Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Crystallization of polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystallization of polymers is a process associated with partial alignment of their molecular chains. These chains fold together and form ordered regions called lamellae, which compose larger spheroidal structures named spherulites. Polymers can crystallize upon cooling from melting, mechanical stretching or solvent evaporation. Crystallization affects optical, mechanical, thermal and chemical properties of the polymer. The degree of crystallinity is estimated by different analytical methods and it typically ranges between 10 and 80%, with crystallized polymers often called "semi-crystalline". The properties of semi-crystalline polymers are determined not only by the degree of crystallinity, but also by the size and orientation of the molecular chains.

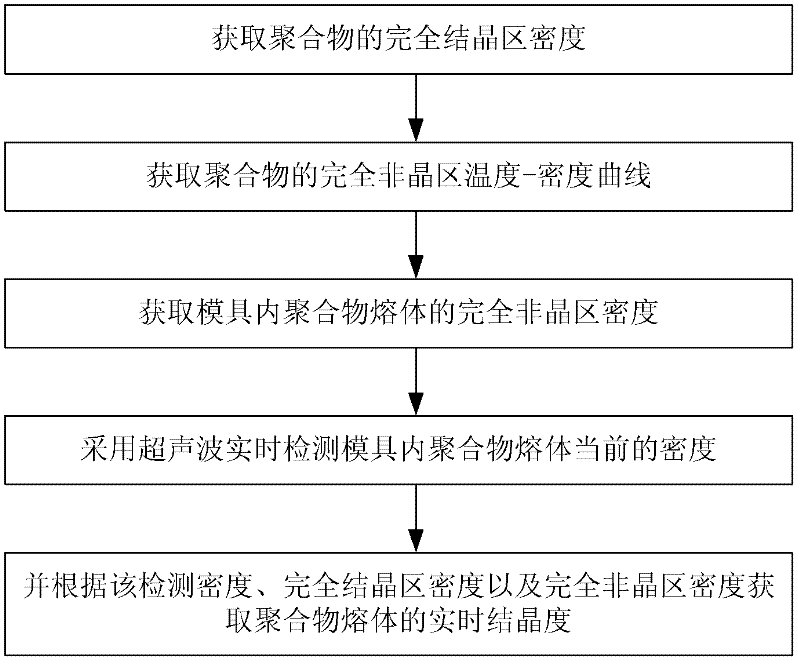

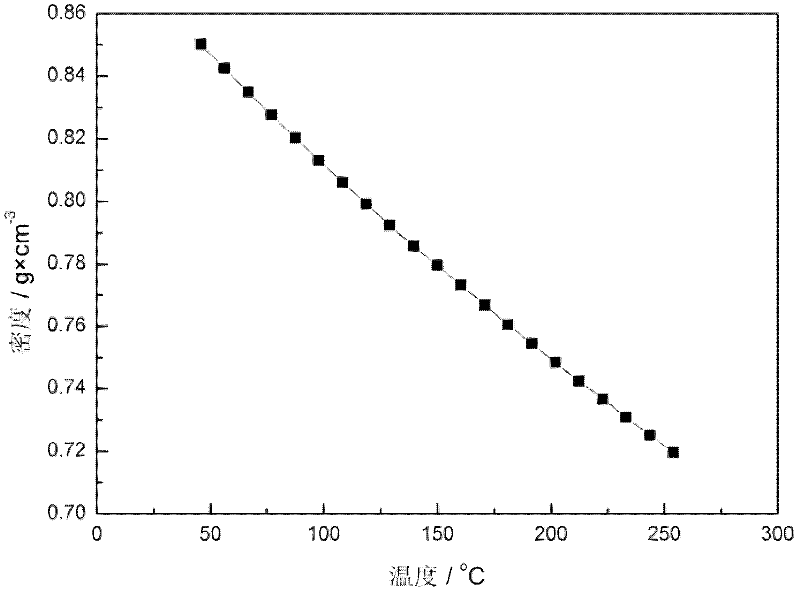

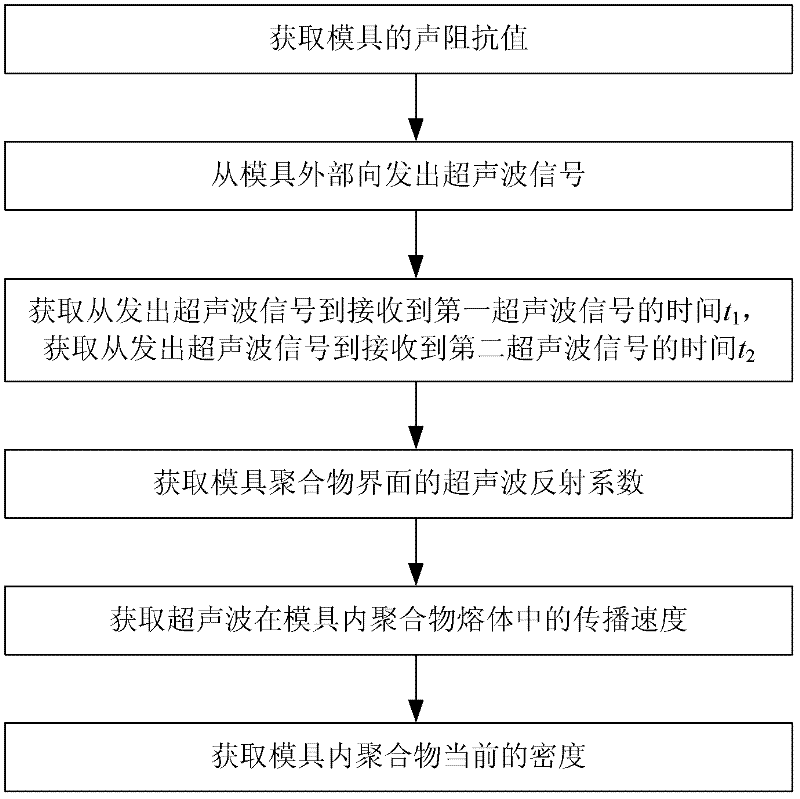

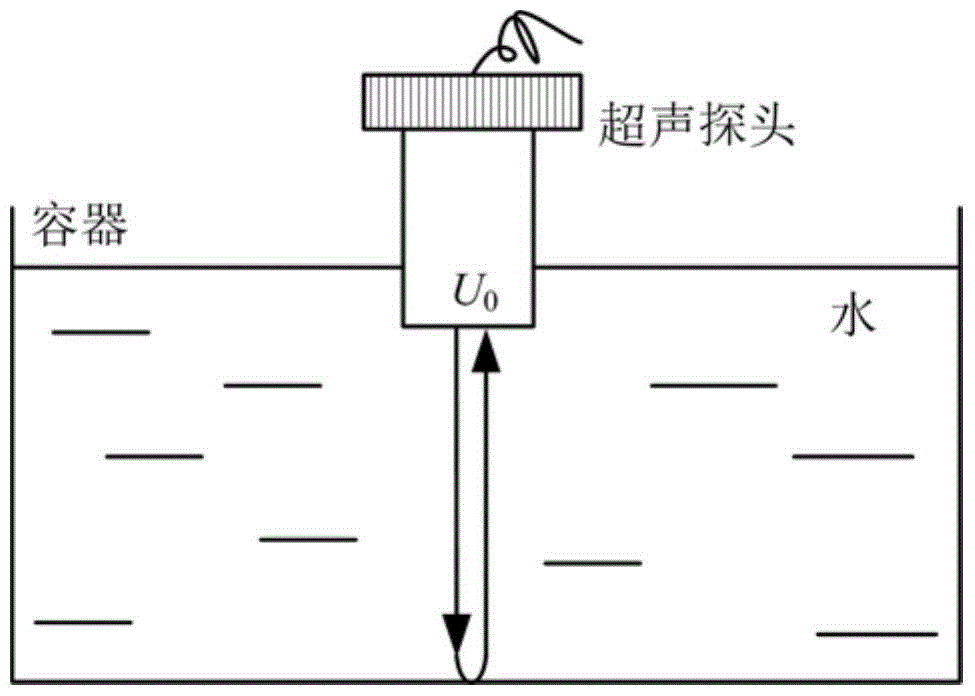

On-line measuring method and apparatus for degree of crystallization of polymer used for injection molding

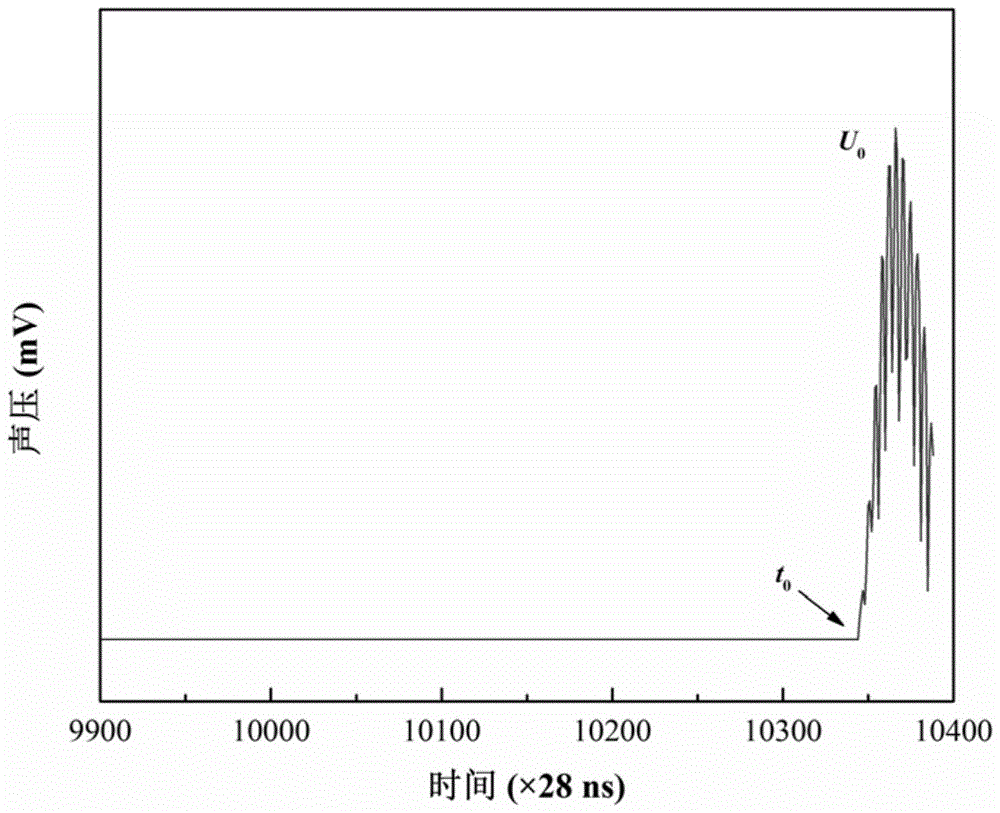

ActiveCN102407595ARealize online measurement of crystallinityRealize online measurementSpecific gravity measurementDensity curveSupersonic waves

The invention discloses an on-line measuring method and apparatus for the degree of crystallization of a polymer used for injection molding. The method comprises the following steps: 1) acquiring the density of a complete crystal region of a polymer and the temperature-density curve of a complete noncrystal region of the polymer; 2) acquiring the density of a complete noncrystal region of a polymer melt in a die; 3) employing supersonic wave for real time detection of the current density of the polymer melt in the die and obtaining the real time degree of crystallization of the polymer melt according to the current density detected, the density of the complete crystal region and the density of the complete noncrystal region. The apparatus provided in the invention comprises a sensor unit, a data acquisition unit and a central processing unit, wherein, the sensor unit comprises a supersonic wave detection unit and a temperature sensor, the supersonic wave detection unit comprises a supersonic wave emitting unit and a supersonic wave receiving unit, and the temperature sensor and the supersonic wave receiving unit are respectively connected with the central processing unit through the data acquisition unit. The invention enables on-line measuring of the degree of crystallization of a polymer in the process of injection molding to be realized; the apparatus provided in the invention has the advantages of a low price and convenient usage.

Owner:ZHEJIANG UNIV

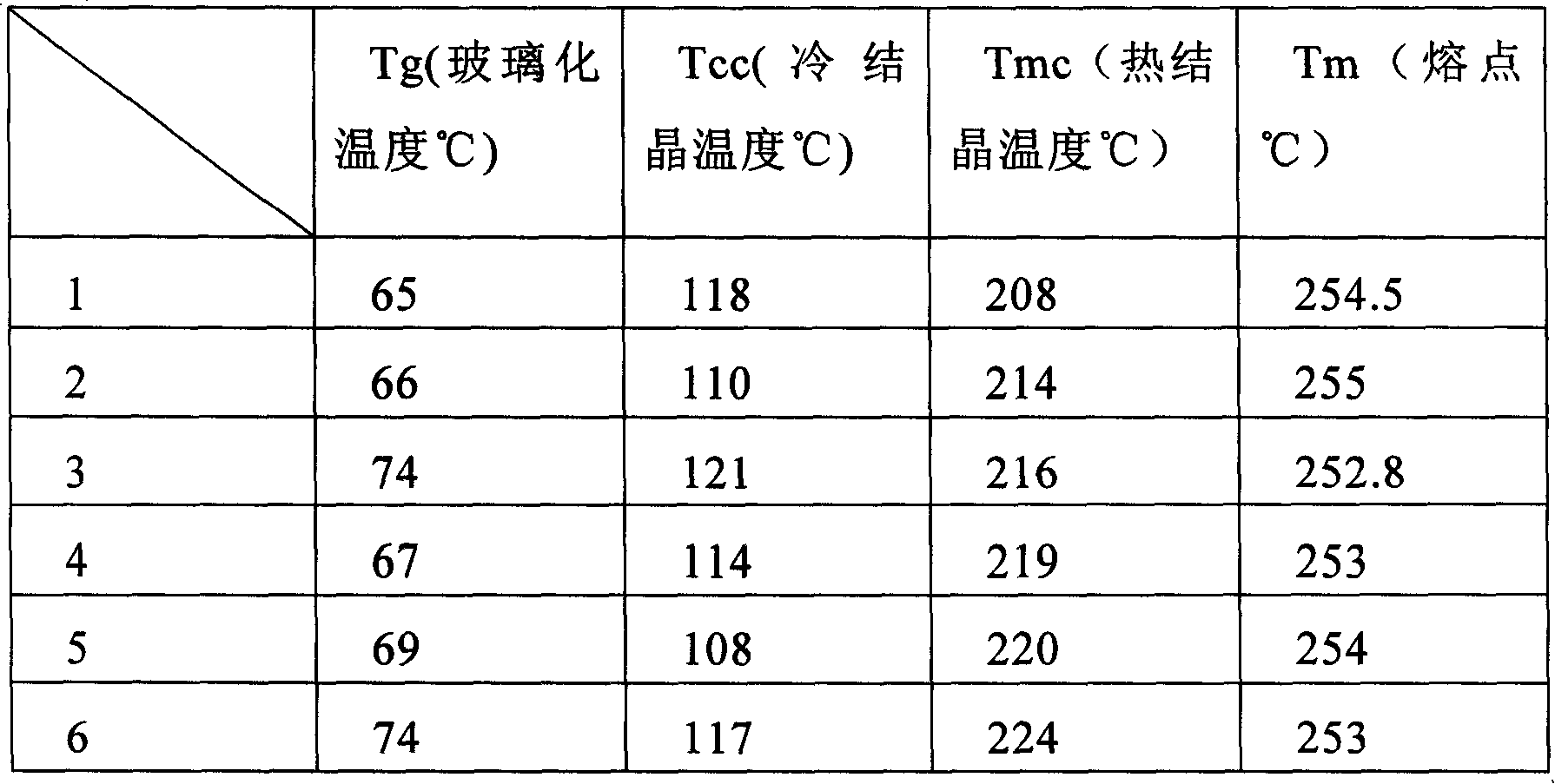

Polyethylene terephthalate composite material and method of producing the same

ActiveCN101153111AIncrease the rate of crystallizationMeet needsLiquid crystal compositionsPolymer sciencePolyethylene terephthalate

The present invention relates to a polyethylene terephthalate composite material and the preparation method. The method comprises: 40 weight portion to 80 weight portion of polyethylene terephthalate, 0.1 weight portion to 4 weight portion of macromolecule nucleating agent testa liquid crystal, 1 weight portion to 6 weight portion of macromolecule crystallization accelerator, and 0.5 weight portion to 1 weight portion of other processing aids are stirred and mixed at a high speed; the mixture is then sent into a double-screw extruder through a material feeder of precise measurement. Then 10 weight portion to 50 weight portion of intensifier is filled into the double-screw extruder through the material feeder of precise measurement. The product can be prepared after plasticization, melting, compounding, and then extruding, bracing, cooling, pelletizing and drying. Compared with the prior art, the present invention has the characteristics of improving the crystallization rate of polyethylene terephthalate, widening the application scope, meeting the demands of engineering plastics for polyethylene terephthalate.

Owner:HEFEI GENIUS NEW MATERIALS

Method for rapid crystallization of polymer at high temperature

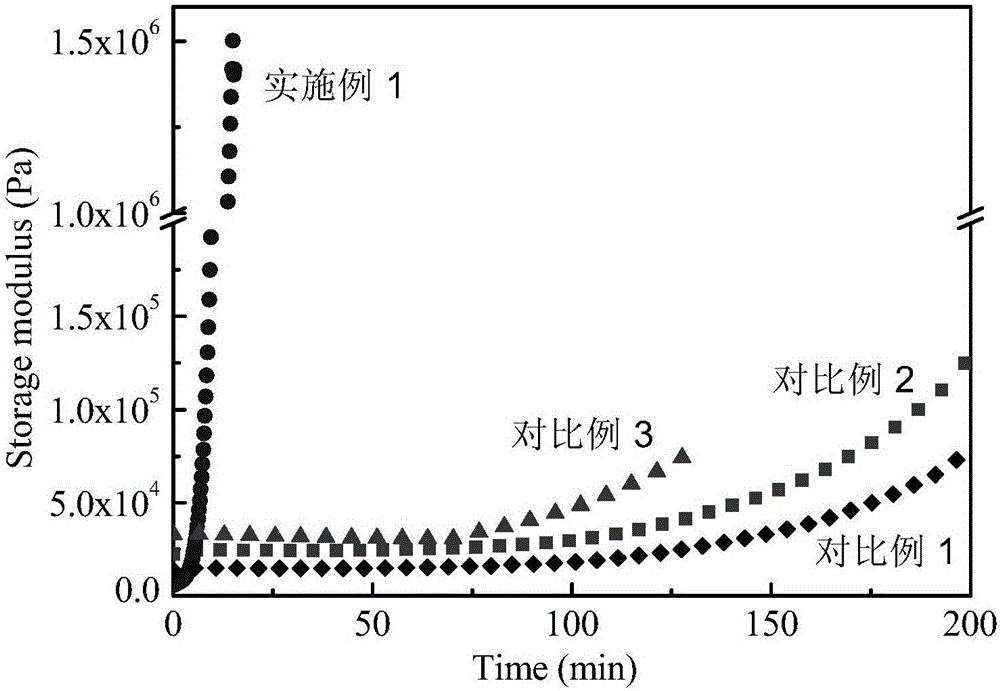

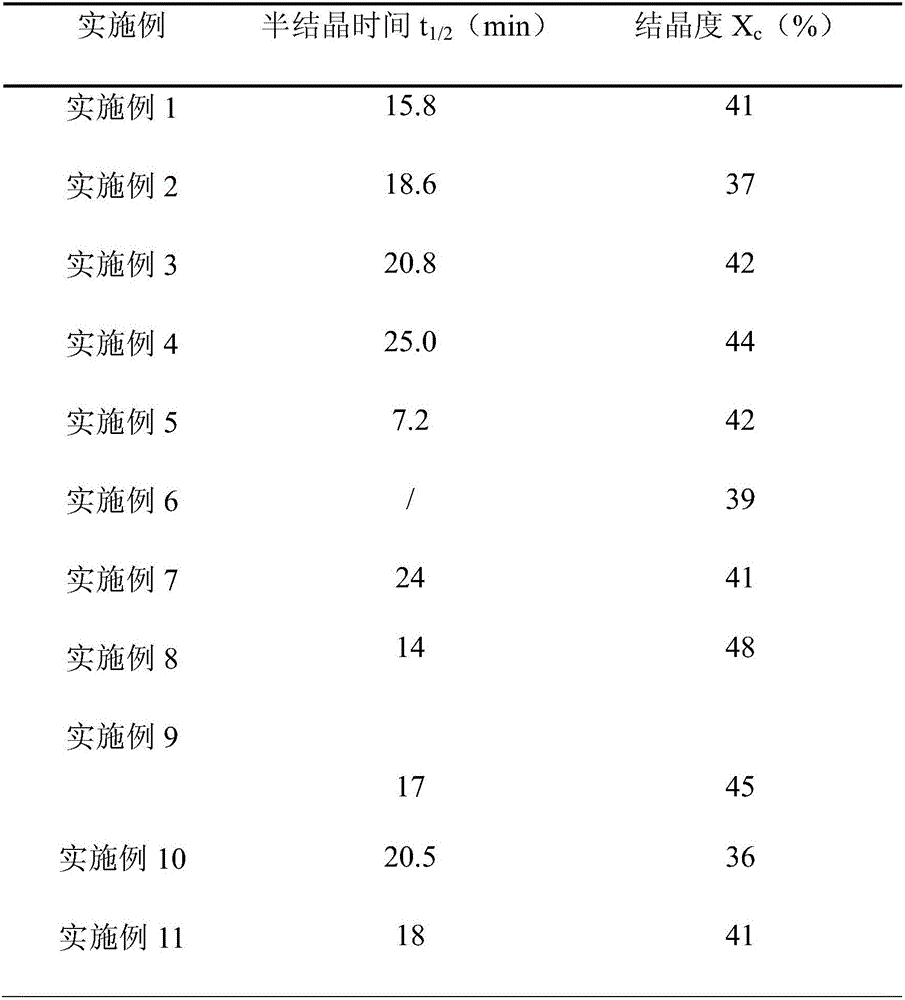

InactiveCN106519610ADoes not affect basic crystallization propertiesEasy to implementPolymer scienceHeat resistance

The invention discloses a method for rapid crystallization of a polymer at high temperature. The method includes the steps of (1) subjecting a polymer and an organic nucleating agent to melt blending according to a weight part at a first temperature to obtain a uniformly dispersed composition; and (2) shearing the composition at a second temperature to promote rapid crystallization of the polymer. At the second temperature, the semi-crystallization time t1 / 2 of the polymer material is shortened to less than 25min, thus endowing the material with excellent physical and mechanical properties and heat resistance, etc.

