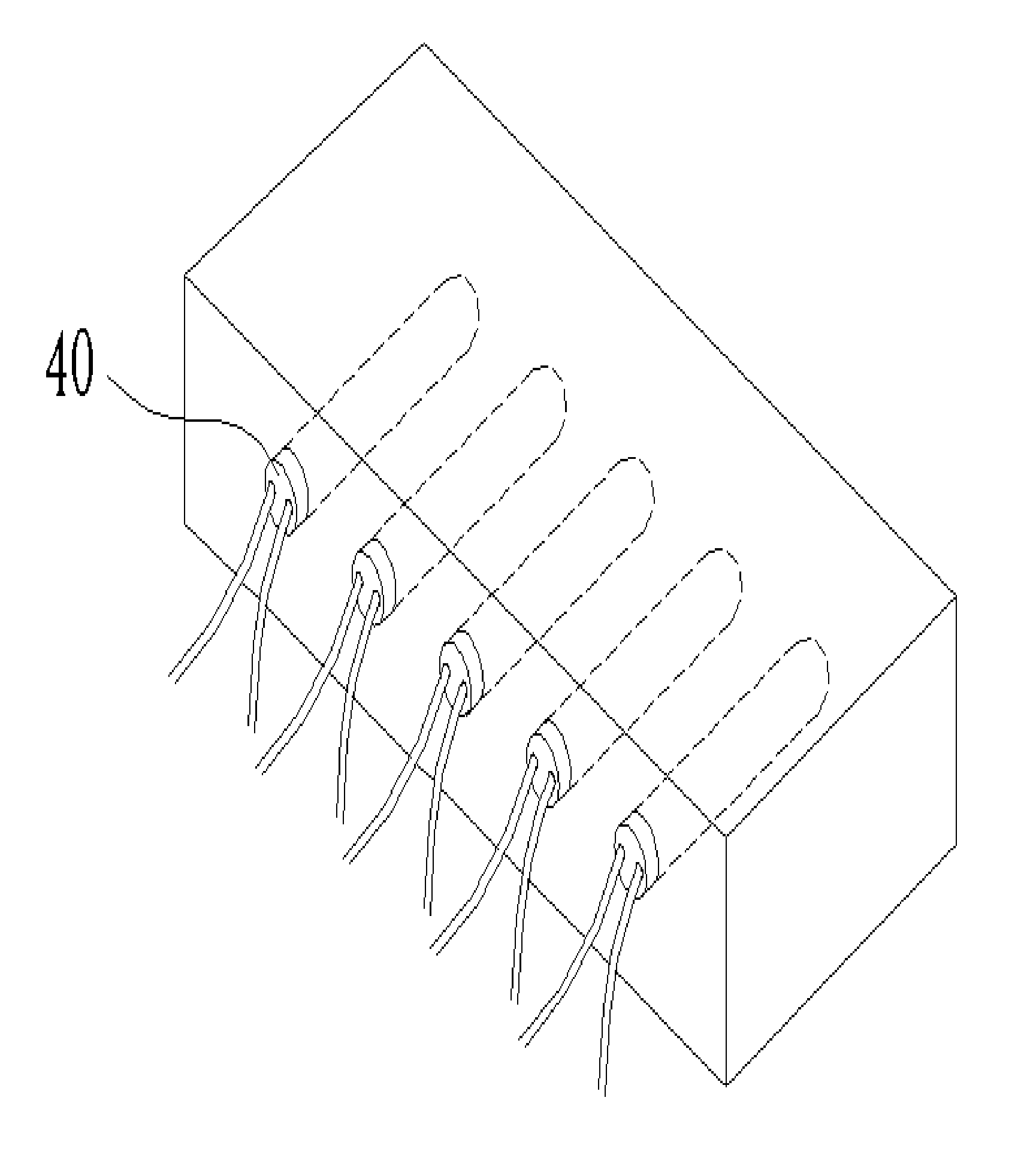

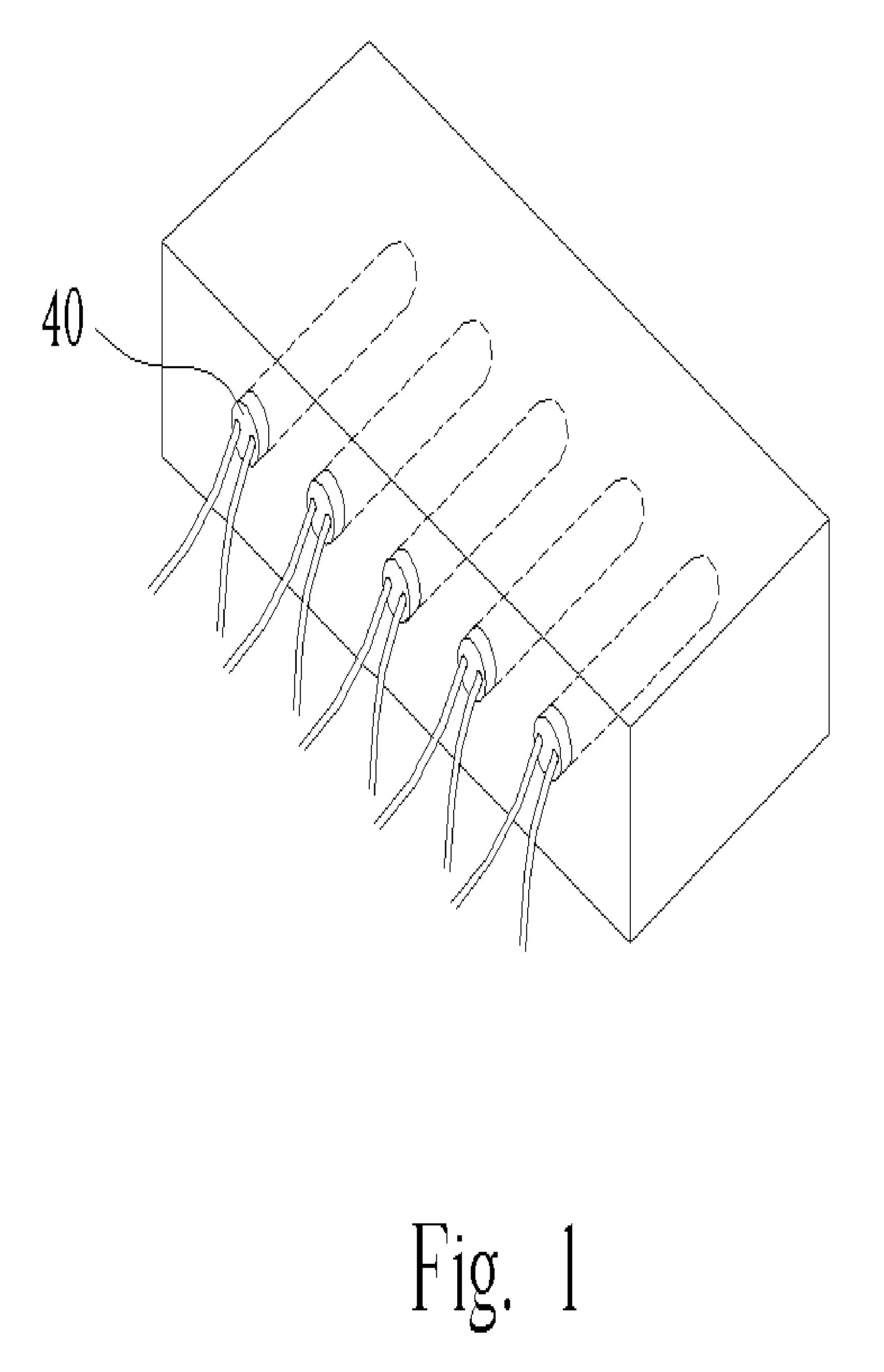

Microheater and microheater array

InactiveUS20120132643A1Uniform temperature distributionSmall temperature differenceOhmic-resistance heating detailsEngineeringStructural engineering

A microheater and a microheater array are provided. The microheater includes a substrate, a column disposed on the substrate and a bridge supported by the column. A width of a portion of a bridge formed on the column is less than a width of a portion of the bridge that does not contact the column. The bridge may include a spring component.

Owner:SAMSUNG ELECTRONICS CO LTD

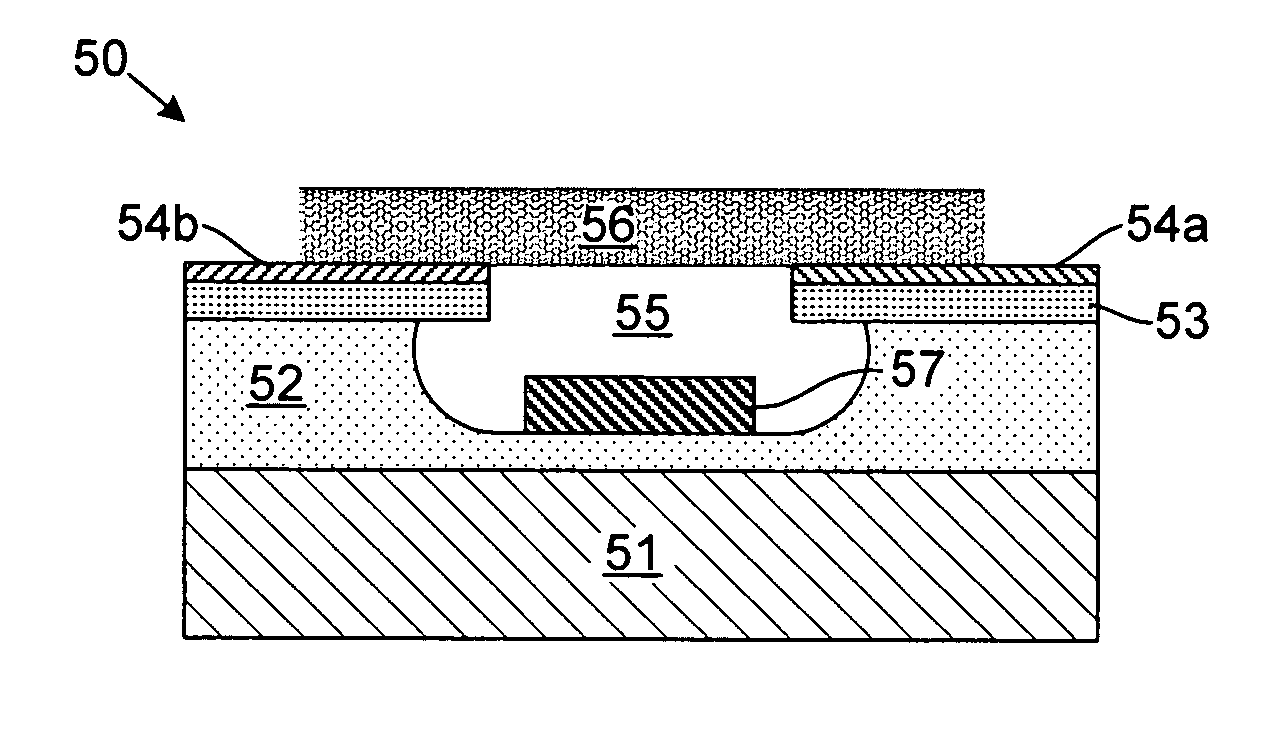

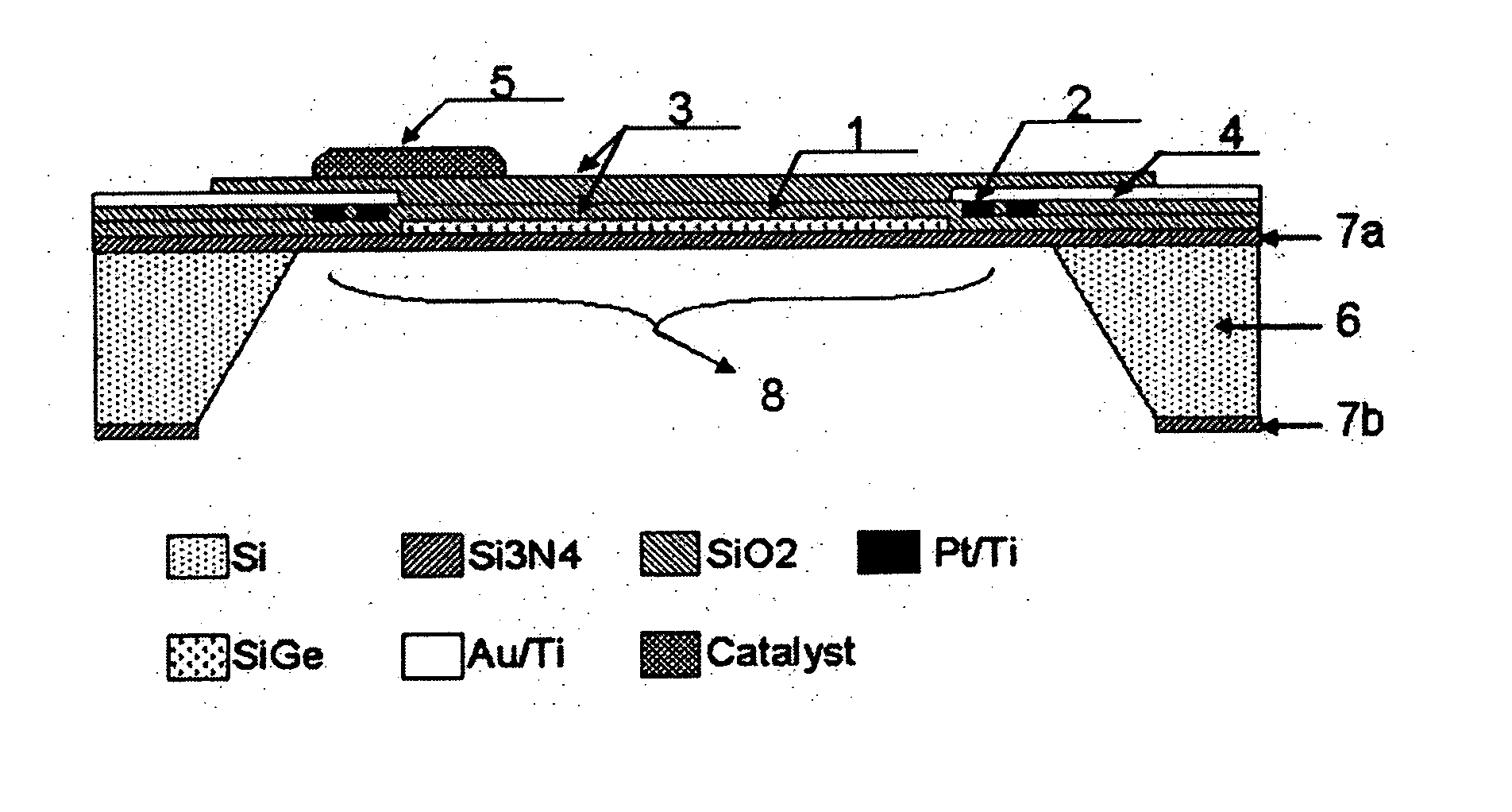

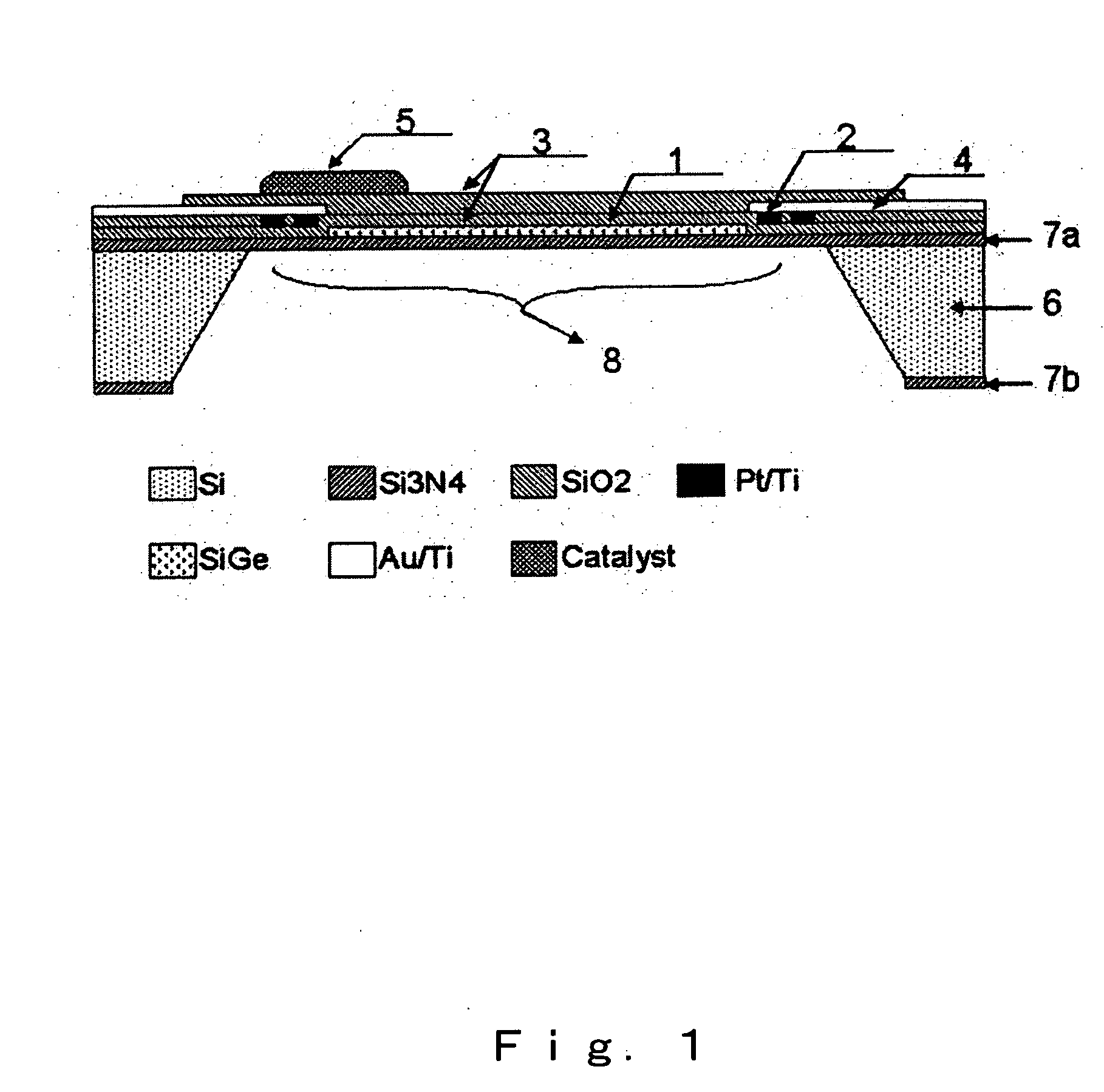

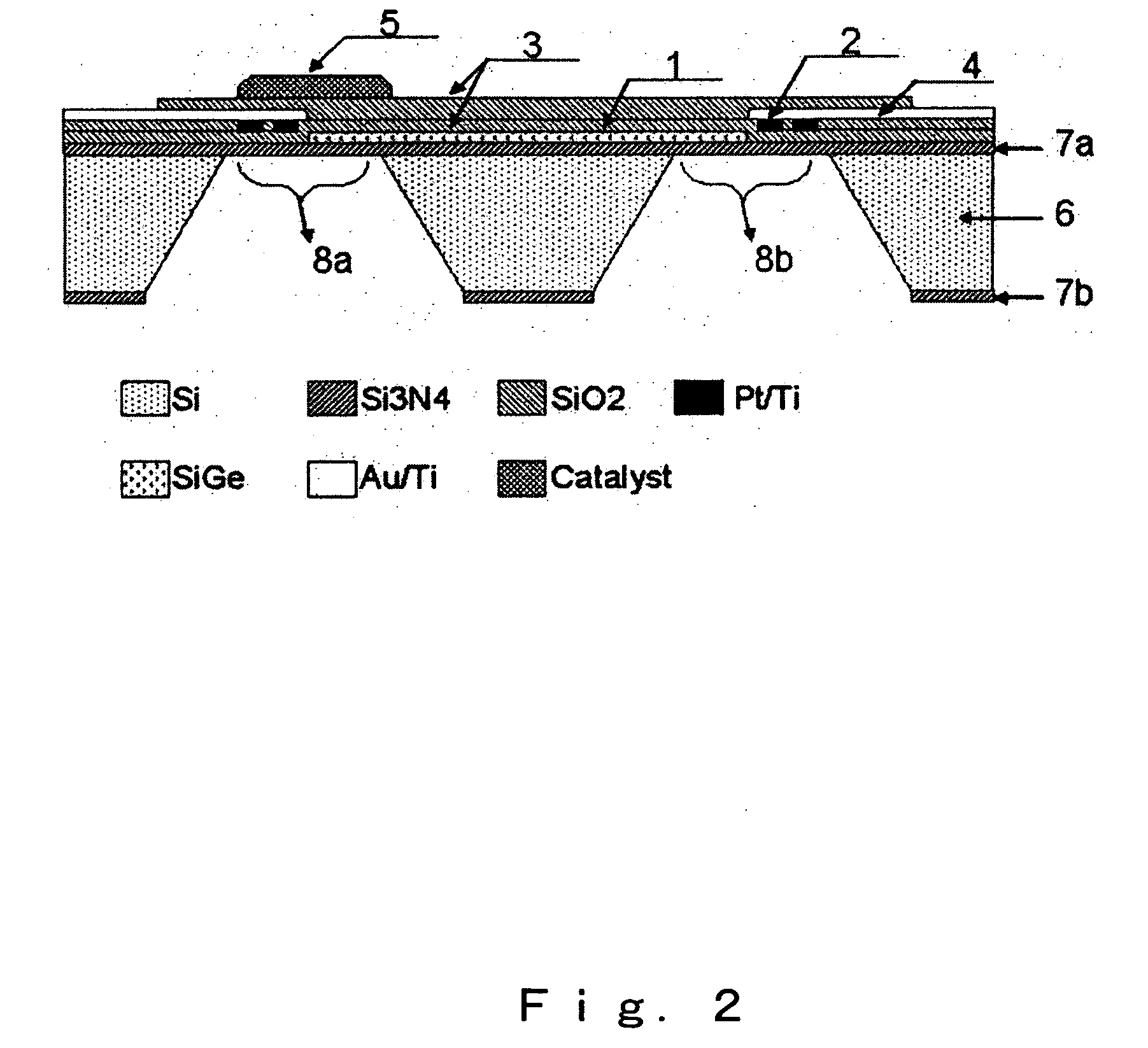

Nanoelectronic sensor with integral suspended micro-heater

InactiveUS20070045756A1Rapid responseImprove responsivenessThermometers using material expansion/contactionNanoinformaticsElectrical conductorEngineering

A nanoelectronic sensing device includes a substrate, a nanostructure element disposed adjacent the substrate, and at least a conductive element electrically connected to the nanostructure element. The device is configured to heat at least a portion of the sensor structure including the nanostructure element. In certain embodiments, the nanostructure element comprises at least one nanotube, the nanotube being electrically connected to at least two conductors so as to permit an electric current on the order of 10 microAmps or greater to be passed through the nanotube, causing the nanotube to heat up relative to the substrate. In alternative embodiments, the sensing device includes a platform or membrane which is at least partially thermally isolated by one or more cavities, the platform supporting at least the nanostructure element adjacent to a microheater element. The heating of the sensor structure may be employed, for example, for thermoregulation, to accelerate and / or increase sensor response, and to improve other sensor characteristics.

Owner:NANOMIX

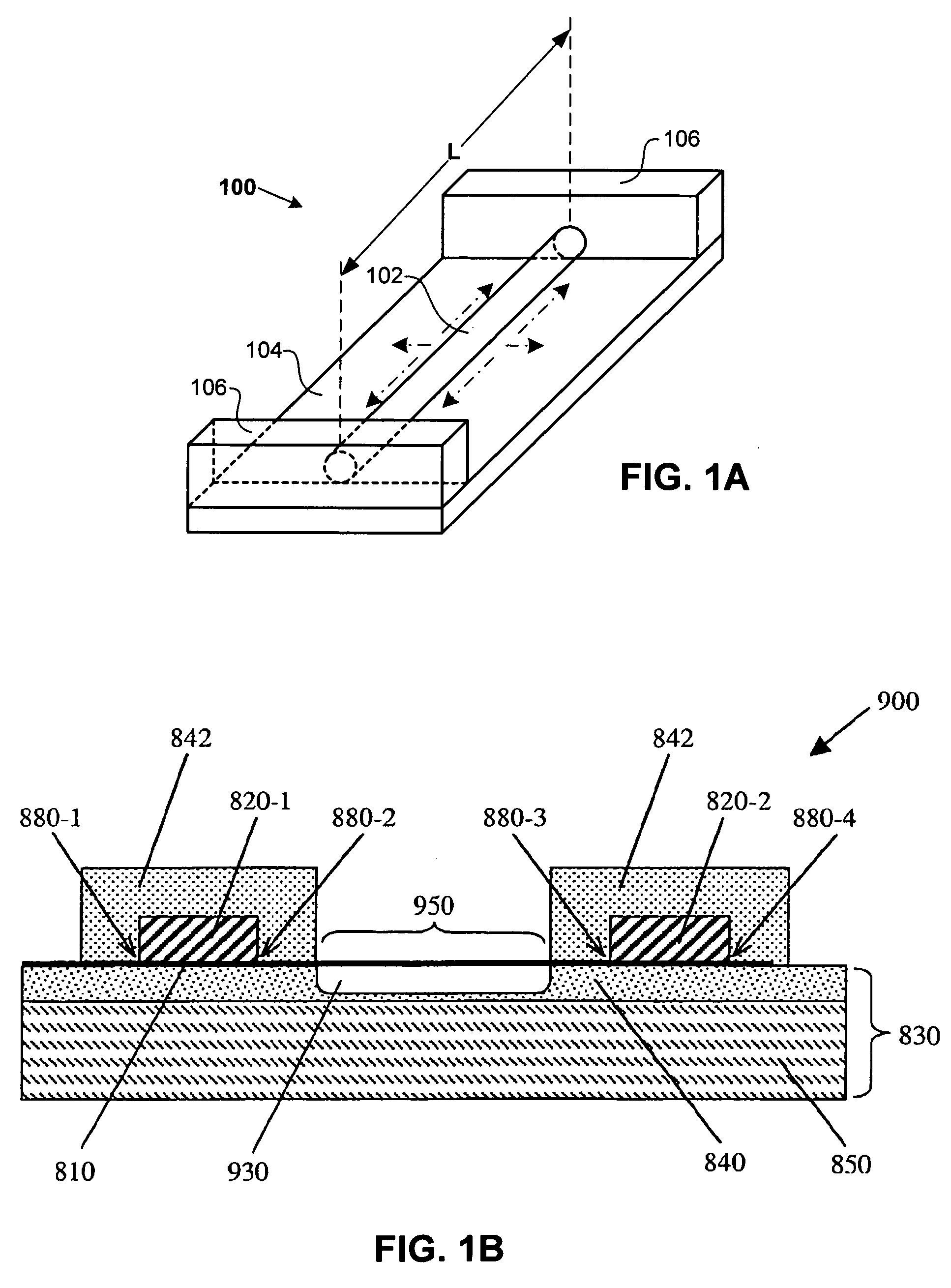

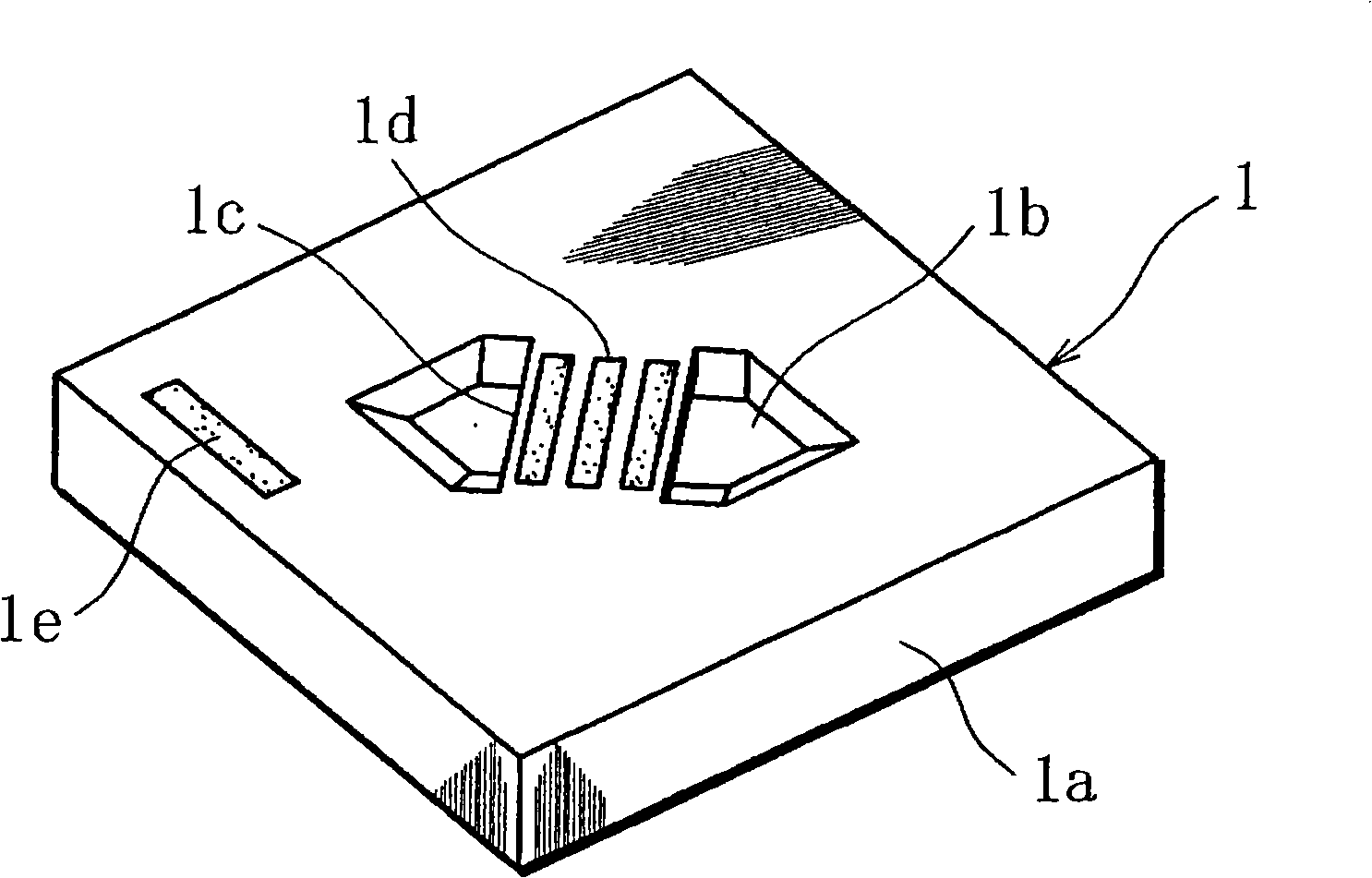

Microfabricated microconcentrator for sensors and gas chromatography

InactiveUS7147695B2High sensitivityImprove signal-to-noise ratioElectrolysis componentsComponent separationSignal-to-noise ratio (imaging)Gas phase

Devices for enhancing the sensitivity of a microsensor or any other micro device by providing on-line preconcentration. Microconcentrators that can be integrated with a sensor or a micromachined GC to enhance the signal to noise ratio can include a miniaturized sorbent trap fabricated on a microchip. The microconcentrator can be made on a silicon substrate so that a sensor can be integrated on the same chip. The microconcentrator is composed of at least one microchannel lined with a microheater for in-situ heating. Preconcentration may be achieved on a thin-film polymeric layer deposited above the heater in the microchannel. Rapid heating by the channel heater generates a “desorption pulse” to be injected into a detector or a sensor.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

