Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Deviation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Standard deviation function return the statistical standard deviation of all values in the set based on a sample of the population (STDEV), or based on a biased population (STDEVP). Standard deviation is useful for measuring variance within a data set and, in application, confidence in statistical results.

Anti-noise-interference redundant manipulator path planning method

ActiveCN108015763AHas global convergence propertiesCalculation speedProgramme-controlled manipulatorRobustificationDynamic method

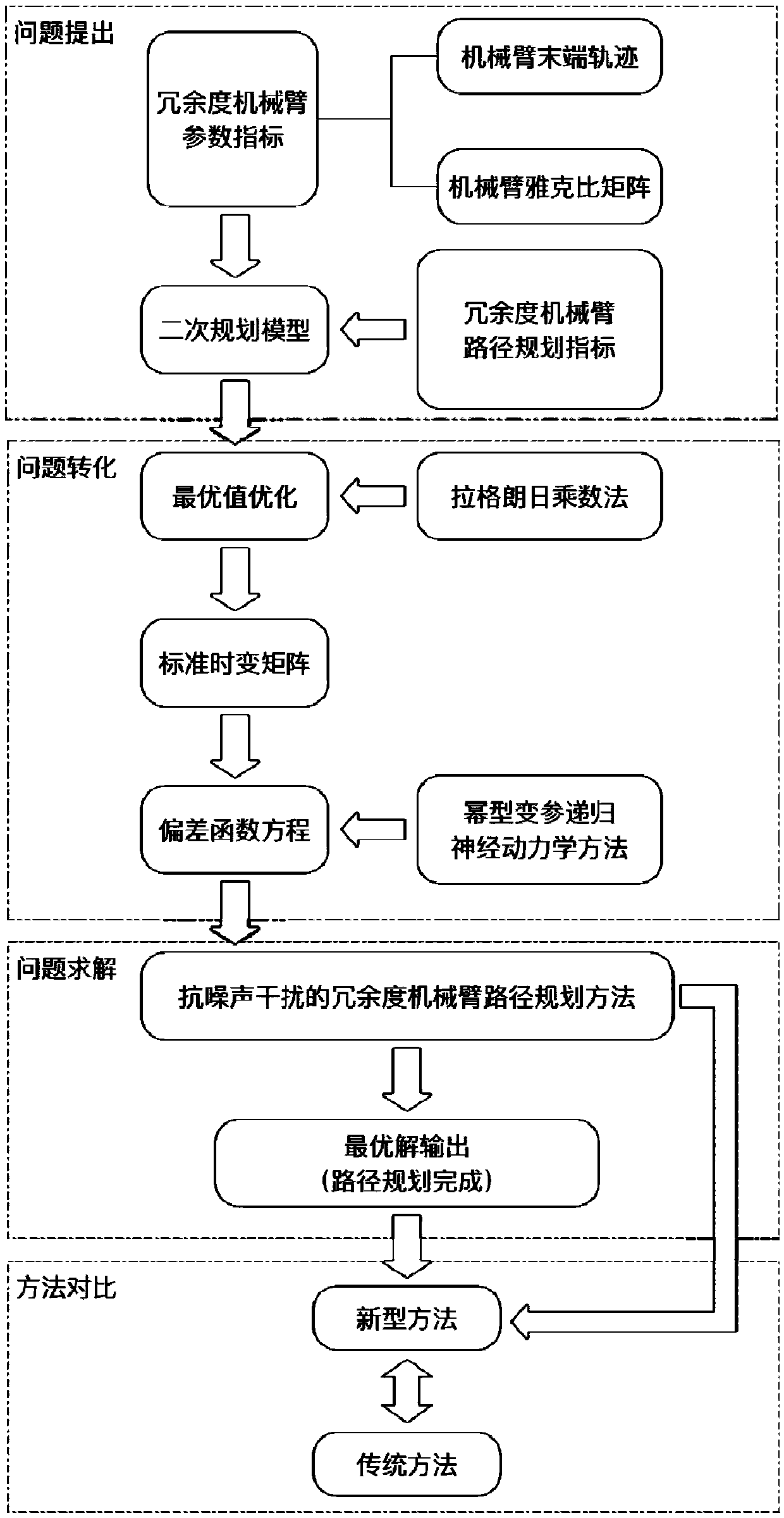

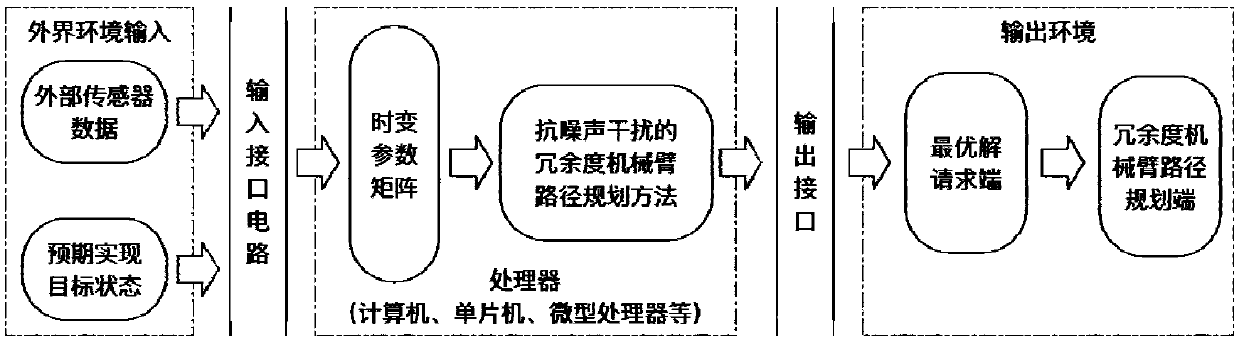

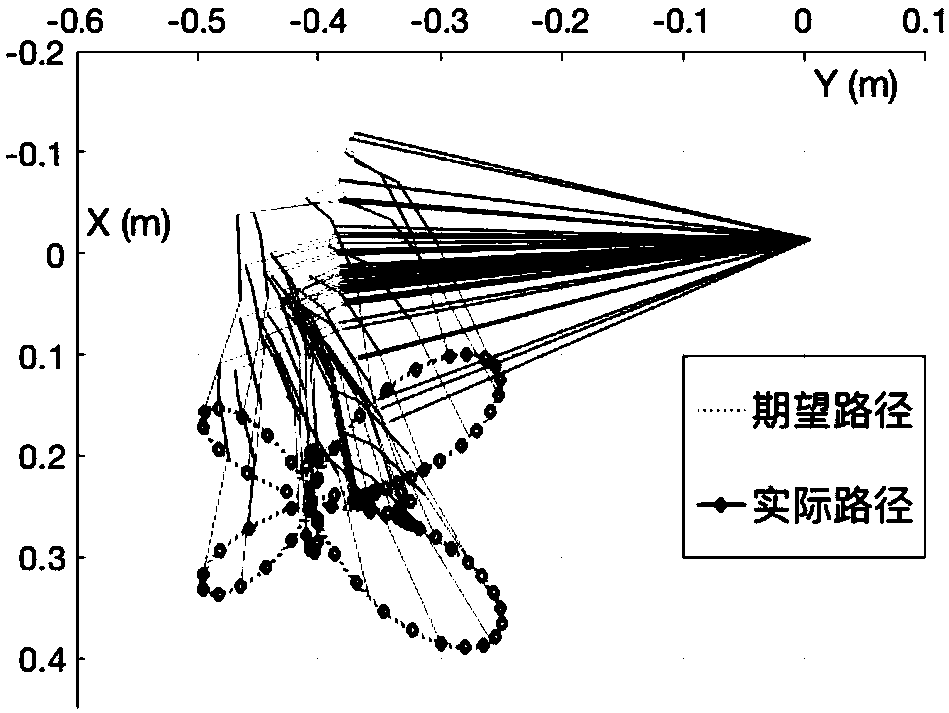

The invention discloses an anti-noise-interference redundant manipulator path planning method and a system. The method comprises the steps of (1) building a time-varying quadratic planning model according to an actual redundant manipulator parameter index, and introducing a performance index of a redundant manipulator; (2) using a lagrange multiplier method for carrying out optimal value optimization on the time-varying quadratic planning model; (3) designing a standard matrix equality according to an optimization formula; (4) designing a deviation function equation of the system according toan actual physical model system and the standard matrix equality; and (5) designing the anti-noise-interference redundant manipulator path planning method according to the deviation function equationand a power type varying parameter recursion neurodynamics method, wherein a network state solution solved by the method is an optimal solution. According to the anti-noise-interference redundant manipulator path planning method and the system provided by the invention, with the interference of an outside noise environment, an actual motion path of a redundant manipulator can further coincide withan expected path, so that the calculating speed is greatly improved, and the method has the characteristics of high precision, fast convergence, high instantaneity, good robustness and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for energy ranking of molecular crystals using dft calculations and empirical van der waals potentials

InactiveUS20070185695A1Chemical property predictionAmplifier modifications to reduce noise influenceHybrid approachRanking