Owner:JIANGNAN UNIV

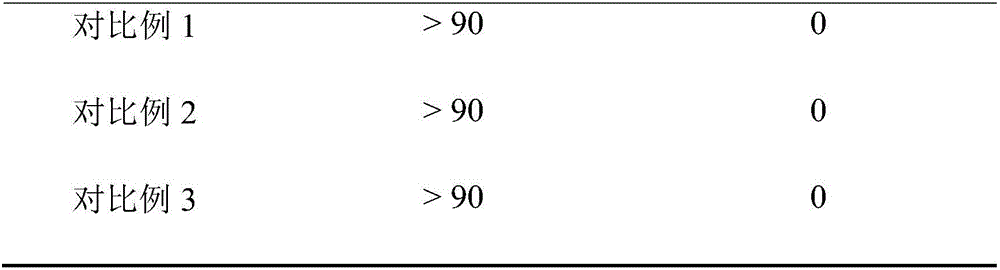

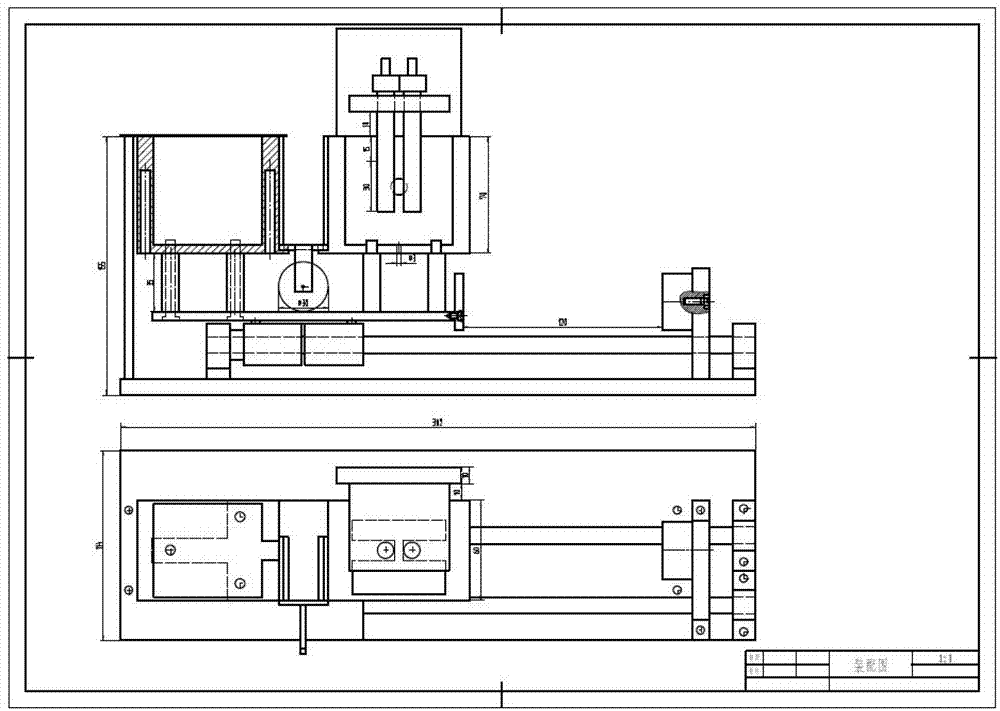

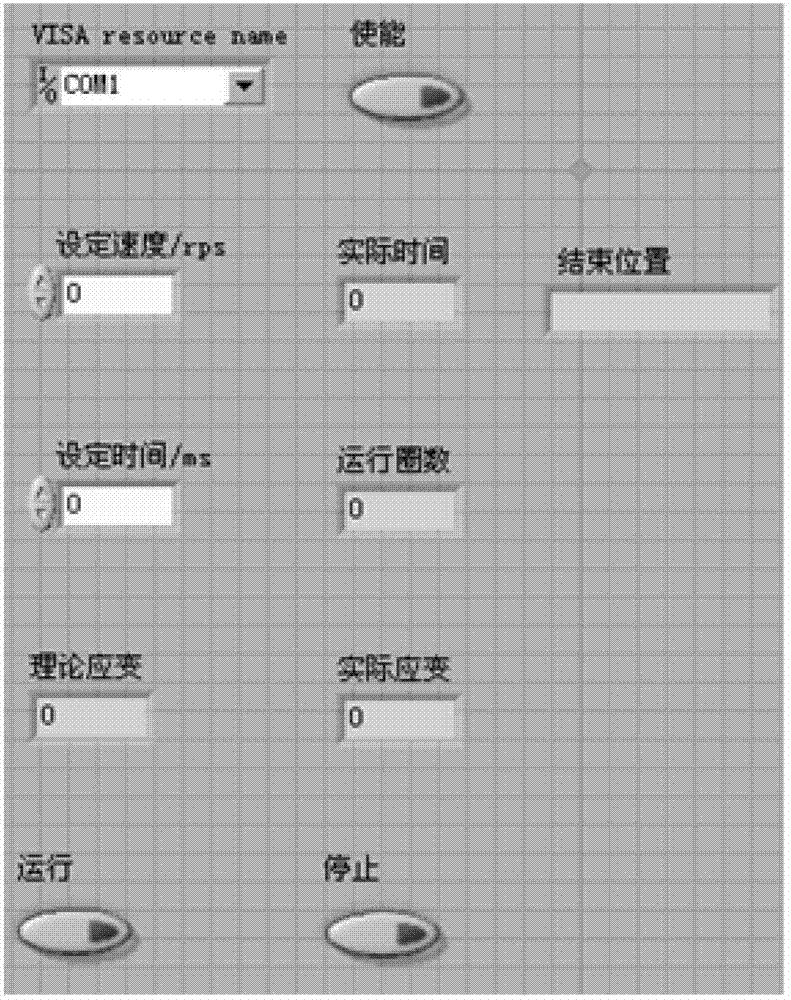

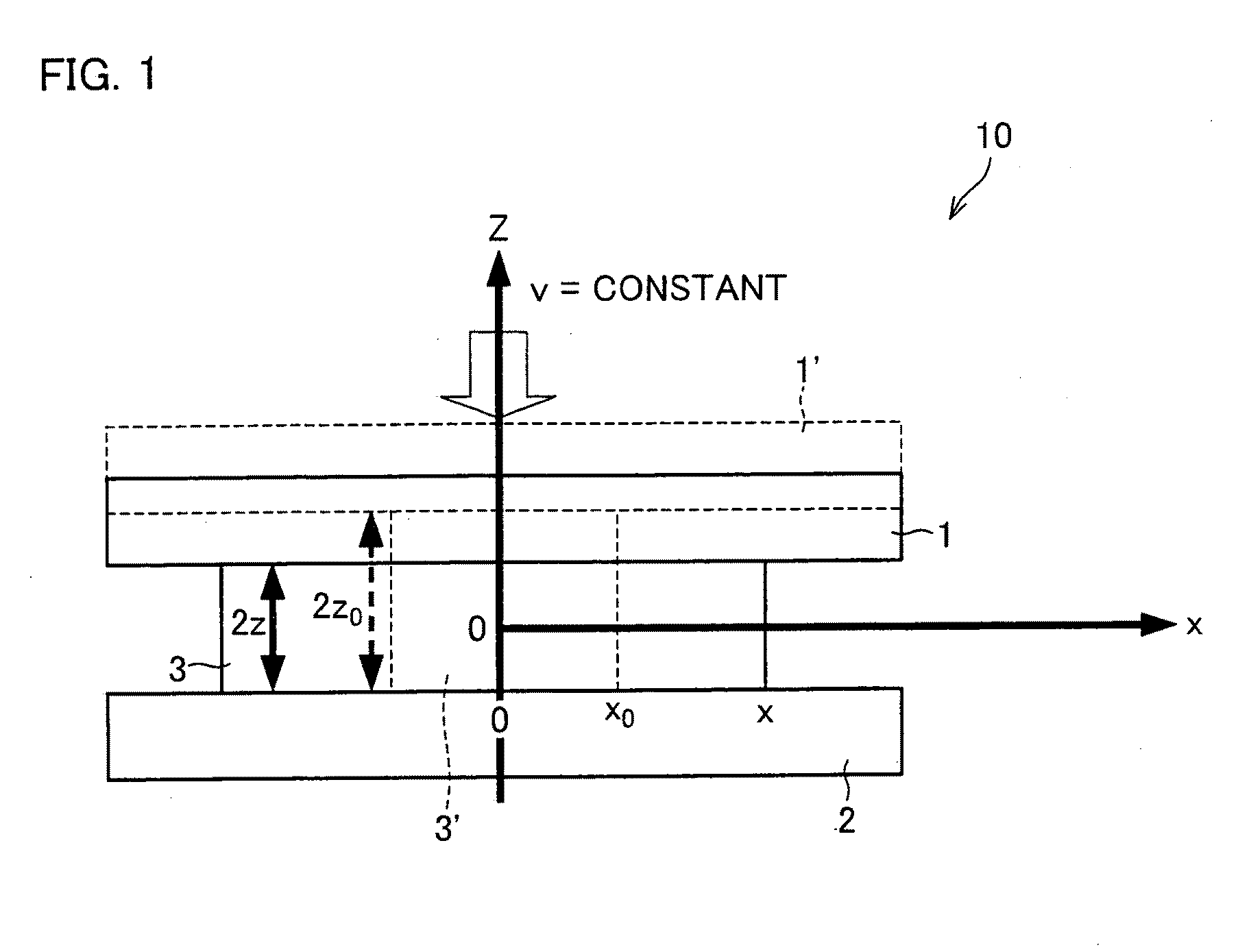

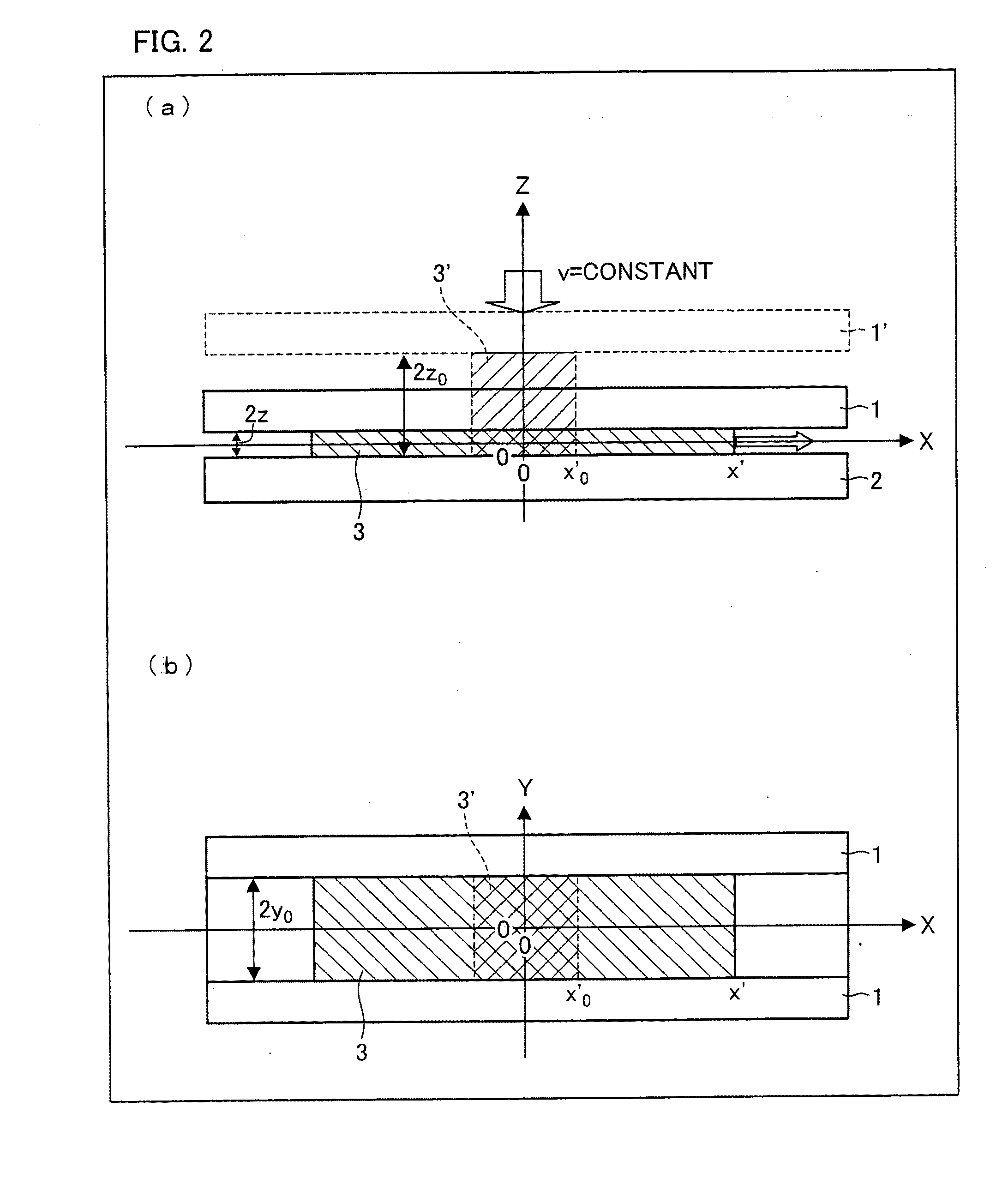

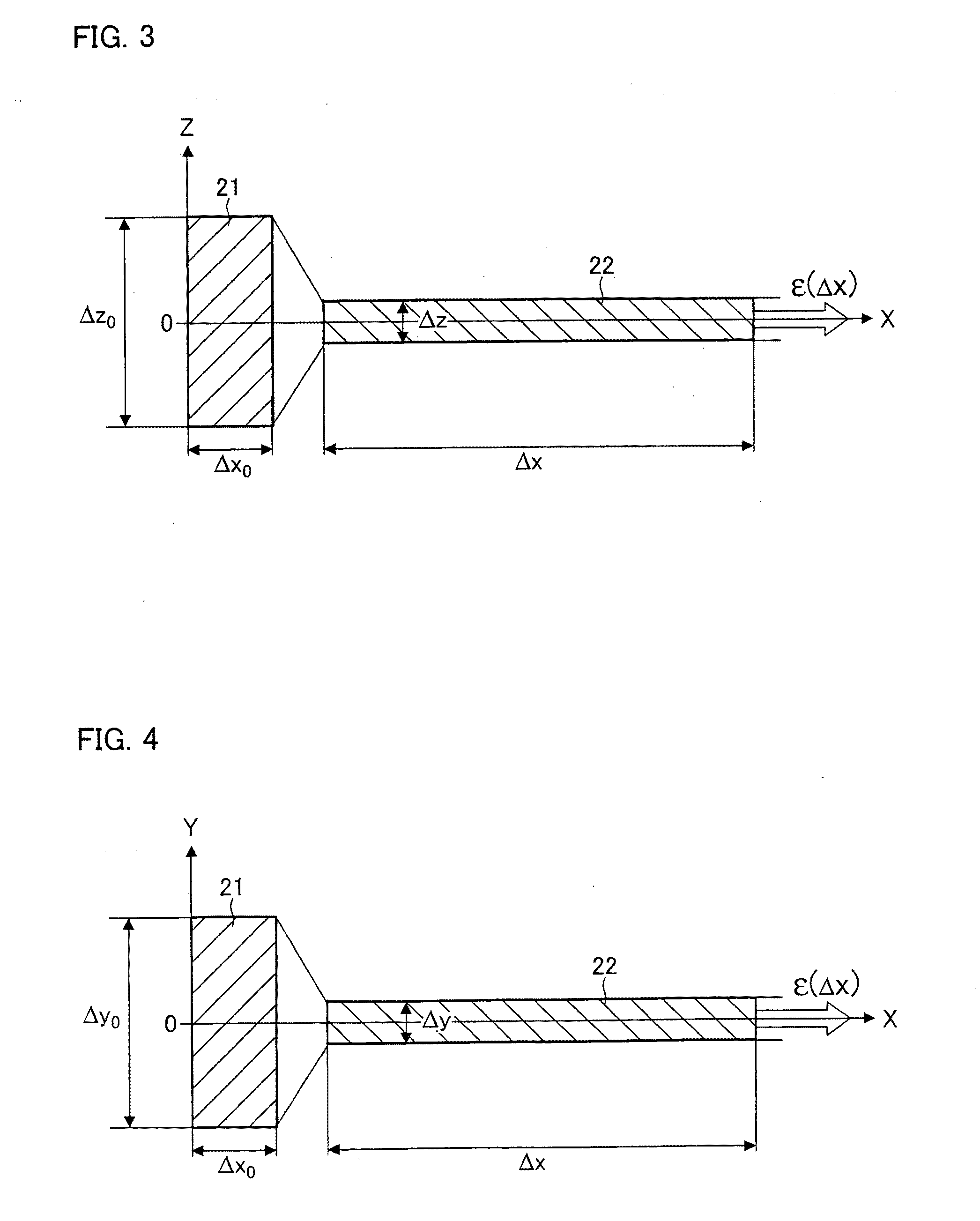

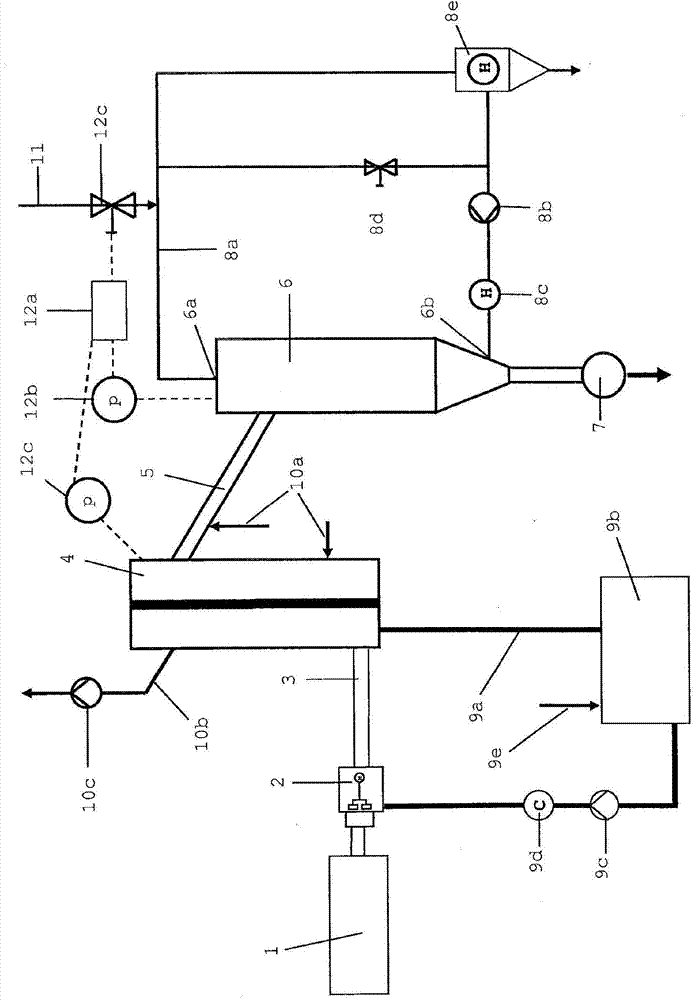

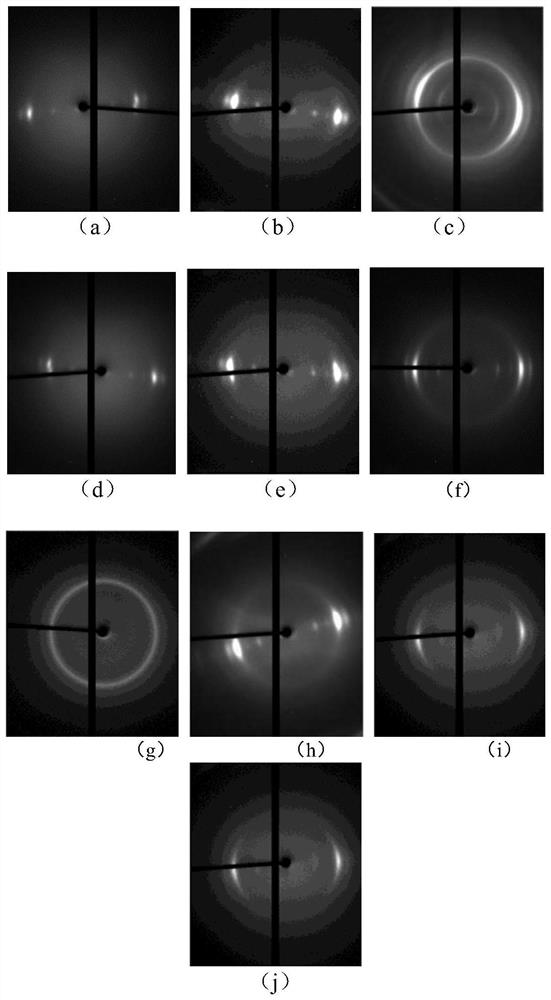

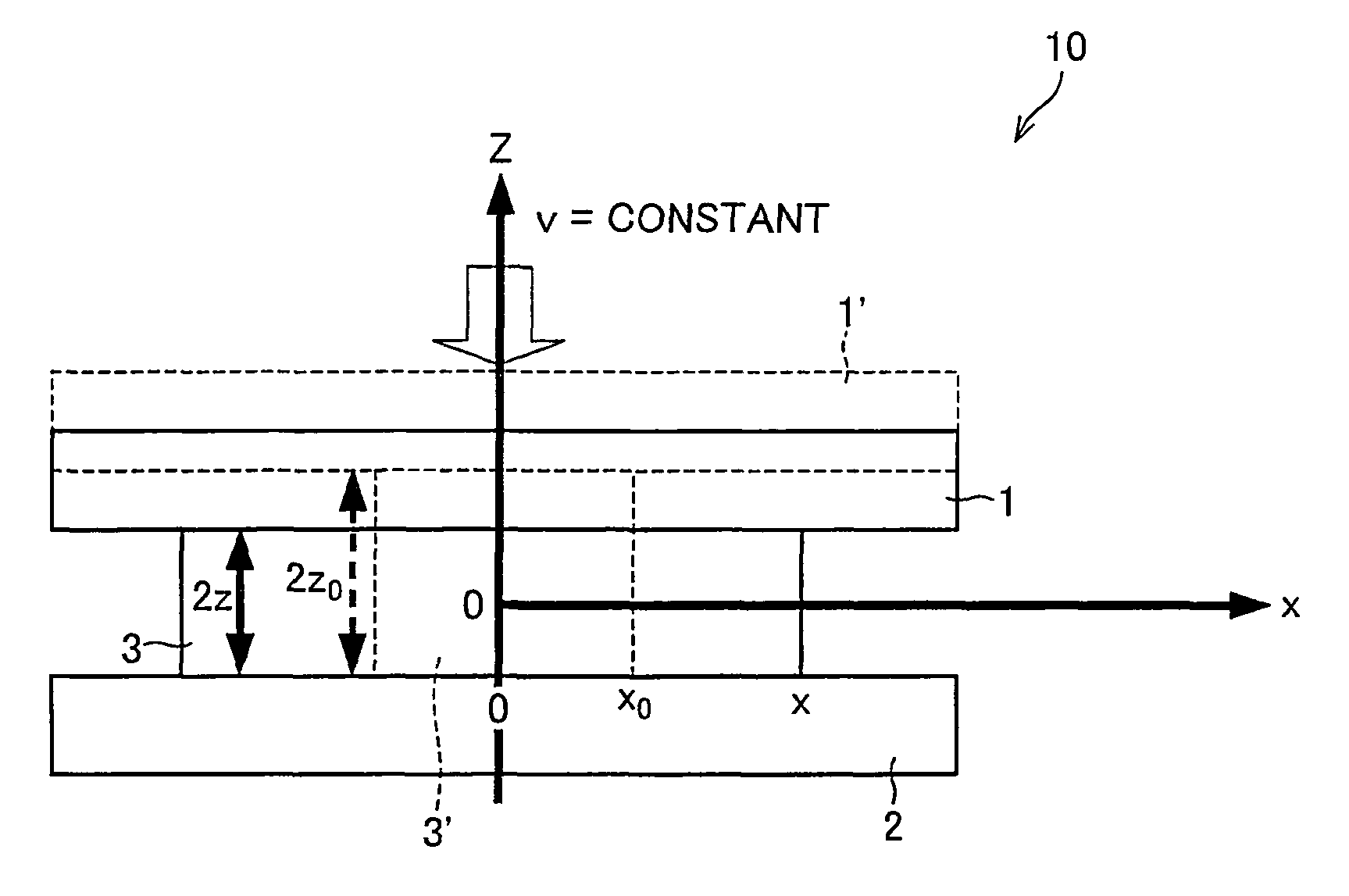

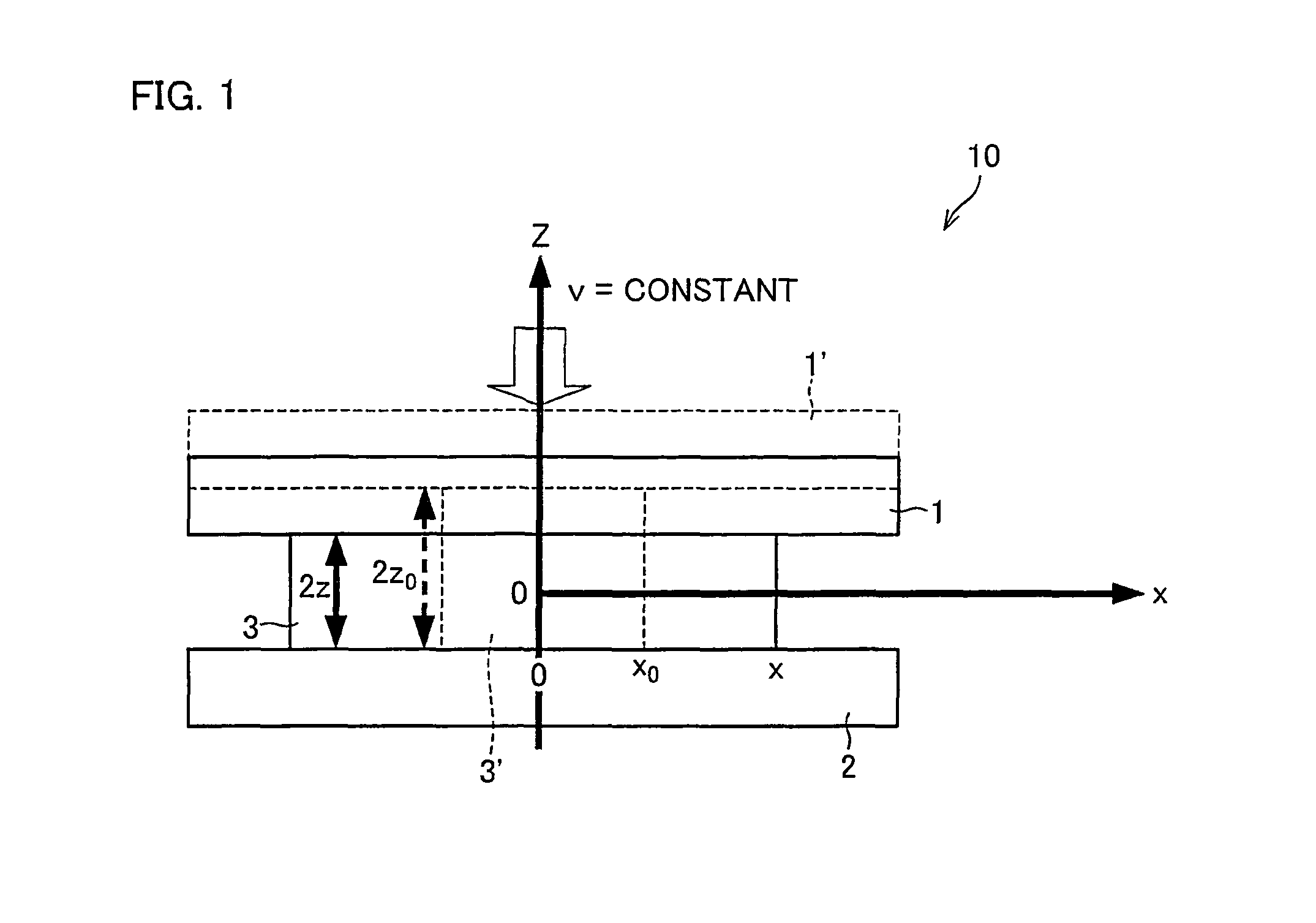

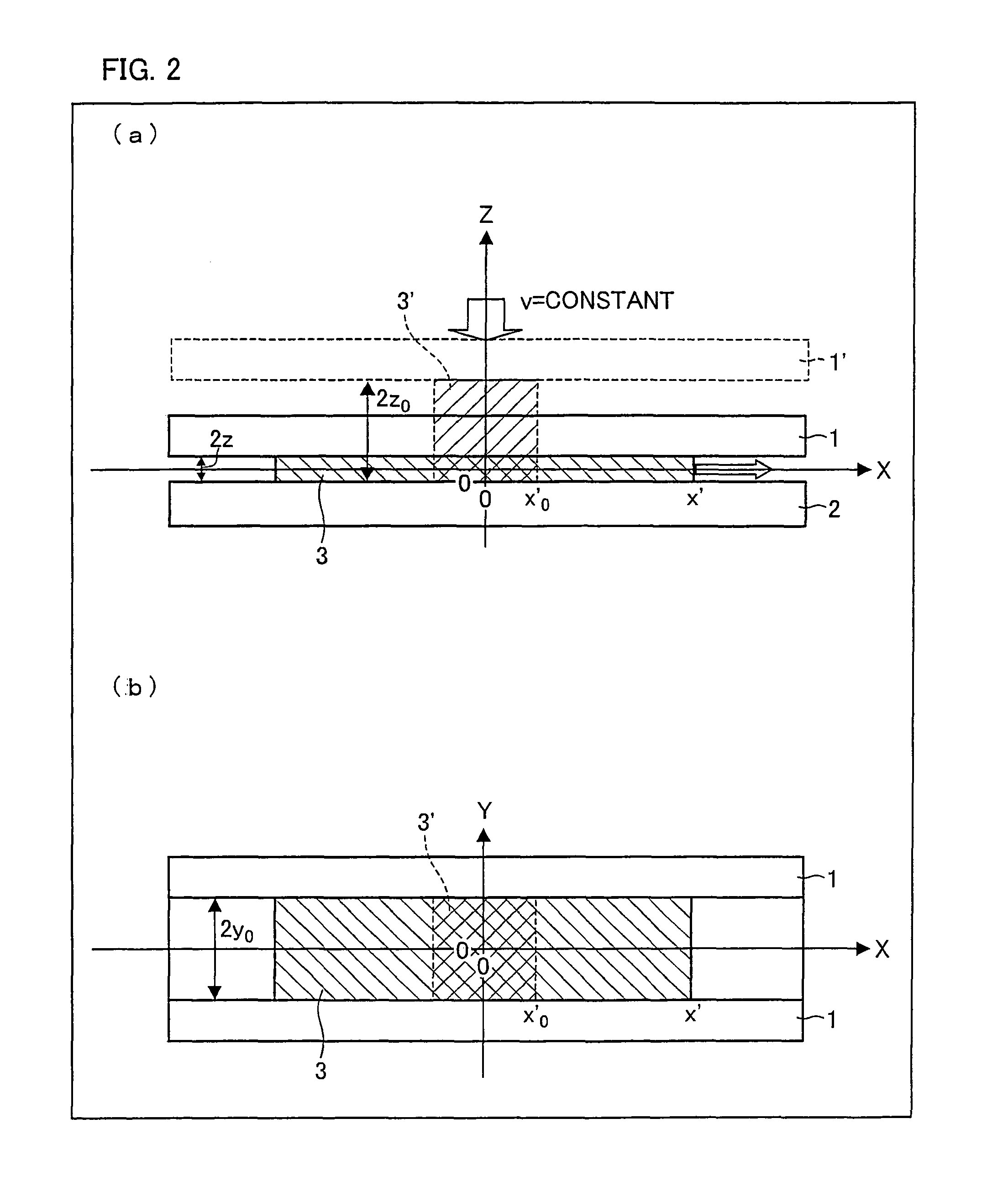

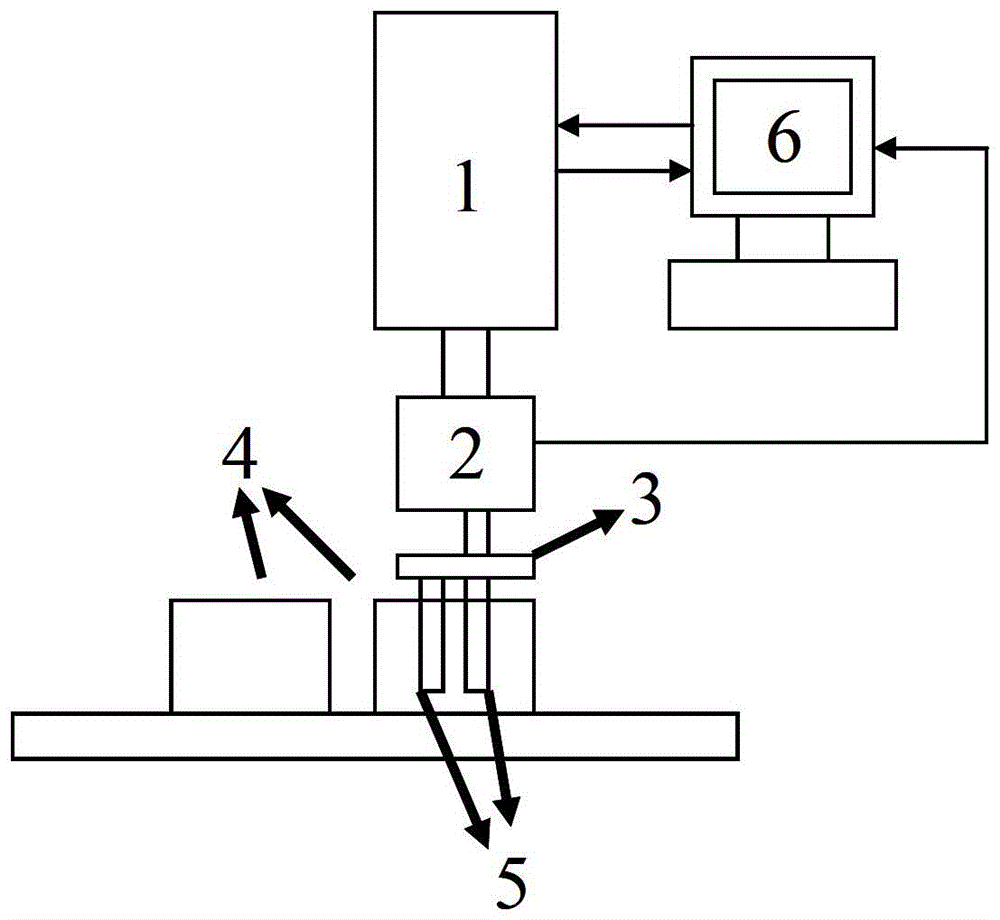

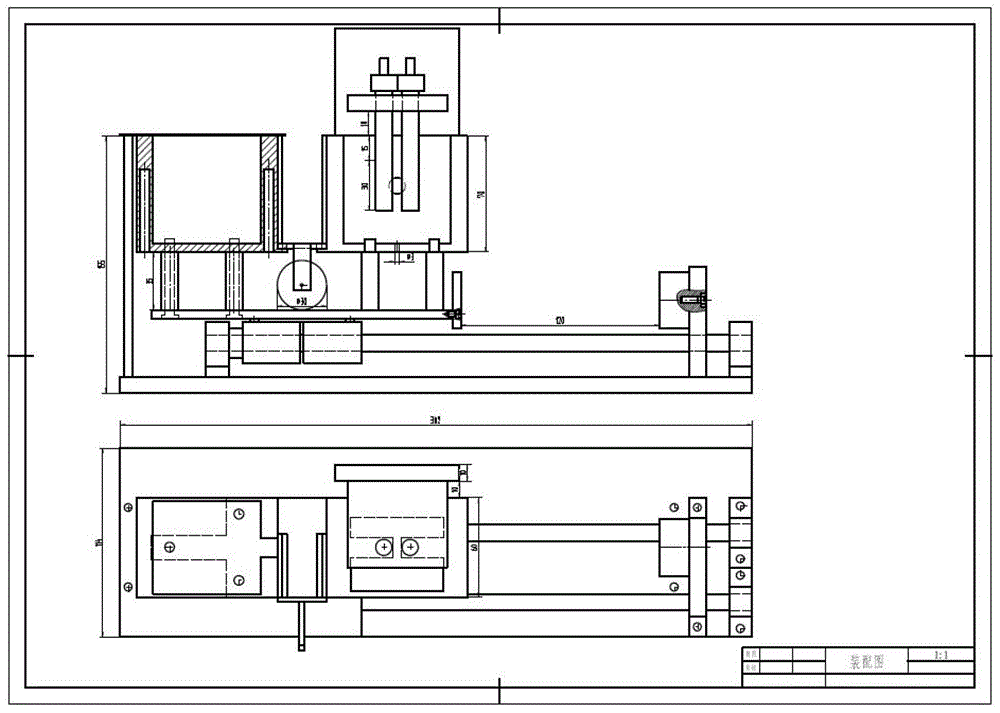

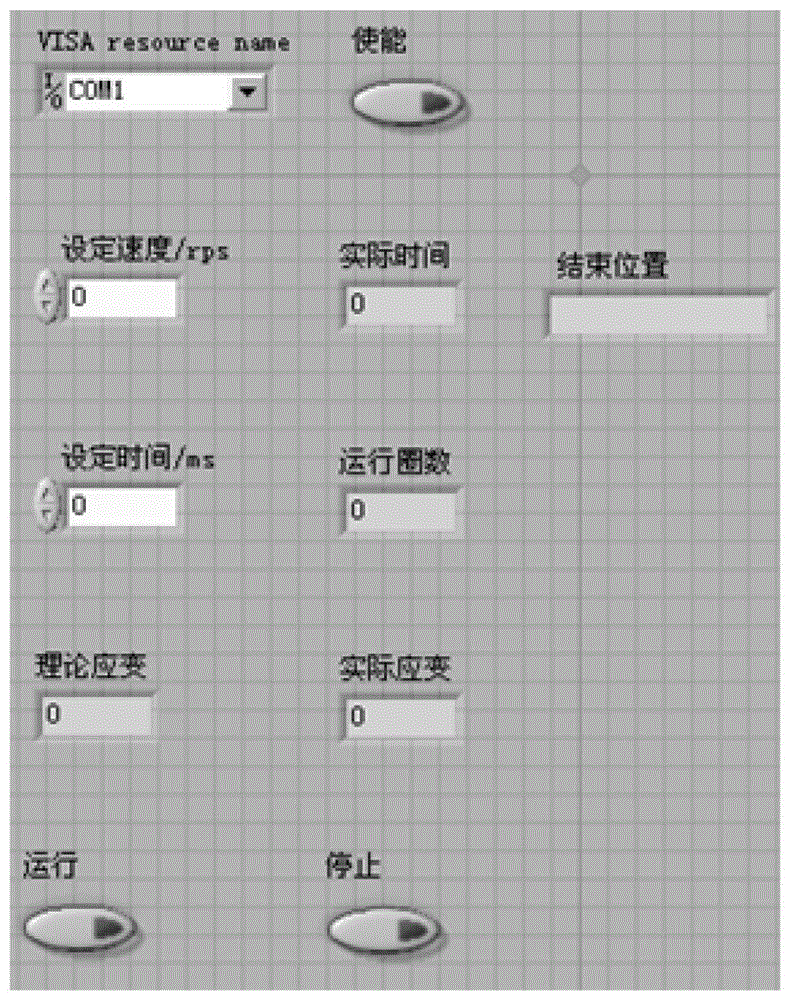

Biaxial uniaxial tension device for in-situ structure detection in combination with scattering of X-rays and experimental method thereof

ActiveCN103207192AEffect of extensional rheologyEfficient use ofMaterial analysis using radiation diffractionLabview softwareX-ray

The invention provides a biaxial uniaxial tension device for in-situ structure detection in combination with the scattering of X-rays and an experimental method of the biaxial uniaxial tension device. The device comprises a high-precision servo motor (1), a torque sensor (2), a precise gear (3), a heating furnace (3), a reverse tension shaft (5) and a Labview software control system (6). A guide rail, the precise gear (3) and a reverse tension rod are adopted for transmission. The rotating speed of the servo motor (1) and the rotational displacement are controlled by the Labview to realize precise displacement and speed tension control. The temperature distribution of the heating furnace (3) is uniformed and the thermal