Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Welding quality is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

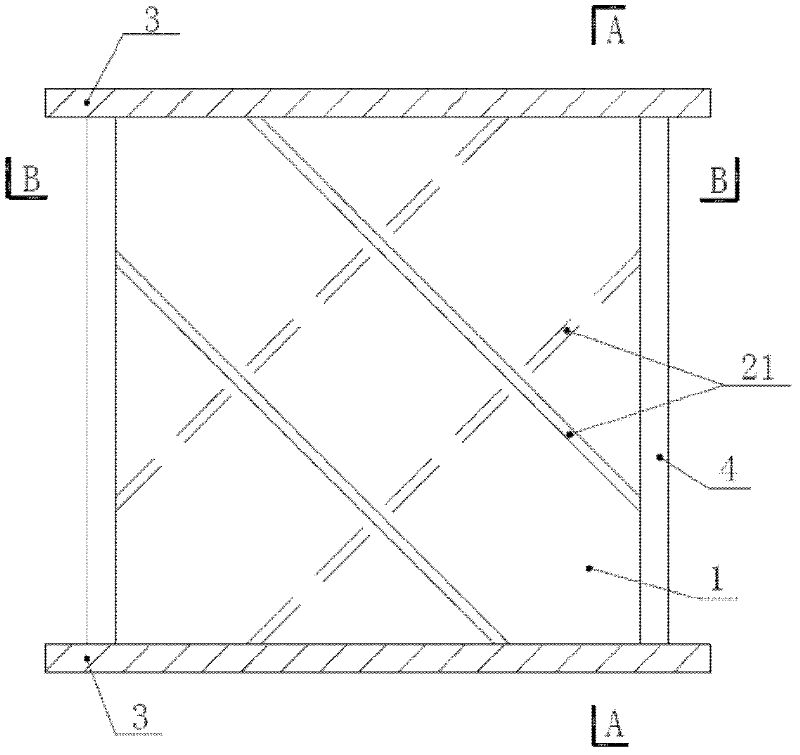

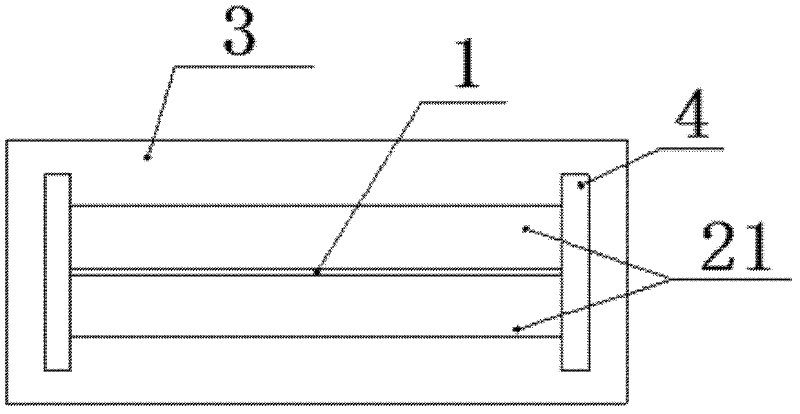

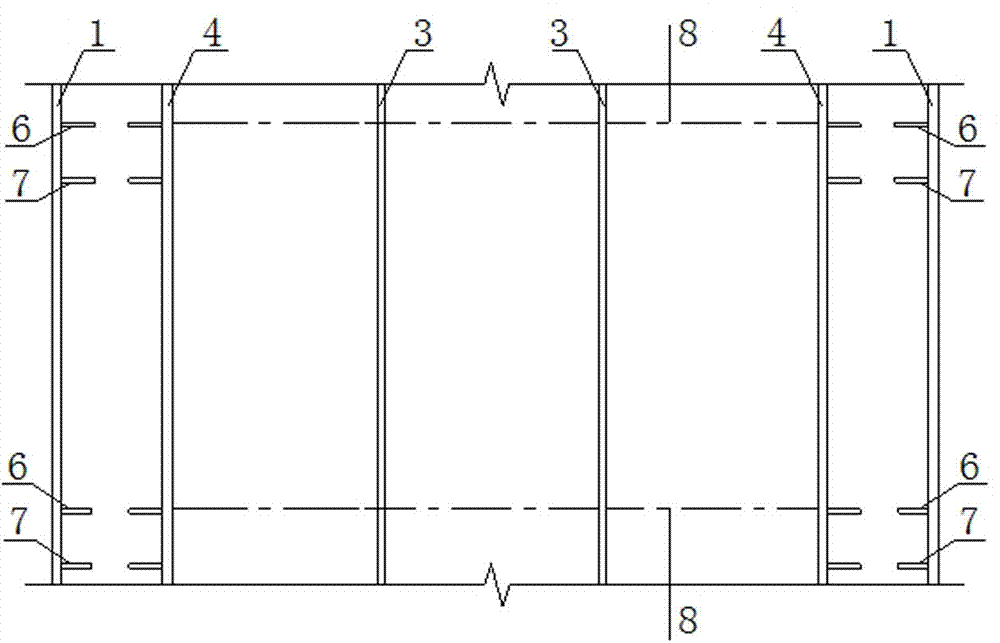

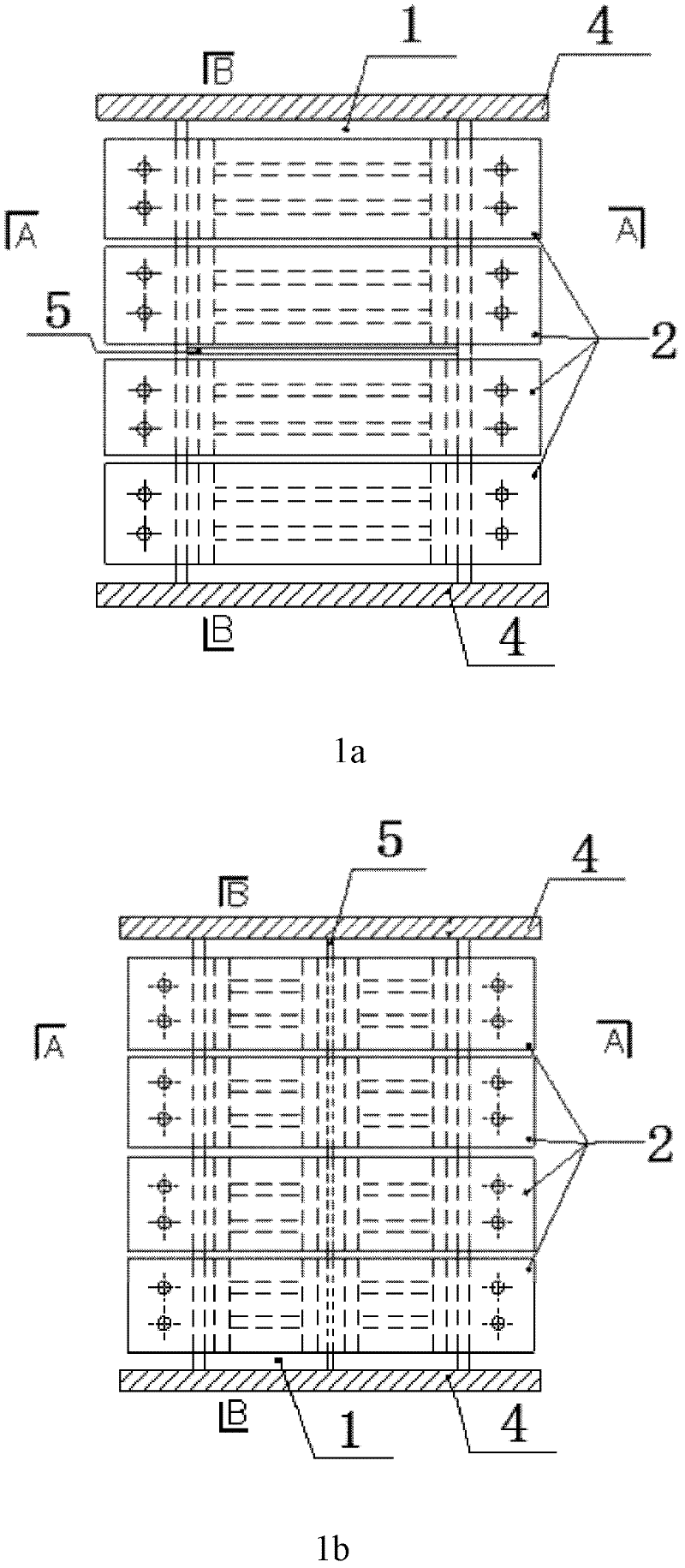

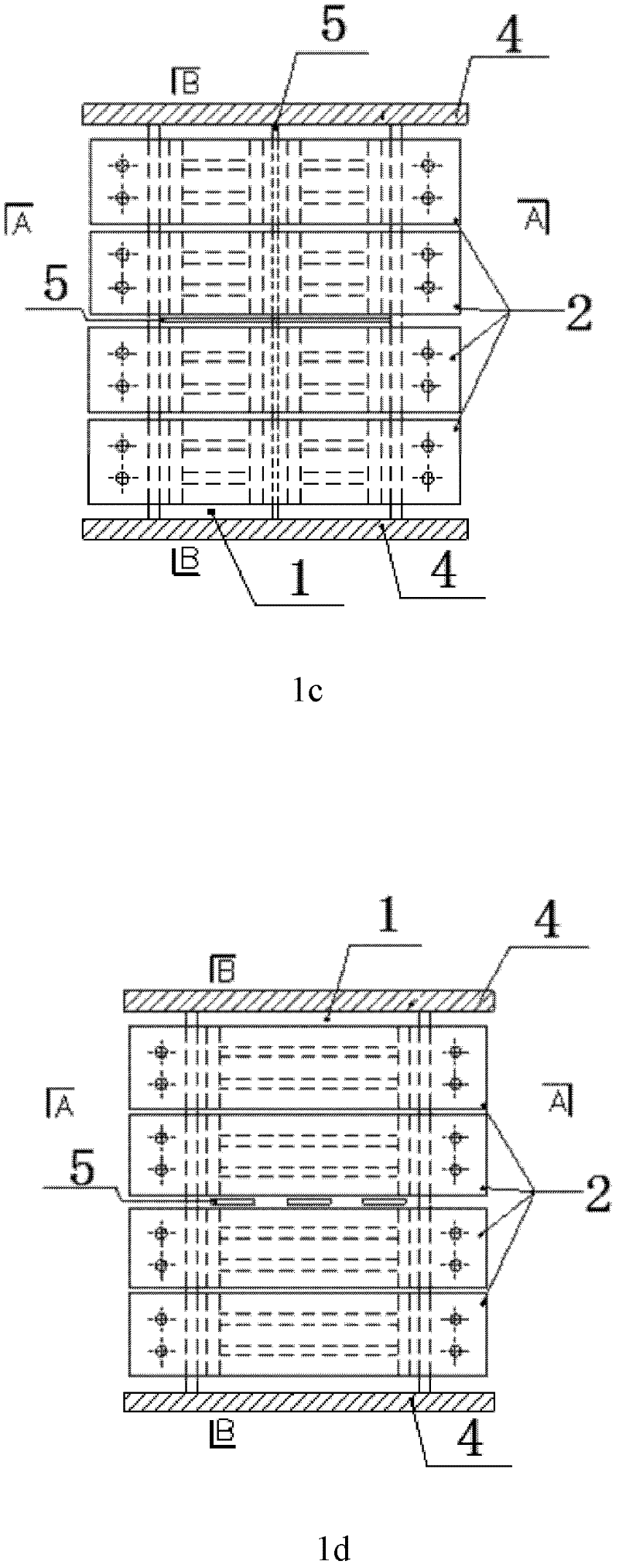

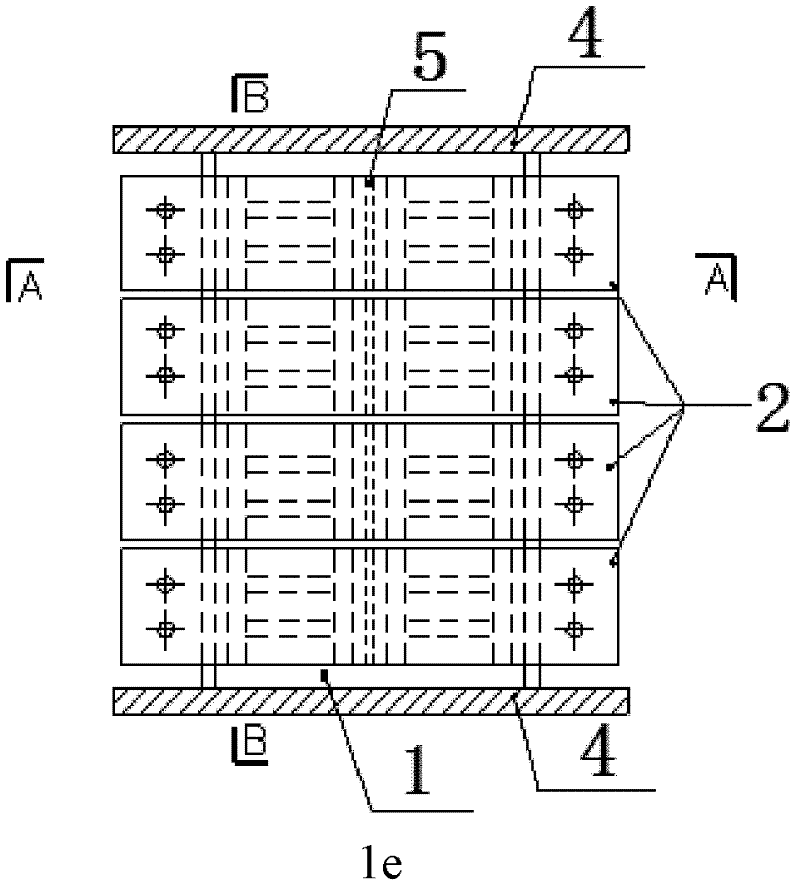

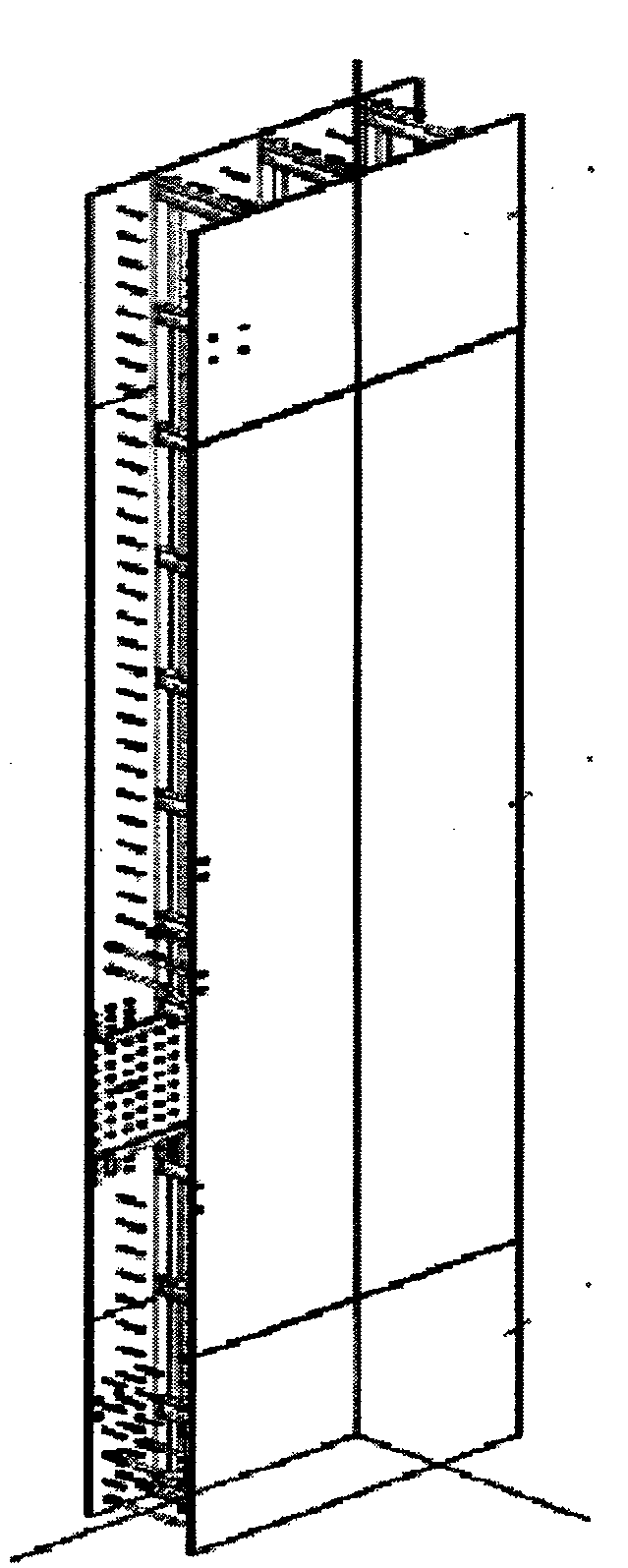

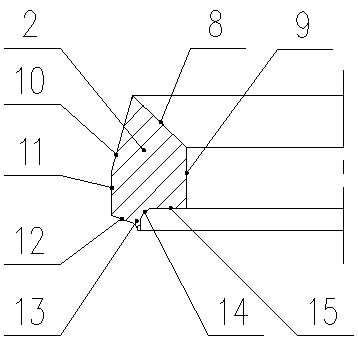

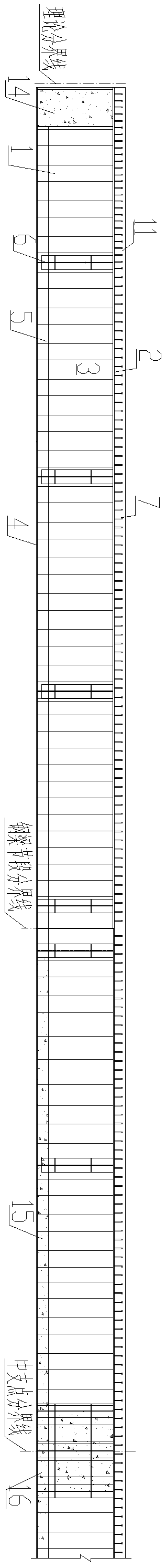

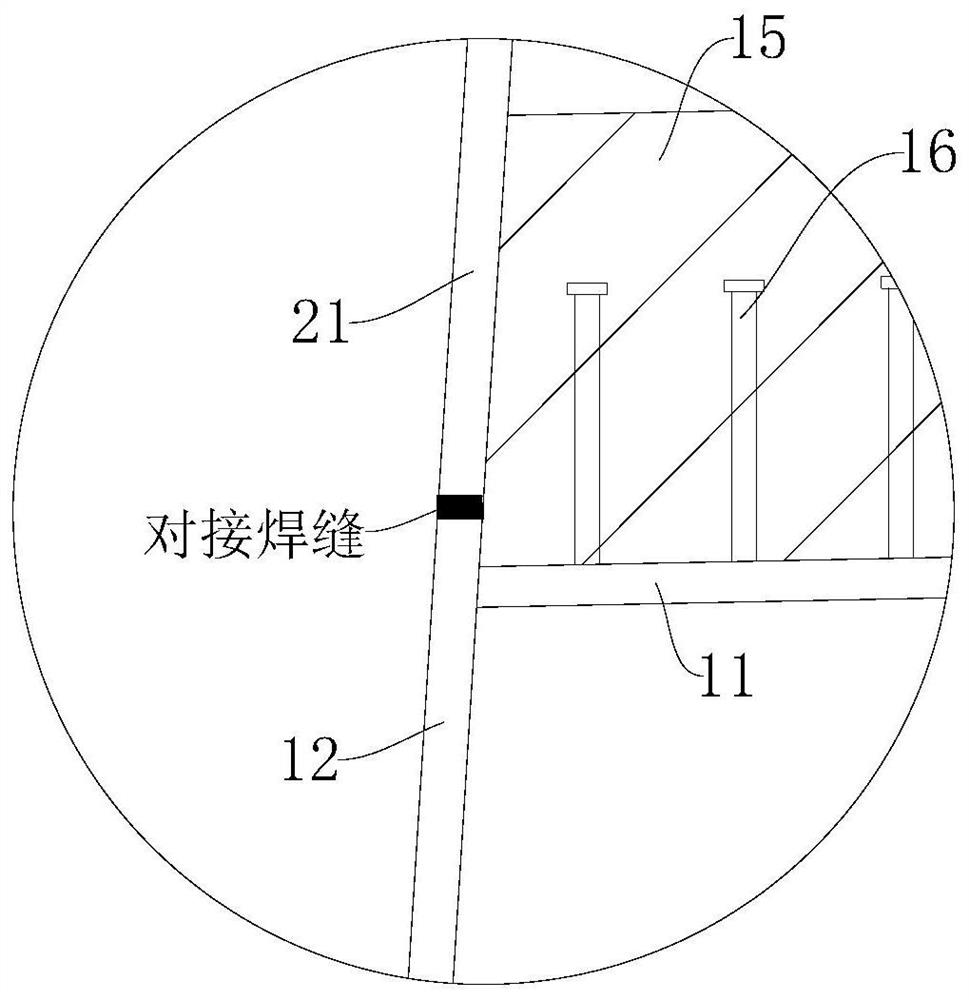

Shear Type Stiffened Metal Damper

The invention discloses a shear-type stiffened metal damper, which comprises an energy-dissipating steel plate, stiffening ribs are respectively arranged on the left and right sides of the energy-dissipating steel plate, horizontal connecting steel plates are respectively arranged on the upper end and the lower end of the energy-dissipating steel plate, Flange plates are arranged at the front end and rear end respectively, the stiffeners on the left side and the right side of the energy dissipation steel plate are arranged symmetrically or asymmetrically, and the stiffeners on the same side of the energy dissipation steel plate are arranged without crossing. The invention utilizes the advantages of relatively large initial rigidity when the steel plate is stressed in the plane, and prevents the buckling of the energy-dissipating steel plate by means of stiffening, thereby ensuring the energy-dissipating capacity and stability of the damper; There are no cross welds, and the stiffeners can be set in full length without truncating, which is convenient for welding, and the welding quality is easy to guarantee.