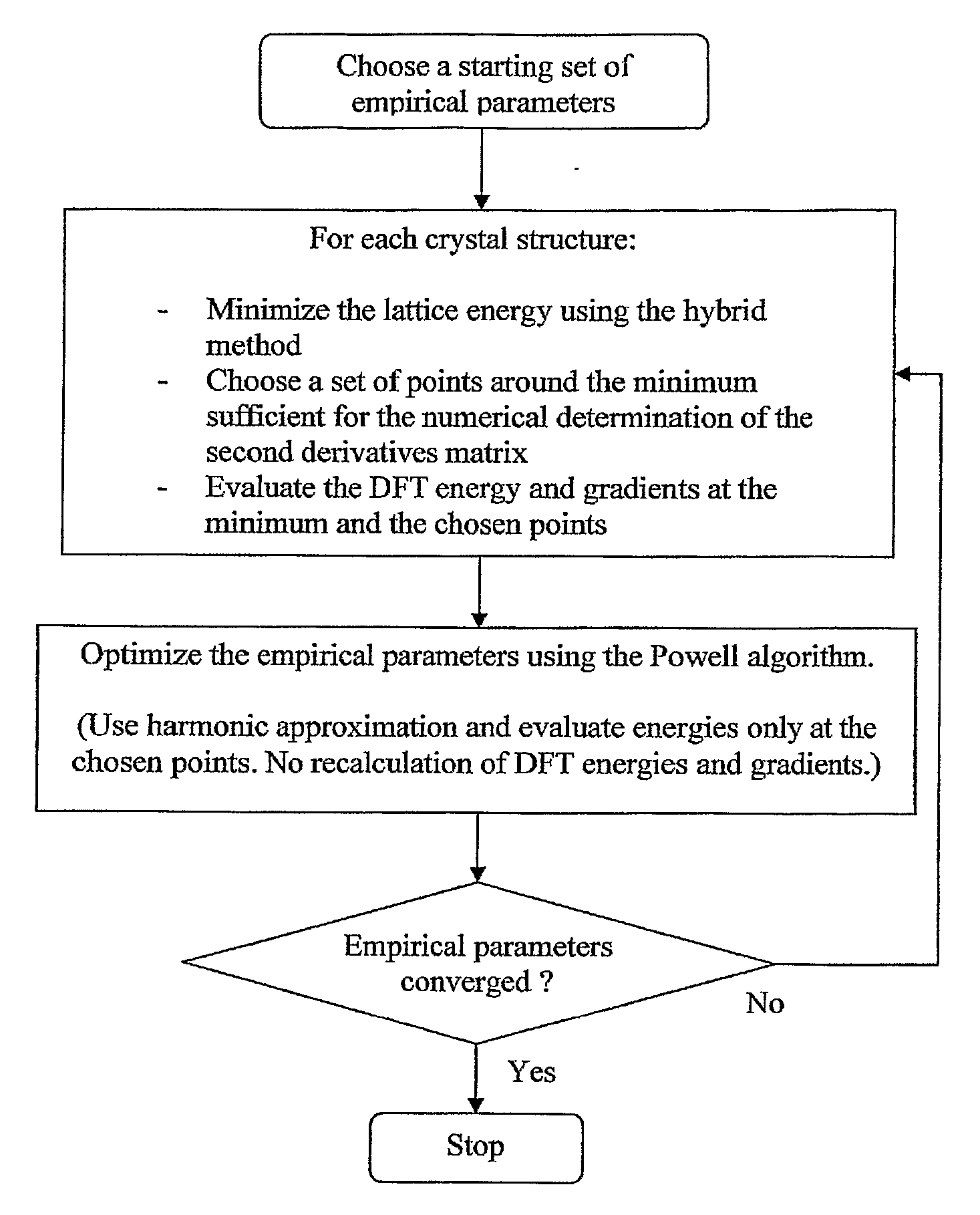

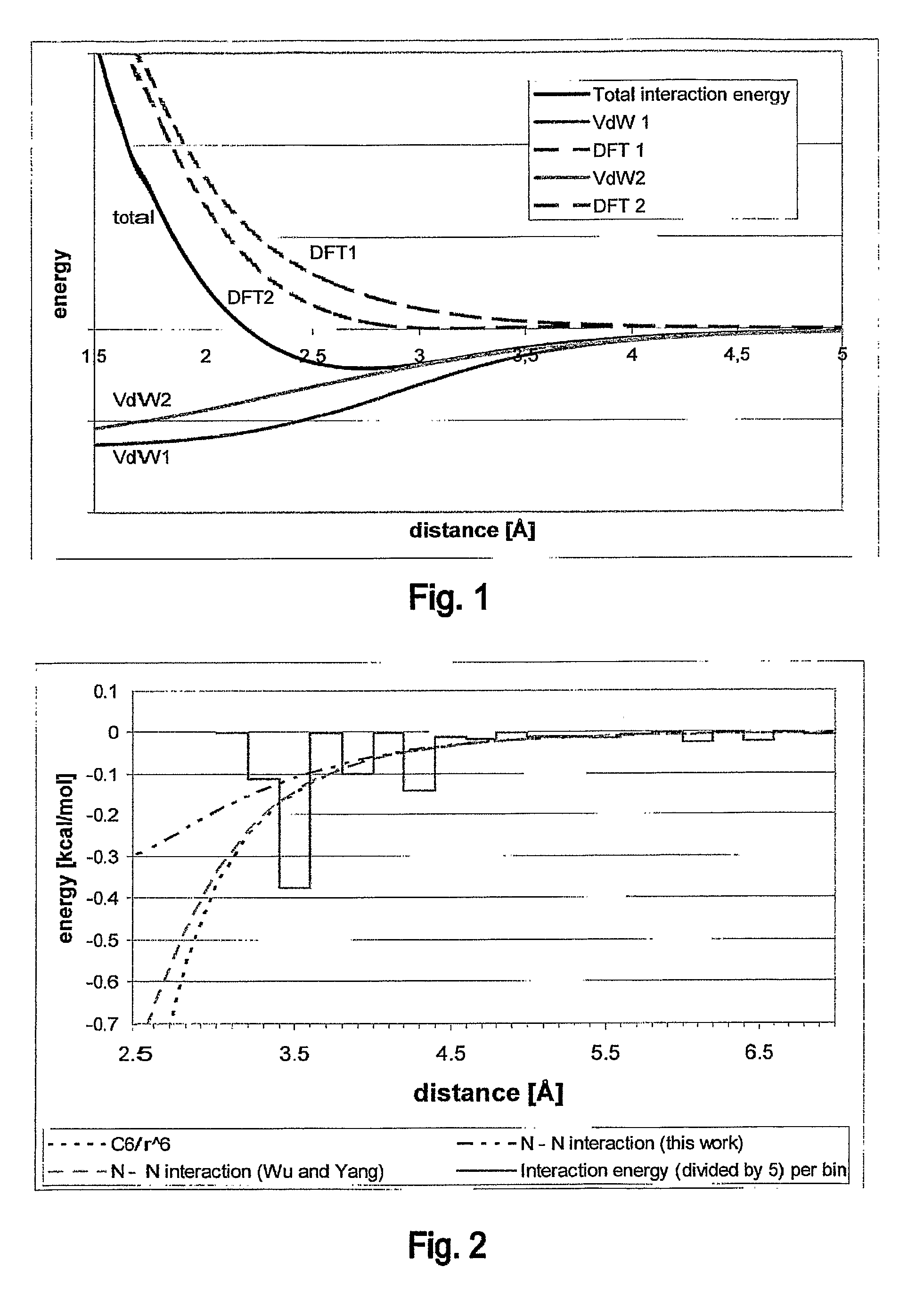

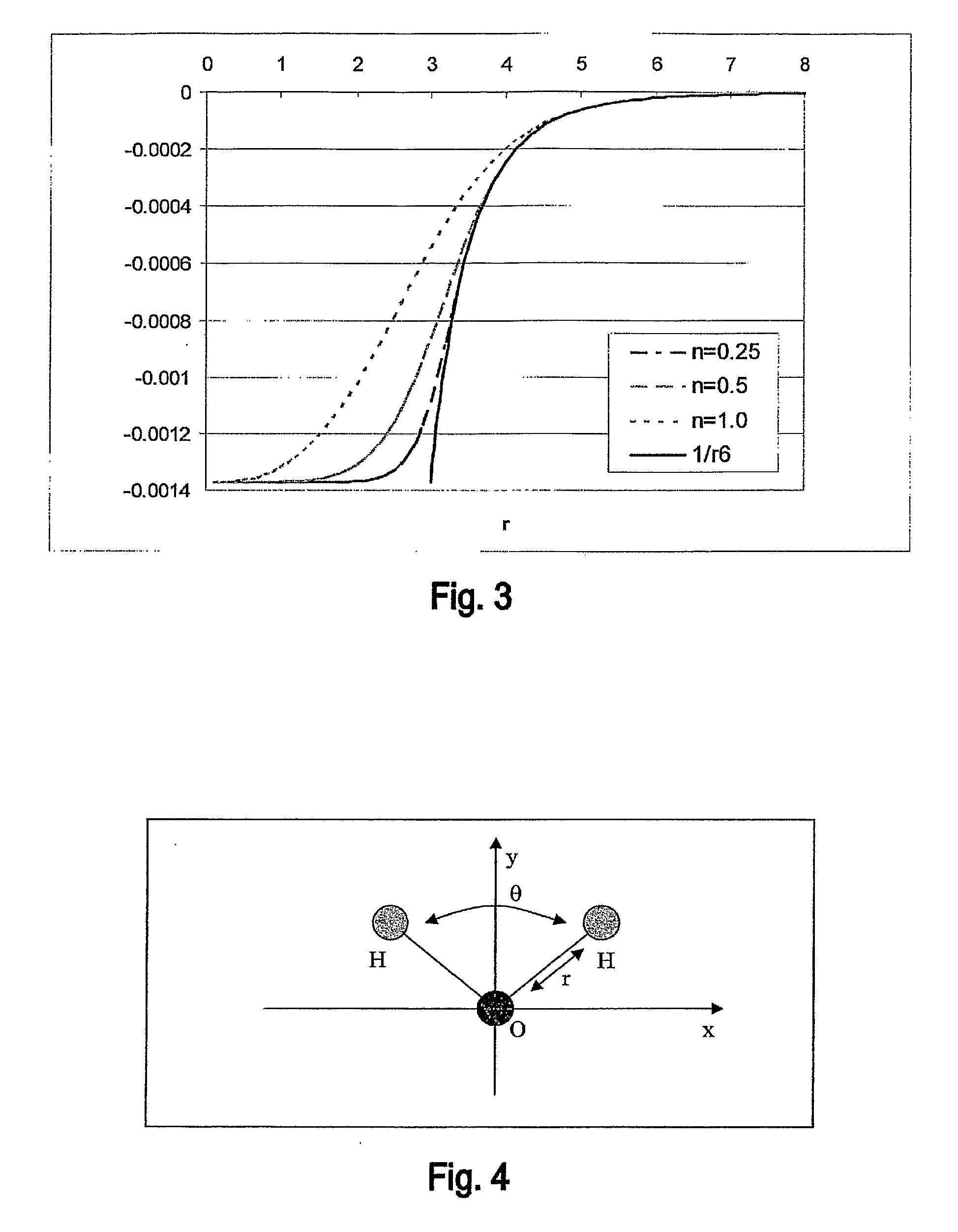

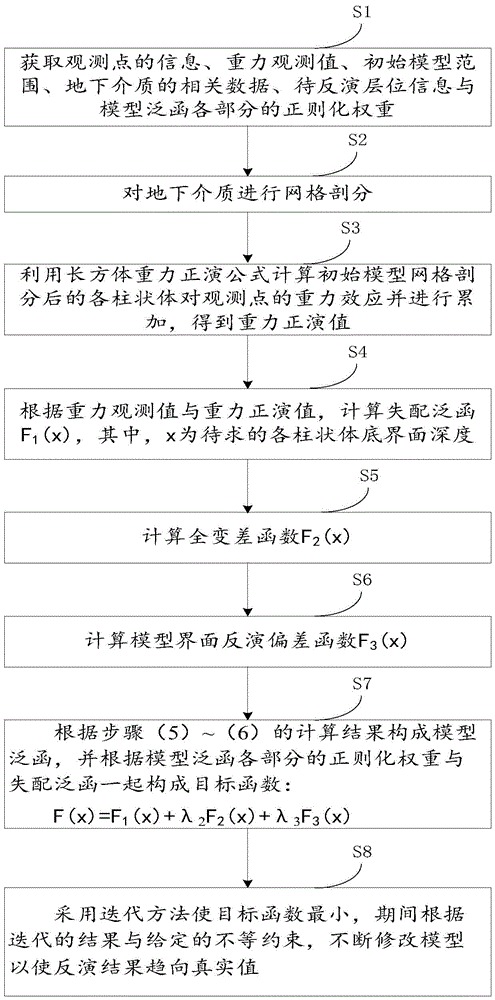

The invention refers to a method for the accurate determination of van der Waals parameters for high-precision determination of crystal structures and / or energies, comprising the steps of: numerically simulating at least one crystal structure based on density functional theory (DFT) calculations combined with a potential energy term representing van der Waals interactions; providing reference data containing accurate information about said at least one crystal structure; defining a deviation function (F) quantifying a deviation between said reference data and said at least one simulated crystal structure; fitting at least one parameter of said van der Waals potential term in such a way as to minimize said deviation function (F); and obtaining the accurate van der Waals parameters from the best fit. The invention furthermore deals with a hybrid method for the accurate van der Waals parameters from the best fit. The invention furthermore deals with a hybrid method for the accurate determination of crystal structures and / or energies based on such a parameter determination as well as the general application of such a hybrid method to the energy ranking of polymorphic crystal structures.

Owner:AVANT GARDE MATERIALS SIMULATION

Gravity multi-interface inversion method

ActiveCN105549106AImprove inversion accuracyImprove efficiencyGravitational wave measurementObservation pointDeviation function

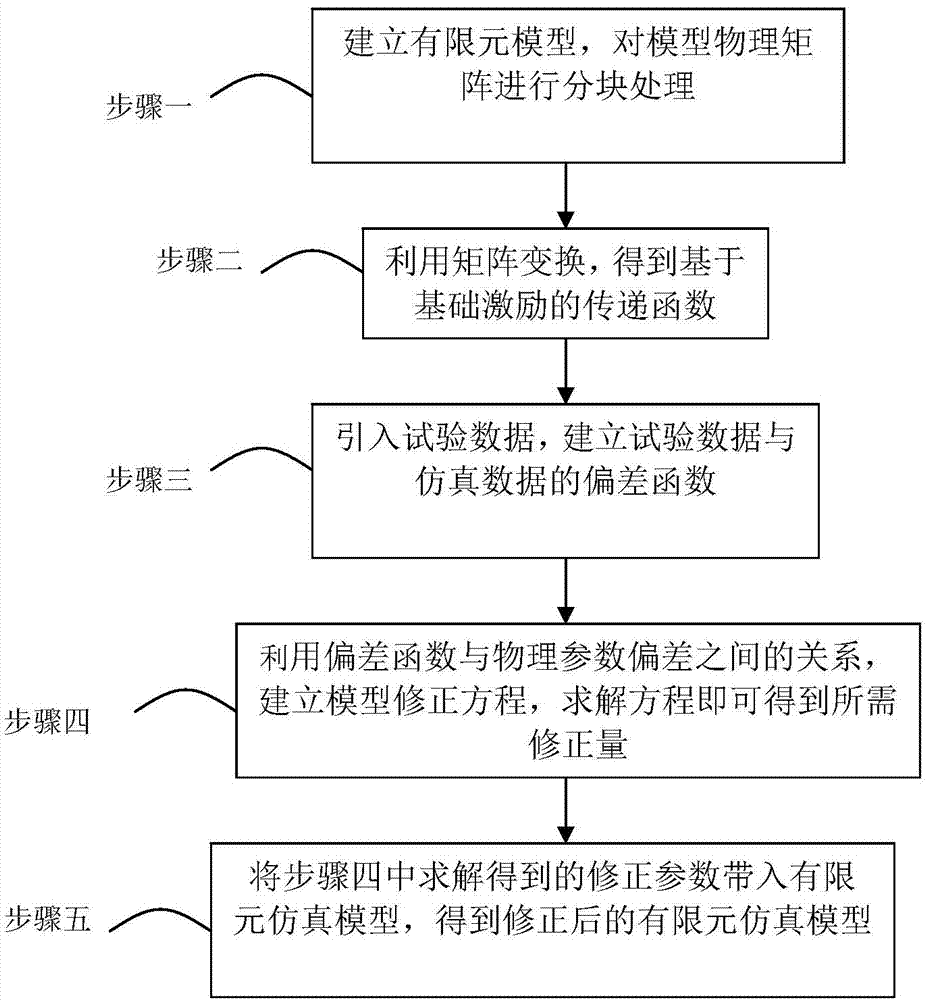

The invention discloses a gravity multi-interface inversion method. The method comprises the following steps: obtaining information of an observation point, a gravity observation value, an initial model scope, underground medium information, to-be-inversed layer position information, and regularization weights of each model functional portion; performing mesh generation on an underground medium; calculating a gravity effect of each cylindrical body for the observation point after the mesh generation of an initial model, performing accumulation, and obtaining a gravity forward modeling value; according to the gravity observation value and the gravity forward modeling value, calculating a mismatch function F1(x); calculating a total variation function F2(x); calculating a model interface inversion deviation function F3(x); according to calculation results, the regularization weights lambda2 to lambda3 of each model functional portion and the mismatch function F1(x), constructing a target function: F(x)=F1(x)+ lambda2F2(x)+ lambda3F3(x); and enabling the target function to be the smallest by use of an iteration method. Through such a mode, the gravity multi-interface inversion method can have quite good inversion precision and efficiency.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Method for detecting island of photovoltaic grid-connecting system based on non-blind area self-adaptive AFDPF (active frequency drift positive feedback) algorithm

InactiveCN106841926AEliminate detection blind spotsImprove detection efficiencyFault locationEngineeringDeviation function

The invention relates to the field of control of a photovoltaic grid-connecting power generation system, in particular to a method for detecting island of a photovoltaic grid-connecting system based on a non-blind area self-adaptive AFDPF (active frequency drift positive feedback) algorithm. The method for detecting the island of the photovoltaic grid-connecting system based on the non-blind area self-adaptive AFDPF algorithm has the advantages that the detection blind area is further eliminated, and the influence to power quality is decreased; under the condition of relative stable frequency, the AFDPF algorithm applies a smaller disturbance; when the frequency deviates from a stable state, the positive feedback on the frequency deviation is introduced into the disturbance; before the disturbance is applied, the frequency deviation direction is judged according to a frequency deviation function; by establishing the relationship of the positive feedback coefficient is in self-adaptive change along with the public coupling point frequency, and improving the frequency deviation function of the positive feedback, the detection blind area is further eliminated, the detection efficiency is improved, and the pollution to electric energy due to introducing of larger disturbance is certainly avoided.

Owner:HARBIN UNIV OF SCI & TECH

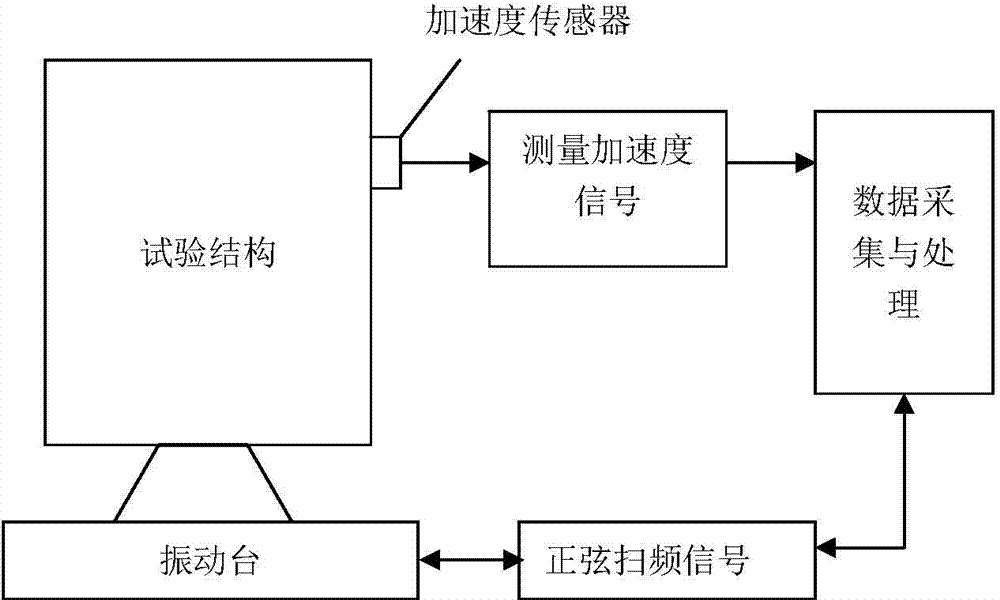

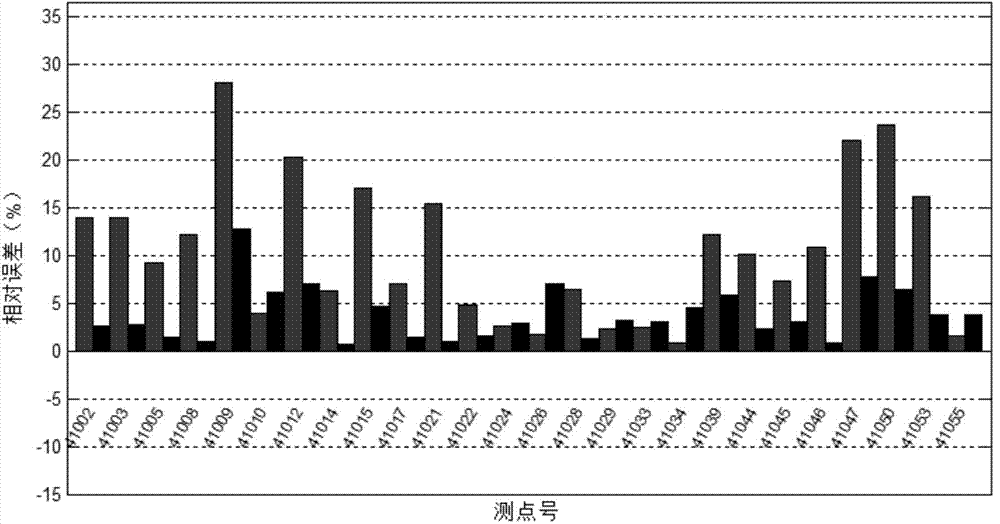

Model modification method with damp considered based on basic stimulation response data

InactiveCN103886160AGood prediction accuracyExtended parameter typeSpecial data processing applicationsElement modelModel modification

The invention discloses a model modification method with damp considered based on basic stimulation response data and relates to model modification methods with damp considered. The model modification method with the damp considered based on the basic stimulation response data aims to solve the problem that damp modification is not considered in the prior art and comprises the steps that (1) a finite element model is established, and partitioning is conducted on a physic matrix of the model; (2) a transfer function based on basic stimulation is obtained by means of matrix transformation; (3) test data are introduced, and a deviation function of the test data and simulation data is established; (4) a model modification equation is established according to the relation between the deviation function and physic parameter deviation, and required modification can be obtained by solving the equation; (5) a modification parameter obtained in the step (4) is plugged into the finite element simulation model, and then a modified finite element simulation model is obtained. The model modification method with the damp considered based on the basic stimulation response data is applied to the field of finite element simulation of structures as well as the relevant fields such as the test field and the design field.

Owner:HARBIN INST OF TECH

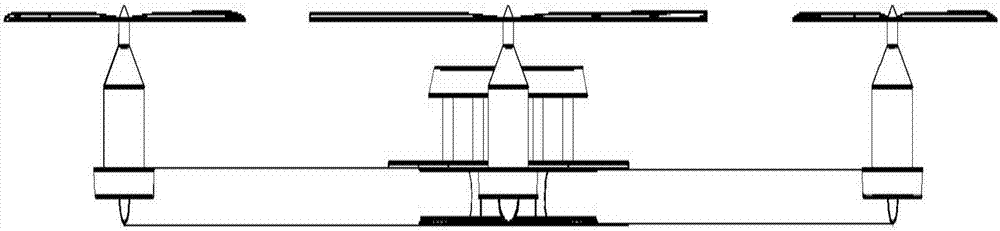

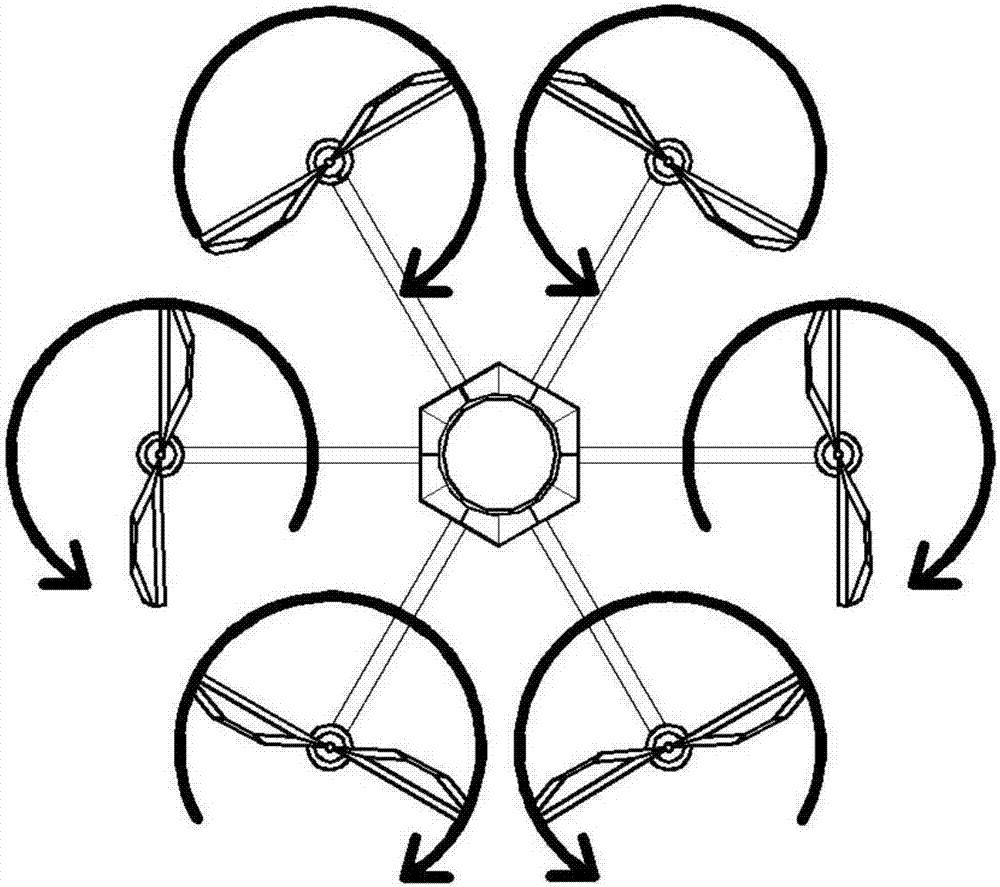

Unmanned aerial vehicle stable flight control method

ActiveCN107957730AGood convergence propertiesImprove robustnessAutonomous decision making processRemote controlled aircraftMotor speedKinematics

