Method for preparing large-size Ce,Nd: YAG crystal based on transverse translation crystallization method

A crystallization method and large-size technology, which is applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as difficulty in preparing large-size crystals, increasing the temperature gradient of solid-liquid interface, and large residual stress of crystals. Achieve the effects of less deformation, improved crystal utilization, and small temperature gradient in the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

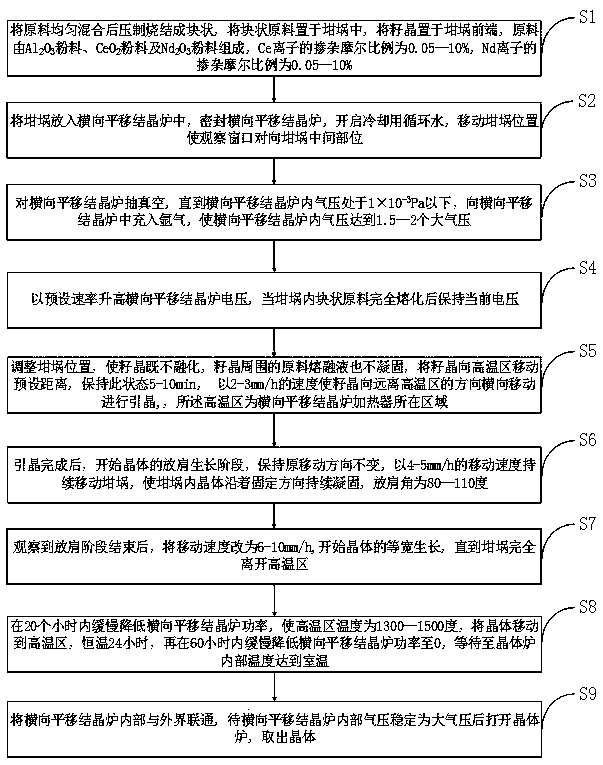

Method used

Image

Examples

specific Embodiment 1

[0057] Use 5N Al 2 o 3 Powder 791.97g, 5N Y 2 o 3 Yttrium oxide raw material 1004.94g, 5N CeO 2 Powder 7.82g, 5N Nd 2 o 3 The powder is 15.28g, and all kinds of raw materials are mixed evenly, pressed and sintered, then put into a boat-shaped tungsten crucible, and YAG seed crystal is placed at the tip of the tungsten crucible. Put the crucible containing the raw materials into the horizontal translational crystal growth furnace, place a heat shield around it, close the crystal furnace, turn on the circulating water, and evacuate to 1×10 -3 Pa, close the vacuum, fill in argon to make the pressure in the crystal furnace reach 1.7×10 5 Pa, stop argon filling, and start to heat up. When the temperature was raised to 1970°C, the powder was found to be melted, and a liquid flow line appeared near the seed crystal. Adjust the position of the crucible to melt the seed crystal slowly. After a period of time, start to move the crucible to keep the seed crystal away from the high...

specific Embodiment 2

[0059] 5N Al is selected according to a certain proportion 2 o 3 Powder 1256.63g, 5N Y 2 o 3 Raw material 1490.34g, 5N CeO 2 Powder 149.68g, 5N Nd 2 o 3 The powder is 123.37g, and the molar ratio of Y, Ce, and Nd ions in the raw material is 18:1:1. After mixing all kinds of raw materials evenly, they are pressed and sintered, and then put into a boat-shaped tungsten crucible, and the YAG seed crystal is placed on the tip of the tungsten crucible. Put the crucible containing the raw materials into the horizontal translational crystal growth furnace, place a heat shield around it, close the crystal furnace, turn on the circulating water, and evacuate to 8×10 -4 Pa, close the vacuum, fill in argon to make the pressure in the crystal furnace reach 1.9×10 5 Pa, stop argon filling, and start to heat up. Raise the temperature to 1900°C and found that the shape of the powder has changed but not completely melted. Continue to raise the temperature to 2000°C. It is found that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com