Owner:SHANGHAI SAFE SEISMIC RETROFIT & VIBRATION CONTROL TECH

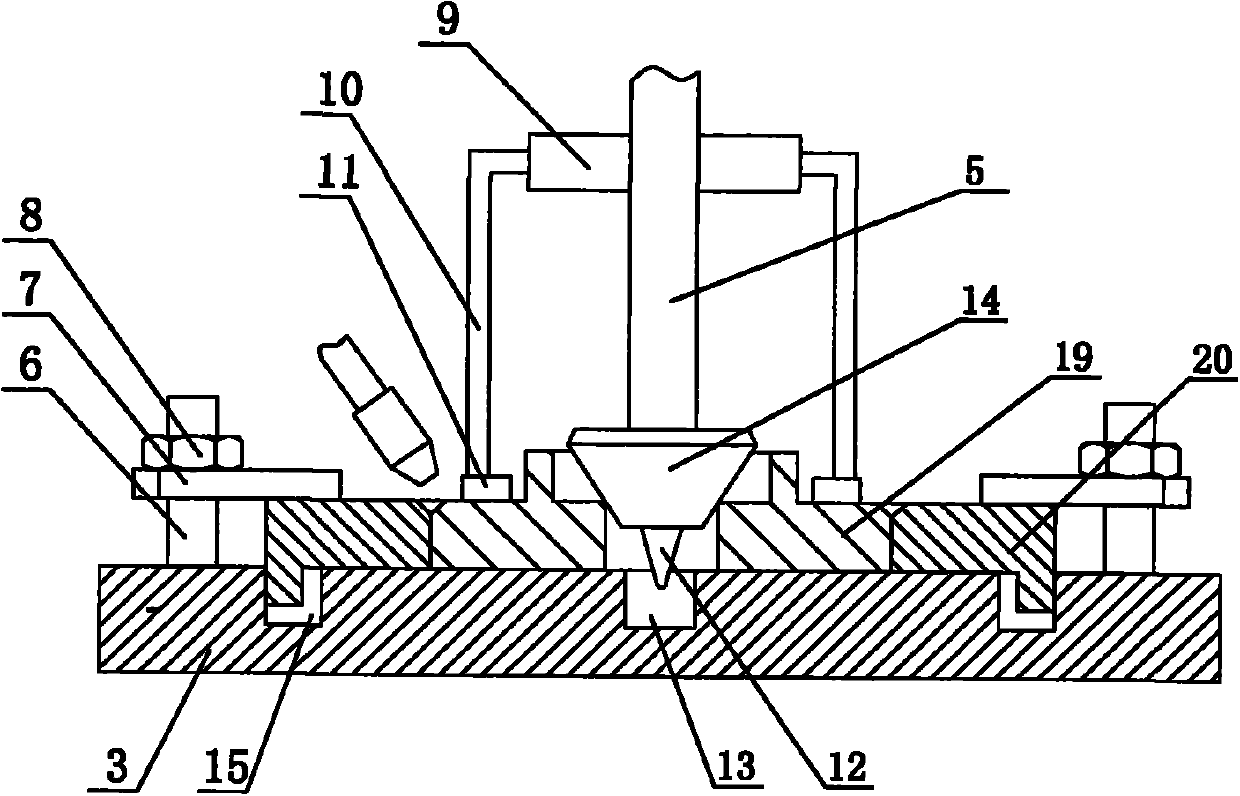

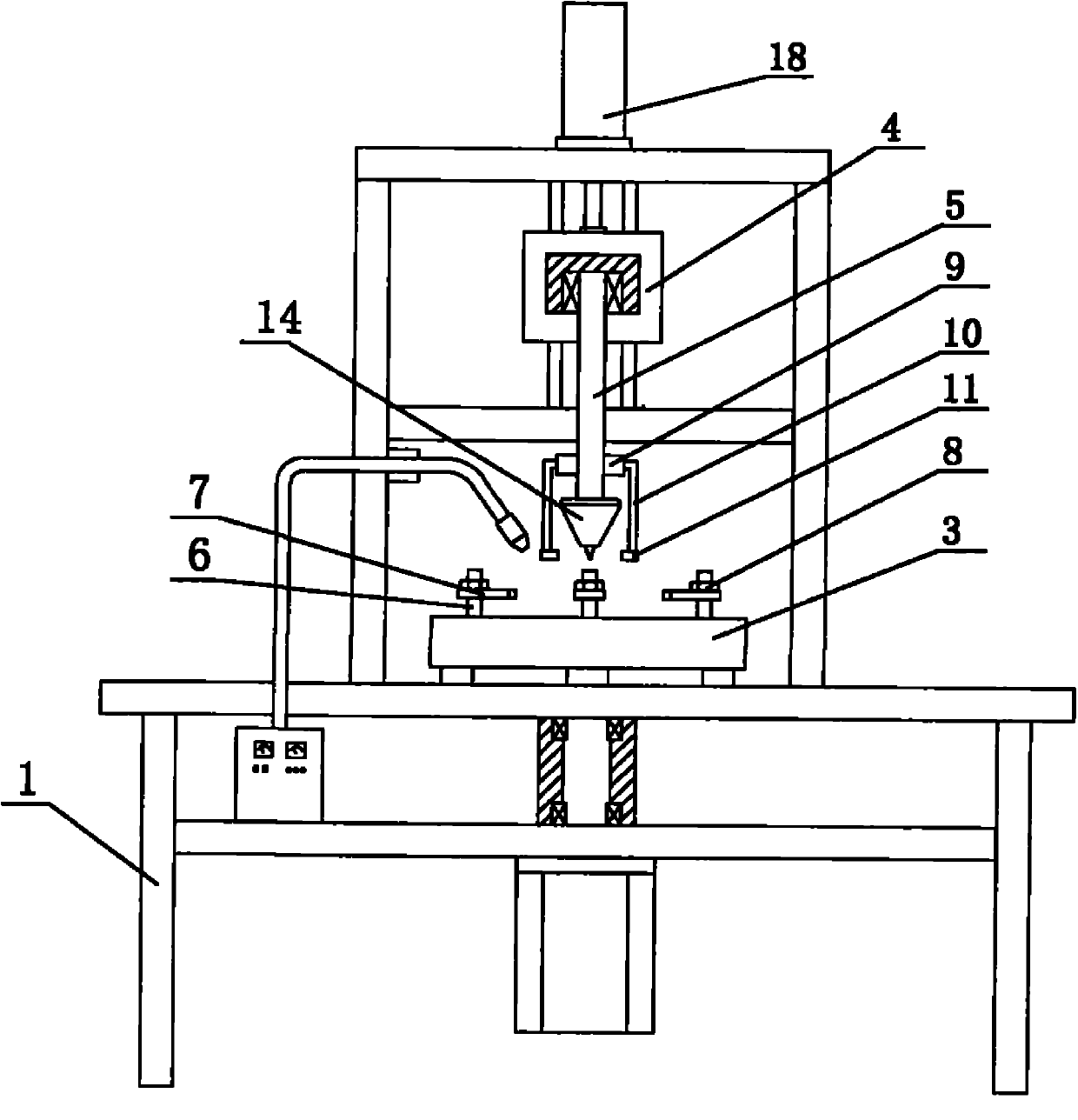

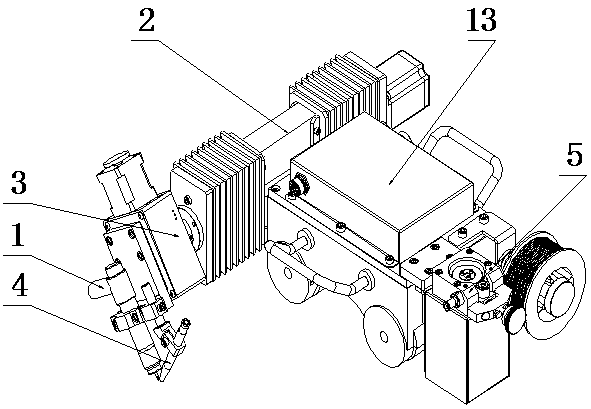

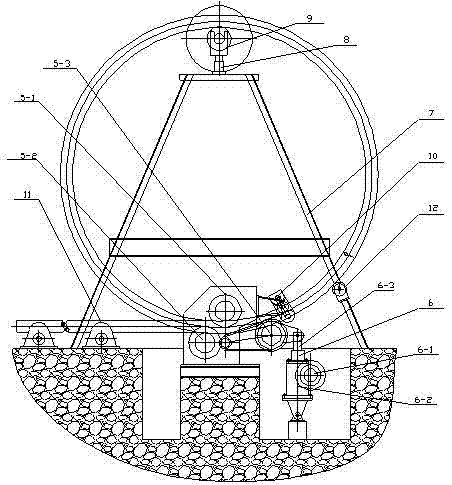

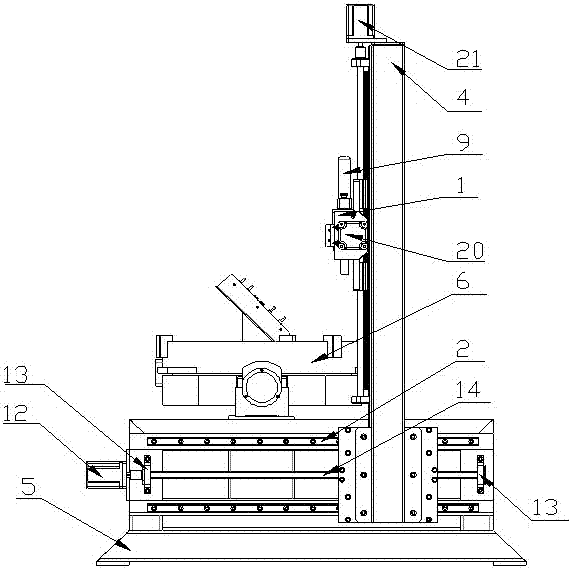

Ring set welding tool

InactiveCN103495828AGuaranteed concentricityGuaranteed clamping effectWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringEngineering

The invention discloses a ring set welding tool. The ring set welding tool comprises a work platform connected to a machine frame, the work platform is provided with an annular groove, an annular protrusion of an outer ring is inserted into the annular groove, the work platform is provided with an outer ring fixture, the machine frame is further provided with a support, the support is driven by a vertical power mechanism to slide vertically, located above the work platform, and is rotationally connected with a supporting arm extending downwards, the supporting arm is provided with an inner ring fixture, and an inner ring locating mechanism is arranged between the downward-extending end of the supporting arm and the work platform. The ring set welding tool has the advantages that an inner ring and the outer ring can be effectively clamped.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

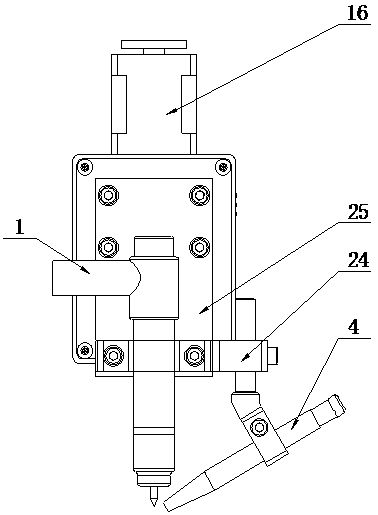

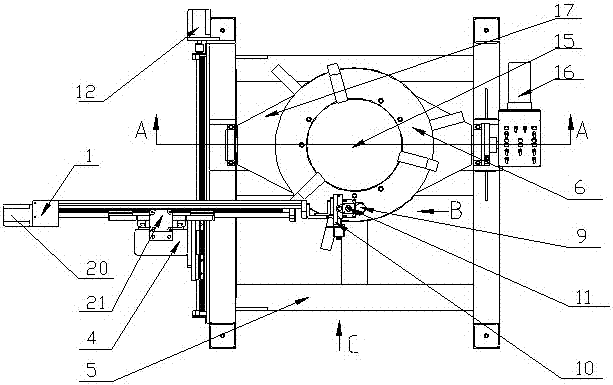

Pipeline all-position automatic tungsten inert gas welding (TIG welding) machine and welding process thereof

PendingCN111054999AWarm up guaranteedReduce labor intensityElectrode supporting devicesWelding accessoriesPipe fittingEngineering

The invention discloses a pipeline all-position automatic tungsten inert gas welding (TIG welding) machine, belongs to the technical field of automatic welding equipment, and has wide applications inpipelines and pipe butt joint all-position automatic welding. The pipeline full-position automatic TIG welding machine comprises a walking welding trolley, wherein the welding trolley performs circular motion along a pipeline; a wire feeding mechanism and a welding gun are arranged on the body of the welding trolley; a hot wire nozzle is arranged at the tail end of the wire feeding mechanism; thehot wire nozzle is a copper pipe; one end of the hot wire nozzle is connected with a heating power supply through a lead wire; an anode connecting wire is also arranged; one end of the anode connecting wire is connected with the heating power supply; and the other end of the anode connecting wire is a free end. The invention solves the problem of preheating welding wires in the prior TIG welding,ensures that the welding wires are preheated before welding, and solves the problem that distance between a welding gun and a welding pipe fitting cannot be conveniently adjusted, so that wire feedingis stable, and welding quality and welding efficiency of the pipeline full-position automatic TIG welding are effectively improved.

