Continuous thermal treatment of bulk material

A technology for loose materials and pellets, which is applied in the field of continuous heat treatment of granular loose materials, can solve problems such as inability to ensure the quality of pellets, achieve economical maintenance and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

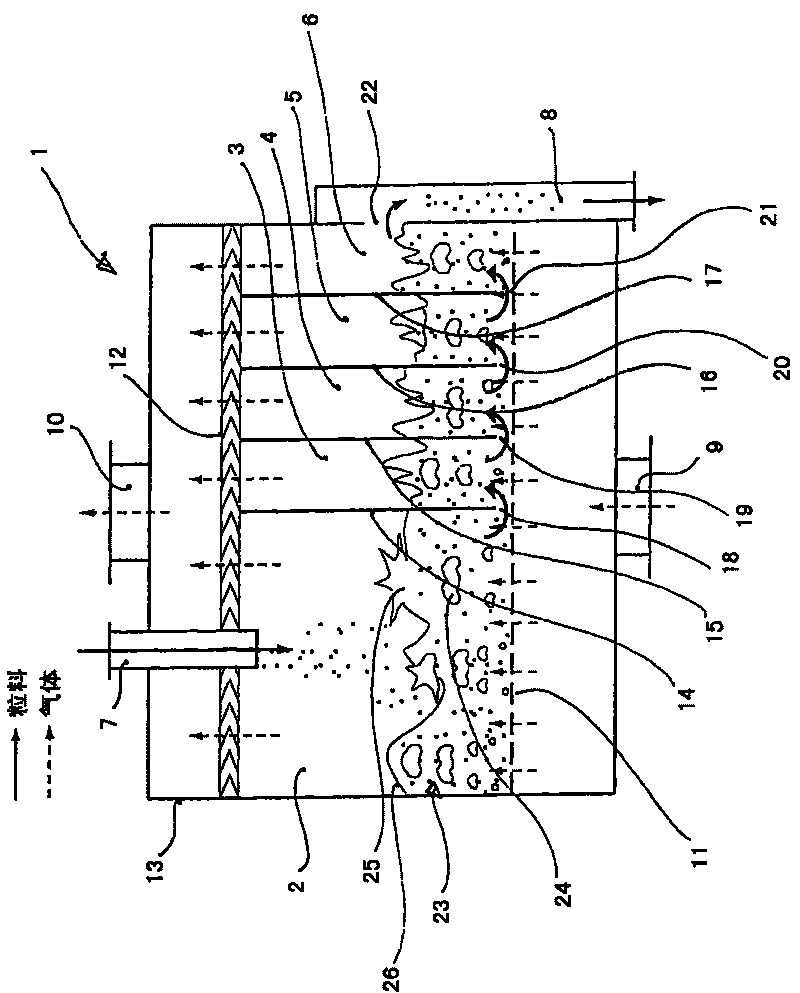

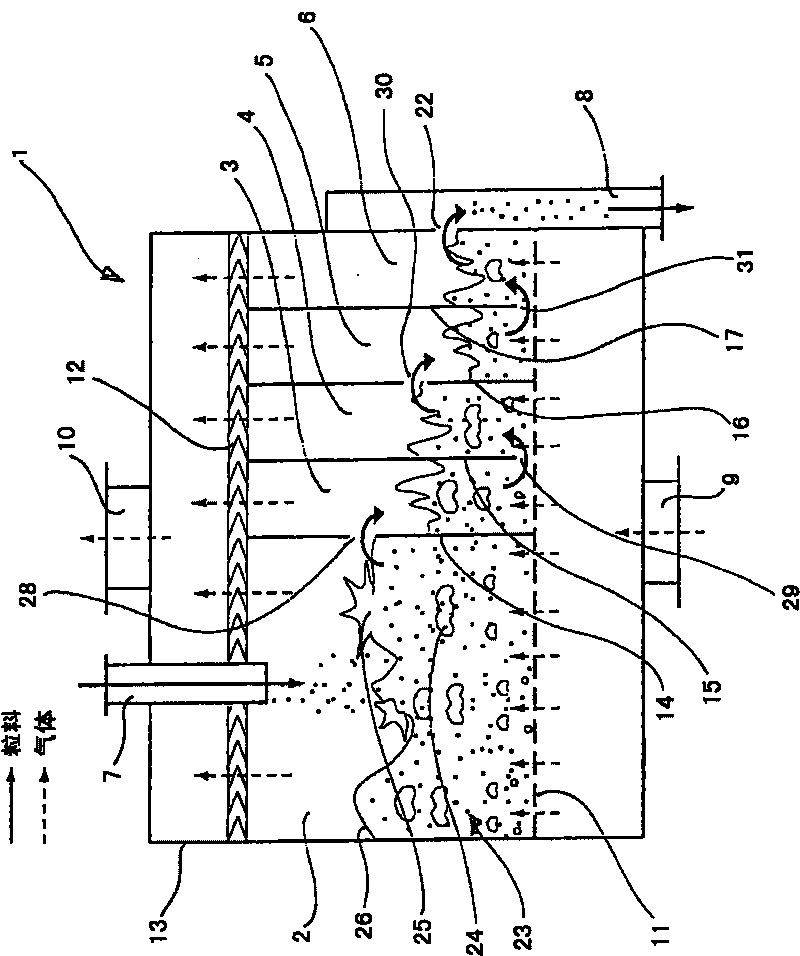

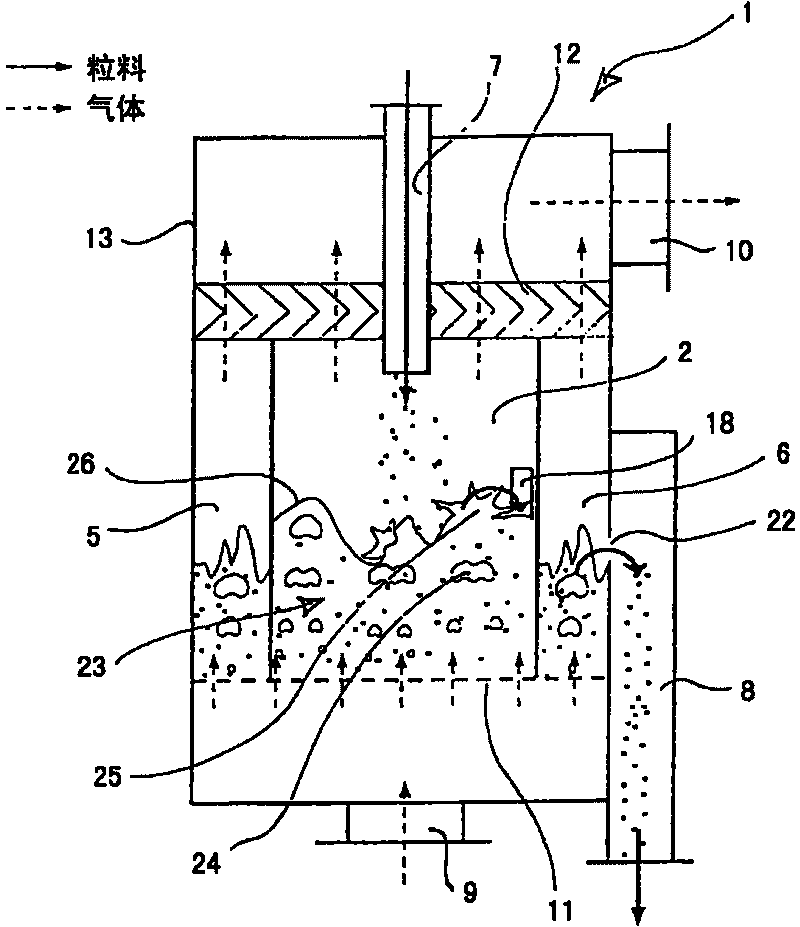

[0045] figure 1 is a schematic vertical section of a first embodiment of the device 1 according to the invention. The device 1 according to the invention forms a compound box crystallizer with a housing 13 , the interior of several chambers 2 , 3 , 4 , 5 and 6 being separated by partition walls 14 , 15 , 16 and / or 17 . The bottom of each chamber is provided with a sieve floor 11 through which fluidizing gas can be supplied from below. Towards the top, the chamber is delimited by a zigzag partition 12 forming the top of the chamber. The front and rear walls of the chambers 2 , 3 , 4 , 5 and 6 extend parallel above and / or below the drawing plane and are therefore not shown in the sectional view.

[0046] The product to be fluidized and heat-treated, in particular polyethylene terephthalate (PET), is introduced into the apparatus 1 from the top via a product inlet 7 and exits the apparatus 1 via a product outlet 8 . Below the screen bottom 11 , fluidization gas is injected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com