Owner:SOUTH CHINA UNIV OF TECH

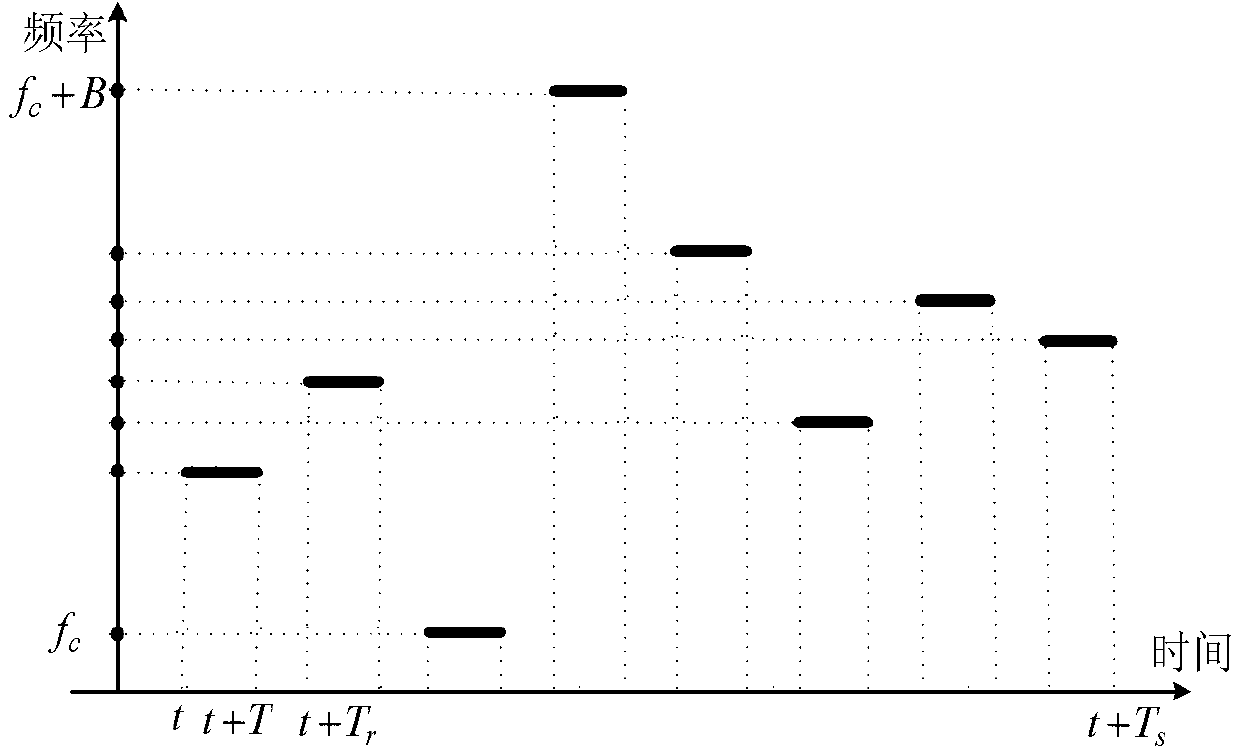

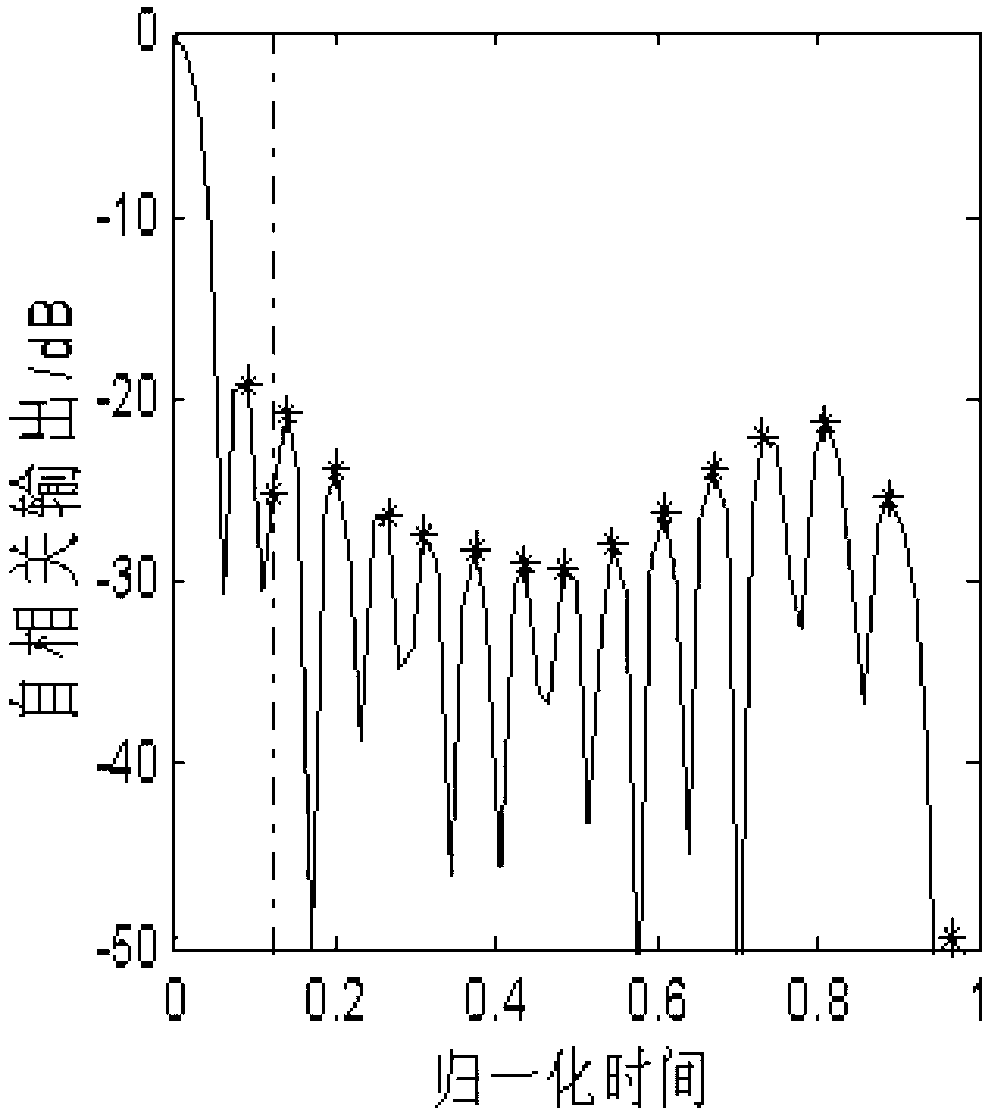

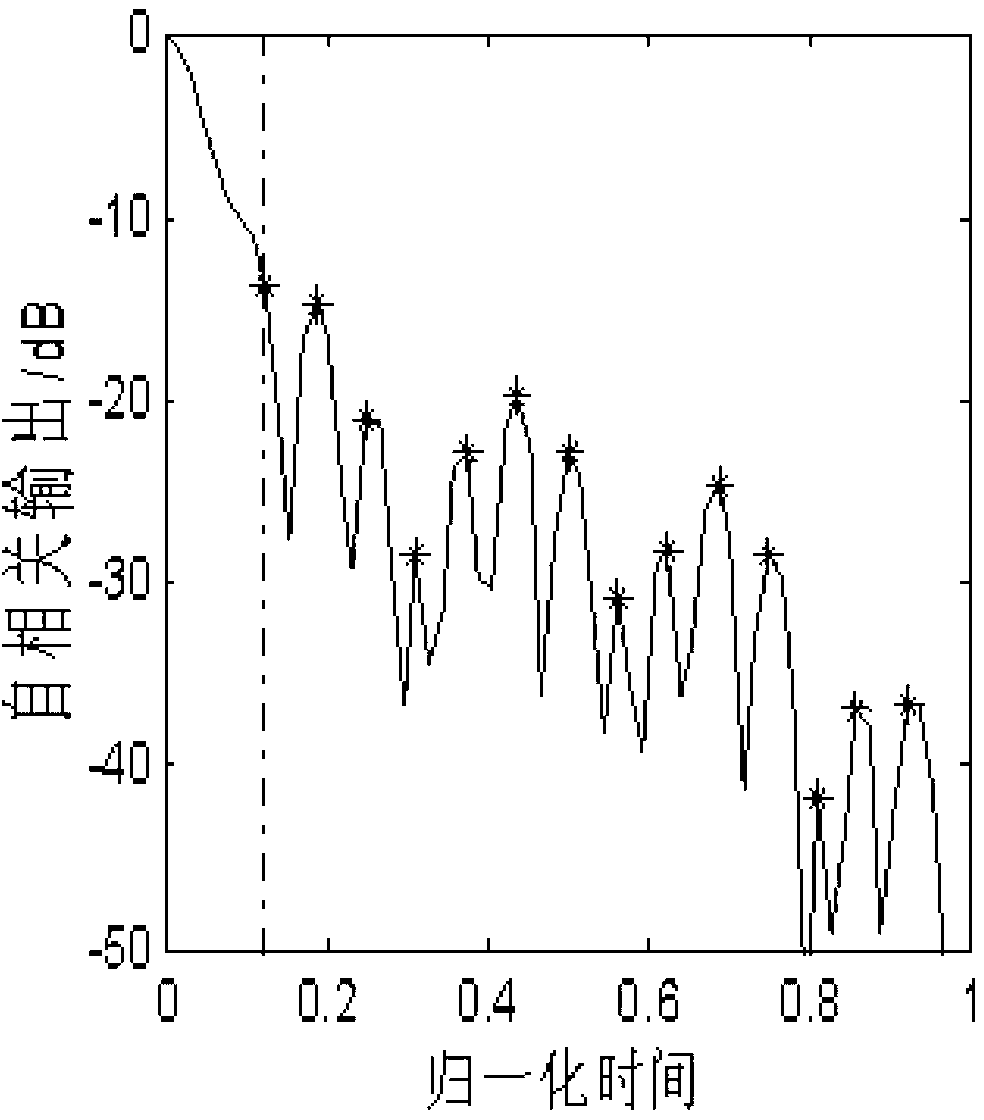

Modulation method of low sidelobe random frequency hopping pulse signal

InactiveCN103138799AFast convergenceAccurate and local precise optimization capabilityWave based measurement systemsTransmissionRandom frequency hoppingSelf correlation

The invention provides a modulation method of a low sidelobe random frequency hopping pulse signal, relates to the modulation method of a frequency hopping pulse signal and solves the problems existing in a traditional modulation method of the low sidelobe random frequency hopping pulse signal that local accuracy optimization ability is bad, the modulation speed of the random frequency hopping pulse signal is low caused by low convergence speed. According to the modulation method of the low sidelobe random frequency hopping pulse, a self-correlation function of the random frequency hopping pulse signal is derived, the self-correlation function is used to calculate a deviation function of the random frequency hopping pulse signal and calculate an initialization frequency combination, the initialization frequency combination is brought into the deviation function to obtain an optimal frequency combination, stochastic disturbance is added, and the deviation function is updated. The updated deviation function is detected, a moment corresponding to the maximum value point of the deviation function is used, according to a gradient theory, the frequency combination is conducted with a-stage frequency adjustment, until a difference value of deviation functions of two adjacent stages is smaller than a set threshold, the frequency combination update is stopped, and the random frequency hopping pulse signal modulation is completed. The modulation method of the low sidelobe random frequency hopping pulse signal is applicable to the field of signal modulation.

Owner:HARBIN INST OF TECH

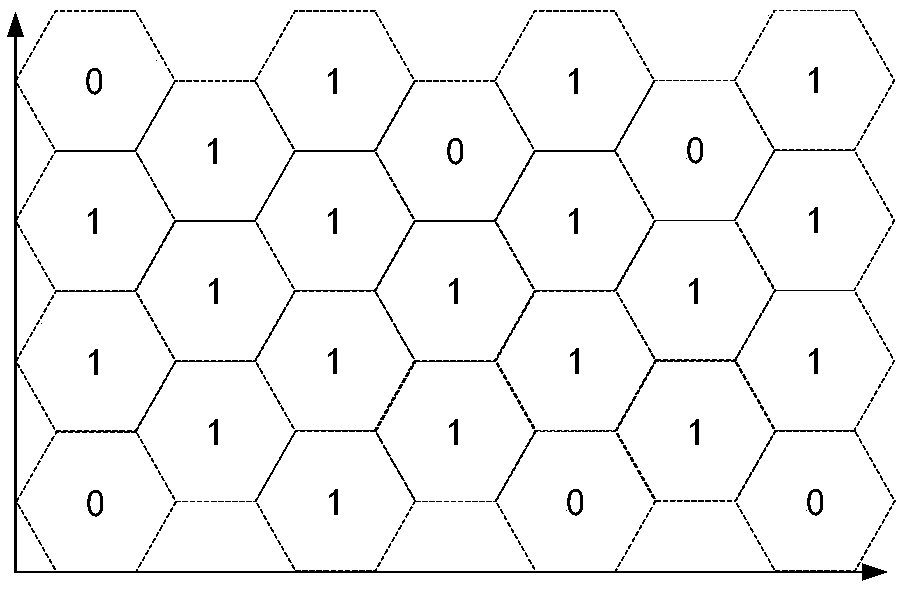

Mobile device limited space path generation method based on intelligent agent

ActiveCN109269518AEfficient movement directionGenerate accurate resultsInstruments for road network navigationSpace environmentSimulation

The invention discloses a mobile device limited space path generation method based on an intelligent agent, supporting a path generation problem of a mobile device in a limited space. The mobile device limited space path generation method based on the intelligent agent comprises the following steps: 1, space intelligent agent packaging: using a regular hexagonal grid to segment and package the space environment of the mobile device, and each grid acts as a space intelligent agent representing a spatial area; 2, mobile device intelligent agent packaging: simplifying the shape of the mobile device in movement to a circle, and defining a deviation function fgoal of the mobile device moving from a starting position to a target position; 3, building a path generation framework for multiple intelligent agents: describing the overall movement of each mobile device intelligent agent as a behavior of running toward the target and obstacle avoidance behaviors; and 4, determination of the path selected based on the space intelligent agent: defining a determination function generating the path of the mobile device intelligent agent, and selecting the next space intelligent agent according to the determination function; and 5, eliminating space intelligent agent conflicts: eliminating the space intelligent agent conflicts by using wait or bypass strategies.

Owner:BEIHANG UNIV

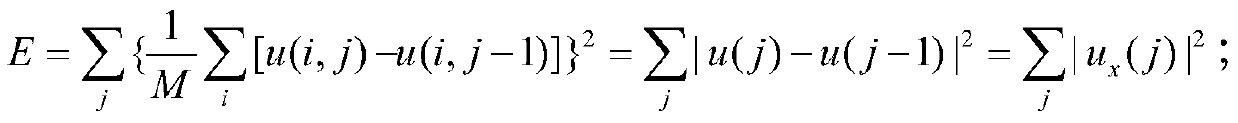

A method for eliminating stripe noise of an infrared image

PendingCN109903235AImprove image qualityEffective correctionImage enhancementPattern recognitionImaging quality

The invention discloses a method for eliminating stripe noise of an infrared image. The method comprises the following steps of: 1, acquiring an original infrared single-frame image containing columnstripe noise; 2, establishing a deviation function between column stripe noises of adjacent columns in the original infrared single-frame image according to the original infrared single-frame image; Step 3, minimizing the deviation function, and estimating the noise value of the column stripe noise of each column by using a recursion mode; And 4, subtracting the estimated noise value of the columnstripe noise of each column from the original infrared single-frame image containing the column stripe noise so as to correct the original infrared single-frame image and obtain the infrared single-frame image without the stripe noise. According to the method for eliminating the stripe noise of the infrared image, the stripe noise existing in the infrared single-frame image can be effectively corrected in time, the image quality of the finally obtained infrared single-frame image is improved, and great practical significance is achieved.

Owner:TIANJIN UNIV

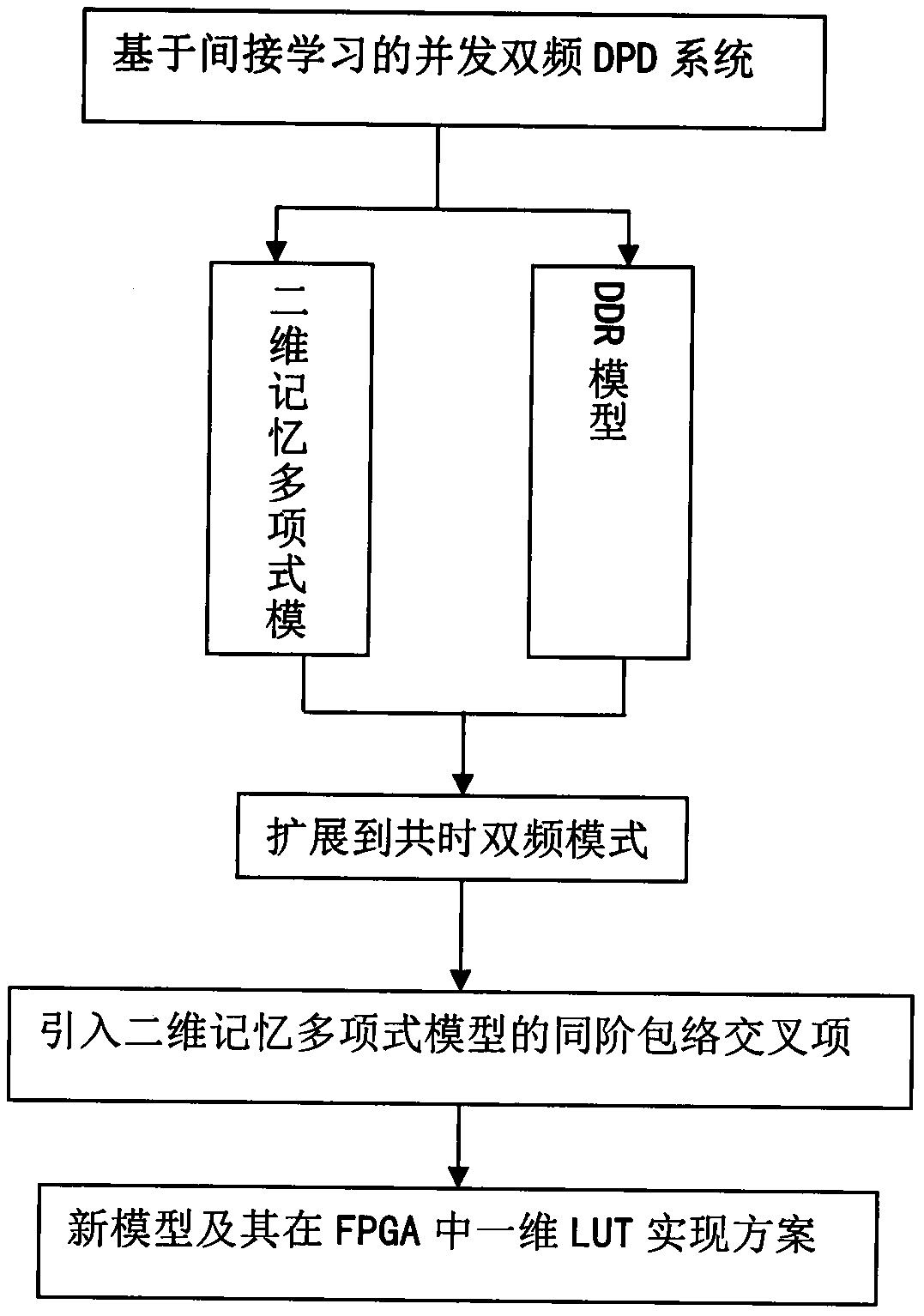

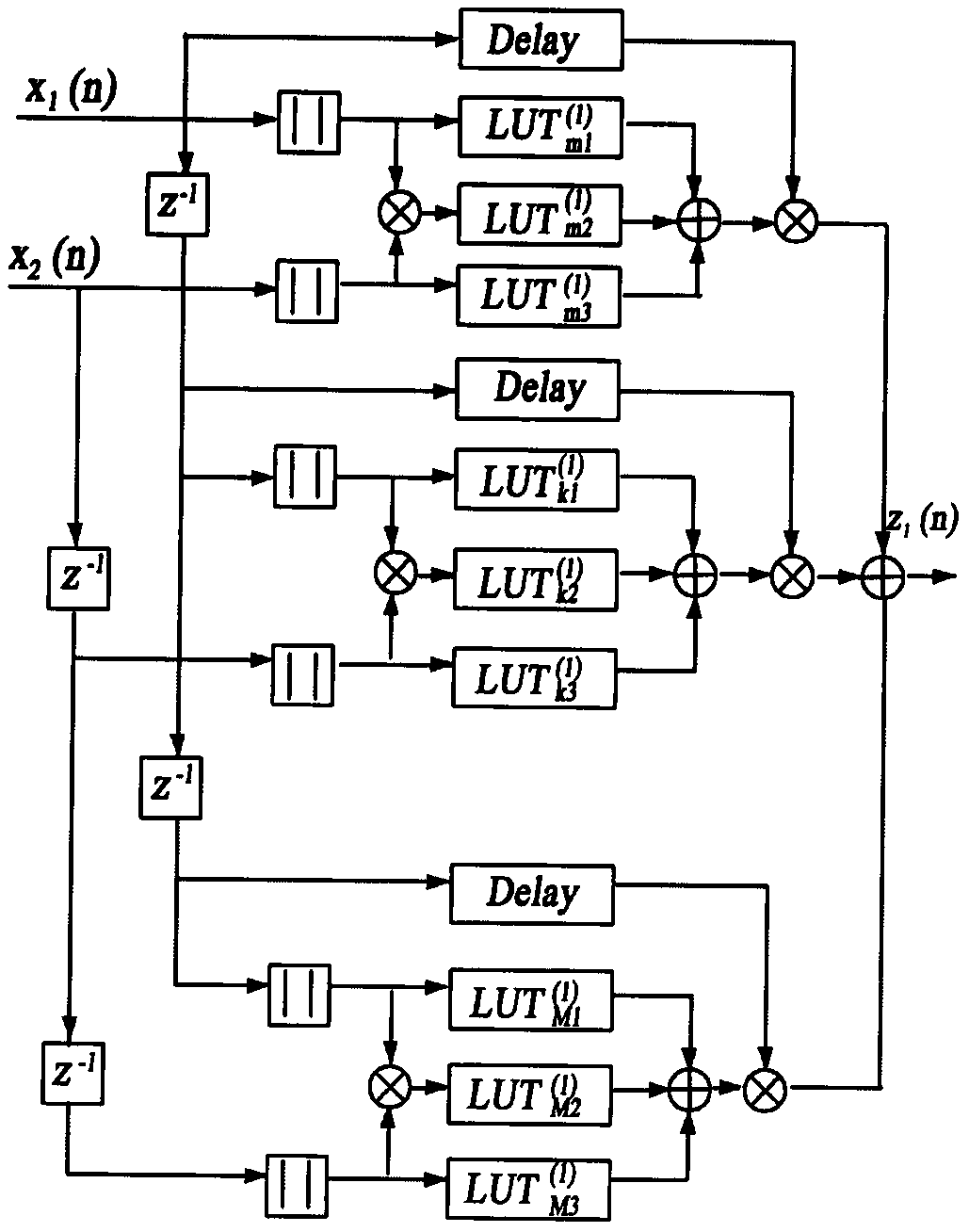

Mixed double-frequency digital pre-distortion model method based on DDR

InactiveCN107895074ACompensation for Nonlinear Intermodulation DistortionImprove modeling accuracyComplex mathematical operationsModel methodSimulation