Owner:JINAN JINLUDING WELDING TECH CO LTD

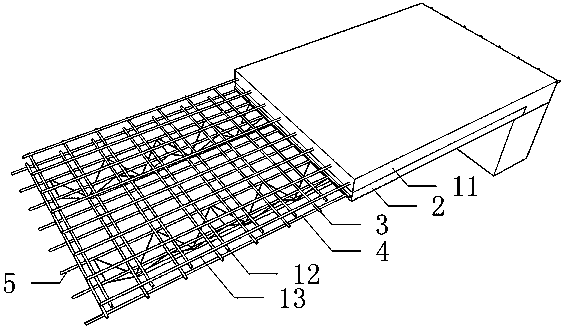

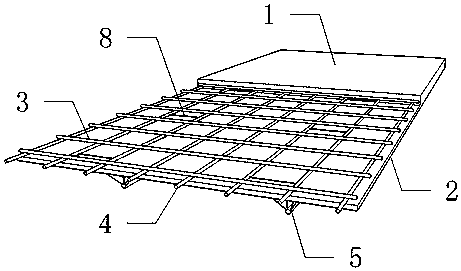

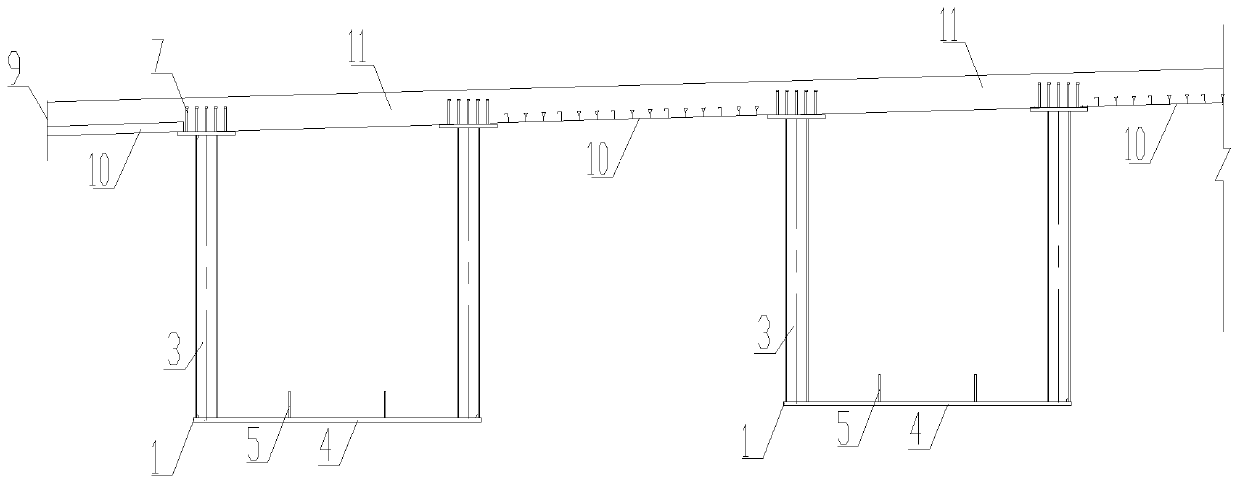

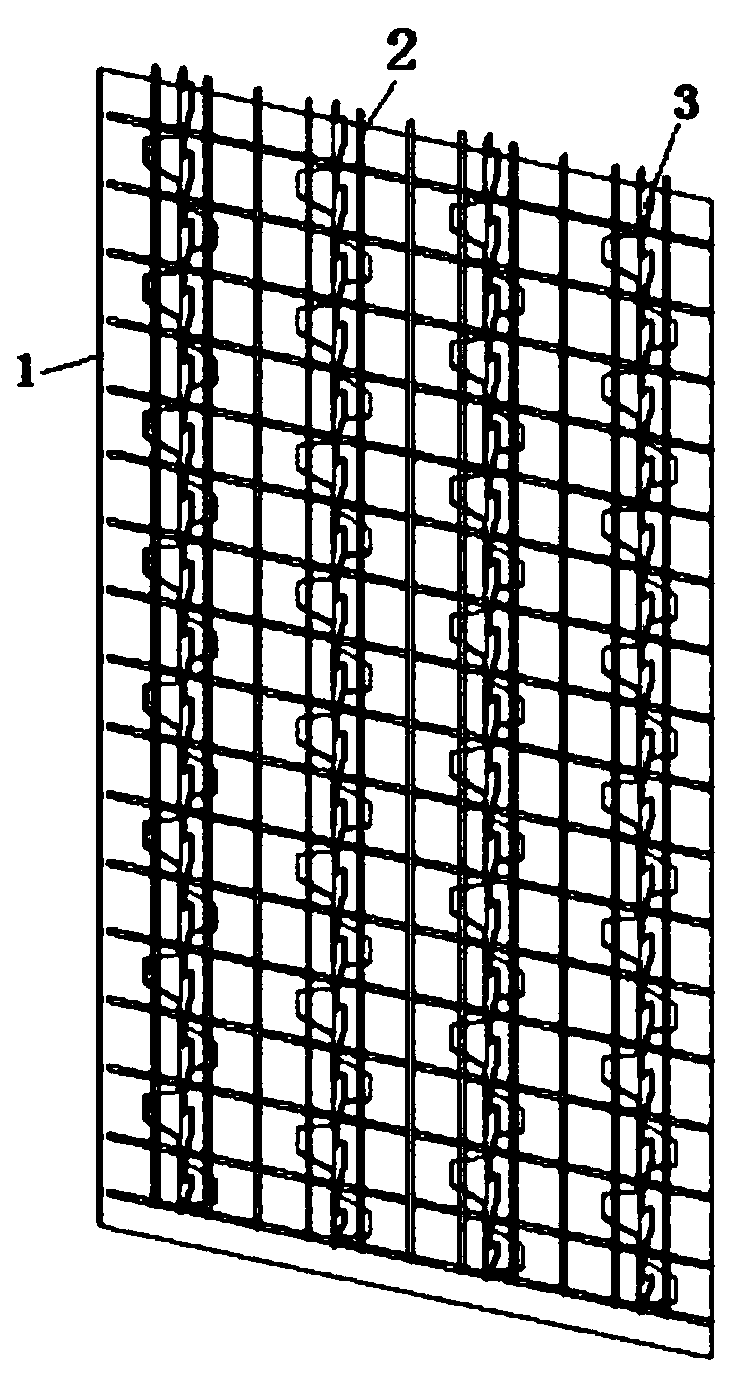

Inverted steel bar truss concrete laminated board and construction method thereof

The invention discloses an inverted steel bar truss concrete laminated board and a construction method thereof. The laminated board is composed of a reinforced concrete precast slab, an inverted steelbar truss and a post-cast reinforced concrete laminated layer. The reinforced concrete precast slab comprises precast slab concrete and precast slab steel bars. The inverted steel bar truss is formedby welding three straight ribs and two curved ribs. The three straight ribs are placed in parallel and respectively located at the three apexes of the inverted triangle. The two curved ribs are welded with the three straight ribs from the sides respectively to manufacture the reinforced concrete precast slab and the inverted steel bar truss integrally, and the two straight ribs on the upper layerare buried in the precast slab concrete. The post-cast reinforced concrete laminated layer includes laminated layer concrete and laminated layer steel bars. The inverted steel bar truss reduces a complex support system at the precast slab bottom during construction, and saves cost. At the same time, the inverted steel bar truss can effectively improve the rigidity and the bearing capacity of thestructure in the construction stage of the inverted steel bar truss, and the deflection and the cracking possibility of the precast slab in the construction stage are greatly reduced.

Owner:王海

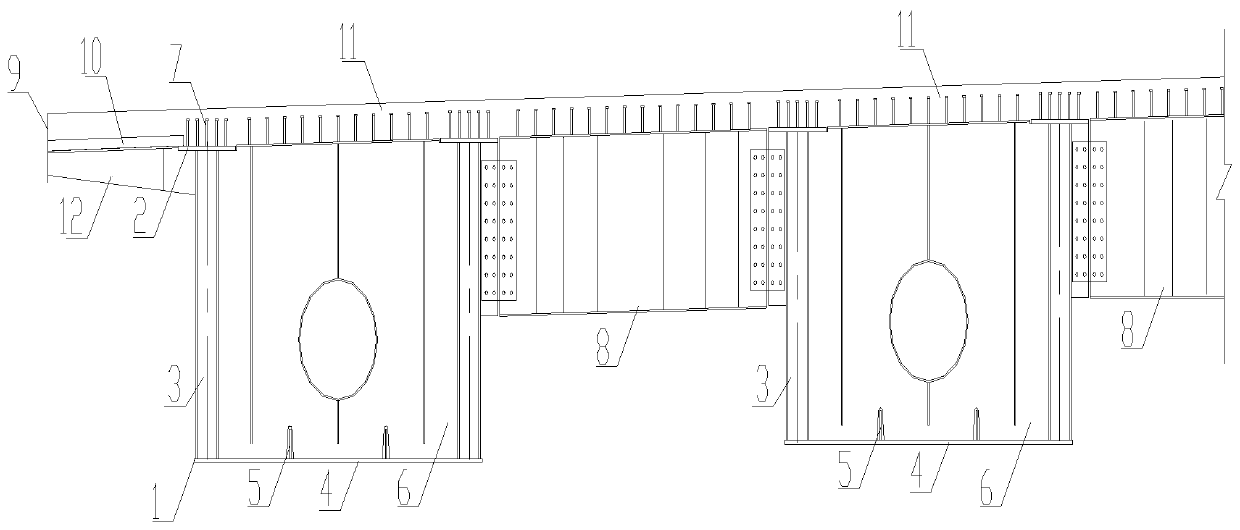

Fabricated corrugated web steel box-UHPC composite beam bridge and construction method thereof

PendingCN111206489AMeet different design needsReduce welding workloadBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a fabricated corrugated web steel box-UHPC composite beam bridge and a construction method thereof, the fabricated corrugated web steel box-UHPC composite beam bridge is composed of corrugated web steel boxes and UHPC bridge deck slabs, each corrugated web steel box is of an open box-shaped structure composed of a flat steel bottom plate, corrugated steel webs and a flat steel top plate, and the adjacent corrugated web steel boxes are connected through cross beams between the boxes; the UHPC bridge deck slabs comprise in-box prefabricated UHPC bridge deck slabs, inter-box prefabricated UHPC bridge deck slabs and cantilever cast-in-place UHPC bridge deck slabs, and the adjacent prefabricated UHPC bridge deck slabs are connected through cast-in-place wet joint UHPC bridge deck slabs; and the multiple UHPC bridge decks are correspondingly installed on the multiple corrugated web steel boxes to form the assembly type corrugated web steel box-UHPC composite beam bridge. According to the fabricated corrugated web steel box-concrete composite beam bridge, the steel consumption configuration is optimized, the self-weight of the structure is further reduced, the prefabricated concrete bridge deck is adopted, the fabricated degree is further improved, the construction period is short, the standardization degree is high, remarkable economic and social benefits areachieved, and the fabricated corrugated web steel box-concrete composite beam bridge has important significance in promoting large-scale application of steel structure bridges.

Owner:甘肃省交通规划勘察设计院股份有限公司

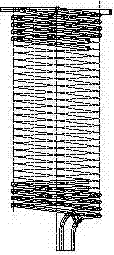

Start-up heating furnace coil pipe production method of synthetic ammonia device

InactiveCN103240313AImprove ergonomicsManufacturing Quality Assurance and EnhancementStraight tubeProcess engineering

The invention relates to a start-up heating furnace coil pipe production method of a synthetic ammonia device. The start-up heating furnace coil pipe production method includes welding and installing materials straight pipes one by one, and then processing the welded and installed straight pipes into coil pipes by a spiral coiler. Compared with the existing method of producing single coil pipe and then welding and installing, the start-up heating furnace coil pipe production method of the synthetic ammonia device greatly improves processing quality and working efficiency, and reduces production cost.