degradation at high temperature of samples is reduced by forced nitrogen flow. A temperature monitoring point is preset in the heating furnace (3) and a temperature controller is adopted to precisely control the temperature. Temperature jump is realized between two heating furnaces (3) of different temperature. The device has the advantages of small volume, light mass, simplicity in disassembling and installing and the like, is particularly suitable for the combination of synchrotron radiation experimental line stations and is a good device for studying the crystallization of polymer melt induced by a flow field.

Owner:UNIV OF SCI & TECH OF CHINA +4

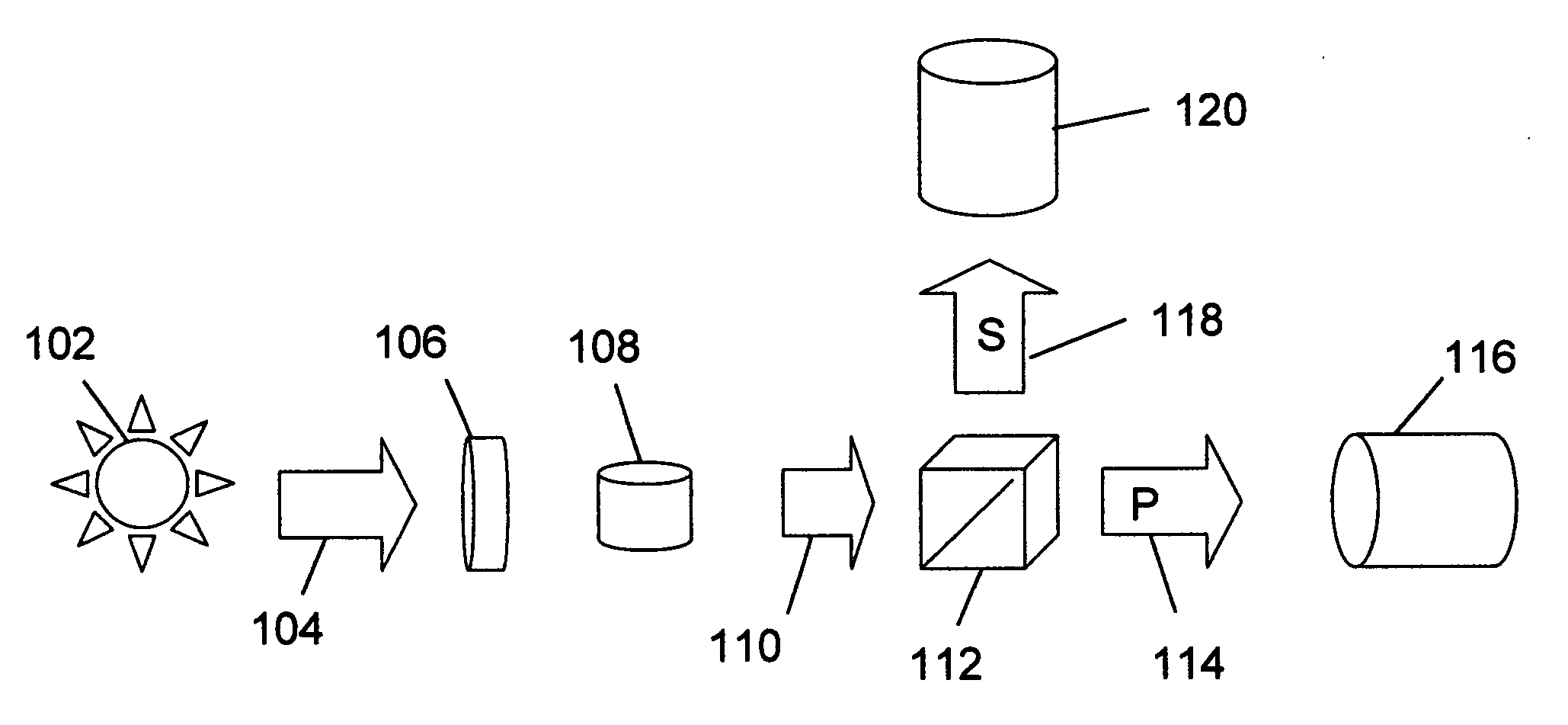

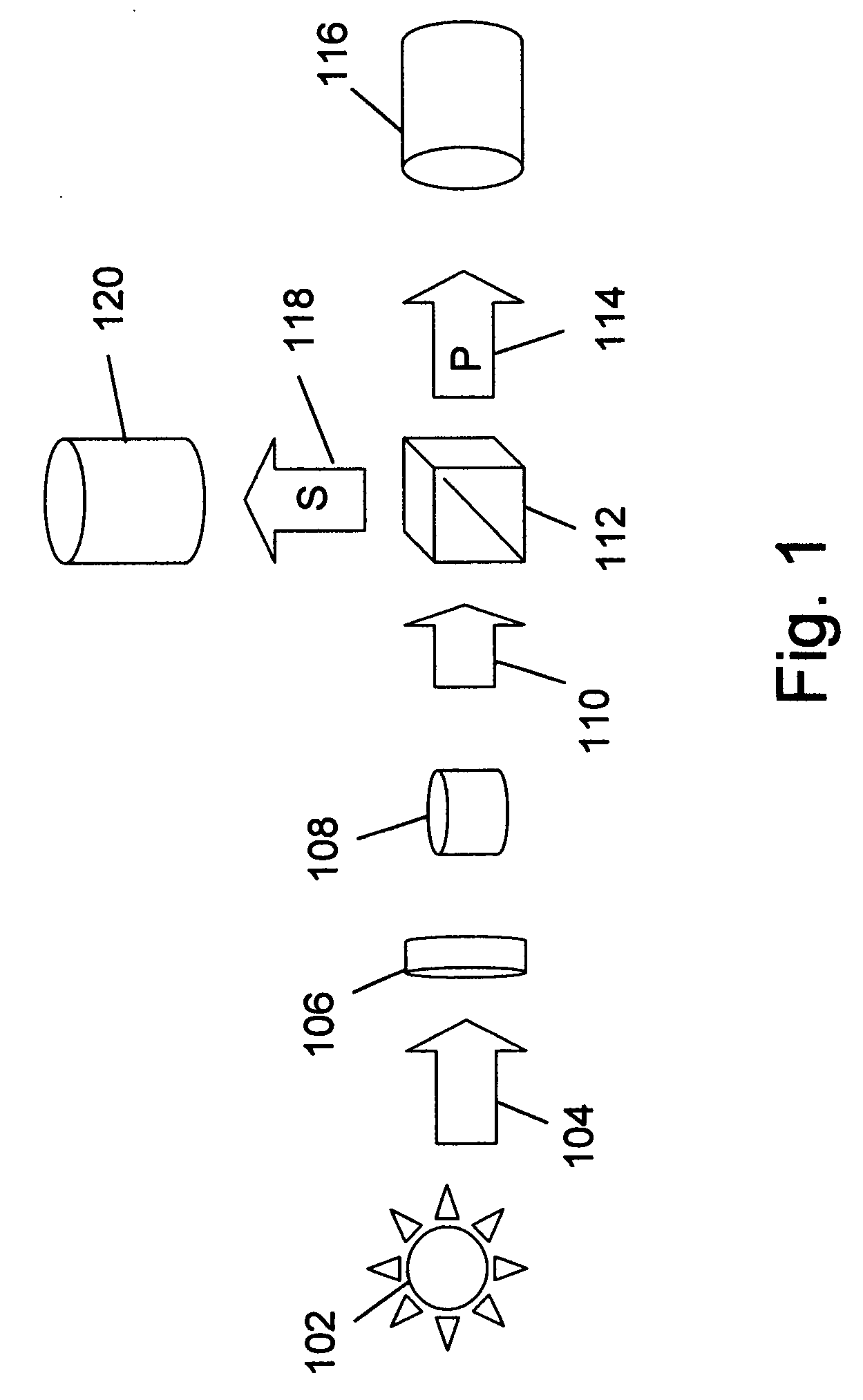

Method and apparatus for finding macromolecule crystallization conditions

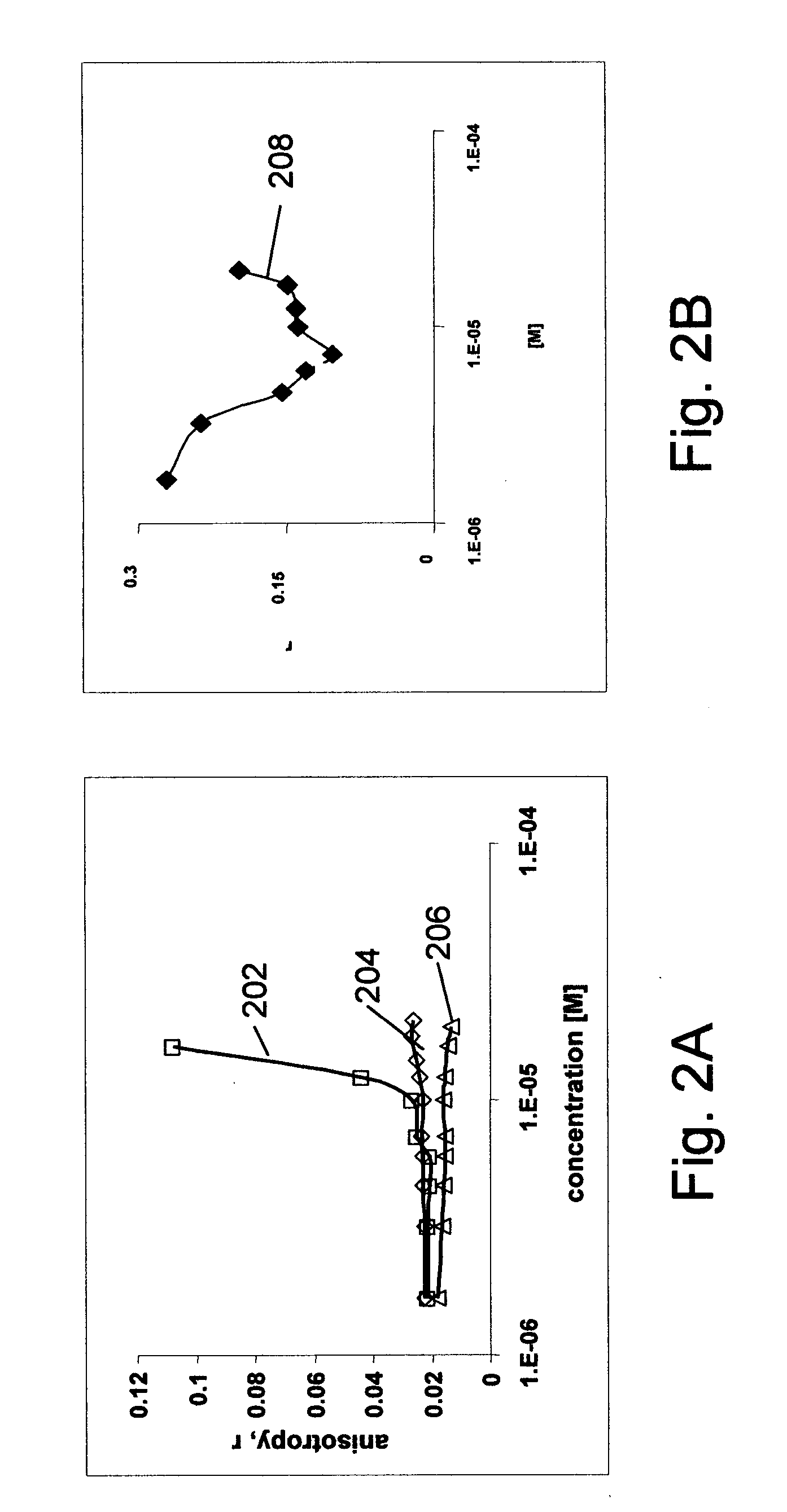

A system and method for determining macromolecule crystallization conditions by measuring the polarization anisotropy of a fluorescent probe attached to the macromolecule in solution as a function of a variation in crystallization conditions. In one exemplary embodiment, the concentration of the macromolecule material is varied and the polarization anisotropy as a function of concentration gives an indication of the proximity to crystallization conditions. A pulse illumination system with time gated detection is disclosed to isolate fluorescence response from excitation to reduce noise due to scattered and reflected light. A microassay system is disclosed to allow a complete 96 condition screen with less than 1 micro-liter of solution.