The invention provides a mixed double-frequency digital pre-distortion model method based on the DDR. The method includes the following steps that a concurrent double-frequency DPD system based on indirect learning is built; an operation sequence is optimized, a one-dimensional LUT achievement model of the 2D-MP is obtained, a one-dimensional LUT achievement model of 2D-MMP is derived, and then aone-dimensional LUT high-frequency concurrent double-frequency DPD achievement scheme and a model are provided; a dynamic deviation function is substituted into a one-order model of the DDR, and a discrete equivalent baseband expression of the one-order DDR model is obtained and extended to be in a synchronic double-frequency mode; a two-dimensional memory polynomial model same-order envelope cross term is introduced, and a new model and a one-dimensional LUT achievement method of the model in an FPGA are obtained. According to the method, the modeling accuracy and the linearization performance better than a simplified two-dimensional memory polynomial model and a traditional DDR model can be obtained; meanwhile, the advantage that achievement can be conveniently conducted through a one-dimensional lookup table is kept, the new model has a good level in the aspects of performance and complexity, and the method is suitable for practical system applying.

Owner:CHONGQING VOCATIONAL INST OF ENG

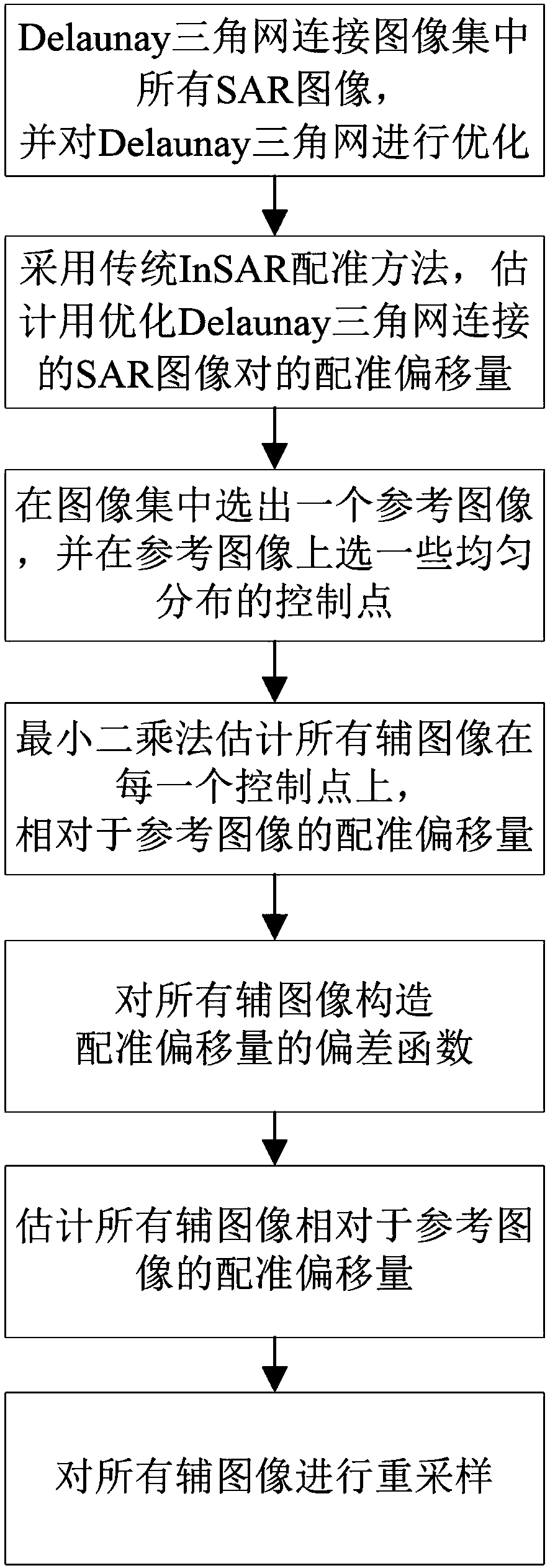

Multi-image joint registration method based on least square estimation

The invention discloses a multi-image joint registration method based on least square estimation. The method solves the problem of improving multi-image registration precision in signal processing ofPS-InSAR and the like, and includes the realization steps of: using Delaunay triangulation to connect all SAR images in an image set, and optimizing the Delaunay triangulation; using an InSAR registration method to estimate registration offsets of already connected SAR image pairs; selecting a reference image in the image set, and selecting certain uniformly-distributed control points on the reference image; using a least square method to estimate registration offsets of all auxiliary images relative to the reference image at each control point; constructing deviation functions of all the auxiliary-image registration offsets, and estimating registration offsets of all the auxiliary images relative to the reference image; and carrying out re-sampling on all the auxiliary images by the offsets to complete multi-image joint registration. The method significantly mitigates time and space decoherence and error propagation effect impacts, improves multi-image joint registration precision, ishigher in a region coincidence degree of the reference image and the auxiliary images at the same pixel, and can be used for signal processing of the PS-InSAR and the like.

Owner:XIDIAN UNIV

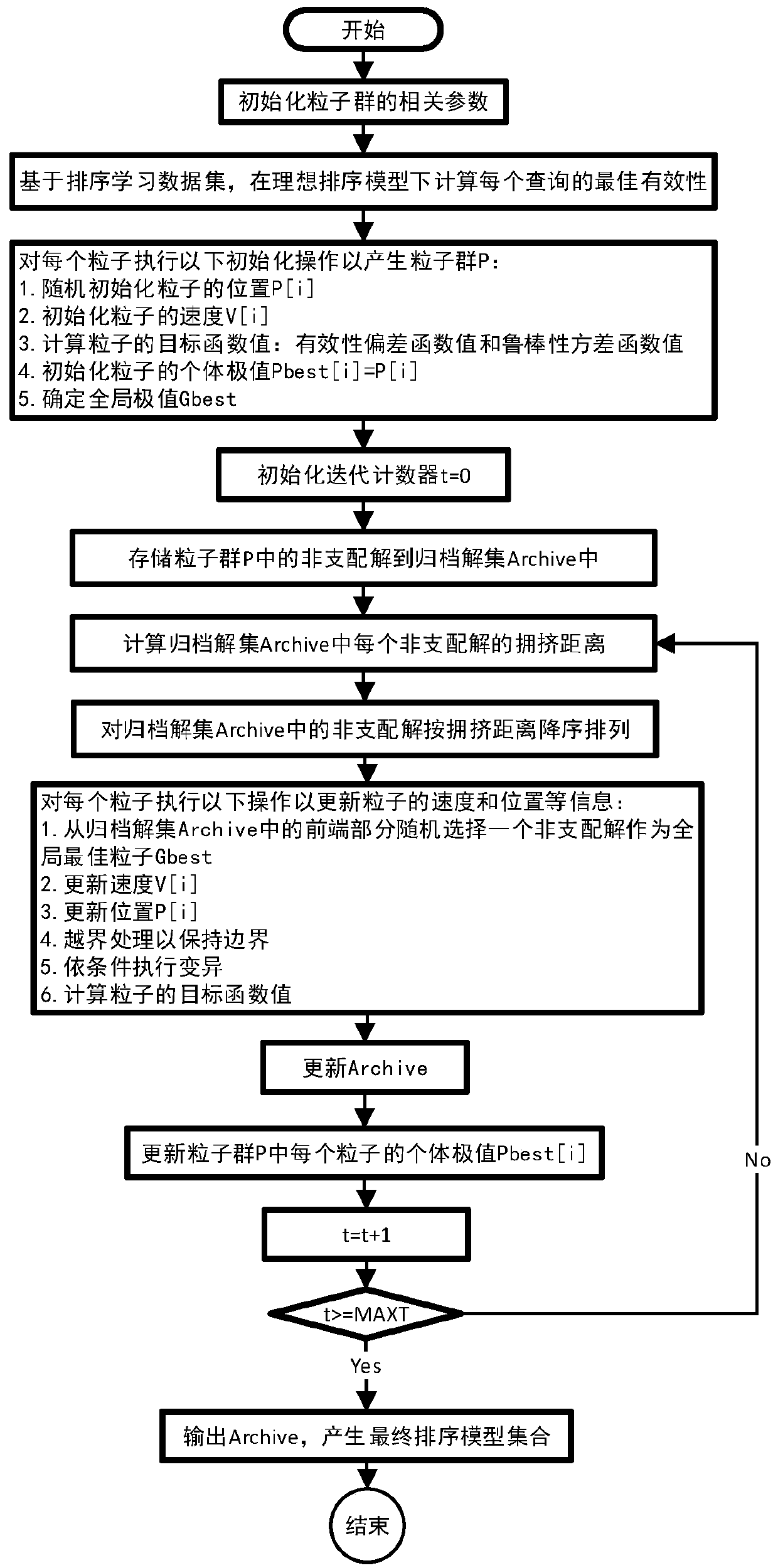

Robustness sorting learning method based on multi-objective particle swarm optimization and application thereof

ActiveCN110046713ANew method for ranking learningImprove experienceDigital data information retrievalArtificial lifeData setPerformance index

The invention relates to a robustness sorting learning method based on multi-objective particle swarm optimization and an application thereof, and the method comprises the following steps of 1, designing an effective deviation function and a robustness variance function of a sorting model based on a deviation-variance equalization theory, and constructing two optimization performance indexes of sorting learning; step 2, on the basis of a multi-objective particle swarm optimization algorithm framework, iteratively optimizing the two objectives of the effectiveness deviation function and the robustness variance function of the sorting model on the sorting learning data set to train the sorting model so as to generate a sorting model archiving solution set; and step 3, selecting a Pareto optimal sorting model with a maximum net flow sorting value from the sorting model filing solution set generated in the previous step as a trained final sorting model based on the idea of a preference sequence structure assessment method PROMEHEE II in a multi-attribute decision theory. Compared with the prior art, the method has the advantages of improving the overall user satisfaction, enhancing theuser experience and the like.

Owner:JINGGANGSHAN UNIVERSITY

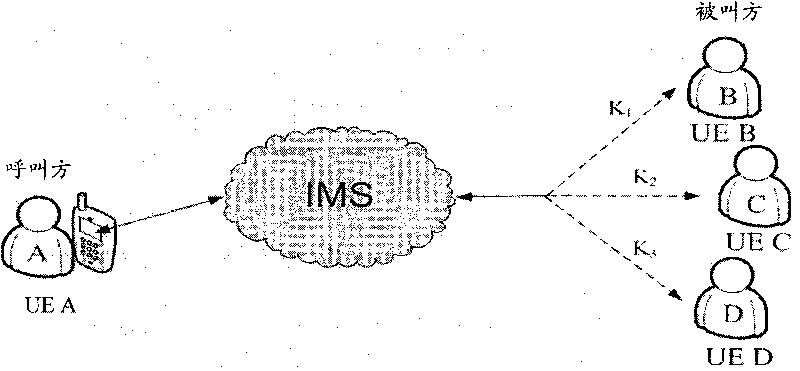

Method and system for realizing safe bifurcation call session in IP multimedia subsystem

InactiveCN101719825AAlleviate storage and computing requirementsReduce computational processing pressureKey distribution for secure communicationInterconnection arrangementsKey-agreement protocolDeviation function

The invention provides a method and a system for realizing a safe bifurcation call session in an IP multimedia system. In the invention, based on Otway Rees key agreement protocol, a key agreement system is provided and is enabled to realize the safe bifurcation call session in the IP multimedia subsystem (IMS). When a called party receives a call, a slave calling key management server (KMS) acquires a media root key K used for deriving media keys; then based on a random number and the media root key K which are derived by each called party, each called party and each calling party can derive a media key respectively by utilizing a media key deviation function (KDF). The media key of each called party is unique and cannot be learned by other terminals, thereby realizing media safety of the bifurcation call session. The invention has simple logic, reduces computing and processing pressure of the calling party, interacts less with a KMS signaling, relieves storage and computation requirements for the KMS, and excellently provides the safety protection for ensuring the bifurcation call session for the IMS.

Owner:ZTE CORP

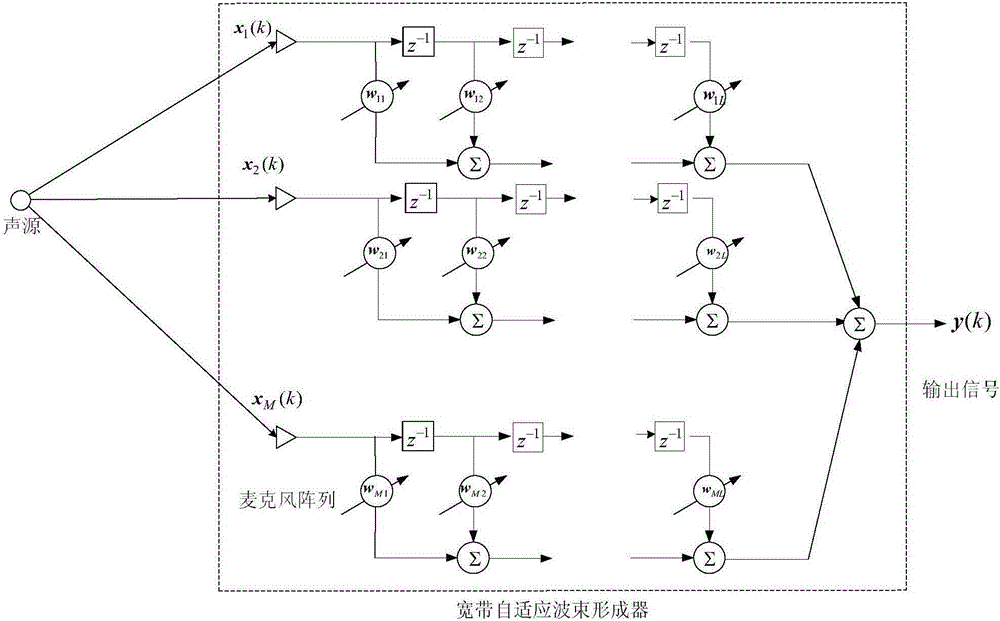

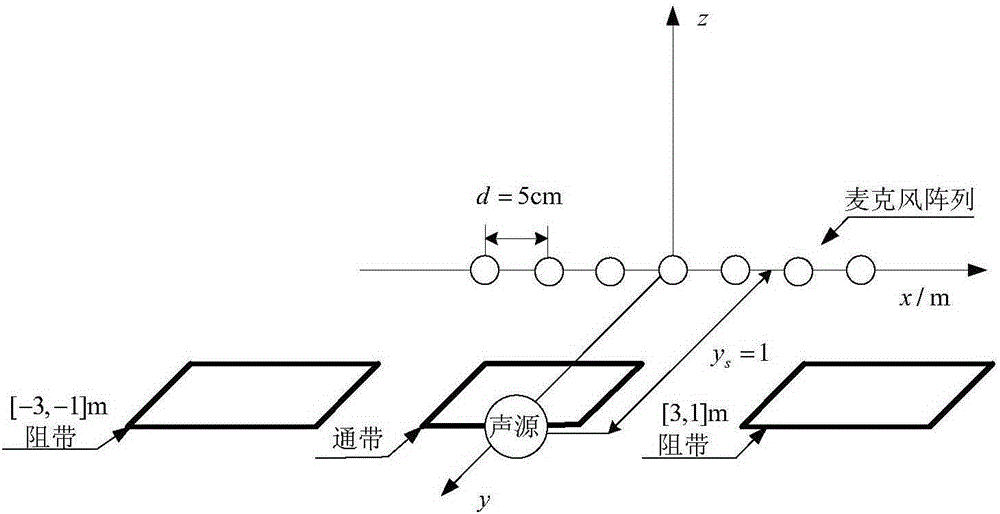

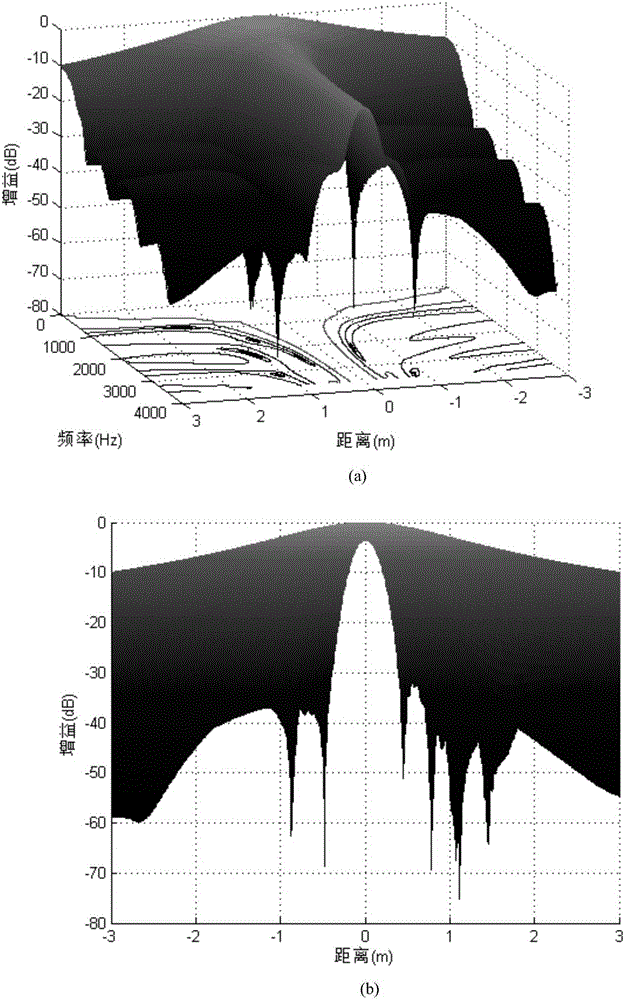

Near-field linear constrained minimum variance adaptive weighted-frequency-invariant beam forming method

