Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Directed crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum

The invention provides a method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum, comprising the technological steps of purification, crystal transforming reaction, oriented crystallization, washing and separation, and drying and pulverization. The method concretely comprises the following steps of: enhancing the taste of calcium sulfate dlhy in the desulfurized gypsum to be greater than 95% through a purification treatment; dissolving and recrystallizing the desulfurized gypsum at 70 to 98 DEG C under the normal pressure through adding prepared habit modifiers, transforming into the alpha semi-hydrated gypsum and then carrying out oriented crystallization on the alpha semi-hydrated gypsum to form a short column-shaped alpha semi-hydrated gypsum crystal under the function of an oriented crystal type stabilizer, wherein the length-diameter ratio of the short column-shaped alpha semi-hydrated gypsum crystal is less than 1:3, the 2h breaking strength is greater than 6.5 MPa, the compression strength is greater than 23 MPa, the dry breaking strength is greater than 25 MPa, and the dry compression strength is greater than 53 MPa. The method can be widely used in the fields of ceramics, automobiles, precise casting, heterogenic casting and the like.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

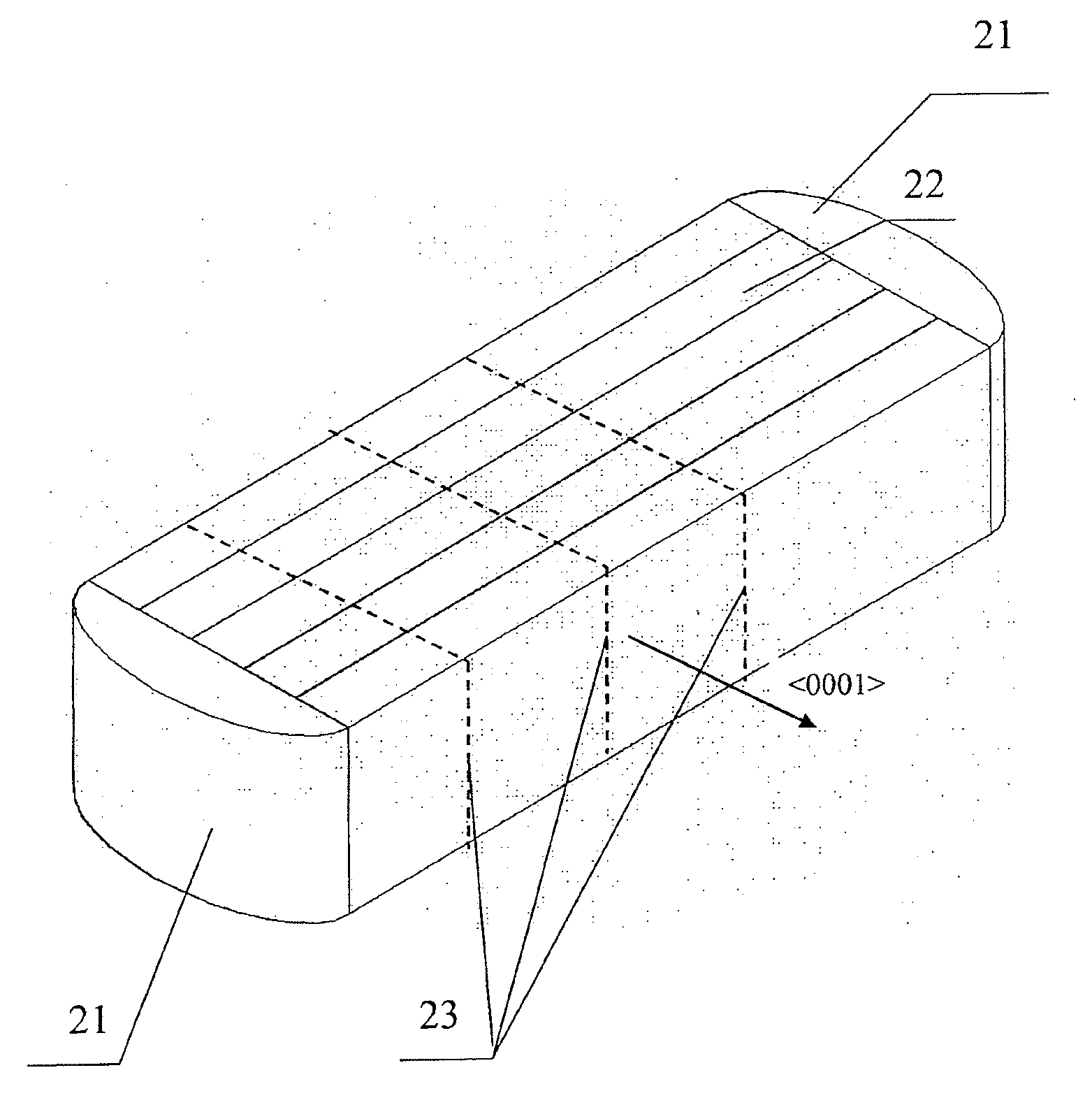

Huge magnetostriction material and mfg. process thereof

InactiveCN1435851AGood low field performanceEase of mass productionInorganic material magnetismMagnetostrictive material selectionChemical compositionHigh volume manufacturing

A giant-magnetostrictive material is (Tb1-x-yDyxRy)(Fe1-z-pBe2Mp)g, where R is chosen from Ho, Er, Pr and Nd, M is chosen from Ti, V, Cr, Co, Ni, Mn, Si, Ga and Al, x=0.65-0.80, y=0-0.15, and g=1.75-2.55. Its preparing process includes smelting mother alloy in Ar atmosphere in vacuum furnace, growing oriented crystallizing material in vacuum or inert gas, and heat treating in vacuum furnace. Its advantages are high magnetostrictive strain ratio, good low-field performance, and low cost.

Owner:UNIV OF SCI & TECH BEIJING

Crystalloid laminae composited from single crystal and directional column crystal and preparing method

InactiveCN1660524AImprove performanceQuality improvementPolycrystalline material growthBlade accessoriesDirected crystallizationEngineering

A monocrystal and orientational cylindrical crystal combined blade used for gas turbine features that its middle region is orientational cylindrical crystals and its gas inlet and outlet edges have monocrystal form. Its manufacture method includes such steps as installing a composite crystallizer to the crystallizer of orientational crystallizing furnace, smelting by 100-150 of overheat, regulating the temp of mould heater to 1500-1530 deg.C for upper region and 1550-1580 deg.C for lower region, casting, and moving mould downward at 5-7 mm / S.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

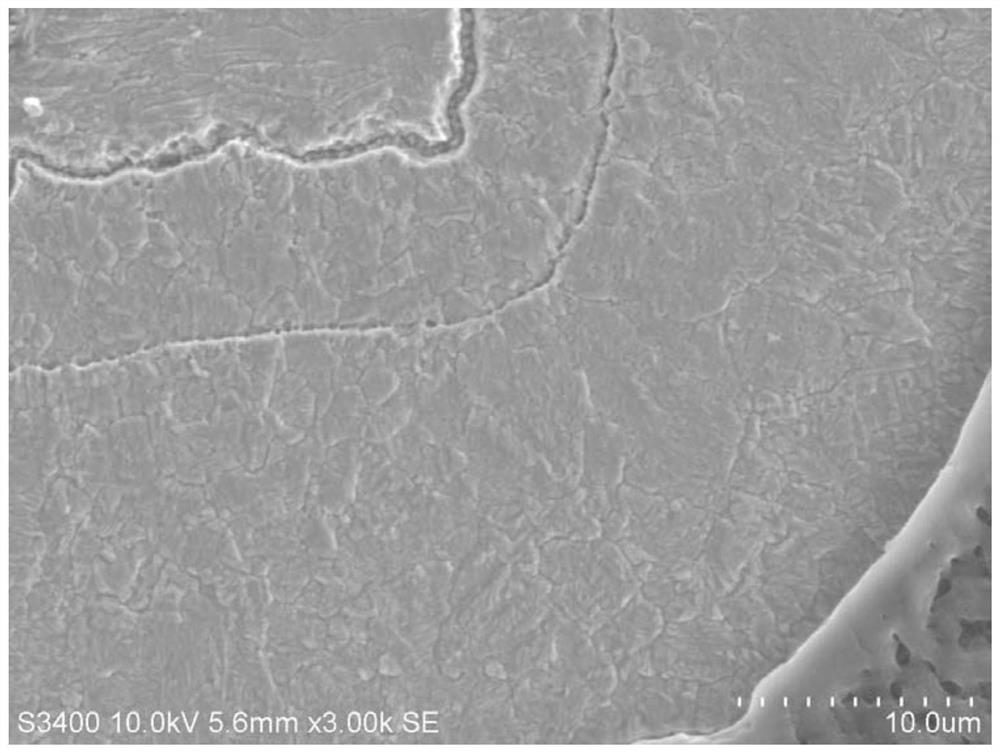

Method for preparing ordered-structure porous polymer material based on directional crystallization technology

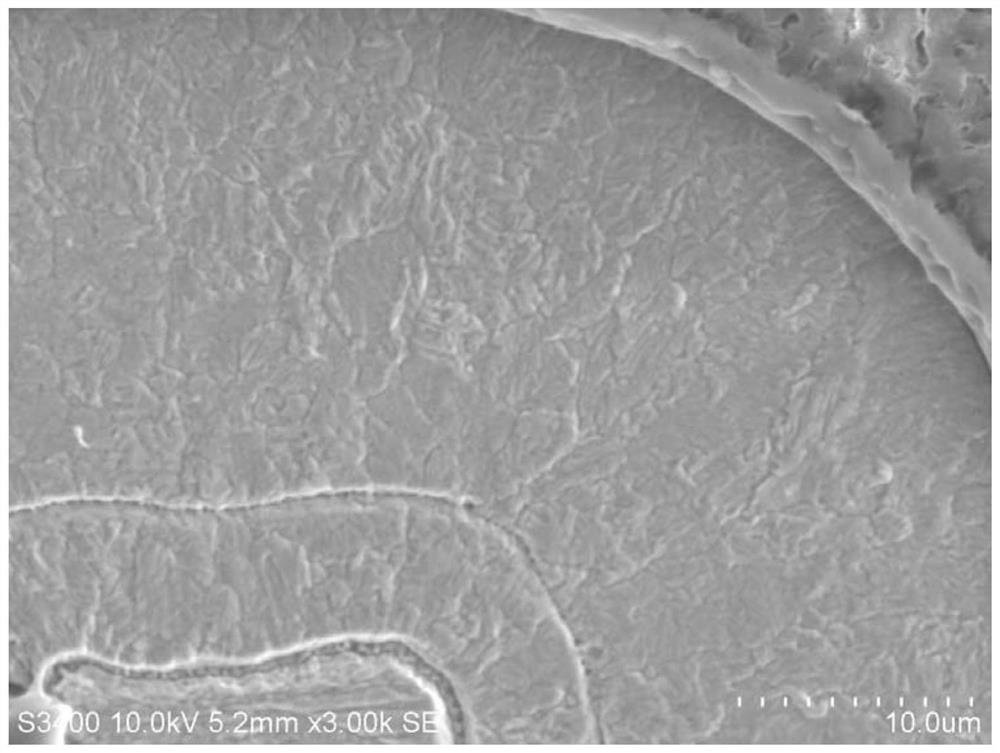

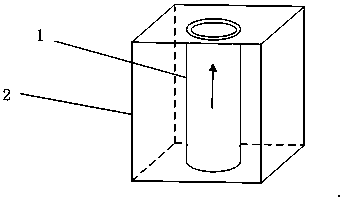

The invention discloses a method for preparing an ordered-structure porous polymer material by using a directional crystallization technology and using a polymer solution as a precursor, wherein dimethyl sulfoxide is used as a solvent of the polymer solution. The method comprises the following steps: adding different polymers into dimethyl sulfoxide, and forming the polymer solution by stirring at a certain temperature; transferring the polymer solution to a square mould, contacting one side of the mould with low temperature, placing in a drying oven after directionally crystallizing the solution, and drying the obtained material to obtain the ordered-structure porous polymer material. The preparation method is simple and feasible, green and environment-friendly, and wide in applicable range, the aperture is 10-30 microns, and the preparation method is a general for preparing the ordered-structure porous polymer material.

Owner:EAST CHINA UNIV OF SCI & TECH

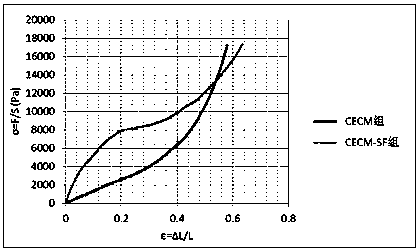

Cartilage extracellular matrix and silk fibroin composite orientation cartilage support and preparation method thereof

ActiveCN105251052AFix performance issuesStructural solutionAnimals/human peptidesProsthesisCell-Extracellular MatrixBiocompatibility Testing

The invention discloses a cartilage extracellular matrix and silk fibroin composite orientation cartilage support and a preparation method thereof and belongs to the biological tissue engineering technology. According to the cartilage extracellular matrix and silk fibroin composite orientation cartilage support and the preparation method of the cartilage support, cartilage extracellular matrixes are prepared through articular cartilage of people, pigs, cows or sheep, silk fibroin is prepared through mulberry silk, after the cartilage extracellular matrixes and the silk fibroin are evenly mixed according to a specific proportion, directed crystallization is performed under a certain temperature, ultraviolet cross linking is firstly performed after freezing and drying, and then cross linking of carbodiimide and N-hydroxysuccinimide or glutaraldehyde and genipin is performed so that the cartilage extracellular matrix and silk fibroin composite orientation cartilage support can be prepared. Due to the design, biocompatibility is good, and immunological rejective reaction is avoided; a composition structure and mechanical properties are similar to those of cartilage extracellular matrixes of people; material sources are wide, cost is low, the preparation technology is simple, the cartilage extracellular matrix and silk fibroin composite orientation cartilage support can be used for constructing tissue engineering cartilage and repairing cartilage degradation, and clinical application prospects are good.

Owner:TIANJIN HOSPITAL

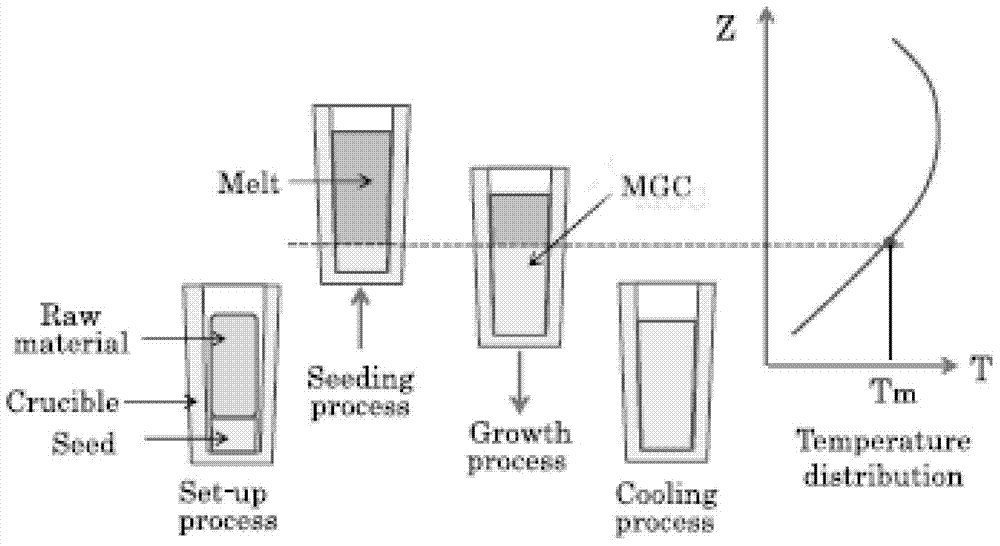

Horizontally directional zone-melting crystallization preparation method for large-size Re:YAG series of laser crystals

InactiveCN103243380AEasy to achieve uniform dopingReduce dislocation densityPolycrystalline material growthBy zone-melting liquidsZone meltingLarge size

The invention relates to a horizontally directional zone-melting crystallization preparation method for large-size Re:YAG series of laser crystals. The horizontally directional zone-melting crystallization preparation method is technically characterized in that the Re:YAG laser crystals are grown by means of horizontally directional zone-melting crystallization in a vacuum condition; and the specific growth process comprises the six processes of material melting, seeding, shouldering, equal-width growing, cooling and annealing. According to the horizontally directional zone-melting crystallization preparation method disclosed by the invention, the advantages of a directional crystallization method and a vertical zone-melting method for crystal growth are combined, so that the prepared Re:YAG laser crystals have the advantages of being higher in quality, larger in size, higher in utilization rate, low in defect density, better in laser performance, without doped ion central cores or lateral cores, and the like.