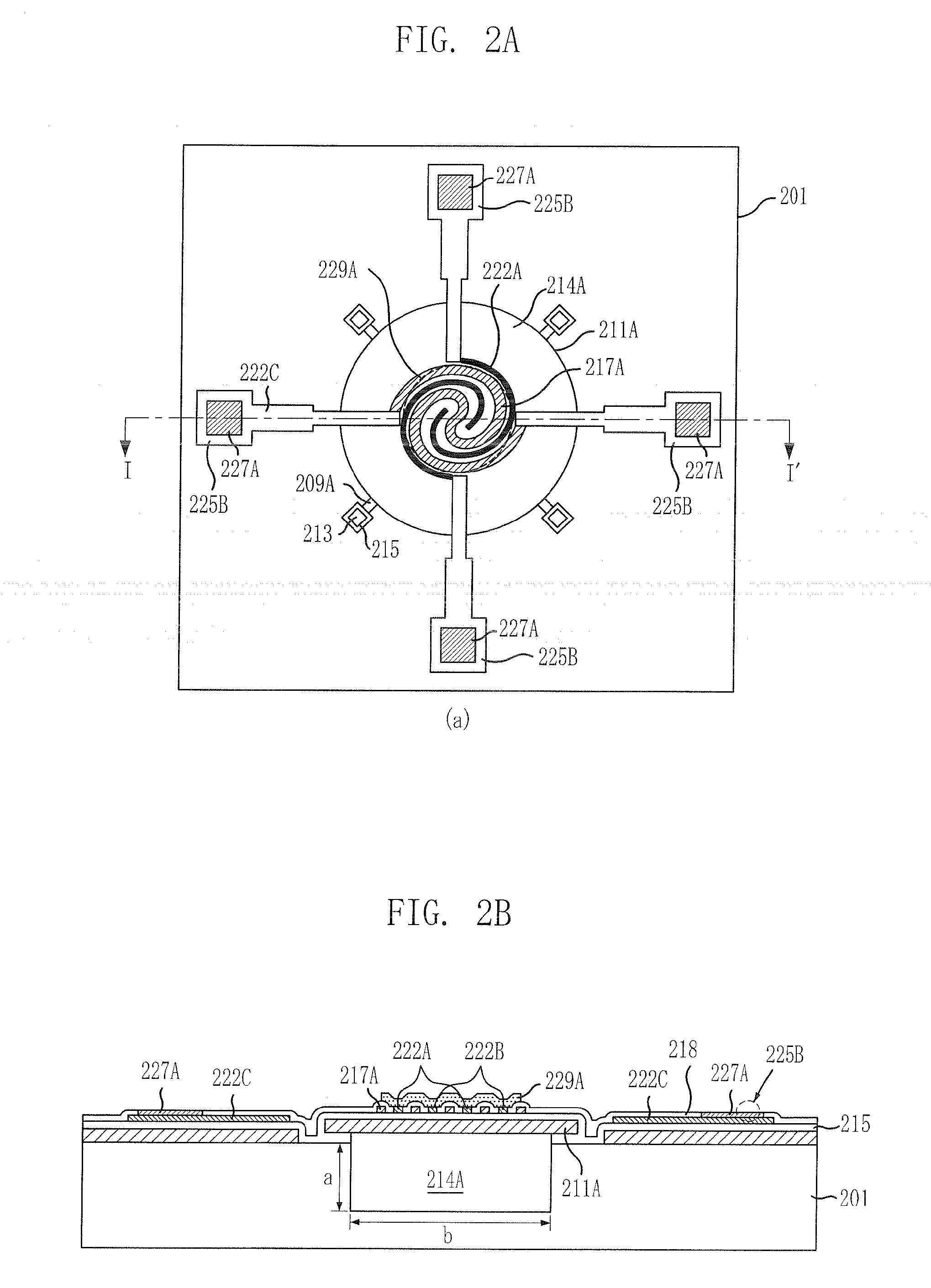

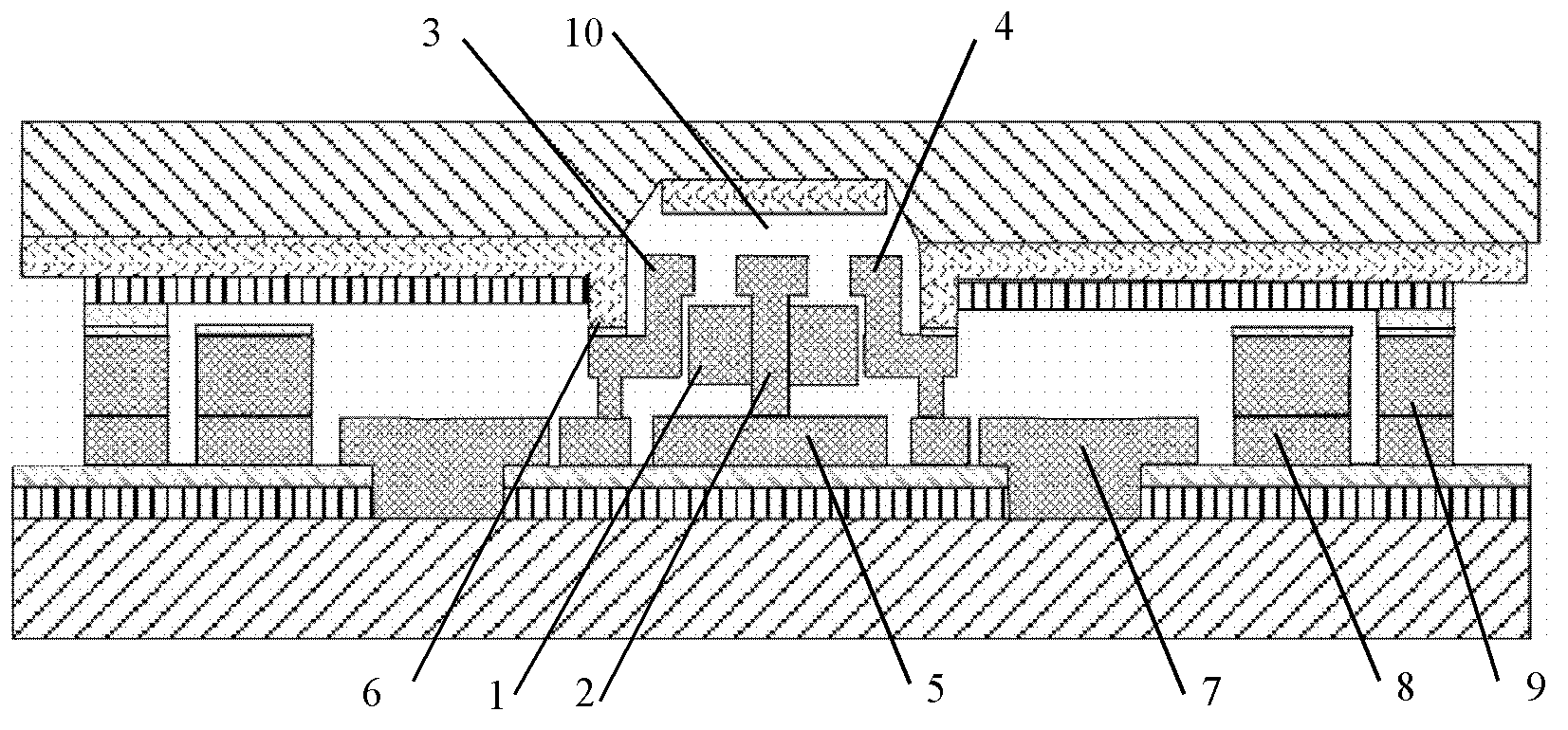

Micro gas sensor and method for manufacturing the same

ActiveUS20080134753A1High measurement accuracyMinimize height differenceAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansThermal impactMechanical impact

Provided are a micro gas sensor for measuring a gas concentration configured to achieve a high heating and cooling rate of a gas sensitive layer, achieve temperature uniformity, and achieve durability against thermal impact and mechanical impact; and a method for manufacturing the micro gas sensor. The micro gas sensor includes: a vacuum cavity disposed in a substrate; a support layer covering the vacuum cavity; a sealing layer sealing the support layer and the vacuum cavity; a micro heater disposed on the sealing layer; a plurality of electrodes disposed on the micro heater, insulated from the micro heater; and a gas sensitive layer covering the electrodes.

Owner:ELECTRONICS & TELECOMM RES INST

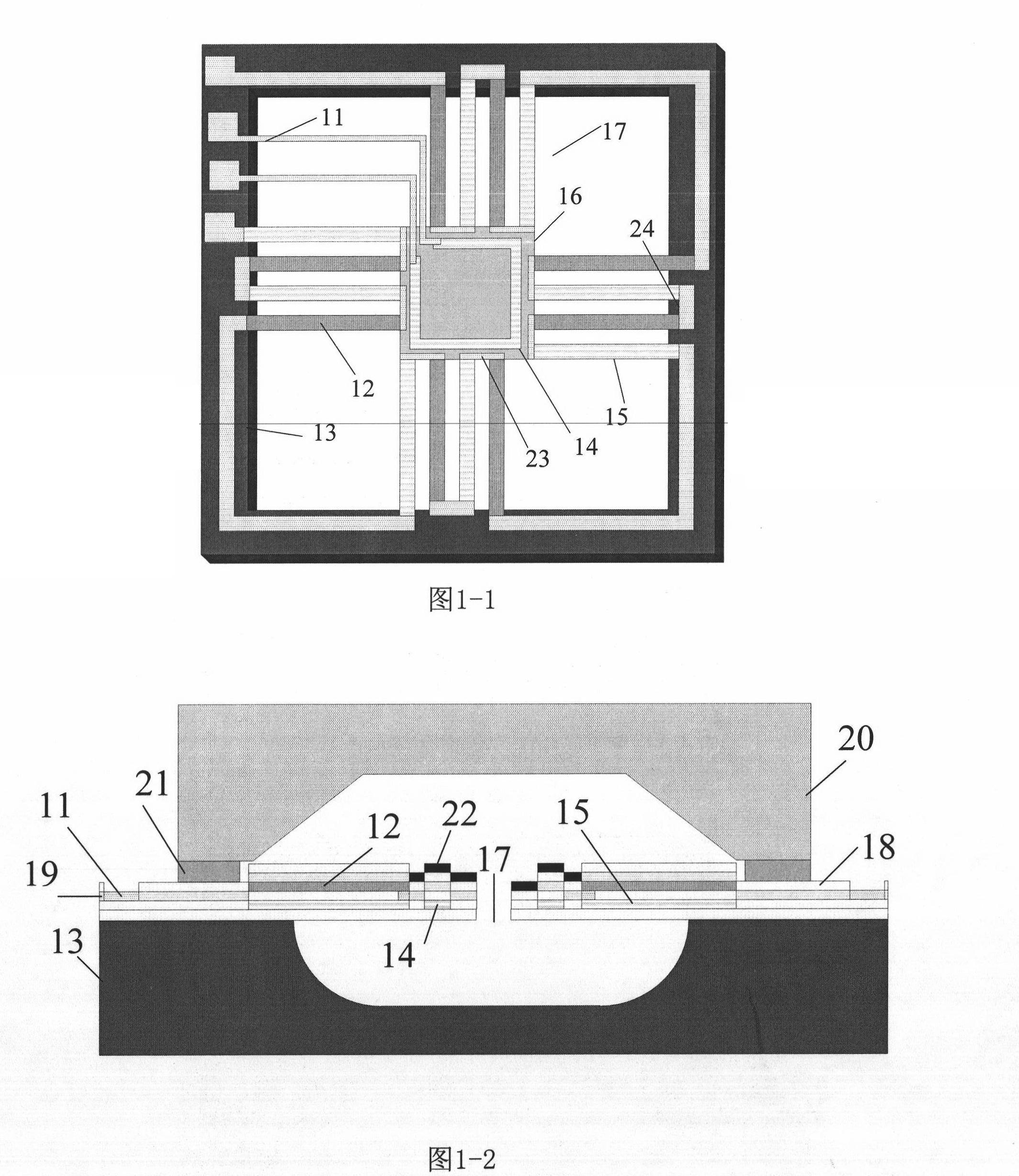

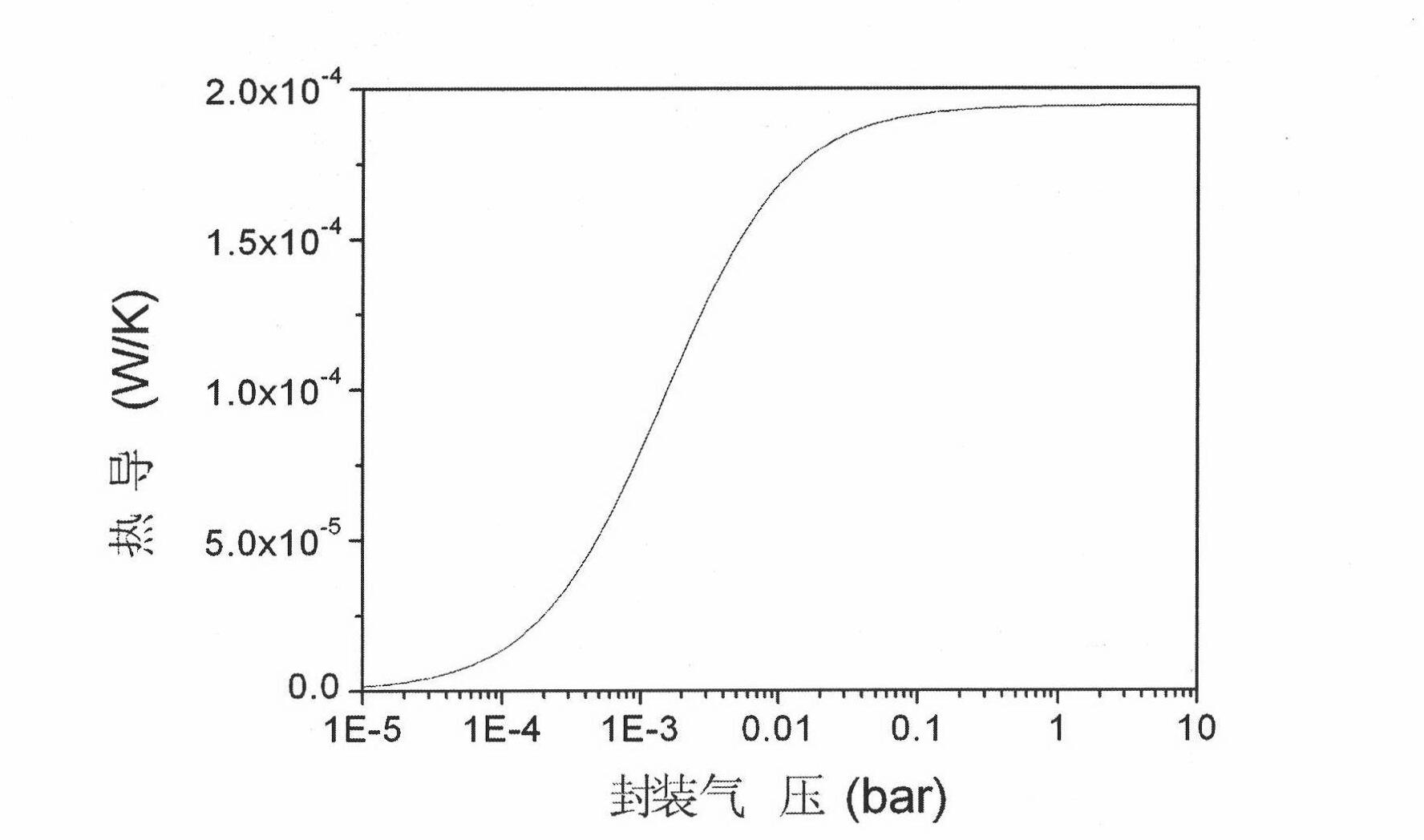

Non-refrigerant thermopile infrared detector and manufacturing method thereof

ActiveCN101776483AFast heat conductionRealize functionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermopileOptoelectronics

The invention relates to a non-refrigerant thermopile infrared detector and a manufacturing method thereof. The invention is characterized in that a micro heater is arranged in the infrared absorption area of a non-refrigerant thermopile infrared detector. Because the manufacturing process of the micro heater is completely compatible with that of the thermopile, the two processes are integrated on one chip. By using the micro heater to measure the thermal conduction of the encapsulated infrared detector, the invention realizes the measurement of the vacuum degree of an encapsulated device; and by using the micro heater to simulate the operation state of the thermopile infrared detector, the invention realizes the wafer level self-test of the infrared performance of the detector. The invention can be used for mass production, can monitor the key process step of wafer level bonding and vacuum encapsulation, and can realize the wafer level measurement of the infrared performance of the detector. Besides, the invention improves the device-testing efficiency, reduces the testing cost, and can realize a low-cost and high-performance non-refrigerant thermopile infrared detector.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

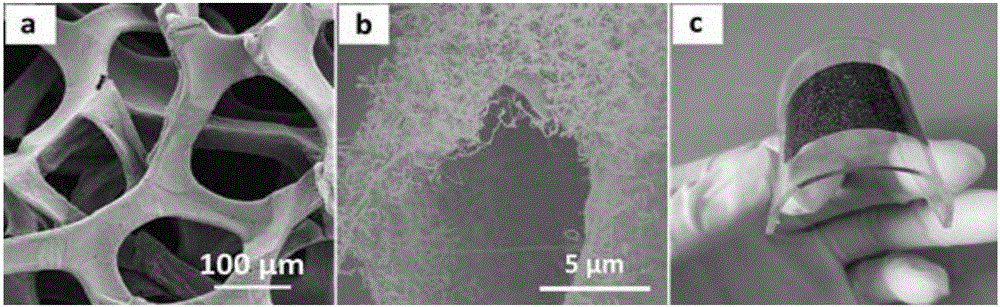

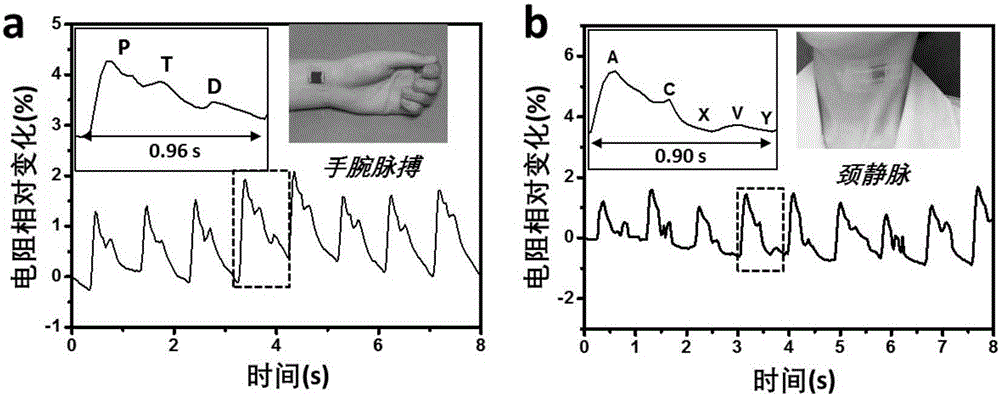

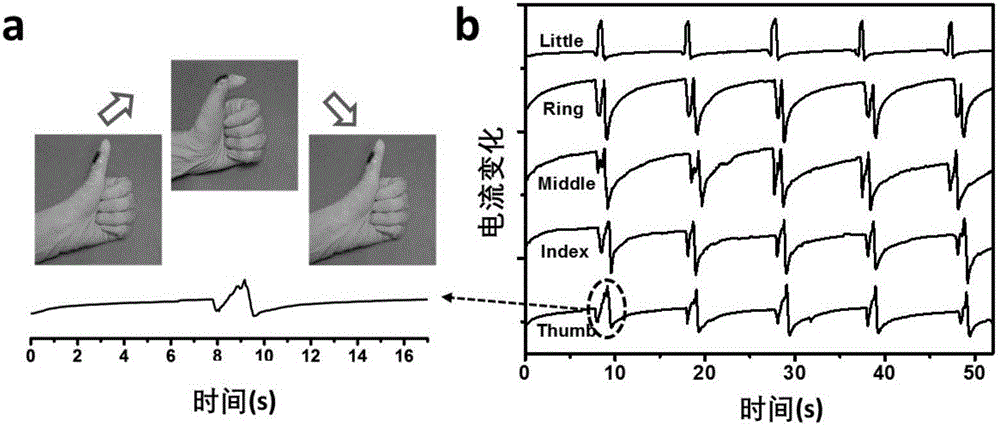

Graphene/carbon nanotube network flexible multifunctional strain sensor preparation method

ActiveCN106767374APractical application value is greatImprove tensile propertiesElectrical/magnetic solid deformation measurementCarbon nanotubeMicroheater

The invention discloses a three-dimensional graphene / carbon nanotube network flexible multifunctional strain sensor preparation method. According to the invention, the three-dimensional network of three-dimensional graphene and a one-dimensional carbon nanotube grows through two-step chemical vapor deposition; and the three-dimensional network and an elastic polymer as a flexible substrate are solidified and combined to acquire a flexible wearable multifunctional electronic strain sensor based on the three-dimensional network of the graphene and the carbon nanotube. According to the invention, the electronic strain sensor breaks the limitation relationship between the strainability and the sensitivity of the strain sensor, has an excellent electronic strain sensing performance and the function of a micro heater, realizes high sensitivity detection of human physiological signals and physical activities, shows excellent electronic skin simulation capabilities and a micro heating source application performance, has the advantage of simple process, and can be widely used in many fields such as clinical diagnosis, health monitoring, a robot, an electronic screen, electronic skin, a flexible micro heater and intelligent home.