Owner:SHIFANG TONGJIA MACHINERY

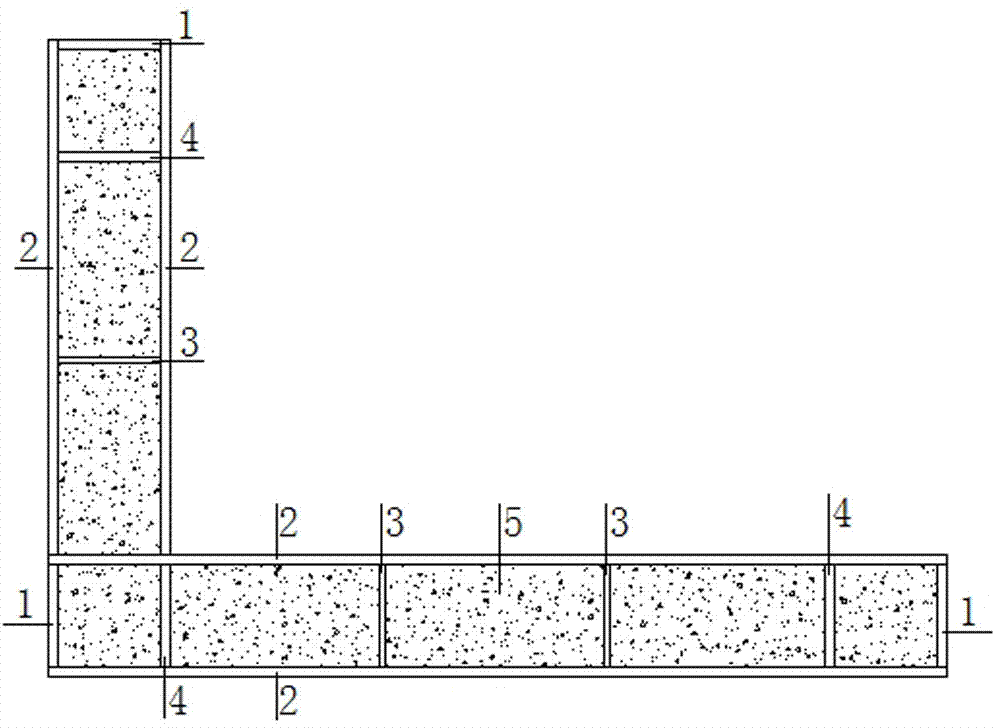

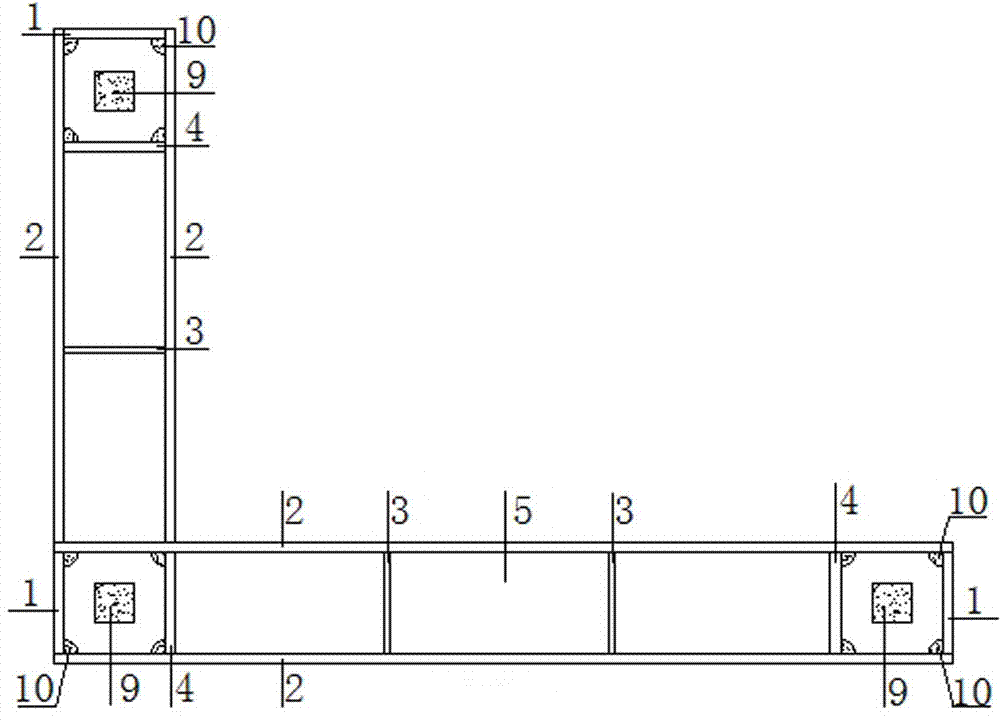

Multi-cavity L-shaped encased-steel plate shearing wall

The invention relates to a multi-cavity L-shaped encased-steel plate shearing wall. The multi-cavity L-shaped encased-steel plate shearing wall is characterized by comprising a first encased-steel plate, a second encased-steel plate, a middle ribbed plate, an end ribbed plate, concrete, an upper ribbed plate, a lower ribbed plate, holes on corresponding positions of floor beams and for pouring concrete in the upper ribbed plate and the lower ribbed plate and exhaust holes in connection corners of the upper ribbed plate and the lower ribbed plate with the first encased-steel plate, the second encased-steel plate or the end ribbed plate, the first encased-steel plate and the second encased-steel plate are respectively arranged at the outer side of the shearing wall along the length direction of a shearing wall body, the middle ribbed plates satisfying the space requirement are arranged along the length direction of the shearing wall, concrete is poured in a cavity respectively formed among the first encased-steel plate, the second encased-steel plate and the middle ribbed plate to form the multi-cavity L-shaped encased-steel plate shearing wall. The multi-cavity L-shaped encased-steel plate shearing wall has the advantages of the ordinary rectangular reinforced concrete wall body and a built-in steel plate shearing wall, the stretchability of the wall body can be improved, the plastic development under the earthquake or strong wind can be delayed, and the thickness of the wall body is reduced.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

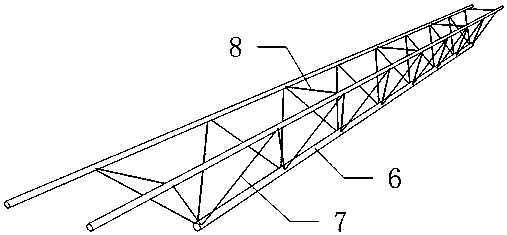

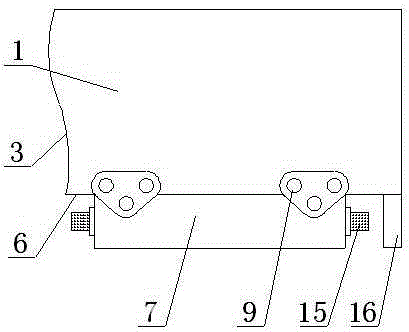

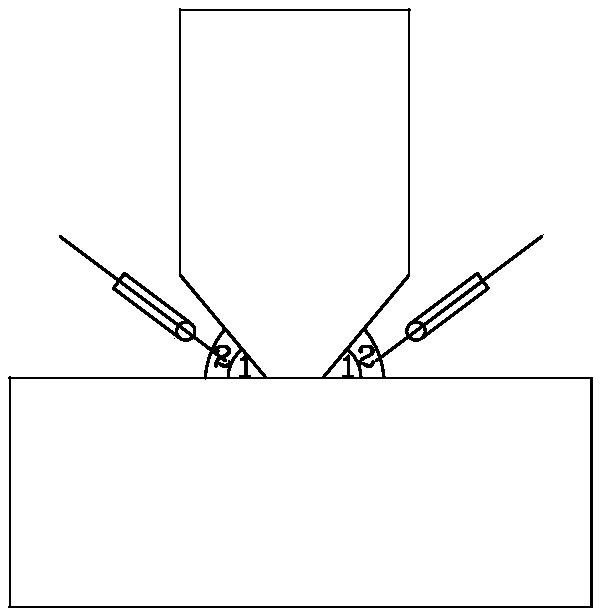

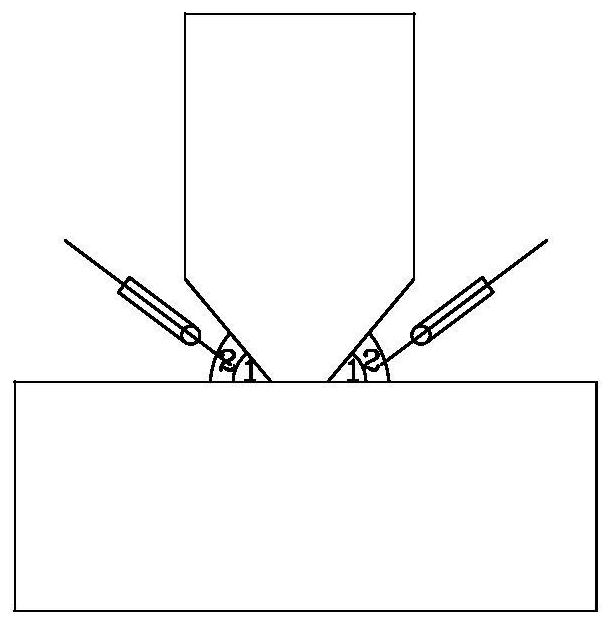

Metal damper provided with restraining devices and stiffening ribs

InactiveCN102644335APrevent bucklingGuaranteed energy consumptionShock proofingEngineeringEnergy consumption

The invention discloses a metal damper provided with restraining devices and stiffening ribs. The metal damper comprises an energy consumption steel plate, horizontal connecting steel plates arranged above and below the energy consumption steel plate, wing edge plates arranged at two ends of the energy consumption steel plate as well as the stiffening ribs and the restraining devices which are arranged on two sides of the energy consumption steel plate, wherein the energy consumption steel plate is welded with the upper and low horizontal connecting steel plates; the energy consumption steel plate is welded with the wing edge plates at two ends of the energy consumption steel plate; the restraining devices are respectively arranged on two sides of the energy consumption steel plate; bolt holes are formed in the restraining devices; and the restraining devices on two sides of the energy consumption steel plate are fixedly connected by bolts. According to the metal damper disclosed by the invention, the energy consumption capability and the stability of the damper are ensured; no cross weld joints exist between the stiffening ribs on the same side of the energy consumption steel plate; the stiffening ribs can be arranged in a through way without being cut off and is convenient to weld; the welding quality is easy to ensure; and the restraining devices are independent from the energy consumption steel plate, so that the damage to the energy consumption steel plate as the welding of the stiffening ribs on the energy consumption steel plate is avoided.