Owner:HARBIN INST OF TECH

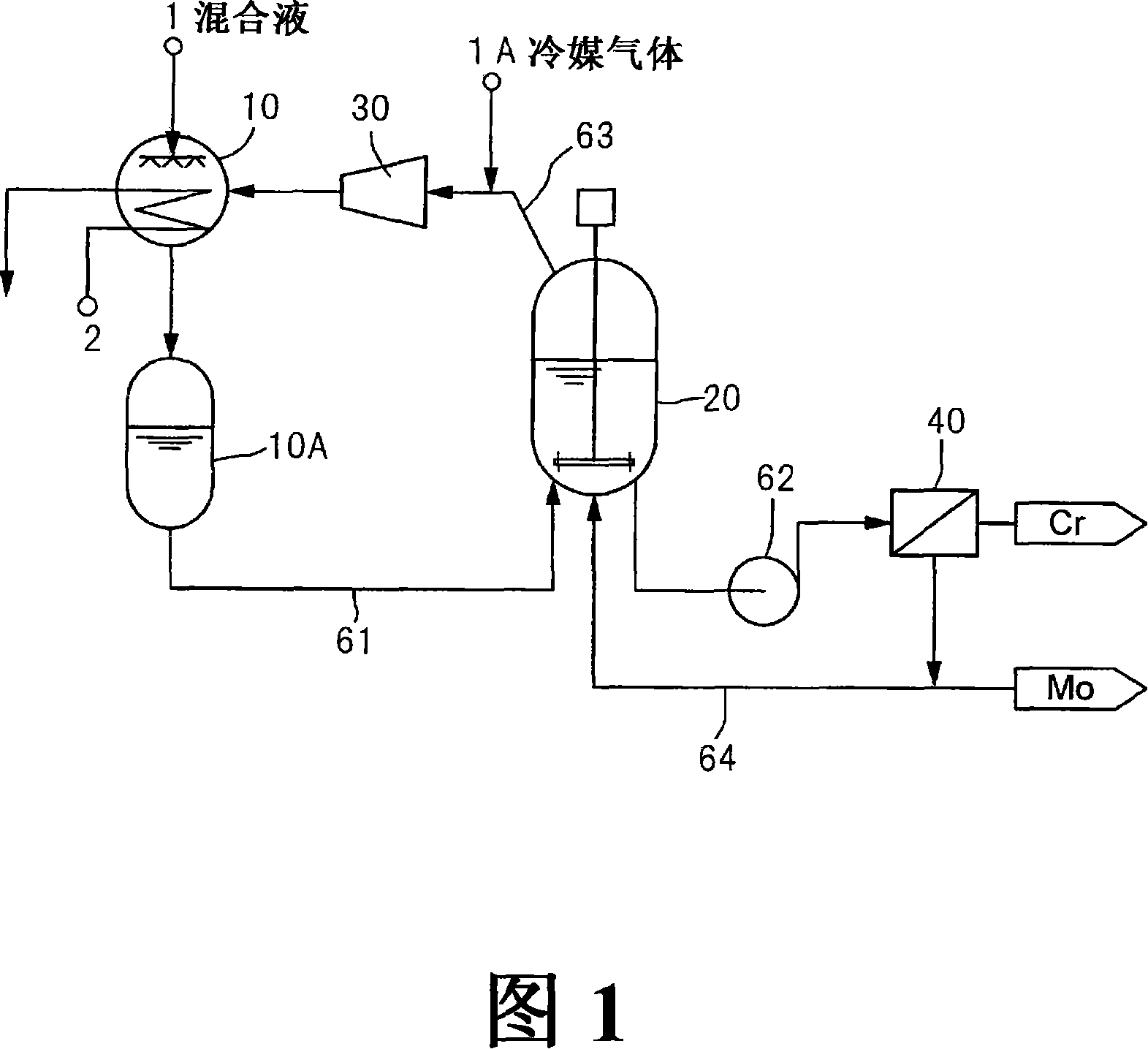

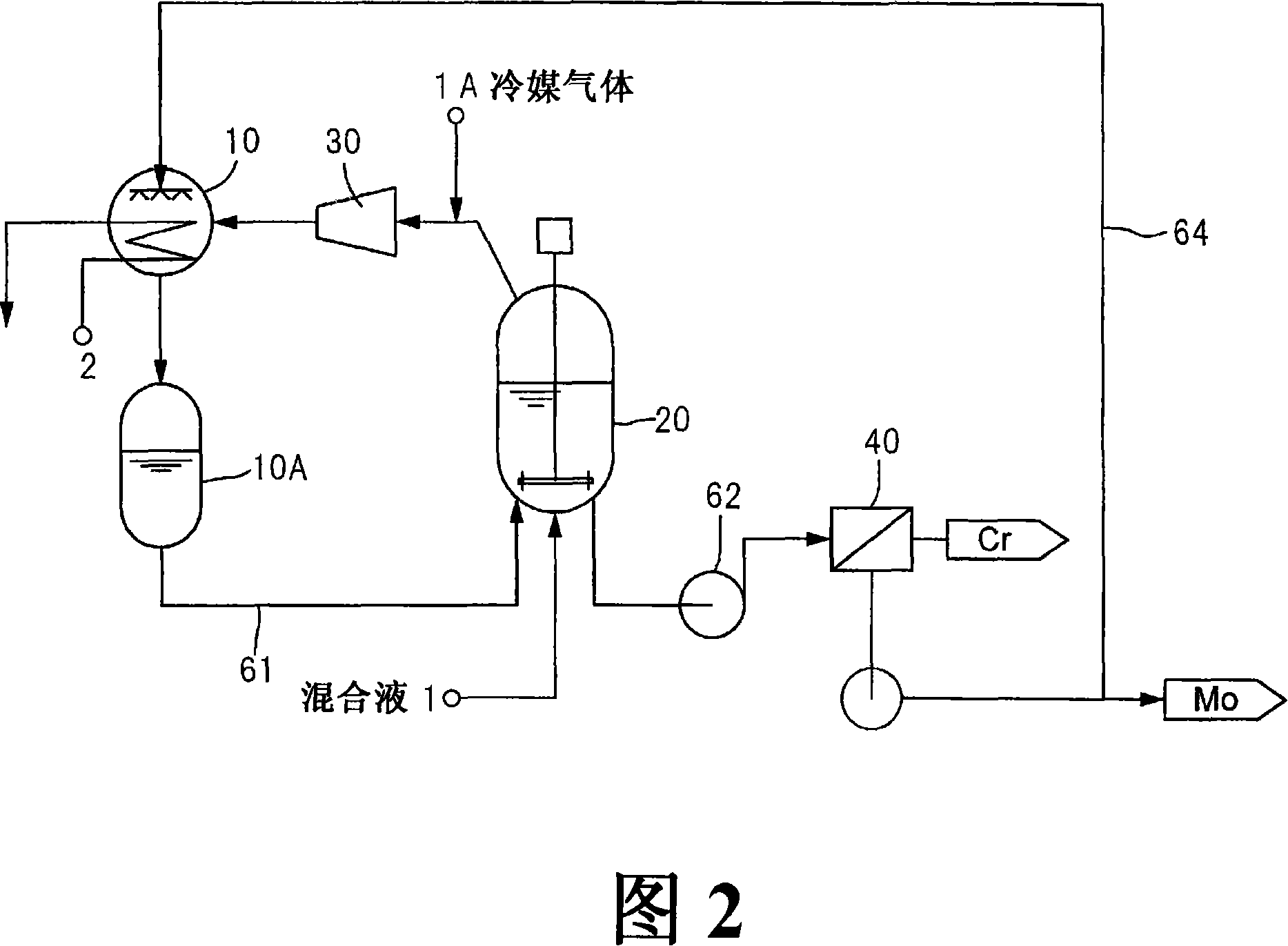

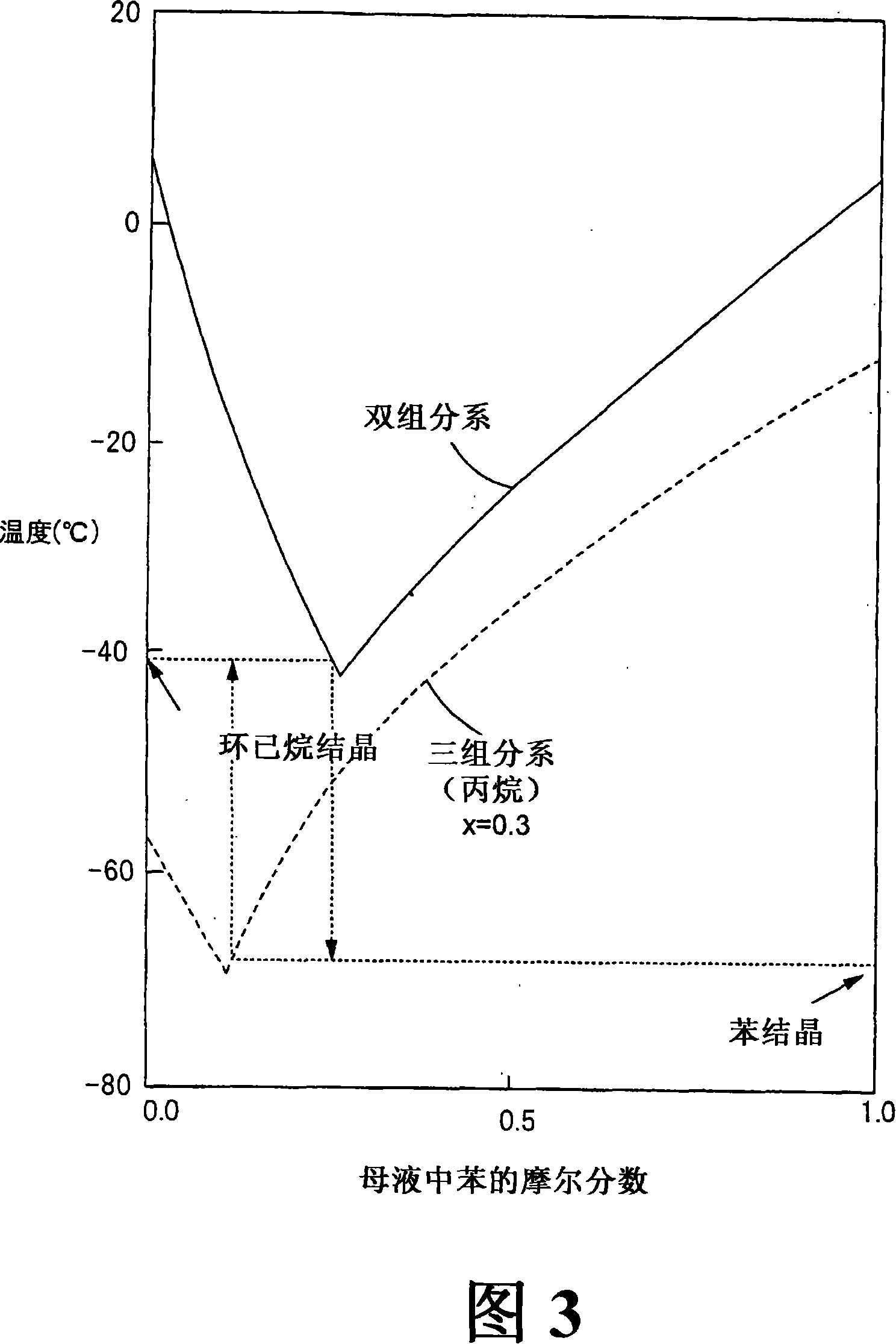

Method and apparatus for crystallization of organic compound through adiabatic cooling

ActiveCN101151080ASave energyReduce performanceSolution crystallizationHeat exchange cooling cystallizationThermal insulationDirected crystallization

The invention provides an organic compound adiabatic cooling crystallization method and device capable of reducing operation cost and equipment cost. In the crystallization tank 20, the target organic compound containing the refrigerant is subjected to adiabatic cooling and evaporation of the refrigerant, and the crystallization slurry generated by this operation is taken out from the crystallization tank 20; operating above pressure and directing it into the absorption condenser 10; in the absorption condenser 10 the pressurized steam is cooled and condensed while remaining in contact with the solution of the organic compound; the liquid from this absorption condensation is finally directed to crystallization slot 20.

Owner:TSUKISHIMA KIKAI CO LTD

Vertical Bridgman preparation method for large-size aluminum oxide-yttrium aluminum garnet eutectic ceramic

InactiveCN104846431ASmall eutectic machining allowanceSmall sizePolycrystalline material growthFrom frozen solutionsBridgman methodArgon atmosphere

The invention relates to a vertical Bridgman preparation method for large-size aluminum oxide-yttrium aluminum garnet eutectic ceramic. The process of the method is characterized in that aluminum oxide-yttrium aluminum garnet eutectic ceramic grows at an argon atmosphere through a VB method. The specific growth process comprises four major processes, including raw material preparation, process before heating, eutectic growth, and cooling and annealing. By combining the advantages of a directed crystallization method and a vertical zone-melting method for crystal growth, the prepared aluminum oxide-yttrium aluminum garnet eutectic ceramic is enabled to have the advantages of large size, few defect, high hardness, outstanding mechanical property at normal temperature and high temperature, strong thermal stability, easiness in processing and the like.

Owner:HARBIN INST OF TECH

Pulse copper electroplating additive, electroplating solution and application of electroplating solution

ActiveCN113373482AImprove mechanical propertiesImprove stabilityProcess efficiency improvementSulfonateGlycidyl ethers

The invention discloses a pulse copper electroplating additive, an electroplating solution and application of the electroplating solution. The additive comprises sulfonate, organic amine modified glycidyl ether, a polyether compound and water, wherein the mass concentration of the sulfonate is 2-20 g / L, the mass concentration of the organic amine modified glycidyl ether is 10-100 g / L, and the mass concentration of the polyether compound is 10-100 g / L. When the additive is added into the electroplating solution for pulse electroplating of a circuit board, especially in the pulse electroplating process of a high-aspect-ratio circuit board, no columnar directional crystal is generated in a hole of the circuit board, no columnar crystal is generated at an orifice corner, the mechanical property of an electroplated copper layer in the hole is improved, the risk of fracture of the copper layer is reduced, and therefore, the stability of a terminal electronic product is improved.