Owner:NANJING UNIV OF TECH

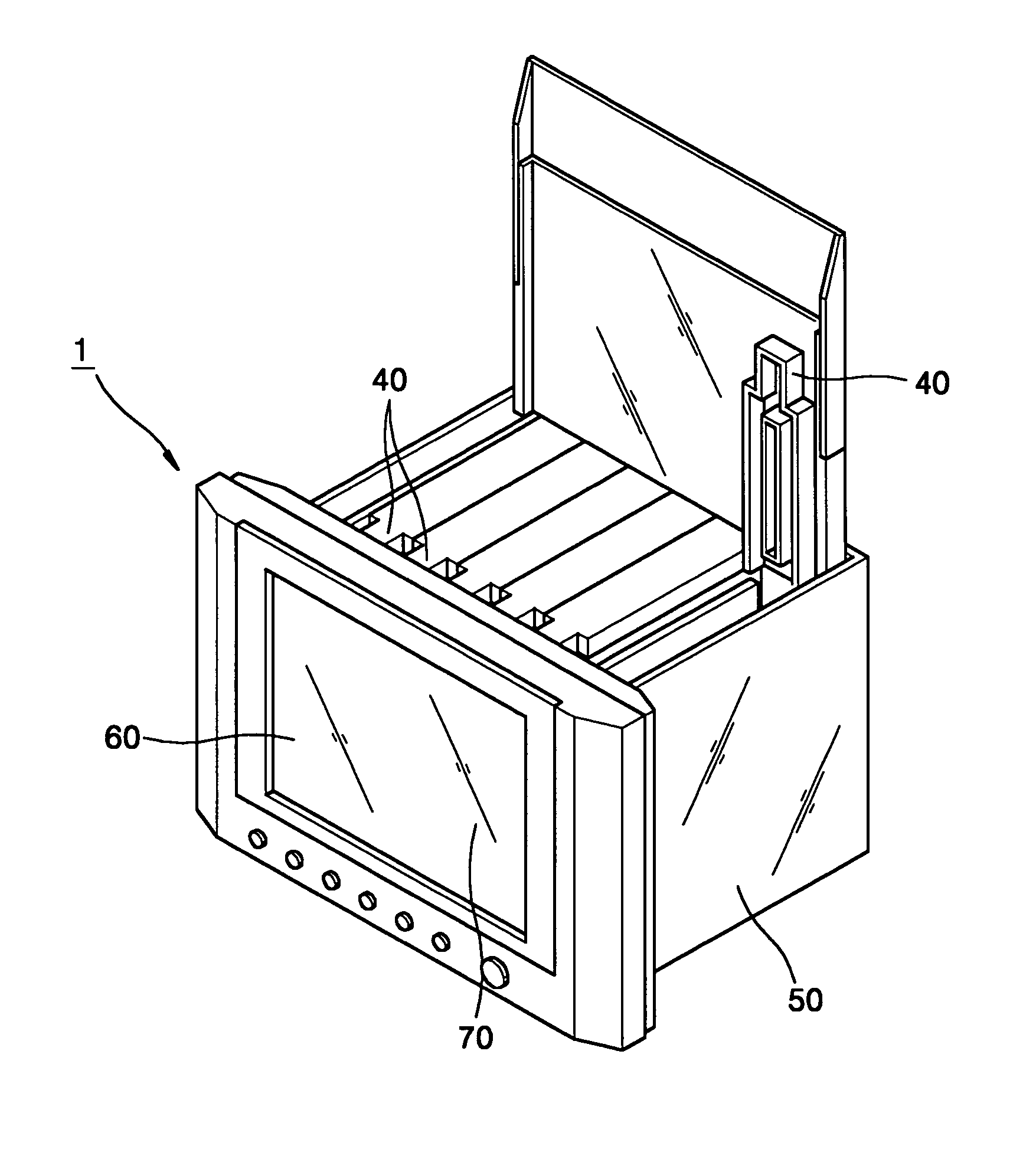

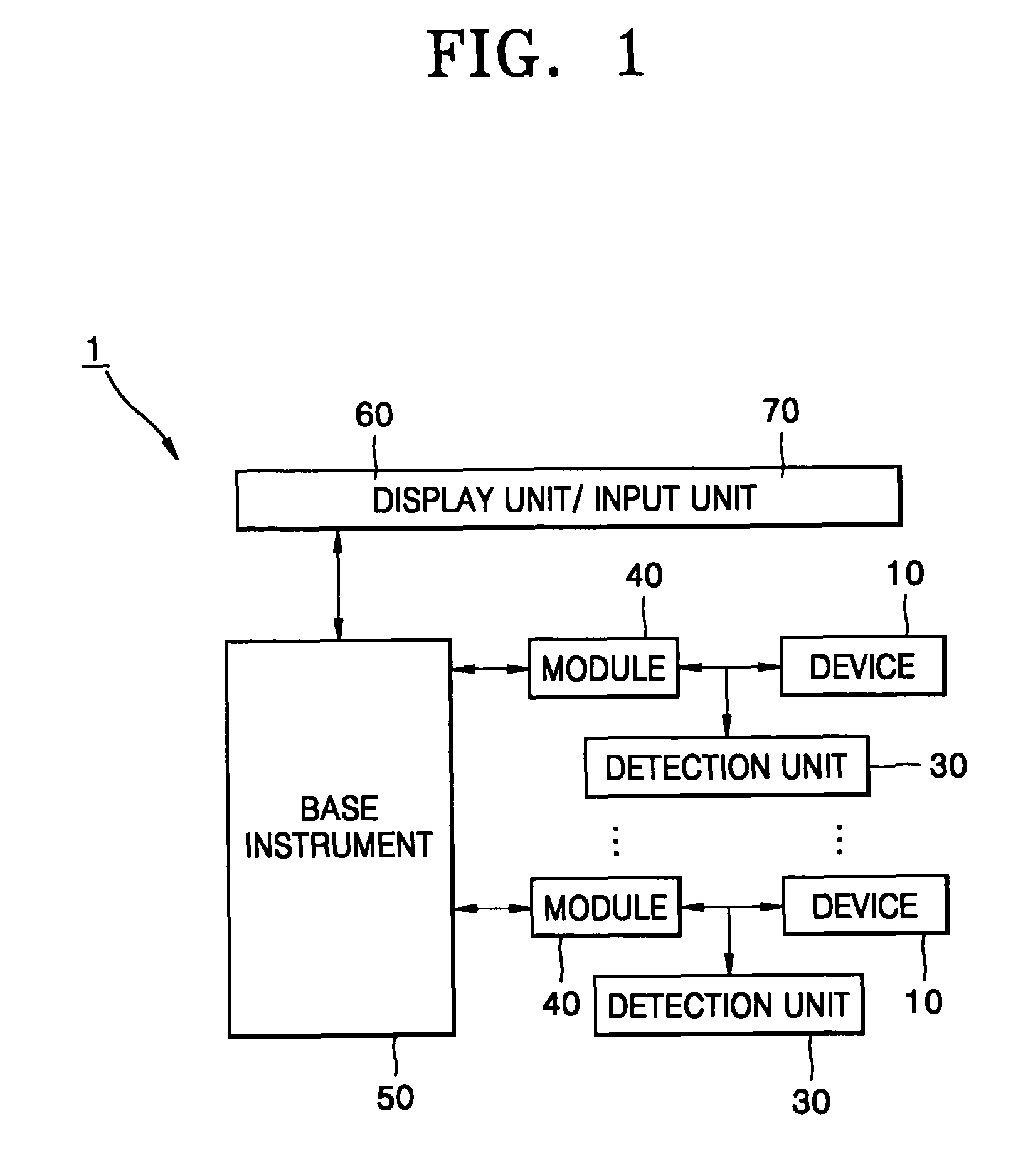

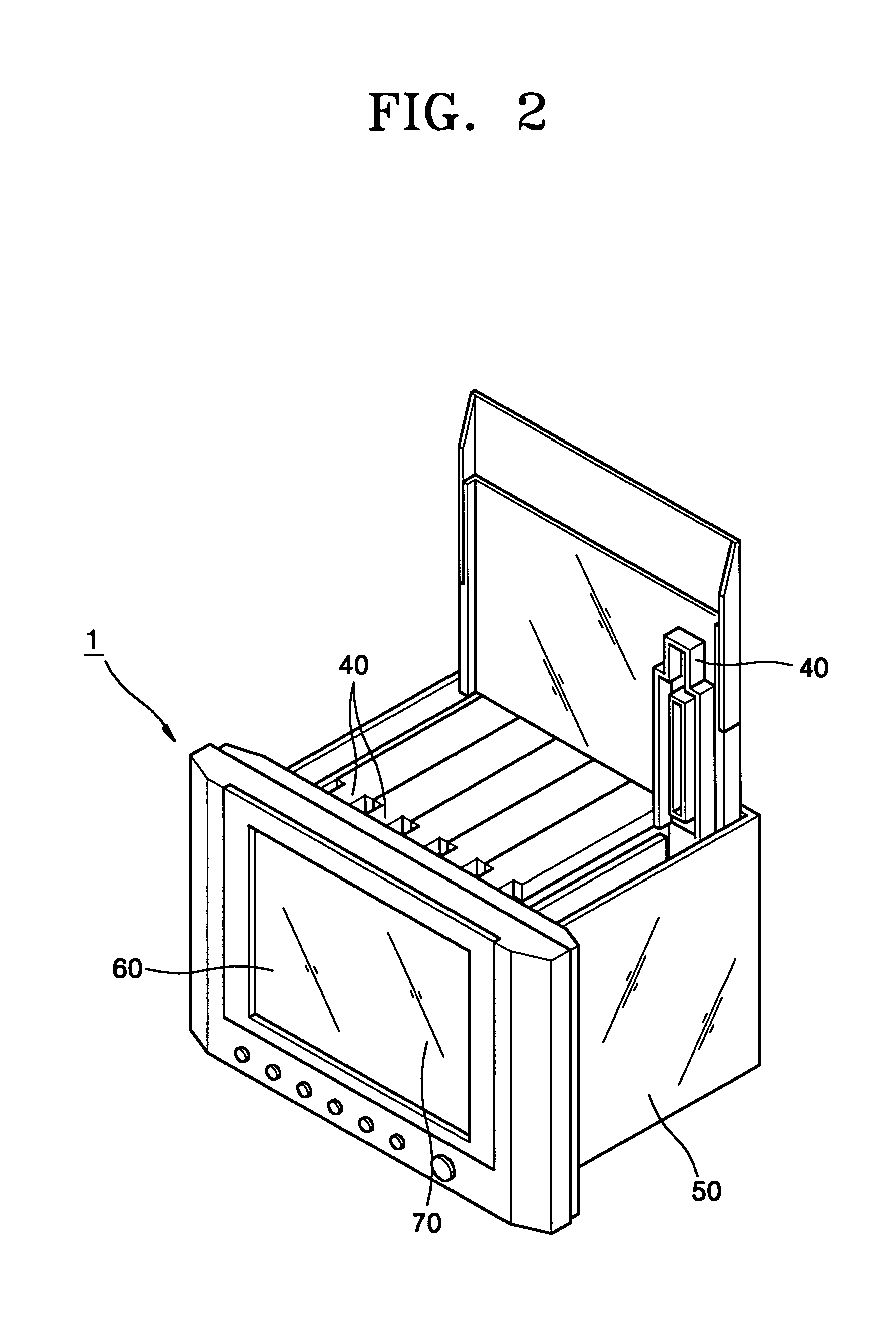

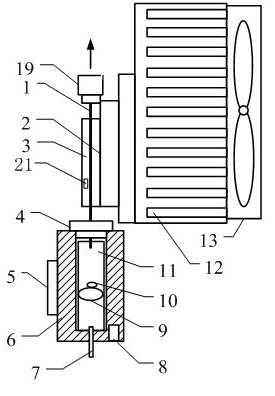

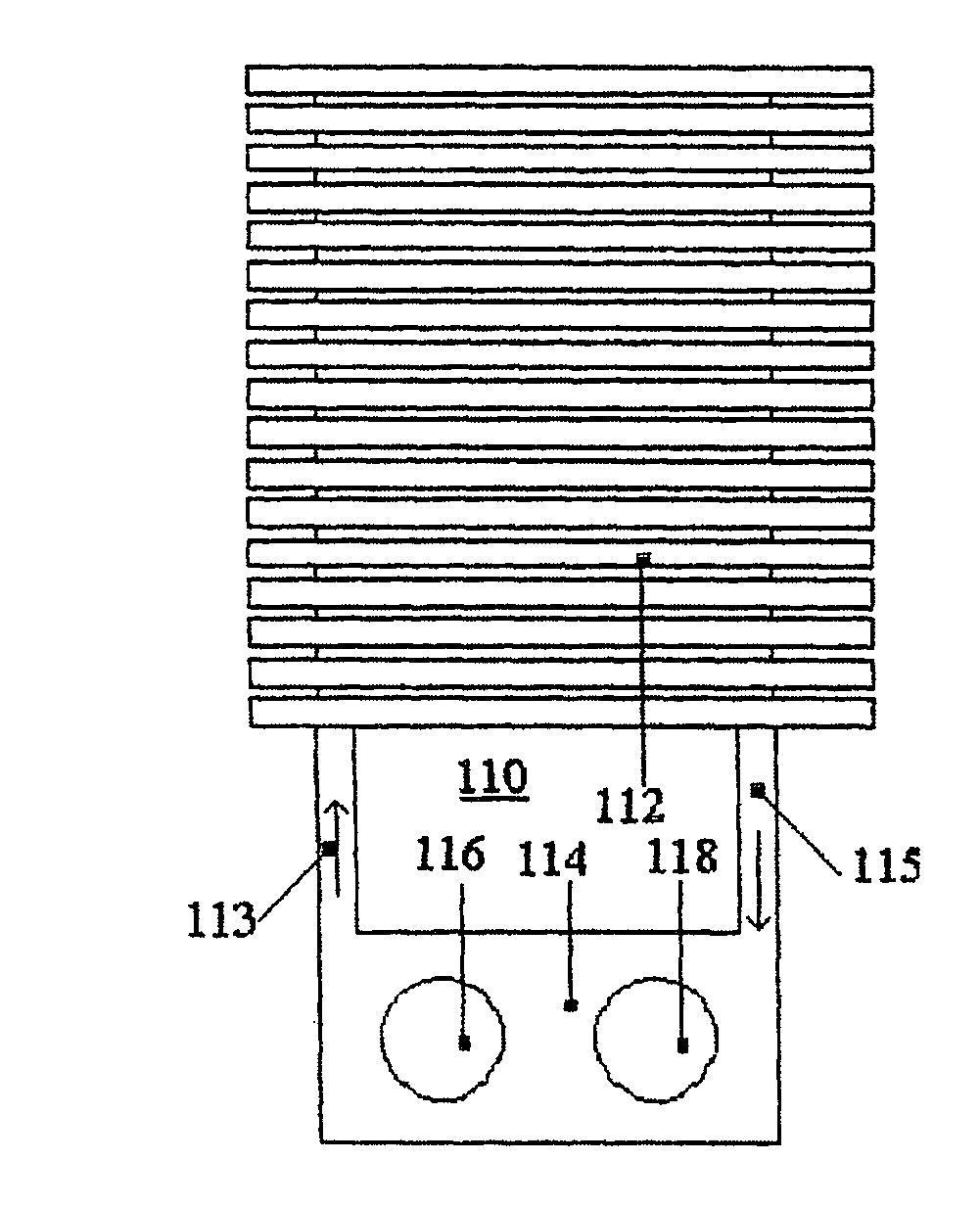

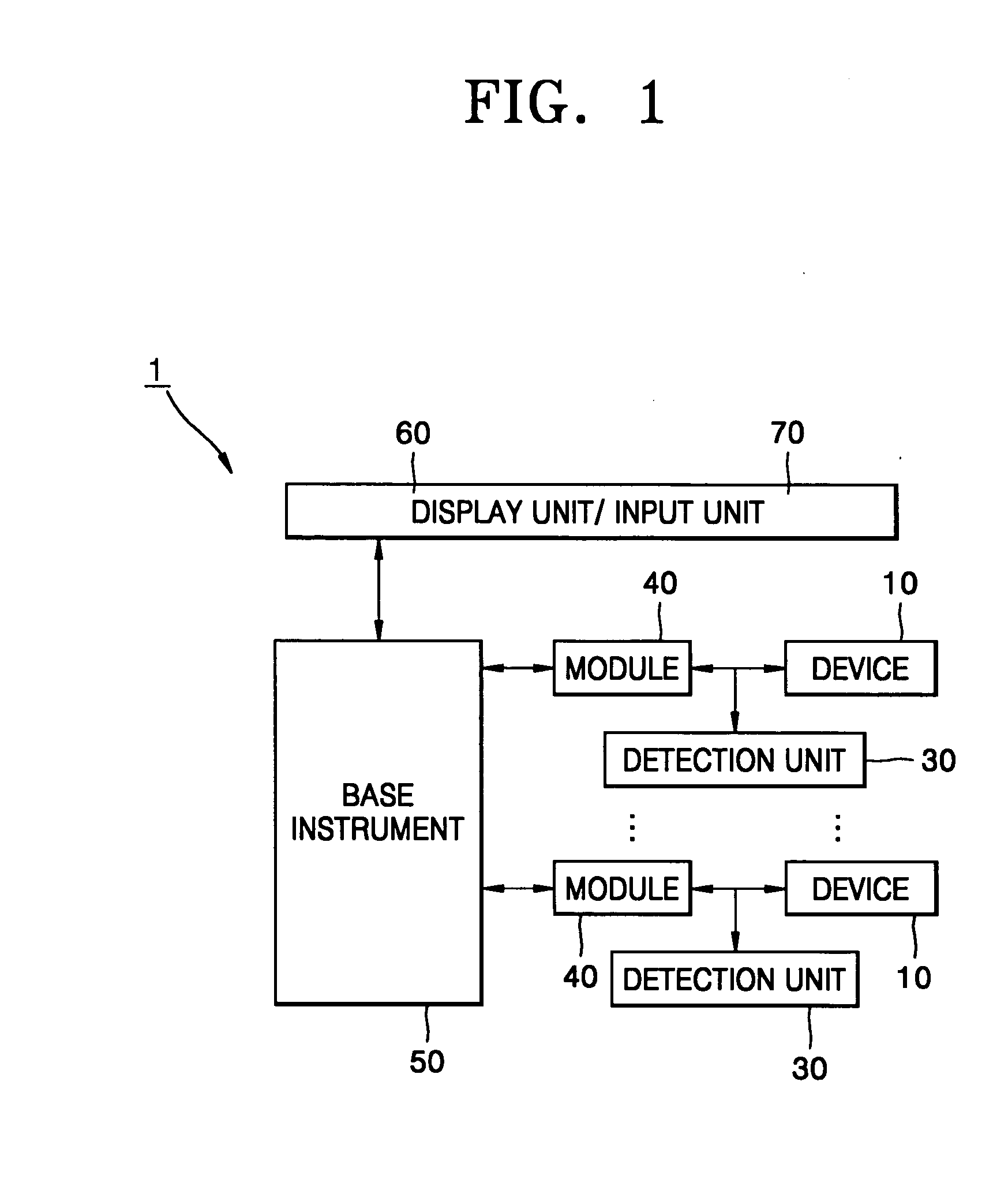

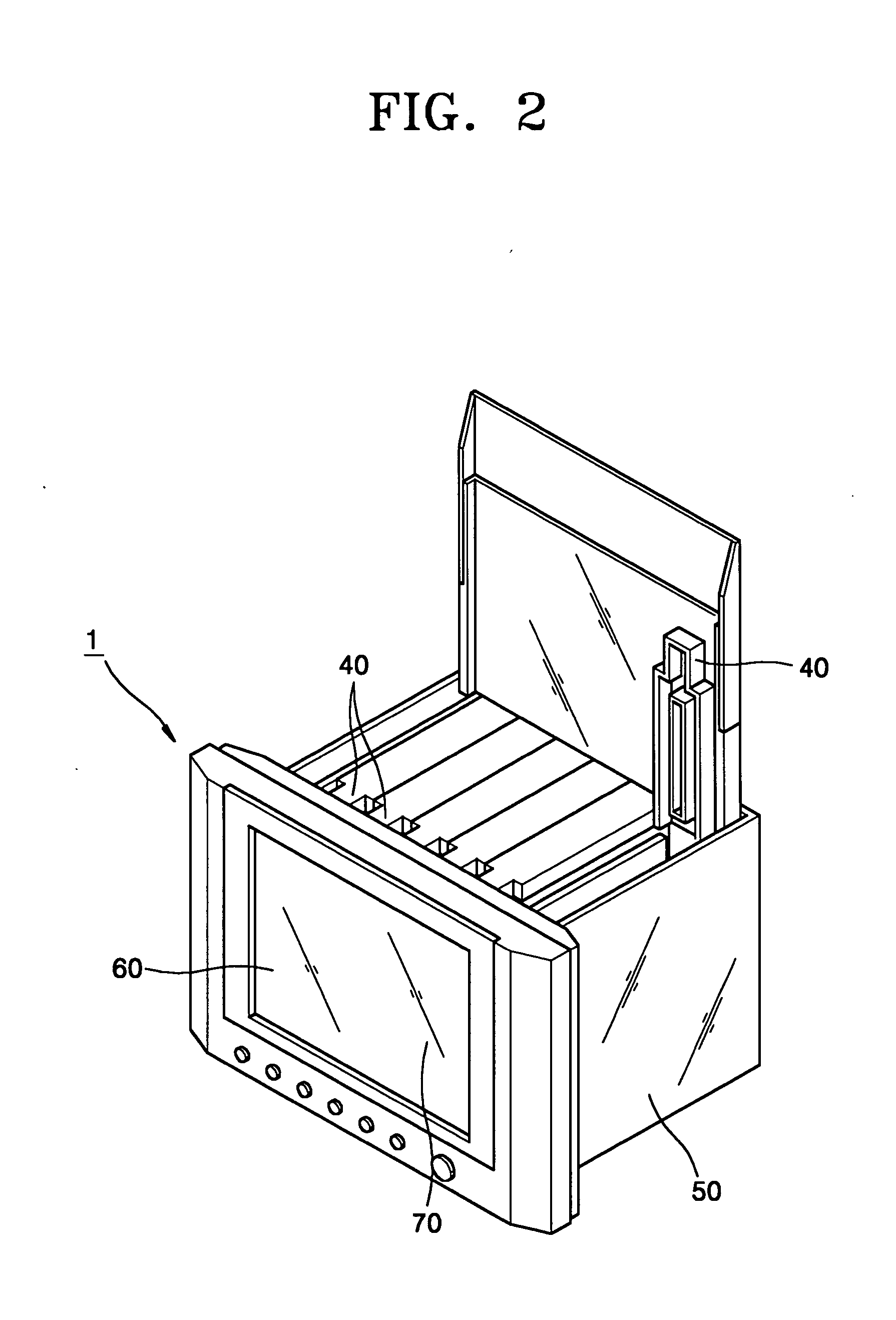

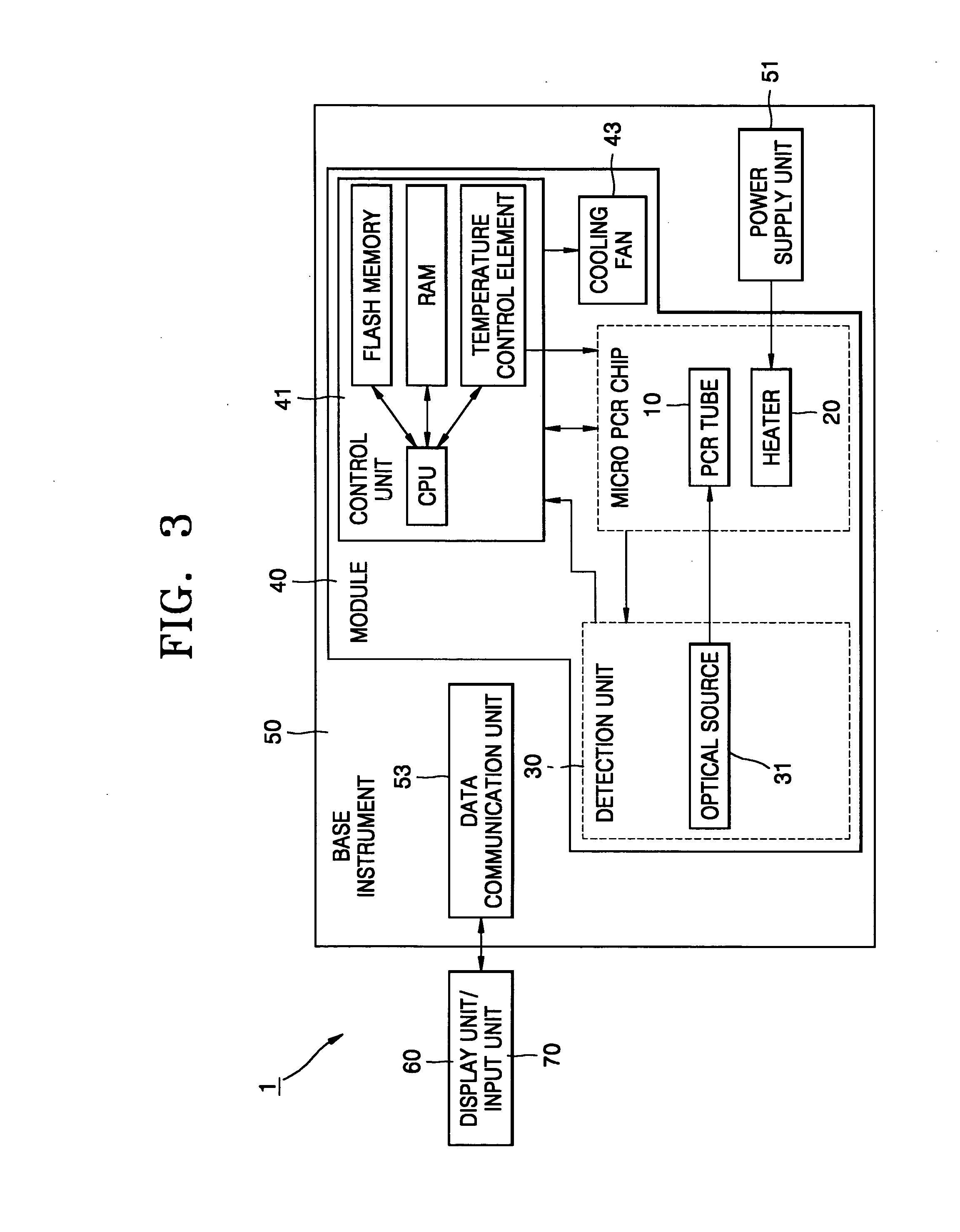

Real-time PCR monitoring apparatus and method

InactiveUS7767439B2Increase conversion rateBioreactor/fermenter combinationsBiological substance pretreatmentsCommunication unitComputer module

A real time polymerase chain reaction (“PCR”) monitoring apparatus includes, a microchip-type PCR tube that has a PCR solution-containing PCR chamber, a micro-heater, a detection unit detecting a PCR product signal based on the PCR solution, a plurality of modules, each of which includes the abovementioned elements in addition to a cooling fan and a control unit controlling the micro-heater and the cooling fan to adjust the temperature of the PCR chamber, a base instrument that comprises a power supply unit connected to the modules and a data communication unit connected to the control unit of each of the modules, and a display unit displaying data from the data communication unit, wherein the control unit of each of the modules independently controls at least one of both the detection unit and the temperature of the PCR chamber of the PCR tube in each of the modules.

Owner:SAMSUNG ELECTRONICS CO LTD

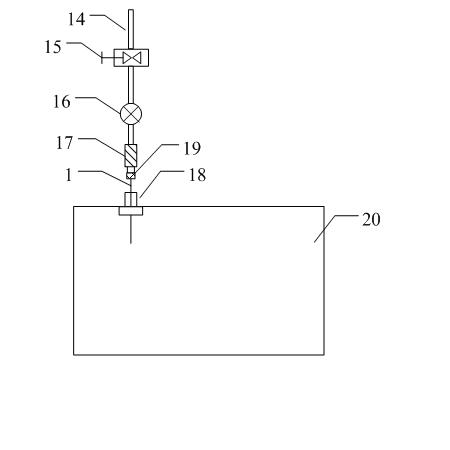

Continuous gas in-tube solid phase microextraction device combined with gas chromatography for use

InactiveCN102636595AAchieve complete extractionIncreased extraction surface areaComponent separationGas solid chromatographyPretreatment method

The invention discloses a continuous gas in-tube solid phase microextraction device combined with gas chromatography (GC) for use. The continuous gas in-tube solid phase microextraction device comprises a continuous gas in-tube solid phase microextraction device and a sampling device, wherein the continuous gas in-tube solid phase microextraction device is composed of an in-tube solid phase microextraction needle, a semiconductor condenser, a microheater and an inert gas connecting pipe, and the sampling device is composed of the in-tube solid phase microextraction needle, and a stop valve, a carrier gas flow controller and a gas source which are connected in sequence through a connector connected with a port of an extraction needle on one end of the in-tube solid phase microextraction needle and are used with the gas chromatography. According to the invention, the extraction needle performs thermal desorption at a GC sample inlet without changing the GC sample inlet and thus the continuous gas in-tube solid phase microextraction device is applied to the GC with any brand. The invention has the advantages of simple operating method, high extraction rate, accurate quantification, hydrophilic environment, convenient automatic operation and the like and also provides a sample pretreatment method integrated with extraction, separation and concentration. The continuous gas in-tube solid phase microextraction device can greatly promote the combination use of the SPME (solid phase microextraction) technology and the GC / MS (mass spectra) technology and applications of micro constituents in complex samples in aspects of on-site analysis, on-line analysis and in-situ analysis.

Owner:YANBIAN UNIV

Micro Thermoelectric Type Gas Sensor

InactiveUS20070212263A1Reduce power consumptionHigh sensitivityMaterial heat developmentMaterial resistanceCombustible gasEngineering

The present invention provides a micro thermoelectric gas sensor having a thermoelectric conversion section, a microheater, a catalyst layer formed on the microheater and to be heated by the microheater, which acts as a catalyst for catalytic combustion of a combustible gas, and a sensor detection section with an electrode pattern therefore formed on a membrane of a predetermined thickness, and a method for forming a micropattern of a functional material of a catalyst or resistor in a predetermined position on a substrate in a state in which the microstructure of the functional material remains controlled.

Owner:NAT INST OF ADVANCED IND SCI & TECH

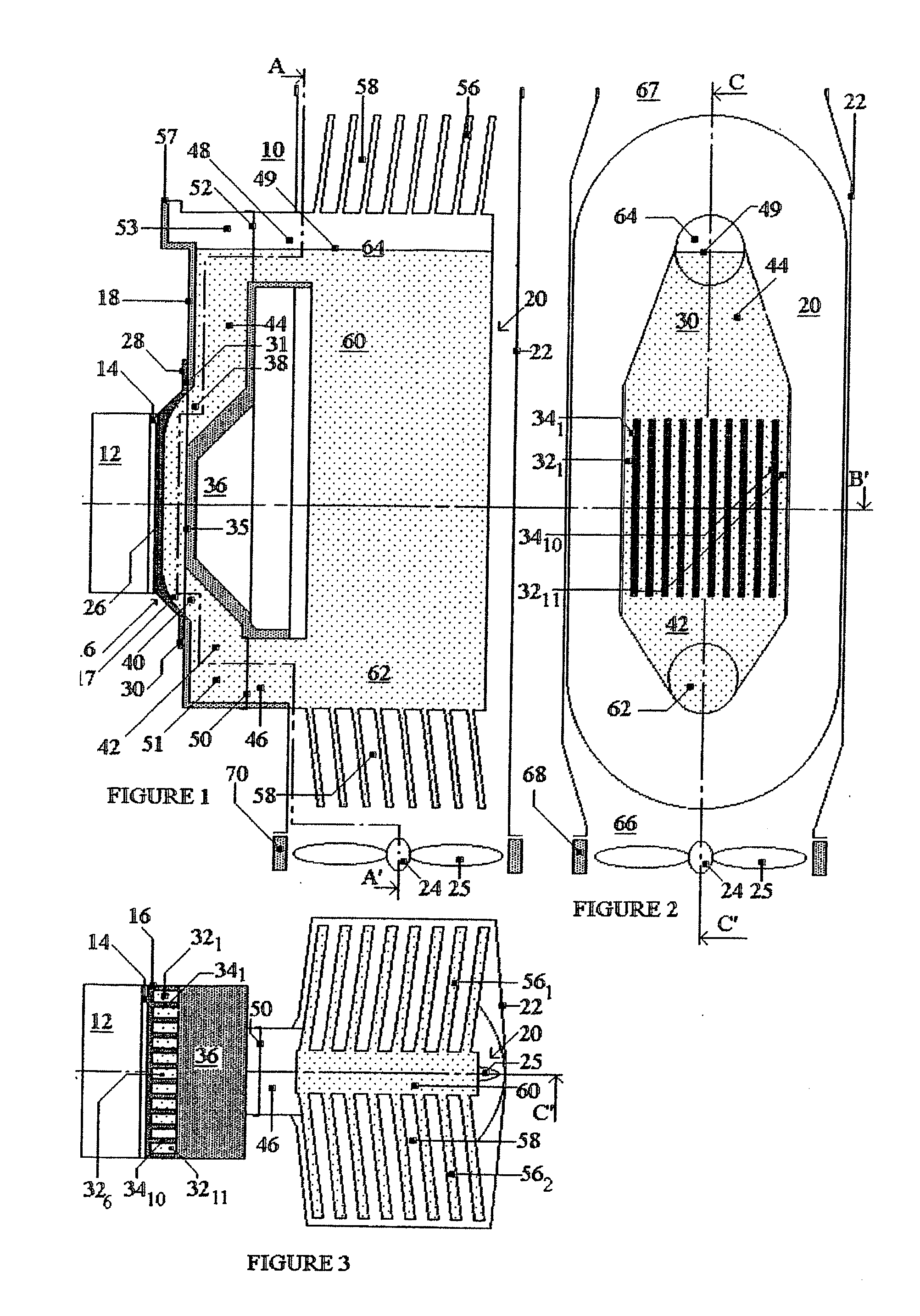

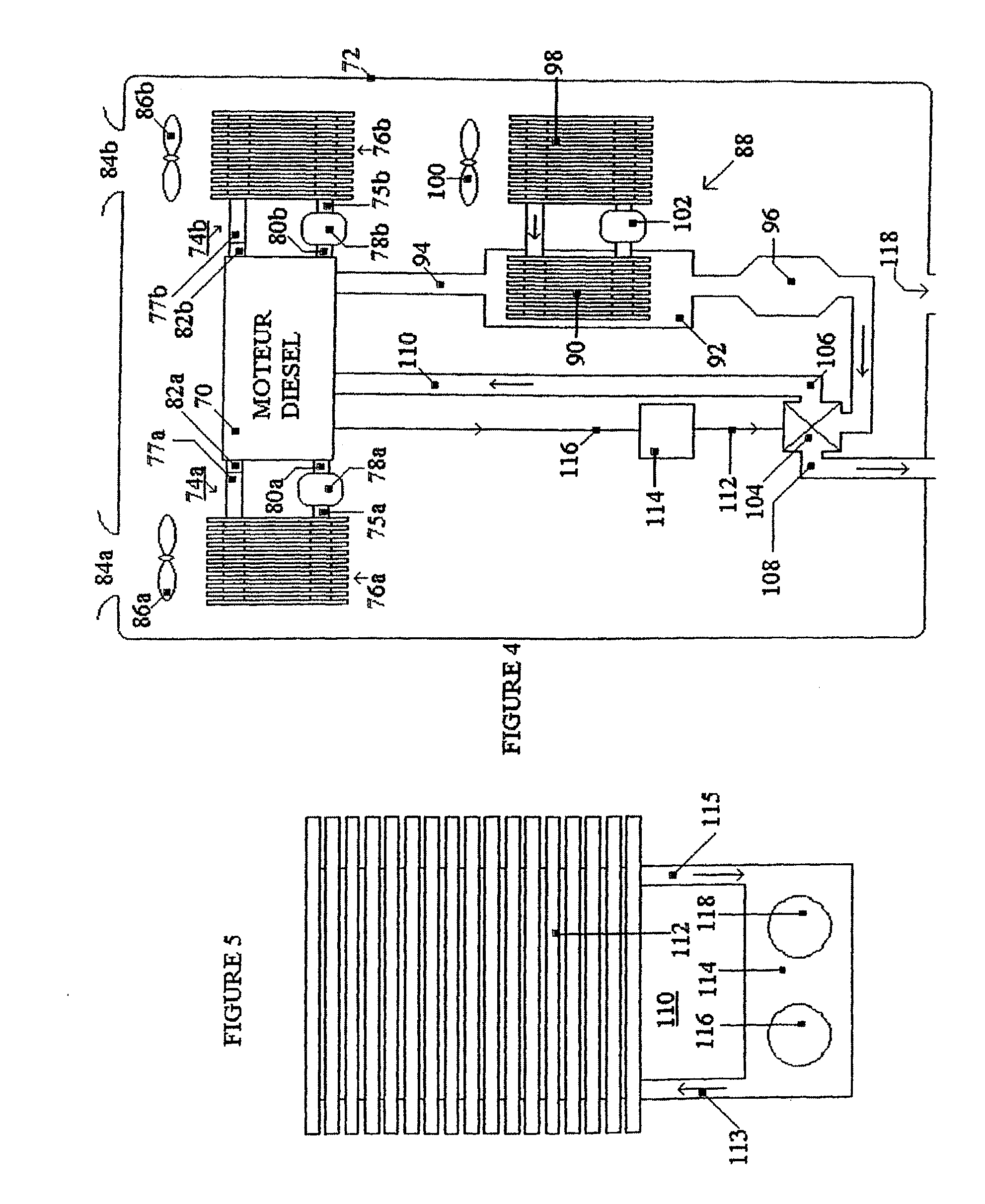

Cooling devices for various applications

InactiveUS20070184320A1Effective, not bulky, and inexpensivePoor heat resistanceInternal combustion piston enginesFuel cells groupingHeat fluxMicroheater

The figure displays the diagram of a laminar flow water cooler (110) for a microprocessor comprising an integral radiator (112) provided with thin-walled and hollow fins which are produced by controlled compression of double convex bellows of a polymer or glass hot-blown blank. In order to form a closed circuit filled with water at the atmospheric pressure, the manifolds (113, 114, 115) of the radiator (112) are connected to the manifolds of an original component (114) formed by a mini heater (116) provided with a copper heating plate with internal grooved face and a mini pump (118) provided with a brushless electric motor devoid of a centrifugal turbine, wherein said mini heater and mini pump are disposed in a rigid small-sized moulded polymer hose. The total thermal resistance of said cooler can be equal to 0.15° / W that is of interest, in particular for high performance microprocessors for dissipating more than 200 W through the very hot central area of 1.5 cm2 of the heat dissipating surface thereof. The concept of the production of the inventive cooler makes it possible to design efficient and low-cost cooling devices which are usable for microprocessors, high-power electronic devices, thermal engines or fuel cells, in particular mounted in a motor vehicle. Said invention can be used for cooling any component dissipating a given thermal flux within the determined power and temperature limits.