Owner:MI RES

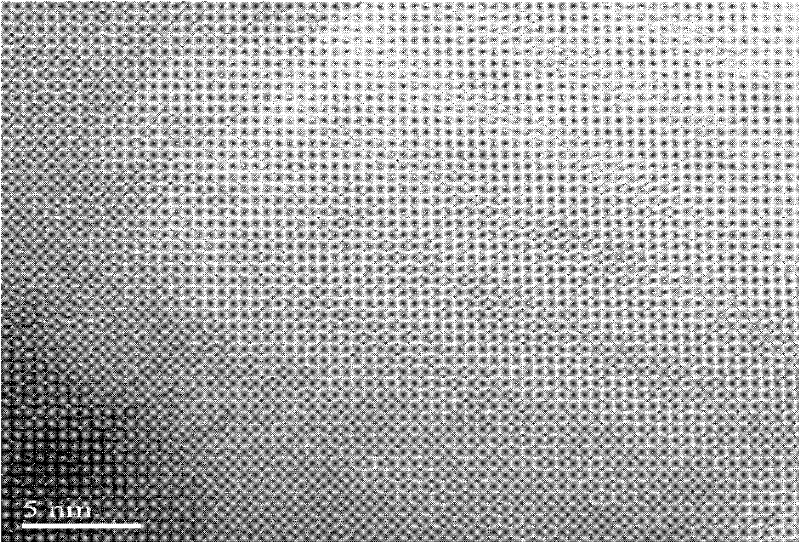

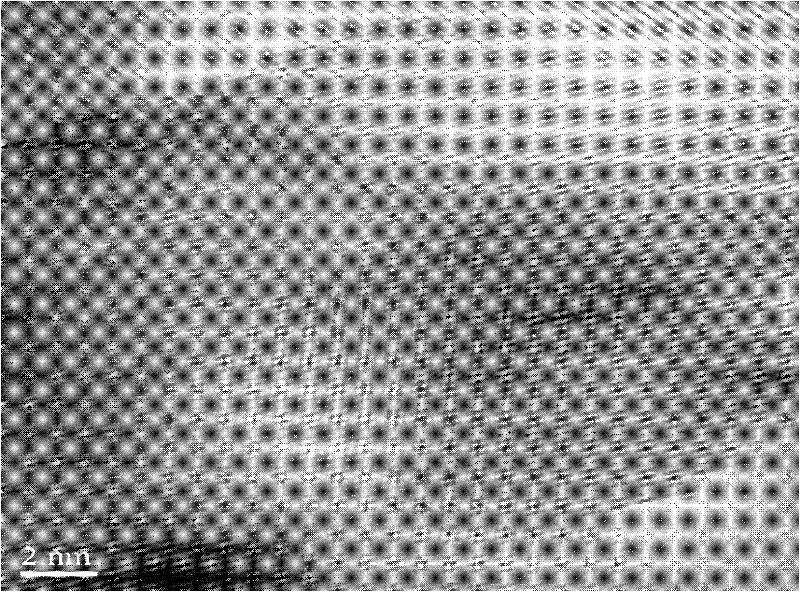

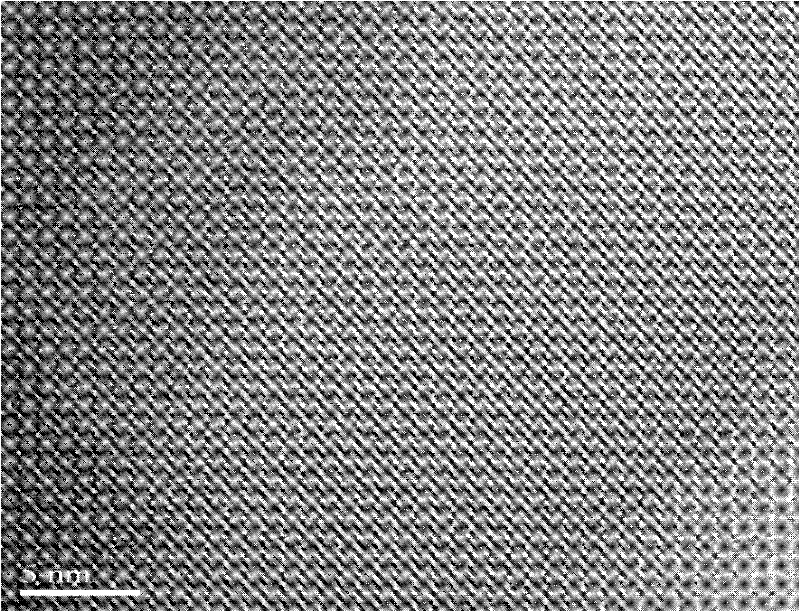

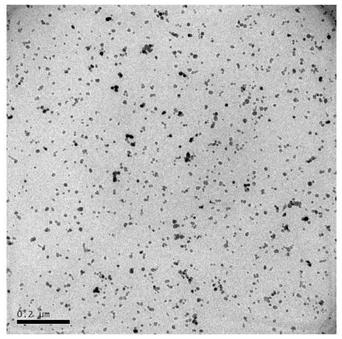

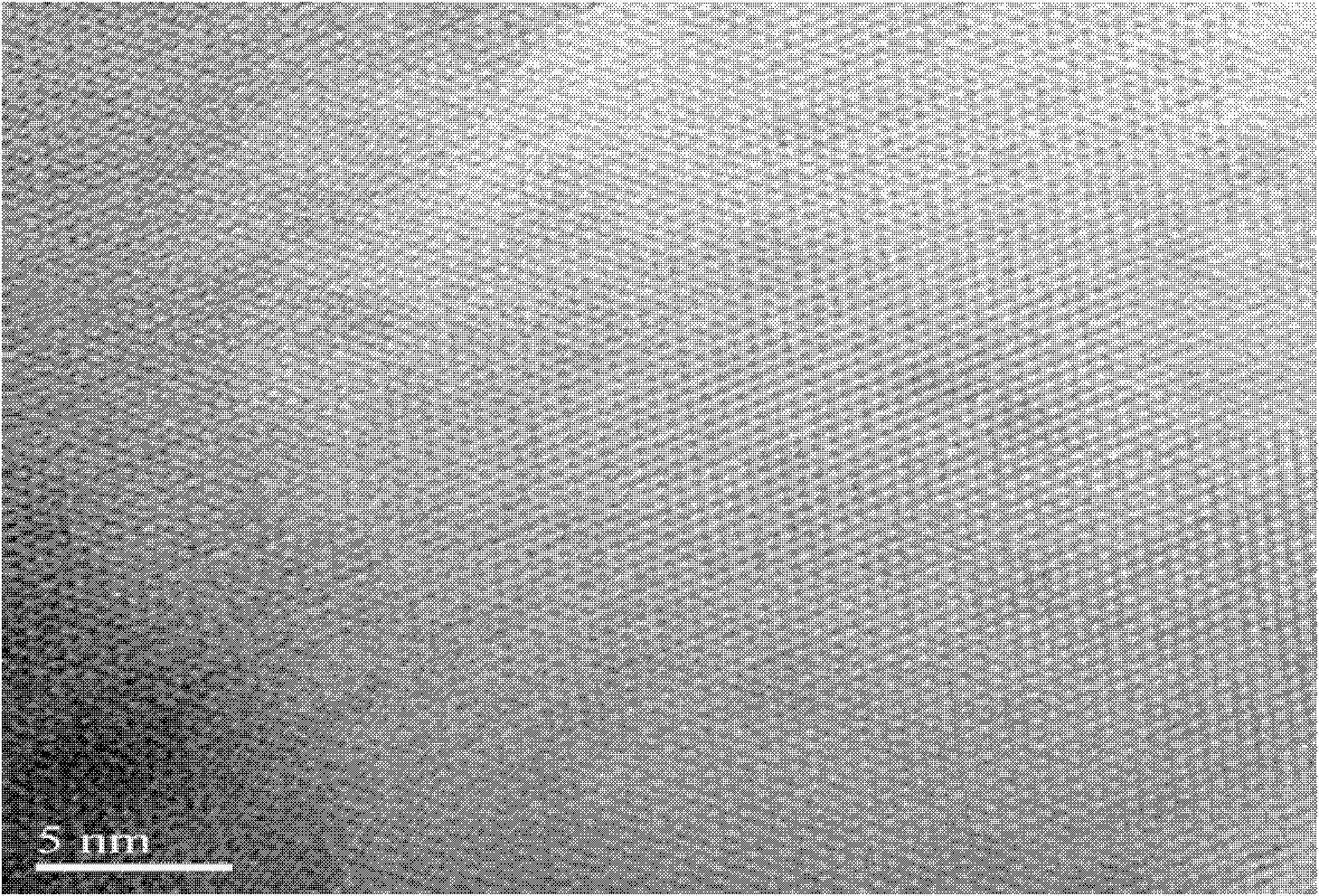

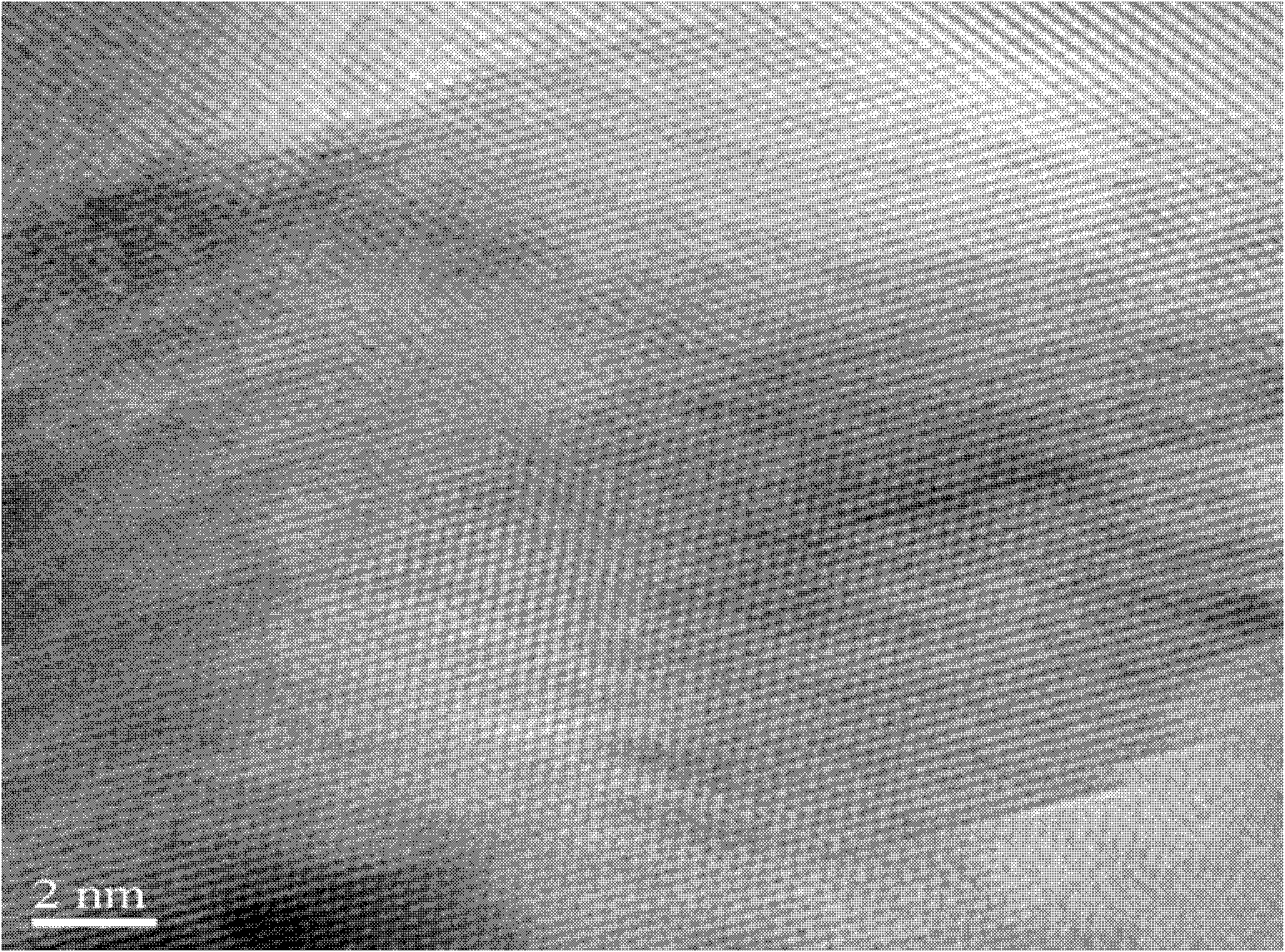

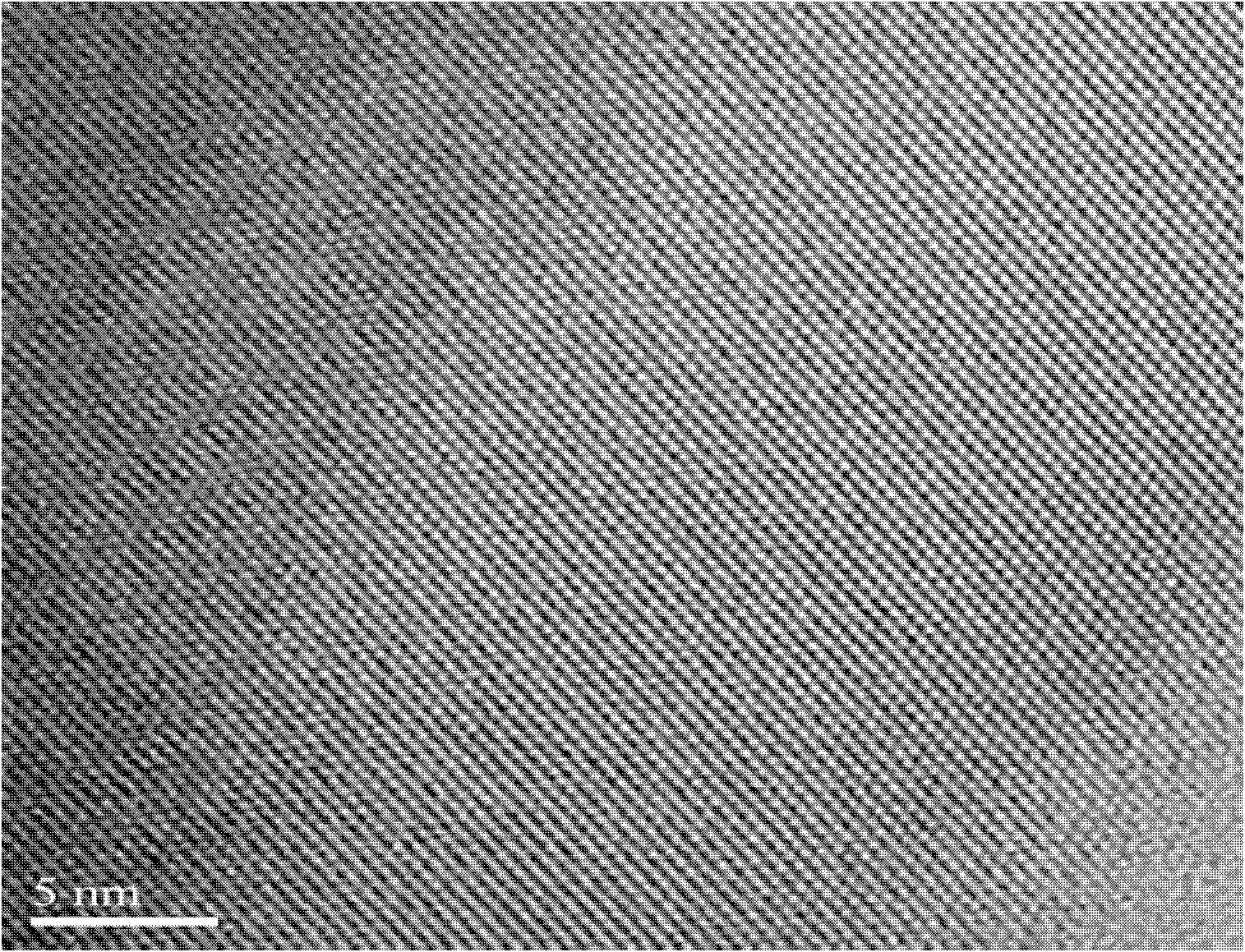

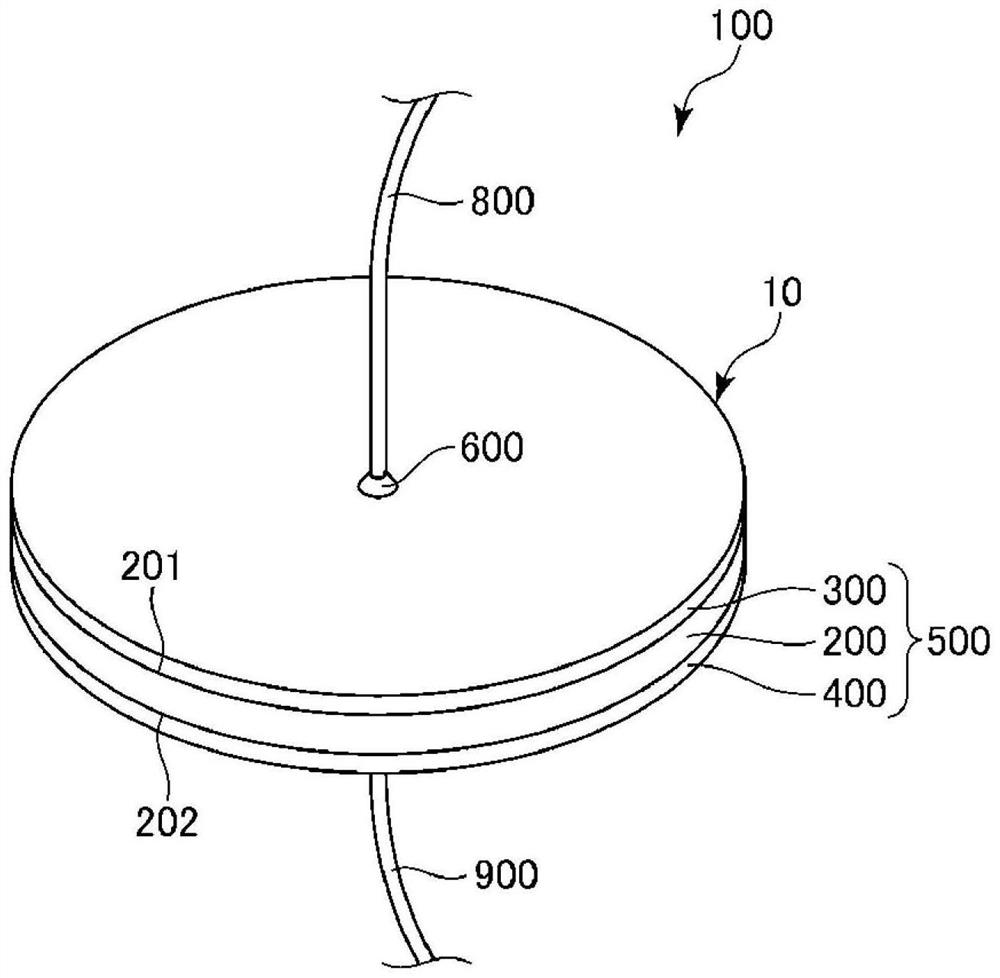

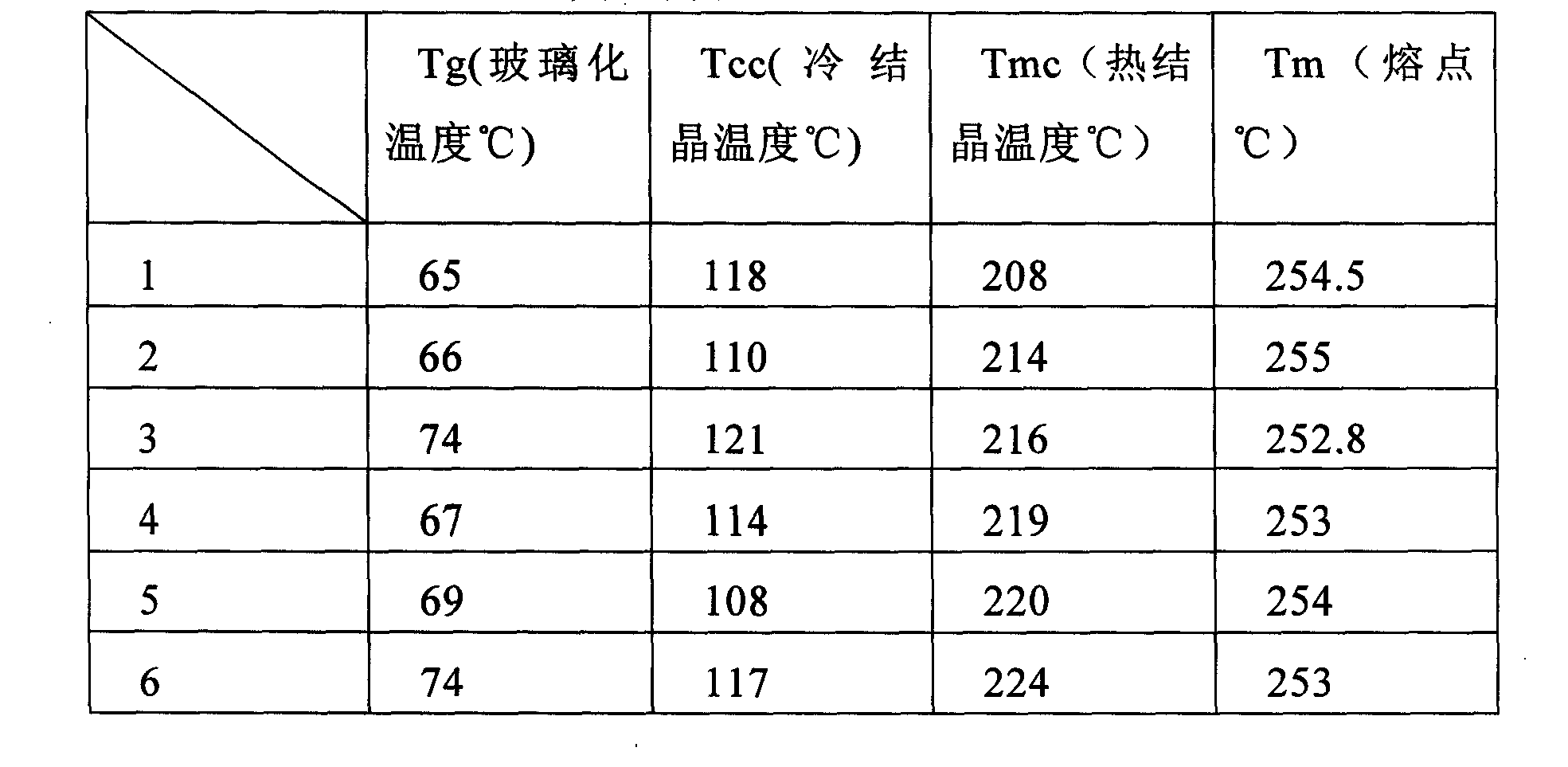

Polymer crystalline materials

ActiveUS20100063235A1Maintain good propertiesGood heat toleranceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceCrystalline materials

One embodiment of the present invention provides polymer crystalline materials containing crystals of the polymer and satisfying the following requirements (I) and (II) or the following requirements (I) and (III): (I) the polymer crystalline materials a crystallinity of 70% or greater; (II) the crystals are 300 nm or less in size; and (III) the crystals have a number density of 40 μm−3 or greater. This allows an embodiment of the present invention to provide polymer crystalline materials which are excellent in properties such as mechanical strength, heat tolerance, and transparency or, in particular, polymer crystalline materials, based on a general-purpose plastic such as PP, which is excellent in properties such as mechanical strength, heat tolerance, and transparency.