ActiveCN105223544AStructure without limitGood near-field broadband frequency invarianceSystems with undesired wave eliminationInteraction systemsVoice communication

The invention discloses a near-field linear constrained minimum variance adaptive weighted-frequency-invariant beam forming method. The method is based on linear constrained minimum variance. A balance matrix of an array spatial response bias function is defined based on the spatial response bias function, and the matrix is introduced into a near-field linear constrained minimum variance beam forming method to obtain the near-field linear constrained minimum variance weighted-frequency-invariant beam forming method. Then, the weighting coefficient in the near-field linear constrained minimum variance weighted-frequency-invariant beam forming method is defined as a function of the field spot distance and the signal frequency, and the function is dynamic and is updated adaptively. The method of the invention is widely applied to multi-channel speech enhancement, man-machine voice interaction systems, hearing aids, vehicular hands-free voice communication, remote video conferencing systems, robot hearing, and other fields.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

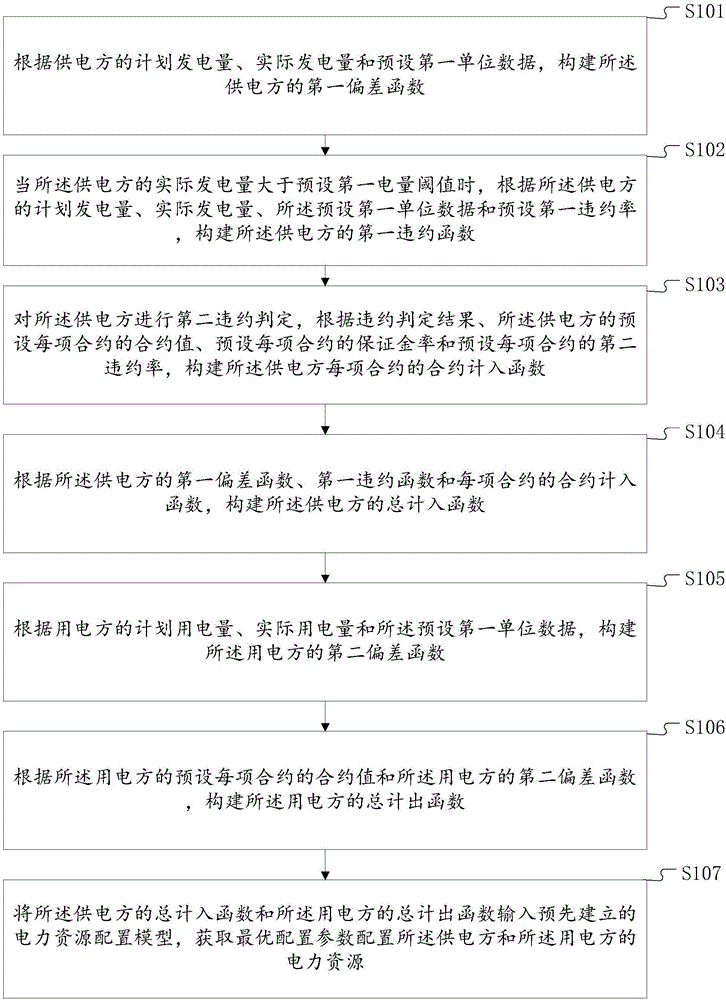

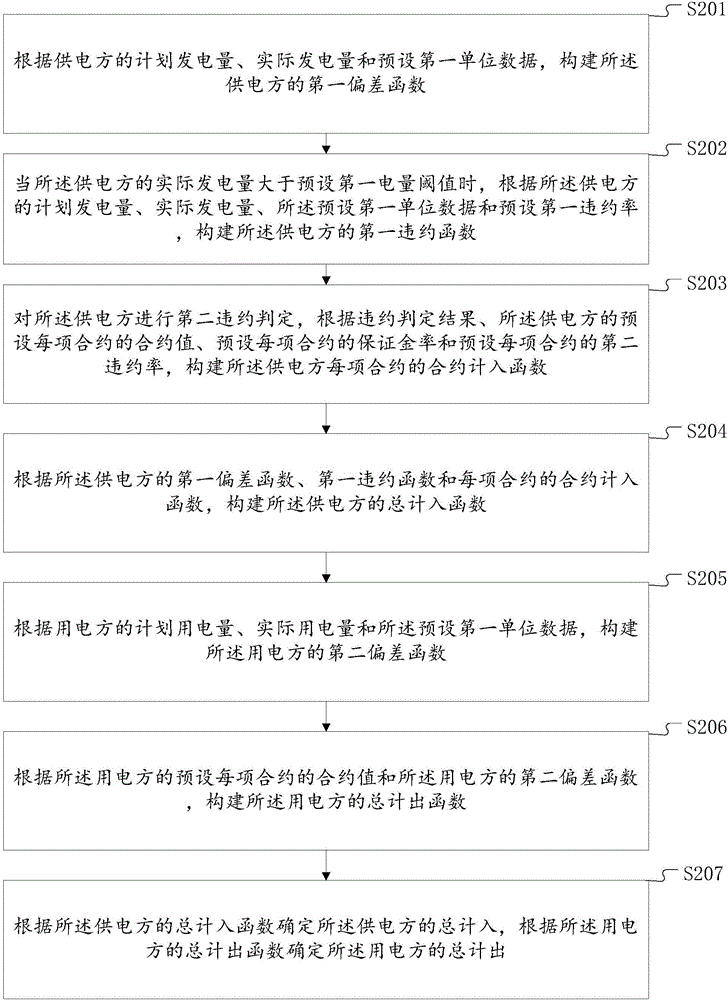

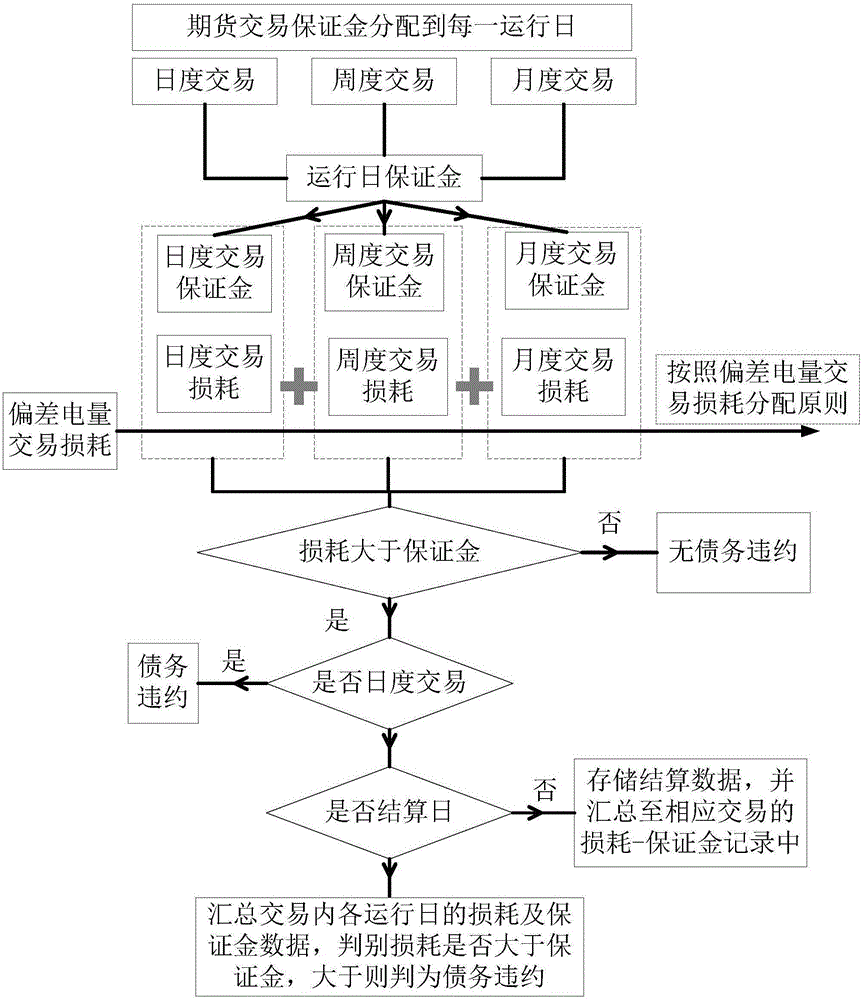

Method and system for power grid resource configuration, and input-and-output metering method and system for power grid resource configuration

InactiveCN106296455ARealize reasonable configurationMeet development needsResourcesDefault ratePower grid

The invention discloses a method and a system for power grid resource configuration, and an input-and-output metering method and system for power grid resource configuration. The power grid resource configuration method comprises steps that a first power supply party deviation function is constructed according to a power supply party plan,actual generating capacity and the first preset unit data; a first default function is constructed according to a first preset default rate; a contract input metering function of each contract of a power supply party is constructed according to a second default determination result of the power supply party, a preset contract value of each contract, a guarantee fund rate and a second default rate; a main power supply party input metering function is constructed according to the functions of the previous steps; a second electricity user party deviation function is constructed, and a main electricity user party output metering function is constructed according to a preset contract value of each contract of an electricity user party; the main power supply party input metering function and the main electricity user party output metering function are written into an electric power resource configuration model, and optimal configuration parameters are acquired for configuring electric power resources of the power supply party and the electricity user party. The method is advantaged in that the electric power resources of the power supply party and the electricity user party are reasonably configured, and development demands of the electric power industry are satisfied.

Owner:POWER GRID TECH RES CENT CHINA SOUTHERN POWER GRID +1

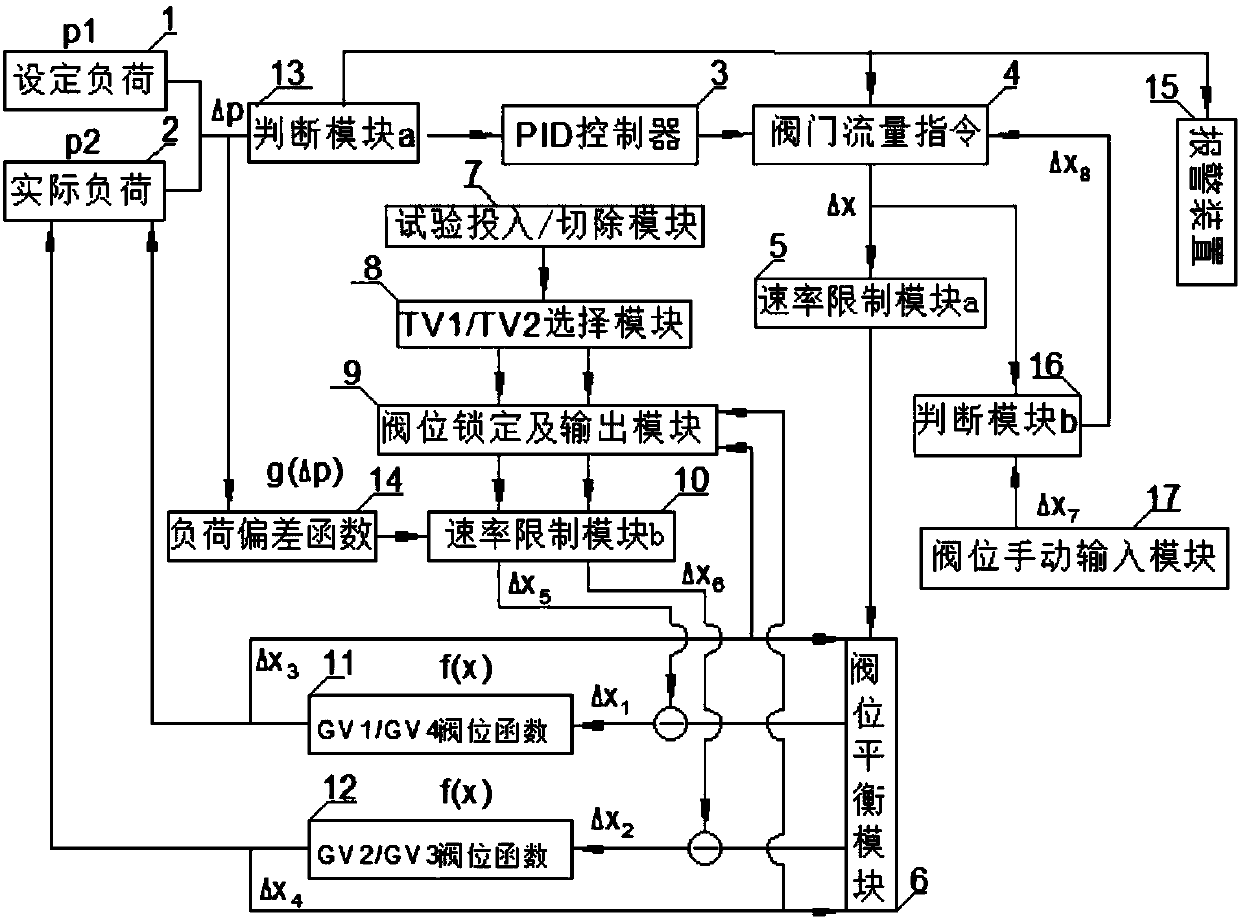

Method for prevention of generation of power oscillation in main stop valve full-stroke test of steam turbine

The present invention discloses a method for prevention of generation of power oscillation in a process of a main stop valve full-stroke test of a steam-turbine generation steam turbine. On the basisof the prior art, a determination module a and an alarm device are added to achieve removal of a power control loop, effectively prevent a unit from generating power fluctuation and power oscillationad emit an acousto-optic alarm after a steam turbine set is large in load deviation; a load deviation function is added to achieve that a high-pressure control valve can be switched on and off at variable speeds and reduce a small steam turbine load fluctuation amplitude; and a determination module b and a valve location manual input module are added to achieve a unit valve location maintenance function and a manual input valve location value function and effectively prevent the unit to generate power fluctuation and power oscillation. The method for prevention of generation of power oscillation in a main stop valve full-stroke test of a steam turbine provides a great guarantee for normal and smooth performing of the main stop valve full-stroke test of the steam turbine, and effectively reduces operators' burden.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Method for designing real number domain smooth time varying Sylvester equation solver

InactiveCN107346299AFast Approximation Problem Correct SolutionAccurately approximate the correct solution of the problemComplex mathematical operationsPhysical systemDomain variable

The invention discloses a design method of a smooth time-varying Sylvester equation solver in the real number field, which comprises the following steps: 1) formulating an actual physical system or a numerical solution system, and establishing the smooth time-varying Sylvester equation in the real number field of the system; 2) Deriving the time-varying parameter matrix of the time-varying Sylvester equation of the system in step 1) in the time domain to obtain the time derivative of the time-varying parameter matrix; 3) according to the time-varying Sylvester equation of the system, design the system's Deviation function equation; 4) According to the system deviation function equation, the time-varying Sylvester equation of the system is designed by using the monotonically increasing odd activation function through the real number field variable parameter convergence differential neurodynamics method and the obtained time-varying parameter matrix and its time derivative 5) The network state solution obtained by solving the time-varying Sylvester equation solver is the only optimal solution of the time-varying Sylvester equation. The method can quickly and accurately approach the correct solution of the problem, and can well solve various time-varying problems.

Owner:SOUTH CHINA UNIV OF TECH

Method for implementing modularized process by utilizing functional element program for numerical control press

InactiveCN101424937AMeet customized needsReduced need for customizationProgramme controlComputer controlGraphicsNumerical control

The invention relates to a processing method of a numerical control machine, in particular to a method of the numerical control machine utilizing a subprogram to realize the modularization processing. The method comprises the steps as follows: firstly, processing environment and program of each processing procedure are solidified and built in a database; when parts are processed, different subprograms are transferred to optimize and combine a complete processing procedure through the display of a menu, required graphs are moved to the appointed position through the deviation function, the required graphs are validated through the drawing function of programming software, thereby the quality of the object is ensured; according to the shape of a workpiece, the processing size, the thickness and the material of the panel, and the allocation information of the cutter, the same 0 point is adopted to be used as a programming origin, a new program is built, the required subprograms are deviated to the processing position and are verified through graph software, and a first workpiece is processed and goes into mass production after being mutually detected. The invention has simple programming, high precision, flexible operation and combination and allocation of modules, and can create products with different demands so as to meet the customized requirements of customers.