Owner:TECH DE LECHANGE THERMIQUE TET

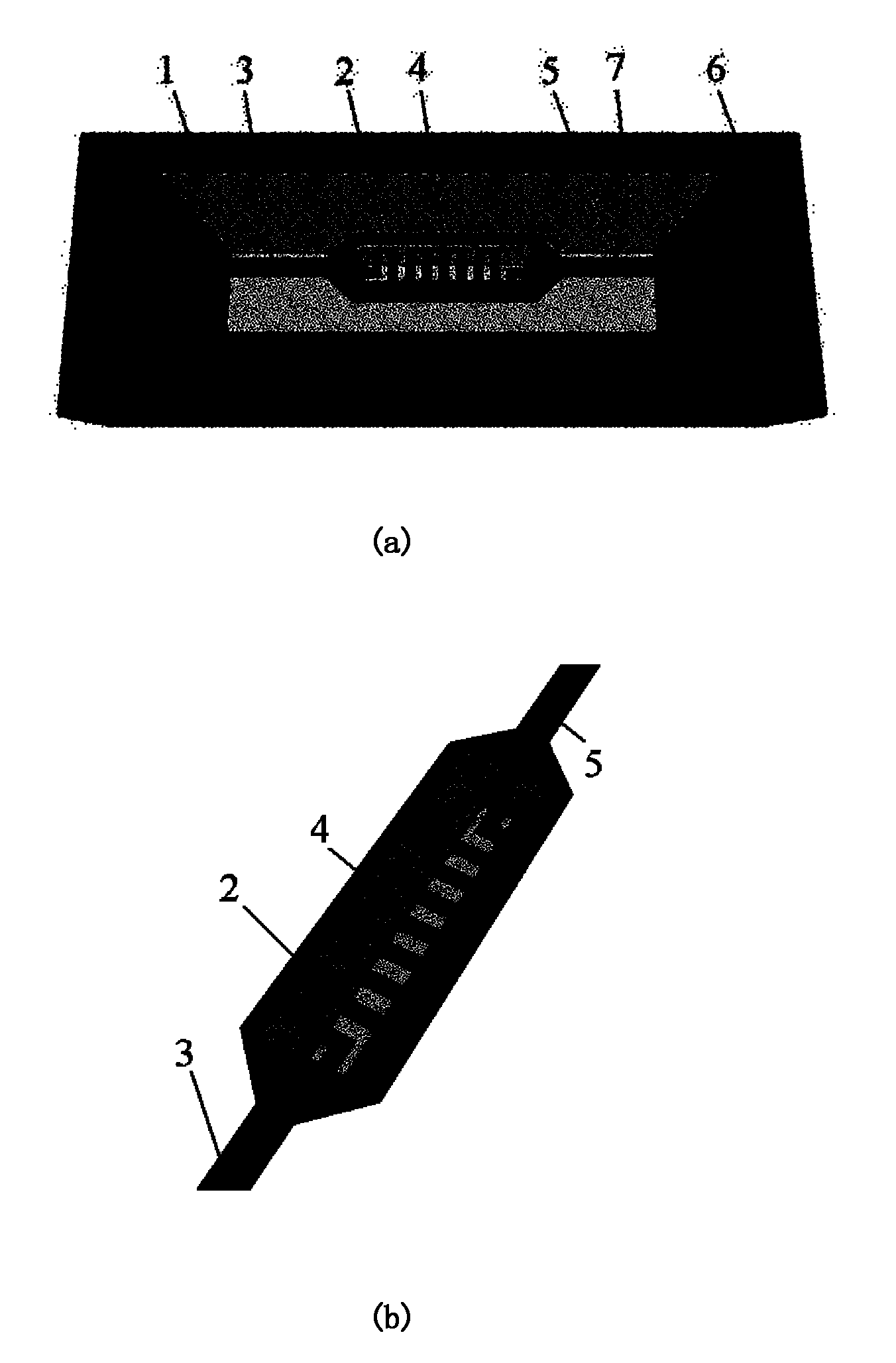

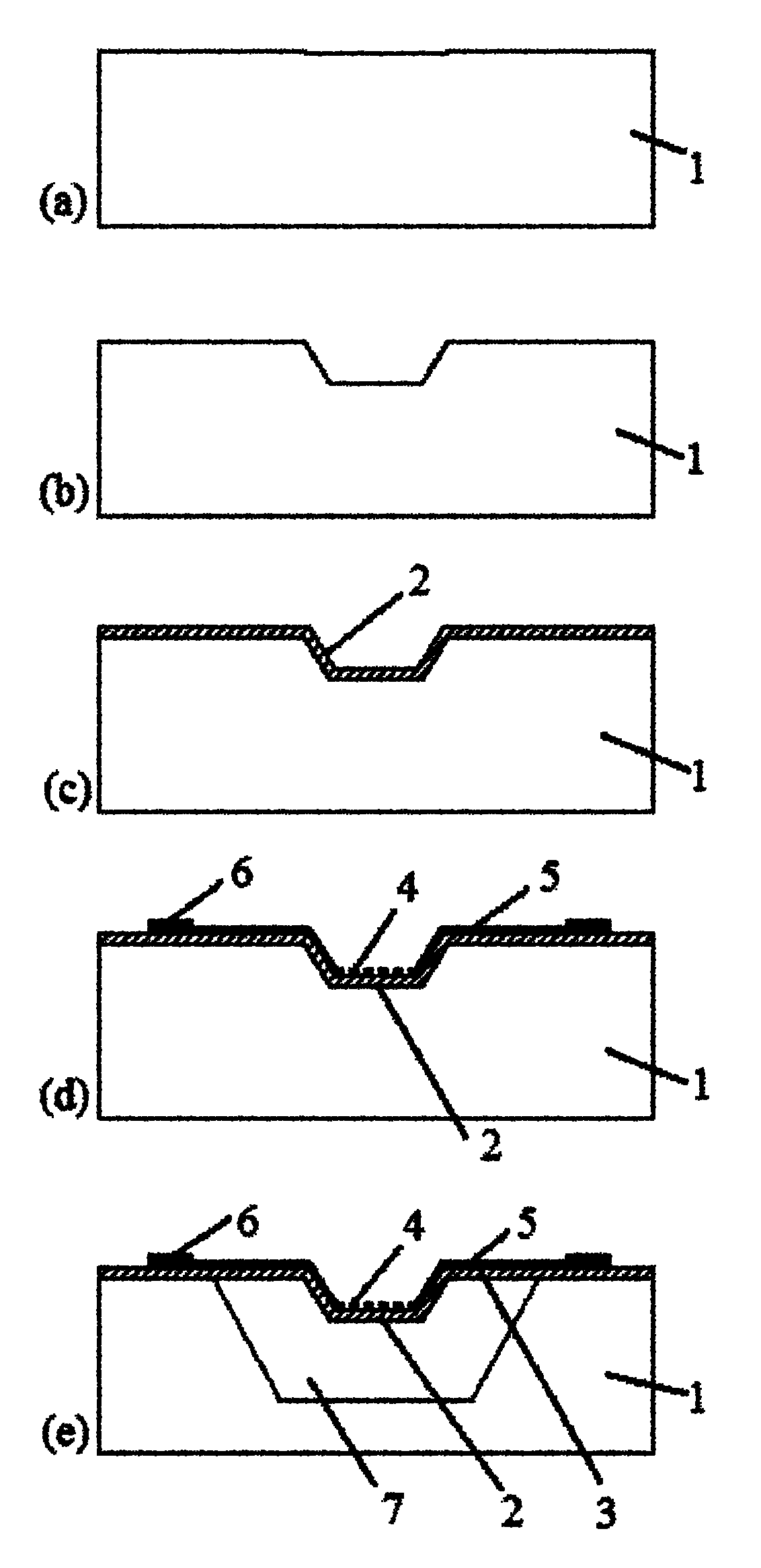

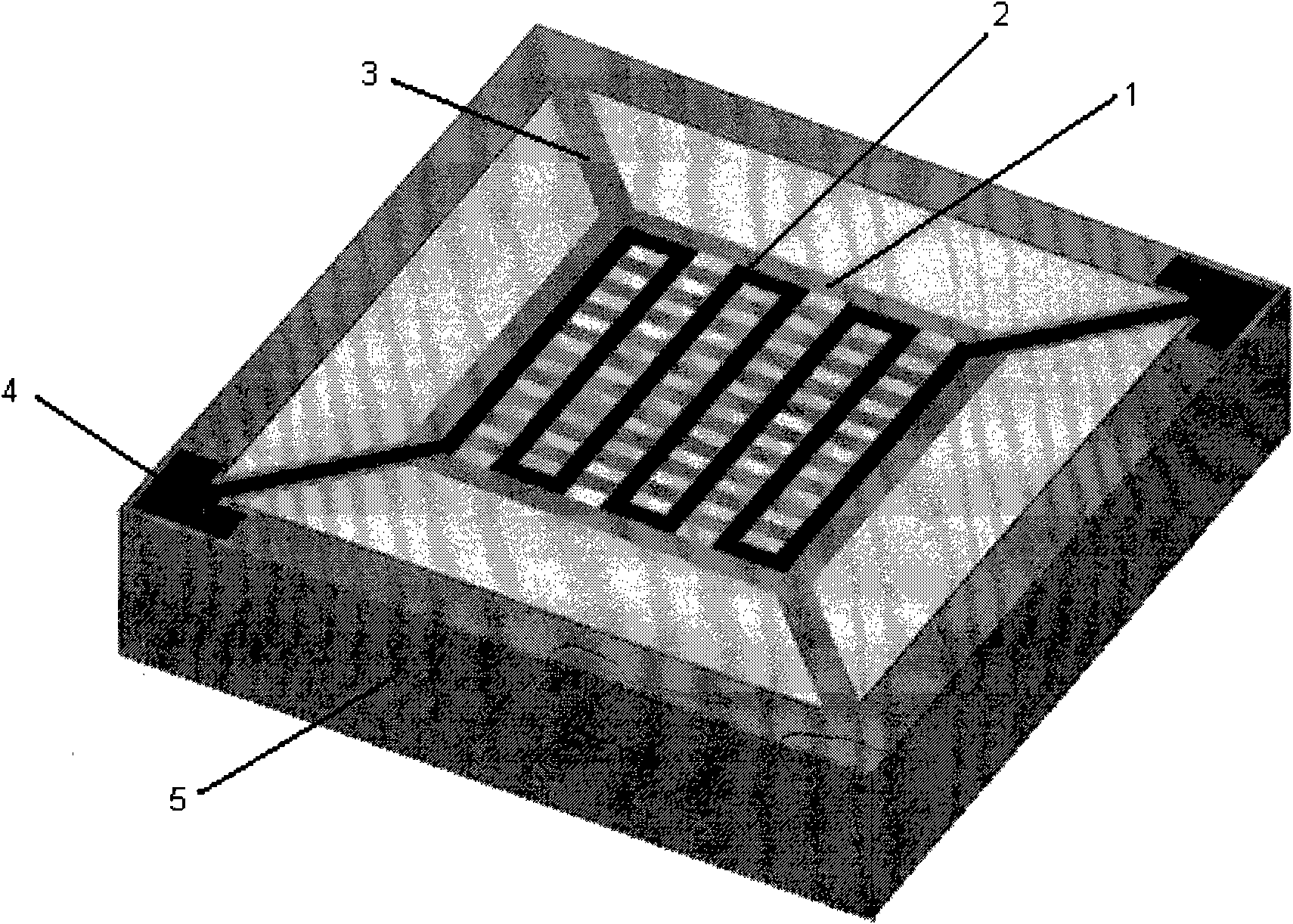

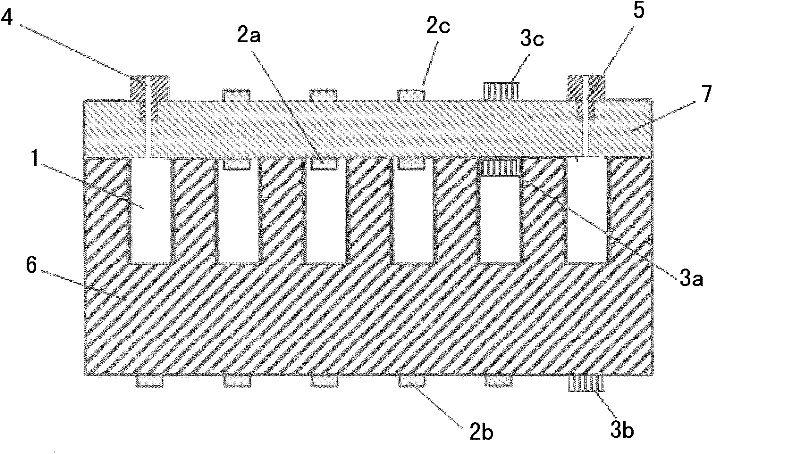

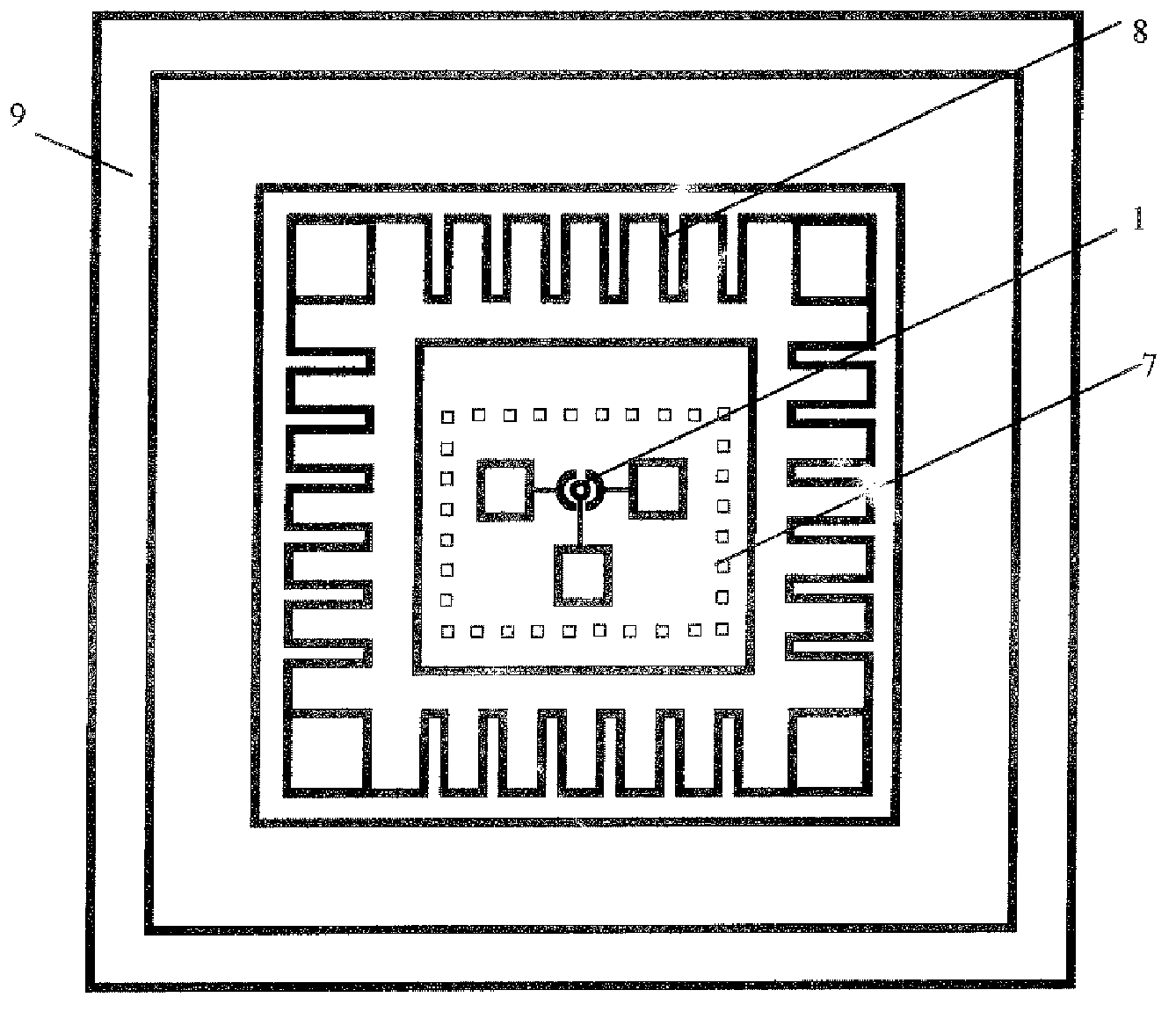

Three-dimensional micro heater with groove-shaped heating film region and manufacturing method thereof

ActiveCN101917784AGood surface smoothnessEasy to controlDecorative surface effectsHeating element materialsElectrical resistance and conductancePolygonal line

The invention relates to a three-dimensional micro heater with a groove-shaped heating film region and a manufacturing method thereof. The three-dimensional micro heater is characterized in that: the groove-shaped heating film region of which the cross section is in a V-shaped or an inverse trapezoid-shaped structure is connected with a substrate framework through a supporting suspended beam; a heat resistance wire is distributed inside a groove of the heating film region in the form of fold line and is connected with the electrode on the substrate framework through a lead wire on the supporting suspended beam; and a heat insulation cavities formed by a silicon anisotropic wet etching method is arranged below the heating film region and the supporting suspended beam. The heat resistance wire of the three-dimensional micro heater is distributed inside the groove of the heating film region with a three-dimensional structure, has low heat loss caused by heat convection and is favorable for reducing power consumption of the heater. The groove structure concentrates heat, improves the heating efficiency and is favorable for application of the heater in the fields of infrared light sources and sensing.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

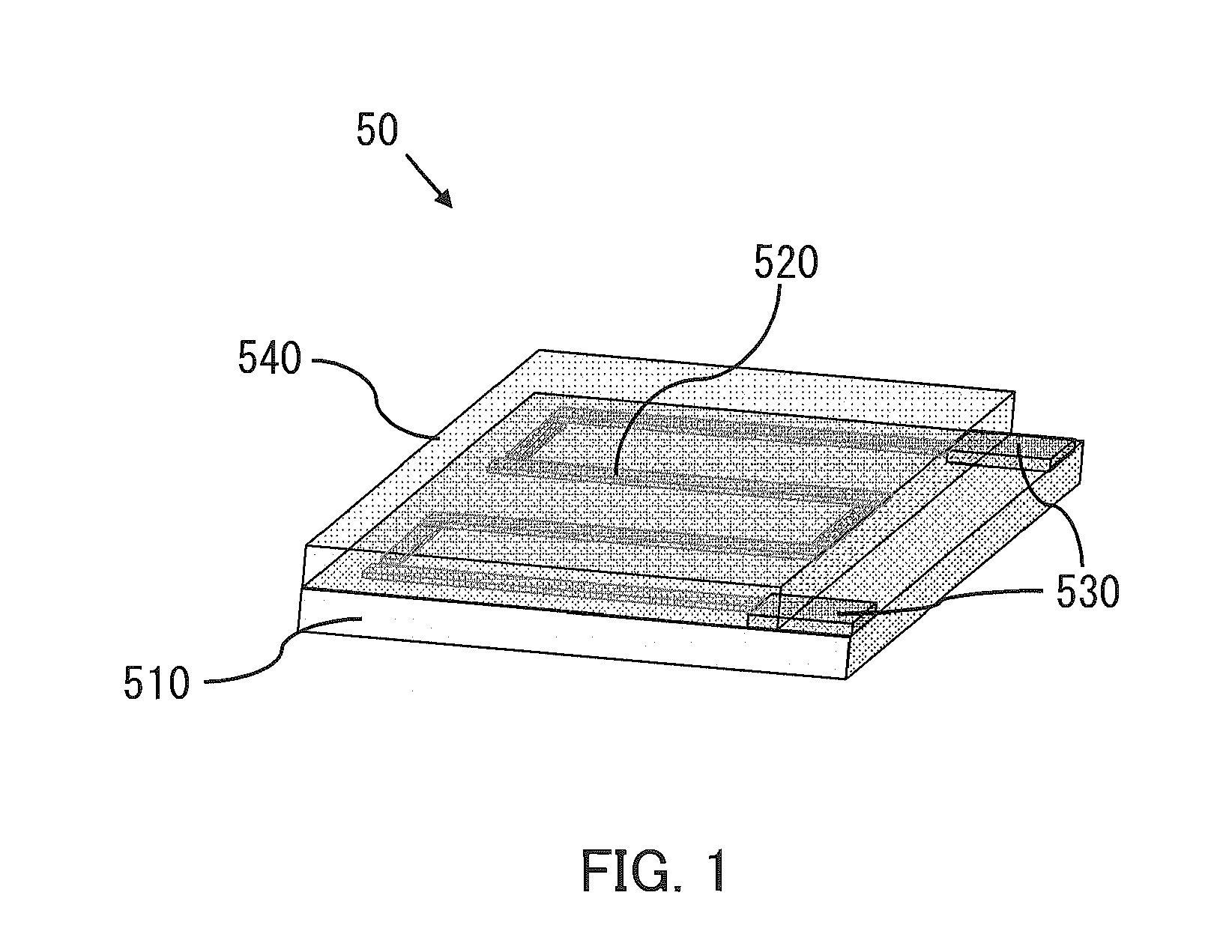

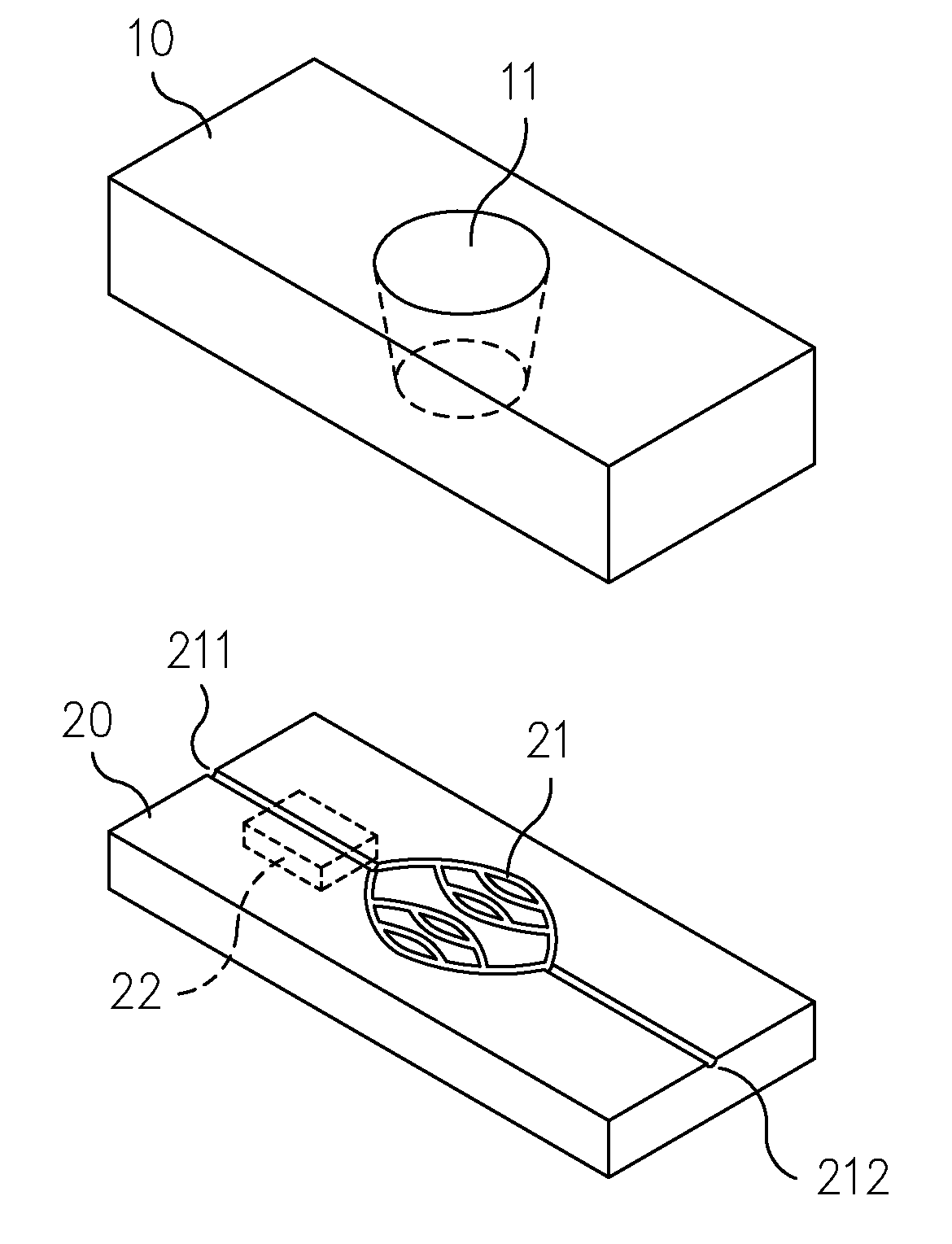

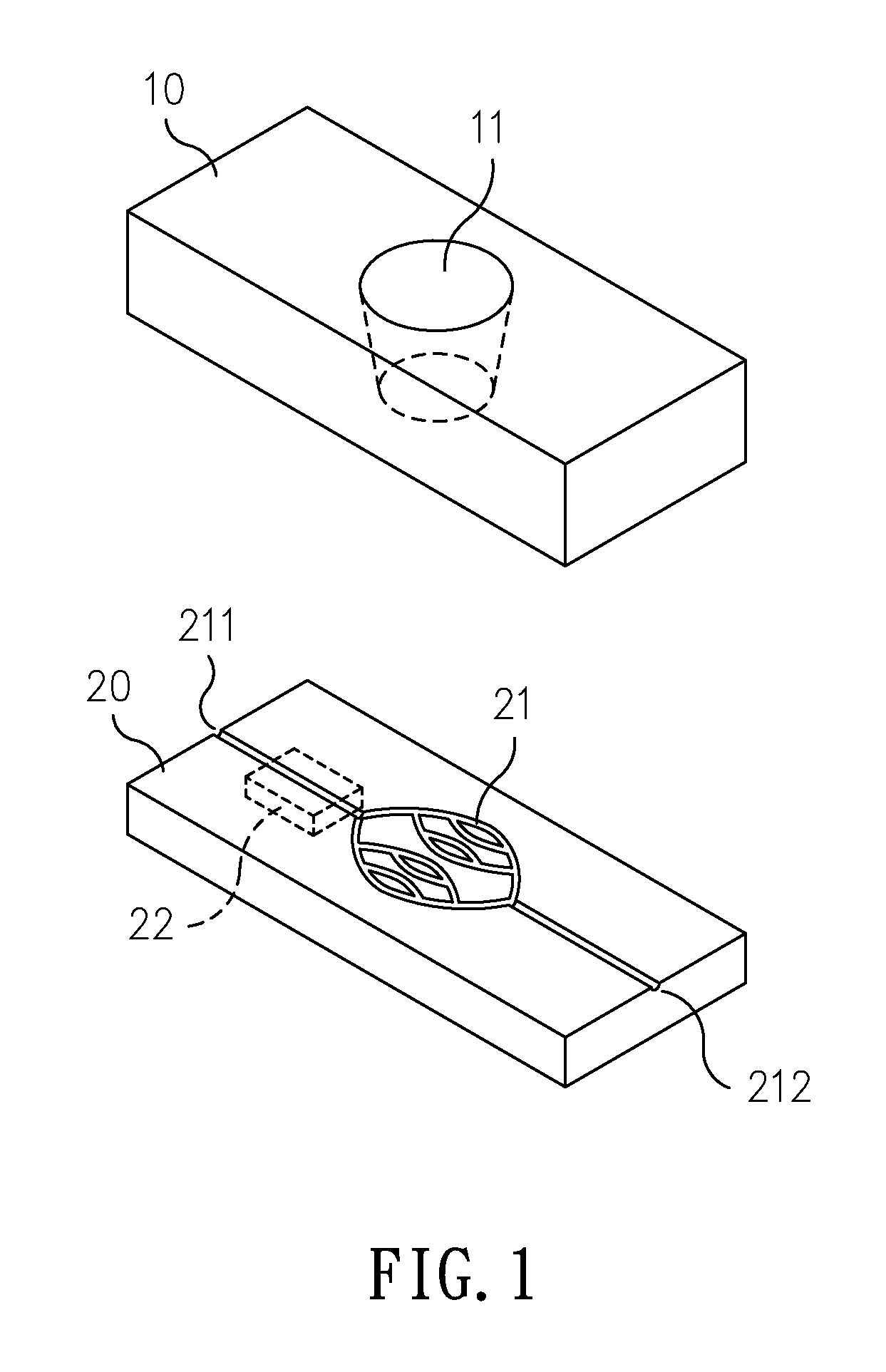

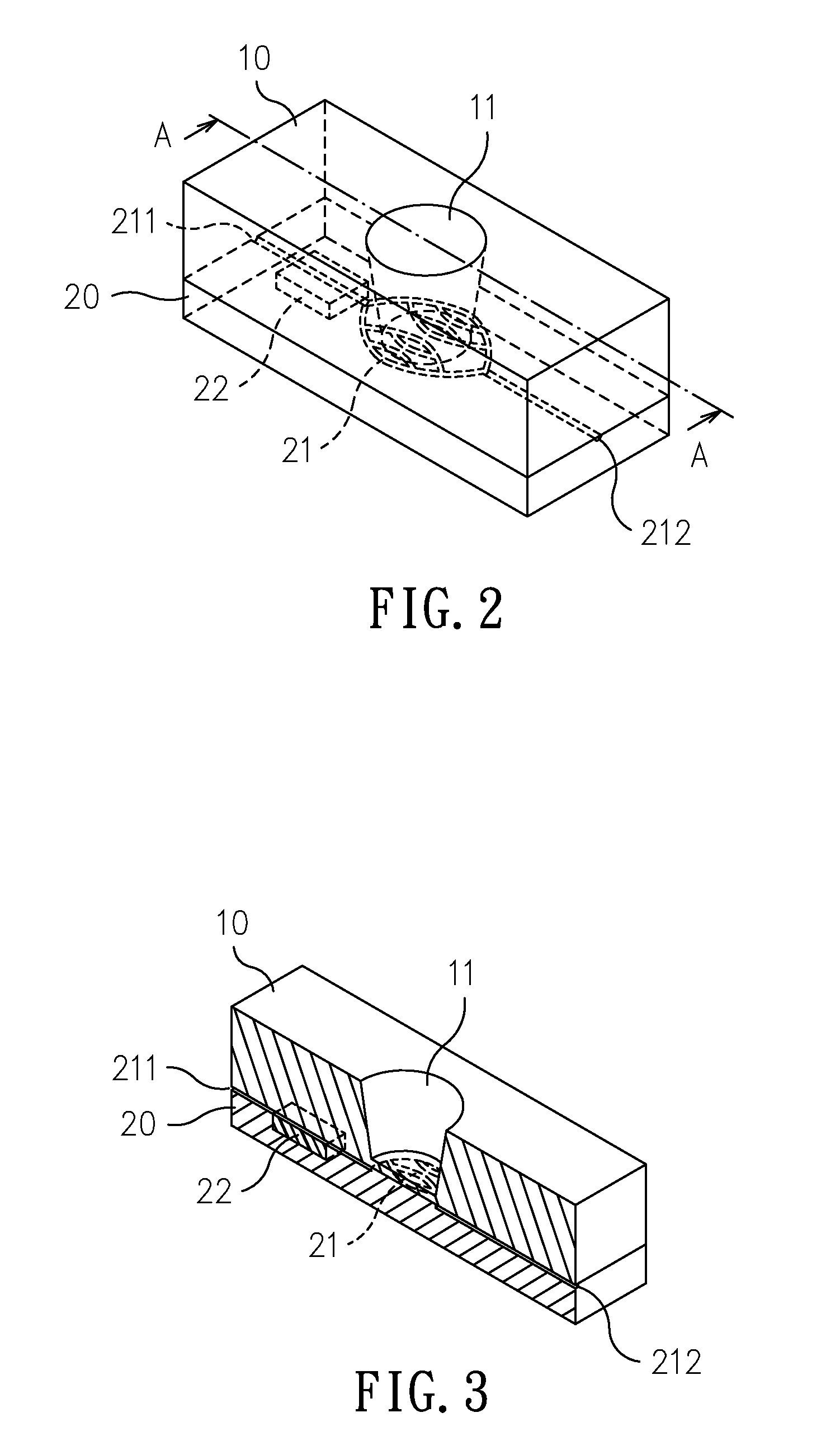

Tissue mimicking phantom

A tissue mimicking phantom is disclosed, in which the tissue-mimicking phantom comprises: at least an upper gelatin layer, each configured with at least a sunken area; at least a lower gelatin layer, each disposed beneath the at least one upper gelatin layer while being configured with at least a microchannel network having blood-mimicking fluid flowing therein; and at least a micro-heater. By the use of the sunken area of the at least one upper gelatin layer to simulate shapes and depths of different trauma wounds, the healing of anyone of the trauma wounds can be accessed clinically through a physical properties test while subjecting the trauma wound under different negative pressures and different dressings.

Owner:IND TECH RES INST

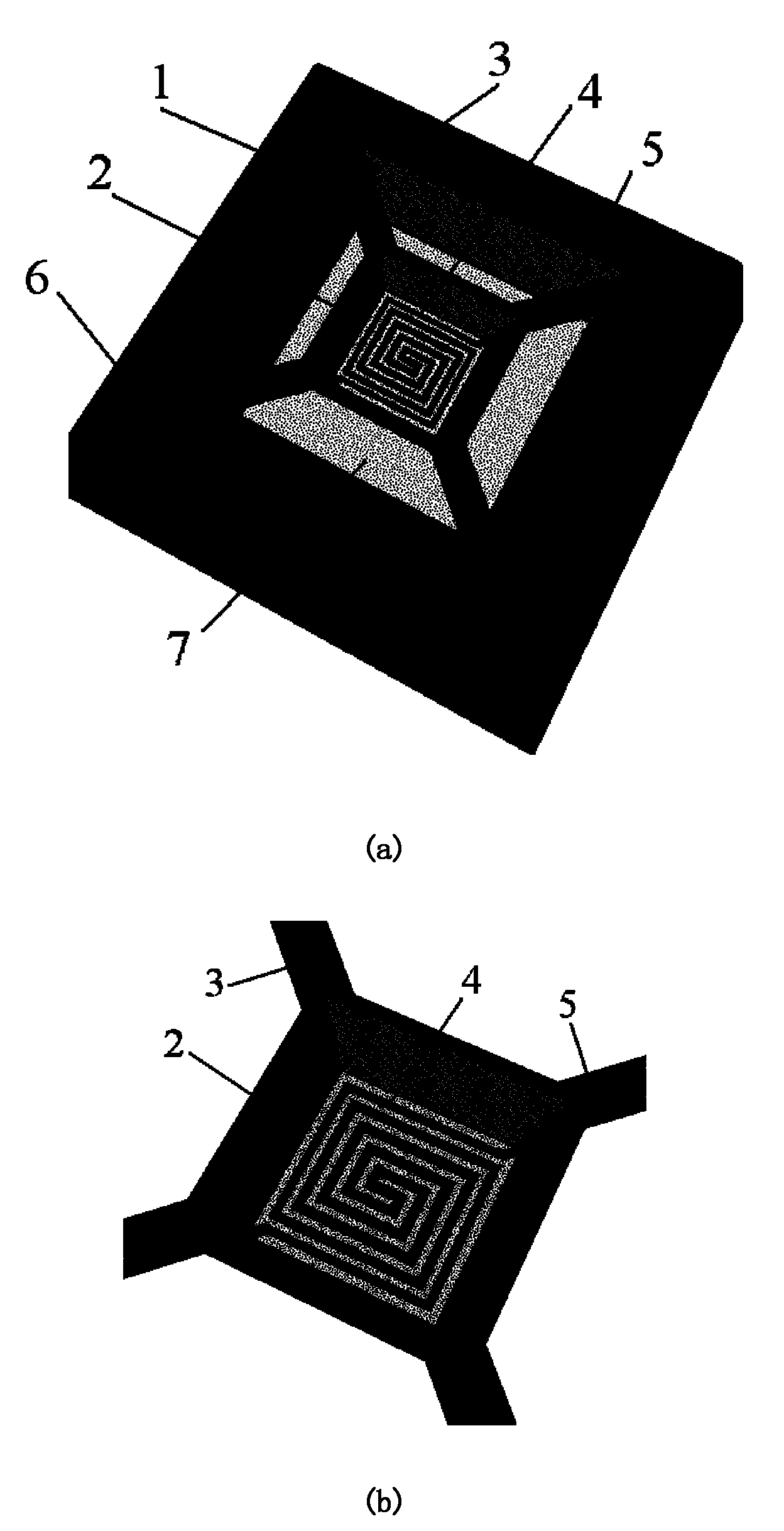

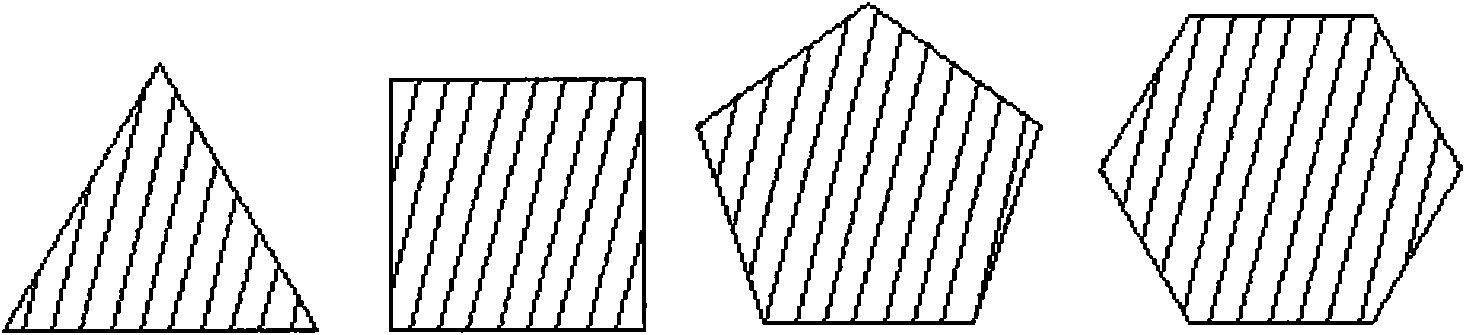

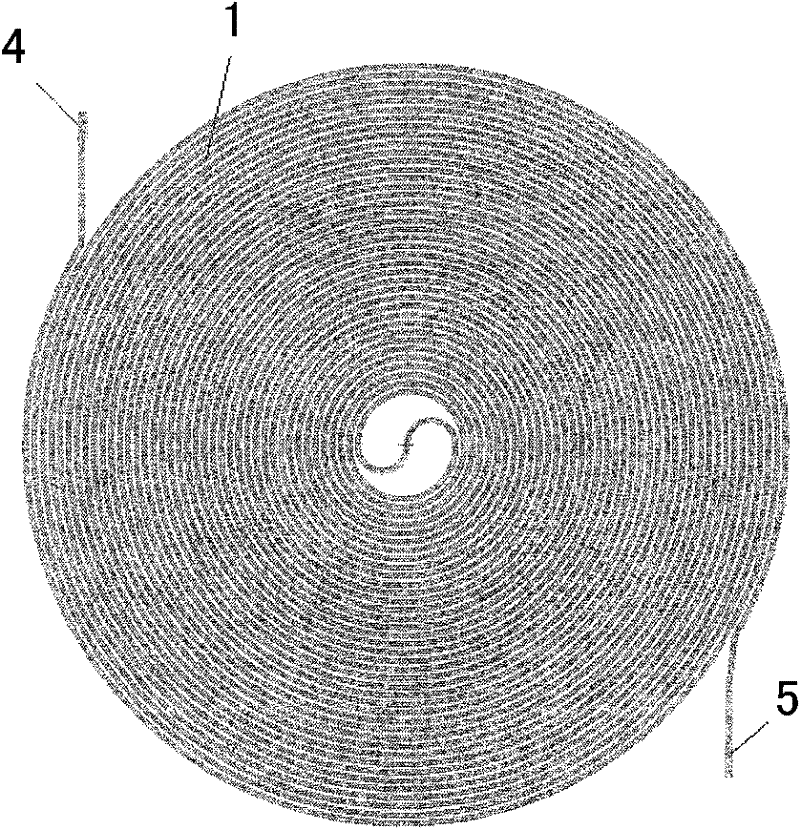

Low-power consumption micro-heater with mesh-structured heating film and fabrication method thereof

ActiveCN101795505AReduce power consumptionReduce conductionDecorative surface effectsOhmic-resistance heatingElectrical resistance and conductanceMicroheater

The invention relates to a low-power consumption micro-heater with a mesh-structured heating film and a fabrication method thereof, and the micro-heater is characterized in that the micro-heater comprises the heating film with a mesh structure formed by regular arrangement of special-shaped meshes according to certain rules, the heating film is connected with a substrate frame through a support cantilever beam, and heating resistance wires are arranged on the heating film in the fold line way and connected with an electrode for a lead wire on the substrate frame through the support cantileverbeam. The structure can not only effectively reduce the heat conduction from the area of the heating film of the heater to the support cantilever beam, further reduce the power consumption of the device and expand the fabrication methods of the heater. The heater is particularly applicable to applications in the field of gas detection.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

Micro gas sensor and method for manufacturing the same

ActiveUS7963147B2High measurement accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansThermal impactMechanical impact

Provided are a micro gas sensor for measuring a gas concentration configured to achieve a high heating and cooling rate of a gas sensitive layer, achieve temperature uniformity, and achieve durability against thermal impact and mechanical impact; and a method for manufacturing the micro gas sensor. The micro gas sensor includes: a vacuum cavity disposed in a substrate; a support layer covering the vacuum cavity; a sealing layer sealing the support layer and the vacuum cavity; a micro heater disposed on the sealing layer; a plurality of electrodes disposed on the micro heater, insulated from the micro heater; and a gas sensitive layer covering the electrodes.