Owner:SHENZHEN BEIJIA ELECTRONICS MATERIAL

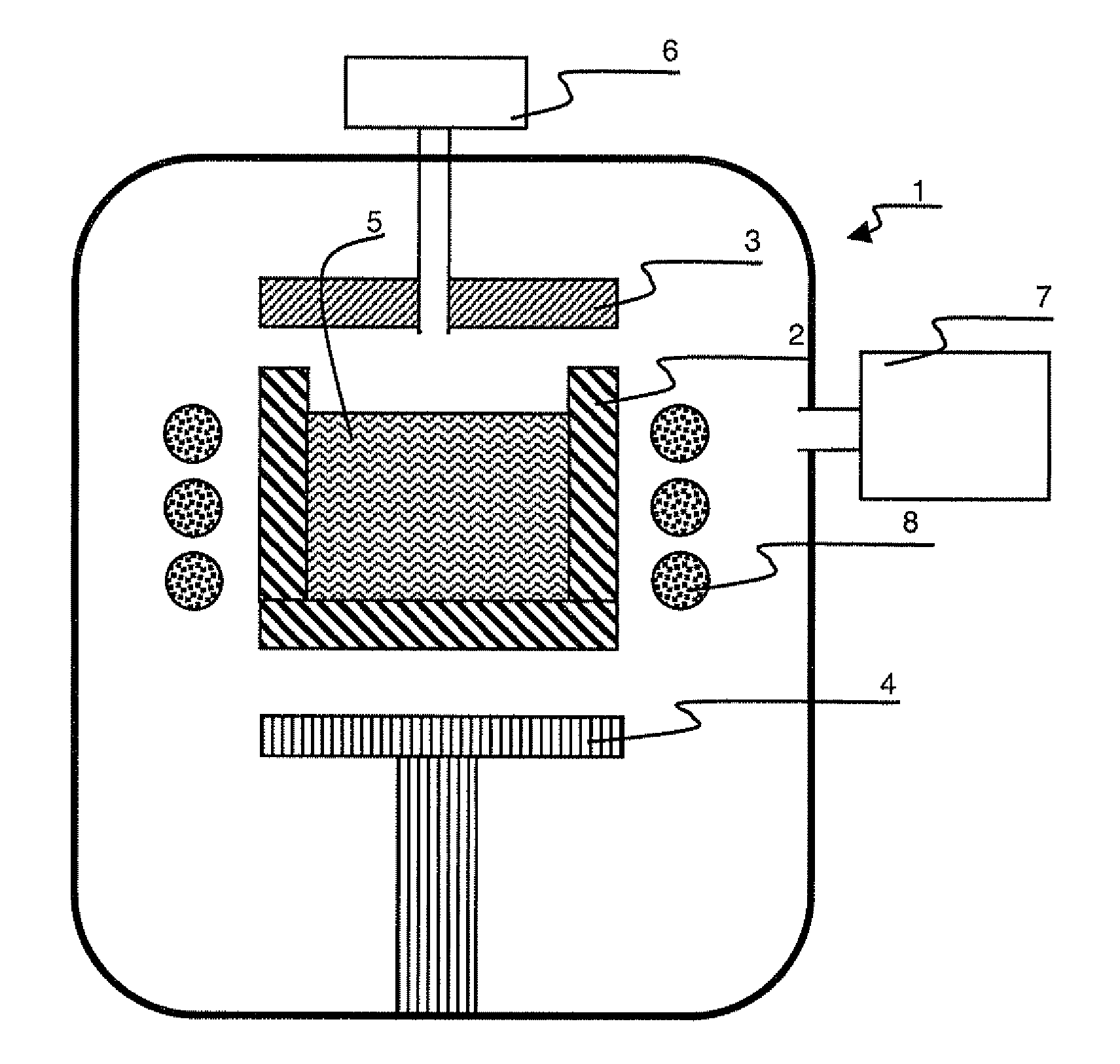

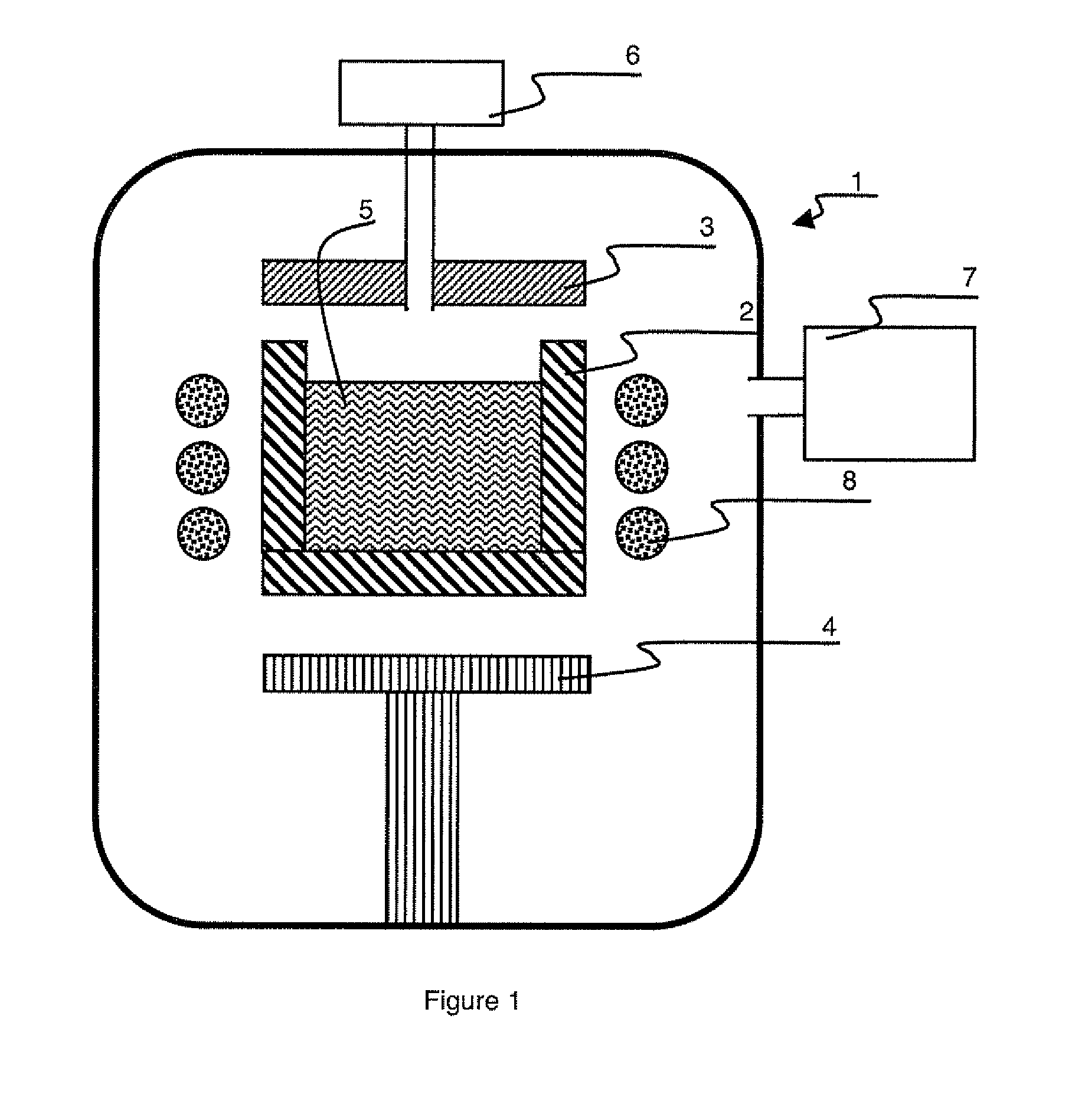

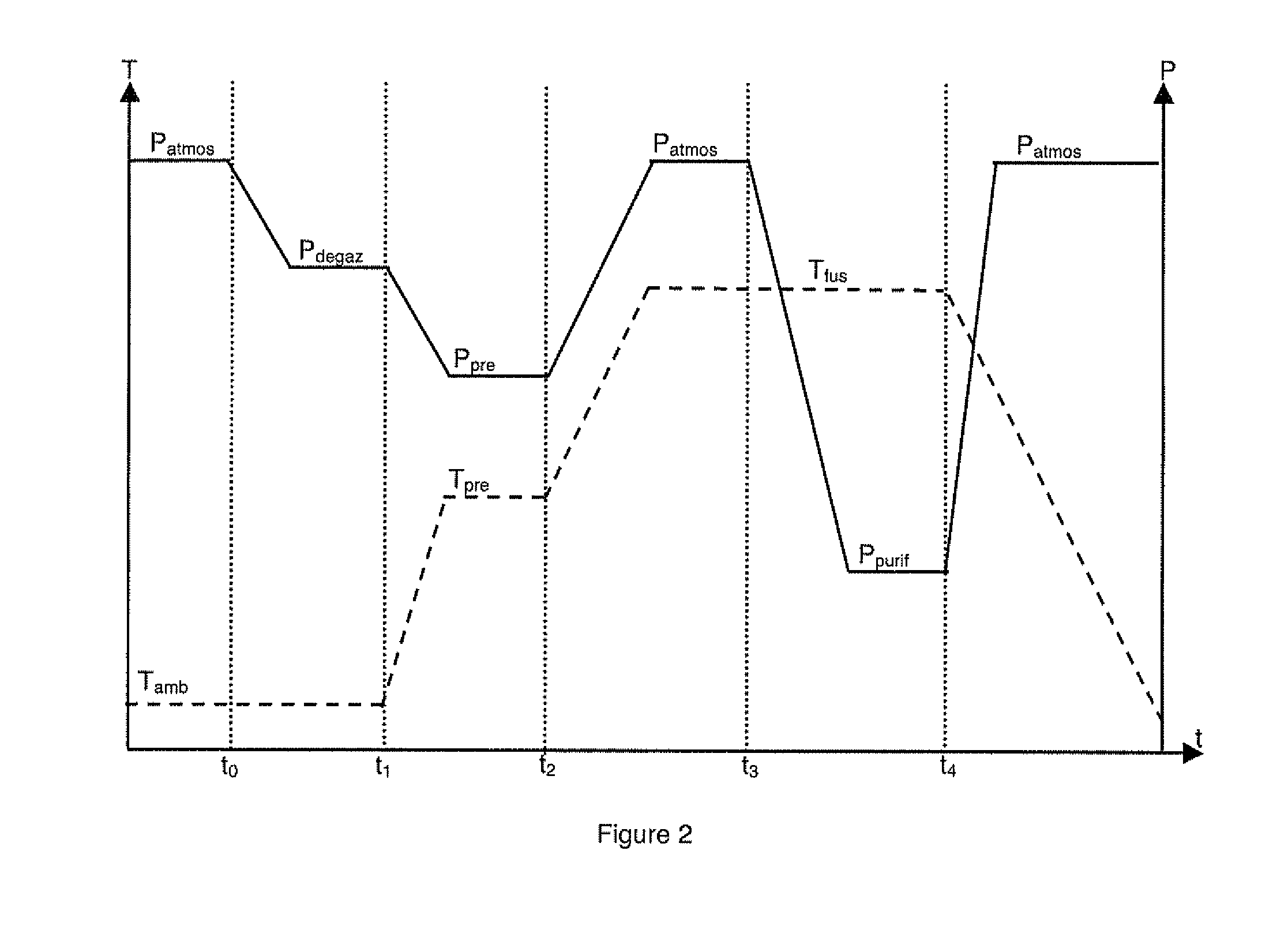

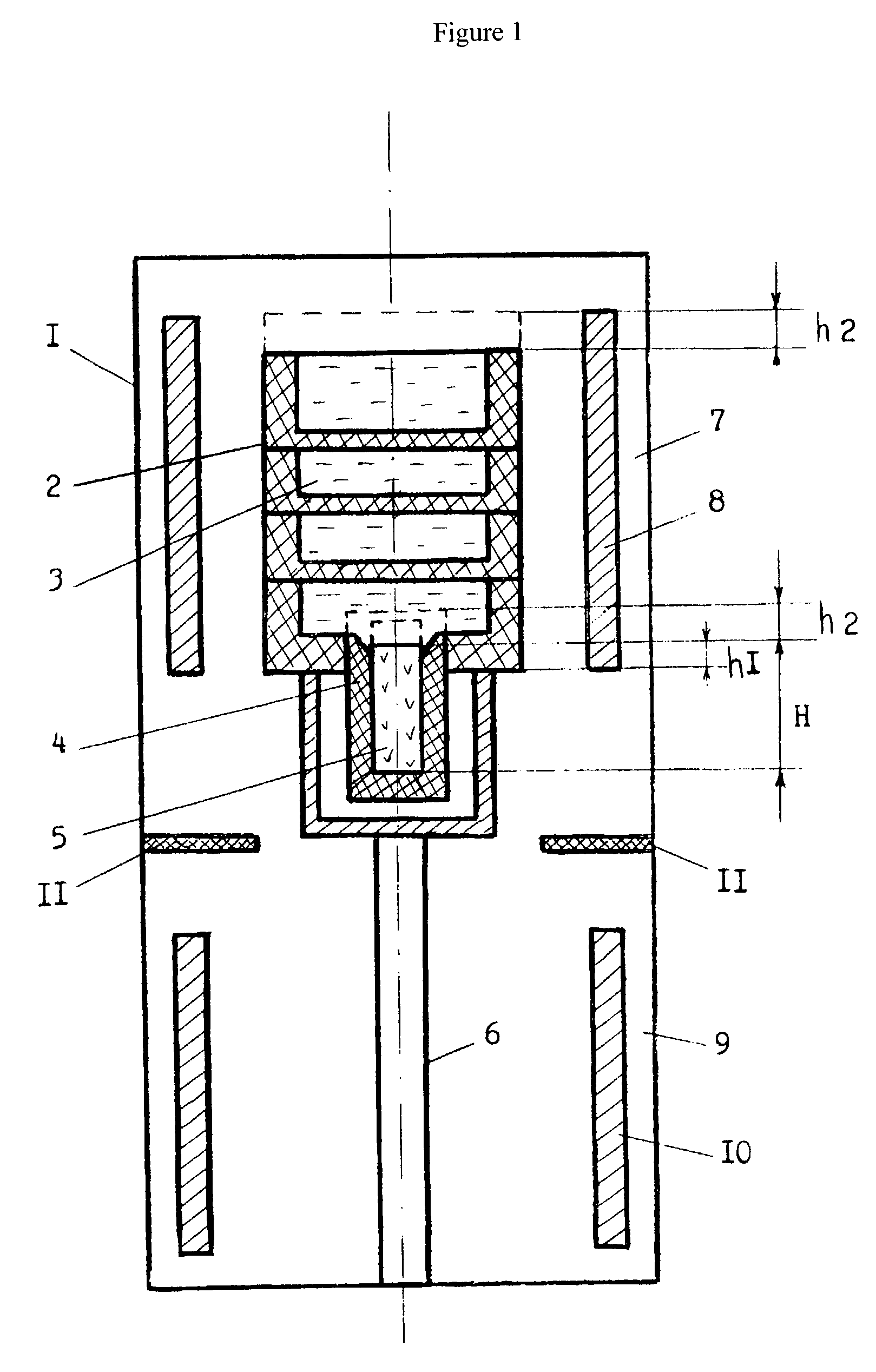

Low pressure device for melting and purifying silicon and melting/purifying/solidifying method

InactiveUS20120178036A1Easy to implementFast and efficient eliminationPolycrystalline material growthCharge manipulationDirected crystallizationCrucible

The device for melting and purifying of a silicon feedstock comprises a crucible arranged inside a sealed chamber. A thermal gradient can be applied to the crucible by an arranged heat exchanger and a heating device. The device likewise comprises a device for reducing the pressure inside the chamber to a value lower than 10−2 mbar and a device for stirring the silicon in the crucible. The silicon feedstock successively undergoes degassing and pre-heating to atmospheric temperature, and then melting and low pressure, high temperature purification. Once the low-pressure purification step has been completed, directed crystallization is carried out.

Owner:APOLLON SOLAR SAS

Crystalline plate, orthogonal bar, component for producing thermoelectrical modules and a method for producing a crystalline plate

InactiveUS20100282284A1Low manufacturing costIncrease control efficiencyThermoelectric device manufacture/treatmentSemiconductor/solid-state device detailsMaterials scienceCrystallization

The invention relates to the thermoelectrical industry and can be used for producing thermoelectrical devices based on the Peltier and Seebeck effects. In particular, the invention relates to a crystalline plate made of thermoelectric laminated material, to a component which is used for producing n- and p-type conductivity legs. The invention is also related to a method of manufacture of crystalline plates of a thermoelectric layered material based on the AVBVI solid solutions by using a directional crystallization process.

Owner:PONOMAREV VLADIMIR FEDOROVICH +1

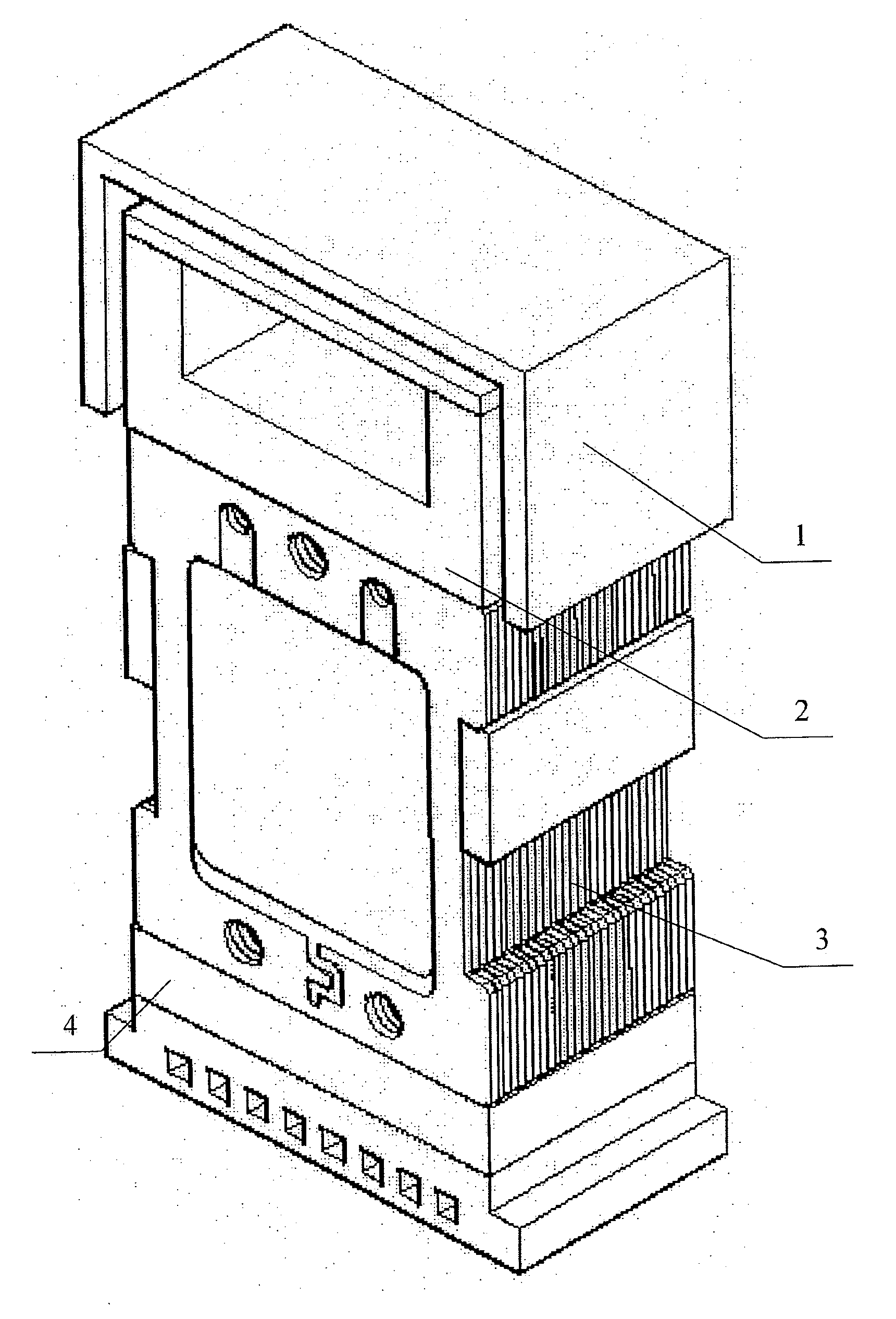

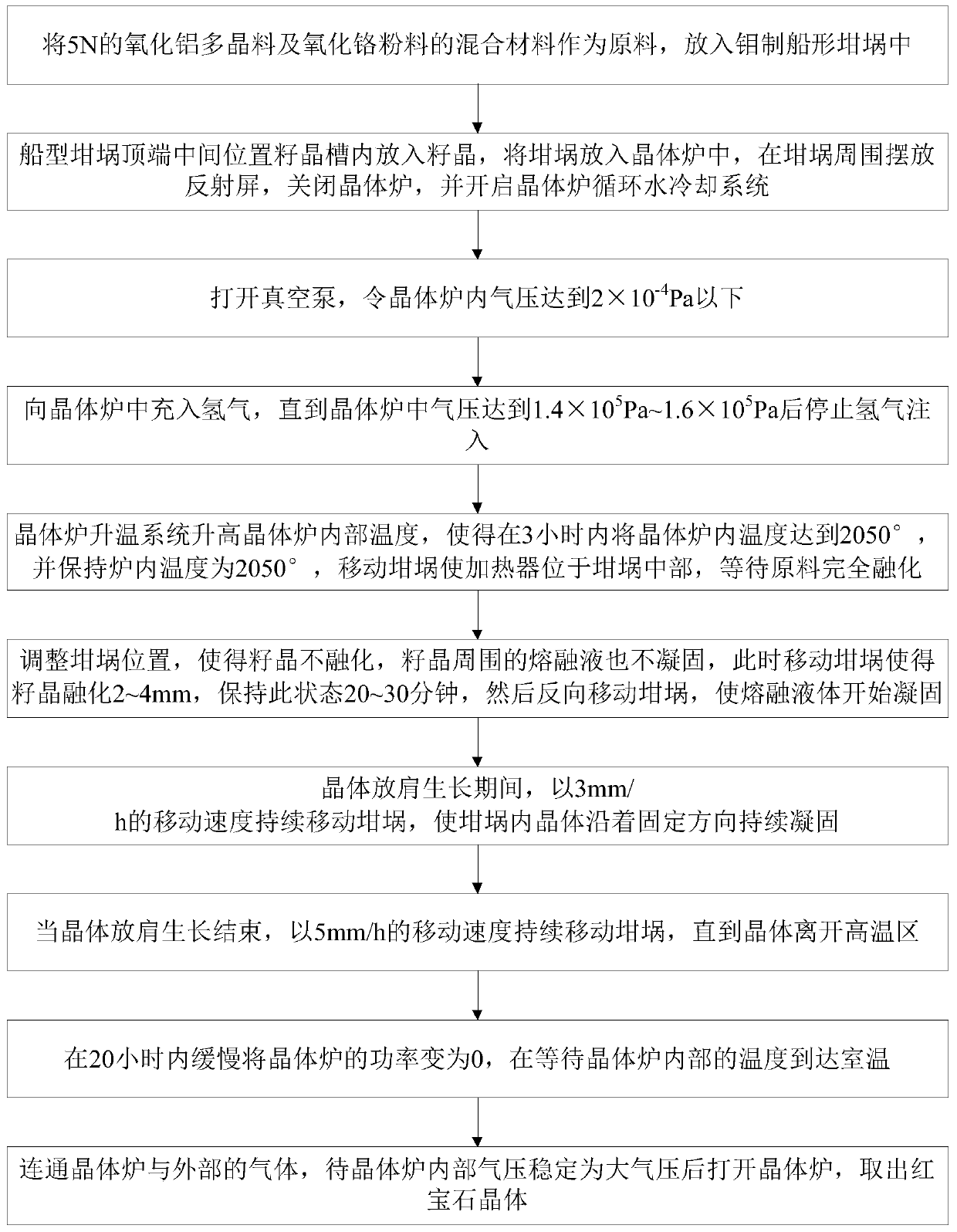

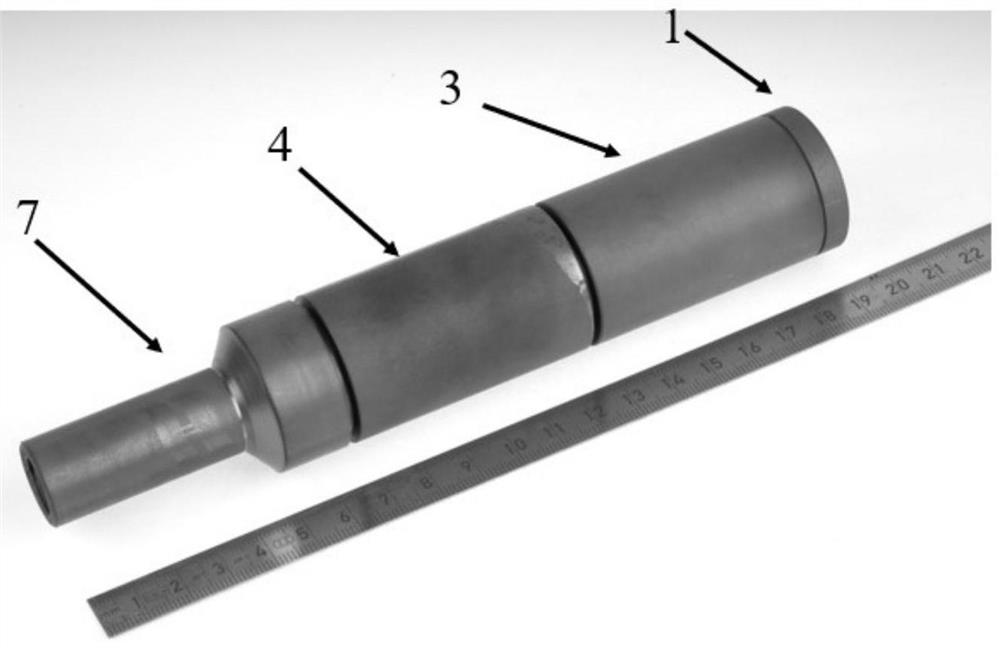

Preparation method of large-size lath-shaped artificial ruby crystal

InactiveCN111519252ASmall sizeIncrease profitPolycrystalline material growthFrom frozen solutionsDirected crystallizationCrucible