Owner:HIROSHIMA UNIVERSITY

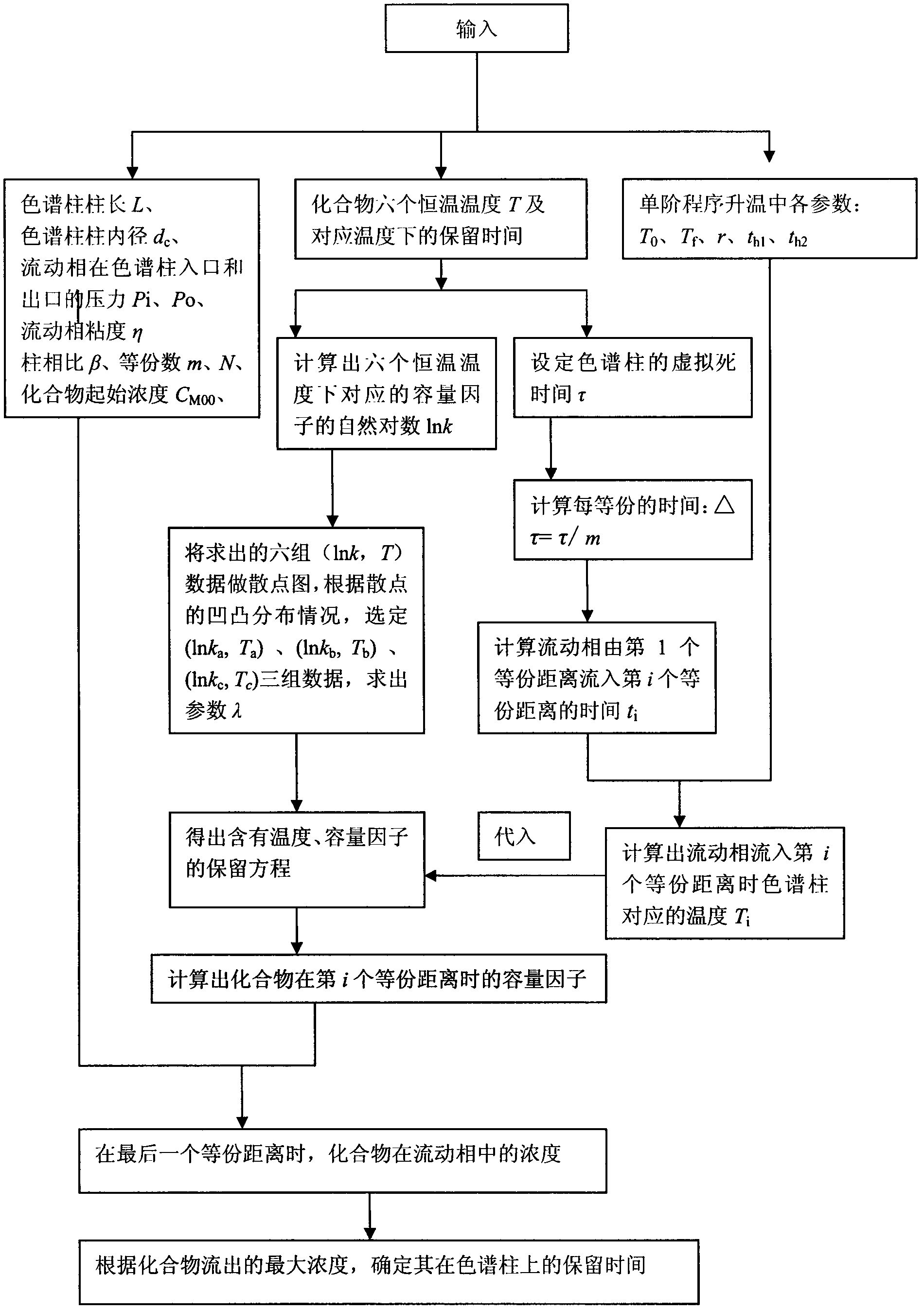

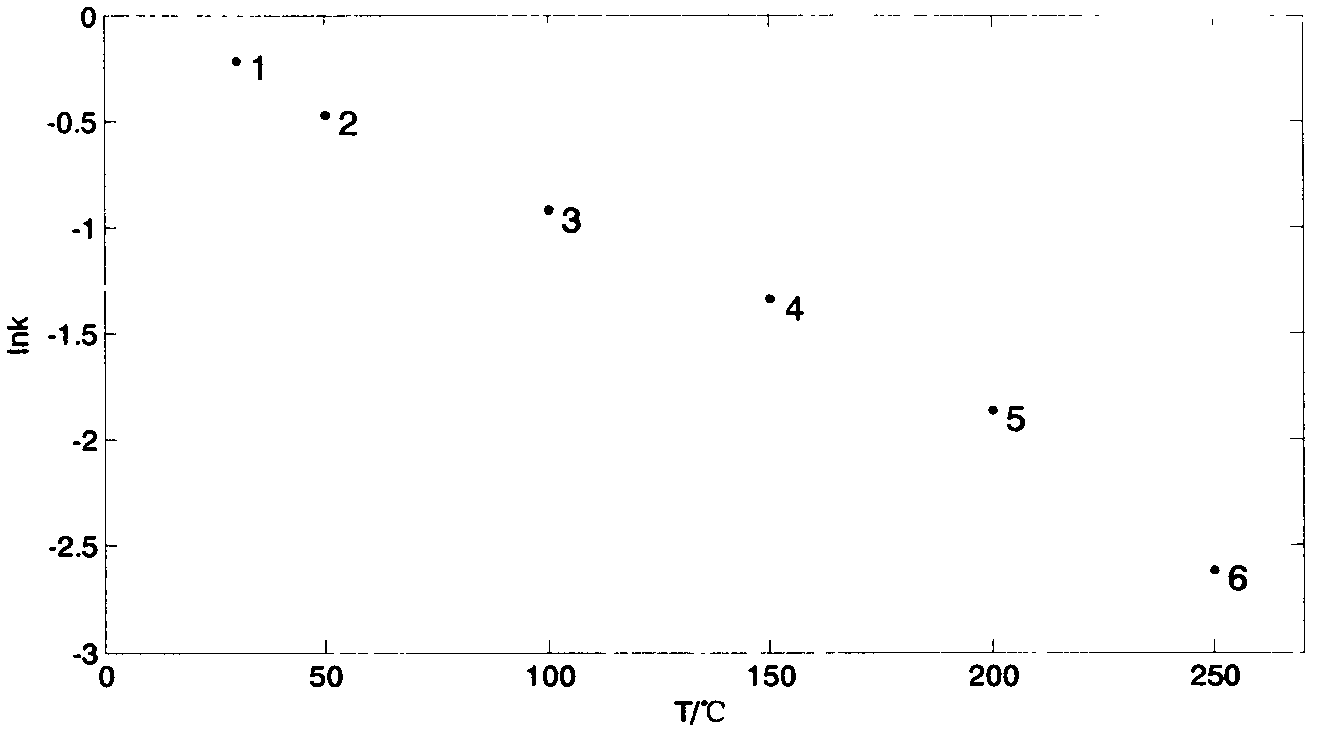

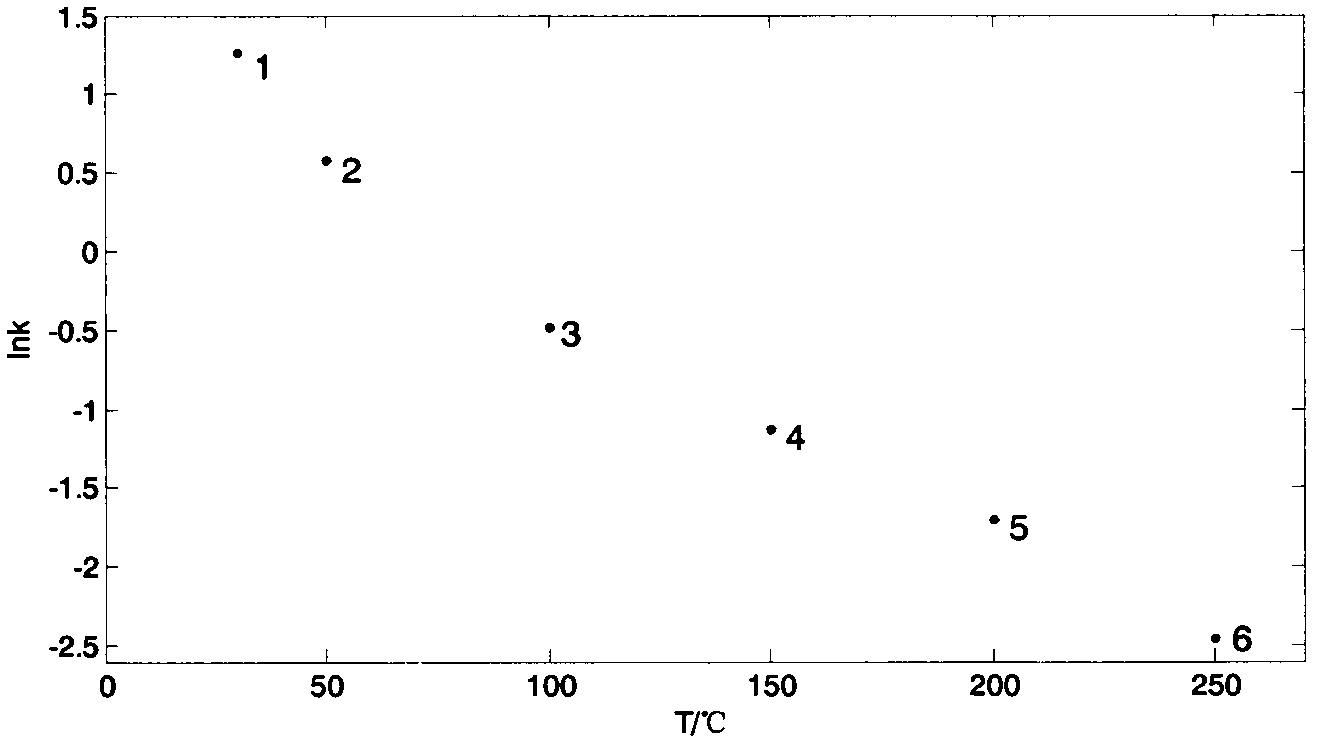

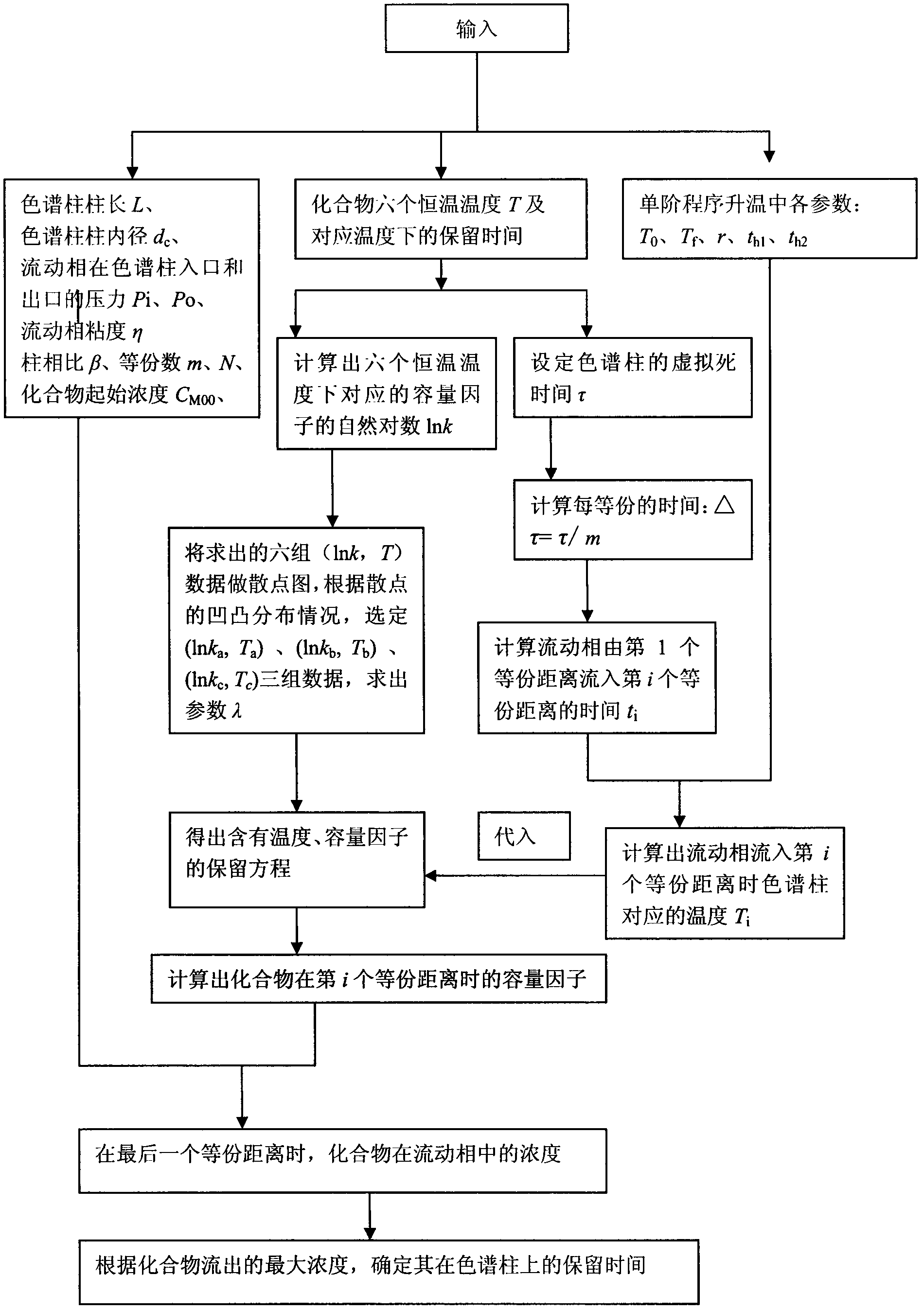

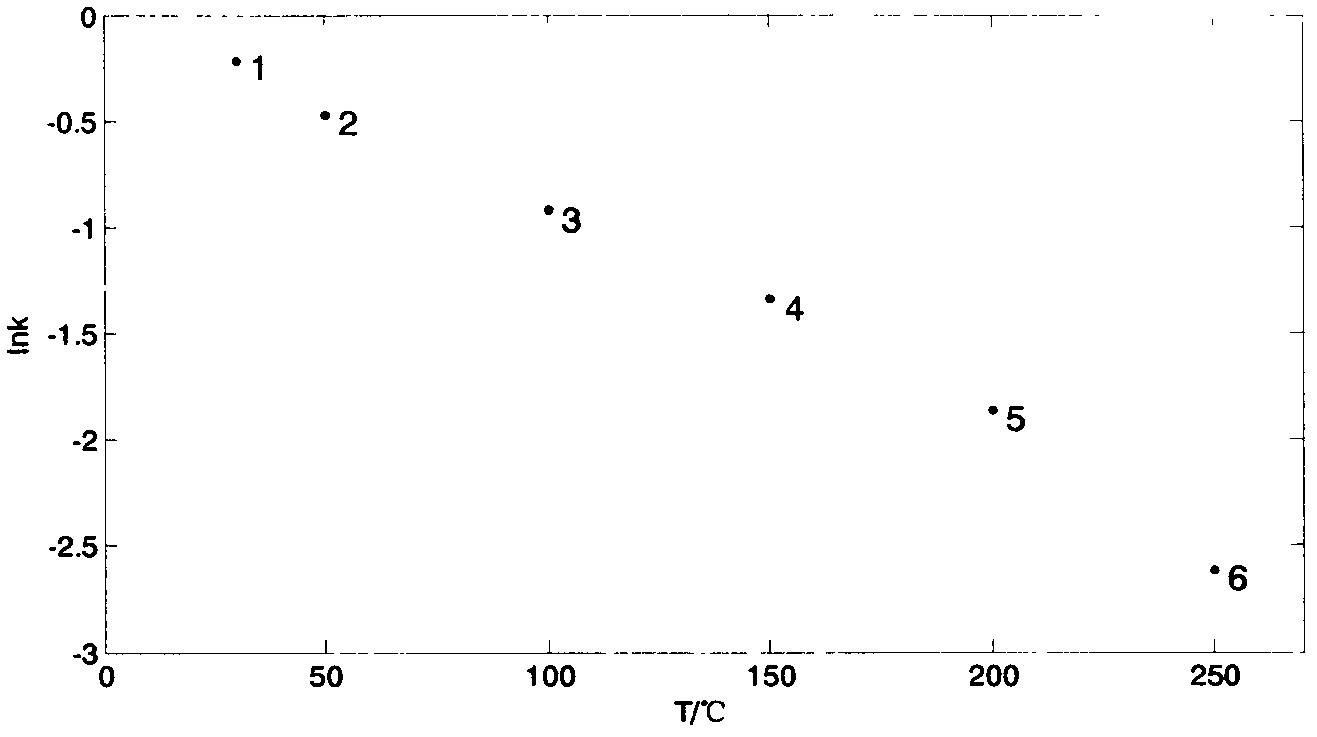

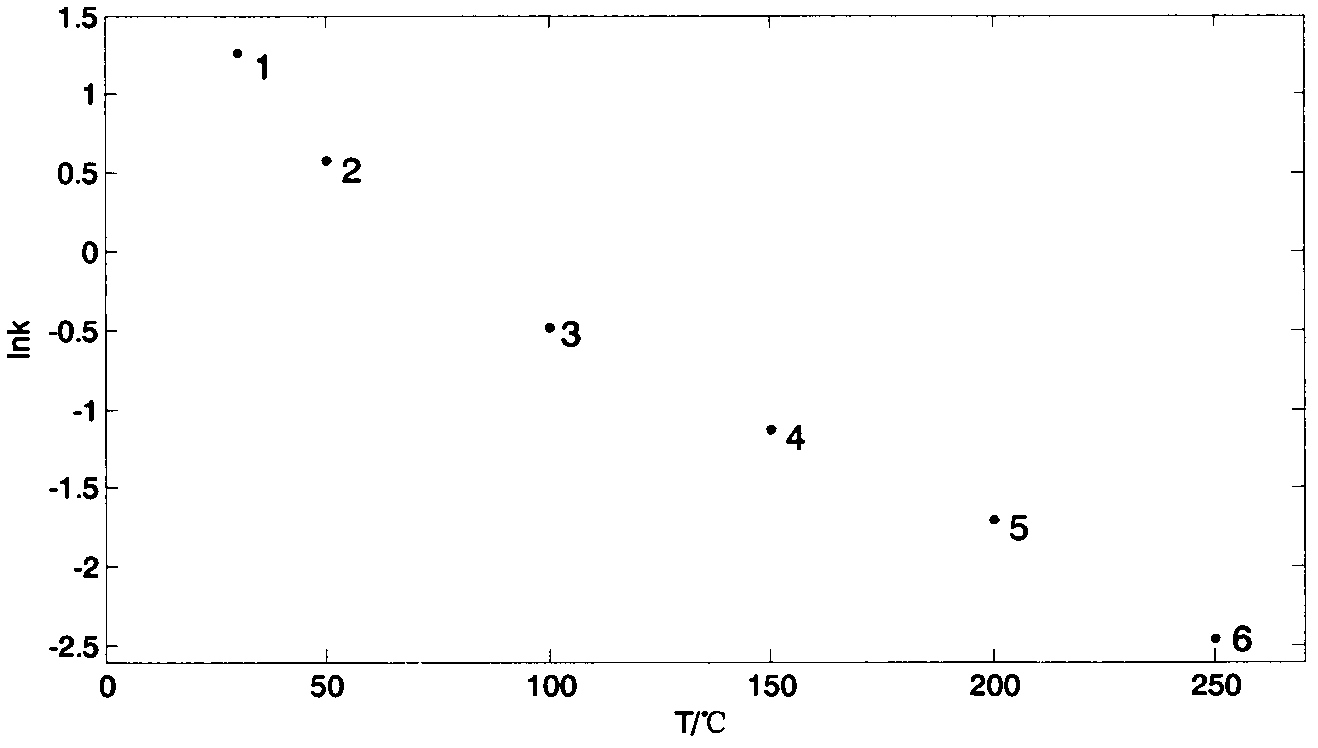

Method for predicting retention time of gas phase chromatogram based on macromolecule crystallization behavior derivation retention equation

InactiveCN102314559AHigh precisionReduce the number of experimentsSpecial data processing applicationsDead timeGas phase

The invention discloses a method for predicting retention time of a gas phase chromatogram based on a macromolecule crystallization behavior derivation retention equation. The method comprises the following processes: deducing a retention equation curve which contains temperature and capacity factors based on macromolecule crystallization behavior, wherein the curve can be set up by only using three known data points which contain temperature and capacity factors of a compound at corresponding temperature; setting virtual dead time for a chromatographic column at a random temperature point according to measured retention time at a constant temperature; determining the capacity factor of the compound at the random temperature point through differentiating and integrating the whole chromatographic column according to the set retention equation curve; and predicting the retention time of the compound on the chromatographic column under a temperature-programming condition by using the data, and comparing the predicted retention time with an actually-measured value. The method for predicting the retention time of the gas phase chromatogram based on the macromolecule crystallization behavior derivation retention equation disclosed by the invention has the following advantages that: the number of adopted data points is few, and the number of experiments is reduced; the dead time has no need of measuring, and the process for predicting is simplified; and the predicting accuracy is high, and the application range is wide.