Owner:SHANGHAI SAFE SEISMIC RETROFIT & VIBRATION CONTROL TECH

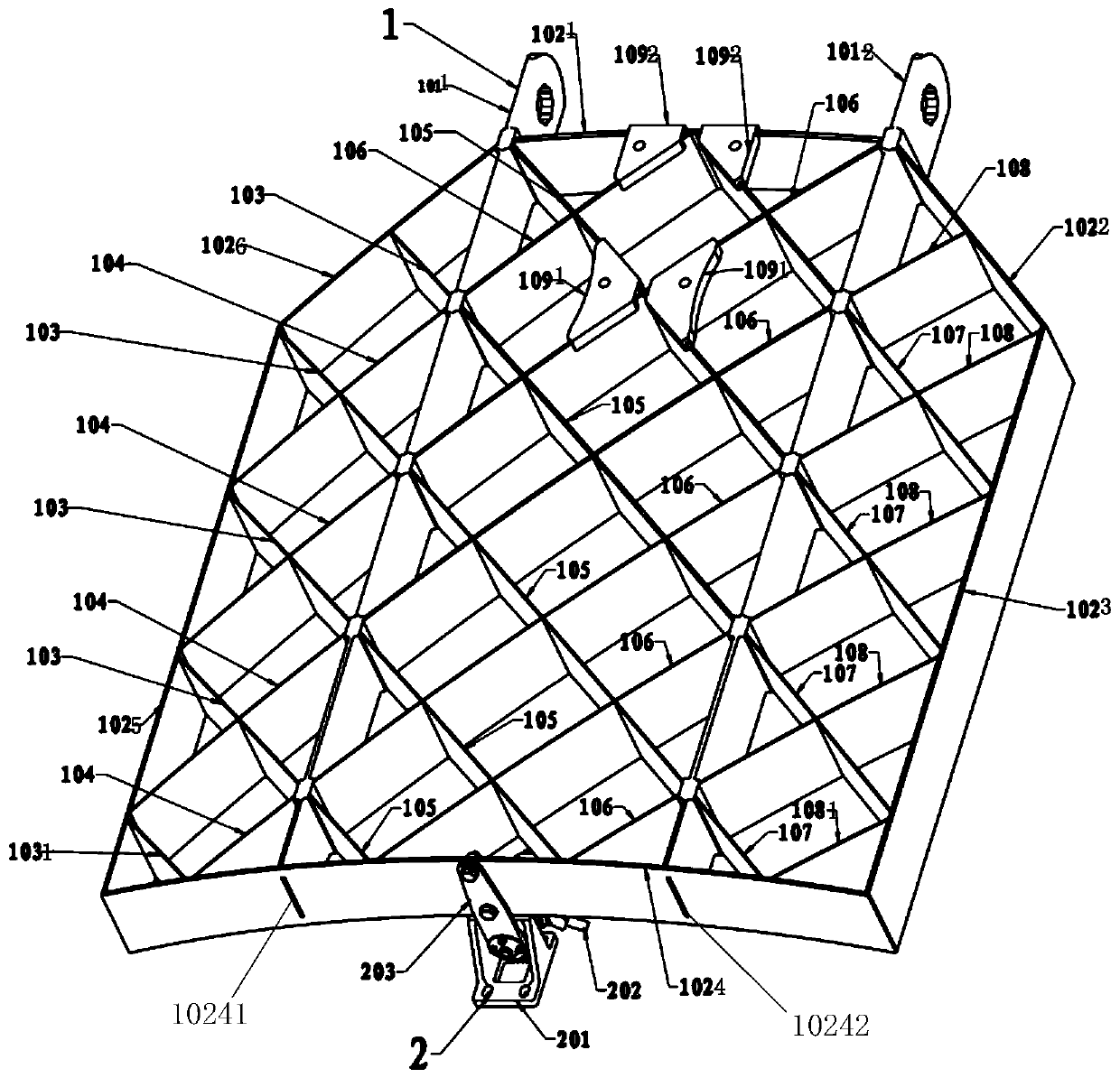

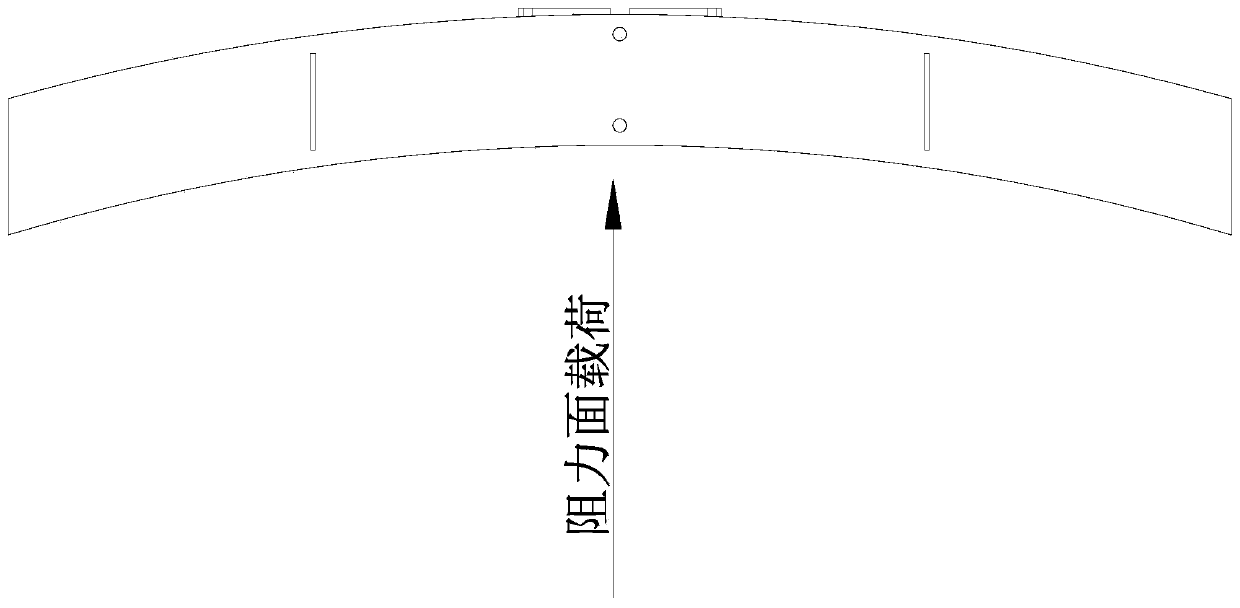

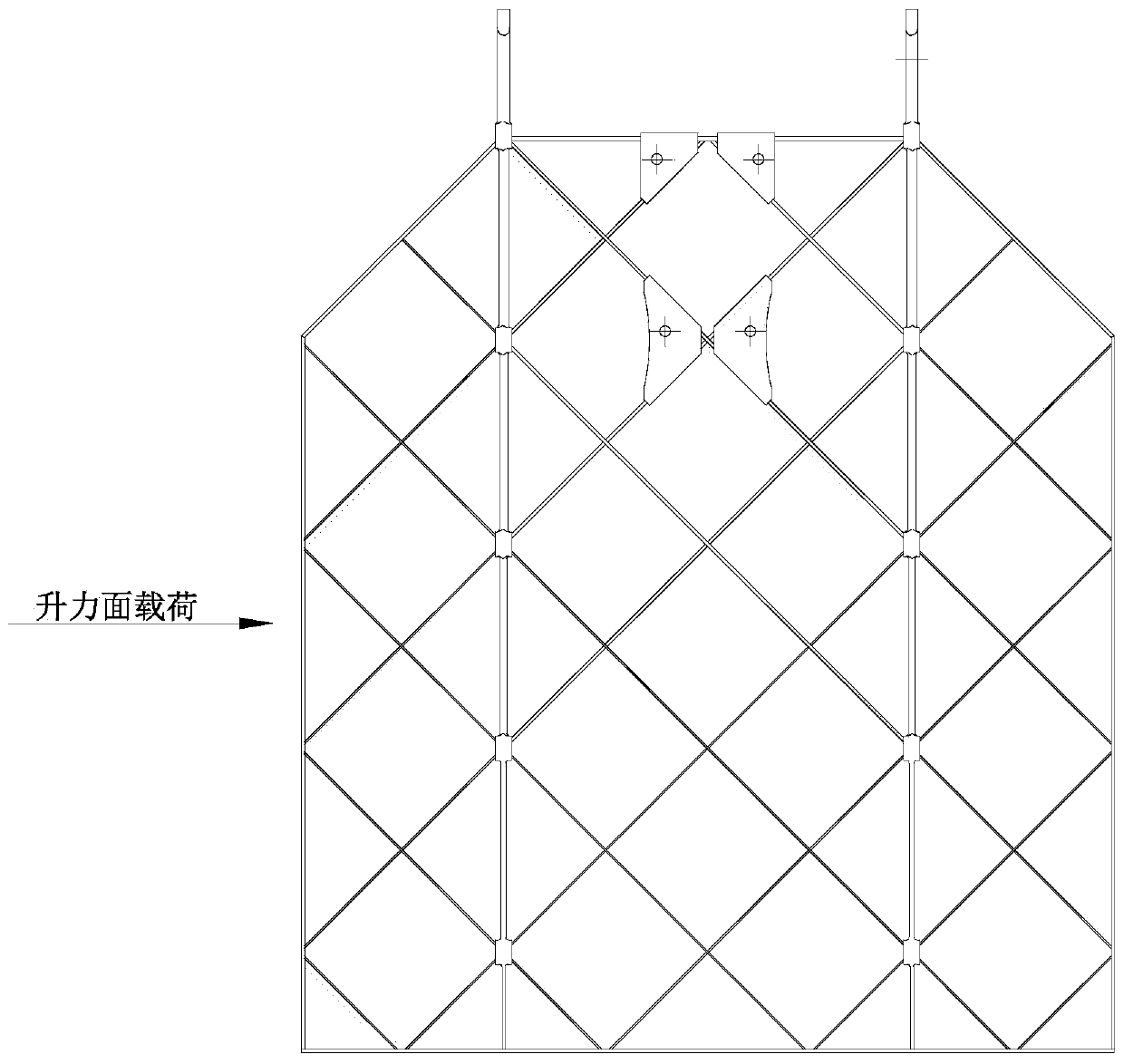

Grid fin device

ActiveCN110260726AImprove reliabilityAvoid welding qualitySelf-propelled projectilesEngineeringSurface structure

The invention discloses a grid fin surface device. The grid fin surface device comprises a fin surface structure and a locking and unlocking device, the fin surface structure is connected with the locking and unlocking device, wherein the fin surface structure comprises a first fin root, a second fin root, a fin frame and several blades, the first fin root and the second fin root are connected with the fin frame correspondingly, moreover, the first fin root and the second fin root divide the fin frame into a first area, a second area and a third area, and the several blades are arranged at the first area, the second area and the third area. According to the grid fin surface device, a structure initial splicing bearing and welding auxiliary positioning scheme is adopted, a scheme of inserting a pin puller pin shaft into a spherical hinge hole is adopted, so that the grid fin surface device has the advantages of being stable and reliable in bearing performance and capable of achieving deformation compensation capability.

Owner:SHANGHAI AEROSPACE SYST ENG INST

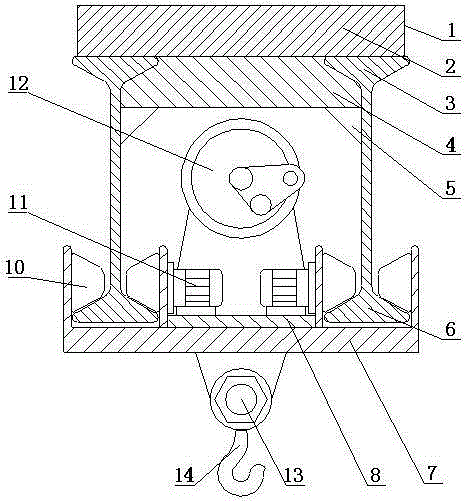

Electric block type double-rail and single-main-beam crane

InactiveCN105293278AMeet job needsAvoid damageLoad-engaging girdersTravelling gearVehicle frameBlock and tackle

The invention relates to an electric block type double-rail and single-main-beam crane. The electric block type double-rail and single-main-beam crane comprises a main beam. An upper wing plate is welded to the top of the main beam. Webs are welded to the lower surface of the upper wing plate. Traveling rails are arranged at the lower ends of the webs. An upper wing plate strengthening plate is welded between the upper wing plate and the webs. Web strengthening rib plates are welded between the upper wing plate strengthening plate and the webs. An electric block is installed in the main beam and connected with an electric block base. A trolley frame is connected with the lower portion of the electric block base. The trolley frame is provided with walking devices which are internally provided with walking wheels. The walking wheels are connected with drive motors, and the electric block is connected with a pulley block. The pulley block is connected with a lifting hook. Buffering devices are arranged at the front end and the rear end of the trolley frame. Limiting devices are arranged at the lower portions of the front end and the rear end of the main beam. The electric block type double-rail and single-main-beam crane has the beneficial effects of being reasonable in design, simple in structure, convenient to detect and maintain, large in lifting height, good in lifting performance, safe, reliable, stable in operation, long in service life and high in working efficiency.