The invention belongs to the technical field of artificial single crystal preparation, and particularly relates to a preparation method of large-size lath-shaped artificial ruby crystal. The preparation method comprises the following steps: putting raw materials into a boat-shaped molybdenum crucible, and injecting hydrogen under the condition that the air pressure in a crystal furnace is lower than 2 * 10 <-4 > Pa to enable the air pressure in the crystal furnace to reach about 1.5 * 10 < 5 > Pa; raising the temperature in the crystal furnace to completely melt the raw materials; adjusting the position of the crucible to complete seeding, crystal shouldering growth and crystal equal-width growth; cooling the crystal furnace, and taking out the prepared ruby crystal. A horizontal directional crystallization method is utilized, the advantages of a directional crystallization method and a vertical zone melting method are achieved at the same time, and the method for preparing ruby has the advantages of being low in cost, short in period, large in size, high in crystal quality, good in product uniformity, adjustable in color size and the like.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

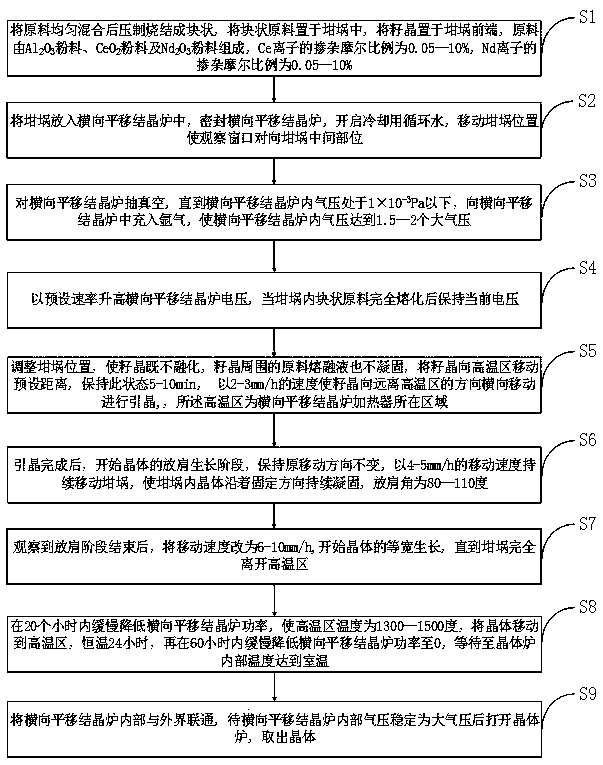

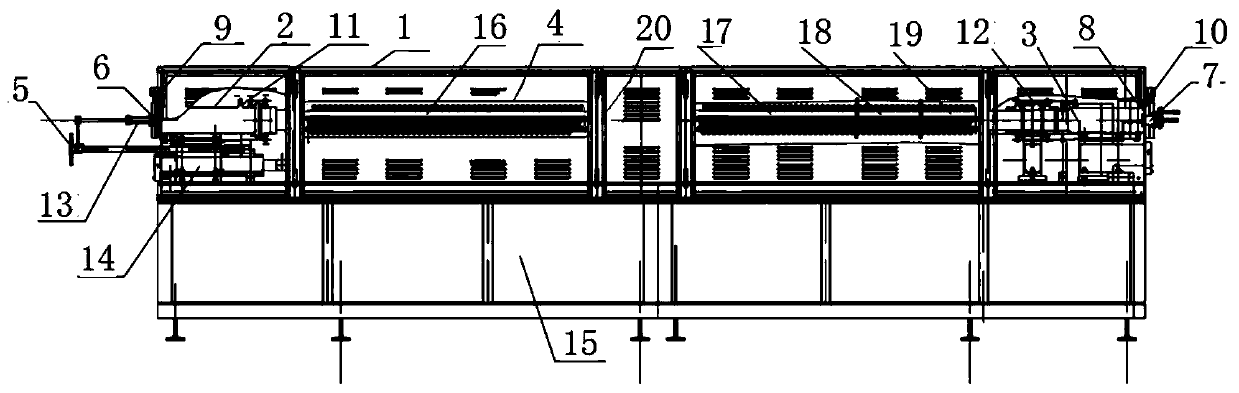

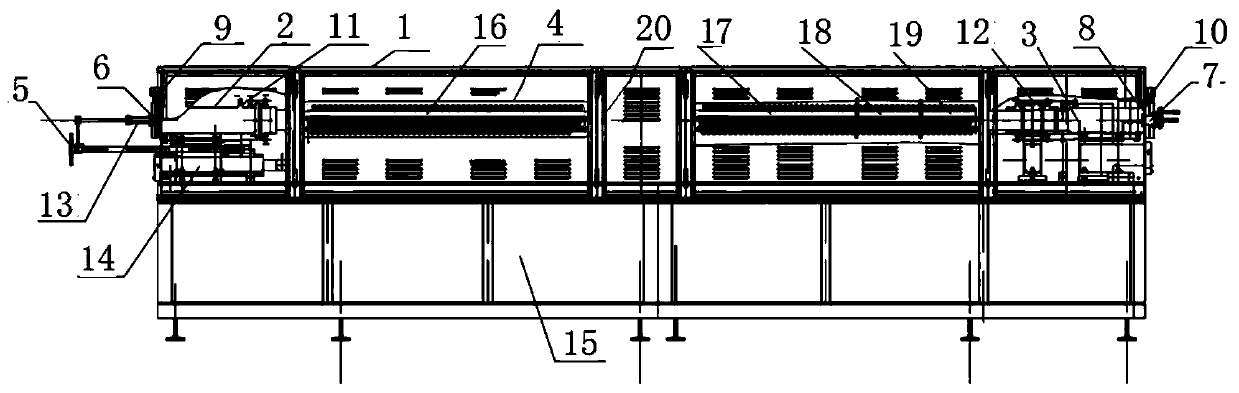

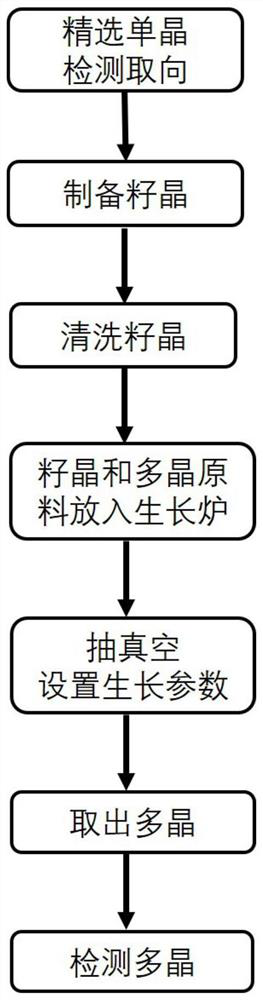

Method for preparing large-size Ce,Nd: YAG crystal based on transverse translation crystallization method

ActiveCN111519242AIncrease profitSmall machining allowancePolycrystalline material growthBy pulling from meltDirected crystallizationZone melting

The invention discloses a method for preparing a large-size Ce,Nd: YAG crystal based on a transverse translation crystallization method. The method comprises the following nine specific technologicalprocedures: burdening, charging into a furnace, vacuumizing and inflating, heating, seeding, shouldering growth of crystals, equal-width growth of the crystals, cooling and in-situ annealing, and taking-out of the crystals. The transverse translation crystallization method is utilized in the invention, the advantages of a directional crystallization method and a vertical zone melting method are achieved at the same time, and the prepared Ce,Nd: YAG crystal has the advantages of low cost, short growth period, high crystal quality, good product uniformity, no core side center, high product utilization rate and the like.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

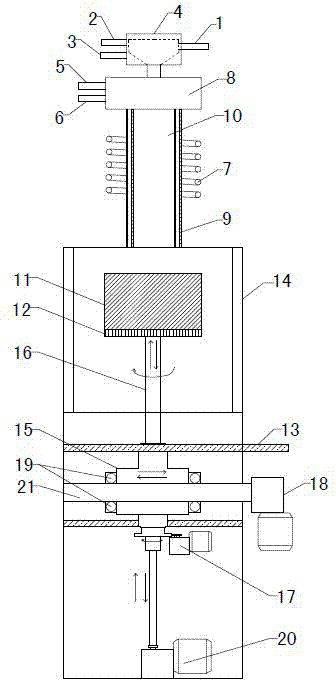

Germanium reduction directional crystallization furnace and crystallization method

PendingCN111172589ALow costEasy to operatePolycrystalline material growthFrom frozen solutionsDirected crystallizationEngineering

The invention discloses a germanium reduction directional crystallization furnace and a crystallization method. The crystallization furnace comprises a shell, a feeding pipe, a discharging pipe, a heating pipe and a propelling mechanism. A feeding port is formed in one end of the shell, a discharging port is formed in the other end of the shell, a hydrogen inlet is formed in the discharging port of the shell, and igniters are arranged at the feeding port and the discharging port of the shell. The feeding pipe is arranged in one end of the shell and connected with the feeding port, and the discharging pipe is arranged in the other end of the shell and connected with the discharging port. A hydrogen inlet is formed in the pipe wall of the feeding pipe, and a graphite boat is arranged in thefeeding pipe. A hydrogen inlet is formed in the pipe wall of the discharging pipe, and the discharging pipe is sleeved with a water cooling sleeve. The heating pipe is horizontally arranged in the shell, one end of the heating pipe is connected with one end of the feeding pipe, and the other end of the heating pipe is connected with one end of the discharging pipe. The propelling mechanism is arranged at the end, provided with the feeding port, of the shell. Reduction heat energy is fully utilized, germanium melting and crystallization are conducted at the same time, reduction and germanium ingot purification are organically combined, operation is convenient, and the structure is designed to be compact.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

Method for growing indium phosphide single crystal by VGF method

ActiveCN113638048AVertically oriented crystallizationImprove pass ratePolycrystalline material growthFrom frozen solutionsDirected crystallizationCrucible

The invention belongs to the field of preparation of indium phosphide single crystals, and particularly discloses a method for growing indium phosphide single crystal by a VGF method. The method comprises the steps of putting raw materials into a crucible and assembling a single crystal growth furnace by adopting the VGF method, and carrying out high-temperature annealing treatment; raising the temperature of the melt, and setting a heating target value in a heating control program for heating and pressurizing; carrying out seed melting growth, setting a growth temperature, when the melting length of the seed crystal reaches 10-15mm and the rotating shoulder growth is carried out, enabling the position of the crucible to begin to descend with the descending speed being not greater than 2.5 mm / h, and automatically stopping the descending of the crucible position after the growth is finished; and conducting cooling and annealing, specifically, automatically conducting cooling and annealing after growth is finished, emptying air pressure in the furnace after the temperature is reduced to 350 DEG C, opening a furnace door after the temperature in the furnace is reduced to about 150 DEG C, and obtaining the single crystal. According to the invention, the pulling speed method is added, so that the thermal field of the indium phosphide single crystal in the growth process is more uniform, vertical orientation crystallization is more stable, more indium phosphide single crystals grow, and the qualified rate of the crystal is higher.

Owner:YUNNAN XINYAO SEMICON MATERIAL CO LTD

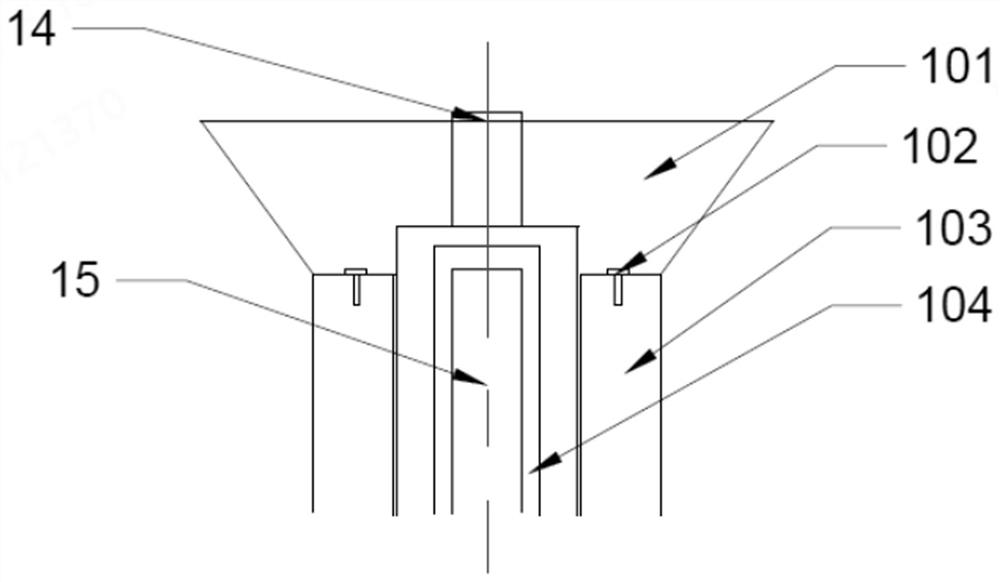

Directional accelerated crystallization device for tunnel drainage system and use method

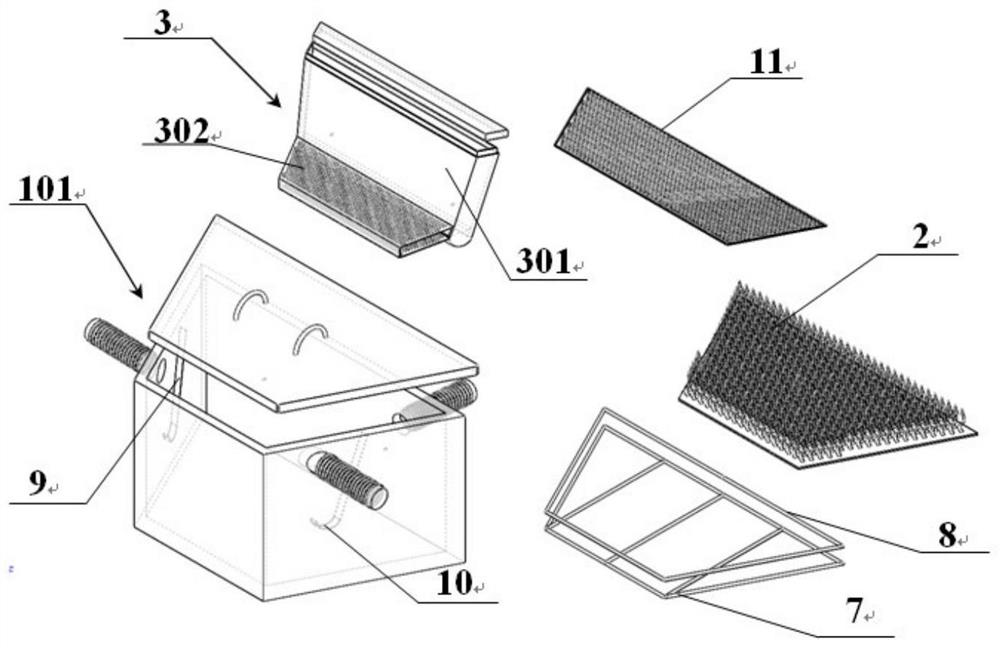

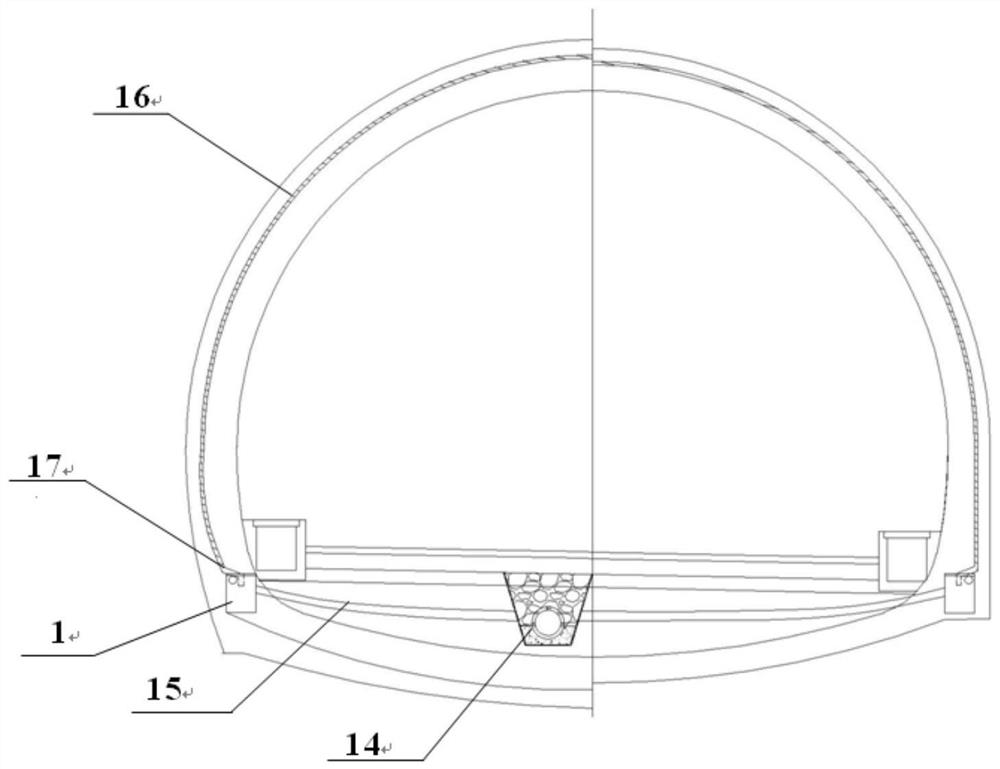

PendingCN114314781AThe idea of realizing directional crystallizationSimple structureDrainageWater/sewage treatment by flocculation/precipitationPharmacy medicineDirected crystallization

The invention relates to the technical field of tunnel drainage, and particularly discloses a directional accelerated crystallization device for a tunnel drainage system and a use method.The directional accelerated crystallization device comprises a crystallization pond assembly, a felt layer and a medicine box assembly, the crystallization pond assembly comprises a crystallization pond, and a pond cover is arranged at the top of the crystallization pond; the crystallizing pond comprises a front wall, a rear wall, an outer wall and an inner wall; the medicine box assembly comprises a medicine storage box, a horizontal net-shaped medicine clamping box is arranged at the box bottom of the medicine storage box and is of a double-layer hollow net-shaped structure, the bottom of the medicine storage box is communicated with the net-shaped medicine clamping box, and reaction medicine is placed in the net-shaped medicine clamping box. Influences of temperature, flow velocity, chemicals, shape and surface morphology of the crystallizing pond on tunnel water body crystallization are considered, the assumption of directional crystallization of the tunnel drainage system can be realized, and the tunnel drainage system has the advantages of simple structure and easiness in chemical supplement, cleaning, maintenance and maintenance, can be applied to tunnels put into operation, and also can be applied to tunnel drainage systems. And the method can also be applied to tunnels in a design period.