Owner:ELECTRONICS & TELECOMM RES INST

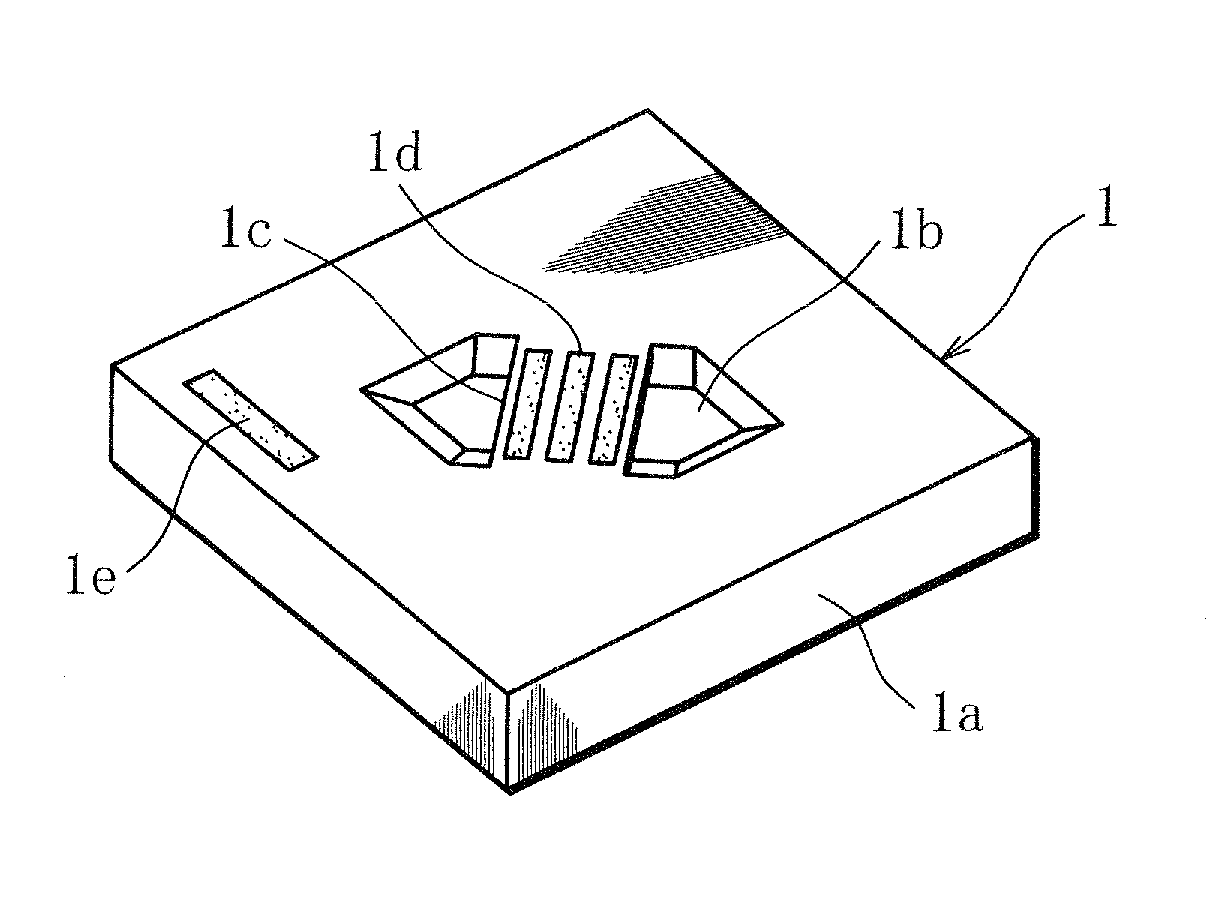

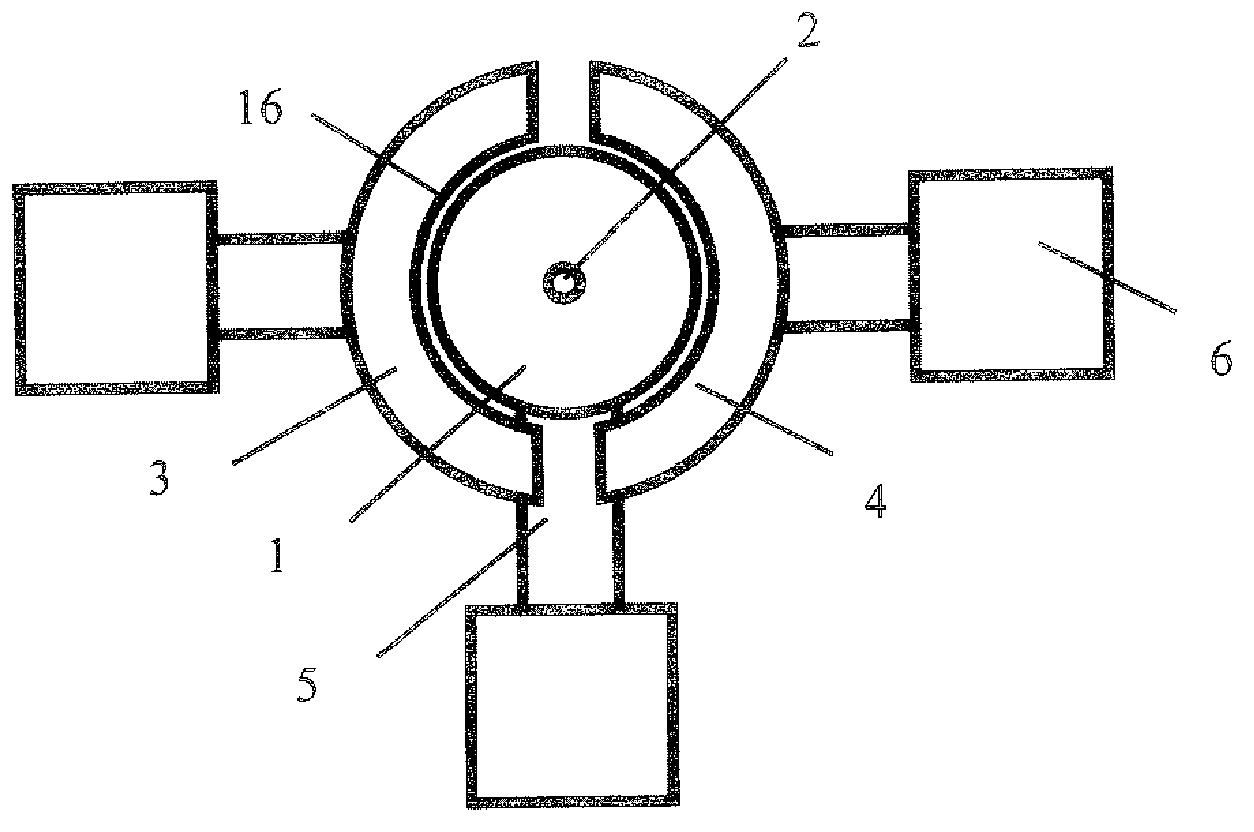

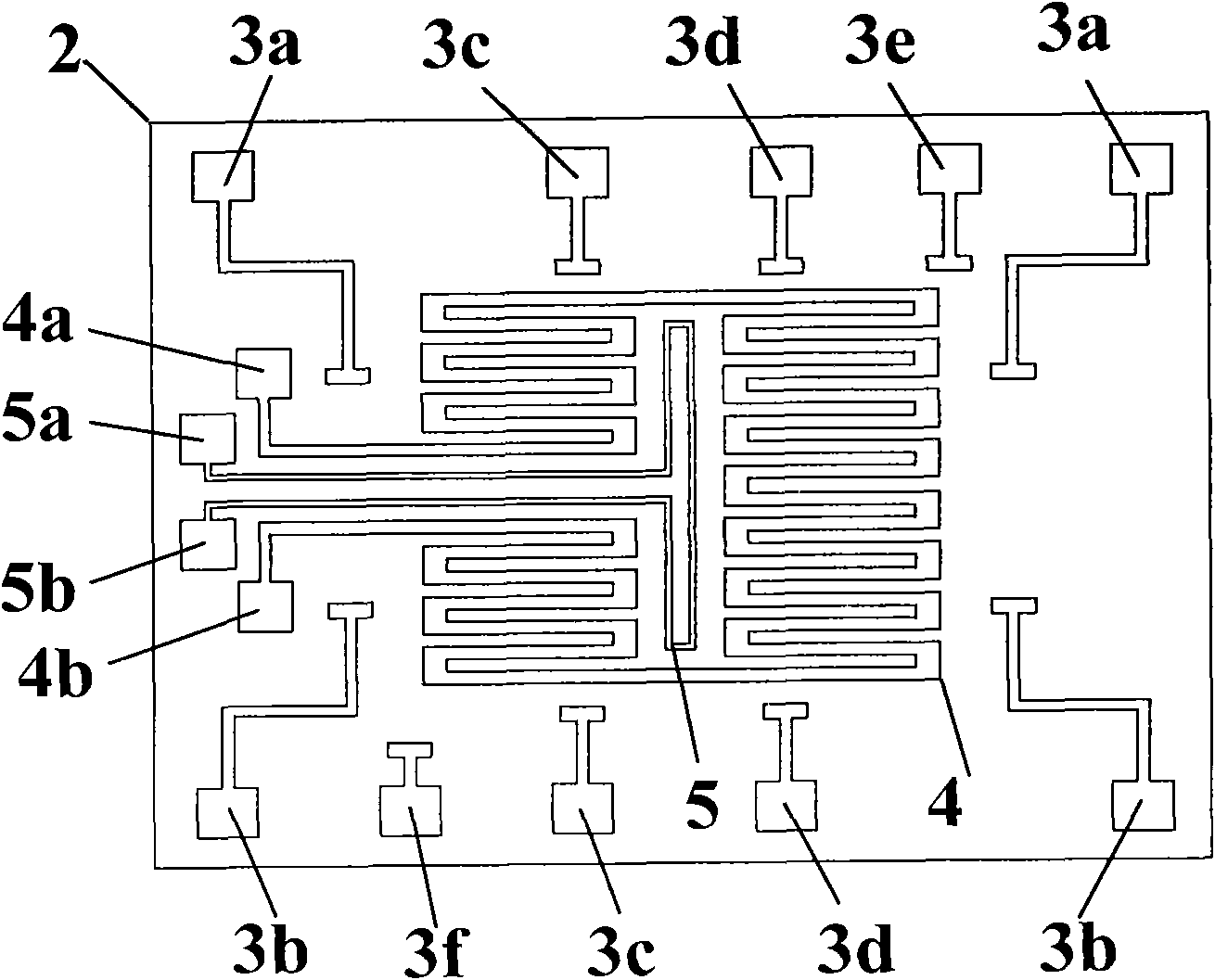

Miniature gas chromatographic column integrated chip with rapid separation function

ActiveCN102680609AEasy to separateIncrease separation speedComponent separationEtchingMicro gas chromatography

The invention discloses a miniature gas chromatographic column integrated chip with rapid separation function, and relates to gas chromatographic column integrated chip technology. The integrated chip includes a miniature chromatographic column, combined miniature heaters, and combined miniature temperature sensors. Miniature chromatographic column channels are formed on a silicon substrate by deep etching or chemical etching based on microelectromechanical system (MEMS) technology, then the silicon substrate is hermetically bonded with glass to form the miniature chromatographic column; before bonding, the combined miniature heaters are integrated in the channels and the substrate bottom where the channels are located; and through combined heating, rapid temperature rise is realized, and separation speed and separation performance of the miniature chromatographic column are improved. Meanwhile, the combined miniature temperature sensors are integrated on the upper and the lower surfaces of the channels and in the channels of the miniature chromatographic column, to real-time respond temperature of a gas sample in the miniature chromatographic column, thereby facilitating heating state adjustment of the miniature heaters by an external control circuit, controlling temperature of the miniature chromatographic column, and enabling the miniature chromatographic column to achieve rapid separation, and excellent total separation performance is realized.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

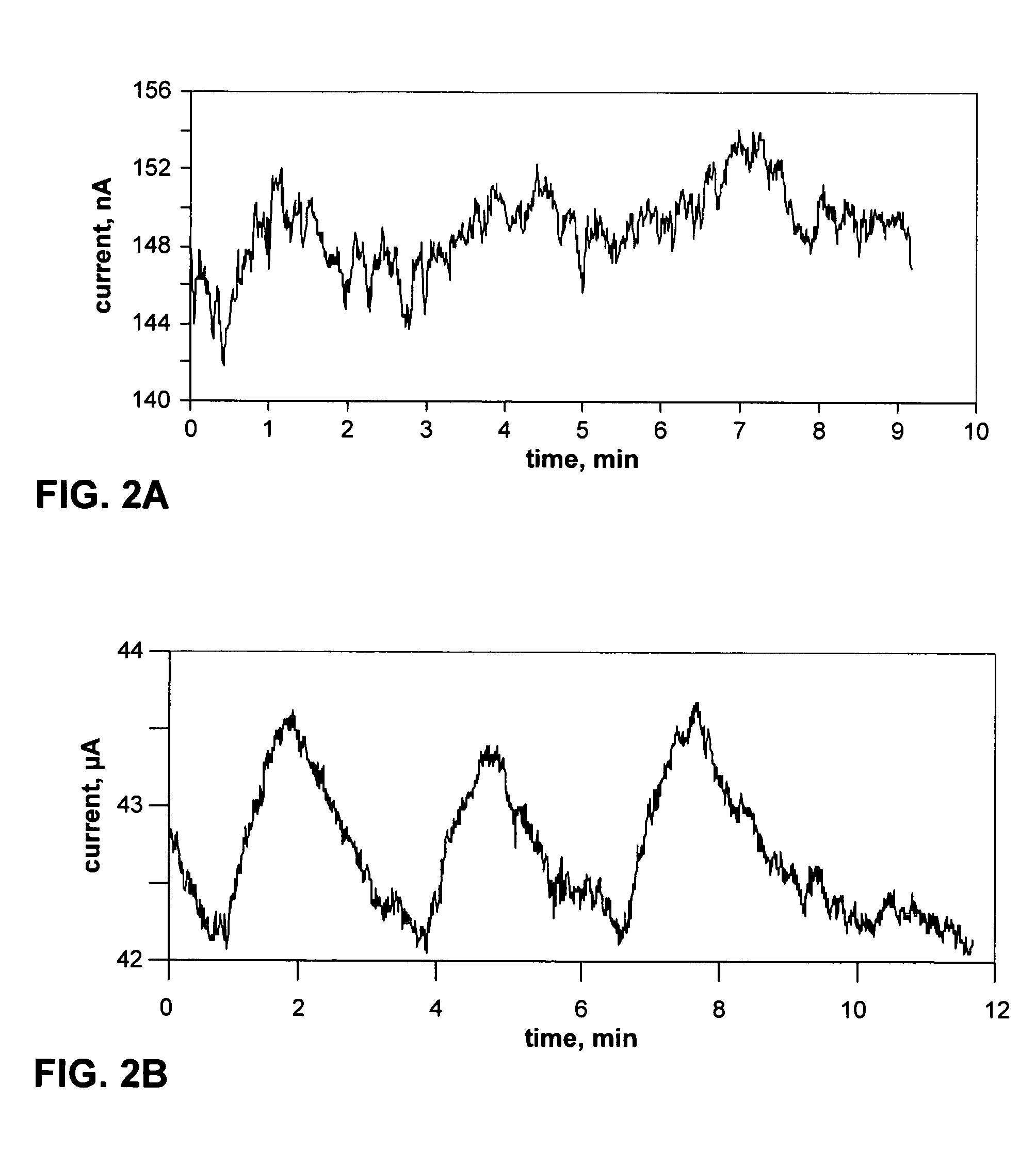

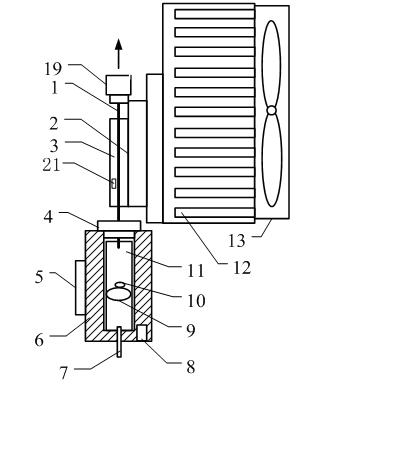

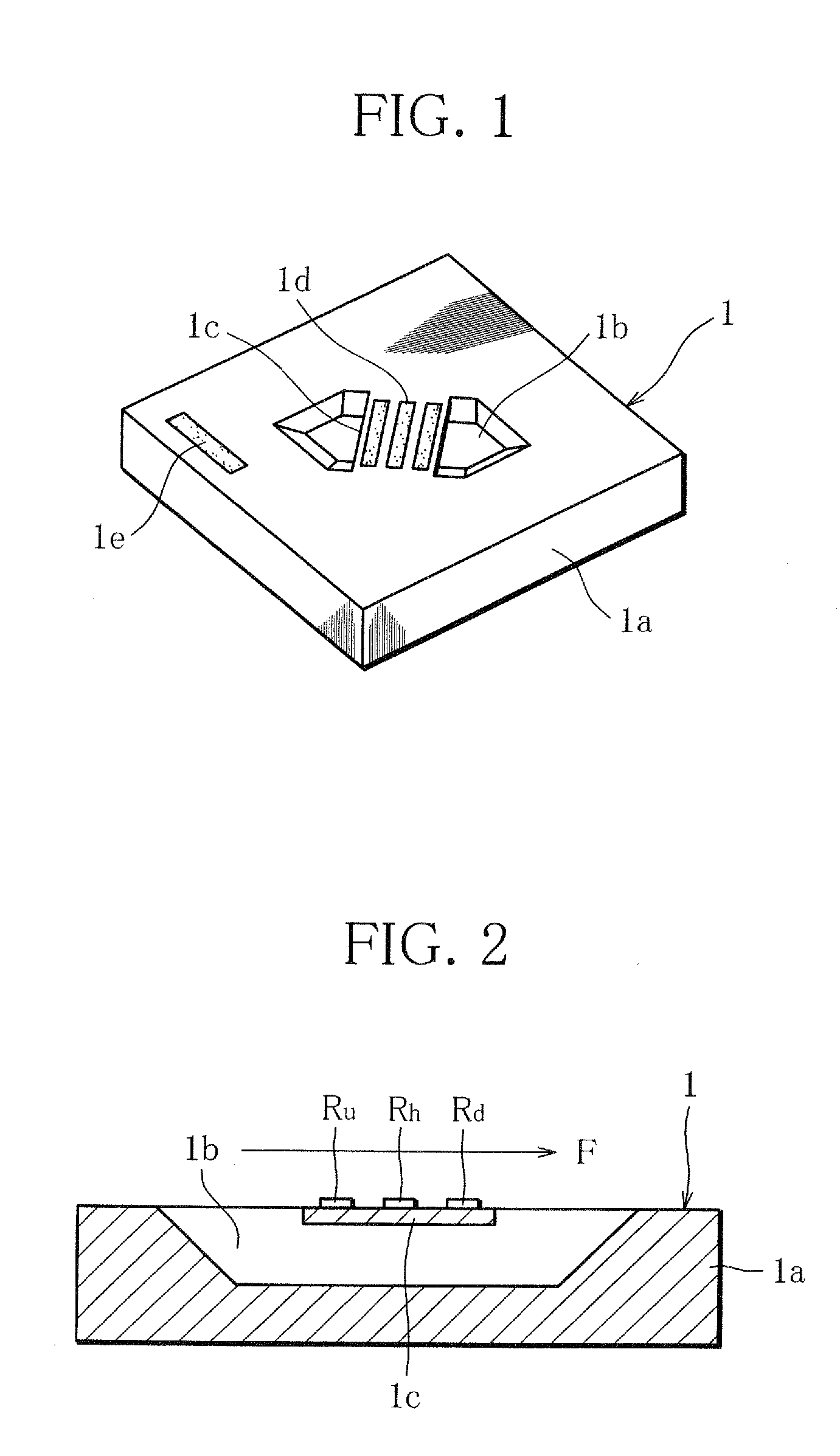

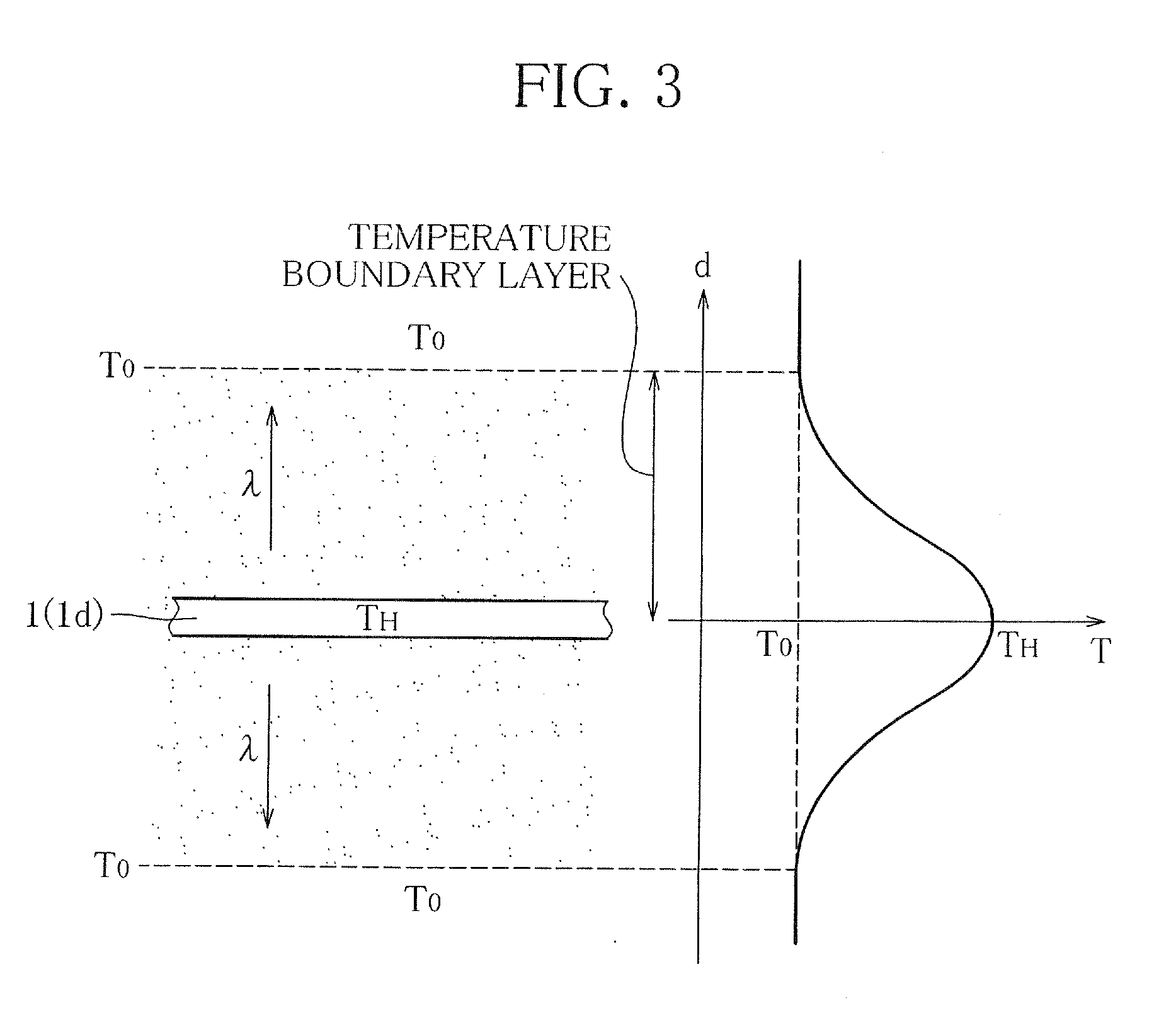

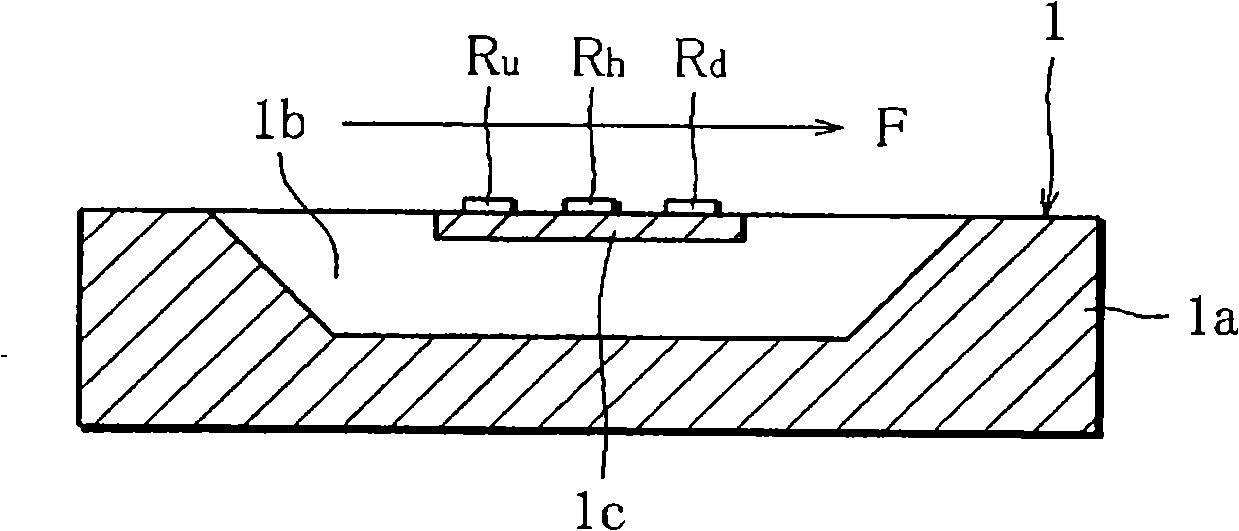

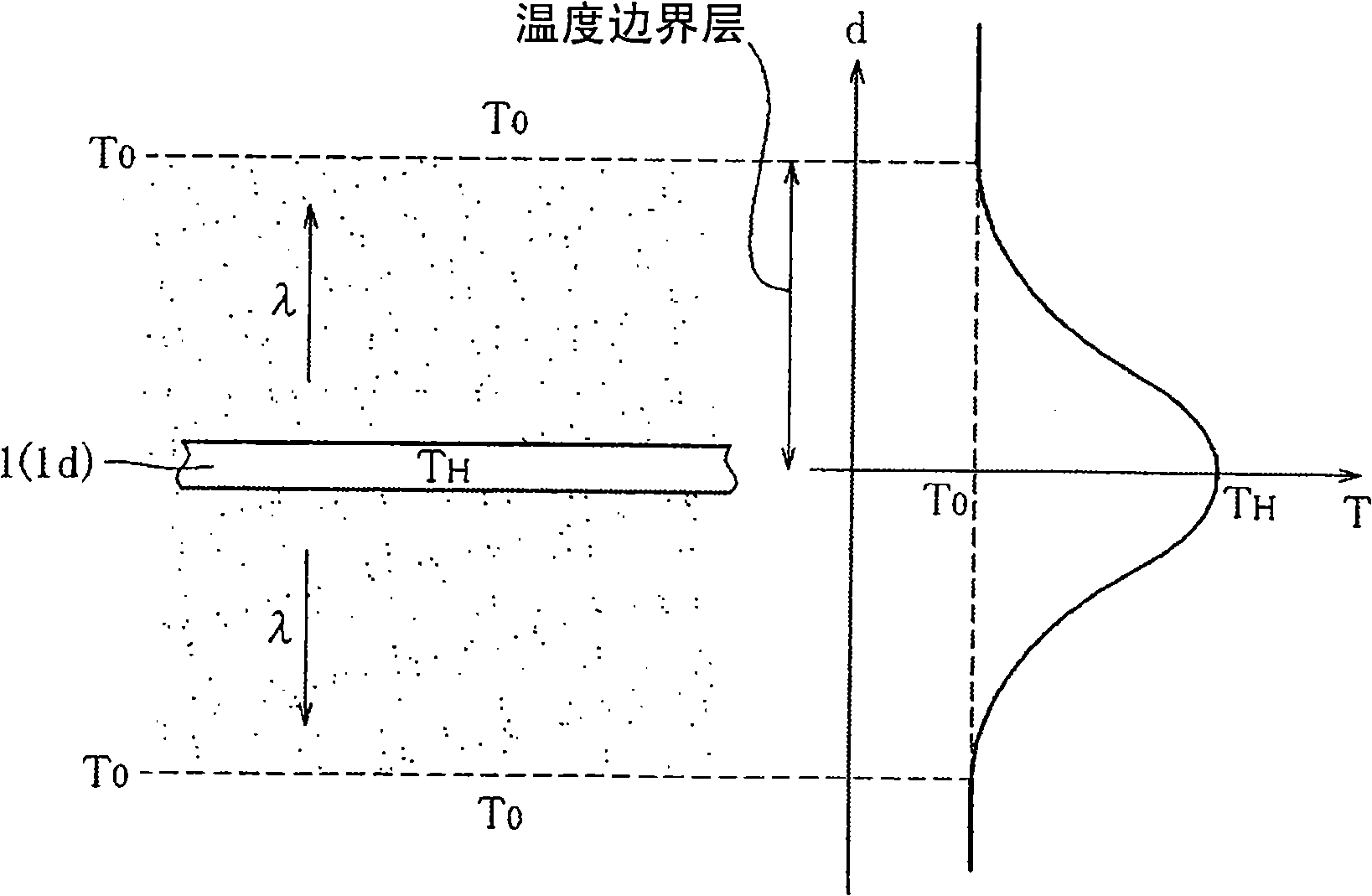

Thermal conductivity measuring method and apparatus, and gas component ratio measuring apparatus

InactiveUS20090277246A1Easy to measureMaterial thermal conductivityMaterial resistanceThermal conductivity measurementMicroheater

A heat radiation coefficient C [=Ph / (Th−To)] from a microheater is calculated in accordance with a power Ph applied to the microheater which is supported in air and provided in an ambient gas, a heater temperature Th, and an ambient temperature To at this moment. Further, a thermal conductivity λ(T) of the ambient gas is obtained from the calculated heat radiation coefficient C based on a proportional relation [C=K·λ(T)] between a thermal conductivity λ(T) of the ambient gas and the heat radiation coefficient C at a measurement temperature T [=(Th−To) / 2].