Owner:CRRC TANGSHAN CO LTD

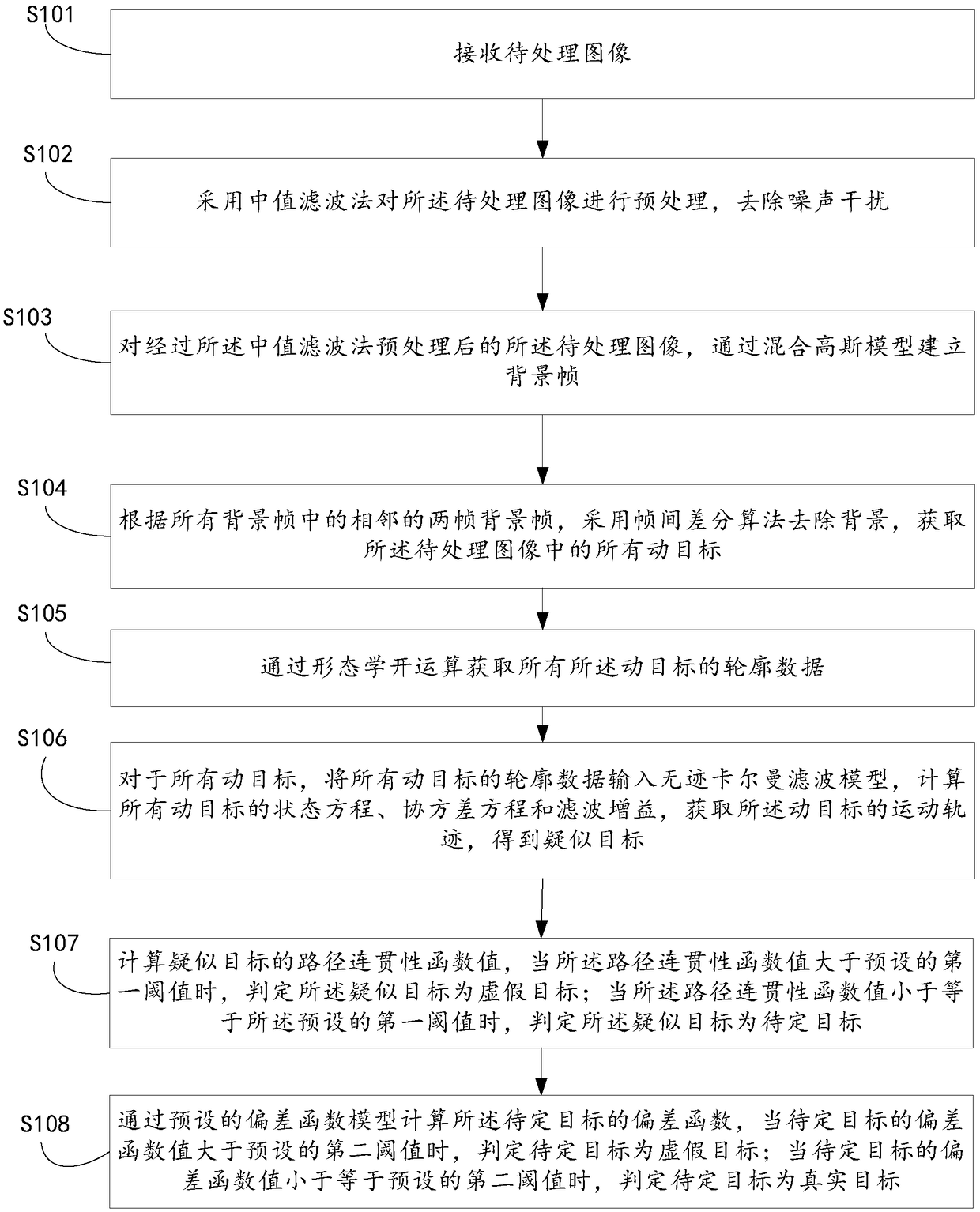

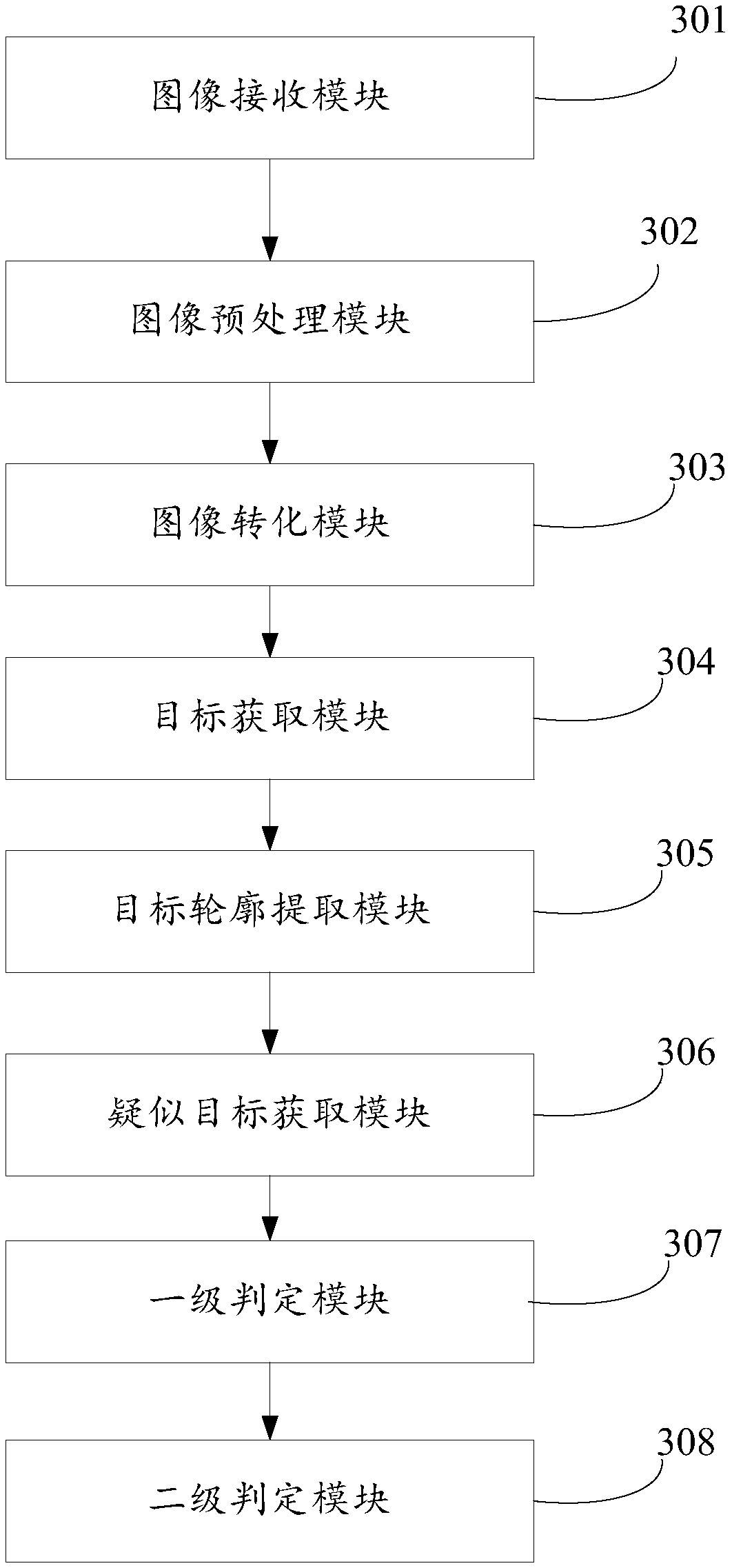

Target tracking method and device in starry sky background based on path coherence function

InactiveCN109063602AMeet real-time requirementsReduce false alarm rateImage analysisScene recognitionFrame differenceSky

The invention discloses a target tracking method and a device under a starry sky background based on a path coherence function. The method comprises the following steps: receiving an image to be processed; The median filter method being used to process the image to remove noise interference. The background frame is established by mixed Gaussian model. Adopting frame difference algorithm to removebackground and obtain all moving targets in the image to be processed; Obtaining the contour data of all moving objects by morphological open operation; The contour data of all moving targets are input into the unscented Kalman filter model to obtain the moving trajectory of the moving targets and the suspected targets. Calculate the value of path coherence function of the suspected target, and exclude the false target according to the value of path coherence function; Calculating the deviation function of the target to be determined, and further eliminating the false target; Achieving real goals; The invention can improve the accuracy of target tracking.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

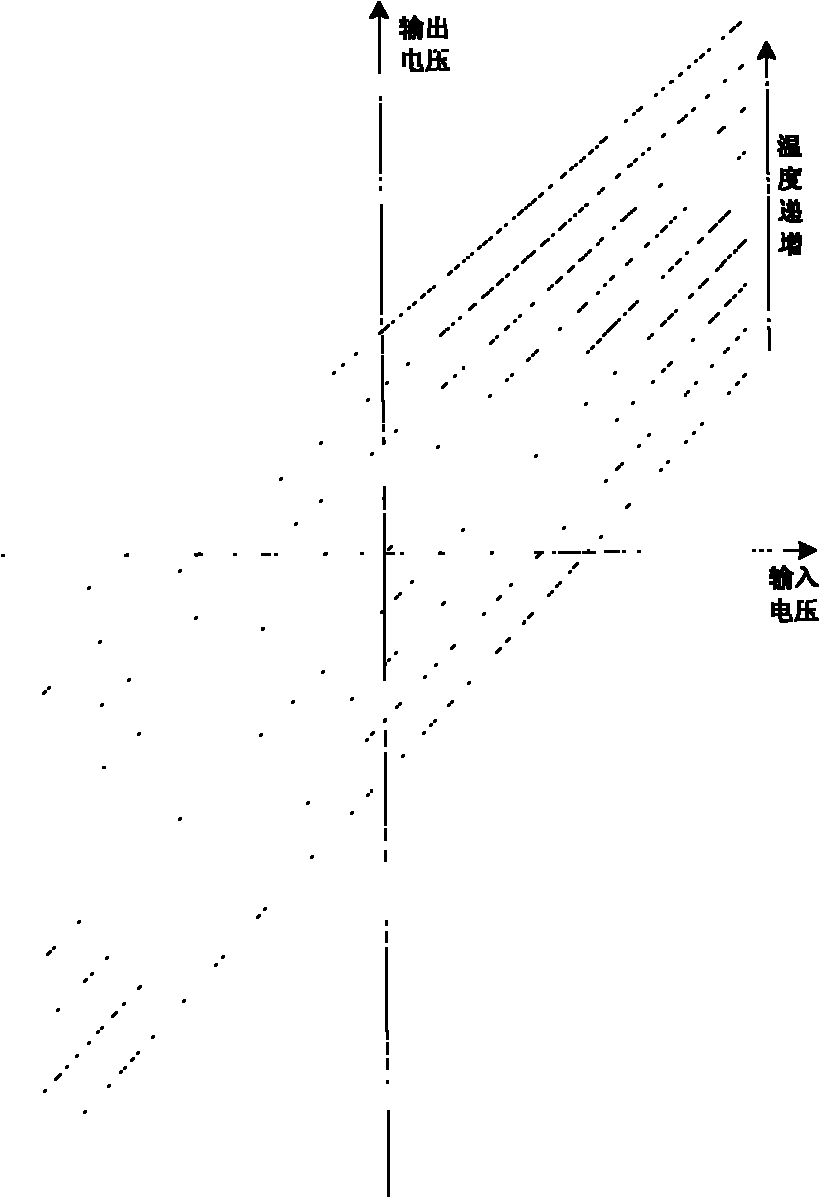

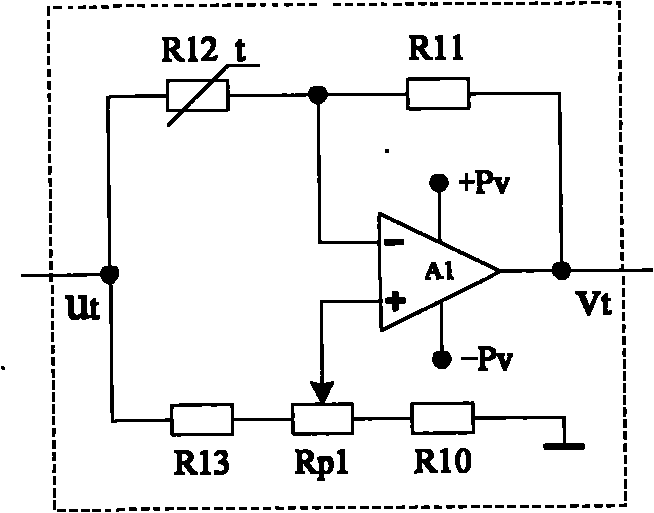

Temperature deviation function generators, zero and multiplying factor temperature deviation adjusters and universal temperature compensator

InactiveCN101860349AEasy to tuneSimple structureElectric pulse generatorAutomatic controlAudio power amplifier

The invention relates to temperature deviation function generators, zero and multiplying factor temperature deviation adjusters and a universal temperature compensator, and belongs to the technical fields of signal conversion, automatic control and measurement. The temperature deviation function generator is composed of an operational amplifier, a thermal element, resistors, a potentiometer and the like. The adjustable multiplying factor temperature deviation generator is composed of a temperature deviation function generator and a gain adjustable amplifier. The adjustable zero temperature deviation generator is composed of a temperature deviation function generator or an adjustable amplification factor temperature deviation generator. The zero temperature deviation adjuster is composed of a zero conditioning circuit and an adjustable zero temperature deviation generator. The multiplying factor temperature deviation generator is composed of an multiplying factor conditioning circuit and an adjustable multiplying factor temperature deviation generator. The universal temperature compensator is composed of a zero temperature deviation adjuster and a multiplying factor temperature deviation generator. The temperature deviation function generator and the temperature compensator are matched with different processing circuits through the devices with different thermosensitive characteristics so as to realize multiple temperature compensation characteristics, thereby meeting the requirements for multiple measurement and control circuits or devices.

Owner:SHANGHAI UNIV

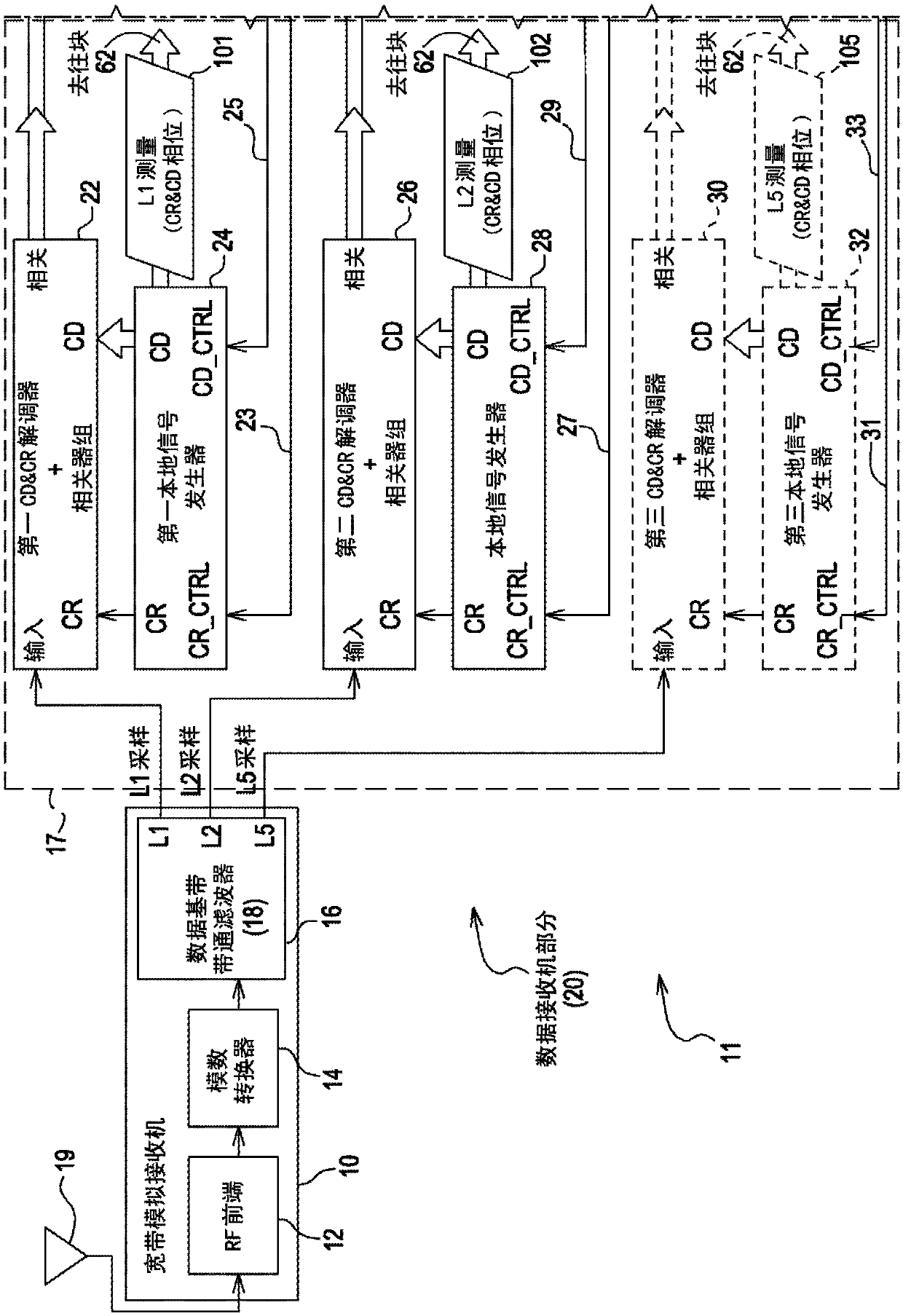

Satellite navigation receiver with fixed point sigma rho filter

ActiveCN108027442AEasy to implement digitallyReduce computing loadSatellite radio beaconingCarrier signalCorrelation function

A multi-band satellite navigation receiver (11) for carrier and code tracking using a fixed point sigma rho filter (42) with improved stability is described. The receiver (11) simplifies and speeds upthe data processing in the filter (42) to adaptively accommodate common information from aggregate bands and obtain the accurate position of the receiver (11) in real time. The filter (42) may utilize a standard deviation function and a cross correlation function while determining adaptive scale factors to ensure that the filter (42) is stable and reliable.

Owner:DEERE & CO

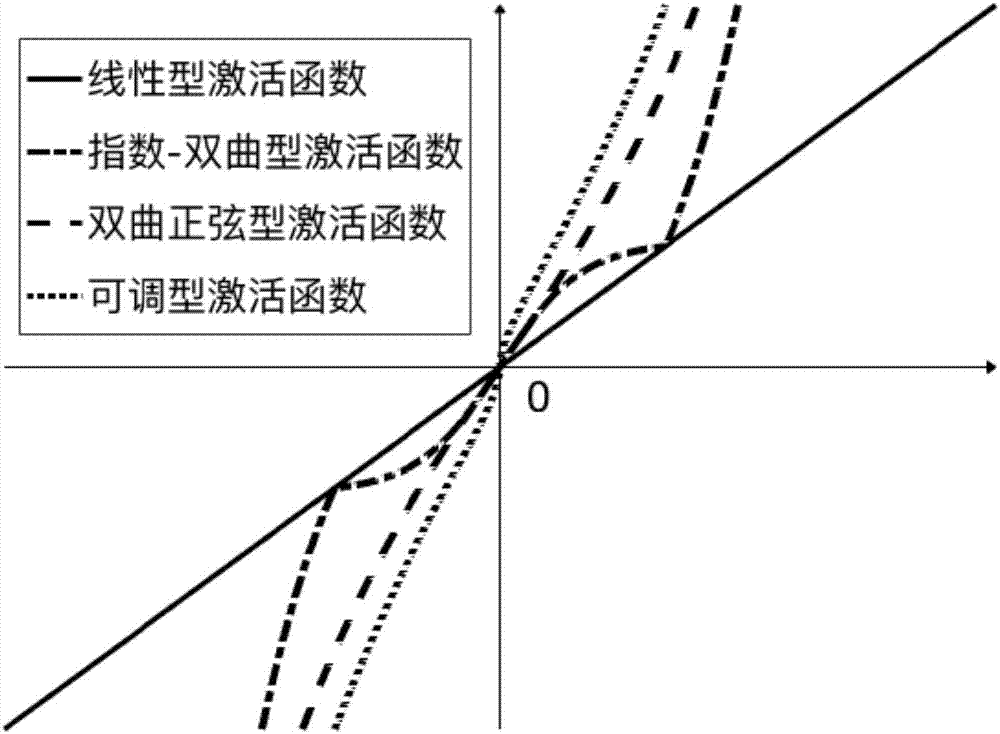

Neurodynamic method for solving noise-containing time-varying problem

The invention discloses a neurodynamic method for solving a noise-containing time-varying problem. The method includes the following steps that: 1) the time-varying quadratic programming problem modelof an actual physical system is established; 2) optimal value optimization is performed on the time-varying quadratic programming problem model, partial derivative information about an optimal solution and Lagrangian multiplier are obtained; 3) the partial derivative information is transformed into a standard time-varying matrix form; 4) a deviation function is designed; and 5) a power type parameter-varying recursive neurodynamic method and four common activation functions are used to design a power type neurodynamic method of the noise-containing time-varying problem in the real-number field, and an obtained solution is the optimal solution of the time-varying quadratic programming problem. According to the neurodynamic method of the invention, on the basis of the parameter-varying recursive neurodynamic method, a global convergence characteristic is realized when the common monotonically increasing odd activation functions are adopted to solve the noise-containing time-varying problem, and error can converge to zero at a superexponential velocity, and therefore, calculation speed can be greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