Owner:CHANGAN UNIV

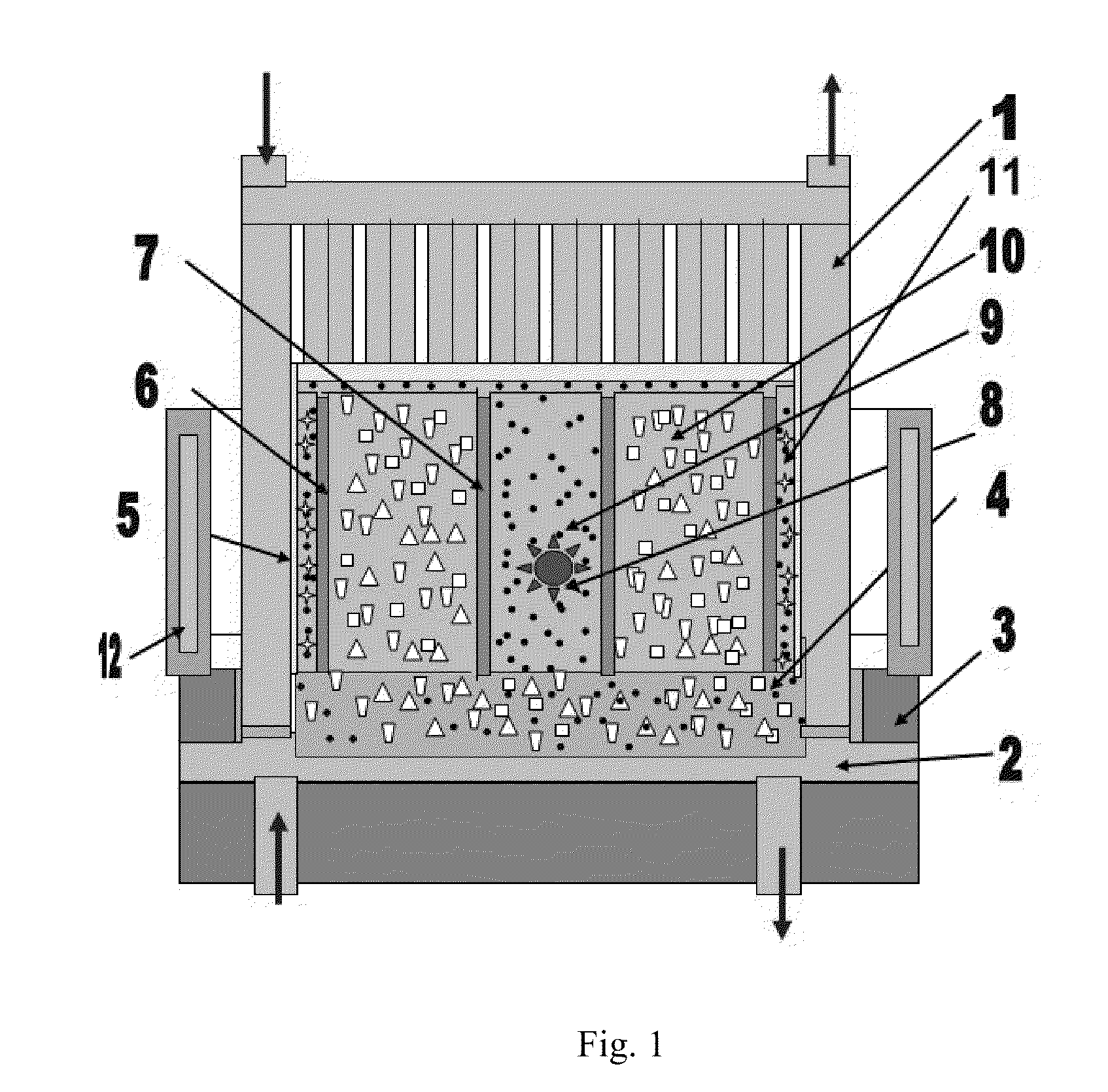

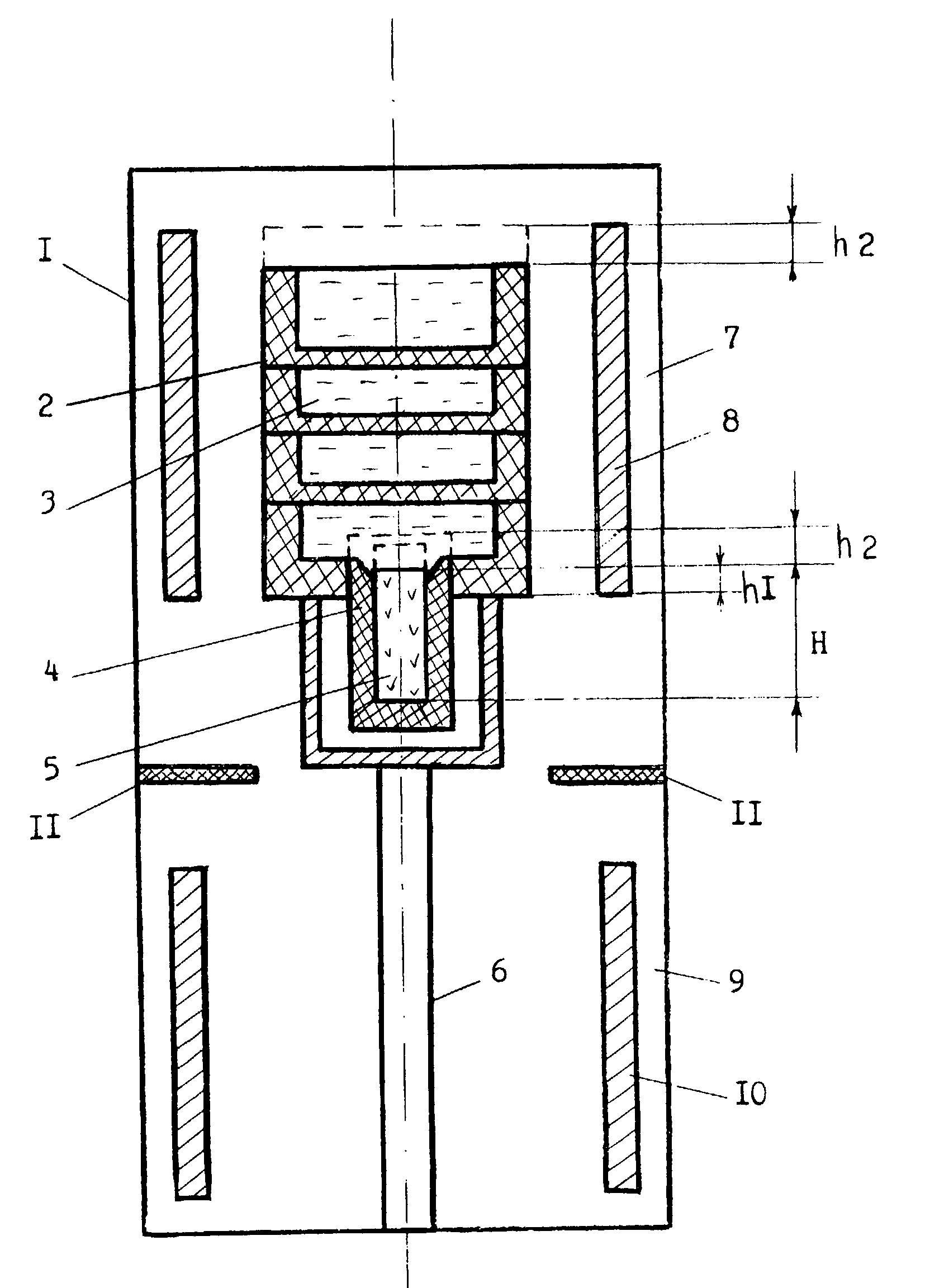

Zirconium dioxide-based material

The invention relates to the field of synthetic materials and is industrially applicable in the manufacture of wear-resistant construction parts for use under conditions of elevated temperatures, loads, and aggressive media, for cutting and machining tools, and in medical equipment. The technical problem of optimization of the performance parameters of the material, including crack resistance, hardness, and wear resistance, is solved. The objective is achieved by the fact that a material based on zirconium dioxide, containing yttrium and obtained by directed crystallization from batch mixture melted in a cold container, contains at least two tetragonal phases whose axes of tetragonality are 80-90°. The components of the batch mixture for obtaining the material are contained in the following ratio (in mol %): yttrium oxide, 2.8-3.7; zirconium dioxide, the remainder. To obtain the material, a thermal insulating layer 4 is formed by placing tamped residual pieces of the material and a powdery batch mixture on the bottom 2 of the container. Layer 9 consists of a powdery batch mixture containing metallic zirconium 8; layer 10, of residual pieces of the material; and layer 11, of powdery batch mixture and fine residual pieces of the material. During directed crystallization the rate of displacement of the container relative to inductor 12 is varied. 11 dependent claims, 2 illustrations.

Owner:OOO NOVYE ENERGETICHESKIE TEHNOLOGII +1

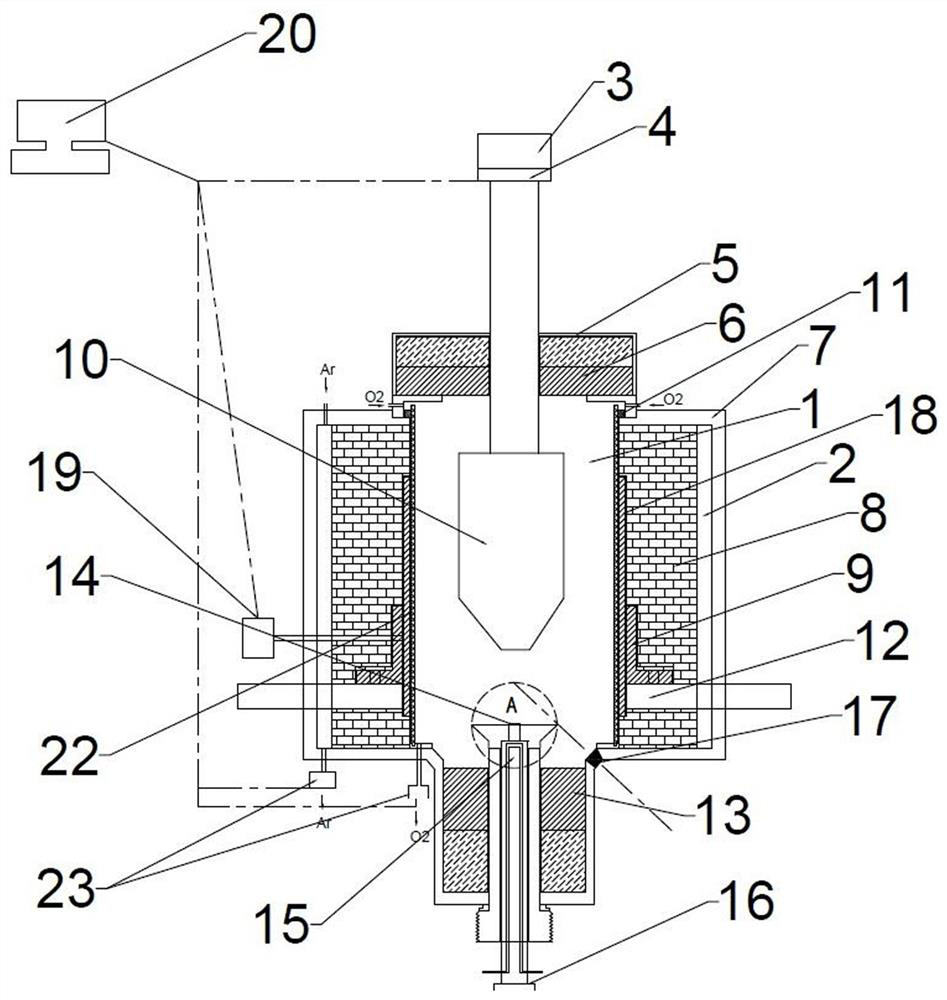

Device and method for machining high-density aluminum oxide by plasma

ActiveCN103691948BUniform densityEnough time to cureMetallic material coating processesHigh densityDirected crystallization

The invention discloses a device and a method for machining high-density aluminum oxide by plasma, and belongs to the technical field of high-density aluminum oxide for sapphire crystals. The device is characterized in that a radio frequency plasma generator (8) and a plasma torch (10) are arranged below a feed hopper, a high-frequency induction coil (7) is wound outside the plasma torch (10), a deposition platform (12) for receiving materials is arranged below the plasma torch (10), and aluminum oxide powder is fed by the feed hopper, instantly melted in the process of falling in the plasma torch (10), solidified in a directional crystallization manner on the deposition platform (12) to obtain the high-purity high-density aluminum oxide. By the aid of the device and the method, the high-purity aluminum oxide cannot be polluted, parts of impurities in the aluminum oxide can be volatilized under the action of high-temperature plasma, and the aluminum oxide is further purified. Continuous process can be kept, production efficiency is accelerated, and the stable performance of the aluminum oxide can be kept.