Owner:YAMATAKE HONEYWELL CO LTD

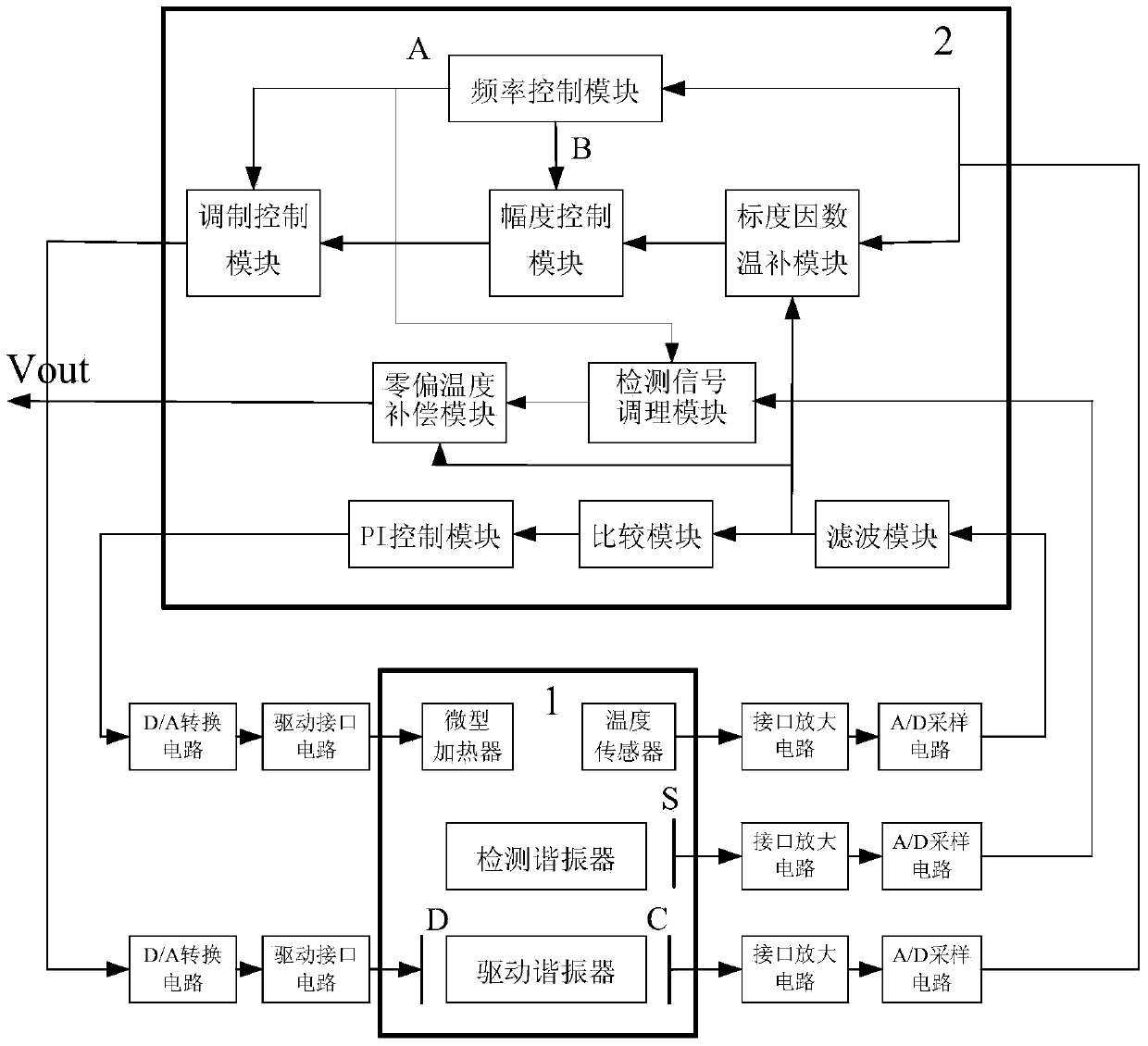

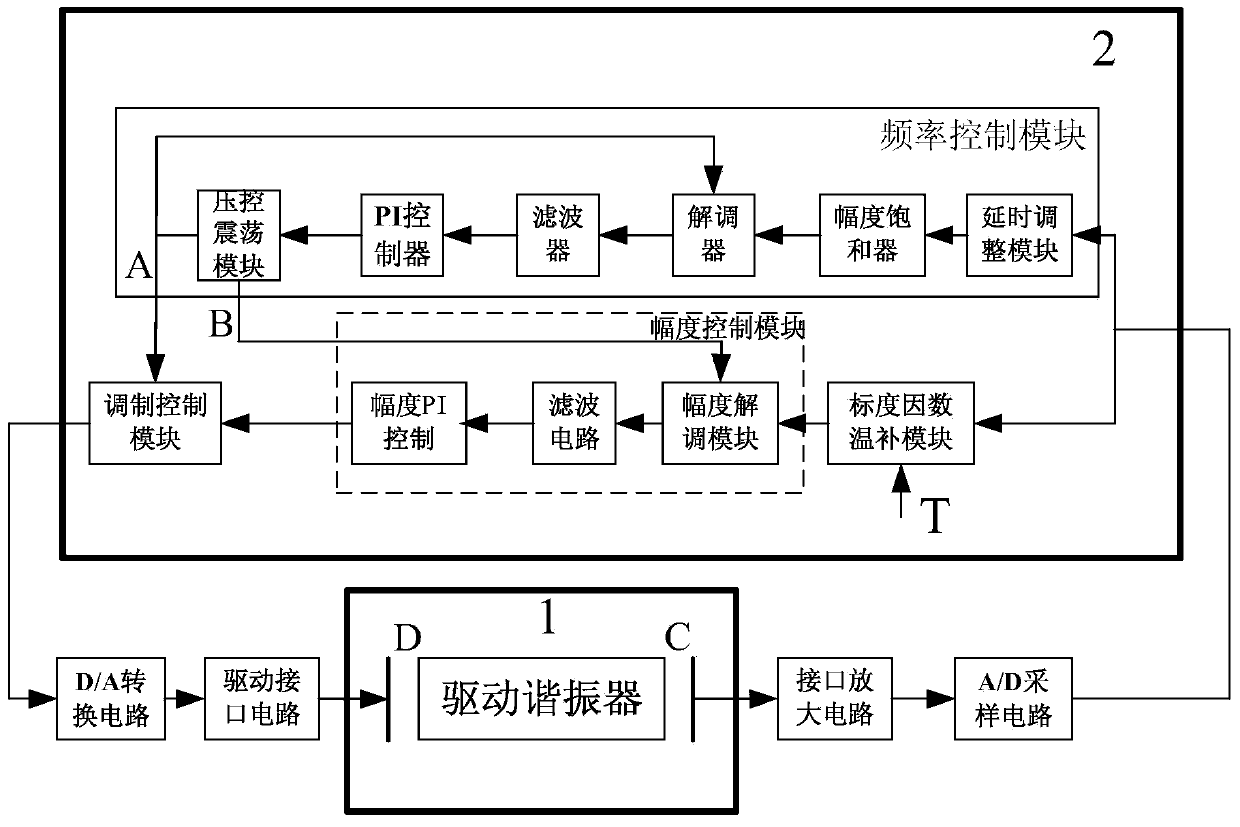

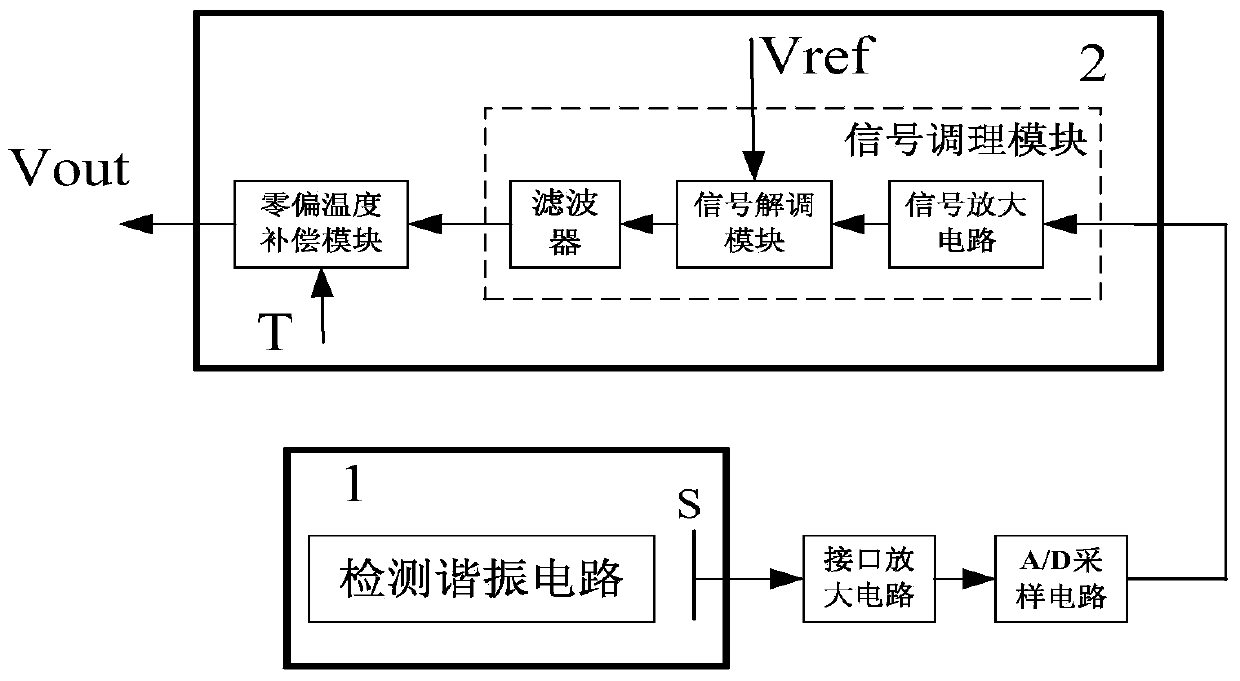

Field programmable gate array (FPGA)-based temperature control and temperature compensation circuit device for silicon microgyroscope

InactiveCN103776469ALevel temperature control and temperature compensation with high sensitivityGood repeatabilityMeasurement devicesTemperature controlMicroheater

The invention discloses a field programmable gate array (FPGA)-based temperature control and temperature compensation circuit device for a silicon microgyroscope. The FPGA-based temperature control and temperature compensation circuit device comprises a microgyroscope integrated with a miniature heater and a temperature sensor, an interface circuit and an FPGA processing circuit; a temperature control loop, a drive control loop and a detection control loop are formed by mutual connection. The chip-level temperature control and temperature compensation of the silicon microgyroscope are achieved by using the temperature sensor and the miniature heater integrated inside the microgyroscope. The FPGA-based temperature control and temperature compensation circuit device has the advantages of high sensitivity, good repeatability, small inertia, high reliability of temperature information, small power consumption, high control accuracy and the like, the effect of temperature drift of an analogue circuit is reduced by an FPGA-based digital temperature control and temperature compensation platform, meanwhile, a digitalized platform is flexible to adjust parameters, and strong in function, kinds of complicated temperature control and temperature compensation algorithms can be flexibly achieved, and optimization of the performance of the system is facilitated.

Owner:SOUTHEAST UNIV

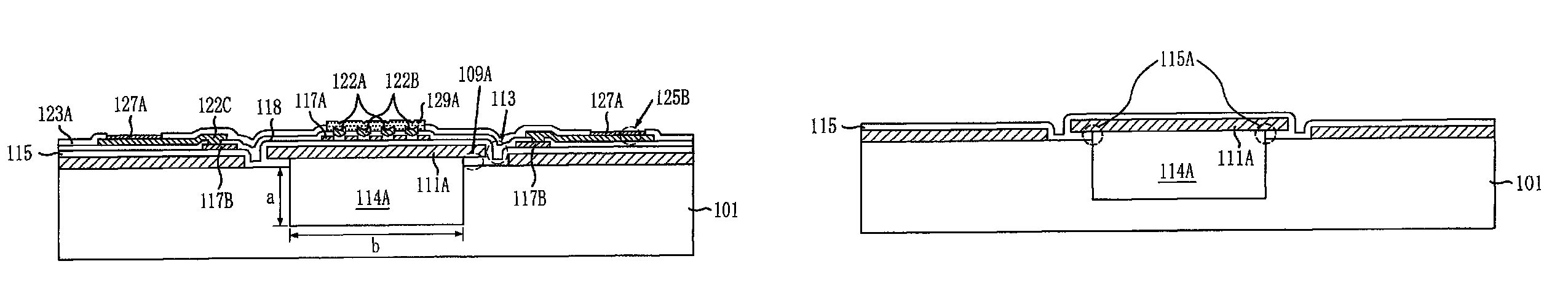

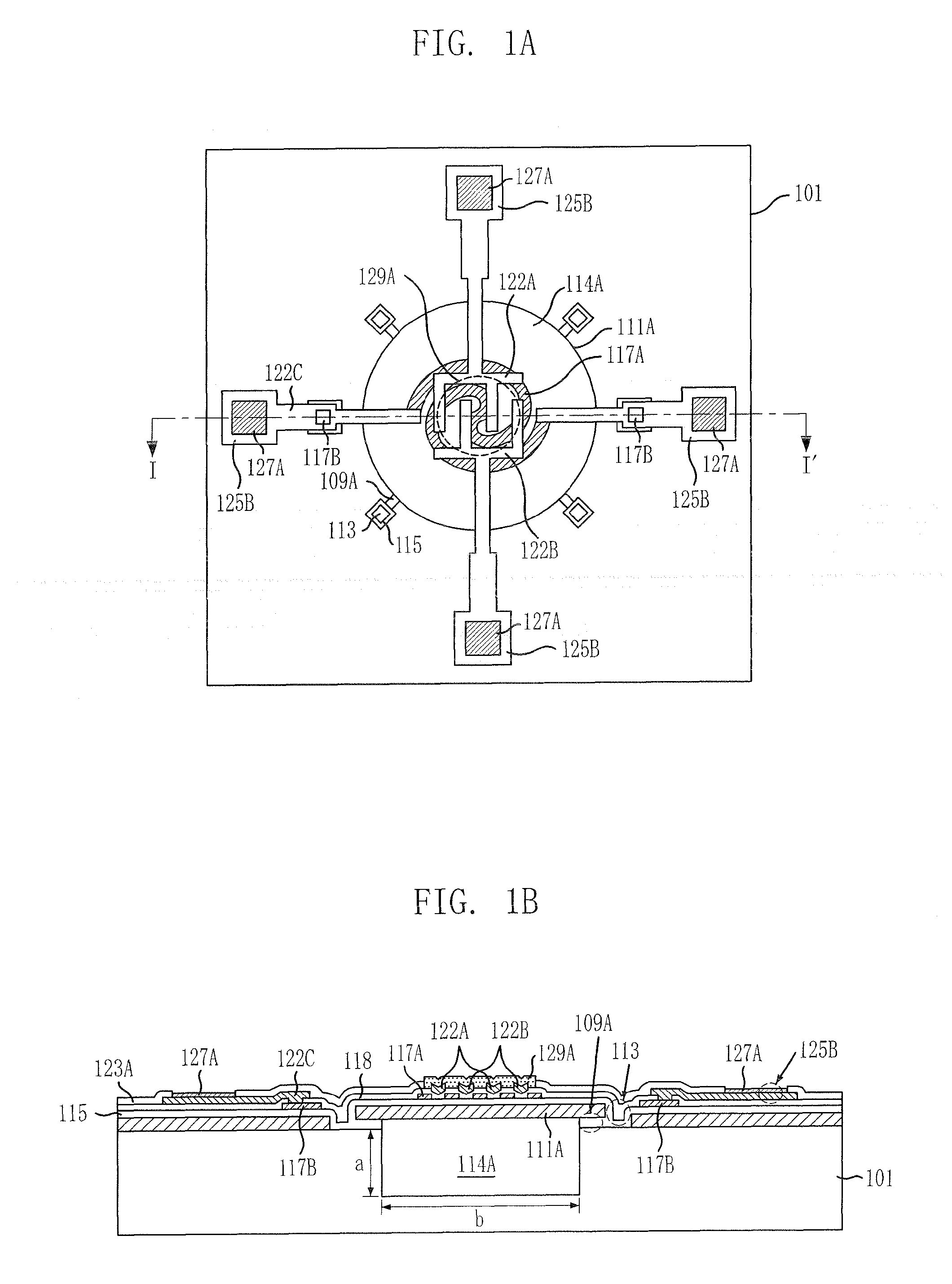

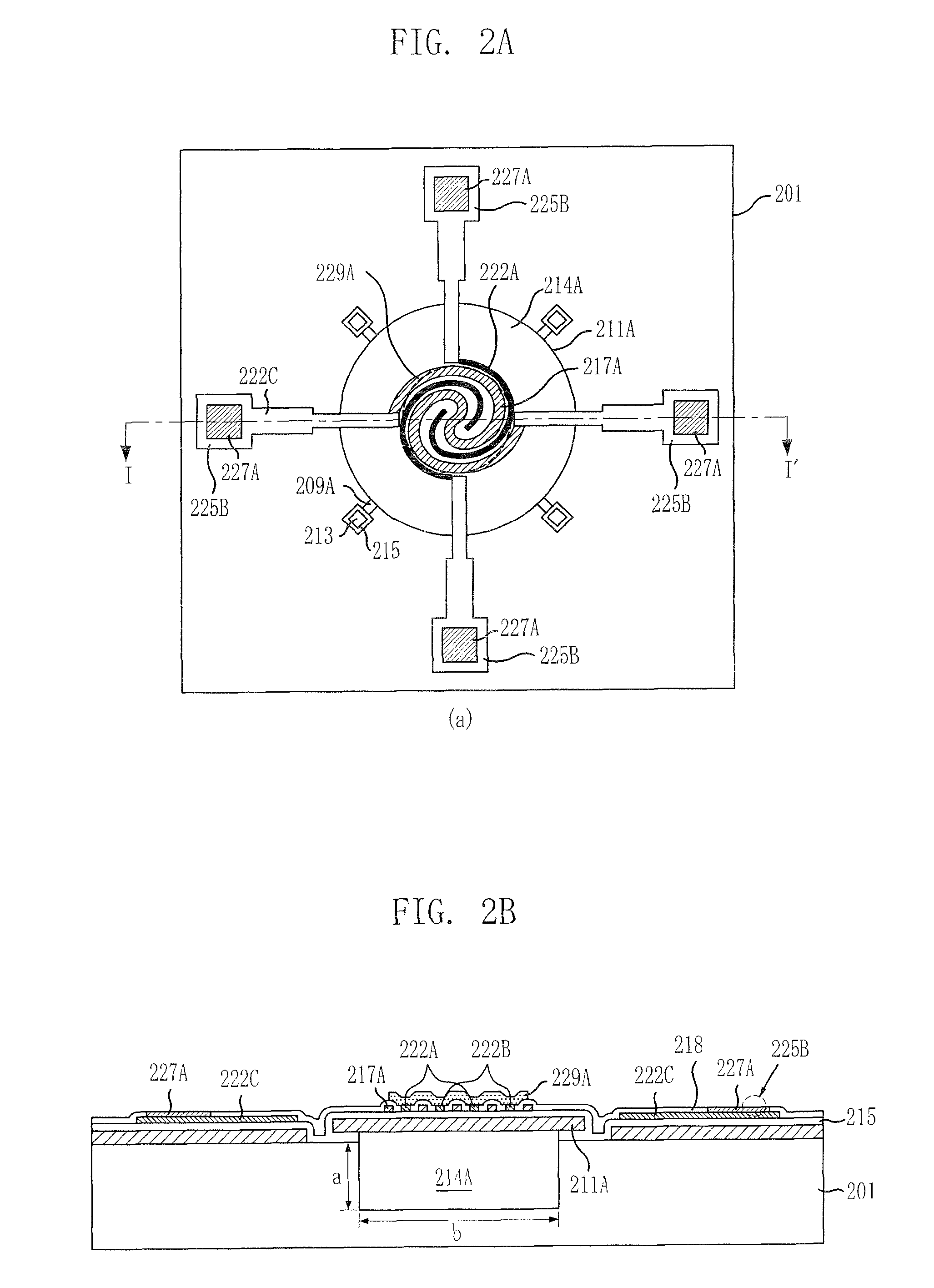

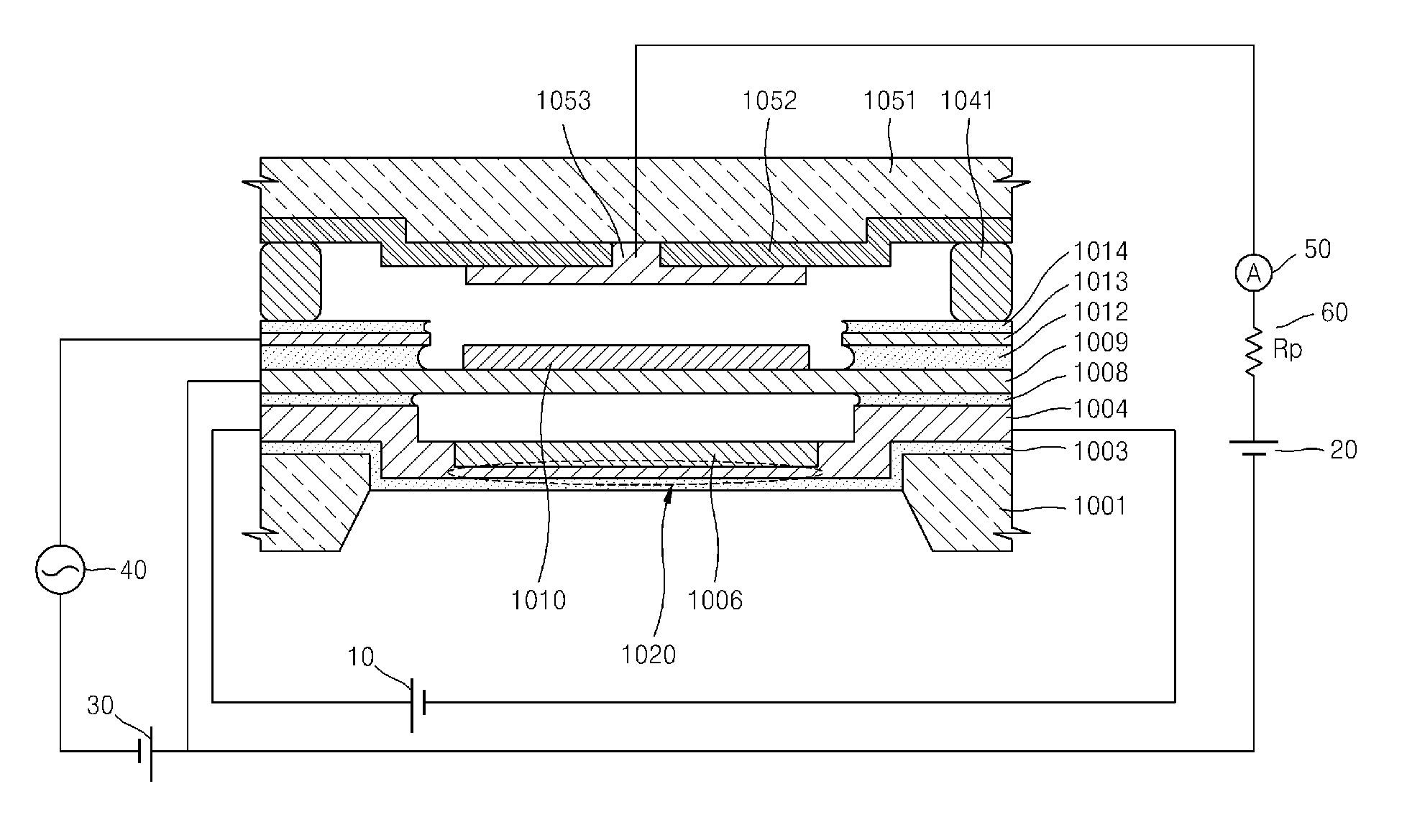

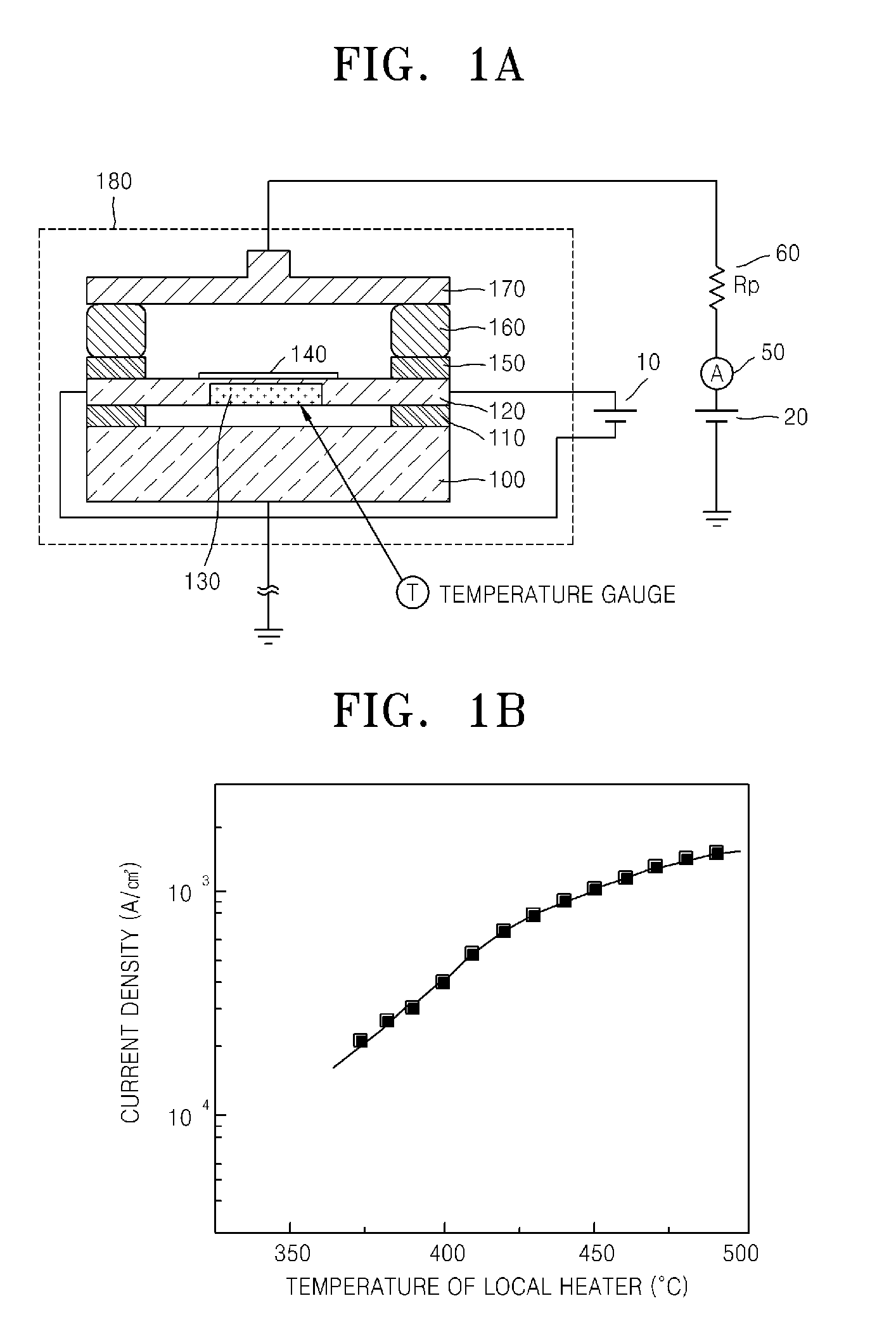

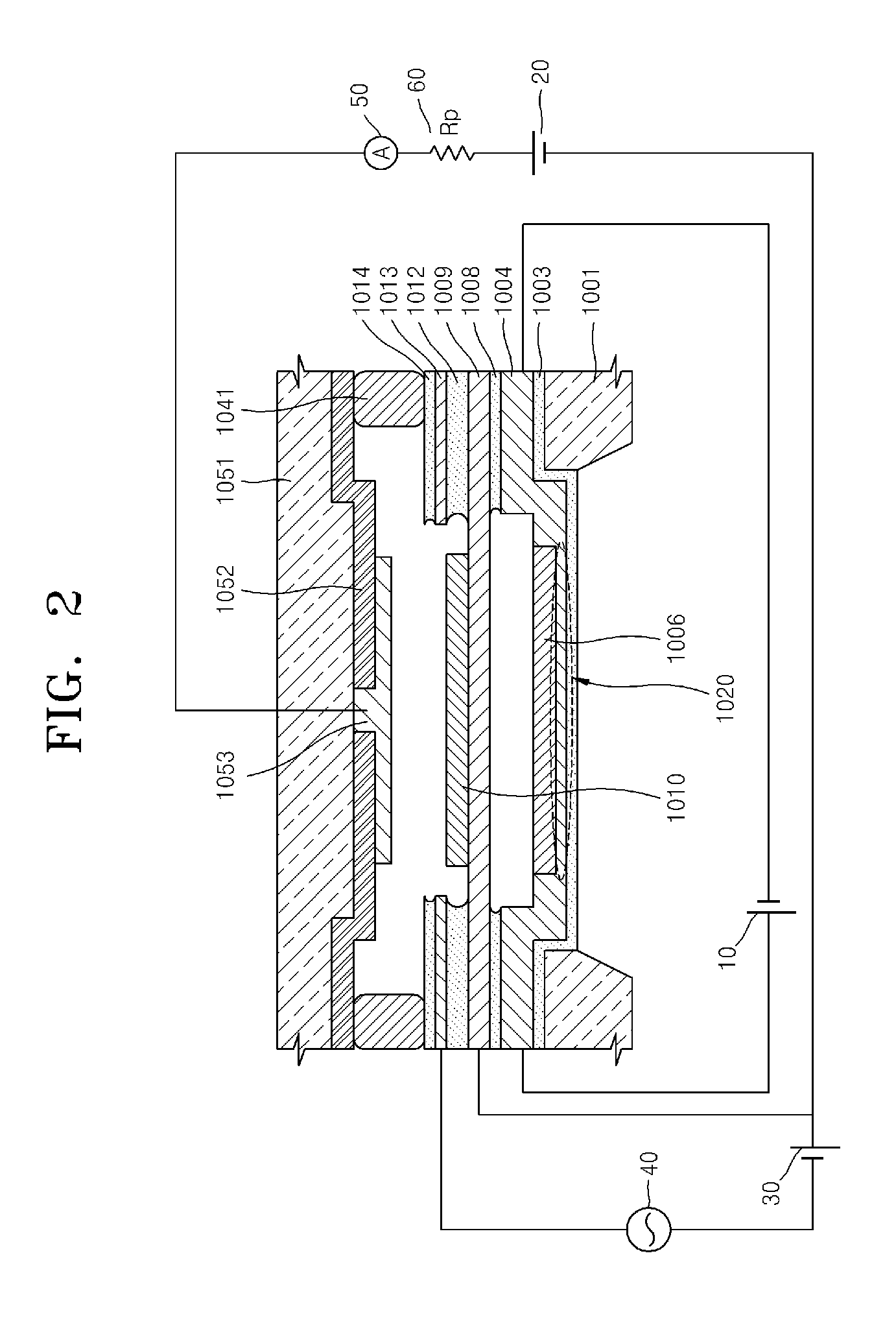

Vacuum channel transistor and diode emitting thermal cathode electrons, and method of manufacturing the vacuum channel transistor

InactiveUS20100102325A1Stable electron emission structureReduce the driving voltageDischarge tube luminescnet screensLamp detailsEngineeringMicroheater

Provided are a transistor and a method of manufacturing the transistor, and more particularly, a vacuum channel transistor emitting thermal cathode electrons and a method of manufacturing the vacuum channel transistor. The vacuum channel transistor includes: a motherboard; a micro heater member having a thin-film structure formed on the motherboard; a cathode member having a thin-film structure spaced apart from a center part of the micro heater member by a first interval and formed on the micro heater member; a gate member formed on both outer walls of upper parts of the cathode member; and an anode member spaced apart from the cathode member by a second interval through spacers disposed on the gate member, wherein a vacuum electron passing area is interposed between the cathode member and the anode member by the second interval.

Owner:ELECTRONICS & TELECOMM RES INST

Method and device for measuring thermal conductivity, and gas component ratio measuring device

A heat radiation coefficient C [=Ph / (Th-To)] from a microheater is calculated in accordance with a power Ph applied to the microheater which is supported in air and provided in an ambient gas, a heater temperature Th, and an ambient temperature To at this moment. Further, a thermal conductivity (lambdaT) of the ambient gas is obtained from the calculated heat radiation coefficient C based on a proportional relation [C=K (lambdaT) ] between a thermal conductivity (lambdaT) of the ambient gas and the heat radiation coefficient C at a measurement temperature lambdaT [=(Th-To) / 2].