Owner:TIANJIN UNIV

Method for preparing polymer crystal at low temperature by using ultraviolet polymerization

InactiveCN102250263AWide temperature rangeEster polymer adhesivesCoatingsUltravioletPolymer crystals

The invention relates to a method for preparing a polymer crystal, and belongs to the field of ultraviolet polymerization method. The method is characterized in that: the method comprises three polymerization reactions according to the following three directions: (1) mixing a photopolymerizable monomer and small amount of an initiator according to a certain ratio, followed by carrying out polymerization under the ultraviolet irradiation; (2) mixing two photopolymerizable monomers and small amount of an initiator according to a certain ratio, followed by carrying out polymerization under the ultraviolet irradiation through copolymerization reaction; (3) dissolving a photopolymerizable monomer in a certain amount of a solvent, followed by adding small amount of an initiator according to a certain ratio to carry out polymerization under the ultraviolet irradiation; then the prepared photopolymerizable system is placed at a low temperature less than -80-0 DEG C to enable the prepared photopolymerizable system to be converted from the transparent liquid to the crystal, then 30-80 mW / cm<2> of the ultraviolet is adopted to carry out irradiation for 1-50 minutes to obtain the polymer crystal. The method provided by the present invention is easy to be controlled, has simple steps, simple post treatment operation, and no pollution to environment.

Owner:BEIJING UNIV OF CHEM TECH

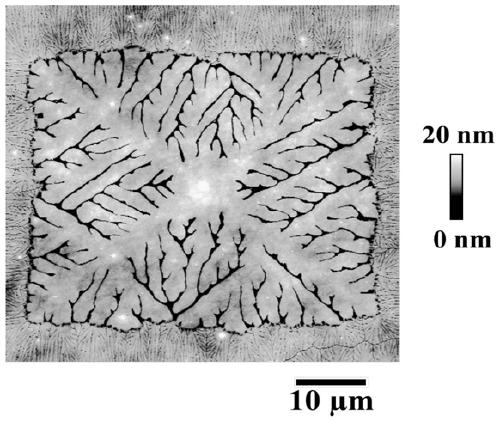

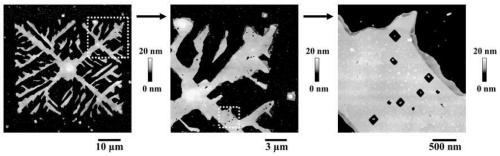

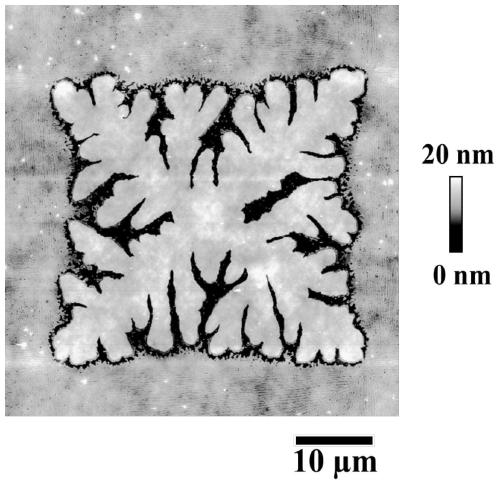

Method for constructing micro-nano patterns in high-molecule film lamellas through selective dissolution

The invention discloses a method for constructing micro-nano patterns in high-molecule film lamellas through selective dissolution. According to the method, polyoxyethylene is utilized as a raw material and is completely dissolved into an organic solvent to obtain a mixed solution; the mixed solution is spin coated to a silicon wafer to obtain a polyoxyethylene film; melting isothermal crystallization is performed on the polyoxyethylene film under a nitrogen protective atmosphere; the organic solvent is utilized to dissolve the film subjected to the isothermal crystallization; the solvent is blown and dried after the dissolution is finished, and the different patterns can be constructed in the film lamellas. The method is simple and easy to operate; the method can be applied to constructing the different structural patterns in the high-molecule lamellas, can judge stability of the inside in the lamellas through structures and can provide technical research contents of important theoretical support and the like for researching the high-molecule crystallization materials. The effects on high-molecule crystallization can be theoretically deepened, a crystallization state can be regulated in actual application, performance is optimized, materials and products with preset performance can be obtained, and very important significances are achieved.

Owner:ZHENGZHOU UNIV

Novel heat insulation and water proof foaming agent and preparation method thereof

The invention relates to a building material and a preparation method thereof, in particular to novel insulating waterproof foaming agent and a preparation method thereof. The novel insulating waterproof foaming agent comprises the following components by weight percentage of the total weight of the novel insulating waterproof foaming agent: 10 to 15 percent of rosin, 2.5 to 3.75 percent of caustic soda, 0.001 to 0.003 percent of citric acid, 0.05 to 0.1 percent of SM efficient water-reducing agent, 0.5 to 1 percent of silica powder, 35 to 47 percent of rubber powder, and 35 to 50 percent of water. The preparation method for the novel insulating waterproof foaming agent comprises the following steps: firstly mixing, stirring and heating the rosin and the caustic soda; then dissolving the SM efficient water-reducing agent, the citric acid and the silica powder into the water, heating and insulating the mixture; and mixing the two mixtures into a heating container, adding water into the mixtures and stirring the mixtures, and adding the rubber powder with required amount into the twice mixtures and stirring the mixtures. Compared with the prior art, the method adopting compound foaming improves quality of the foam greatly, the inner wall of a bubble formed by foaming can form a layer of extremely thin high-molecular crystal glue film with waterproof function, and mortar added with the foaming agent also has better heat-insulating property.

Owner:WUHAN XIN HEARS THE LUCKY ENVIRONMENTAL PROTECTION ARCHITECTURAL ENG TECH

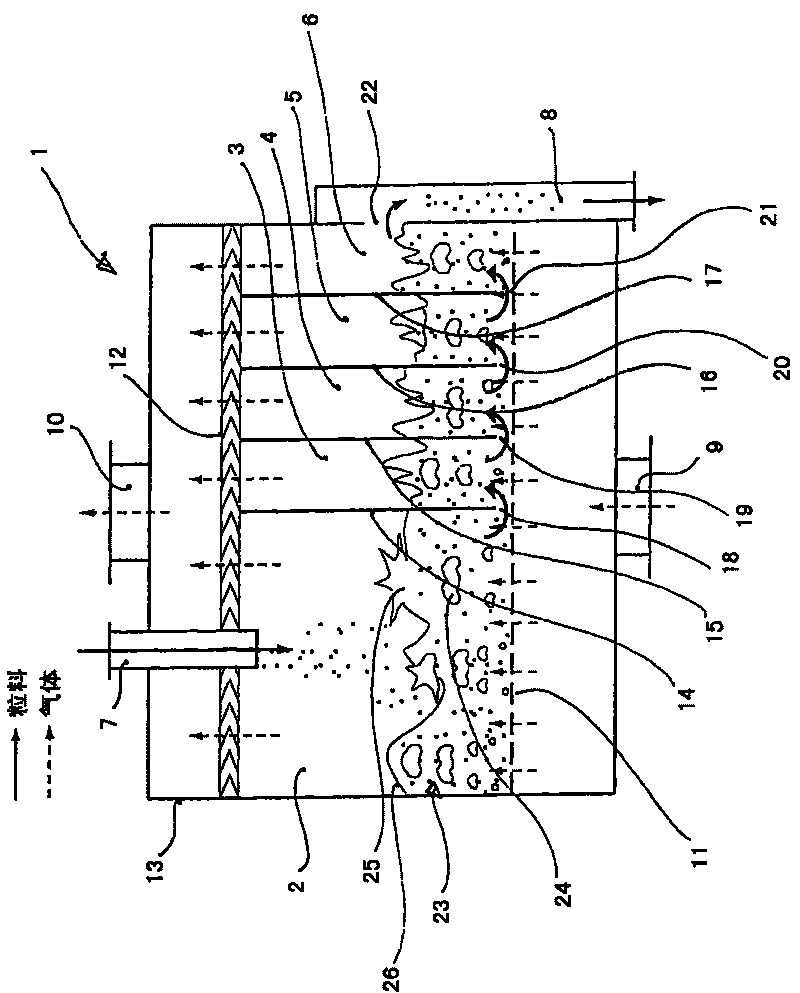

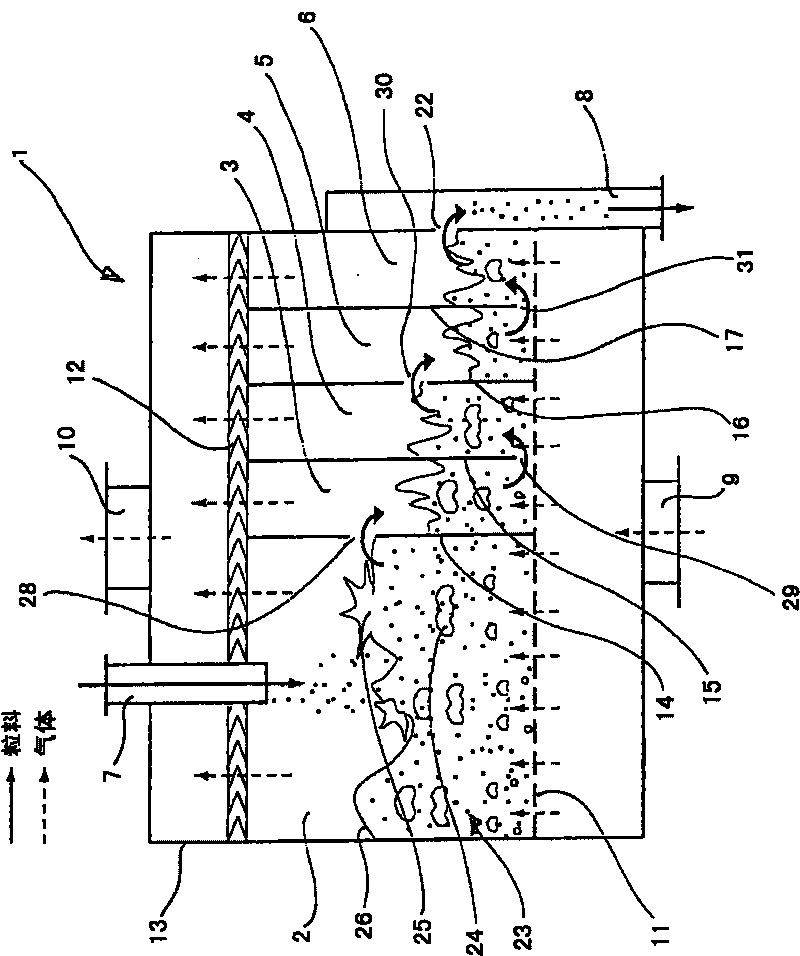

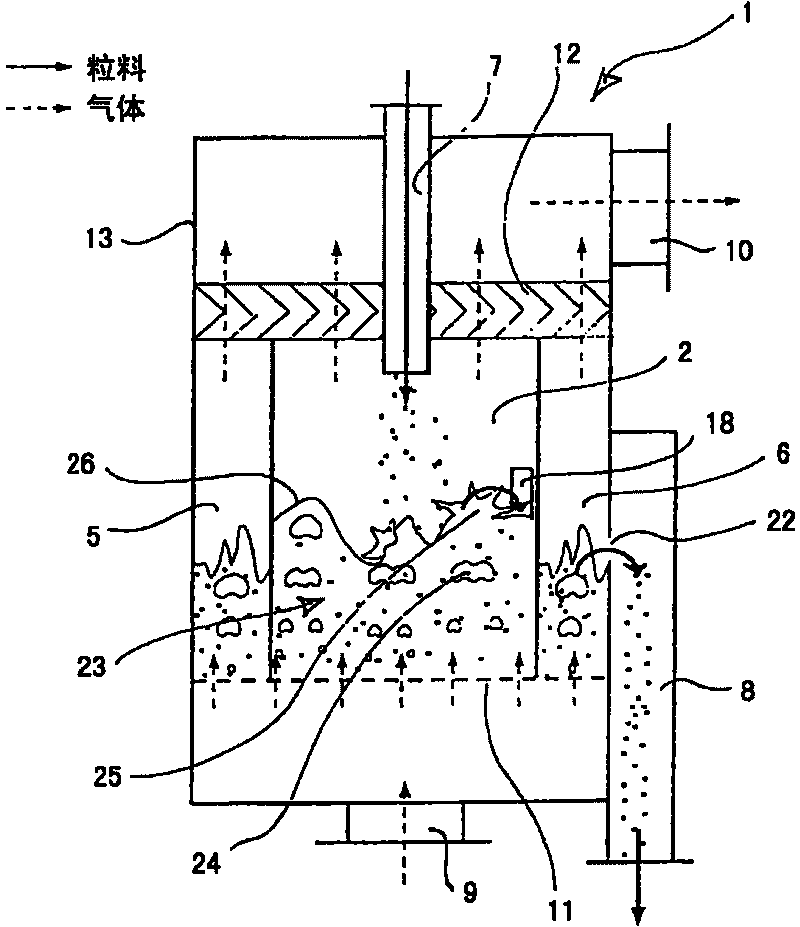

Process and apparatus for direct crystallization of polymers under inert gas

ActiveCN103660065APressurized chemical processMaterial granulationEngineeringCrystallization of polymers

An apparatus for continuous pelletization and crystallization of a polymer includes a unit for forming a polymer pellet material and cooling the pellet material in a liquid cooling medium. An after-connected drying unit has an exit opening for exporting gas and preferably selecting air and a crystallizer for crystallizing the pellet material. The crystallizer communicates via a connection line (5) with a pre-connected unit for separating the liquid cooling medium from the pellet material and drying the pellet material. The crystallizer (6) communicates with an inert gas tank via an inlet (6a), whereby the pressure in the crystallizer can be increased relative to the pressure in the drying unit (4). In addition, A related process for continuously preparing the partially crystallized polymer particles is also disclosed.

Owner:POLYMETRIX AG

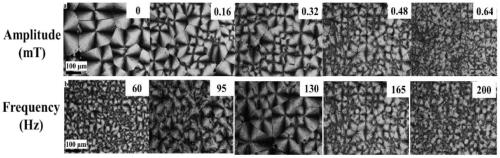

Method for controlling crystallization of polylactic acid through alternating electromagnetic field

InactiveCN109810260AAlternating magnetic field strength is smallReduce energy consumptionCrystallographyOxide composite

The invention discloses a method for controlling the crystallization of polylactic acid through an alternating electromagnetic field and belongs to the technical field of polylactic acid crystallization modification. The method comprises the following steps: firstly, uniformly dispersing ferroferric oxide particles into the polylactic acid by adopting a solution blending or melt blending method, so as to obtain a polylactic acid / ferroferric oxide composite material; then putting a polylactic acid / ferroferric oxide composite material sample into the alternating electromagnetic field and carrying out heat insulation and crystallization; the movement of a polylactic acid molecular chain can be accurately controlled through controlling the frequency and strength of the alternating electromagnetic field, so that the crystallization morphology and the crystallization degree are controlled, and cannot be controlled through other methods for regulating the crystallization of the polylactic acid; furthermore, the strength of the electromagnetic field needed by the method is low and the method hopefully becomes one method which is widely used for controlling the crystallization of polymers.

Owner:HUBEI UNIV OF TECH

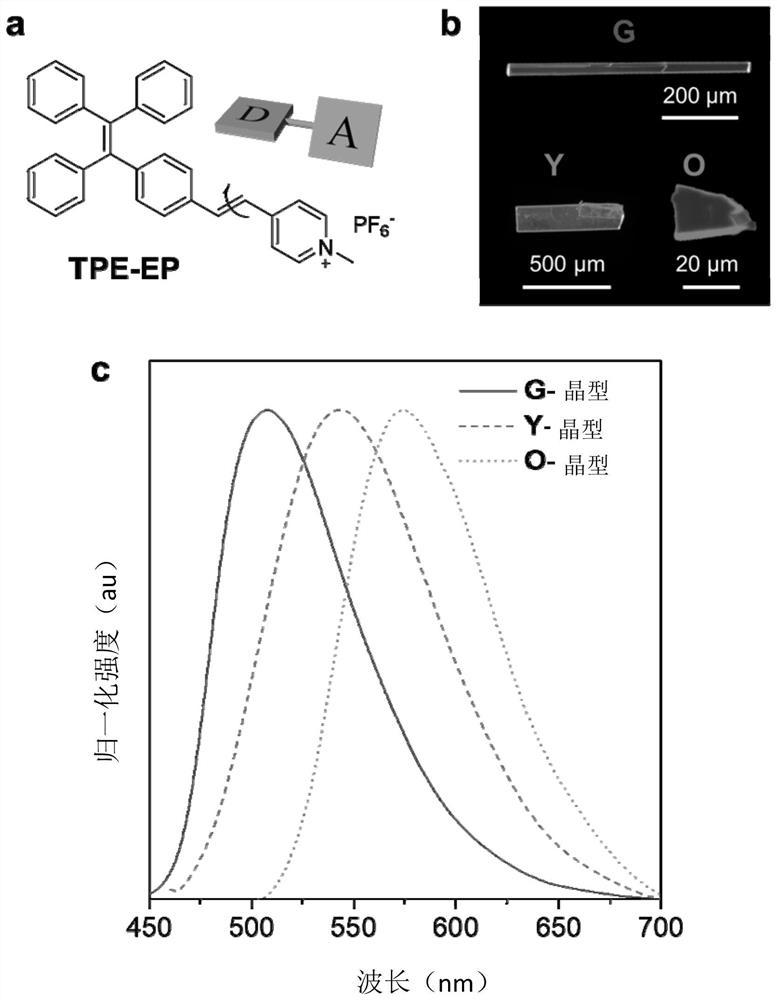

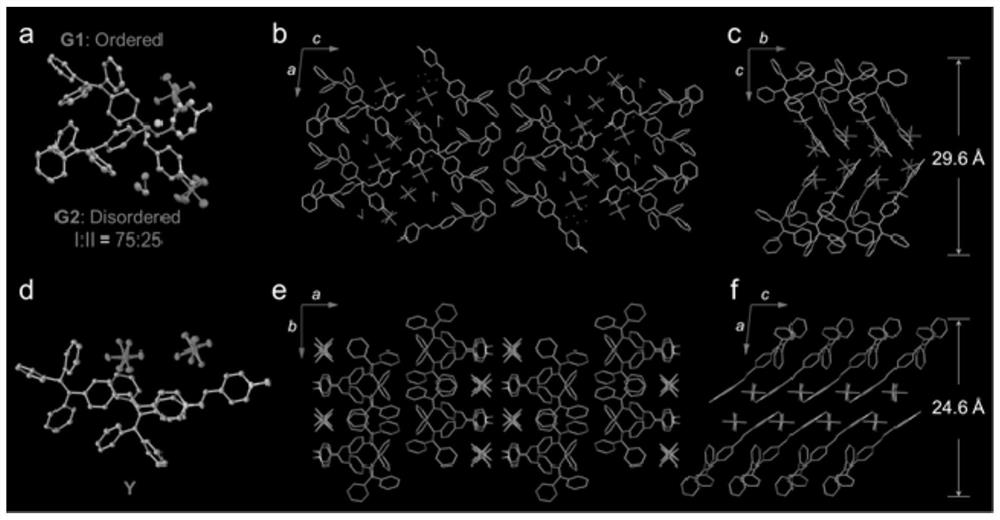

AIE macro-molecule crystallinity fluorescence visualization method

The invention relates to an AIE luminescent compound and application thereof in the aspect of visual characterization of polymer crystal fluorescence. The polymer fluorescence visualization method comprises the following steps: synthesizing an aggregation-induced emission (AIE) luminophor; and dissolving the IE molecules and general polymer polylactic acid (PLLA) to form a mixture; PLLA with different crystallinity degrees is obtained through a solvent evaporation method; according to different aggregation modes of the AIE molecules in the macro-molecule crystallization area / amorphous area, different light emitting colors of the macro-molecule crystallization / amorphous area are obtained, and visualization of the macro-molecule crystallinity is achieved.

Owner:THE HONG KONG UNIV OF SCI & TECH

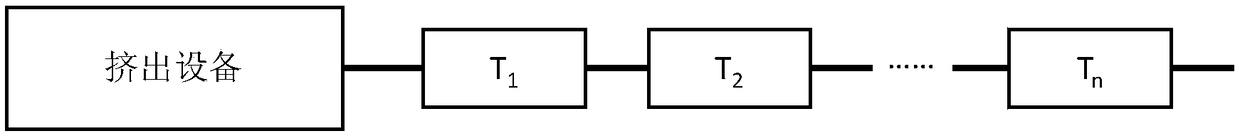

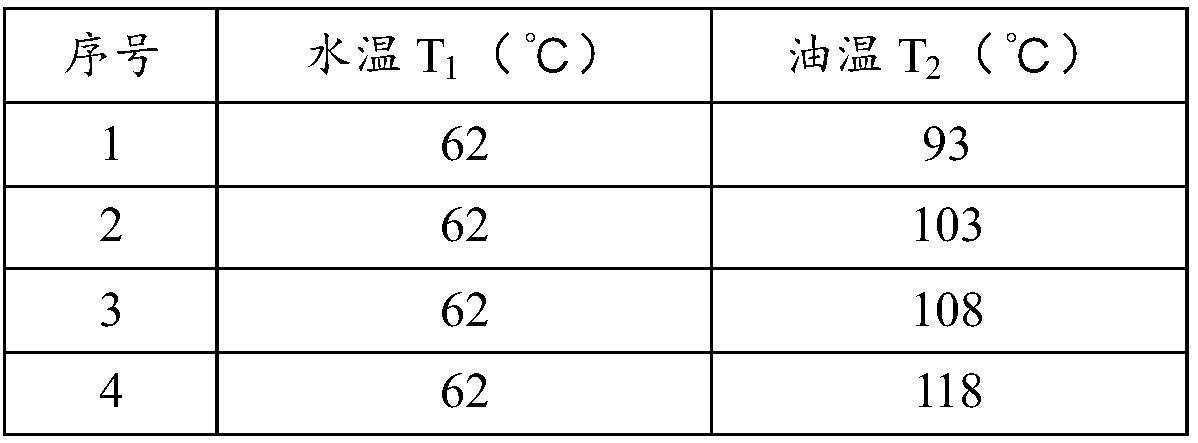

Technology for controlling polymer crystallization degree in extrusion processing process

The invention relates to the field of polymer crystallization degree control, and provides a technology for controlling polymer crystallization degree in an extrusion processing process. The technology for controlling the polymer crystallization degree in the extrusion processing process comprises the following steps that a crystalline polymer is melted and extruded; the extruded crystalline polymer melt is prepared the wire rod of the polymer material through a heat medium combination, the heat medium combination comprises n sections of heat medium, wherein n is a positive integer; and the number of the heat medium passing through the melt is 1, 2, 3...and n in sequence, and the temperature of the corresponding heat medium is T1, T2, T3...and Tn. The technology heat medium for controllingthe polymer crystallization in the extrusion processing process is divided into a plurality of sections, the section number of the heat medium and the specific temperature of each section can be selected flexibly combining with the crystallization behavior, the chemical property, the cost requirement and the like of the material; then the heat history of the material after extrusion is controlled, the crystallization of the materials is promoted, and the extruded products is guaranteed to have stable and uniform crystallization.