Owner:德马科起重机械有限公司

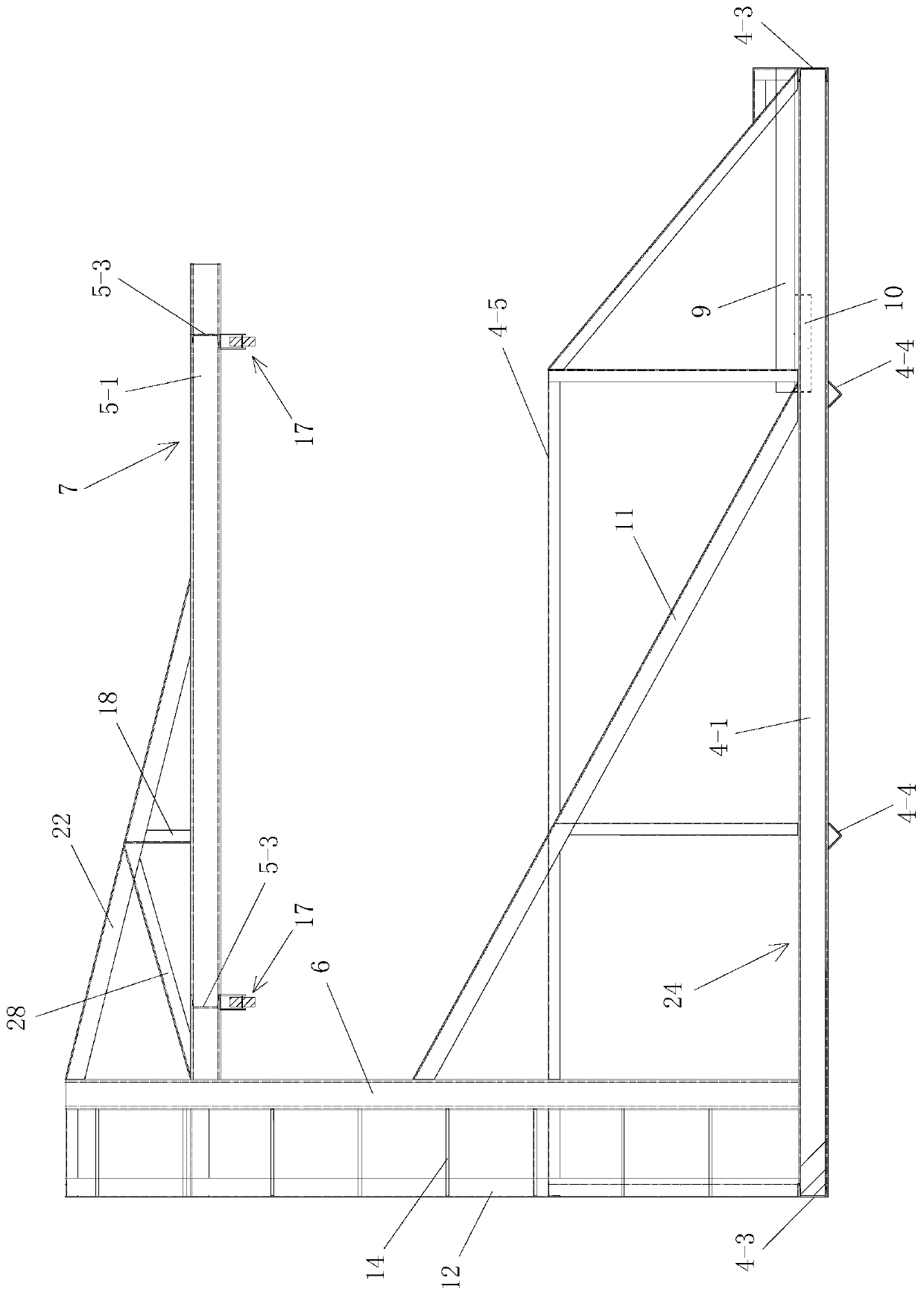

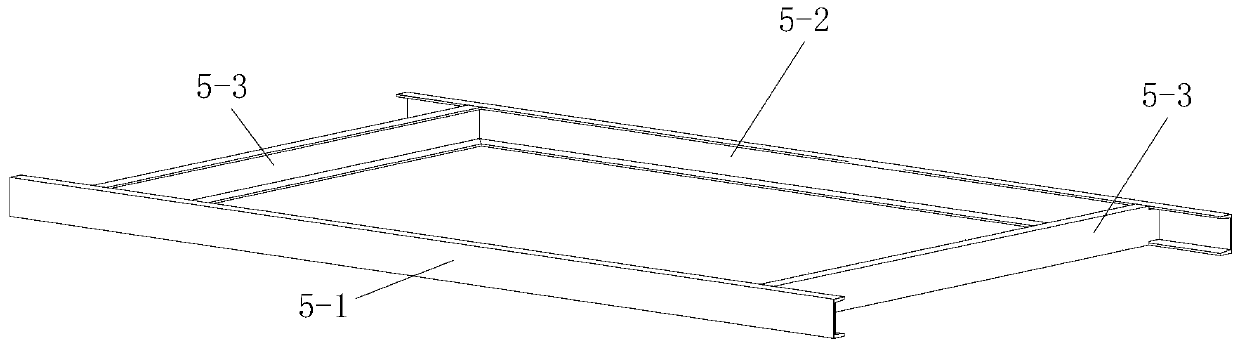

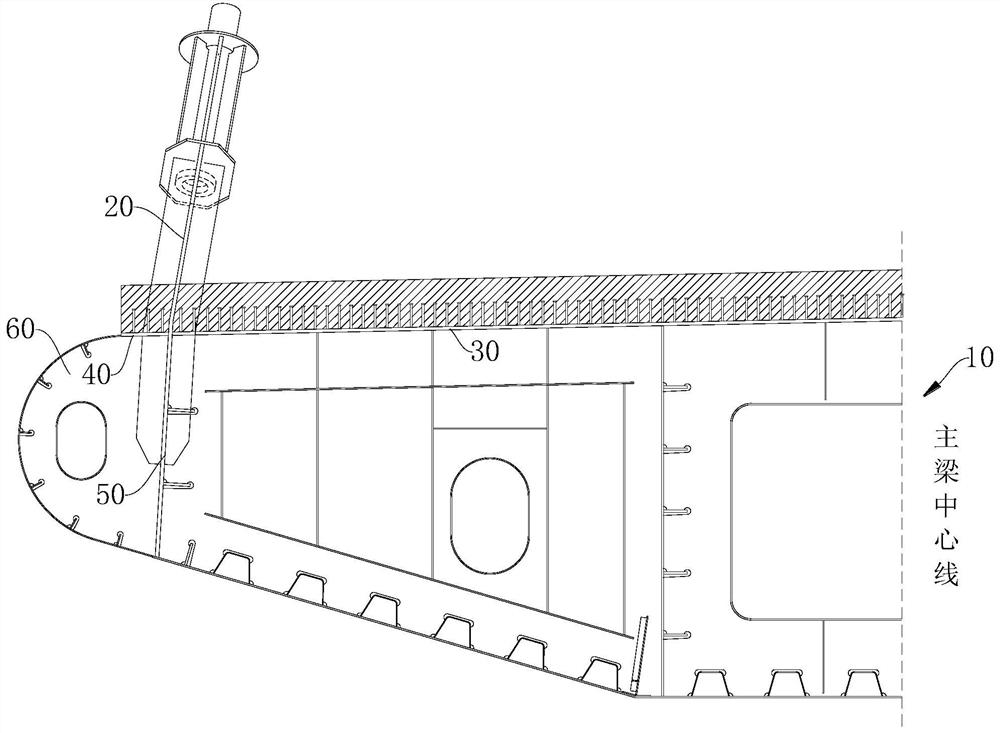

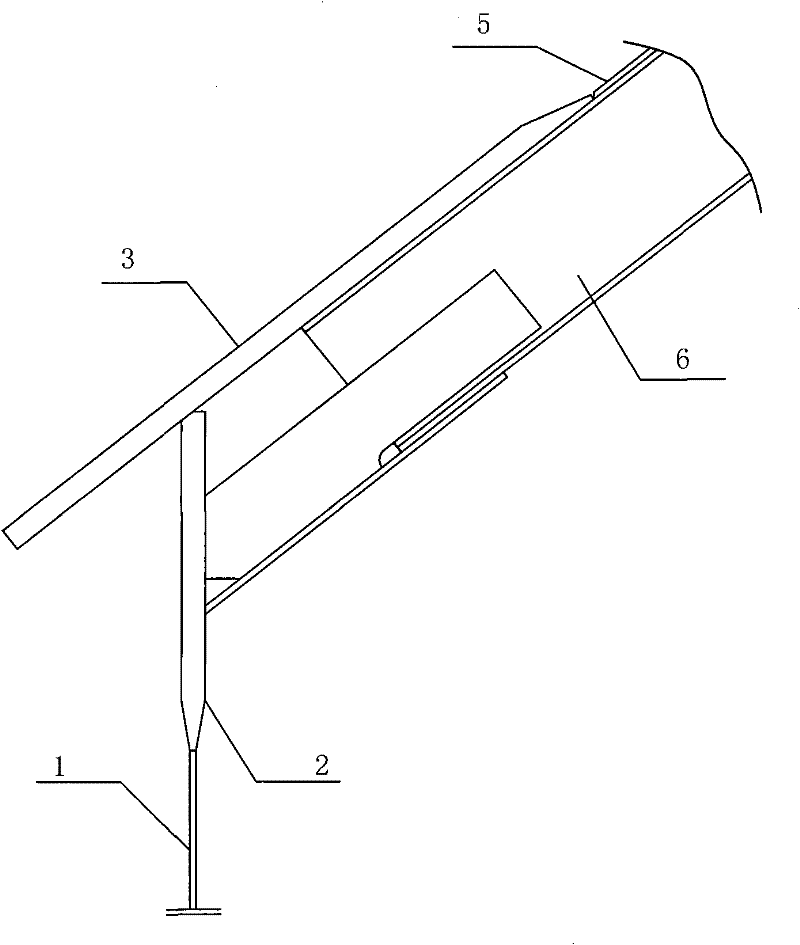

Movable cantilever hanging basket for steel box girder construction and construction method

PendingCN110593107ASimple structureEasy to processBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a movable cantilever hanging basket for steel box girder construction and a construction method. The movable cantilever hanging basket for steel box girder construction comprises a hanging basket body which can horizontally move on the steel box girder, a hanging basket walking device arranged on the hanging basket body and a walking track for the hanging basket walking device to walk, and the hanging basket walking device is arranged on the walking track. The hanging basket body is arranged on a flange plate of the steel box girder, the hanging basket body is providedwith a welding construction platform, and the welding construction platform is a telescopic construction platform. The construction method comprises the first step of construction of a middle girder body of the steel box girder, the second step of welding construction of the flange plate of the steel box girder and the third step of construction completion of the steel box girder. The movable cantilever hanging basket for steel box girder construction is reasonable in design, easy and convenient to construct and good in using effect, the hanging basket can horizontally move on the steel box girder in the longitudinal bridge direction, welding requirements under the situation that widths of cantilever segments are unequal can be met through the telescopic construction platform on the hanging basket, the construction process of the steel box girder can be easily, conveniently and rapidly completed, the welding process of the flange plate of the steel box girder is easy and convenient, the welding efficiency is high, and the welding quality is easy to guarantee.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