Owner:YAMATAKE HONEYWELL CO LTD

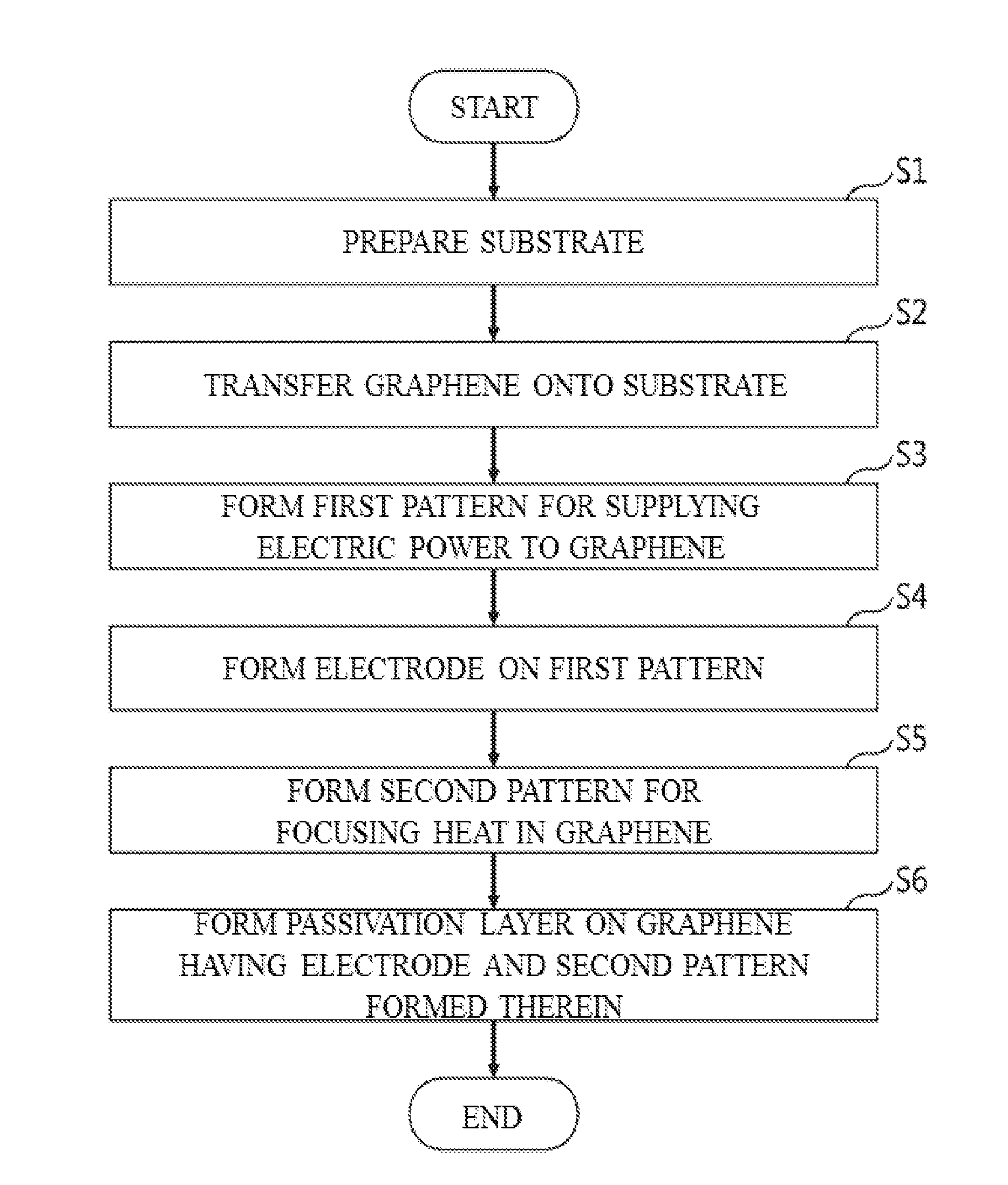

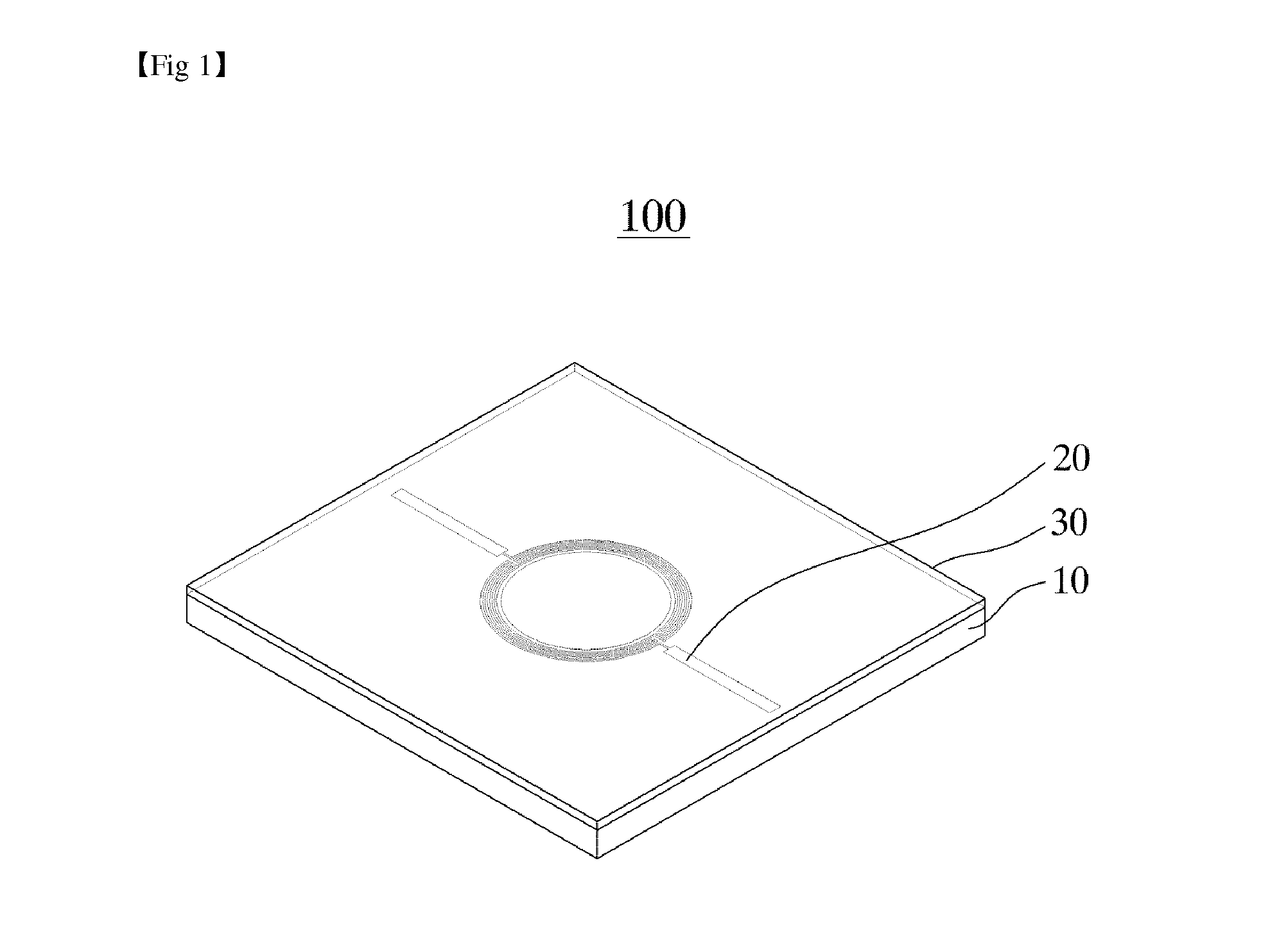

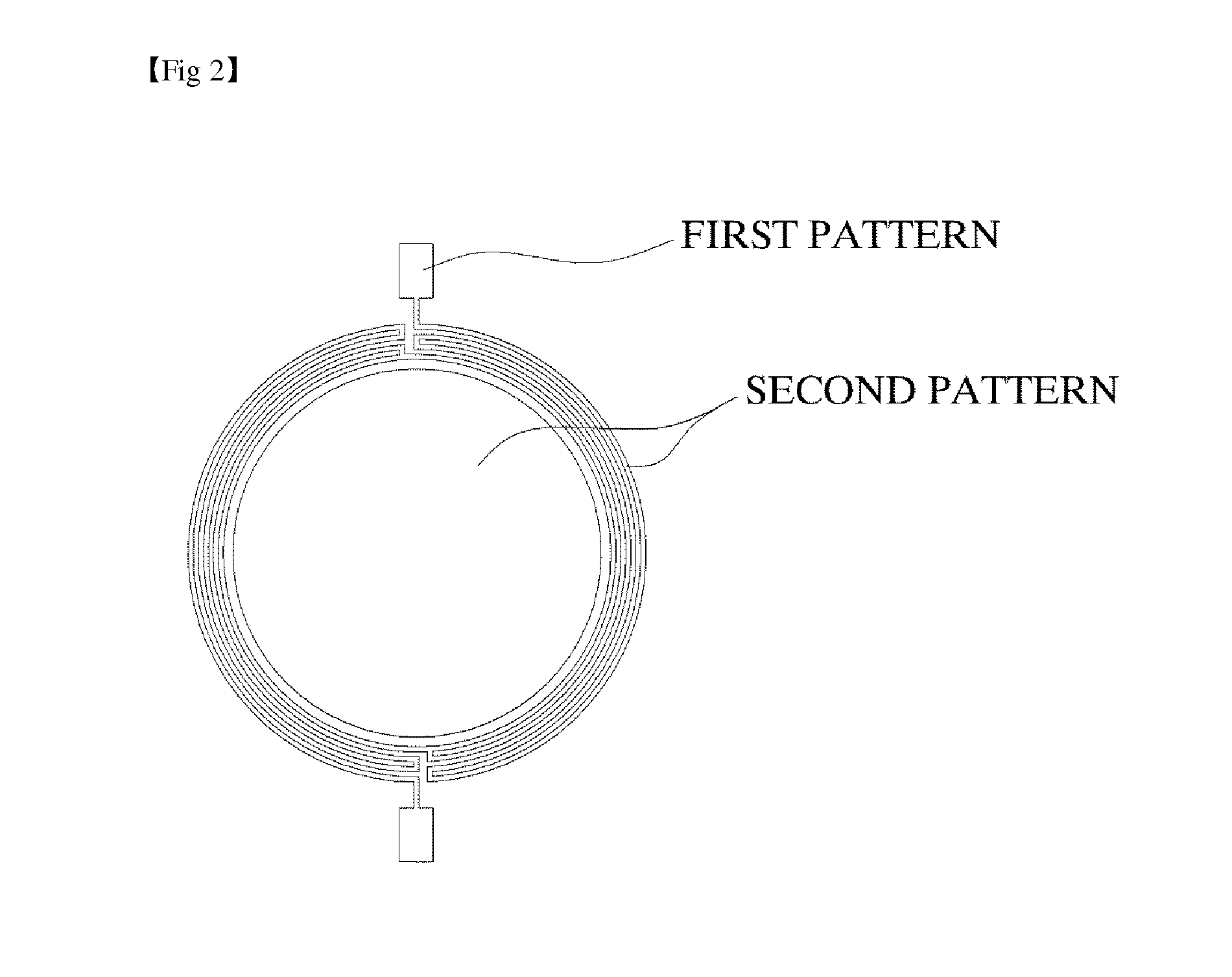

Graphene microheater and method of manufacturing the same

InactiveUS20150181650A1Well formedHeating element materialsResistive material coatingMicroheaterOptoelectronics

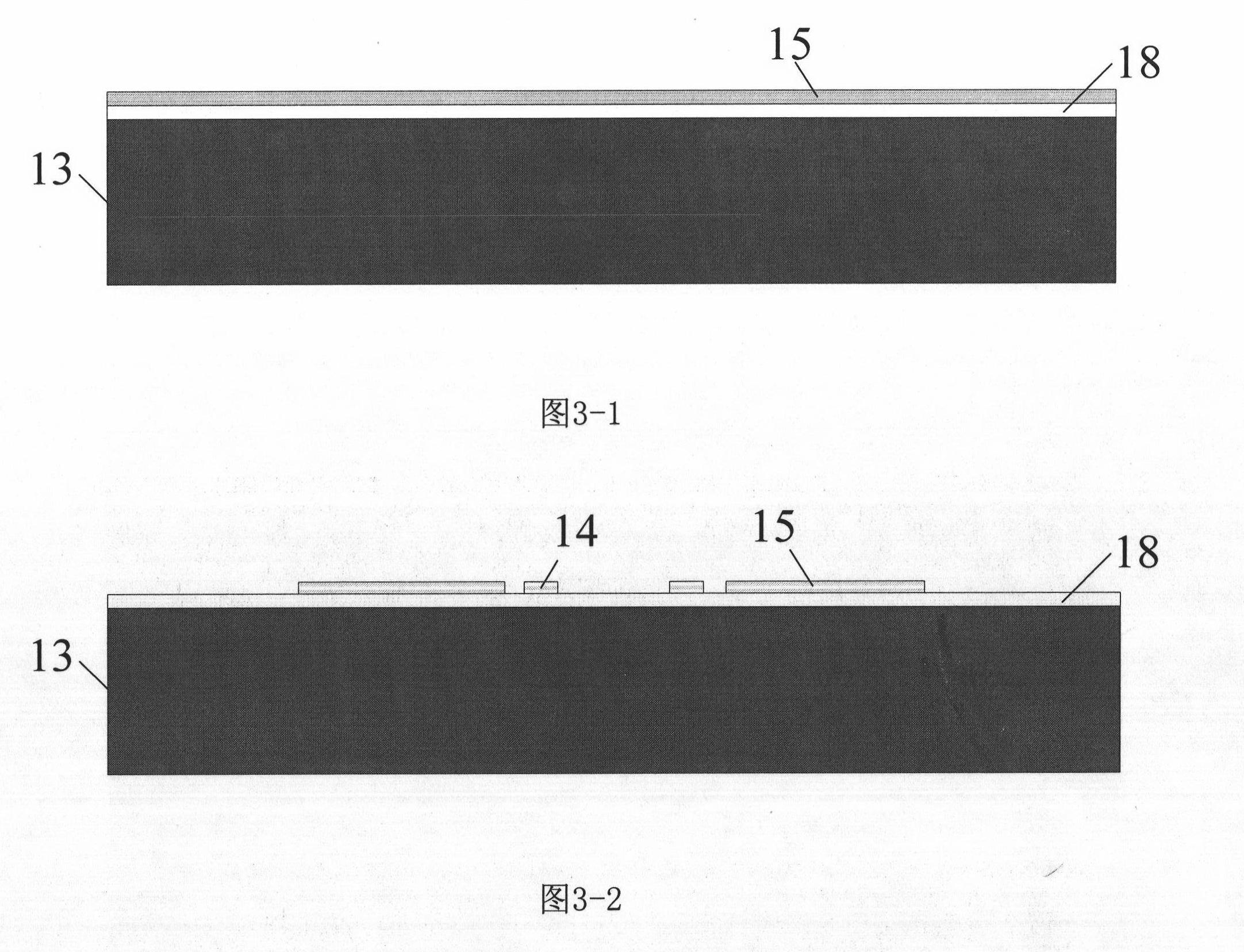

A microheater and a method of manufacturing the same are disclosed. The microheater includes a substrate, graphene disposed on the substrate and formed in a pattern; and a passivation layer disposed on the graphene. The method of manufacturing a microheater involves transferring graphene to a substrate, forming a first pattern for supplying electric power to the graphene, forming an electrode on the first pattern, forming a second pattern for focusing heating in the graphene, and forming a passivation layer on the graphene having the electrode and the second pattern formed therein.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

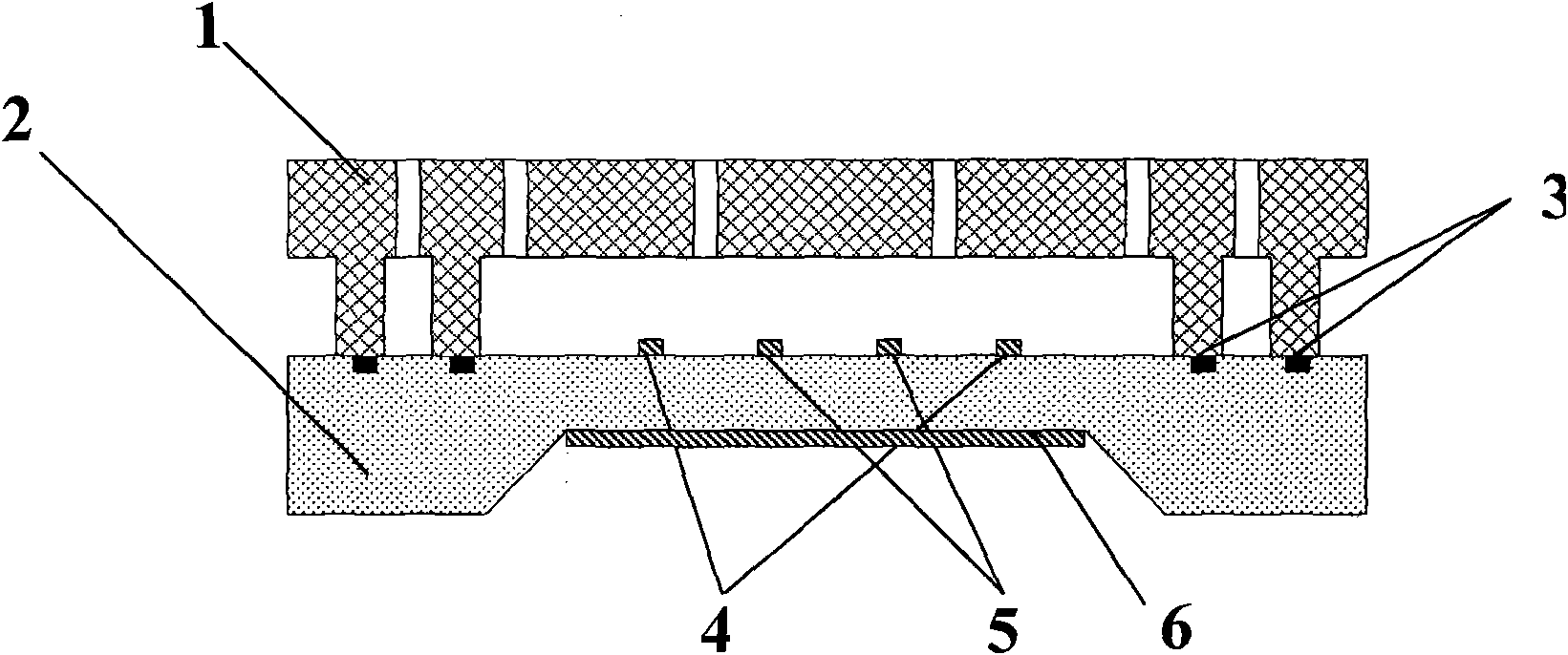

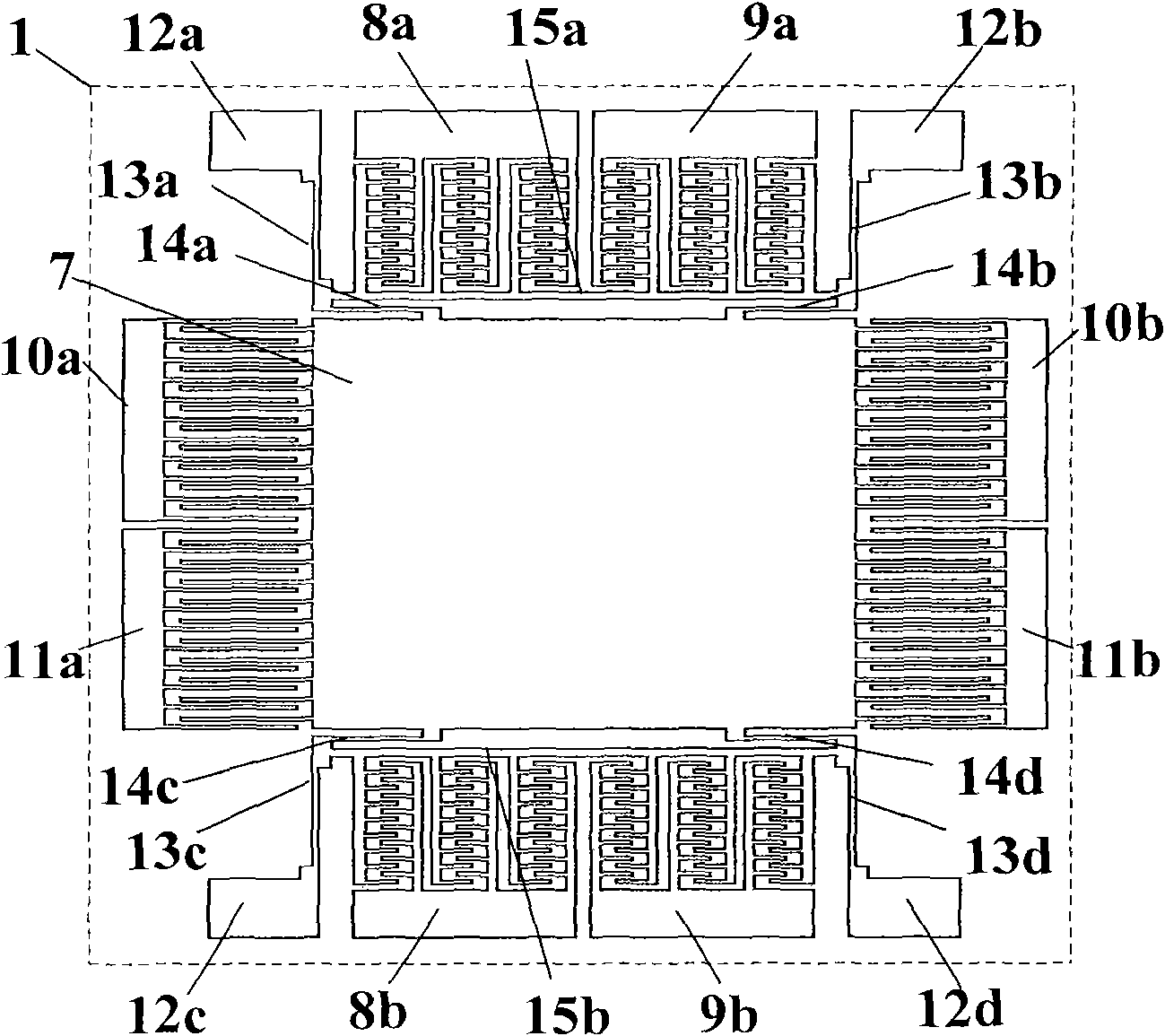

Micromechanical resonator and manufacturing method thereof

ActiveCN103281048AAchieve high frequencyEnable signal feedthroughImpedence networksResonanceMicroheater

The invention discloses a micromechanical resonator and a manufacturing method thereof. The micromechanical resonator is formed by a resonator crystal plate and a packing cover piece through bonding and sealing. The resonator crystal plate comprises an input electrode, an output electrode, a bias electrode, a resonance unit and a supporting structure. Larger-area grounding holes around the resonator structure reduce feed-through signals, and micro heaters around the resonator achieve high-precision temperature compensation. The outermost peripheral structure of the resonator crystal plate is a bonding packing ring, and the packing cover piece comprises a packing cavity, the bonding packing ring and an electrical leading-out structure. According to the micromechanical resonator and the manufacturing method thereof, high-precision and large-scale manufacturing of the high-performance resonator is achieved, wafer-level air impermeability bonding packing is achieved, and the manufacturing method can be applied to low-cost large-scale production of high-performance MEMS resonators.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

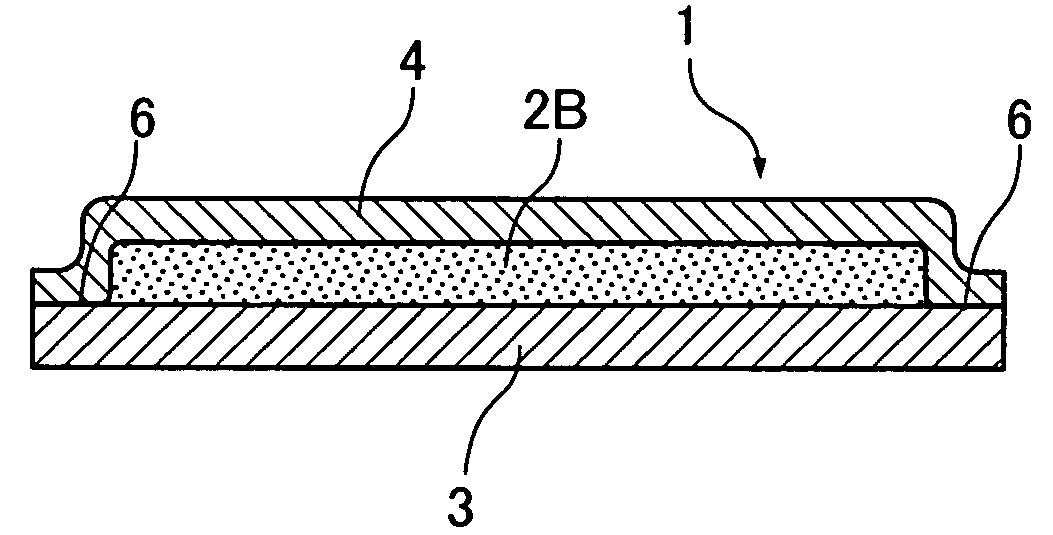

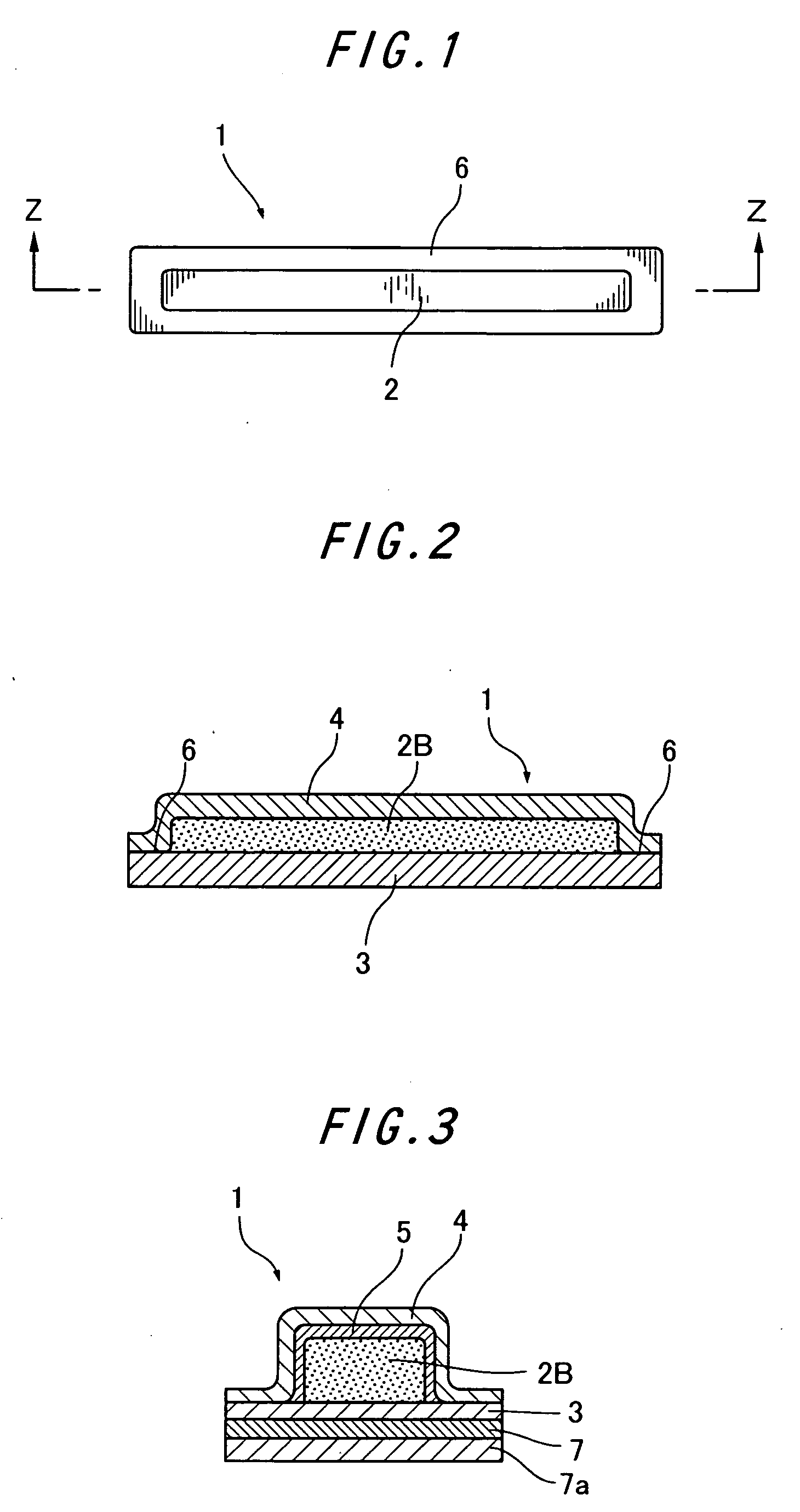

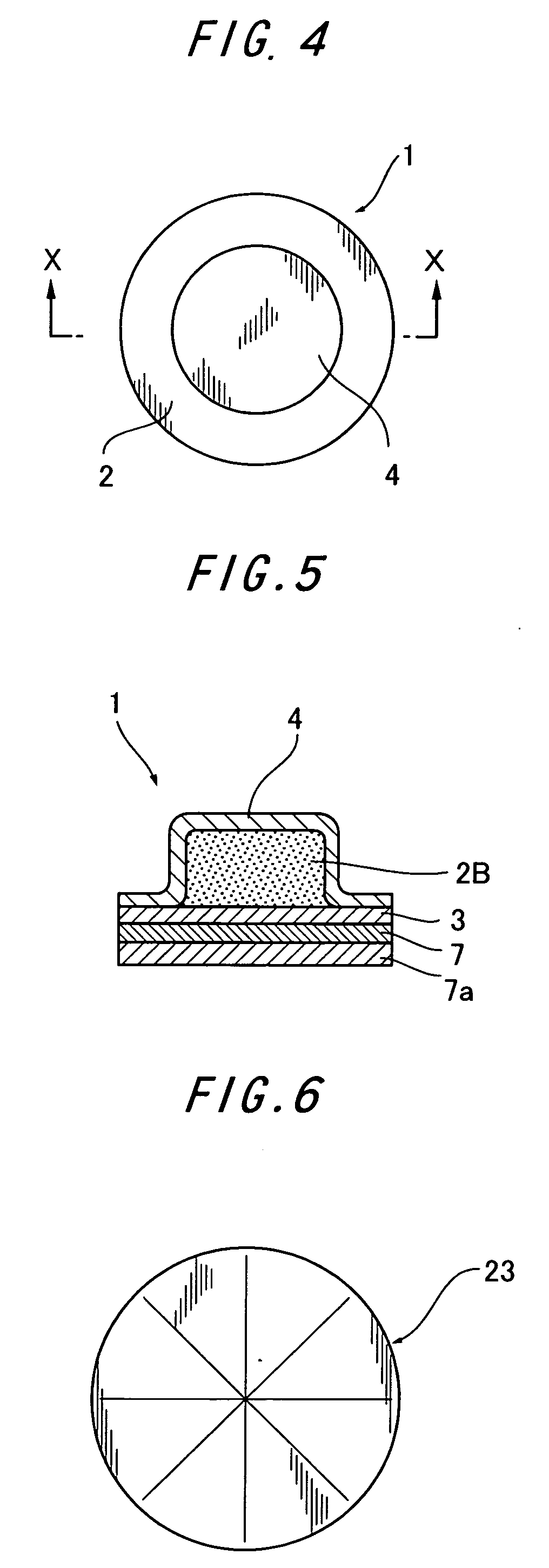

Microheater and Process For Producing the Same

InactiveUS20090000610A1High thermal moxibustion effectUniform and convenient and comfortable heatDevices for heating/cooling reflex pointsExothermal chemical reaction heat productionIron powderShell molding

To provide a microheater which gives a desired temperature and starts an exothermic reaction upon immediate contact with air and in which plural microheaters can be chained or incorporated in a packaging material.A microheater having a heat generating composition molded body made of a moldable heat generating composition containing surplus water as a connecting substance accommodated in an air-permeable accommodating bag, which is characterized in that the accommodating bag is made of a heat seal layer-containing substrate and a covering material and has an exothermic part as formed by laminating a heat generating composition molded body as molded on the substrate which is substantially planar and does not have a pocket, an accommodating division and an accommodating section, covering by the covering material and heat sealing the periphery of the heat generating composition molded body; that the moldable heat generating composition contains, as essential components, an iron powder, a carbon component, a reaction accelerator and water, has a content of water in the moldable heat generating composition of from 1 to 60%, does not contain a flocculant aid, a flocculant, an agglomeration aid, a dry binder, a dry binding agent, a dry binding material, a sticky raw material, a thickener and an excipient, contains surplus water so as to have a water mobility value of from 0.01 to 20, with the water in the heat generating composition not functioning as a barrier layer, and is capable of causing an exothermic reaction upon contact with air; that a volume of the heat generating composition molded body is from 0.1 to 30 cm3, and a ratio of a capacity of the exothermic part to the volume of the heat generating composition molded body is from 0.6 to 1.0; and that a maximum height of the exothermic part is from 0.1 to 10 mm.