Owner:晶鑫晶体(内蒙古)科技有限公司

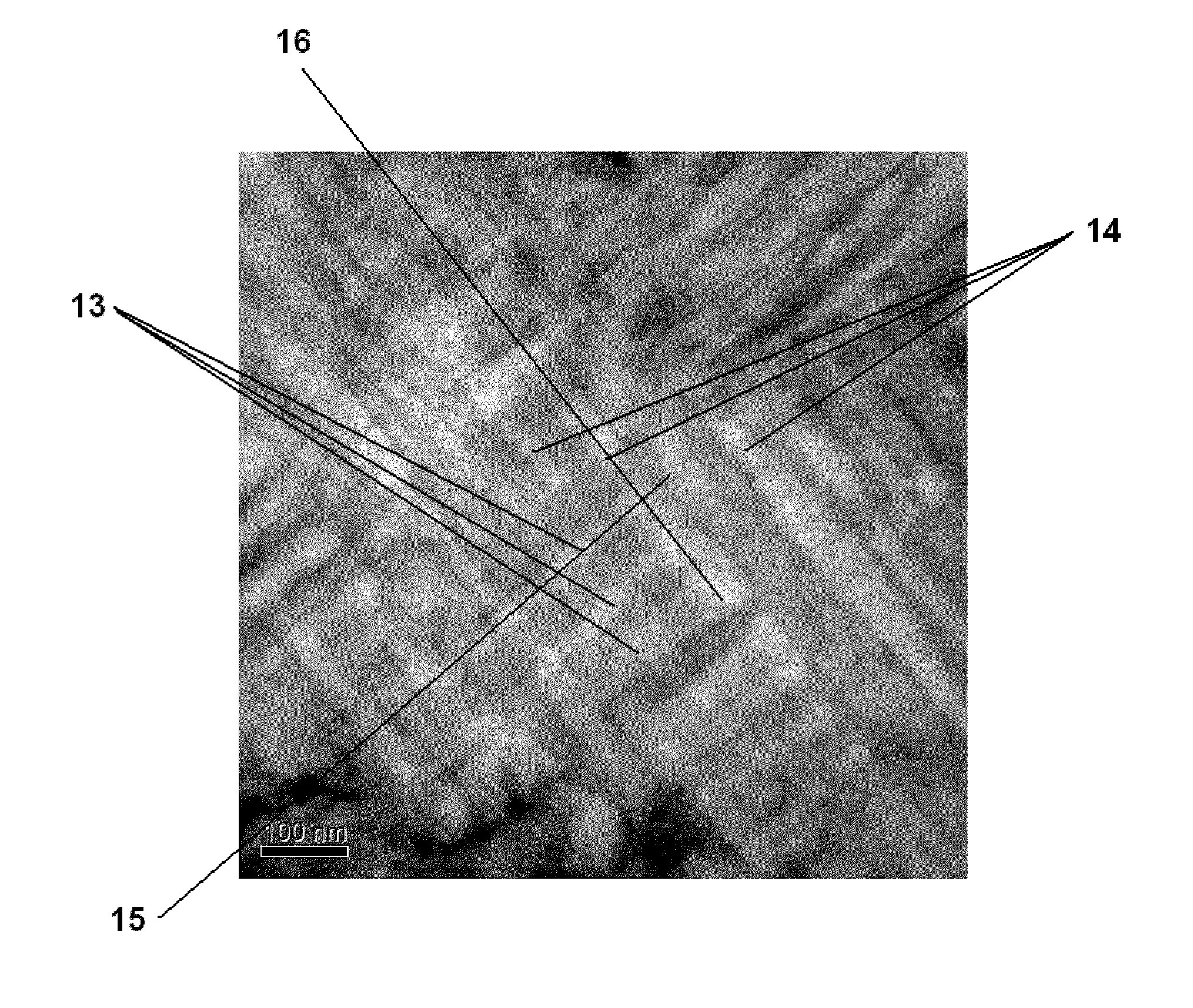

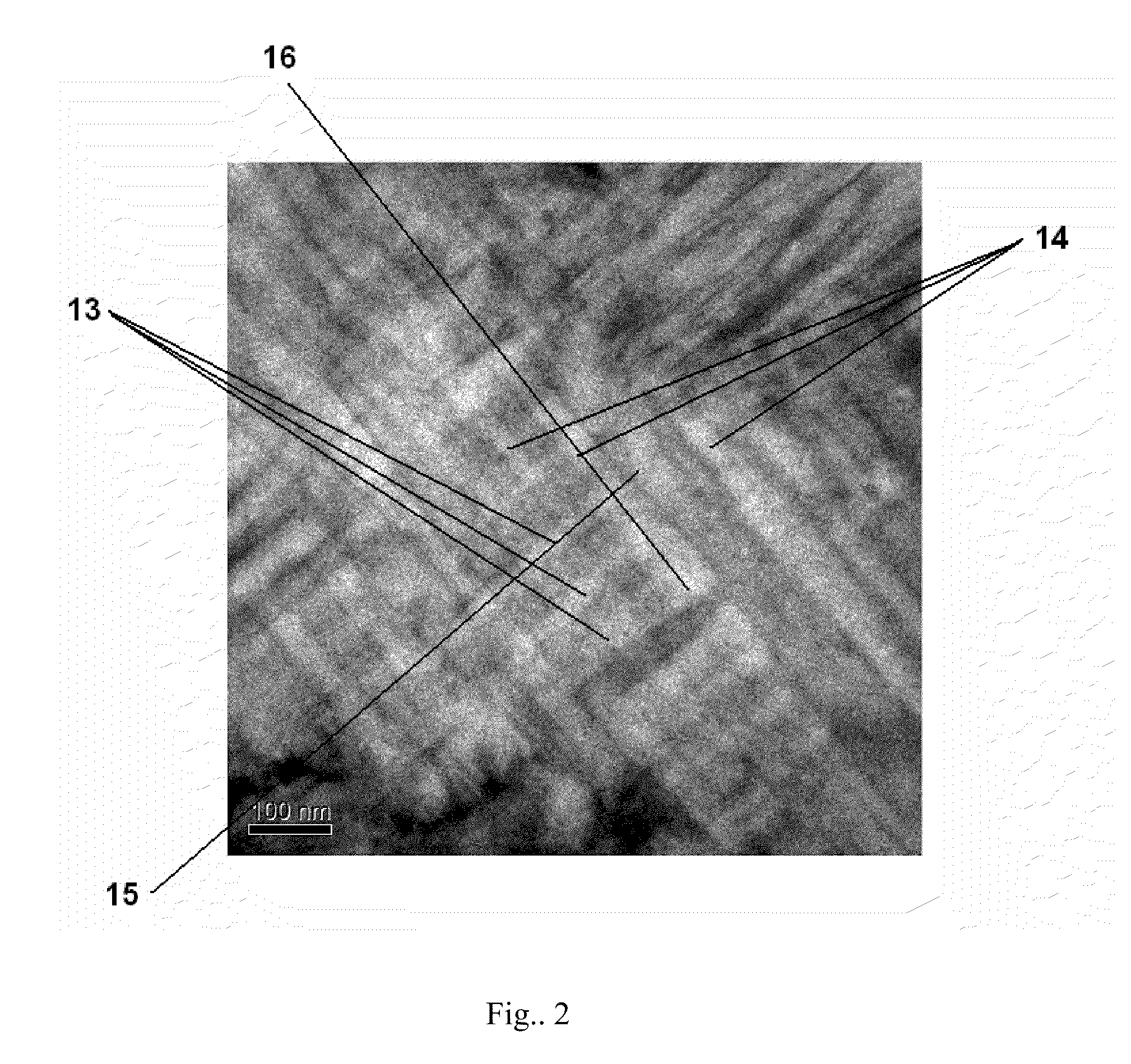

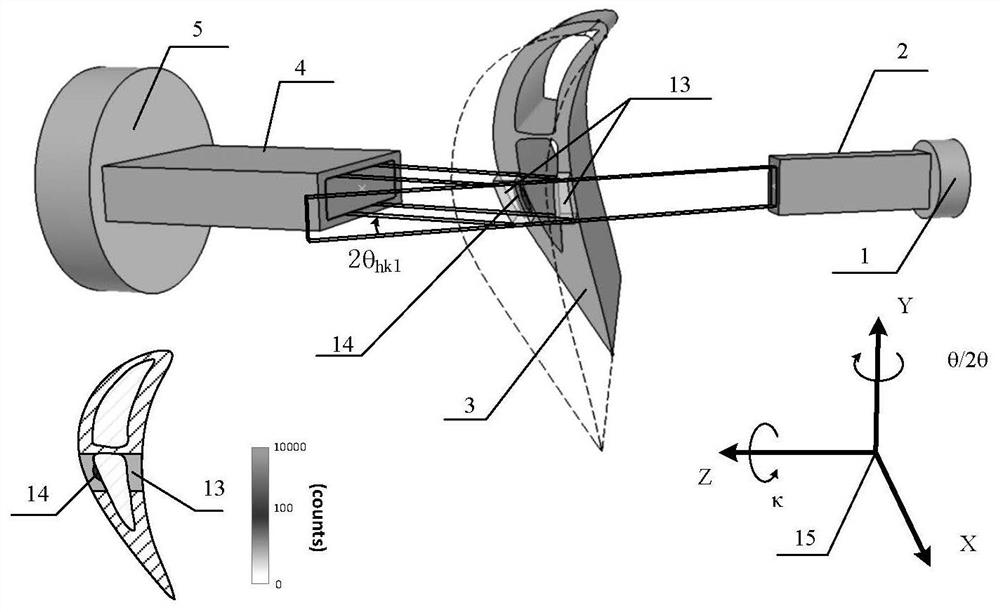

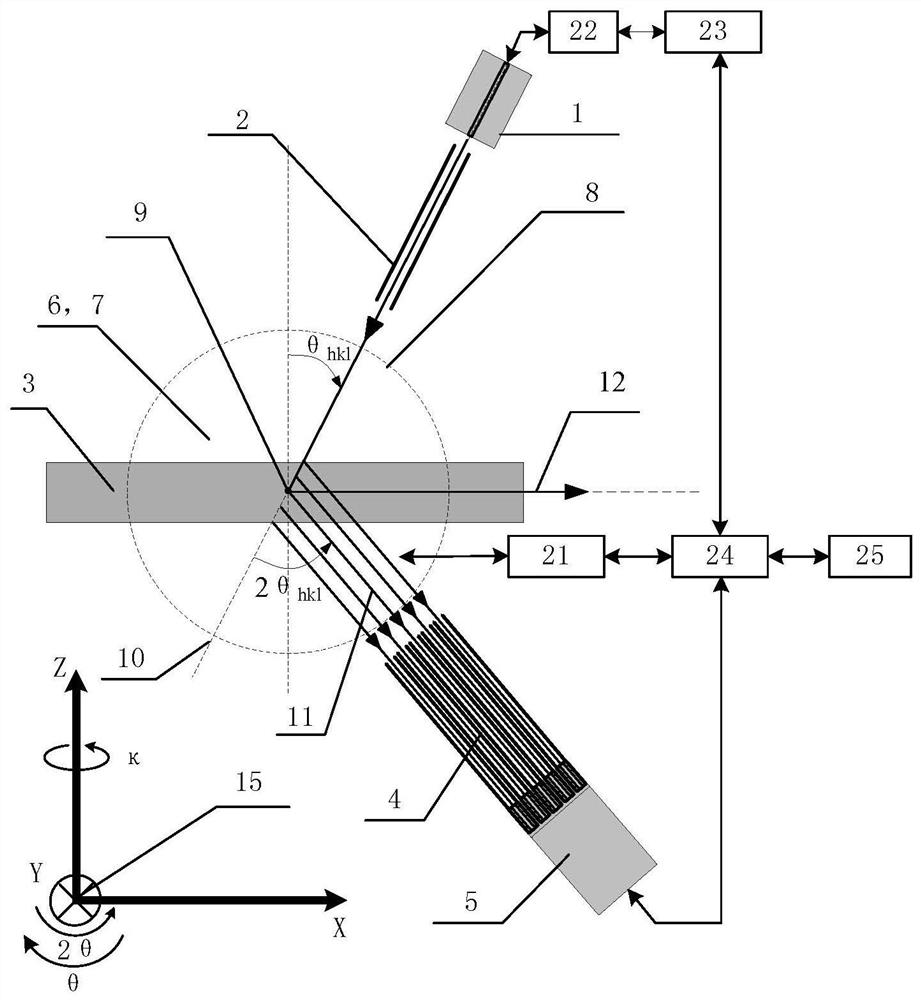

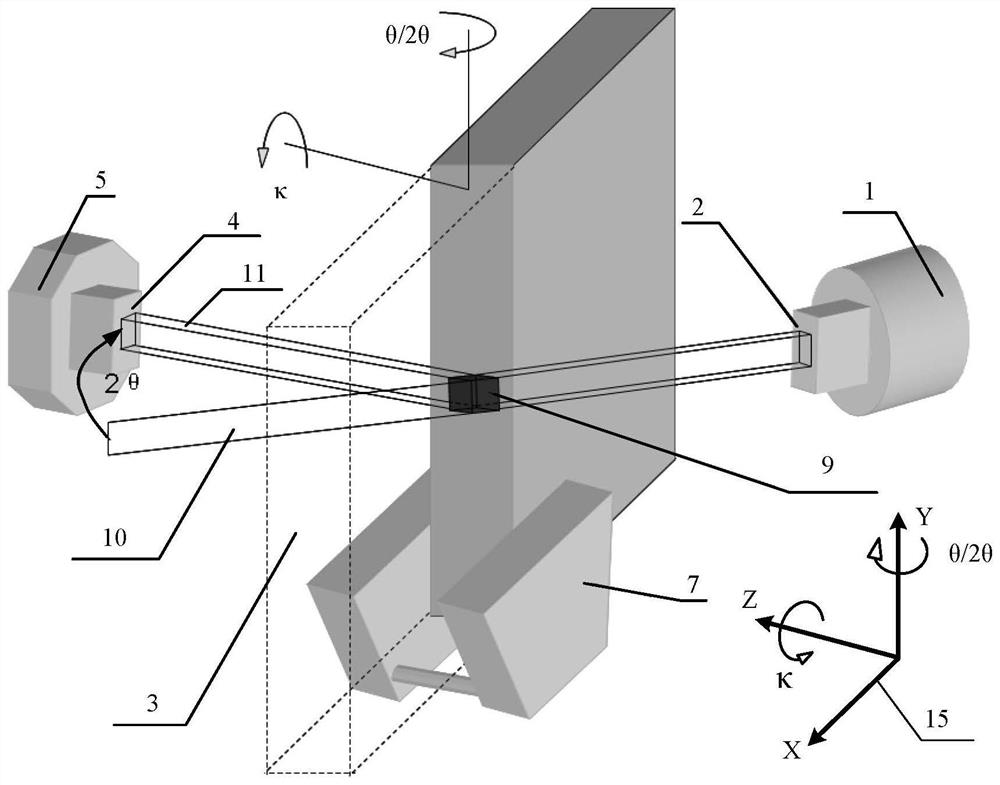

Method and device for nondestructive testing of crystal orientation difference and grain boundary defects in single crystal or oriented crystal

PendingCN113740366ANon-destructive testingSolving the problem of non-destructive determination of single crystal bladesMaterial analysis using radiation diffractionDirected crystallizationTest sample

The invention provides a method and device for nondestructive testing of crystal orientation difference and grain boundary defects in a single crystal or oriented crystal. The method comprises the following steps of: carrying out nondestructive testing of a crystal orientation angle (theta1, kappa1) of a crystal face in a certain direction (h1k1l1) in a sample by adopting transmission short-wavelength characteristic X-ray diffraction, and determining whether the orientation angle of the crystal face of the sample is out of tolerance or not; and in the (theta1, kappa1) direction of the crystal face, translating the sample, scanning and measuring the diffraction intensity and distribution of the (h1k1l1) crystal face of each part of the tested sample, and judging whether a grain boundary defect and a sub-grain boundary defect exist in the tested sample or not according to a measurement result. The device comprises a sample table, an X-ray irradiation system, an X-ray detection system, a rotating mechanism and the like, wherein the rotating mechanism is used for changing an included angle between an incident X-ray beam and a sample. With the method adopted, the problem that crystal defects such as crystal orientation difference, sub-grain boundary and grain boundary in the single crystal and the oriented crystal cannot be quickly, accurately and nondestructively measured is solved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Mold for preparing tricrystal and preparation method of tricrystal

InactiveCN112080790AEasy to manufactureUnderstand the purposePolycrystalline material growthFrom frozen solutionsTemperature controlDirected crystallization

The invention provides a mold for preparing a tricrystal and a preparation method of the tricrystal, and relates to the field of metal materials. The preparation method specifically comprises the following steps of: cleaning trapezoidal columnar seed crystals with nitric acid, putting the cleaned trapezoidal columnar seed crystals into a specially designed mold in a Bridgman crystal growth furnace, putting a polycrystalline raw material into a raw material barrel, controlling the growth temperature and the heat preservation time of the tricrystal by using a temperature control system, enablingthe molten polycrystalline raw material to flow into the mold, controlling the growth speed of the tricrystal by moving a movable bracket, detecting the orientation of the tricrystal by using an X-ray Laue method, thus obtaining the result that the molten polycrystalline raw material is directionally crystallized along the direction of the seed crystals, and the tricrystal is formed according tothe relative orientation relationship among the seed crystals. The mold adopted by the invention is simple and can be repeatedly used, and the tricrystal body with a preset grain boundary structure can be easily obtained.

