Vacuum melting furnace for purifying high-purity oxygen-free copper

A vacuum smelting furnace and oxygen-free copper technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems of low degree of automation, power cannot meet process requirements, and cannot effectively remove metal impurities, etc., to achieve performance consistency Good, less melting loss, the effect of product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

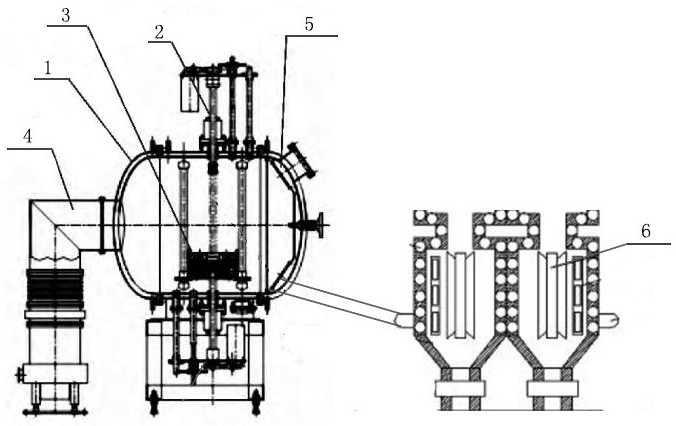

[0023] In this example, if figure 1 As shown, a vacuum melting furnace for the purification of high-purity oxygen-free copper includes a feeding bin, a regional melting chamber and a control mechanism; the control mechanism includes a console, a controller and a host computer, and the controller is set on the console to control The feeder is connected with the upper computer; the feeding bin is equipped with a vibrating feeder, and the vibrating feeder is connected to the controller; a regional melting furnace is fixedly installed inside the regional melting room, and the entrance of the regional melting furnace is connected with the outlet of the feeding bin; the pouring room is equipped with A columnar crystal directional crystallization chamber, the entrance of the columnar crystal directional crystallization chamber is connected to the outlet of the regional melting furnace, the inner wall of the columnar crystal directional crystallization chamber is inlaid with a condense...

Embodiment 2

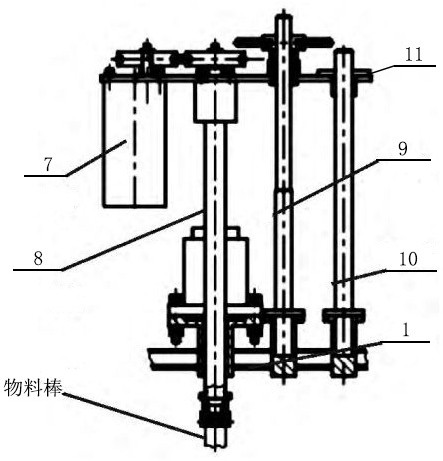

[0032] In this embodiment, the structure and working principle of the regional smelting furnace are mainly designed in detail.

[0033] In this embodiment, the regional smelting furnace includes a furnace body, an electron gun, a driving device and a vacuum system; the furnace body is circular and adopts a double-layer water-cooled jacket structure. One end of the furnace body is a double-layer head structure, and the other end is provided with a furnace The door; the electron gun is arranged inside the furnace body; the controller is respectively connected with the electron gun, the driving device and the vacuum system.

[0034]In the process of electron beam zone melting, X-rays will be generated when high-speed electrons bombard metal materials. In order to prevent X-rays from harming operators, effective shielding and protection measures must be taken, and parts that meet the requirements must be used. The furnace body is made of stainless steel, and the parts connected to...

Embodiment 3

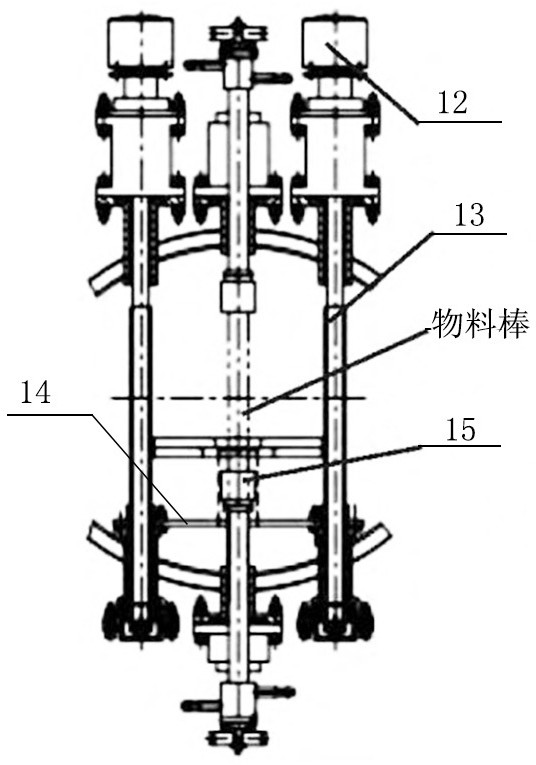

[0043] In this example, the electron beam zone melting device in the zone melting furnace is designed on the basis of the equipment provided in Example 1 and Example 2.

[0044] In this embodiment, the regional smelting furnace includes a furnace body, an electron gun, a driving device and a vacuum system; the furnace body is circular and adopts a double-layer water-cooled jacket structure. One end of the furnace body is a double-layer head structure, and the other end is provided with a furnace The door; the electron gun is arranged inside the furnace body; the controller is respectively connected with the electron gun, the driving device and the vacuum system.

[0045] In the process of electron beam zone melting, X-rays will be generated when high-speed electrons bombard metal materials. In order to prevent X-rays from harming operators, effective shielding and protection measures must be taken, and parts that meet the requirements must be used. The furnace body is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com