Owner:MYCOAL PRODS CORP

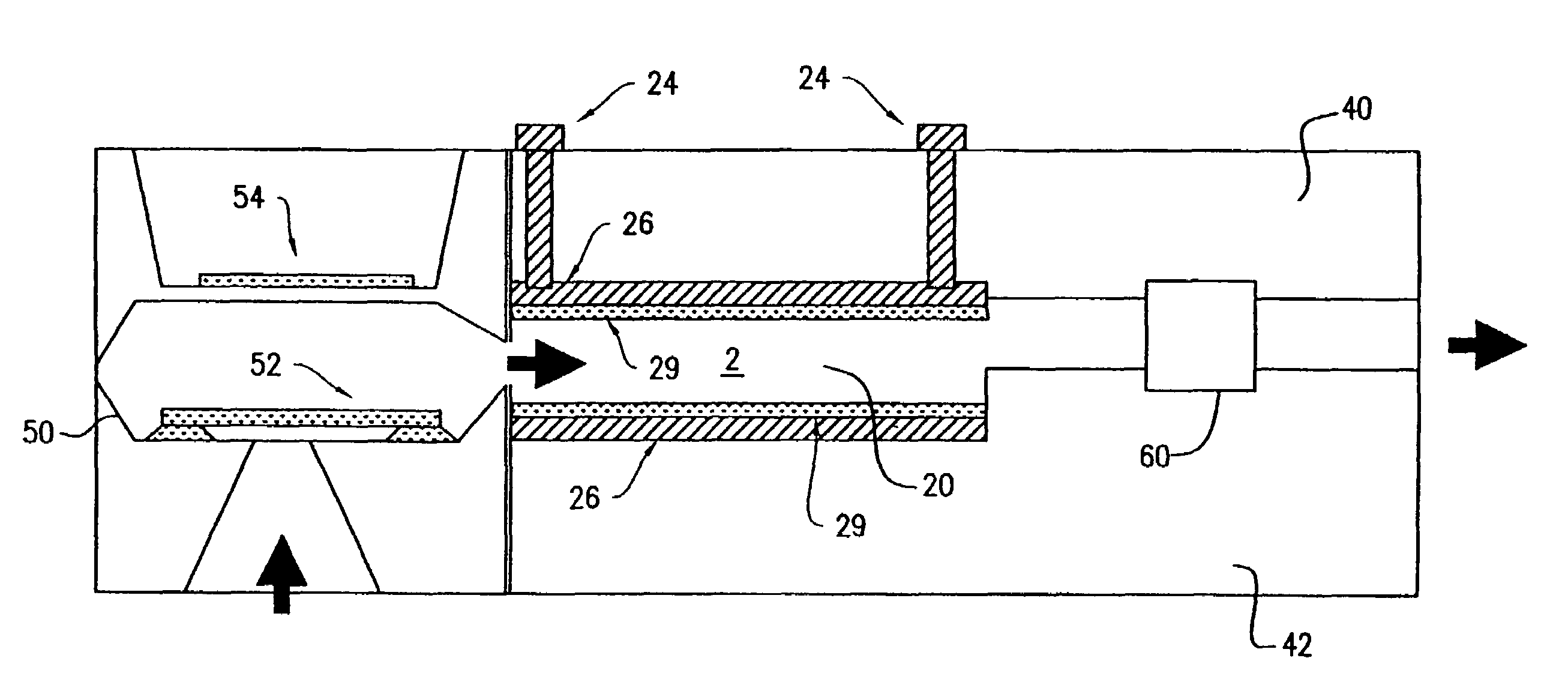

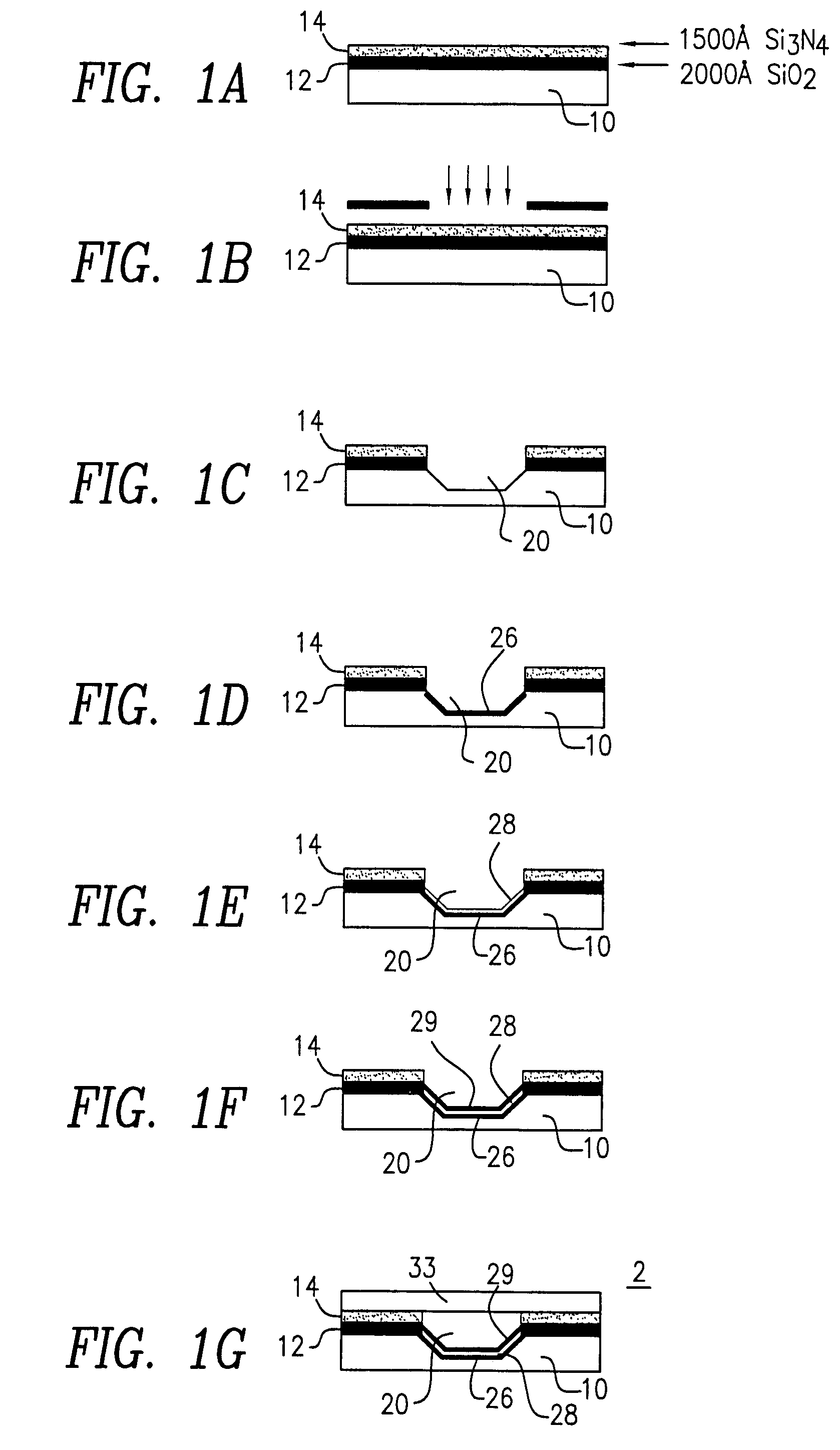

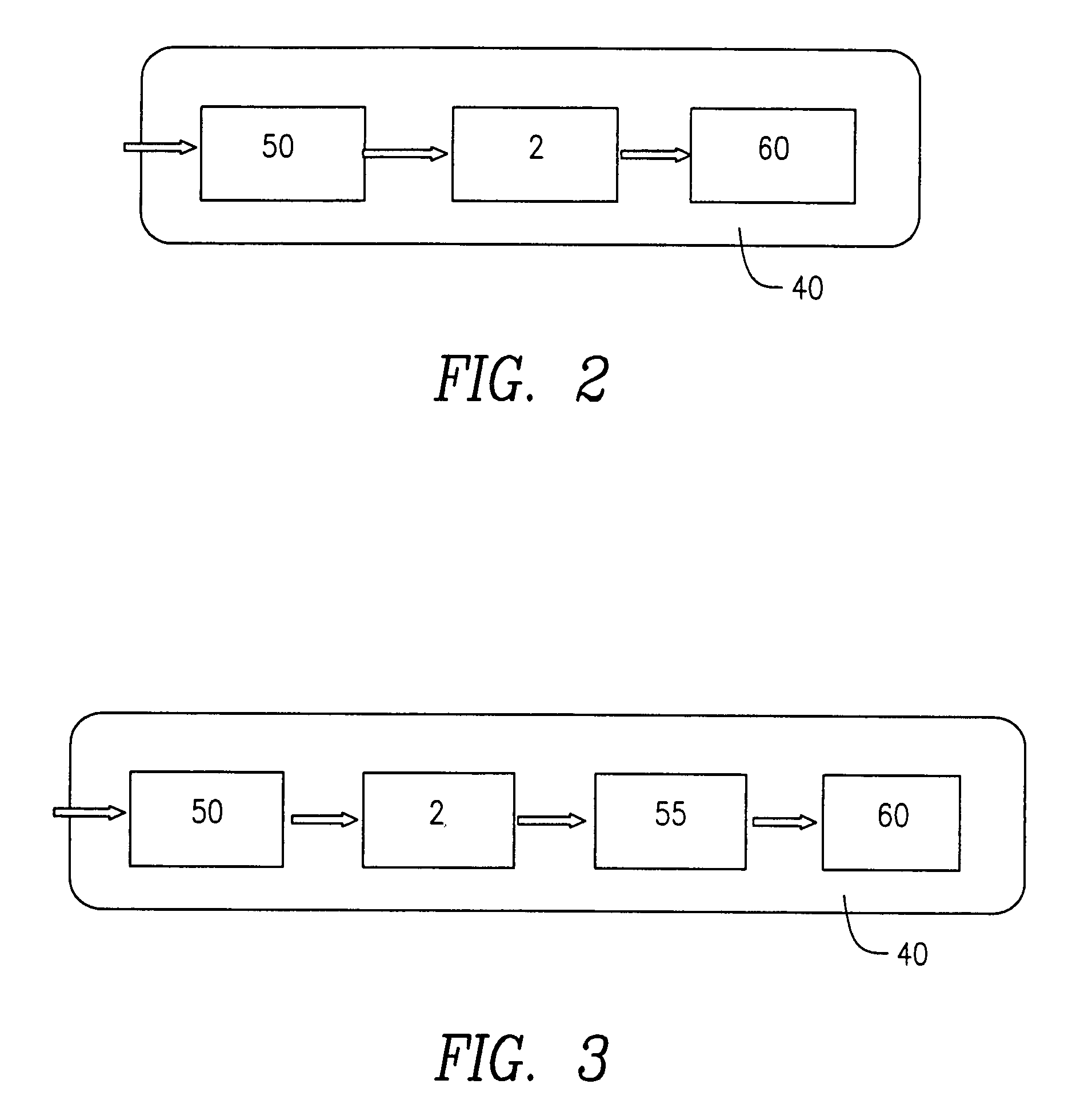

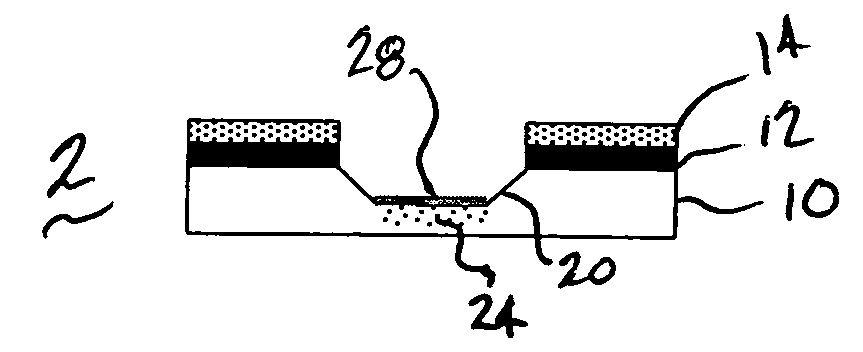

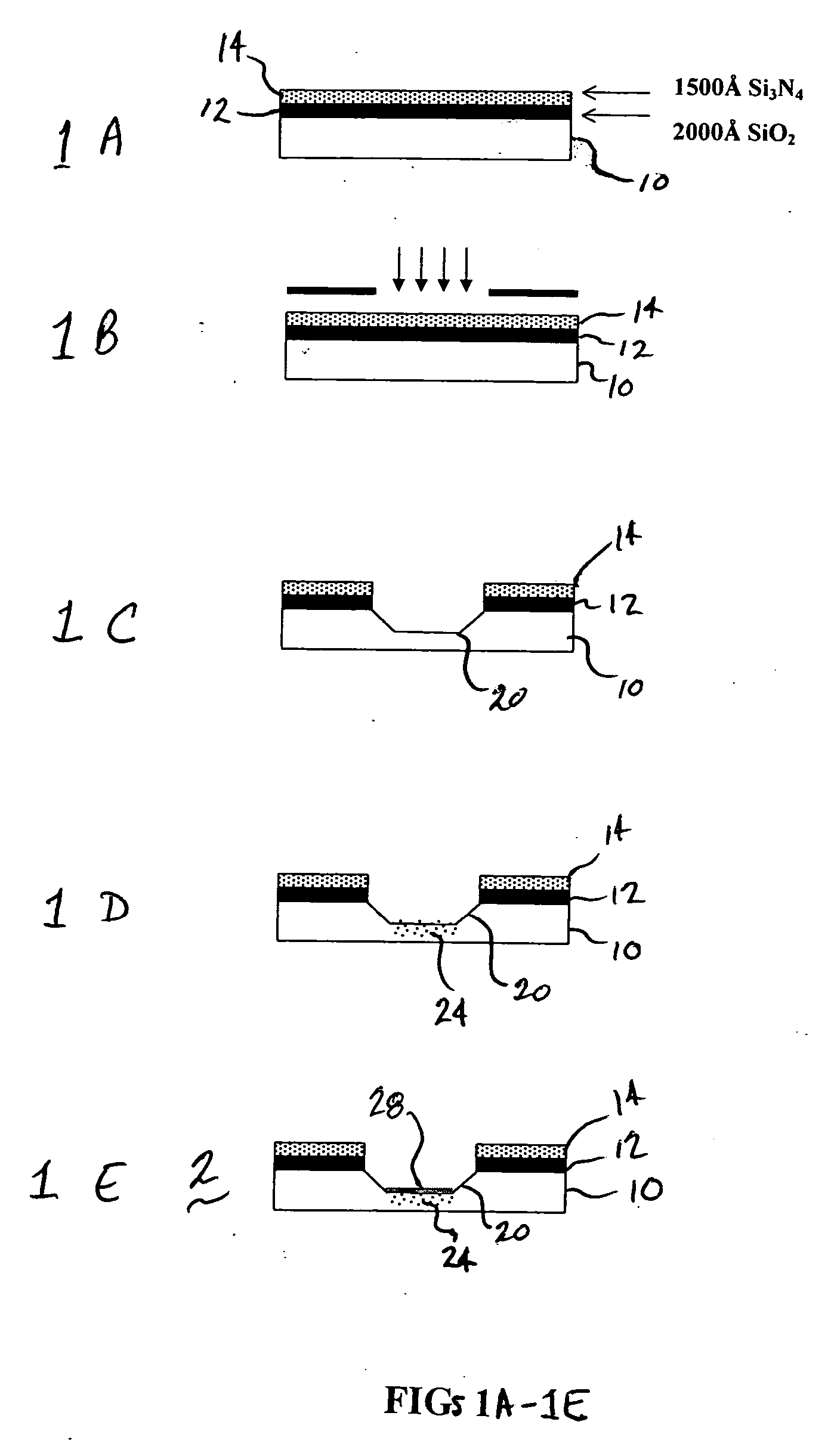

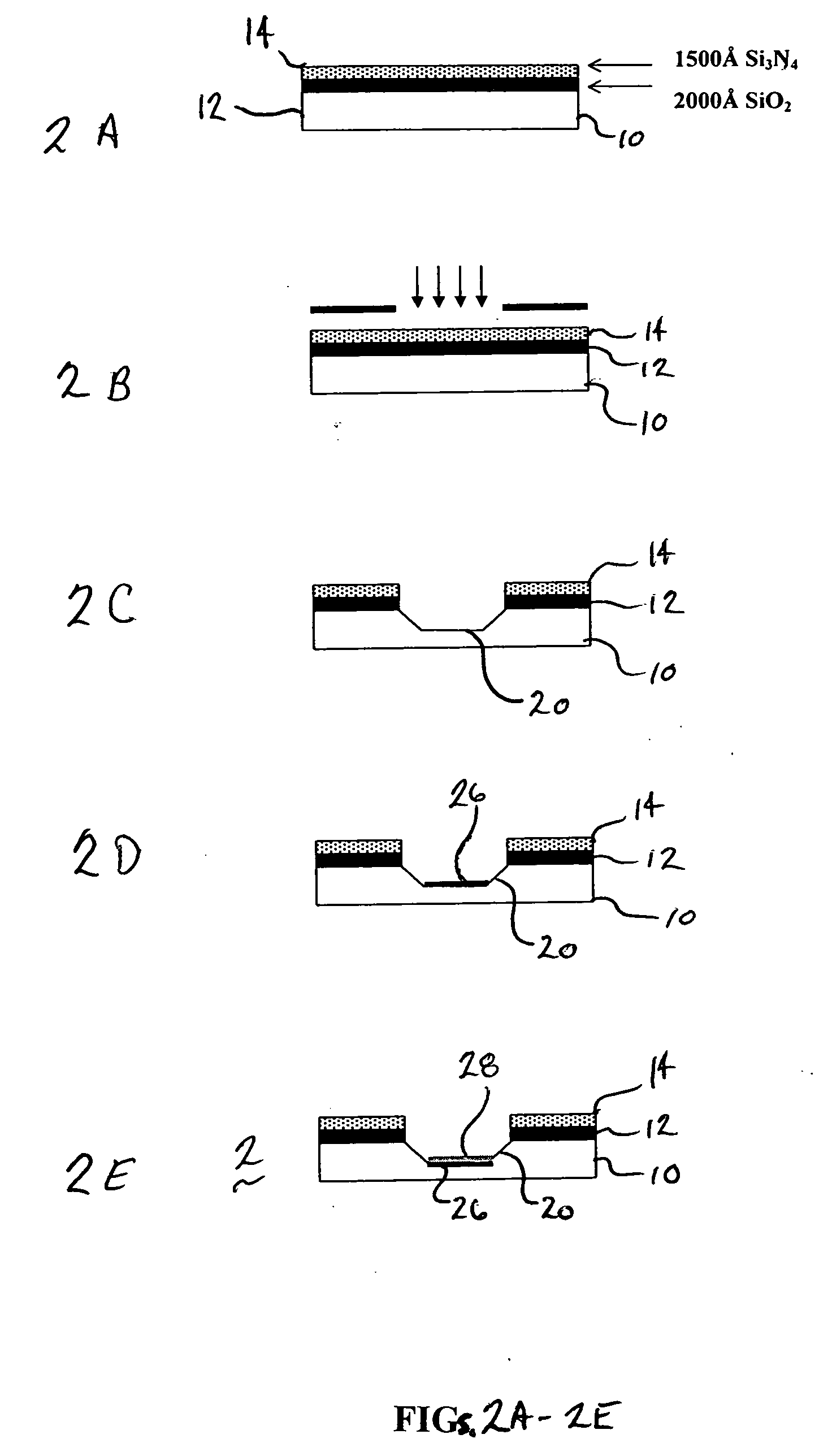

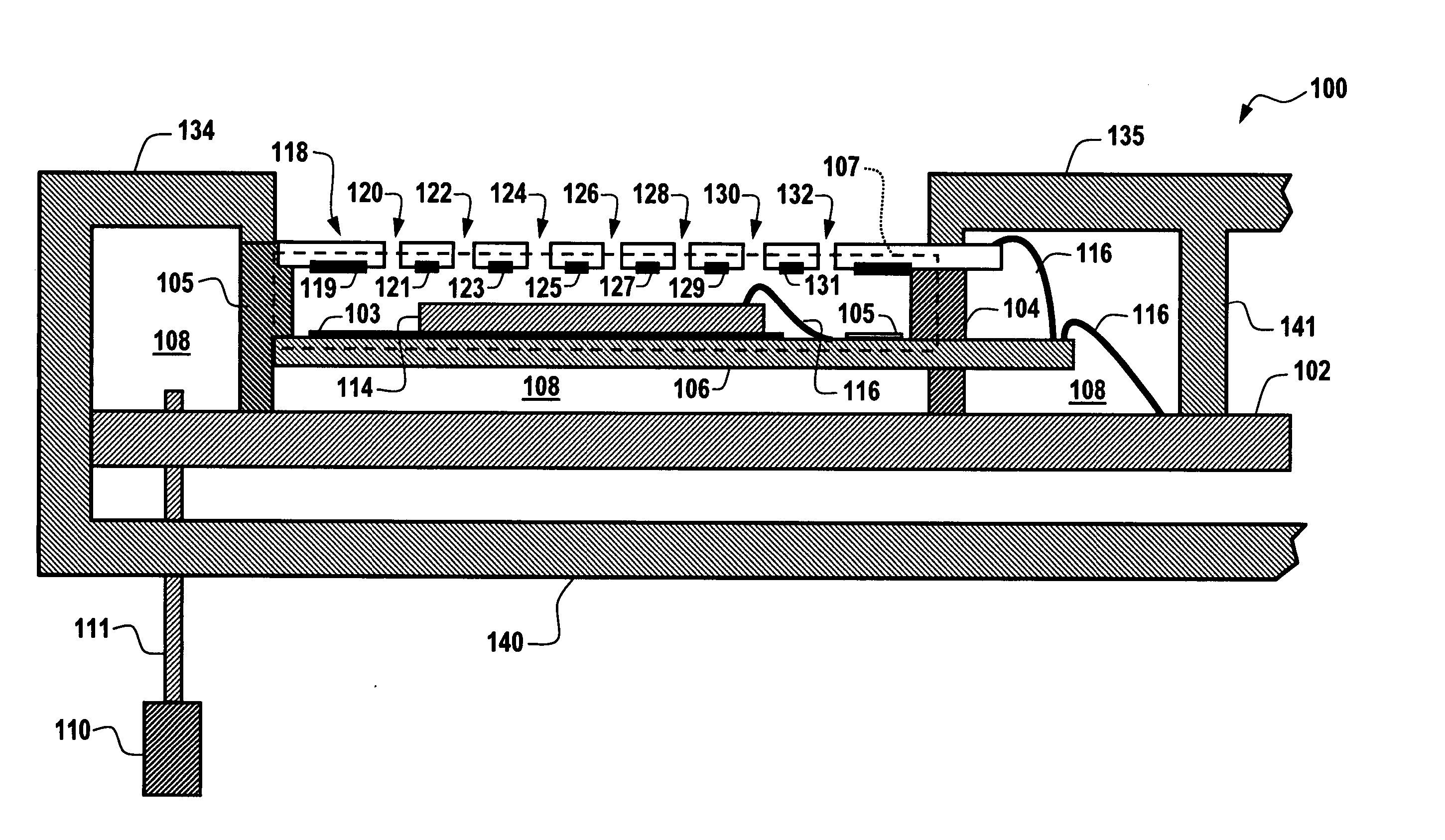

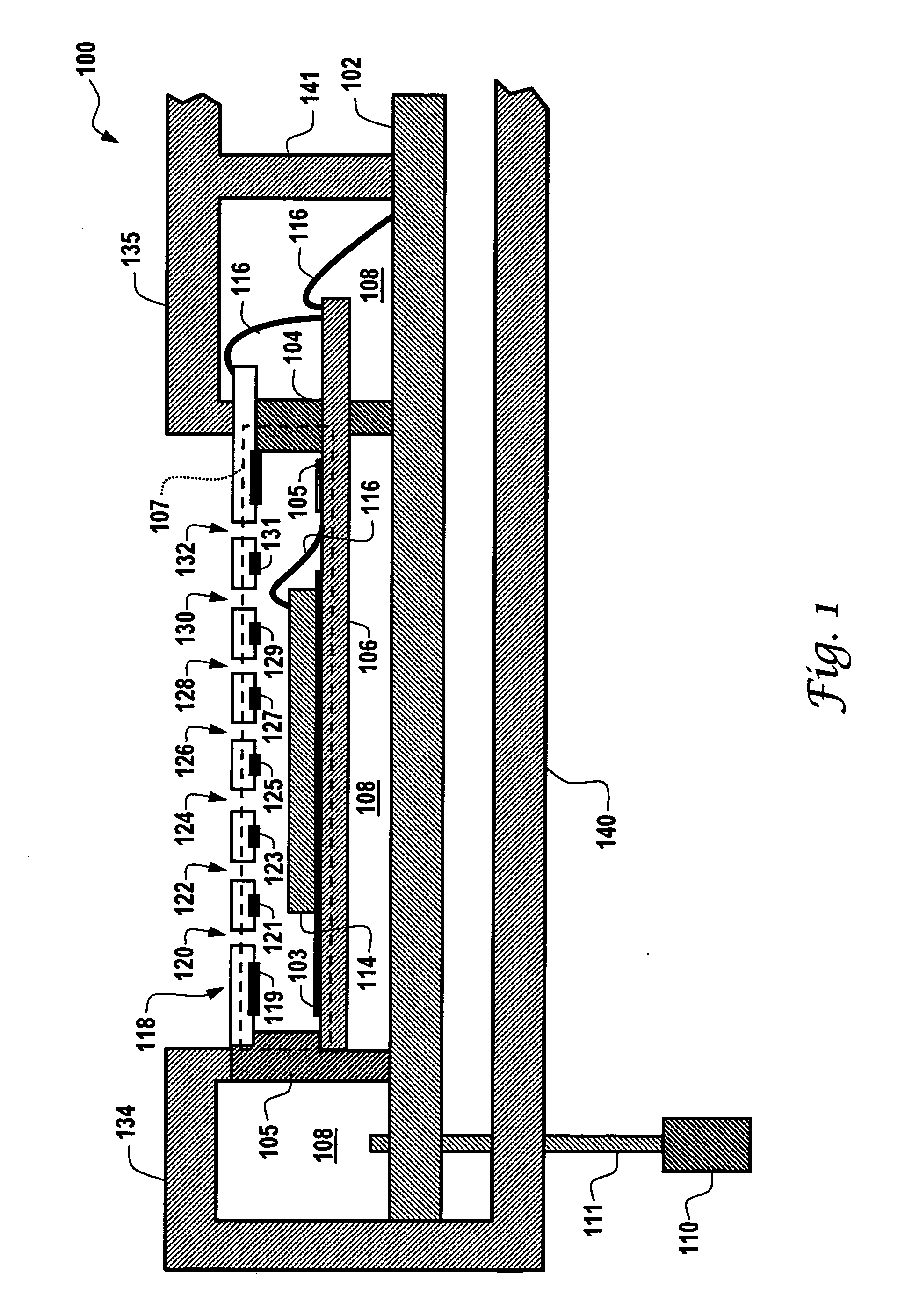

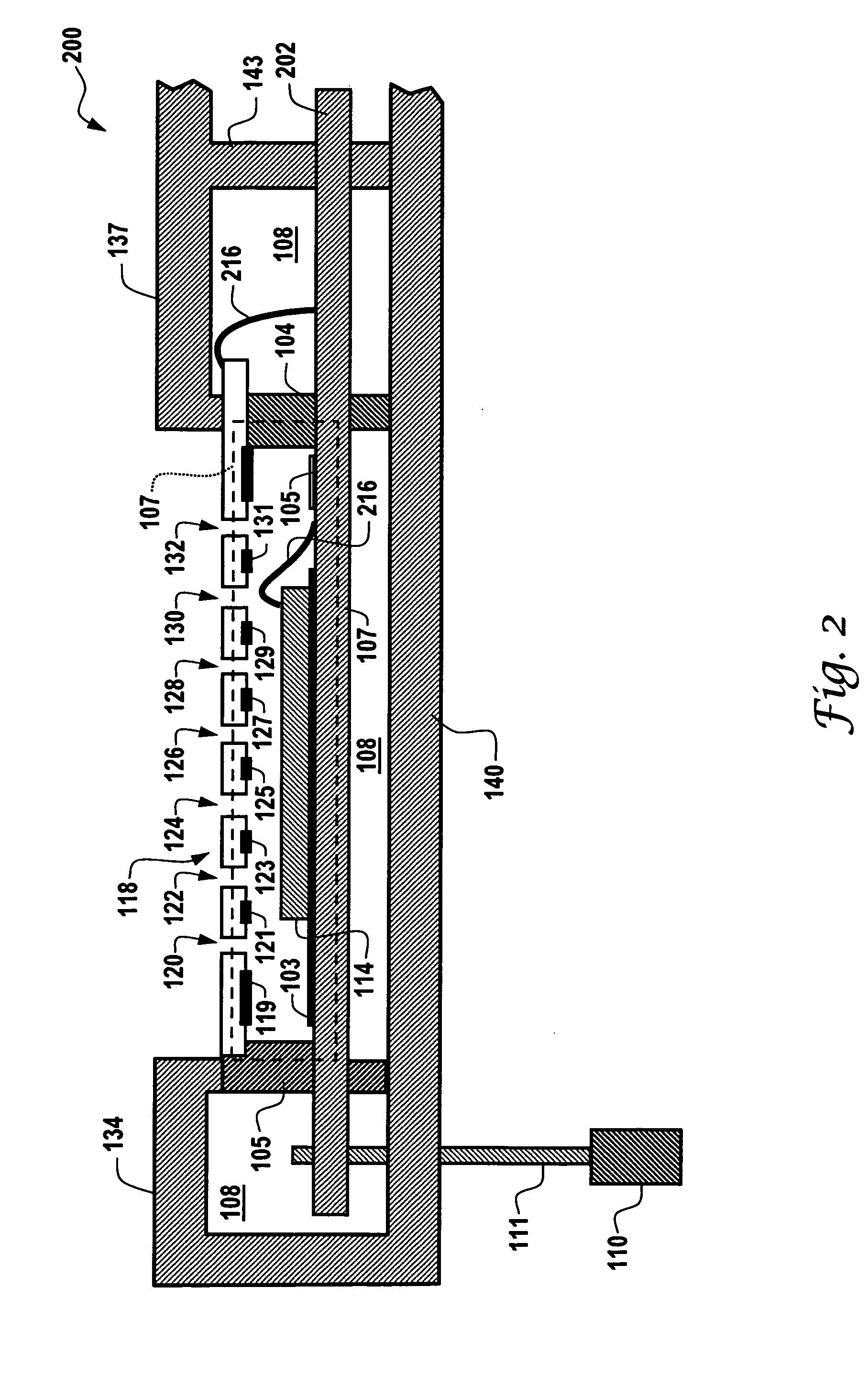

Micromachined heaters for microfluidic devices

InactiveUS20040178879A1Good electrical insulatorImprove surface propertiesSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorLab-on-a-chip

Microfabricated heaters for microfluidic devices for lab-on-a-chip applications comprising channels using deposited conductors such as sputtered metal, alloys, polymers and composites thereof; or conductors prepared by ion implantation, and methods for fabricating same are disclosed. Rapid heating to temperatures above 360° C. and rapid cooling is possible using these microheaters. Repeated heating does not lead to the microheater devices weakening or burning out. Preferred embodiments include application of spin-on-glass on the microheater surface.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

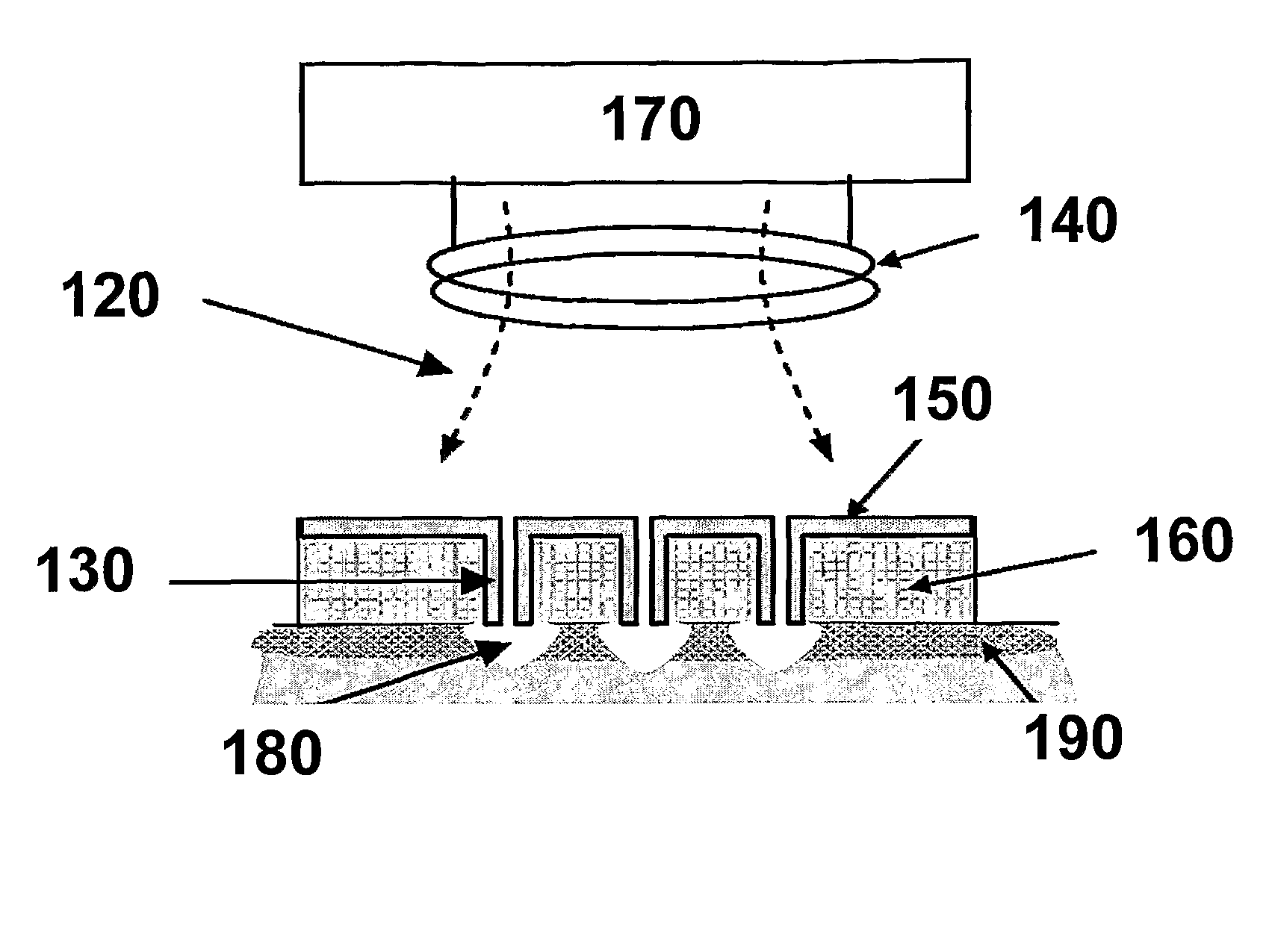

Methods and devices for thermal treatment

ActiveUS8690865B2Improve breathabilityMinimizing barrier propertySonopheresisElectrotherapyAnalyteMedicine

The present invention comprises methods and devices for thermal treatment of a barrier to increase the permeability of the barrier. One form of increasing the permeability of the barrier comprises forming micropores which may be used for administration of active agents across the barrier, or may be used for sampling or collecting fluids, or may be used for detecting, measuring or determining analytes, or may be used for monitoring of physiological or other conditions. Devices of the present invention may comprise microheaters that are activated by inductive or ohmic heating power supply components.

Owner:KONINK PHILIPS ELECTRONICS NV +1

Micro electro mechanical system (MEMS) gyroscope, chip level temperature control method thereof and processing method thereof

InactiveCN102042832AHigh sensitivityGood repeatabilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesTemperature controlGyroscope

The invention relates to a micro electro mechanical system (MEMS) gyroscope, a chip level temperature control method thereof and a processing method thereof. A microheater and a temperature sensor are processed on a glass substrate by a micromachining technique; the glass substrate is bonded with an MEMS gyroscope structure chip; the MEMS gyroscope chip is heated by applying voltage at the two ends of the microheater; and the integrated temperature sensor monitors the temperature of the MEMS gyroscope chip in real time so as to drive a peripheral circuit to adjust the voltage at the two ends of the heater and keep the temperature of the gyroscope chip constant and a little higher than the upper limit of the temperature of the working environment. The heater and the temperature sensor are integrated on the glass substrate, the volume is small and the temperature sensitivity is high. The chip level temperature control method has the characteristics of low power consumption, small volume, high applicability and high repeatability, can be compatible with the micromachining process, can realize batch production, and can be widely applied to chip level temperature control of other MEMS chips.

Owner:SOUTHEAST UNIV

Micro-heating apparatus for locally controlling the temperature in a mold

InactiveUS20050115955A1High heating effectIncreasing the thicknessHeating element materialsPlastic materialsMicroheater

A micro-heating apparatus for locally controlling a temperature in a mold includes substrate, at least a micro-heating module installed on the substrate, and at least a temperature detector installed on the substrate near the micro-heater for measuring the local temperature. The micro-heating module includes a micro-heater, an external power circuit, and a connection electrode for connecting the external power circuit and a programmable external power device. The substrate with the micro-heating module and the temperature detector thereon is capable of combining with the mold so that the micro-heater contacts a plastic material in the mold. The programmable external power device is used for connecting to the external power circuit to control the micro-heater to heat the plastic material so as to control the temperature when the temperature around an interface of the plastic material and the micro-heater is measured.

Owner:U TECH MEDIA

Humidity sensor for measuring supersaturated water vapor utilizing a mini-heater

InactiveUS20060225488A1Minimize airflowReduce humiditySamplingMaterial moisture contentDiffusionWater vapor

A humidity sensing apparatus and method includes a humidity sensor capable of measuring relative humidity and a heater located about and proximate to the humidity sensor wherein a portion of the heater comprises a material that permits a diffusion of air through the material of the heater. A sensing area is generally formed between the heater and the humidity sensor, wherein the heater provides a heated environment within the sensing area in order to evaporate water droplets that form within the sensing area and reduce relative humidity to a measurable level and measure supersaturated air within the sensing area.

Owner:HONEYWELL INT INC

Real-time PCR monitoring apparatus and method

InactiveUS20050130183A1Enhanced temperature transition rateIncrease conversion rateBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityCommunication unit

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com