Owner:SHANGHAI JIAO TONG UNIV

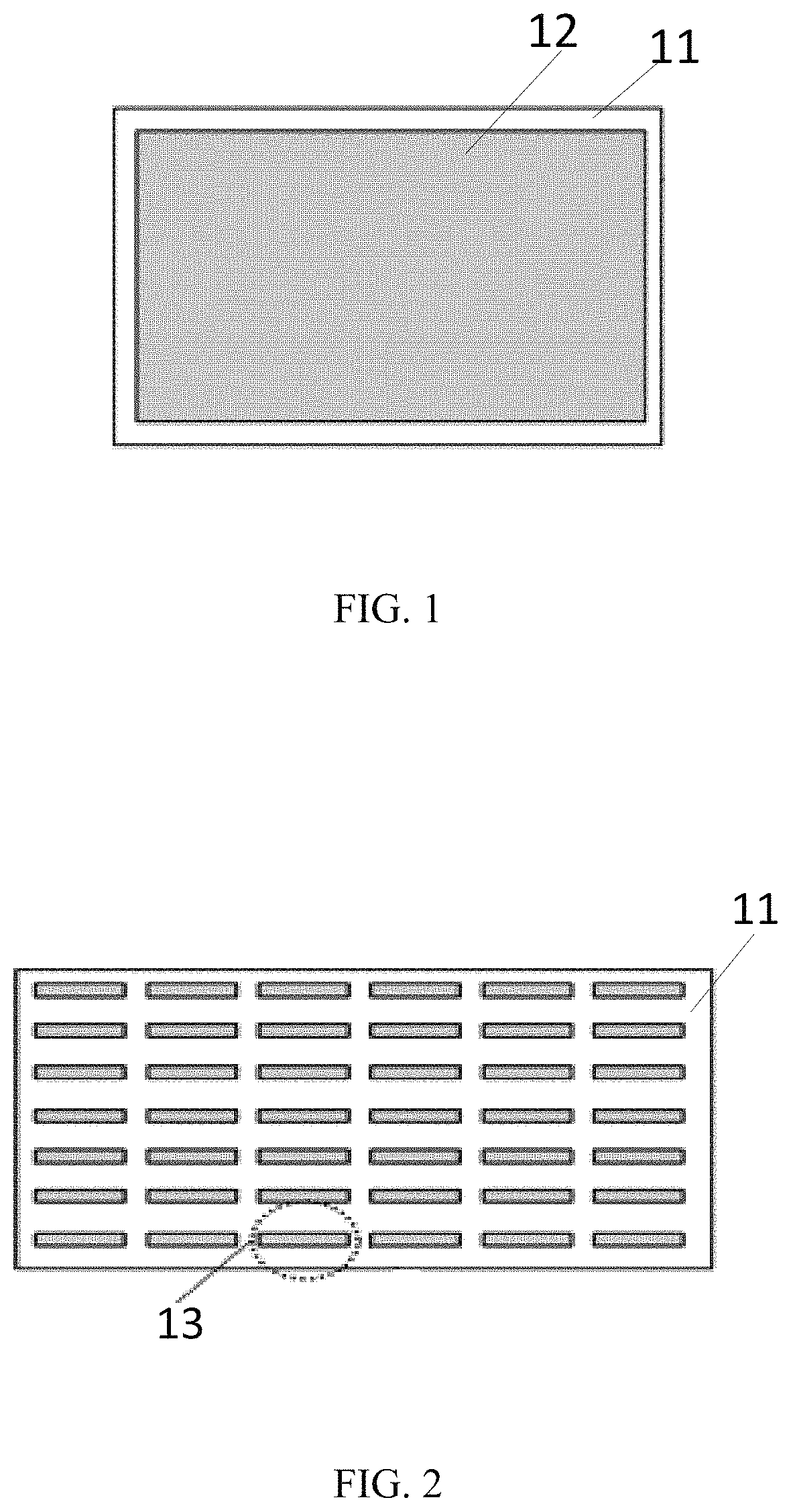

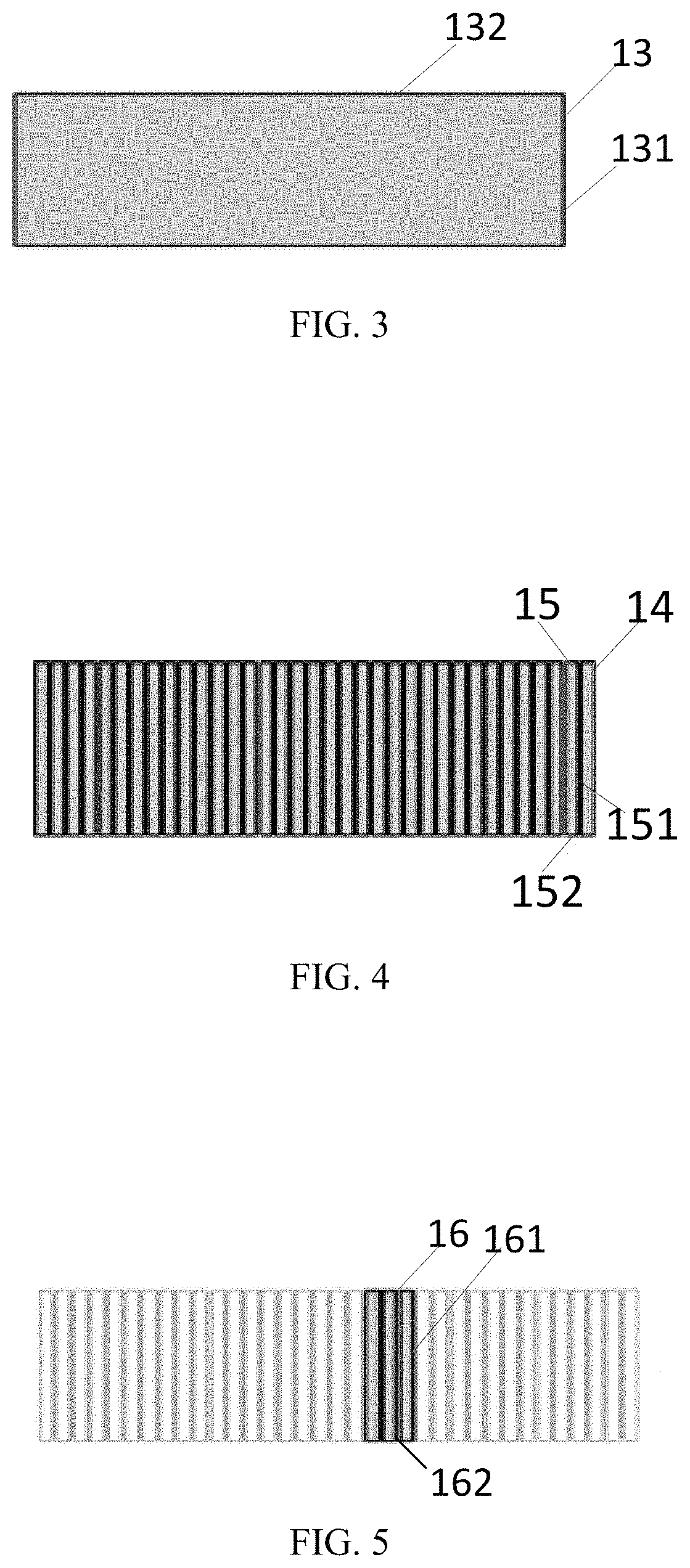

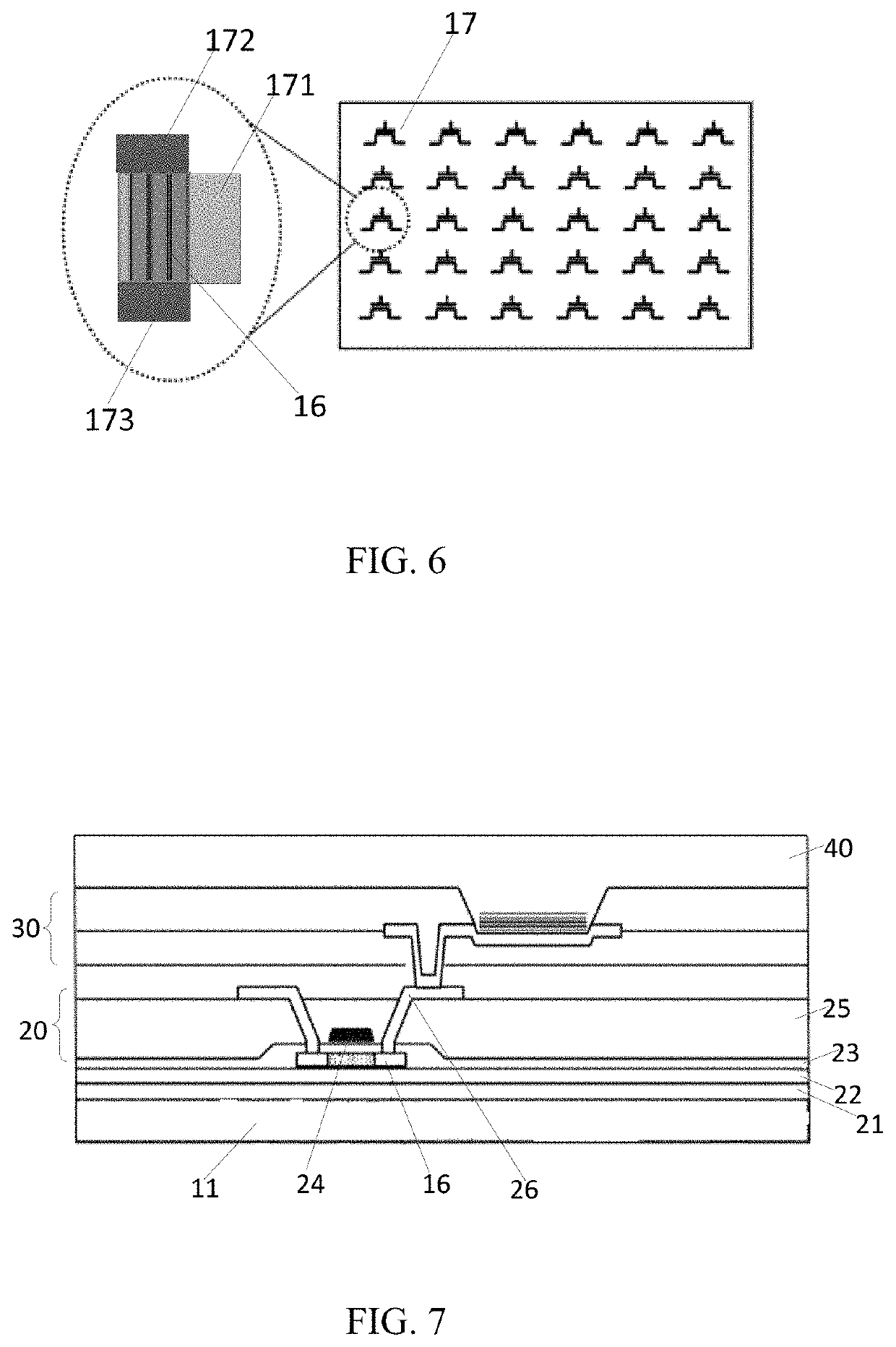

Flexible organic light emitting diode display with directional crystallized channel and manufacturing method thereof

ActiveUS10573671B2Low densityImprove electrical performanceTransistorFinal product manufactureFlexible organic light-emitting diodeDisplay device

A flexible organic light emitting diode display and manufacturing method thereof are provided. The method includes: performing a first patterning process on an amorphous silicon film; performing a crystallization treatment on the amorphous silicon film which has been processed by the first patterning process to form an oriented crystalline polycrystalline silicon film; performing a second patterning process on the polycrystalline silicon film to form a channel; and sequentially forming a gate, a source, a drain, an OLED display layer, and a packaging layer over the channel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

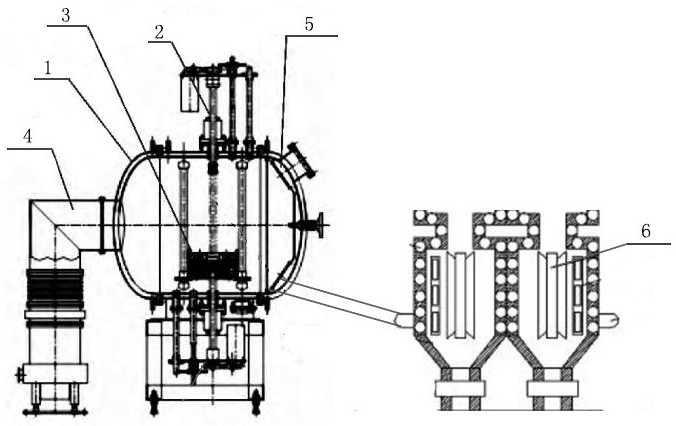

Vacuum melting furnace for purifying high-purity oxygen-free copper

PendingCN114318001AEfficient removalImprove purityRotary drum furnacesCrucible furnacesDirected crystallizationMetal impurities

The invention discloses a vacuum melting furnace for purifying high-purity oxygen-free copper. The vacuum melting furnace comprises a feeding bin, a zone melting chamber and a control mechanism. The control mechanism comprises a console, a controller and an upper computer, the controller is arranged on the console, and the controller is connected with the upper computer; a vibration feeder is arranged in the feeding bin and connected with the controller. A zone smelting furnace is fixedly mounted in the zone smelting chamber, and an inlet of the zone smelting furnace is connected with an outlet of the feeding bin; a column crystal orientation crystallization cavity is formed in the pouring chamber, an inlet of the column crystal orientation crystallization cavity is communicated with an outlet of the zone melting furnace, a condensation pipe is embedded in the inner wall of the column crystal orientation crystallization cavity, and a water inlet pipe and a water outlet pipe are installed on the outer wall of the column crystal orientation crystallization cavity; and the other end of the condensation pipe is communicated with the water outlet pipe. By means of the method, metal impurities and gas in the copper rod can be effectively removed, the purity of oxygen-free copper is improved, and the melting loss of alloy components in the crystallization technological process can be small.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Growth device and growth method of iridium-free zone-melting gallium oxide crystal

ActiveCN114686965AAvoid lossAvoid cost inputPolycrystalline material growthBy zone-melting liquidsIridiumDirected crystallization

The invention discloses a growth device and a growth method of an iridium-free zone-melting gallium oxide crystal. The iridium-free zone-melting method provided by the invention belongs to a method for growing single crystals by a melt method, precious metal is not used as a heating source, an external heating body is used for heating, heat passes through an atmosphere isolation device made of a high-transmittance and high-heat-conduction material to heat and melt a solid gallium oxide polycrystal charge rod or a ceramic rod, then seed crystals are in contact with a melt, and the single crystals are grown by a single crystal growing method. By controlling process conditions such as temperature, rising and falling, rotating speed and the like, a melting region gradually moves upwards, so that a melt region far away from a thermal field is subjected to directional crystallization according to the crystal orientation of seed crystals, and finally, large-size and high-quality gallium oxide single crystals with determined crystal orientation are obtained.

Owner:杭州镓仁半导体有限公司

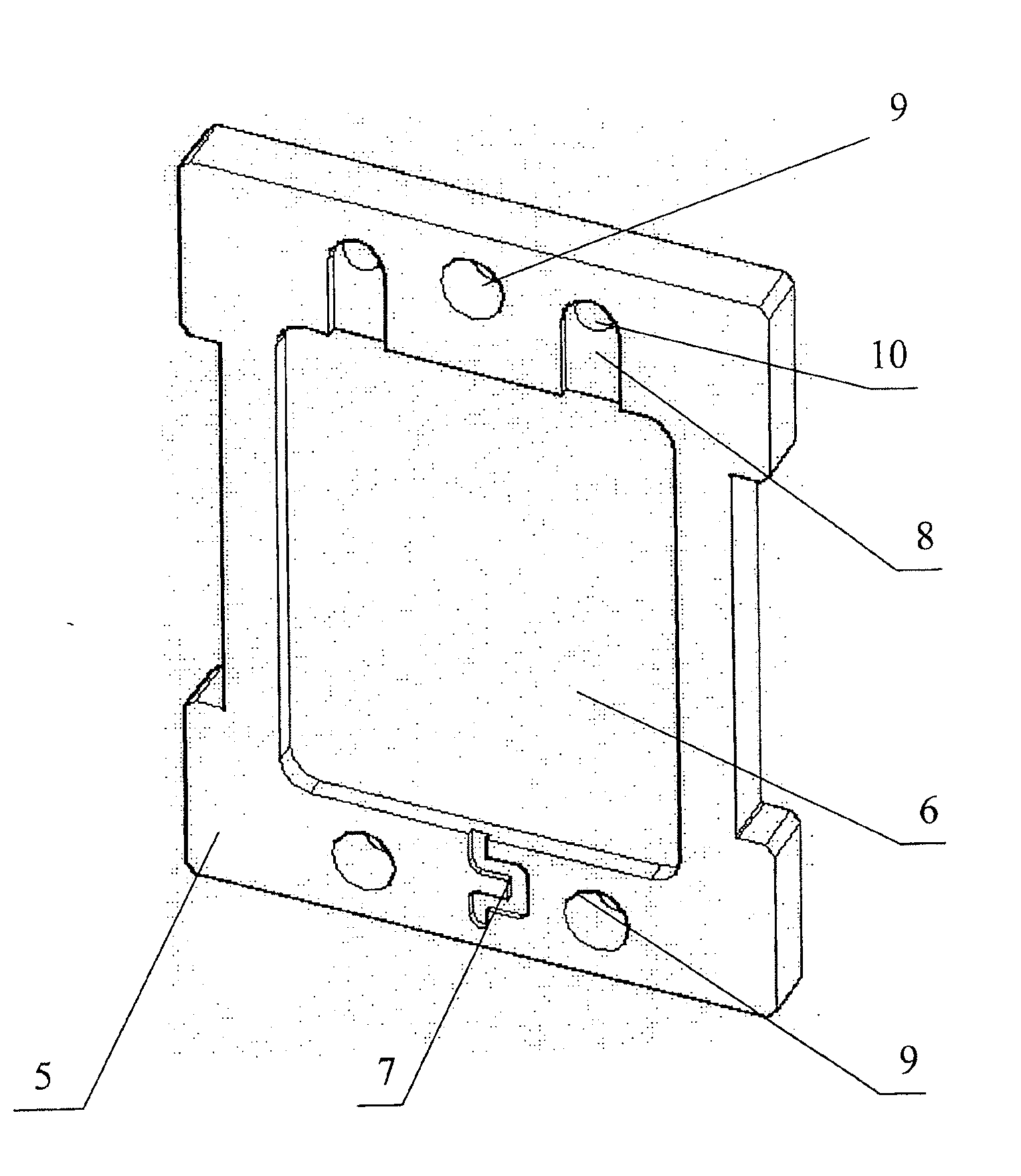

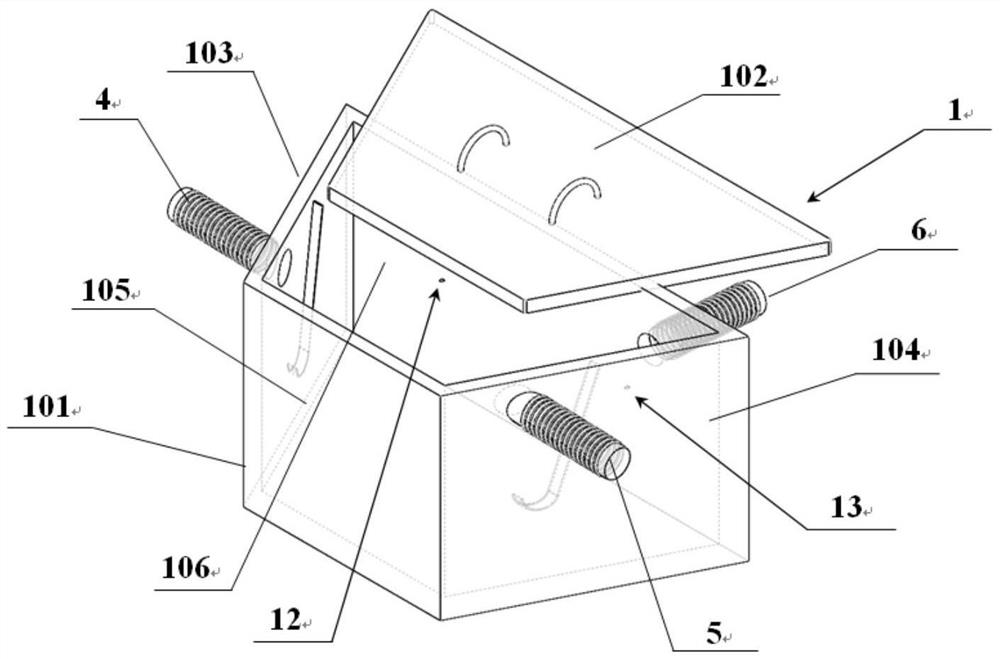

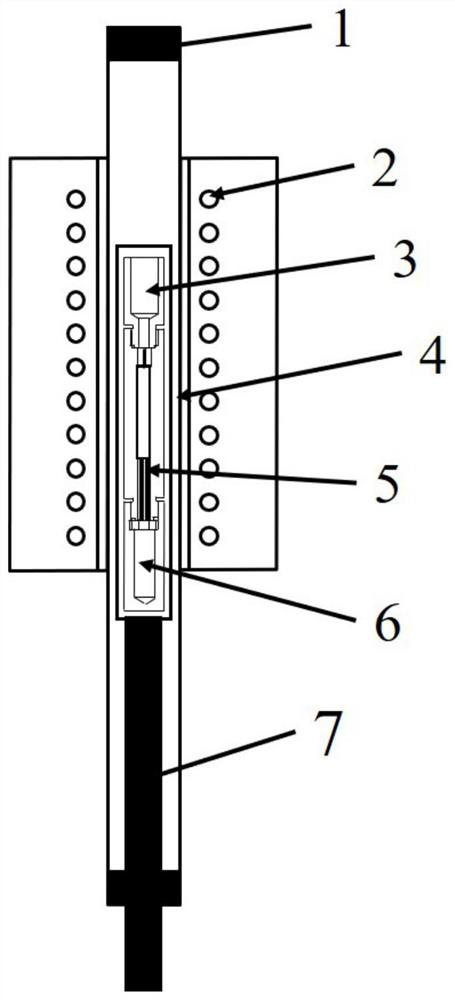

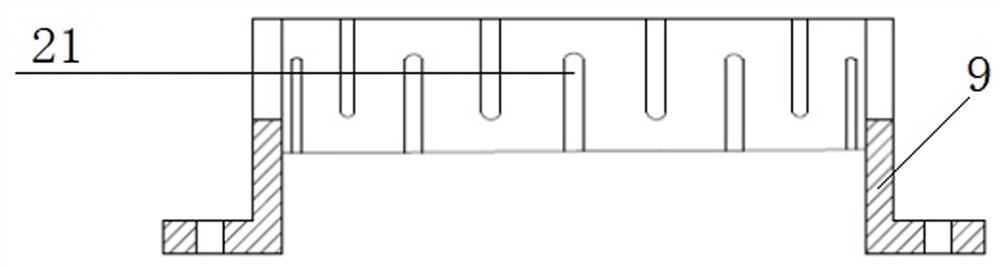

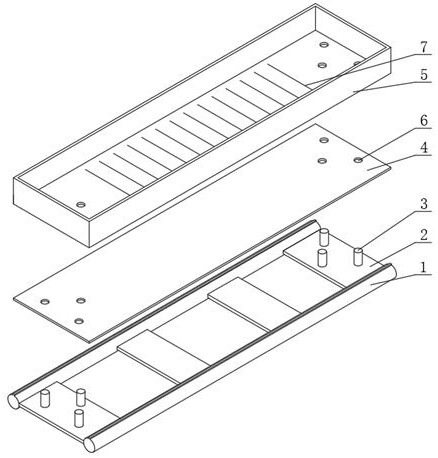

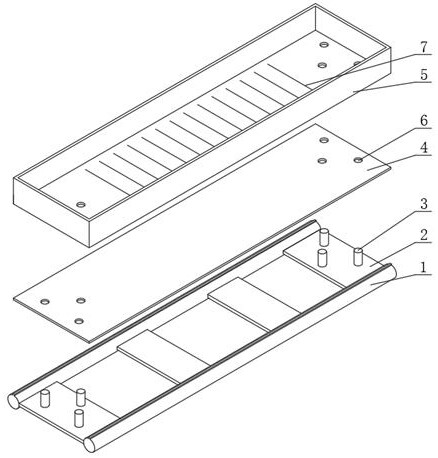

Tray device for growing crystals by horizontal directional crystallization method and use method

PendingCN113957516AAvoid deformationHigh strengthPolycrystalline material growthFrom frozen solutionsDirected crystallizationCrucible

The invention discloses a tray device for growing crystals by a horizontal directional crystallization method and a use method, the tray device comprises a guide rail and a tray placed on the guide rail, and a buffer plate is arranged between the guide rail and the tray; a plurality of transversely-arranged tungsten wires are evenly laid on the upper surface of the tray in the length direction at intervals so that a crucible to be placed can be placed on the tray through the tungsten wires, the guide rail is composed of two guide rail rods and a plurality of transverse plates evenly installed between the two guide rail rods, and a plurality of positioning columns are evenly and fixedly installed on the surfaces of the transverse plates located at the two ends at intervals respectively; Aand positioning holes through which the corresponding positioning columns penetrate are formed in the surfaces of the buffer plate and the tray in a one-to-one correspondence manner. The stability of the tray during guide rail moving is effectively improved, the tray is prevented from being bonded with the bottom of the crucible, meanwhile, deformation of the tray and the guide rail is reduced, the service life of the tray and the guide rail is prolonged, and the crystal growth quality is improved.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Process for growing of optical fluorite single crystals

InactiveUS7001458B2Polycrystalline material growthSemiconductor/solid-state device manufacturingDirected crystallizationCrucible

The present invention relates to the technical field of preparing artificial calcium fluoride (optical fluorite) single crystals by growing from a melt by the directed crystallization and by using a seed crystal. The aim of the invention is to obtain oriented single crystals with a small deviation from the given direction. The technical result is achieved by the selection of a concrete technological mode in which the leading role has a period for melting of seed crystal. The optical fluorite single crystals are grown by crystallization on the oriented seed inserted into the central part of a bottom of crucible. Before the beginning of crystallization the crucible with a melt is maintained in a melt zone for a time that is sufficient for the homogenization of the whole melt and in this time the bottom part of a seed crystal appears below a melt zone. Subsequently, the crucible with a melt and with a seed crystal is moved from the melt zone into the annealing zone with the given speed. The method differs from the prior art in that the crucible with a melt is kept in a melt zone for 24–48 hours, then the crucible is relocated upwards into the melt zone at a speed of 5–50 mm / hr to a level making 10–40% of the height of the seed crystal within the melt zone. The crucible is kept in such condition from 10 about 20 minutes, and then the crucible is moving downwards out of the melt zone in accordance to the given mode of crystallization.

