Polyethylene terephthalate composite material and method of producing the same

A technology of polyethylene terephthalate and composite materials, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of narrow application areas, unsatisfactory requirements, and few varieties of industrial production, so as to meet the needs, Wide range of applications and the effect of increasing the crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

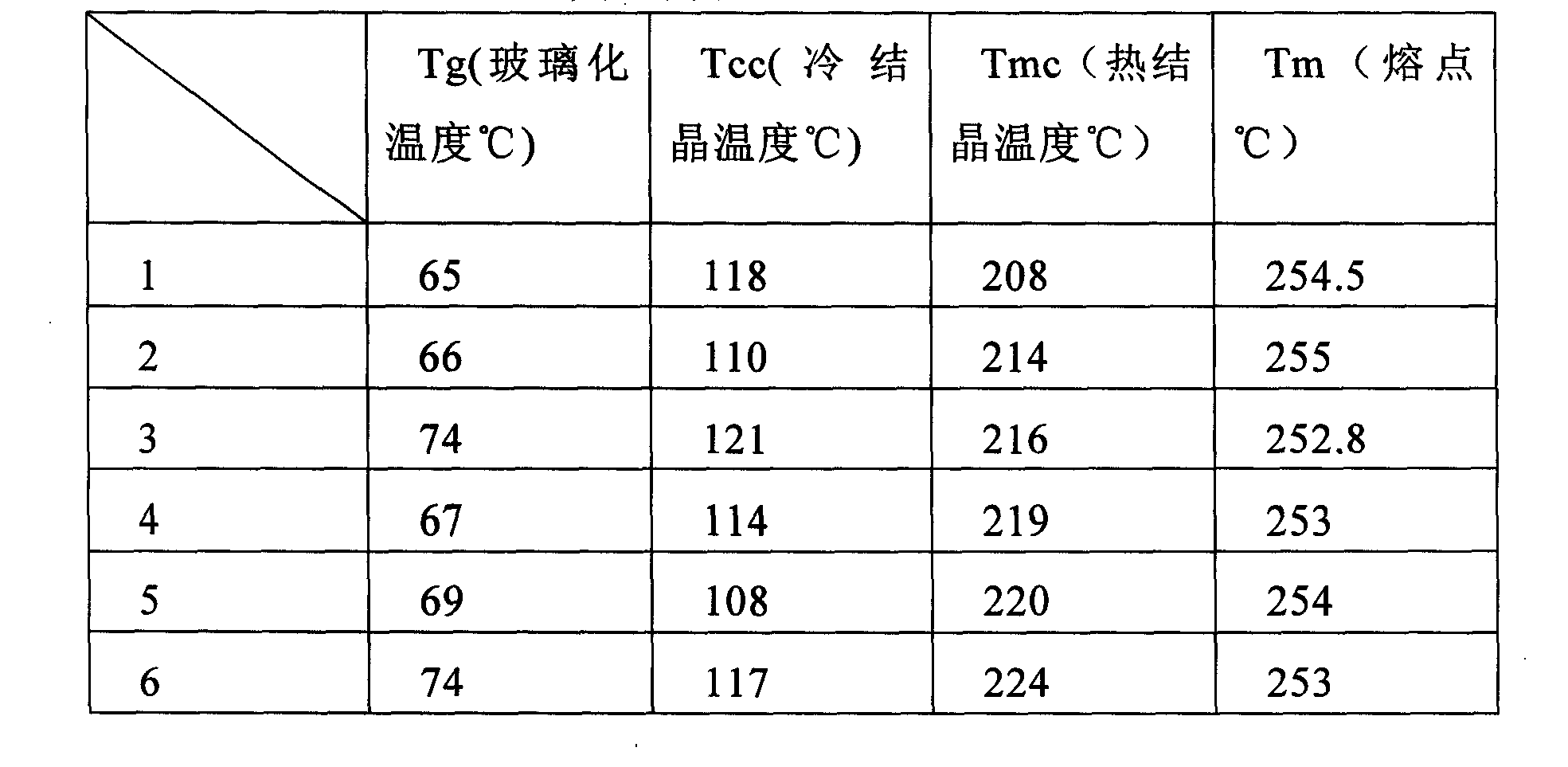

Embodiment 1

[0016] 70 parts of polyethylene terephthalate, carapace liquid crystal poly[vinyl terephthalate (p-methoxyphenol) ester] (PMPCS) molecular weight 15000, 1 part of molecular weight distribution 1.5, crystallization accelerator polyethylene glycol 5 parts of alcohol and 1 part of other additives are mixed by high-speed stirring. Then it is sent into the twin-screw extruder by the precision metering feeder, and then 23 parts of the glass fiber filled with reinforcing agent are sent into the twin-screw extruder from the precision metering feeder, plasticized, melted, compounded, and then extruded, Stranding, cooling, pelletizing, drying and packaging the finished product.

Embodiment 2

[0018] 80 parts of polyethylene terephthalate, carapace liquid crystal poly[vinyl terephthalate (p-methoxyphenol) ester] (PMPCS) molecular weight 25000, 1 part of molecular weight distribution 1.3, crystallization accelerator polypropylene glycol 4 1 part and 1 part of other additives are stirred and mixed at high speed, and then sent into the twin-screw extruder by a precision metering feeder, and then 13 parts of glass fiber filling reinforcement are sent into the twin-screw extruder from the precision metering feeder, Plasticizing, melting, compounding, and then extruding, drawing, cooling, pelletizing, drying and packaging the finished product.

Embodiment 3

[0020] 60 parts of polyethylene terephthalate, carapace liquid crystal poly[vinyl terephthalate (p-methoxyphenol) ester] (PMPCS) molecular weight 35000, 1 part of molecular weight distribution 1.8, 6 parts of crystallization accelerator and 1.7 parts of other additives are mixed with high-speed stirring, and then sent to the twin-screw extruder by a precision metering feeder, and then 31 parts of carbon fiber filled with a reinforcing agent are sent to the twin-screw extruder from the precision metering feeder, plasticized , melting, compounding, and then extruded, drawn, cooled, pelletized, dried and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com