A Method for Characterizing Crystallinity of Polymer Products Based on Ultrasonic Velocity

An ultrasonic and polymer technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, can solve the problems of the lack of economical and effective polymer crystallinity measurement methods, the destructiveness of polymer products, and the lack of versatility. Market application prospect and marketing value, increasing actual usability, effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

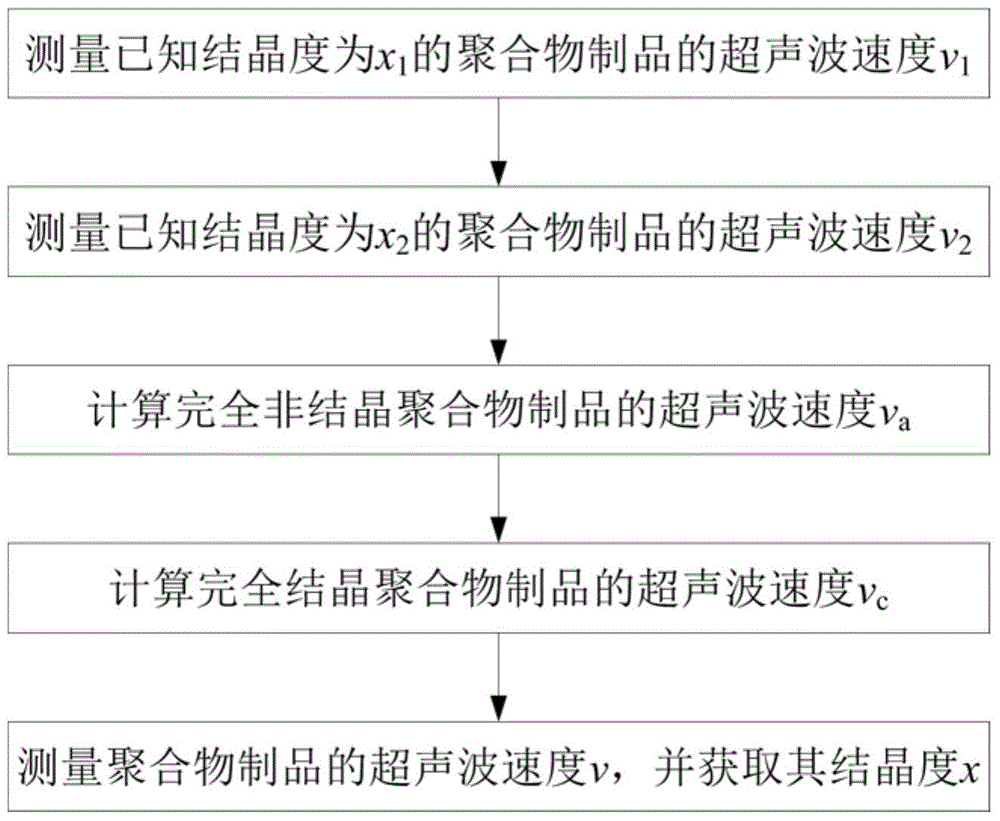

[0043] In this embodiment, the polymer material is polylactic acid (PLA), such as figure 1 As shown, the implementation steps of the method for characterizing the crystallinity of polymer products based on ultrasonic velocity in this embodiment are as follows:

[0044] 1) Measure the known crystallinity as x 1 The ultrasonic velocity v of the polymer product 1 ;

[0045] 2) Measure the known crystallinity as x 2 The ultrasonic velocity v of the polymer product 2 ;

[0046] 3) According to the formula,

[0047]

[0048] Calculation of the ultrasonic velocity v for a completely amorphous polymer product a ;

[0049] 4) According to the formula,

[0050]

[0051] Calculation of ultrasonic velocity v for fully crystalline polymer articles c ;

[0052] 5) measure the ultrasonic velocity v of the polymer product, according to the formula,

[0053]

[0054] Obtains the crystallinity x of the polymer article.

[0055] Crystallinity of polymer product in step 1) x 1...

Embodiment 2

[0075] In this embodiment, the polymer material is selected polypropylene (PP), such as figure 1 As shown, the implementation steps of the method for characterizing the crystallinity of polymer products based on ultrasonic velocity in this embodiment are as follows:

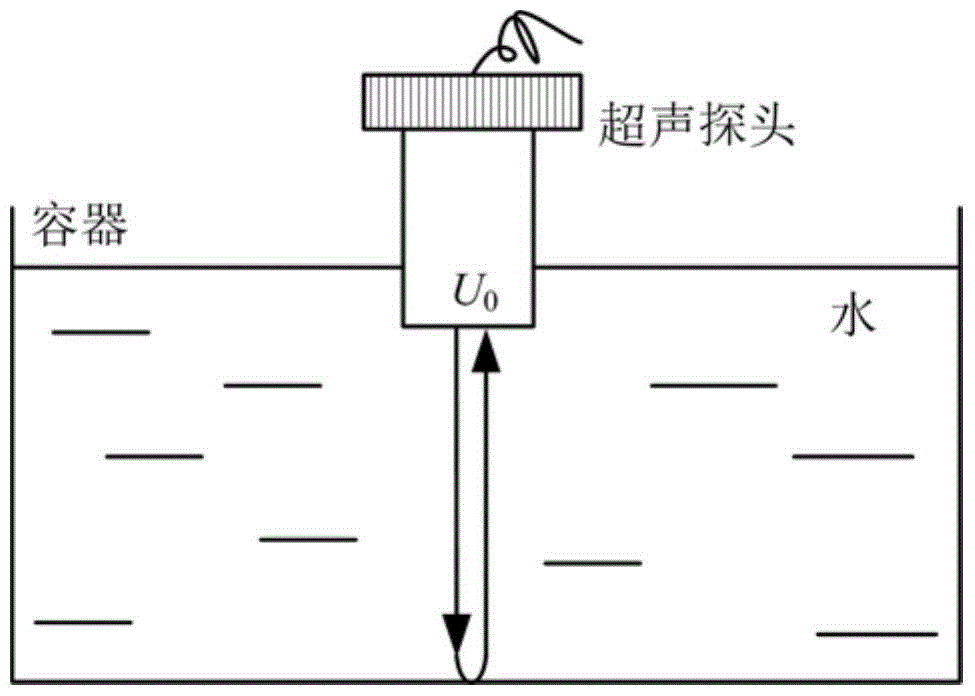

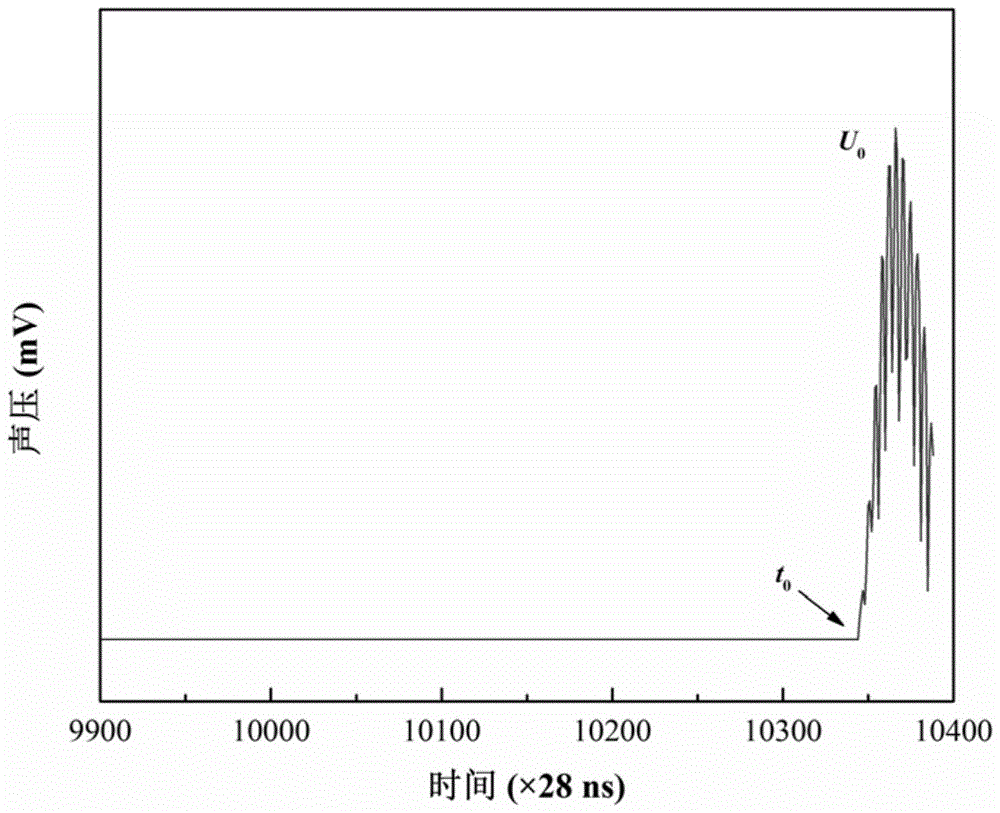

[0076] 1) Measure the known crystallinity as x 1 The ultrasonic velocity v of the polymer product 1 . According to the water immersion ultrasonic measurement method, in the present embodiment, the crystallinity of the polymer product is x 1 is 67.72%, the ultrasonic velocity v of the polymer product 1 It is 1521.57m / s.

[0077] 2) Measure the known crystallinity as x 2 The ultrasonic velocity v of the polymer product 2 ; According to the water immersion ultrasonic measurement method, in the present embodiment, the crystallinity of the polymer product is x 2 is 79.07%, the ultrasonic velocity v of the polymer product 2 It is 1827.42m / s.

[0078] 3) According to the formula,

[0079]

[0080] Calculati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com