Owner:CORNING INC

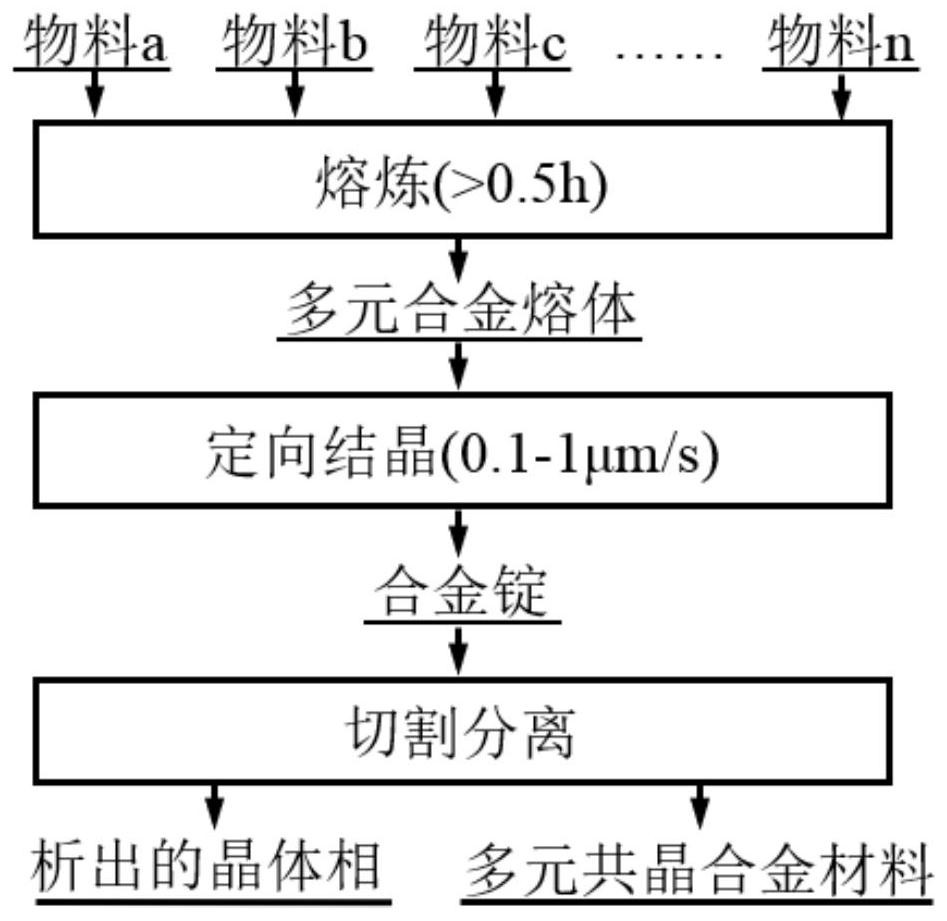

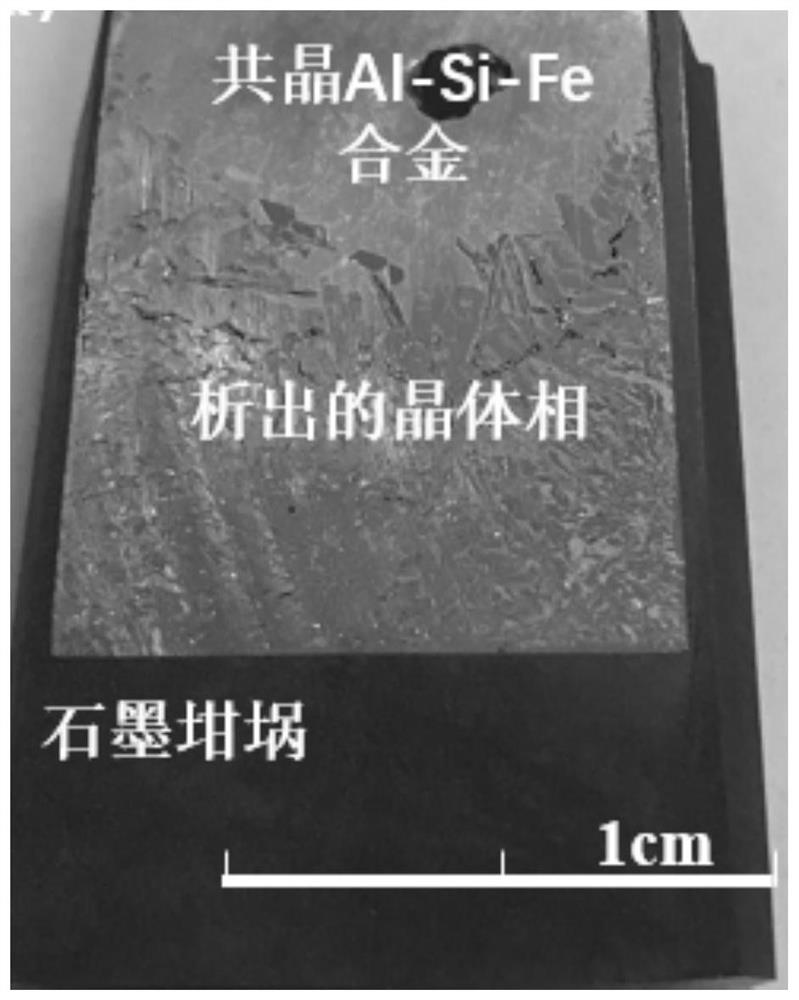

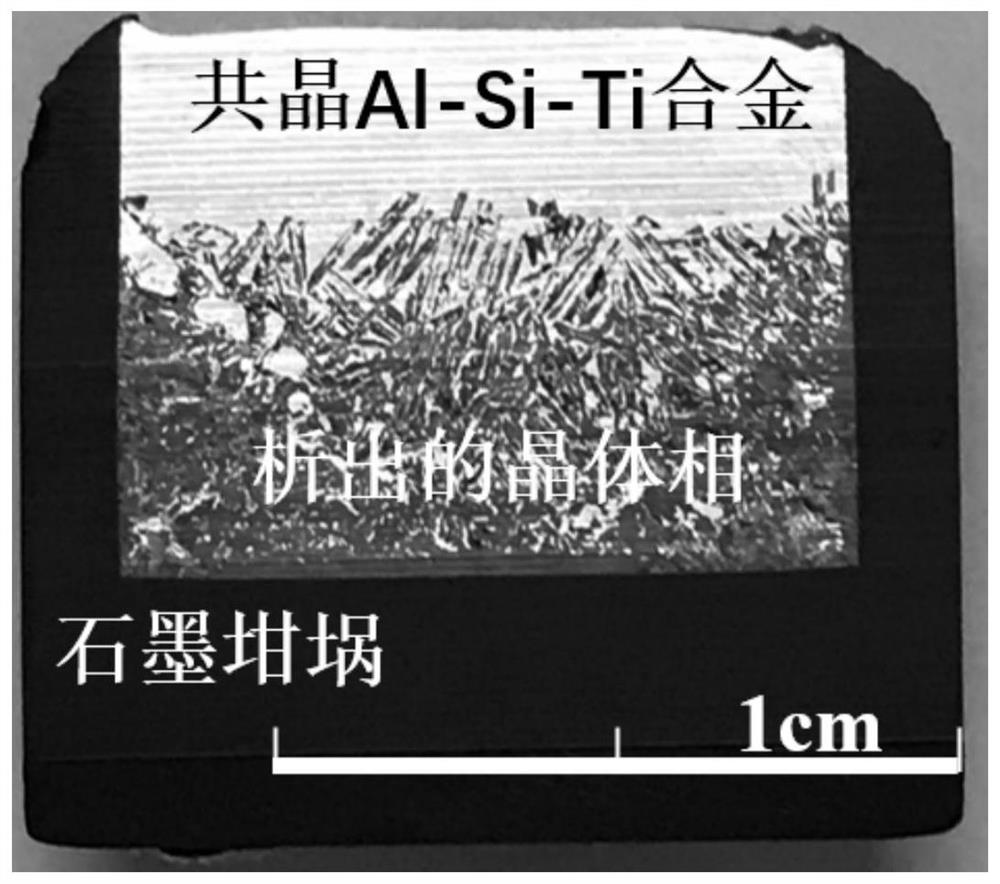

Method for determining eutectic point components in multi-element alloy phase diagram

PendingCN112986318AImprove performanceInvestigating phase/state changeHigh entropy alloysDirected crystallization

The invention relates to a method for determining eutectic point components in a multi-element alloy phase diagram, and belongs to the technical field of alloy materials. The method comprises the steps of uniformly mixing materials of two or more high-purity alloy elements, heating in a protective gas atmosphere until the materials are completely molten to obtain a multi-element alloy melt, and directionally crystallizing the multi-element alloy melt to obtain a crystal phase and a multi-element eutectic alloy; and cutting and separating the crystal phase and the multi-element eutectic alloy to obtain the multi-element eutectic alloy material, and analyzing the components of the multi-element eutectic alloy material, namely the eutectic point components in the multi-element alloy phase diagram. According to the method, the proportion of materials of high-purity alloy elements does not need to be controlled, the multi-element eutectic alloy or the eutectic high-entropy alloy is designed without relying on thermodynamic data, and the eutectic point components in the multi-element alloy phase diagram are directly determined without relying on thermodynamic data.

Owner:KUNMING UNIV OF SCI & TECH

Cartilage Extracellular Matrix and Silk Fibroin Composite Oriented Cartilage Scaffold and Preparation Method

ActiveCN105251052BFix performance issuesStructural solutionAnimals/human peptidesProsthesisCell-Extracellular MatrixBiocompatibility Testing

The invention discloses a cartilage extracellular matrix and silk fibroin composite orientation cartilage support and a preparation method thereof and belongs to the biological tissue engineering technology. According to the cartilage extracellular matrix and silk fibroin composite orientation cartilage support and the preparation method of the cartilage support, cartilage extracellular matrixes are prepared through articular cartilage of people, pigs, cows or sheep, silk fibroin is prepared through mulberry silk, after the cartilage extracellular matrixes and the silk fibroin are evenly mixed according to a specific proportion, directed crystallization is performed under a certain temperature, ultraviolet cross linking is firstly performed after freezing and drying, and then cross linking of carbodiimide and N-hydroxysuccinimide or glutaraldehyde and genipin is performed so that the cartilage extracellular matrix and silk fibroin composite orientation cartilage support can be prepared. Due to the design, biocompatibility is good, and immunological rejective reaction is avoided; a composition structure and mechanical properties are similar to those of cartilage extracellular matrixes of people; material sources are wide, cost is low, the preparation technology is simple, the cartilage extracellular matrix and silk fibroin composite orientation cartilage support can be used for constructing tissue engineering cartilage and repairing cartilage degradation, and clinical application prospects are good.

Owner:TIANJIN HOSPITAL

Crystalloid laminae composited from single crystal and directional column crystal and preparing method

InactiveCN1317095CImprove performanceQuality improvementPolycrystalline material growthBlade accessoriesDirected crystallizationEngineering

A monocrystal and orientational cylindrical crystal combined blade used for gas turbine features that its middle region is orientational cylindrical crystals and its gas inlet and outlet edges have monocrystal form. Its manufacture method includes such steps as installing a composite crystallizer to the crystallizer of orientational crystallizing furnace, smelting by 100-150 of overheat, regulating the temp of mould heater to 1500-1530 deg.C for upper region and 1550-1580 deg.C for lower region, casting, and moving mould downward at 5-7 mm / S.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

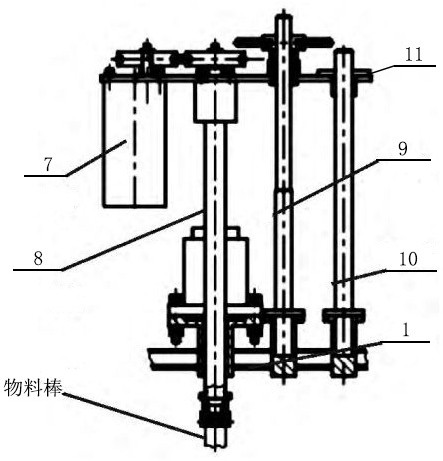

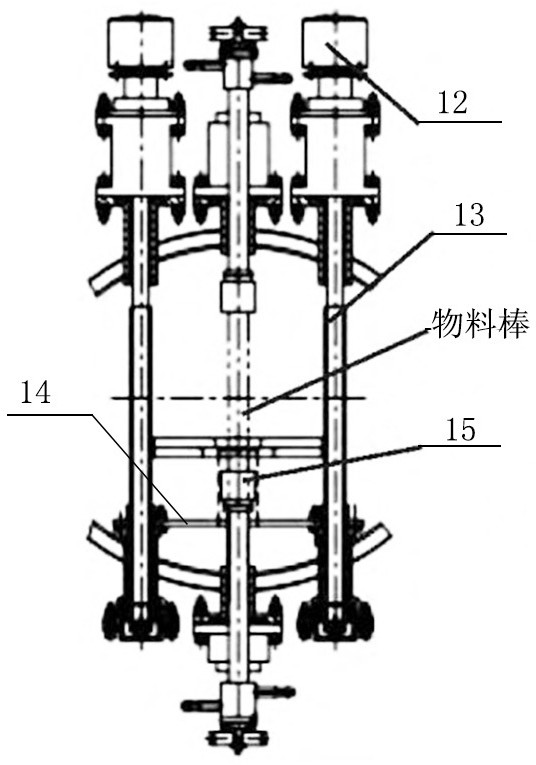

Method for preparing Fe-Ga-In-Tb alloy bar by filtering and undercooling ceramic

A method for preparing Fe-Ga-In-Tb alloy rods by deep supercooling through ceramic filtration, using a new Fe-Ga-In-Tb giant magnetostrictive alloy composition system to overcome the difficulty of melting iron-gallium binary composition alloys Disadvantages: For the first time, a nanoporous ceramic filter is used to filter the alloy melt to improve the purity of the Fe-Ga-In-Tb melt, so that the alloy melt is deeply supercooled, and then the alloy is heated again to make the alloy liquid through the deep subcooling directional crystallization system Metals stimulate directional crystal growth. The alloy bar prepared by the invention has smooth surface, high degree of orientation, precise and uniform composition, and good comprehensive performance.

Owner:NANCHANG INST OF TECH

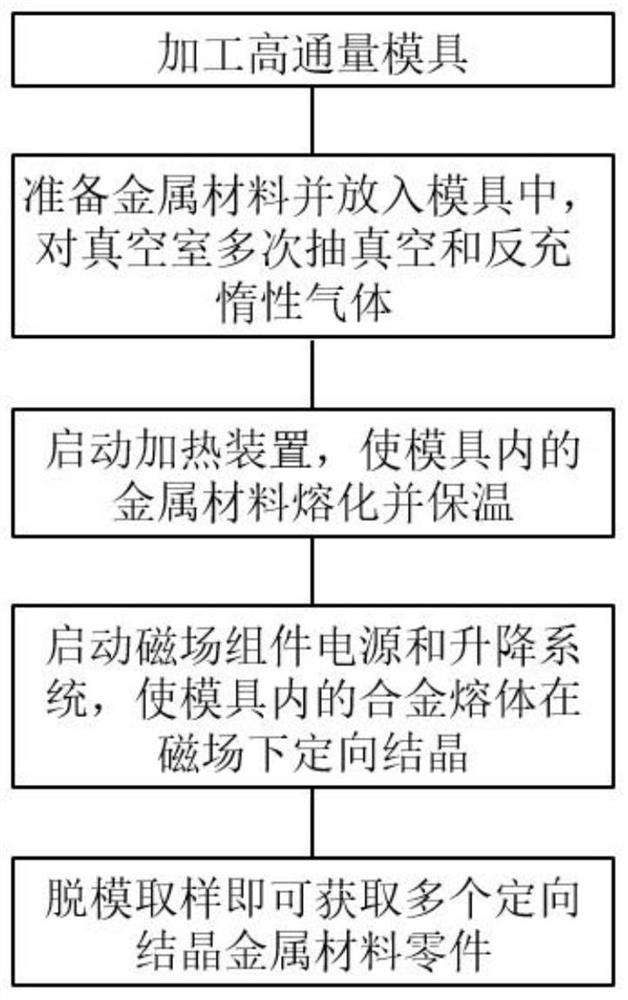

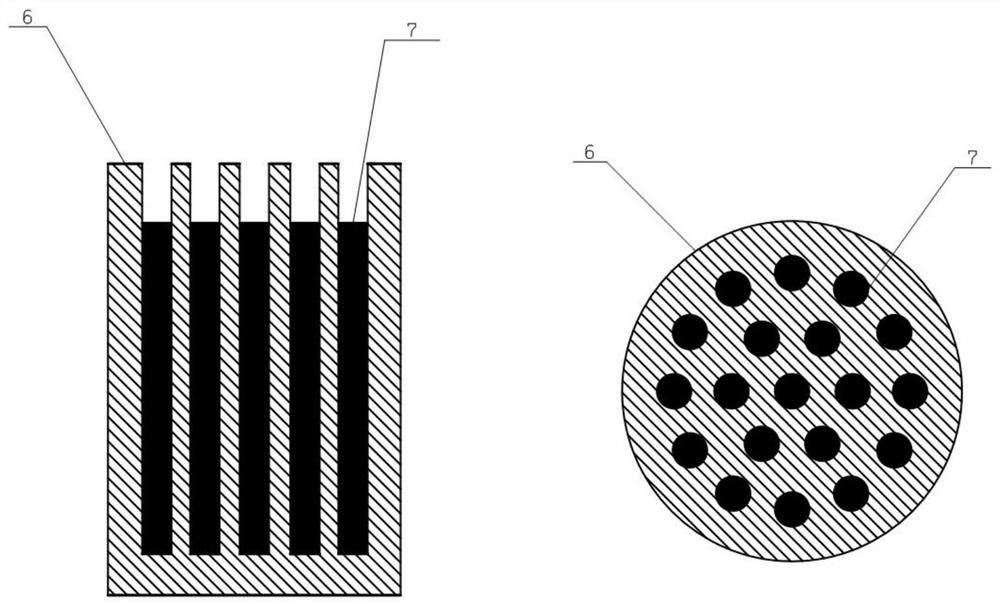

High-throughput preparation method for metal parts

PendingCN113305283AImprove mechanical propertiesImprove yield rateDirected crystallizationMetallogorgia

The invention belongs to the technical field of solidification, and particularly relates to a high-throughput preparation method for metal parts. The invention provides the high-throughput preparation method for the metal parts. The high-throughput preparation method for the metal parts comprises the following steps that metal raw materials are put into a high-throughput mold; the metal raw materials in the high-throughput mold are heated and melted in a protective gas atmosphere so as to obtain a metal melt, and then directional crystallization is carried out on the metal melt under a magnetic field condition; and the number of part sample grooves in the high-throughput mold is greater than or equal to 4, and the shape of the part sample grooves is the same as that of the metal parts. According to the preparation method, the metal raw materials are put into the high-throughput mold to be subjected to in-situ melting and directional crystallization, a plurality of metal part products with excellent performance can be prepared through a single experiment, the experimental quantity in the material research and development process is remarkably decreased, and the period in the material research and development process is remarkably shortened.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com