Owner:JF POLYMERS (SUZHOU) CO LTD

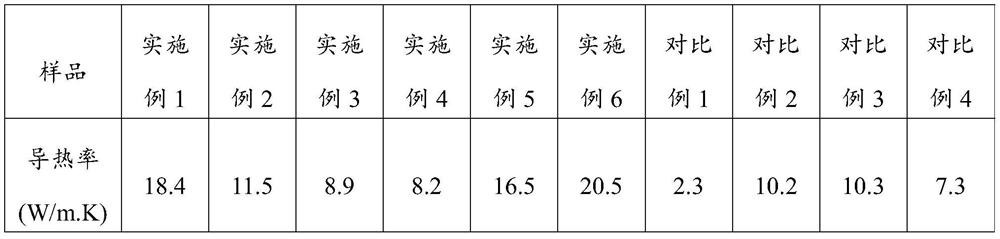

Composite fiber, preparation method of composite fiber and electronic component

The invention discloses a composite fiber, a preparation method of the composite fiber and an electronic component. The preparation method of the composite fiber comprises the following steps of mixing a biodegradable water-soluble polymer, a heat-conducting filler and a solvent to prepare a spinning solution, and performing spinning by adopting the spinning solution to prepare a nascent composite fiber, wherein before spinning, the spinning solution is subjected to molecular chain disentanglement treatment; and / or, after spinning, stretching treatment is performed on the nascent composite fiber. Through the mode, the heat-conducting filler is added into a polymer matrix to construct a heat-conducting channel in the polymer matrix, and the spinning solution is subjected to molecular chain disentangling treatment to improve the molecular crystallinity and orientation degree, and / or the nascent composite fiber is subjected to stretching treatment to optimize the orientation and arrangement of the heat-conducting filler in the polymer fiber matrix, so that the prepared composite fiber has high thermal conductivity.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

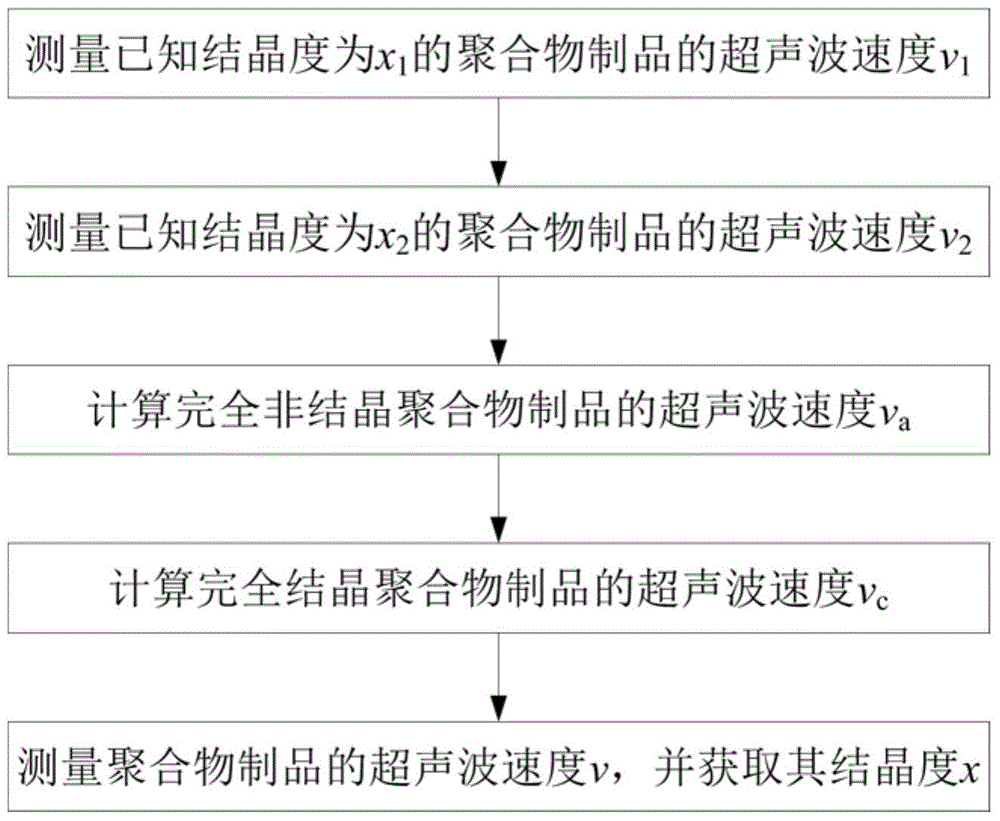

A Method for Characterizing Crystallinity of Polymer Products Based on Ultrasonic Velocity

ActiveCN104407055BNon-destructive measurementThe detection process is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesProduct baseUltrasonic velocity

The invention discloses a characterization method of the degree of crystallinity of a polymer product based on ultrasonic wave velocity. The implementation steps of the method are as follows: 1), measuring the ultrasonic wave velocity v1 of a polymer product with the degree of crystallinity of x1; 2), measuring the ultrasonic wave velocity v2 of a polymer product with the degree of crystallinity of x2; 3), calculating the ultrasonic wave velocity va of a non-crystallizable polymer product; 4), calculating the ultrasonic wave velocity vc of a completely crystallizable polymer product; 5), measuring the ultrasonic wave velocity v of the polymer product and obtaining the degree of crystallinity x of the polymer product. The invention provides a nondestructive measuring method for the degree of crystallinity of the polymer product, is low in cost, convenient to use, expected to provide a brand new and universal experimental measurement means for research on crystallization of polymer products, and has a huge market application prospect and a high market promotion valve.

Owner:ZHEJIANG UNIV

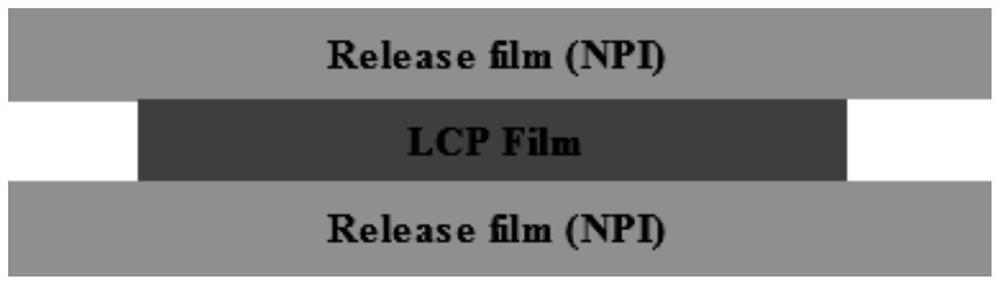

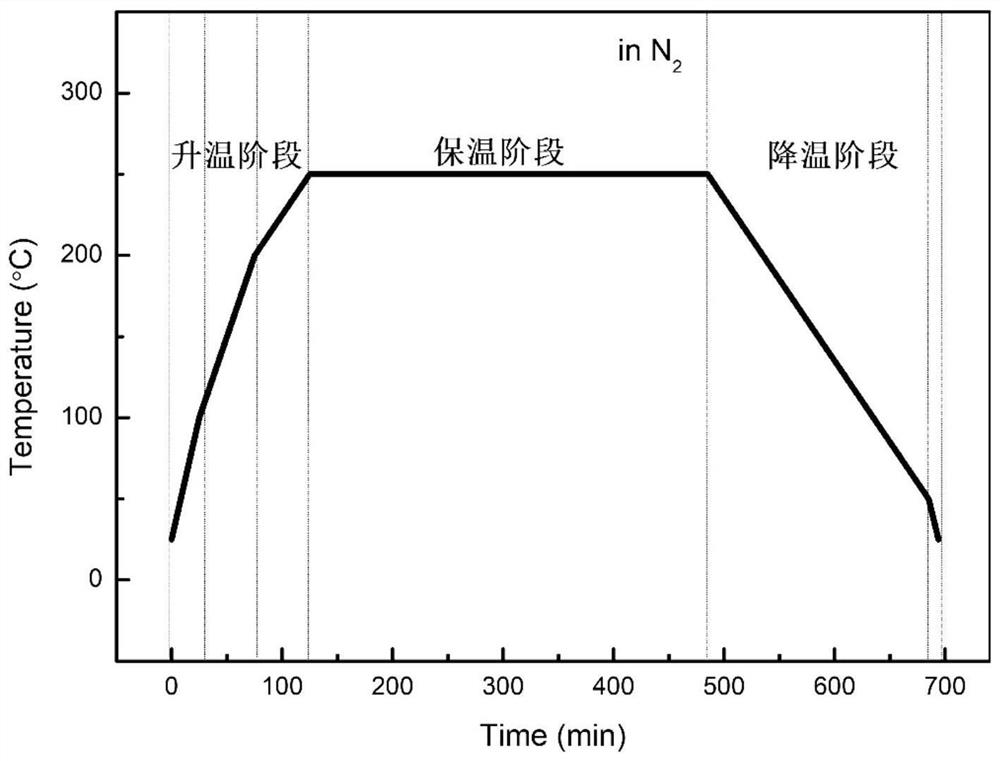

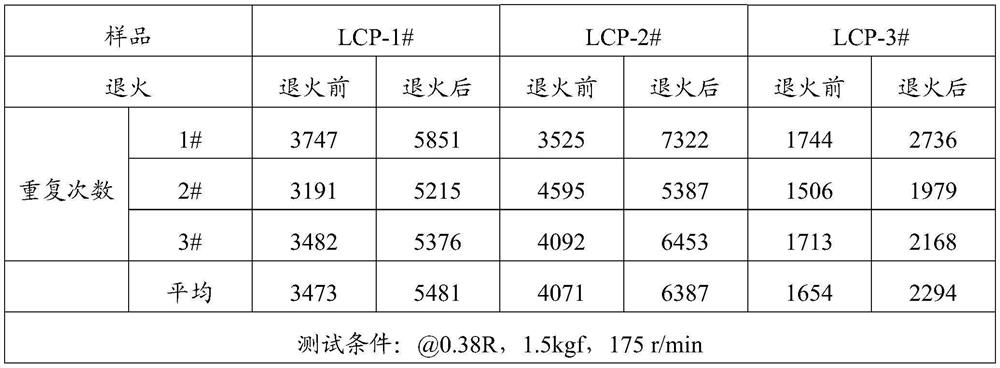

A method for improving the mechanical properties of liquid crystal polymer products

ActiveCN110760310BImprove mechanical propertiesImprove crystallization inhomogeneityLiquid crystal compositionsPolymer sciencePolymer composites

Owner:SHENZHEN SUNWAY COMM

Method for preparing polymer crystal at low temperature by using ultraviolet polymerization

The invention relates to a method for preparing a polymer crystal, and belongs to the field of ultraviolet polymerization method. The method is characterized in that: the method comprises three polymerization reactions according to the following three directions: (1) mixing a photopolymerizable monomer and small amount of an initiator according to a certain ratio, followed by carrying out polymerization under the ultraviolet irradiation; (2) mixing two photopolymerizable monomers and small amount of an initiator according to a certain ratio, followed by carrying out polymerization under the ultraviolet irradiation through copolymerization reaction; (3) dissolving a photopolymerizable monomer in a certain amount of a solvent, followed by adding small amount of an initiator according to a certain ratio to carry out polymerization under the ultraviolet irradiation; then the prepared photopolymerizable system is placed at a low temperature less than -80-0 DEG C to enable the prepared photopolymerizable system to be converted from the transparent liquid to the crystal, then 30-80 mW / cm<2> of the ultraviolet is adopted to carry out irradiation for 1-50 minutes to obtain the polymer crystal. The method provided by the present invention is easy to be controlled, has simple steps, simple post treatment operation, and no pollution to environment.

Owner:BEIJING UNIV OF CHEM TECH

Continuous thermal treatment of bulk material

InactiveCN1549762BReduce lossesReduced thermal insulationDrying solid materials with heatCrystallization by component evaporationEngineeringThermal treatment

The invention relates to a device (1) for continuous heat treatment of granulated materials, especially to the crystallization of polymer granulate, such as polyethylenterephthalate (PET) for example.The device comprises several adjacent fluidization chambers (2, 3, 4, 5, 6) respectively provided with a sieve plate (11) through which a fluidization gas used to fluidize the granulate can be insufflated into the respective chamber from below via a gas inlet (9), said gas being able to escape via a gas outlet (10) in the top area of the device. The first chamber (2) takes up the greater part ofthe overall volume of all chambers (2, 3, 4, 5, 6) and neighbouring chambers are, respectively, fluidically connected by means of product throughflow openings (18, 19, 20, 21; 28, 29, 30, 31) in the separating walls (14, 15, 16, 17) arranged therebetween. According to the inventive method, using the inventive device (1), the granulated material is guided through several adjacent fluidization chambers (2, 3, 4, 5, 6), the absolute filling level of the fluidized granulating material in the first chamber (2) being at least as high as the absolute filling level of the other adjacent chambers (3, 4, 5, 6) disposed downstream therefrom.

Owner:POLYMETRIX AG

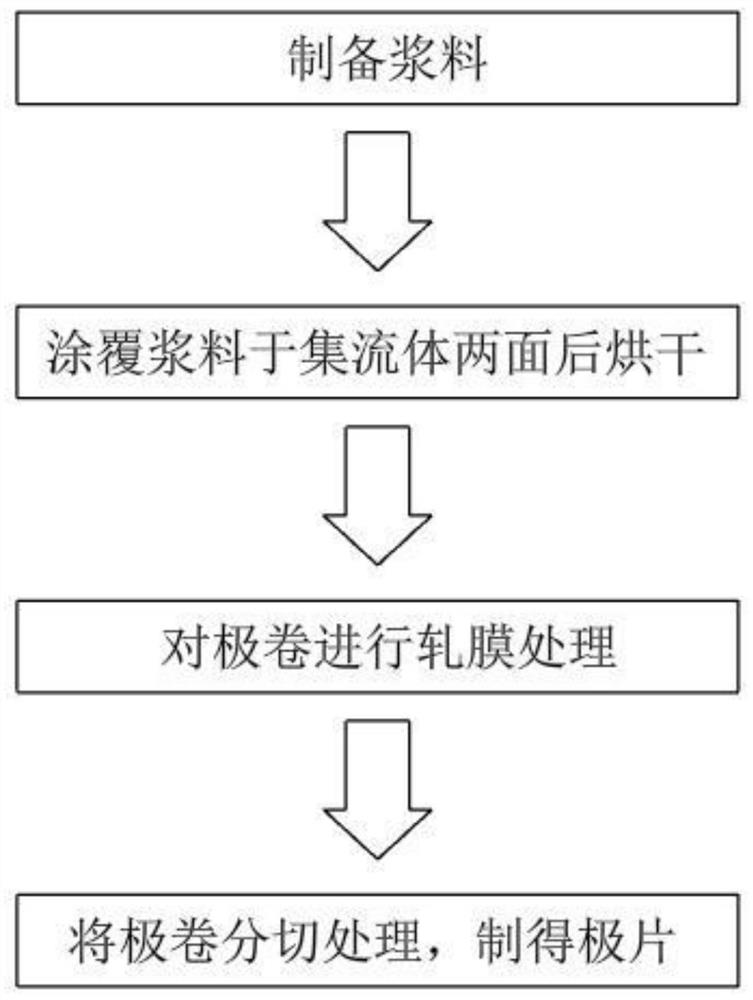

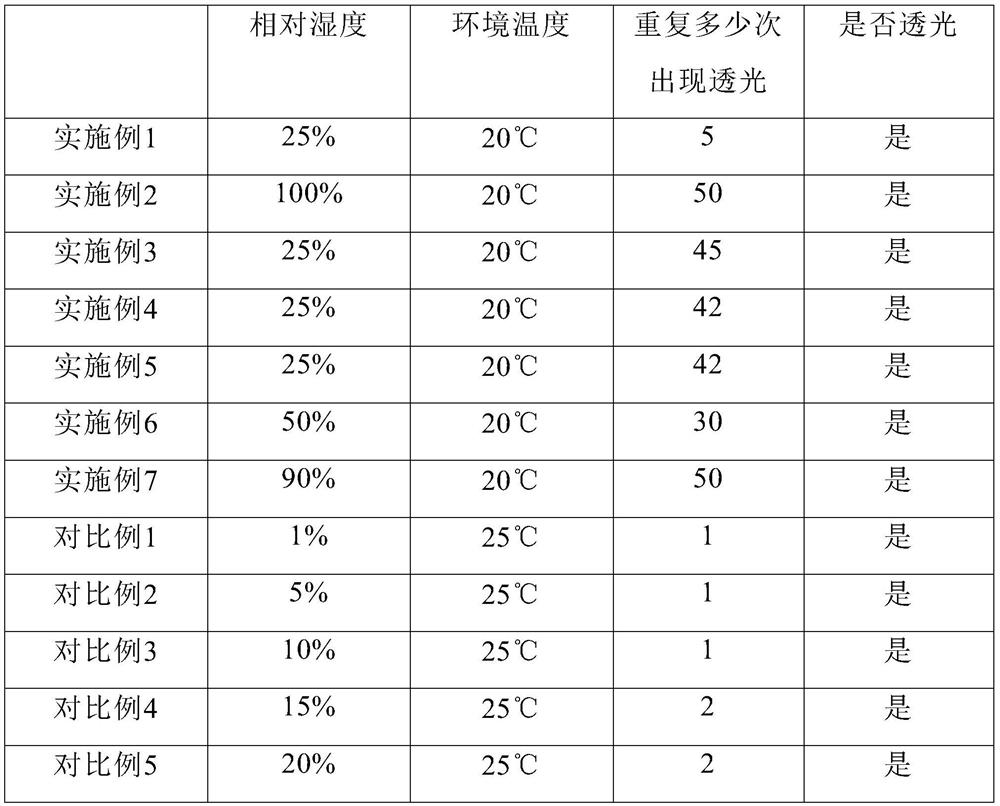

Preparation method of lithium battery positive plate, positive plate and lithium ion battery

PendingCN114864874AGood flexibilitySolve the problem of brittle fractureElectrode rolling/calenderingElectrode thermal treatmentPole piecePolymer crystals

The invention provides a lithium battery positive plate preparation method, which comprises: (1) mixing a positive electrode active material, a conductive agent, a water-based binder and a solvent according to a certain ratio, and stirring to prepare a slurry; (2) uniformly coating the slurry on the surface of a current collector, drying, and then rolling to obtain a pole roll; (3) carrying out film rolling treatment on the pole roll; (4) carrying out slitting and slicing treatment on the pole roll to prepare a pole piece; wherein the relative humidity of one or more procedures of the steps (2)-(4) is 25%-100%. According to the invention, by controlling the environment relative humidity of one or more procedures (2)-(4) to be 25-100%, the aqueous binder in the positive plate absorbs moisture in air, so that a polymer crystal chain segment of the aqueous binder is fully stretched, the flexibility of the pole plate is improved, and the problem of brittle failure of the pole plate in the processing process is solved.

Owner:陈钦湘

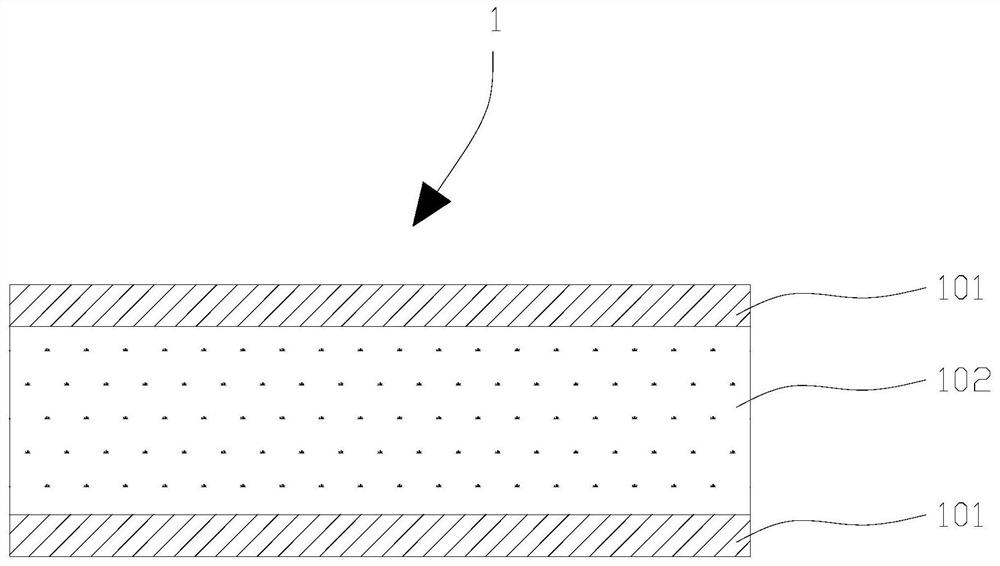

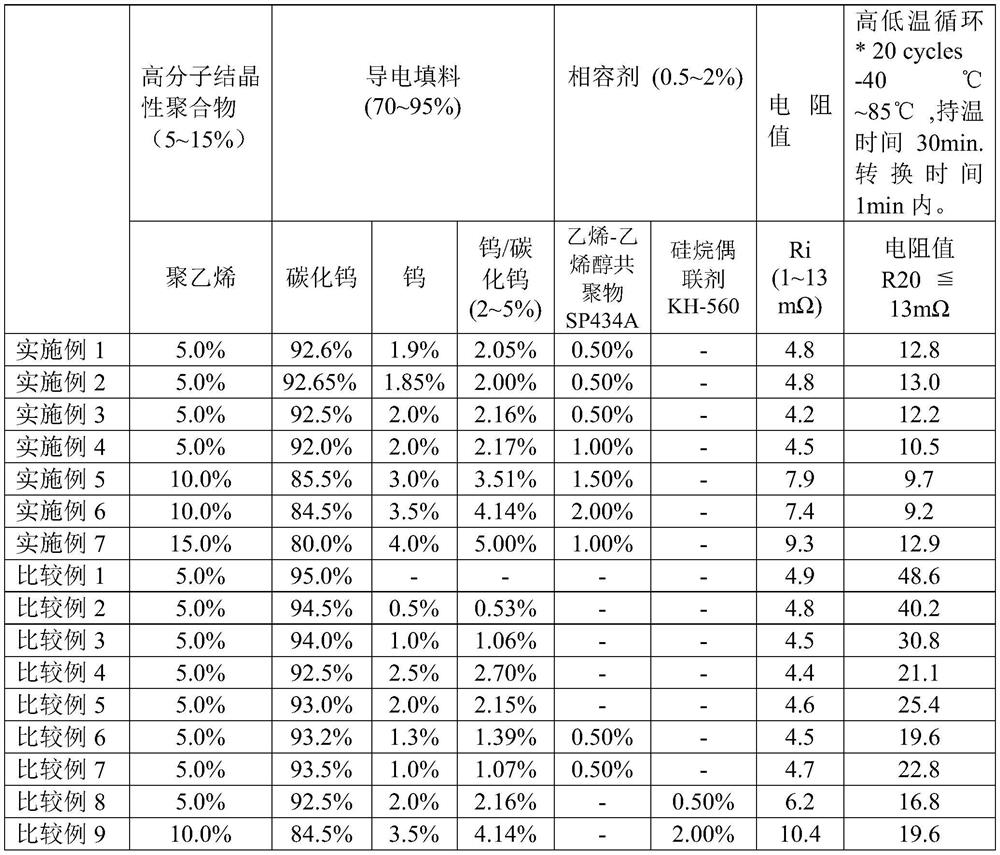

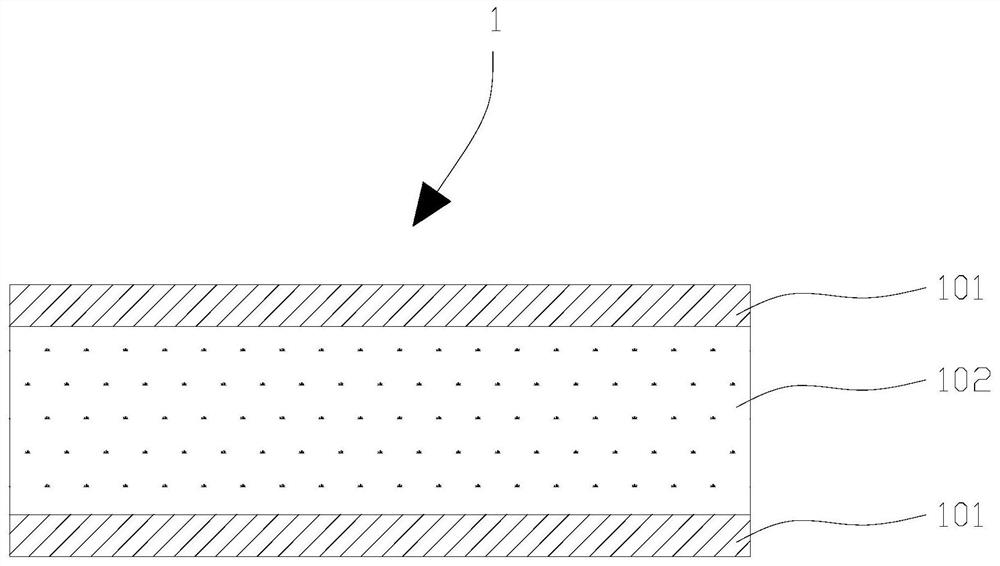

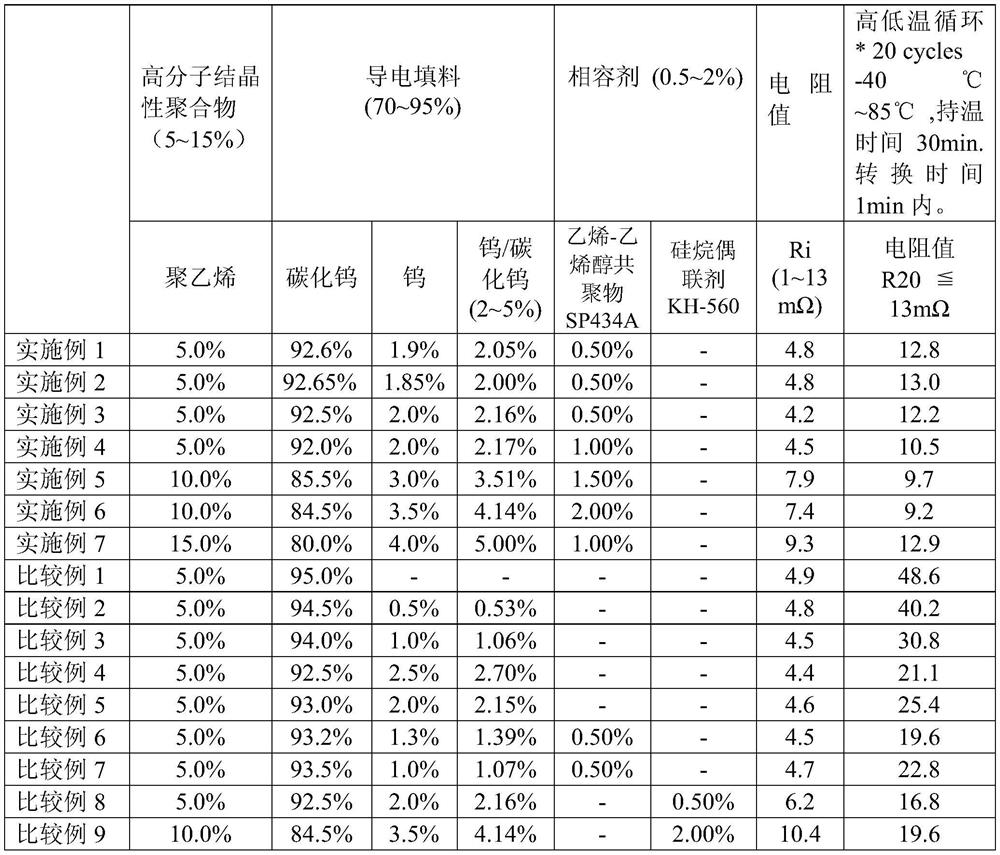

Composite material and macromolecule positive temperature coefficient thermistor made of composite material