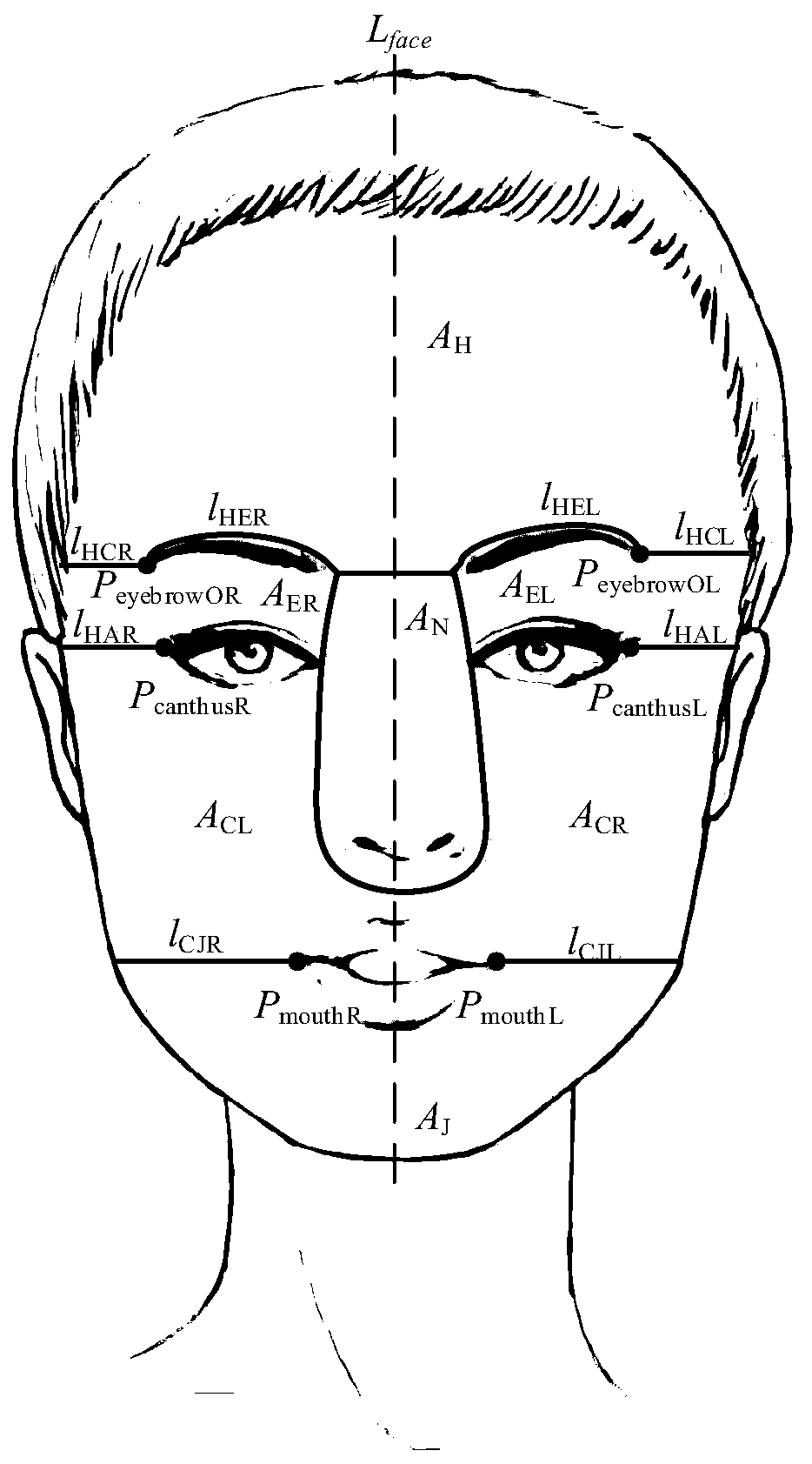

Skin problem diagnosis method based on deep learning face partitioning

ActiveCN110472605AImprove applicabilityGuaranteed real-timeHealth-index calculationCharacter and pattern recognitionOrbital AreasPattern recognition

The invention discloses a skin problem diagnosis method based on deep learning face partitioning. The method comprises the steps that multiple face images are collected, faces are marked according toseven partitions including a forehead area AH, a left orbital area AEL, a right orbital area AER, a nose bridge area AN, a left cheek area ACL, a right cheek area ACR and a jaw area AJ, and a face partition marking data set is formed; a deep learning instance segmentation model is trained on the human face partition annotation data set to enable three deviation functions, namely partition classification cross entropy LCrossEntropy, partition outer frame positioning accuracy function LDetect and partition pixel classification accuracy LMask, to have minimum values; a face region is segmented byusing the trained instance segmentation model, and that a skin problem exists in each partition is determined; a skin problem is diagnosed according to the regional priori knowledge, and a corresponding treatment scheme is given. According to the method, the skin problem diagnosis for human face partitioning is realized, the applicability is good, and an intelligent skin problem partitioning classification diagnosis and treatment scheme is provided on the premise of ensuring the real-time performance.

Owner:广州纳丽生物科技有限公司

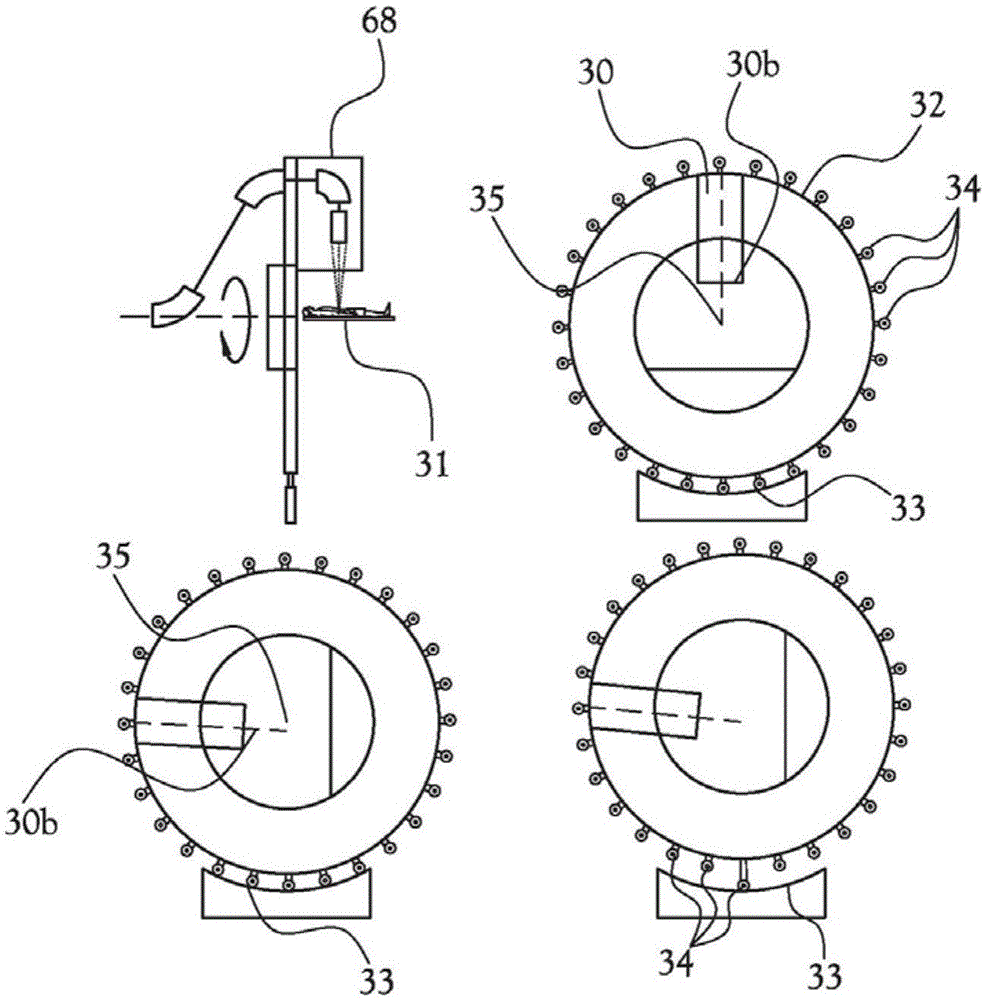

Systems and methods of adjusting rotating gantry system

ActiveCN105797281AConvenient careGuaranteed accuracyX-ray/gamma-ray/particle-irradiation therapyProtonEngineering

Owner:PRONOVA SOLUTIONS

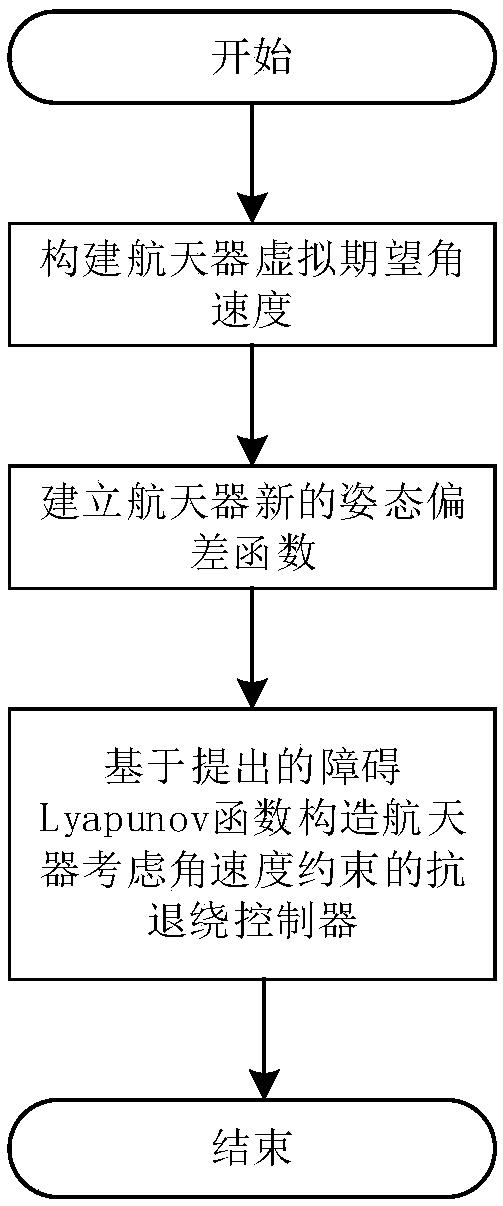

Spacecraft attitude anti-unwinding control method considering angular velocity constraint

ActiveCN108415444AAttitude anti-unwinding control implementationAvoid the disadvantage of requiring a large control input in the initial stageCosmonautic vehiclesCosmonautic partsSpacecraft attitude controlAngular velocity

The invention provides a spacecraft attitude anti-unwinding control method considering angular velocity constraint. The method comprises the steps of (1) considering spacecraft attitude control and constructing a virtual desired angular velocity, (2) constructing a new anti-unwinding attitude deviation function based on the virtual desired angular velocity established in the first step to realizethe processing of a spacecraft unwinding problem, and (3) establishing a new obstacle Lyapunov function based on the first step and the second step and designing a spacecraft attitude anti-unwinding controller in the condition of considering the angular velocity constraint on the above basis. According to the method, a spacecraft attitude maneuvering process with the angular velocity constraint and an unwinding factor is considered, the angular velocity of a spacecraft is maintained within an actual constraint range, the problem of unwinding does not occur, a useless extra rotation path of thespacecraft is avoided, and thus the control method has good practicability.

Owner:BEIHANG UNIV

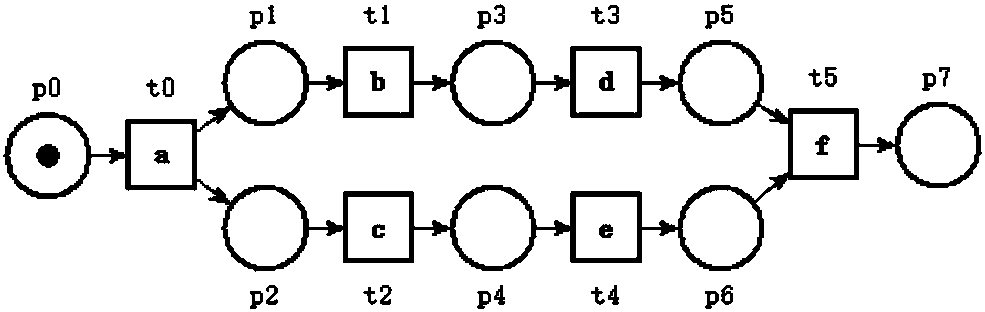

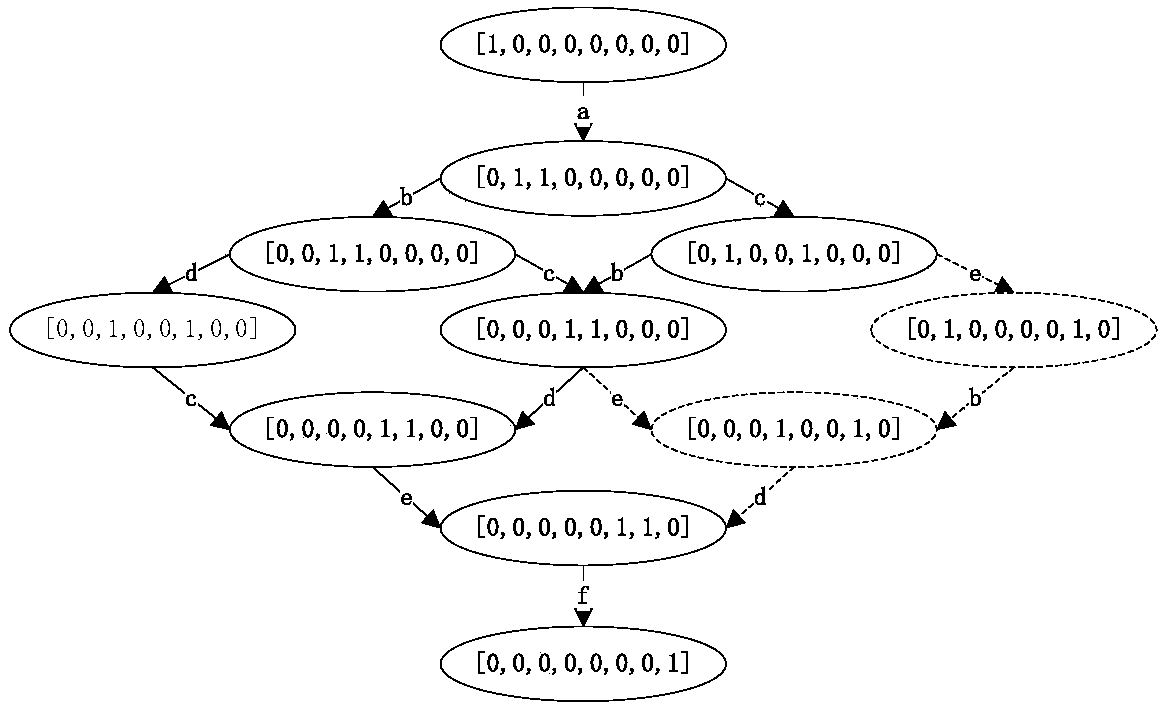

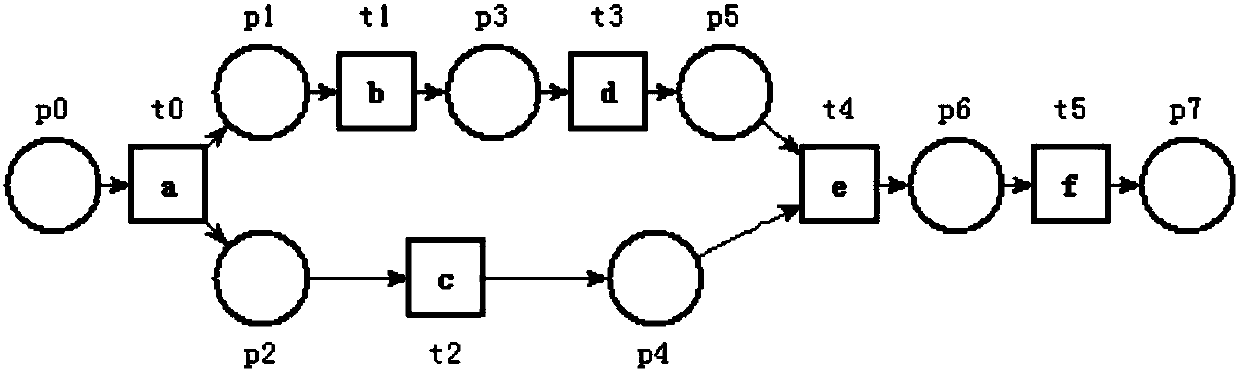

Deviation reduction-based big data transaction model analysis and restoration method

ActiveCN108399284AReasonable designGood effectDesign optimisation/simulationOffice automationRestoration methodValidation methods

The invention discloses a deviation reduction-based big data transaction model analysis and restoration method, and belongs to the field of business process management. The method specifically comprises the following steps of discovering a deviation set Rd between event logs and a model through a reachable marking graph-based deviation discovery method; and according to the deviation set Rd, obtaining an adjacent side relationship difference set Rp, and obtaining an adjacent side relationship difference sequence set PS. Through the deviation reduction-based model restoration method, effectivedeviation-based model restoration is realized; and a restoration result is subjected to model fitting degree, accuracy, conciseness and time complexity assessment to verify the validity of the method.

Owner:SHANDONG UNIV OF SCI & TECH

Crude oil blending optimization method

ActiveCN102643662BAvoid damageEnsure safetyHydrocarbon distillation control/regulationLower limitControl system

The invention discloses a crude oil blending optimization method, which supports minimum deviation of property and content of blended crude oil to target oil for crude oil manufacturers, namely under certain constraint conditions, percentages of various blended crude oils are obtained by minimization using a deviation function for related properties and contents of the blended crude oils and the set target. For safety and economy, the method further supports three optimization ways for property and content of the crude oil, namely in-range characterization, lower limit oriented optimization and upper limit oriented optimization. The method further supports economic optimization of targets, namely the minimum deviation between property and content of the blended crude oil and the targets is considered, and minimization of production cost is achieved. By the method, blending percentages of the crude oils are automatically generated and downloaded to a control system for execution, the crude oils meeting processing requirements are provided for CDUs (central distillation units), damage of the CDUs and subsequent processing devices due to property change of the crude oils is avoided, production efficiency and economic benefit are improved, and the method is especially applicable to crude oil processing in oil refinery.

Owner:南京富岛信息工程有限公司

Tunnel axial difference deformation design value determination method based on surrounding rock spatial variability

ActiveCN112818442AEasy to predictThe result is reasonableGeometric CADDesign optimisation/simulationElement modelEngineering

The invention discloses a tunnel axial difference deformation design value determination method based on surrounding rock space variability. The method comprises the following steps: obtaining a random distribution function of surrounding rock mechanical parameters; dividing finite element model units according to the characteristics, determining the number of types of different mechanical parameter units, and performing assignment on each unit by adopting a random sampling method to obtain a finite element model of space variation distribution of the surrounding rock; obtaining the displacement value of any point of the surrounding rock through each assignment; obtaining a displacement statistical rule considering random distribution of surrounding rock space through multiple times of calculation; calling the difference value between the displacement value w1 corresponding to the cumulative probability P1 and the displacement value w2 corresponding to the cumulative probability P2 as a tunnel difference deformation probability design value; changing the value of the mechanical parameter standard deviation, obtaining a displacement statistical rule under a plurality of standard deviation working conditions through multiple times of assignment, obtaining a probability design value of tunnel differential deformation, obtaining a probability design value-standard deviation function of surrounding rock space random distribution tunnel differential deformation, and providing a theoretical basis for realizing tunnel reliability design.

Owner:HOHAI UNIV +1

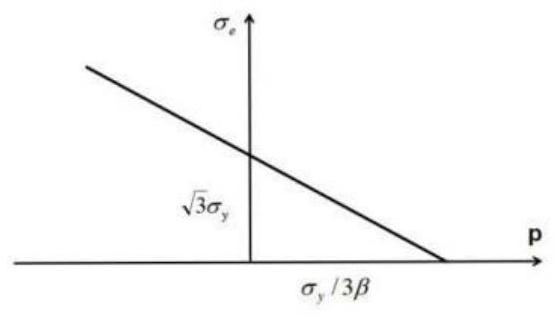

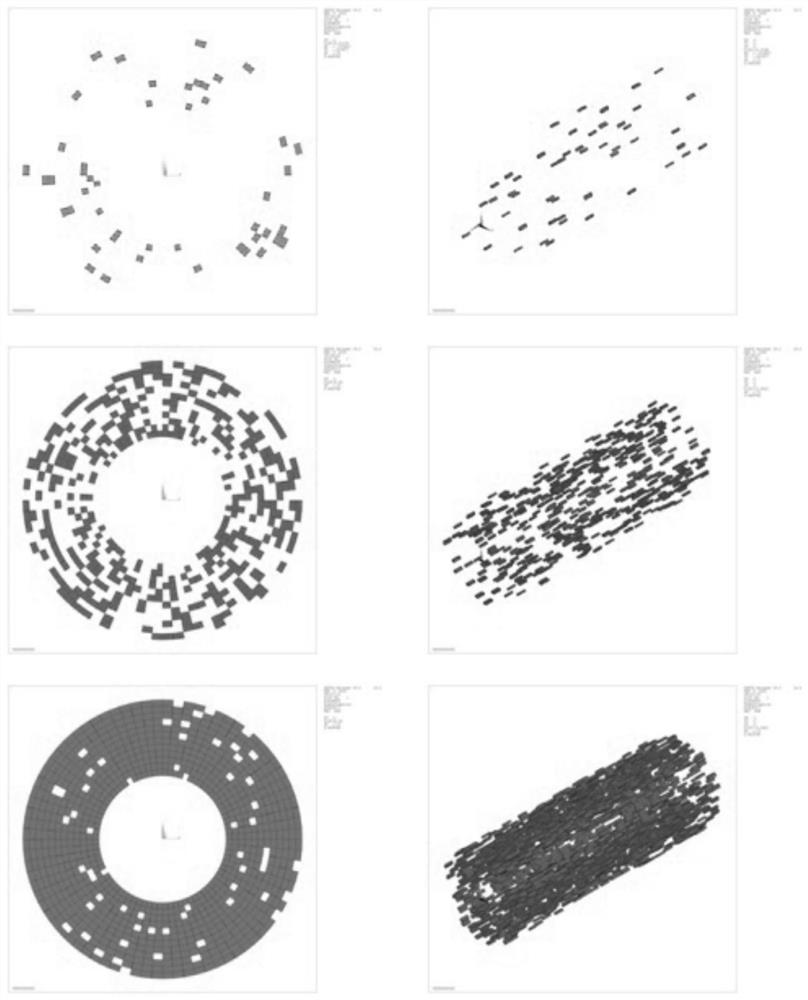

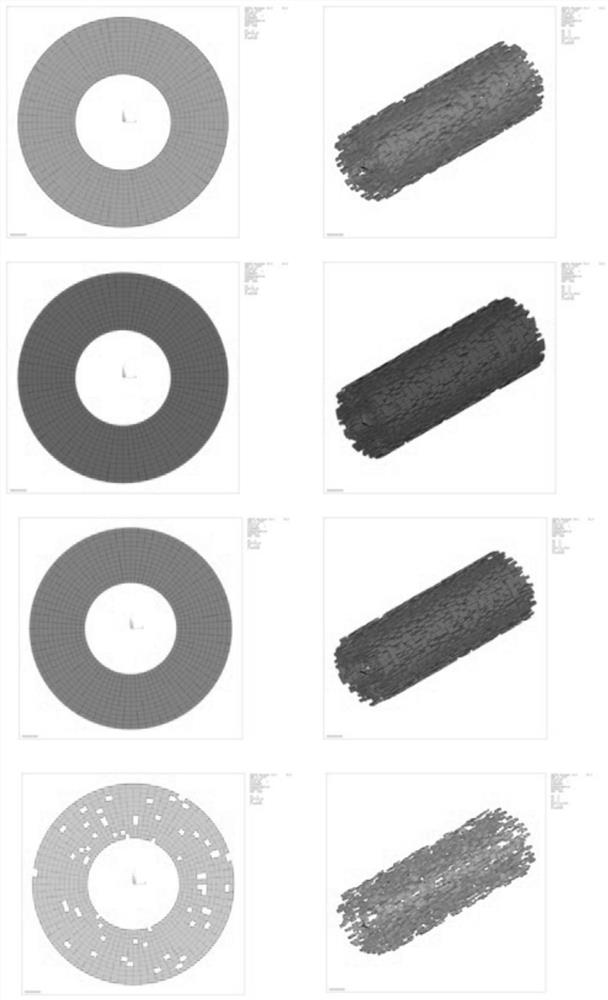

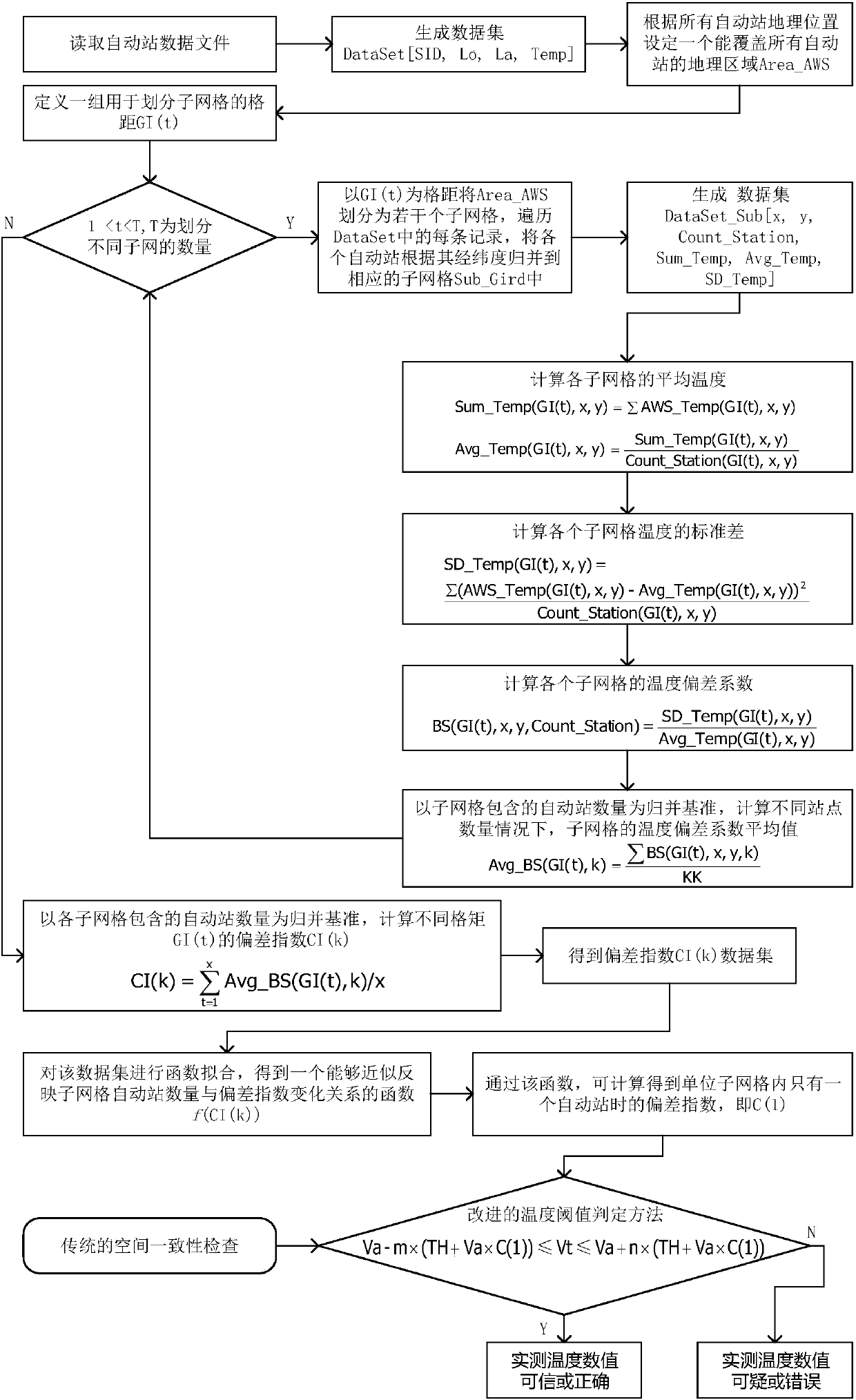

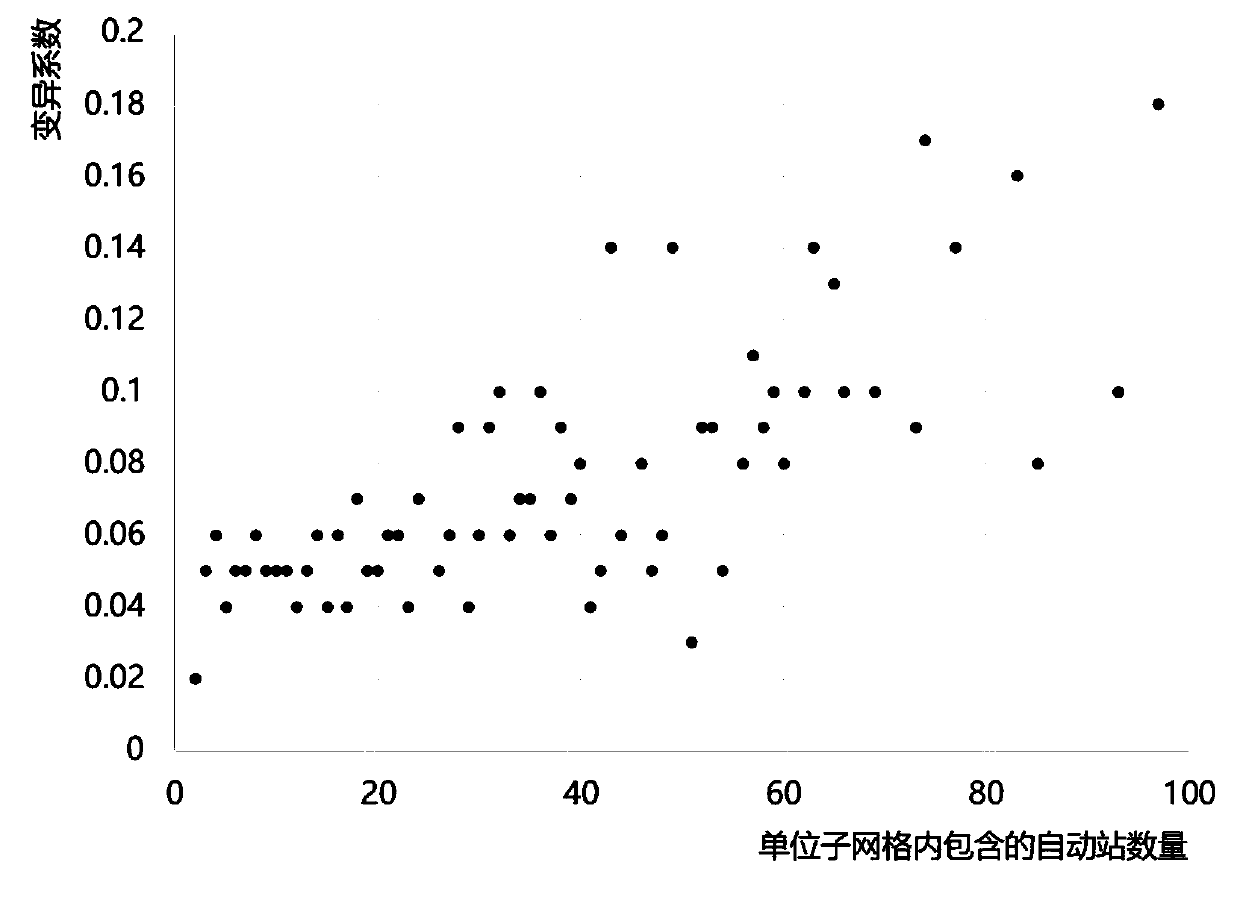

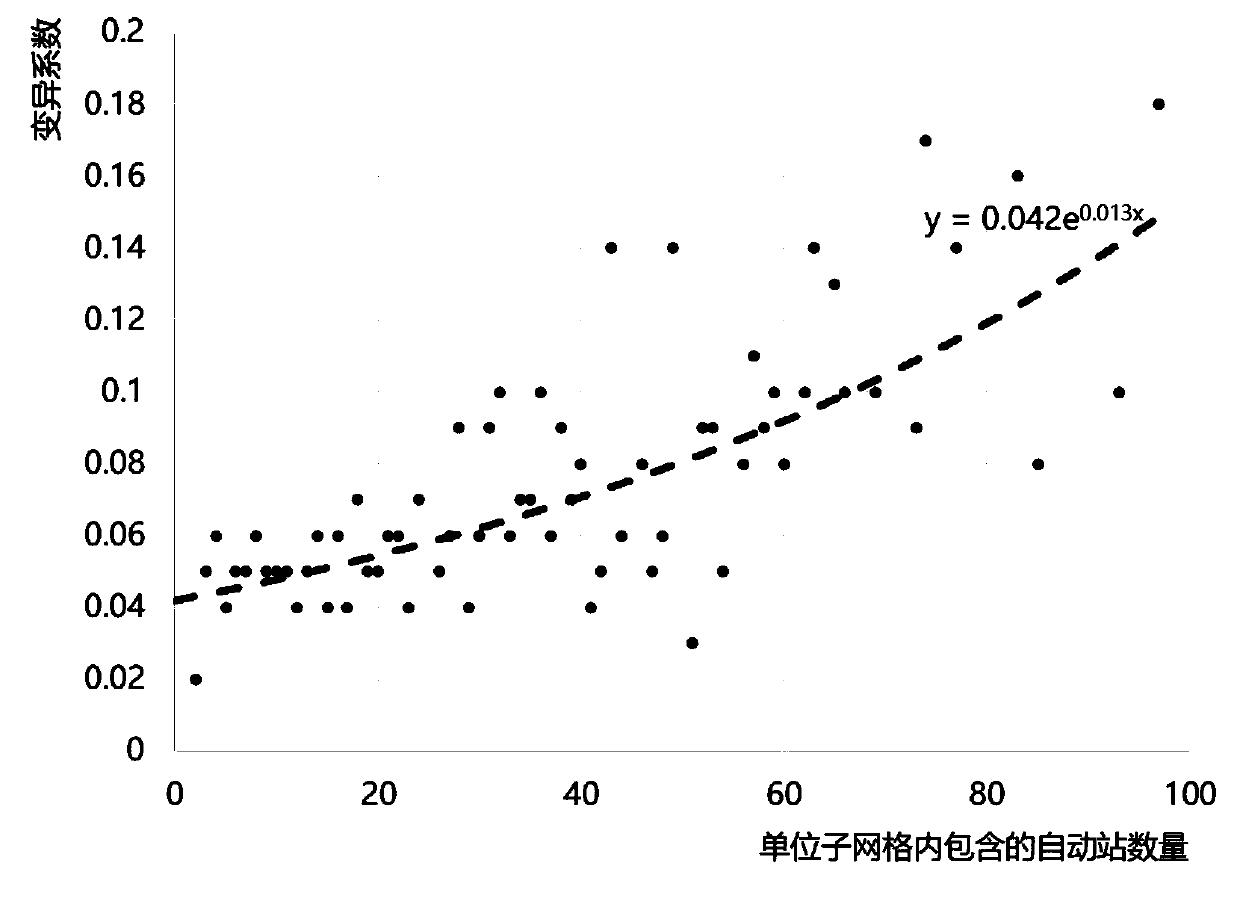

Method for quality inspection of measured temperature values of intensive automatic weather station

ActiveCN108268646AImprove accuracyGeographical information databasesSpecial data processing applicationsQuality controlVisual inspection

The invention relates to a method for quality inspection of measured temperature values of an intensive automatic weather station. According to the method, the deviation index of the measured temperature of the intensive automatic weather station in each sub-grid is calculated through partition of multi-level spatial sub-grids, a temperature deviation function is obtained through fitting, thus, the deviation index of the measured temperature of the intensive automatic weather station in each fine-grained sub-grid is calculated by use of the function, the ideal error between different intensiveautomatic weather stations is calculated by using the index, the error is used as part of threshold determination during spatial consistency inspection, a threshold determination algorithm is improved, and the accuracy of the quality control method based on spatial consistency inspection is improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Corrosion resistant multifunctional high-pressure well mouth apparatus

InactiveCN101012738AWith offset adjustment functionReduce replacement timeSealing/packingEngineeringExchange time

The invention relates to a corrosion resistance multi-function high-pressure wellhead equipment. The technological project is that on the upper end of catch hoop a spherical base, a spherical pressure cap, more than one scavenging cavity, more than one scavenging pressure cap, an oil slot and an pressure cap are connected in turn and a smooth rod passes through them in turn; there are a ball in the spherical hollow cavity constituted by the spherical base and the spherical pressure cap; the upper scavenging cavity is connected with the lower scavenging cavity by locking screw cap to form said scavenging cavity; the upper scavenging cavity is cylinder structure and the lower scavenging cavity is cone structure. There are multiple packing in inner cavities of said upper and lower scavenging cavities; the appearance of said smooth rod is fixed with the protective case tightly by a connector. The benefit of invention is that there is a protective case on the appearance of smooth rod to play the role of wear resistance and corrosion resistance and the spherical seat has the adjusting deviation function to prevent the eccentric wear; the exchanging time for packing is shortened more effectively by two packing boxes while the demand of high-temperature and high-pressure resistance is achieved.

Owner:SHANDONG JUCHENG GASOLINEEUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com