ActiveCN112037961ARestricted movementReduce stressNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsPolymer scienceCarbide

The invention discloses a composite material and a macromolecule positive temperature coefficient thermistor prepared from the composite material. The composite material comprises a macromolecule crystalline polymer, a conductive filler and a compatilizer, wherein the macromolecule crystalline polymer accounts for 5-15 wt% of the composite material, the conductive filler accounts for 70-95 wt% ofthe composite material, the compatilizer accounts for 0.5-2 wt% of the composite material, the conductive filler is a mixture of a carbide and metal tungsten, the metal tungsten accounts for 2-6 wt% of the weight of the conductive filler, the compatilizer is an ethylene-vinyl alcohol copolymer, the thermistor comprises two conductive layers and a composite material layer, the composite material layer is arranged between the two conductive layers, the composite material layer is made of a composite material, and the thermistor has the characteristic of low initial resistance and can still keepthe characteristic of low resistance after multiple high-low temperature cycles so as to meet lithium battery stability.

Owner:THINKING ELECTRONIC IND CO LTD

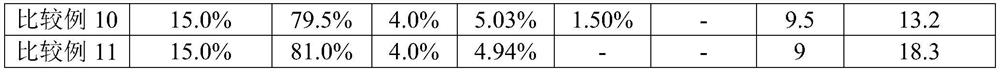

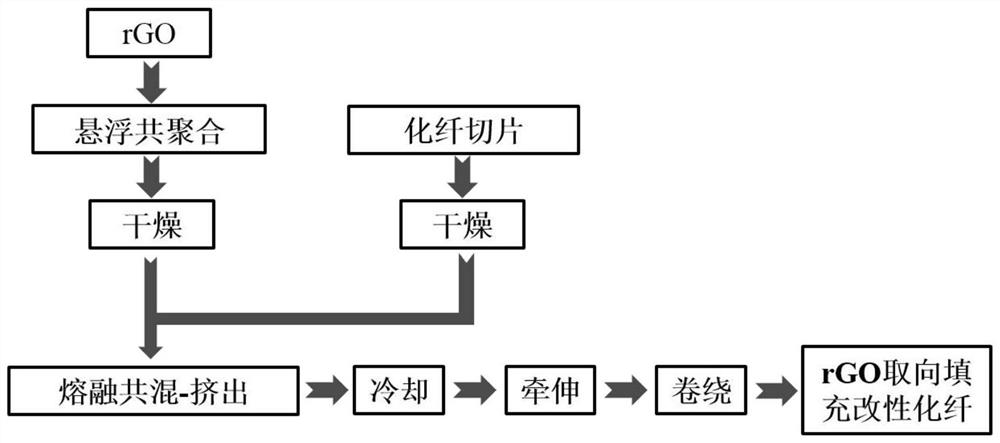

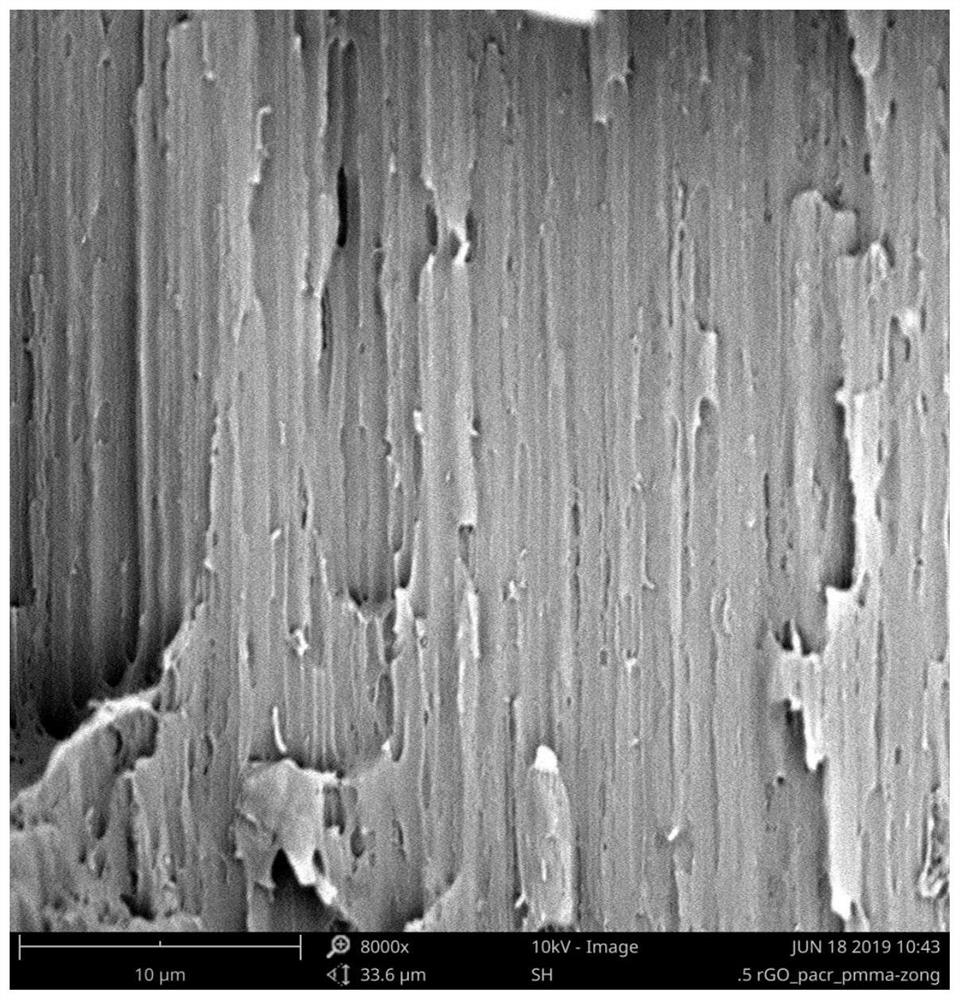

Graphene/polymer multi-orientation filling modified chemical fiber and preparation method thereof

ActiveCN112011845AImprove controllabilityMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentPolymer scienceMicrosphere

The invention provides a graphene / polymer multi-orientation filling modified chemical fiber and a preparation method thereof, and relates to the technical field of fiber modification. According to thepreparation method, graphene is coated by adopting in-situ suspension polymerization, so that the dispersion effect of the graphene is greatly improved; the compatibility between the graphene and thepolymer microspheres is improved by utilizing a comonomer, so that relatively strong interaction is formed between the graphene and the PA microspheres; the low-melting-point and high-toughness graphene / polymer microsphere oriented filling modified chemical fiber is adopted, the strength and toughness of the chemical fiber can be improved at the same time, and the electric and heat conduction performance of a chemical fiber product is expected to be improved; oriented graphene / polymer microspheres can form a microfiber structure with a high length-diameter ratio in a single fiber, and the structure can inhibit the formation of cracks in the radial direction (the main fracture direction of the fiber) on one hand, and can induce the high orientation and crystallization of polymer moleculesin a chemical fiber matrix on the other hand, so that the strength of a fiber material is improved.

Owner:ZHEJIANG SCI-TECH UNIV

Method for predicting retention time of gas phase chromatogram based on macromolecule crystallization behavior derivation retention equation

InactiveCN102314559BHigh precisionReduce the number of experimentsSpecial data processing applicationsDead timeCapacity factor

The invention discloses a method for predicting retention time of a gas phase chromatogram based on a macromolecule crystallization behavior derivation retention equation. The method comprises the following processes: deducing a retention equation curve which contains temperature and capacity factors based on macromolecule crystallization behavior, wherein the curve can be set up by only using three known data points which contain temperature and capacity factors of a compound at corresponding temperature; setting virtual dead time for a chromatographic column at a random temperature point according to measured retention time at a constant temperature; determining the capacity factor of the compound at the random temperature point through differentiating and integrating the whole chromatographic column according to the set retention equation curve; and predicting the retention time of the compound on the chromatographic column under a temperature-programming condition by using the data, and comparing the predicted retention time with an actually-measured value. The method for predicting the retention time of the gas phase chromatogram based on the macromolecule crystallization behavior derivation retention equation disclosed by the invention has the following advantages that: the number of adopted data points is few, and the number of experiments is reduced; the dead time has no need of measuring, and the process for predicting is simplified; and the predicting accuracy is high, and the application range is wide.

Owner:TIANJIN UNIV

High-heat-preservation and aging-resistant three-layer agricultural greenhouse film and preparation method thereof

InactiveCN111247998AImprove insulation effectGood anti-fog performanceAgricultural articlesClimate change adaptationBlow moldingGreenhouse

The invention provides a high-heat-preservation and aging-resistant three-layer agricultural greenhouse film and a preparation method thereof. The greenhouse film comprises an outer layer, a middle layer and an inner layer, wherein the outer layer comprises EVA(14 / 0.7), talcum powder, an anti-aging agent, the macromolecular crystallization modifier T-1 and the processing coordinator; the middle layer comprises EVA(5 / 0.3), talcum powder, an IR regulator, the macromolecular crystallization modifier T-1 and the processing coordinator; and the inner layer comprises LDPE, LLDPE, EVA(5 / 0.3), talcumpowder, an antifogging drop, the macromolecular crystallization modifier T-1 and the processing coordinator. The preparation method comprises the following steps: compounding the outer layer, the middle layer and the inner layer through a three-layer co-extrusion film blowing machine, carrying out extrusion, carrying out blow molding to form a film, and carrying out traction and rolling so as to obtain a greenhouse film finished product. The greenhouse film finished product can reach a photosynthetic strength of 0.88 mg * CO<2> / m<2> * S, a light transmittance of 92%, a haze of 25% and an infrared transmittance of 20%, can be continuously used for 6 months or more, and has the advantages of good heat preservation performance and fog drop antifogging property and long service life.

Owner:TAIZHOU ANFANG PLASTIC IND CO LTD

Composite material and polymer positive temperature coefficient thermistor made of composite material

ActiveCN112037961BRestricted movementReduce stressNon-conductive material with dispersed conductive materialPositive temperature coefficient thermistorsCarbideCopolymer

The invention discloses a composite material and a high molecular positive temperature coefficient thermistor made of the composite material. The composite material includes a high molecular crystalline polymer, a conductive filler and a compatibilizer; the high molecular crystalline polymer occupies a composite The weight percentage of the material is 5-15 wt%, the conductive filler occupies 70-95 wt% of the composite material, and the compatibilizer occupies 0.5-2 wt% of the composite material; the conductive filler is a mixture of carbide and metal tungsten, and the metal tungsten occupies the weight of the conductive filler Percentage 2~6wt%; compatibilizer is ethylene-vinyl alcohol copolymer, thermistor comprises two layers of conductive layers and a composite material layer, composite material layer is placed between two layers of conductive layers, composite material layer is made of composite material The thermistor has the characteristics of low initial resistance, and at the same time, it can still maintain low resistance characteristics after multiple high and low temperature cycles, which meets the stability of lithium batteries.

Owner:THINKING ELECTRONIC IND CO LTD

Polymer crystalline materials

ActiveUS8735523B2Maintain good propertiesHigh crystallinityHollow wall articlesThin material handlingGeneral purposeNumber density

One embodiment of the present invention provides polymer crystalline materials containing crystals of the polymer and satisfying the following requirements (I) and (II) or the following requirements (I) and (III): (I) the polymer crystalline materials a crystallinity of 70% or greater; (II) the crystals are 300 nm or less in size; and (III) the crystals have a number density of 40 μm−3 or greater. This allows an embodiment of the present invention to provide polymer crystalline materials which are excellent in properties such as mechanical strength, heat tolerance, and transparency or, in particular, polymer crystalline materials, based on a general-purpose plastic such as PP, which is excellent in properties such as mechanical strength, heat tolerance, and transparency.

Owner:HIROSHIMA UNIVERSITY

Biaxial uniaxial stretching device coupled with x-ray scattering for in situ structure detection and its experimental method

ActiveCN103207192BEffect of extensional rheologyEfficient use ofMaterial analysis using radiation diffractionLabview softwareX-ray

The invention provides a biaxial uniaxial tension device for in-situ structure detection in combination with the scattering of X-rays and an experimental method of the biaxial uniaxial tension device. The device comprises a high-precision servo motor (1), a torque sensor (2), a precise gear (3), a heating furnace (3), a reverse tension shaft (5) and a Labview software control system (6). A guide rail, the precise gear (3) and a reverse tension rod are adopted for transmission. The rotating speed of the servo motor (1) and the rotational displacement are controlled by the Labview to realize precise displacement and speed tension control. The temperature distribution of the heating furnace (3) is uniformed and the thermal degradation at high temperature of samples is reduced by forced nitrogen flow. A temperature monitoring point is preset in the heating furnace (3) and a temperature controller is adopted to precisely control the temperature. Temperature jump is realized between two heating furnaces (3) of different temperature. The device has the advantages of small volume, light mass, simplicity in disassembling and installing and the like, is particularly suitable for the combination of synchrotron radiation experimental line stations and is a good device for studying the crystallization of polymer melt induced by a flow field.

Owner:合肥中科优材科技有限公司

Polyester composite material and method for preparing same

The invention relates to a kind of polyester composite and the method for preparing the same. The comprised components with their content by weightfor said polyester composite are: polybutylene terephthalate (PET) 40- 80 units, super branched polyamide (HBPA) 0.1- 4 units, polymer promoter 1- 6 units, packing intensifier 10- 50 units, processing aid 0.5- 1 unit. The said polymer promoter possesses good flexiblility, which is good for polybutylene terephthalate movement, and can coordinate with crystallization nucleating agent to fasten crystallization, and increase flexibility and plasticity and improve demoulding.

Owner:HEFEI GENIUS NEW MATERIALS

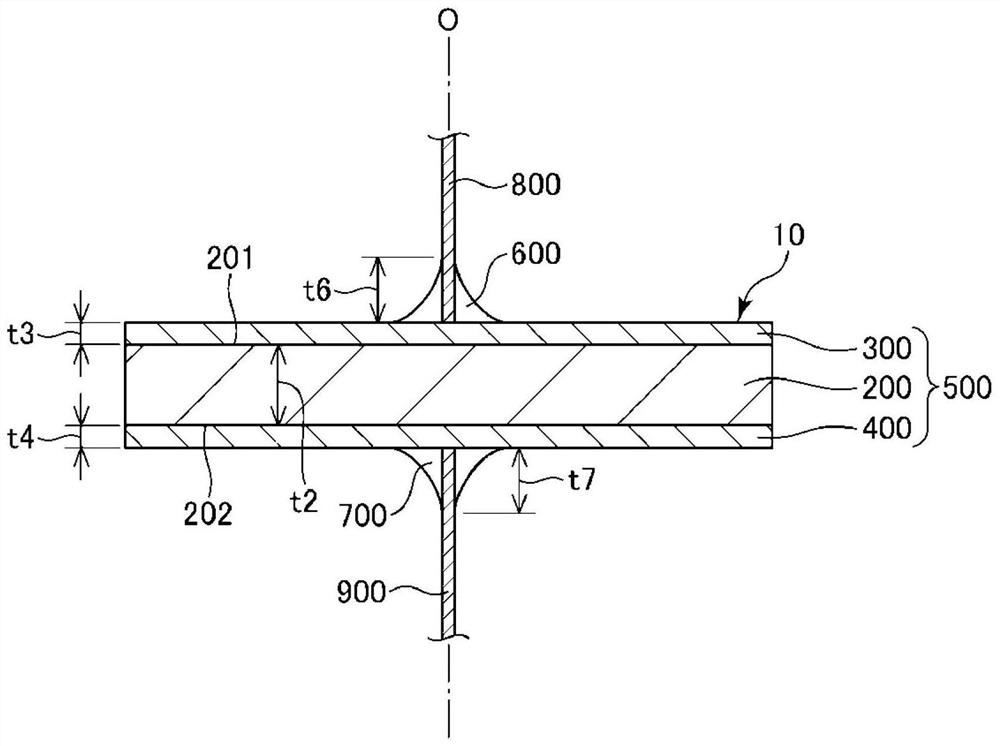

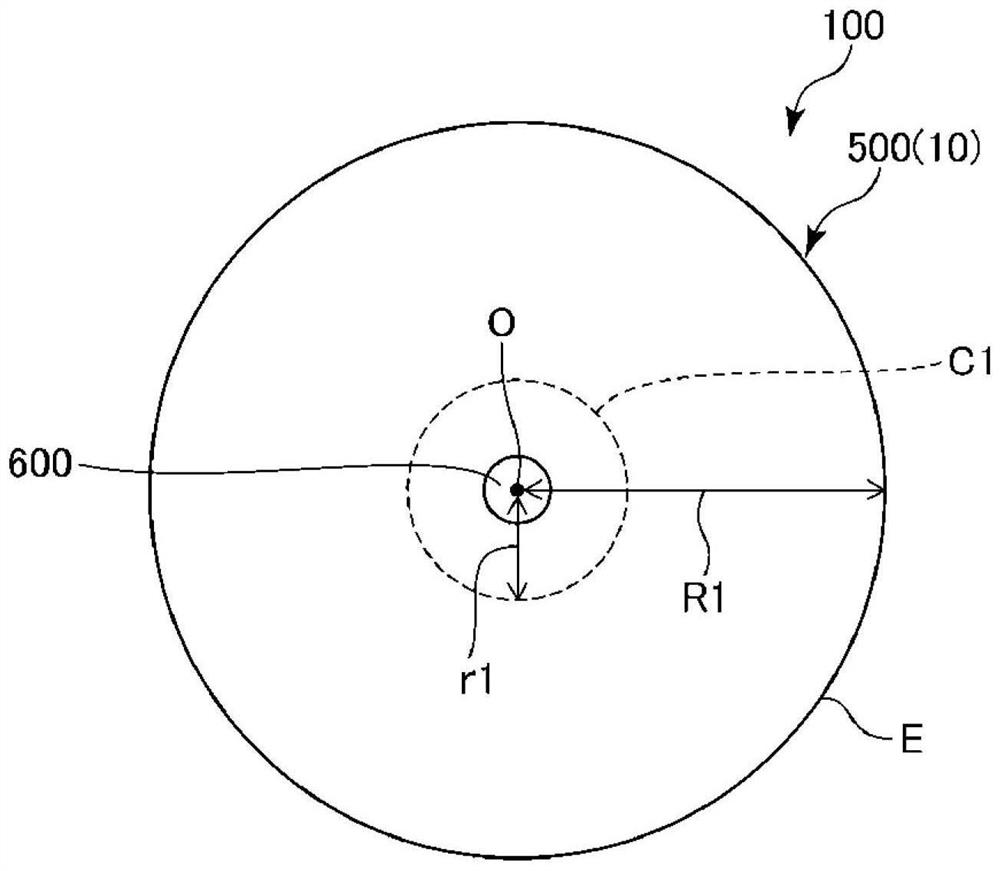

Piezoelectric element

PendingCN114824059APiezoelectric/electrostrictive/magnetostrictive devicesShearing deformationMechanical engineering

Provided is a piezoelectric element in which the piezoelectricity is easily utilized by converting shear deformation into expansion and contraction deformation. The piezoelectric element is characterized by comprising an electric layer containing a helical chiral polymer crystal showing piezoelectricity, a first electrode layer, a second electrode layer, a first connection part provided on the side of the first electrode layer opposite to the piezoelectric layer, and a second connection part provided on the side of the second electrode layer opposite to the piezoelectric layer, when viewed in the thickness direction of the piezoelectric layer, an overlapping portion where the piezoelectric layer, the first electrode layer, and the second electrode layer overlap each other has a circular shape, and when viewed in the thickness direction of the piezoelectric layer, the first connection portion and the second connection portion overlap the center of the overlapping portion.

Owner:SEIKO EPSON CORP

Polyethylene terephthalate composite material and method of producing the same

InactiveCN101153111BIncrease the rate of crystallizationMeet needsLiquid crystal compositionsPolyethylene terephthalate glycolPolymer science

The present invention relates to a polyethylene terephthalate composite material and a preparation method thereof. The method comprises that: 40 weight portions to 80 weight portions of polyethylene terephthalate, 0.1 weight portions to 4 weight portions of macromolecule nucleating agent testa liquid crystal, 1 weight portion to 6 weight portions of macromolecule crystallization accelerator, and 0.5 weight portions to 1 weight portion of other processing aids are stirred and mixed at a high speed; the mixture is then sent into a double-screw extruder through a material feeder of precise measurement. Then 10 weight portions to 50 weight portions of intensifier is filled into the double-screw extruder through the material feeder of precise measurement. The product can be prepared after plasticization, melting, compounding, and then extruding, bracing, cooling, pelletizing and drying. Compared with the prior art, the present invention has the characteristics of improving the crystallization rate of polyethylene terephthalate, widening the application scope, meeting the demands of engineering plastics for polyethylene terephthalate.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com