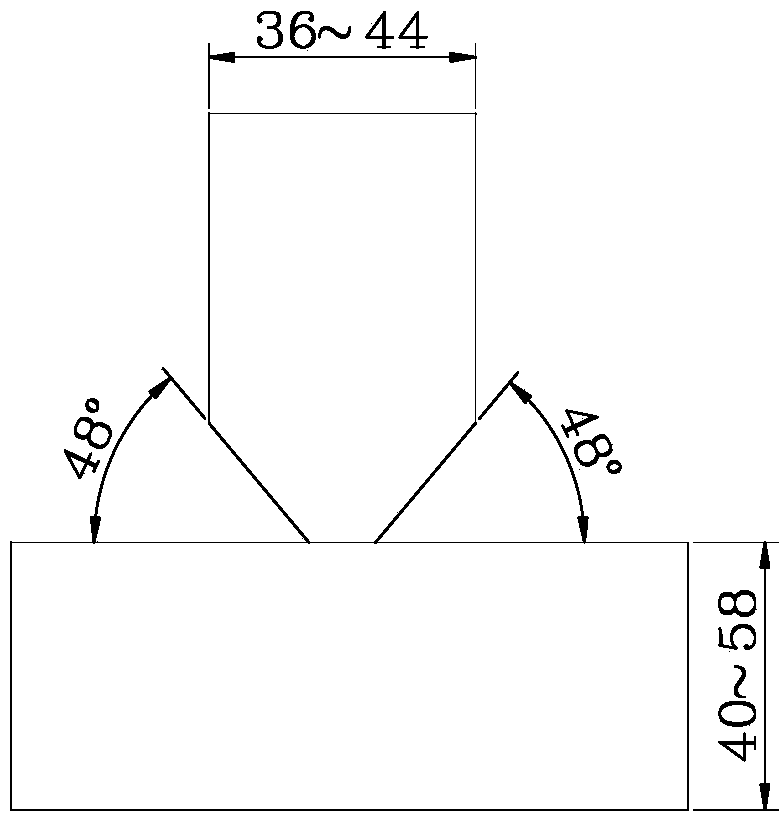

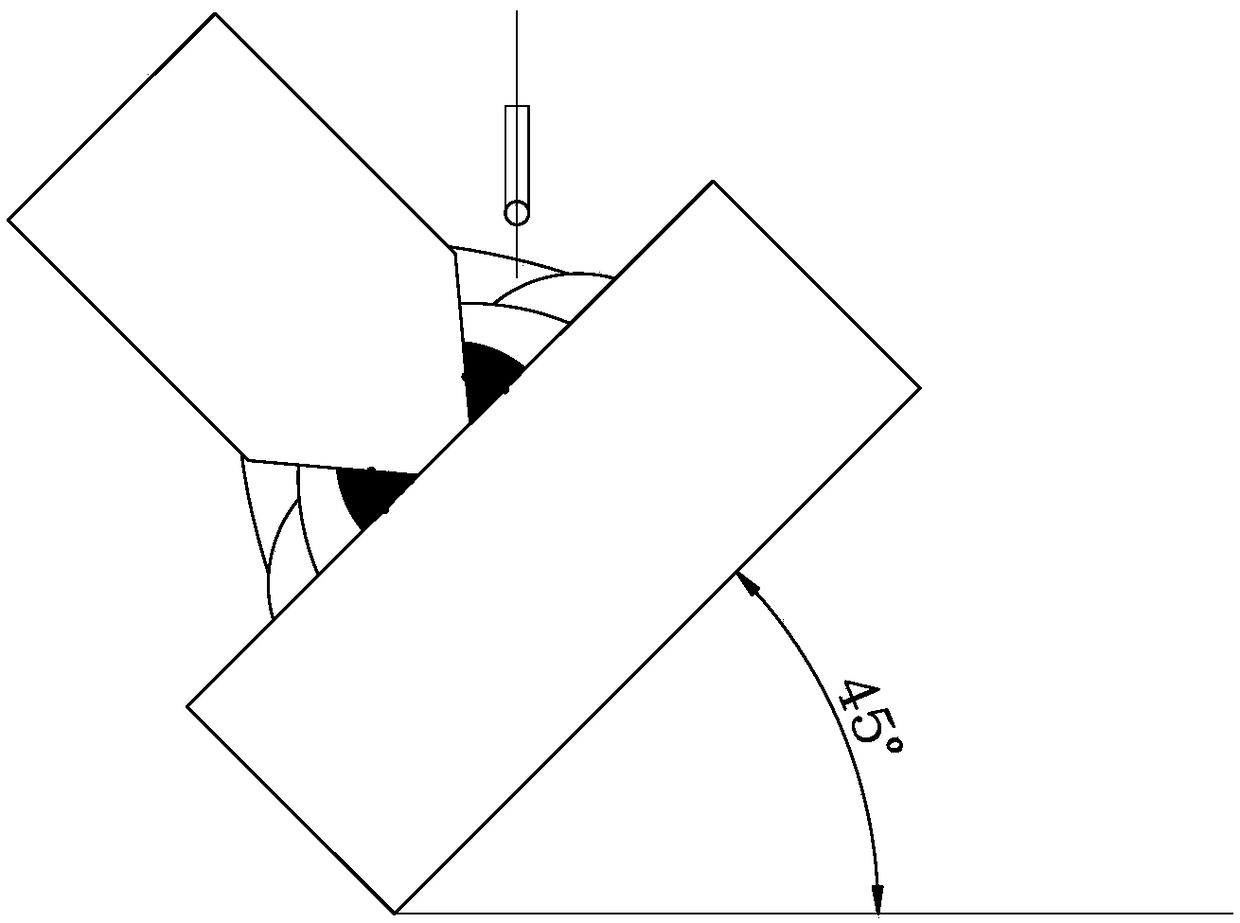

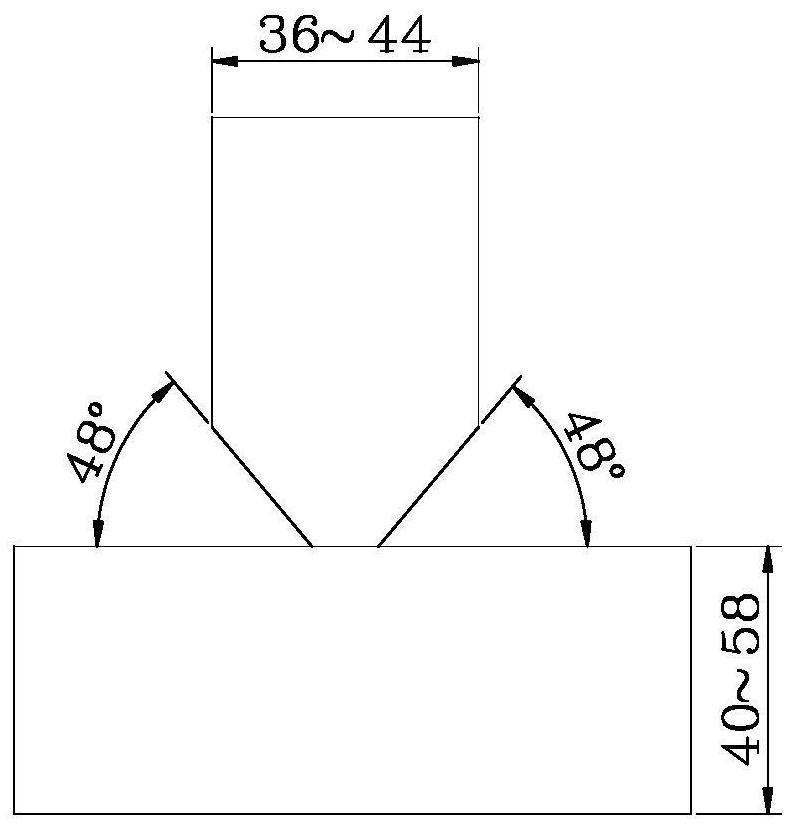

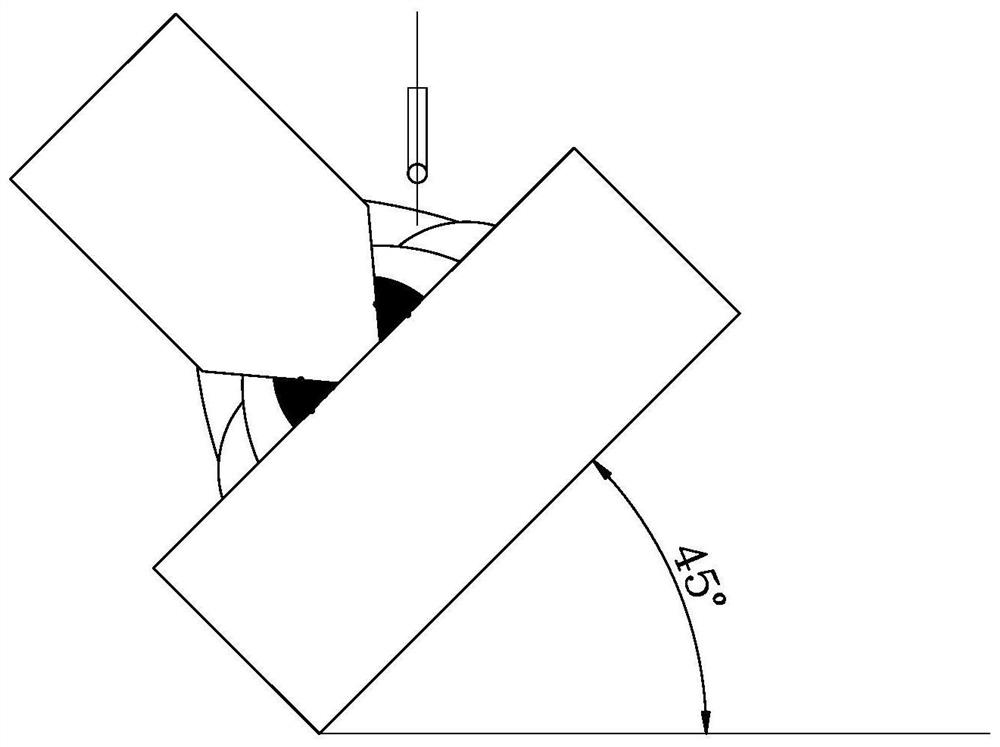

Q500qE high-strength bridge steel corner joint welding method

ActiveCN108817617AAvoid welding deformationGuaranteed verticalityArc welding apparatusWelding/cutting media/materialsSheet steelThick plate

Provided is a Q500qE high-strength bridge steel corner joint welding method. Two sides of a rib plate are provided with partially penetrated two-sided symmetrical grooves, groove angles are 48 degrees, and then the rib plate is vertically assembled and positioned on a base plate; during welding, an ER60Q solid wire and a CO2 gas shielded welding technology are firstly adopted to weld passes transversely, synchronously and symmetrically, and the rib plate is vertically fixed to the base plate; then, an H60Q submerged arc welding wire, an SJ105q submerged arc welding agent and an automatic submerged arc welding process are adopted to perform sequential filling of two sides of a ship's position and cover surface welding, and the angle of the ship's position is 45 degrees. According to the welding method integrating transverse gas shielded welding and ship's position submerged arc welding, preheating is not needed before welding, deformation correction is not needed after welding, formed welded appearance is attractive, and weld joints are internally reliable in performance, stable in quality, small in welding deformation and high in production efficiency. The Q500qE high-strength bridge steel corner joint welding method is suitable for welding of high-strength large and thick bridge steel plate units.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +2

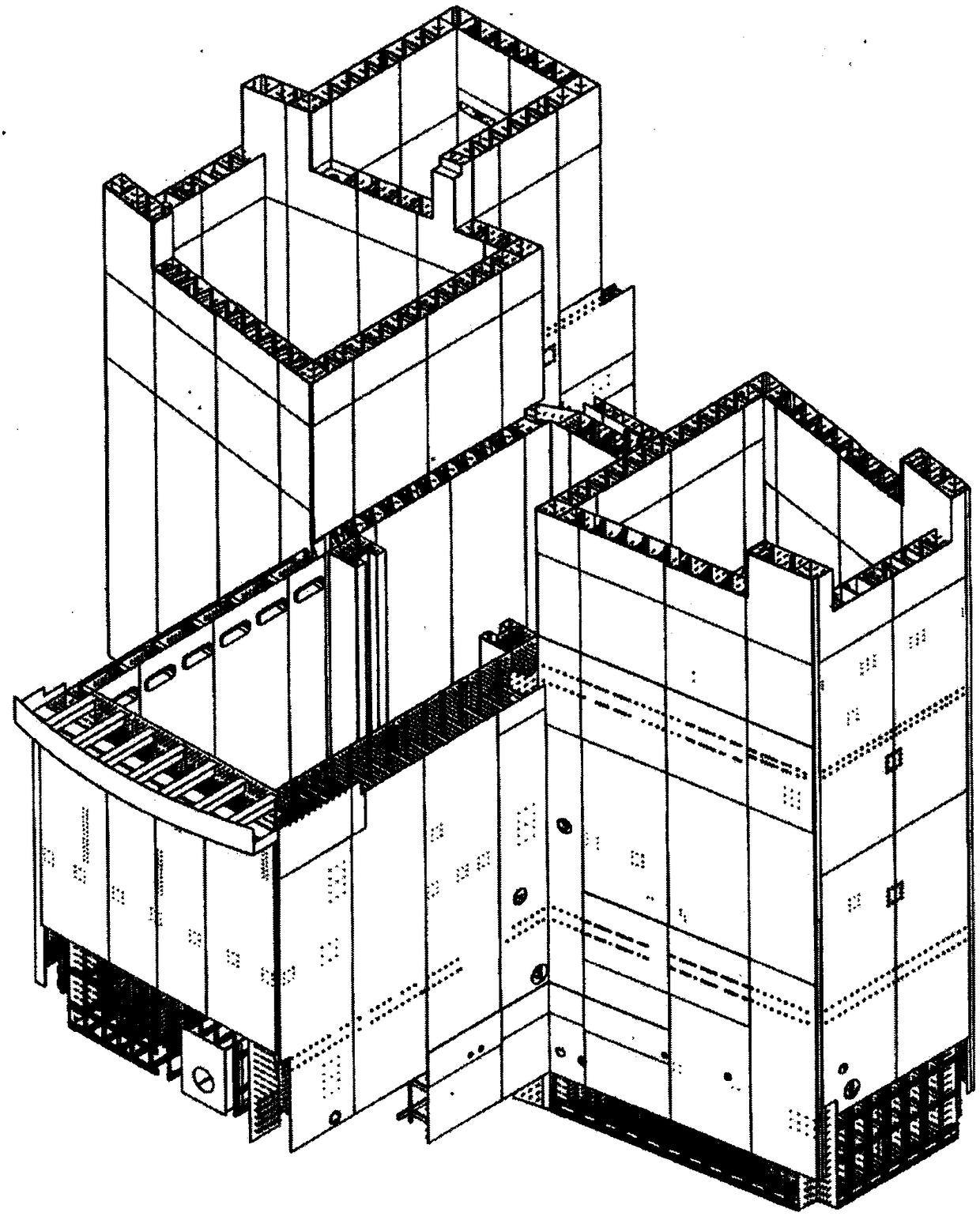

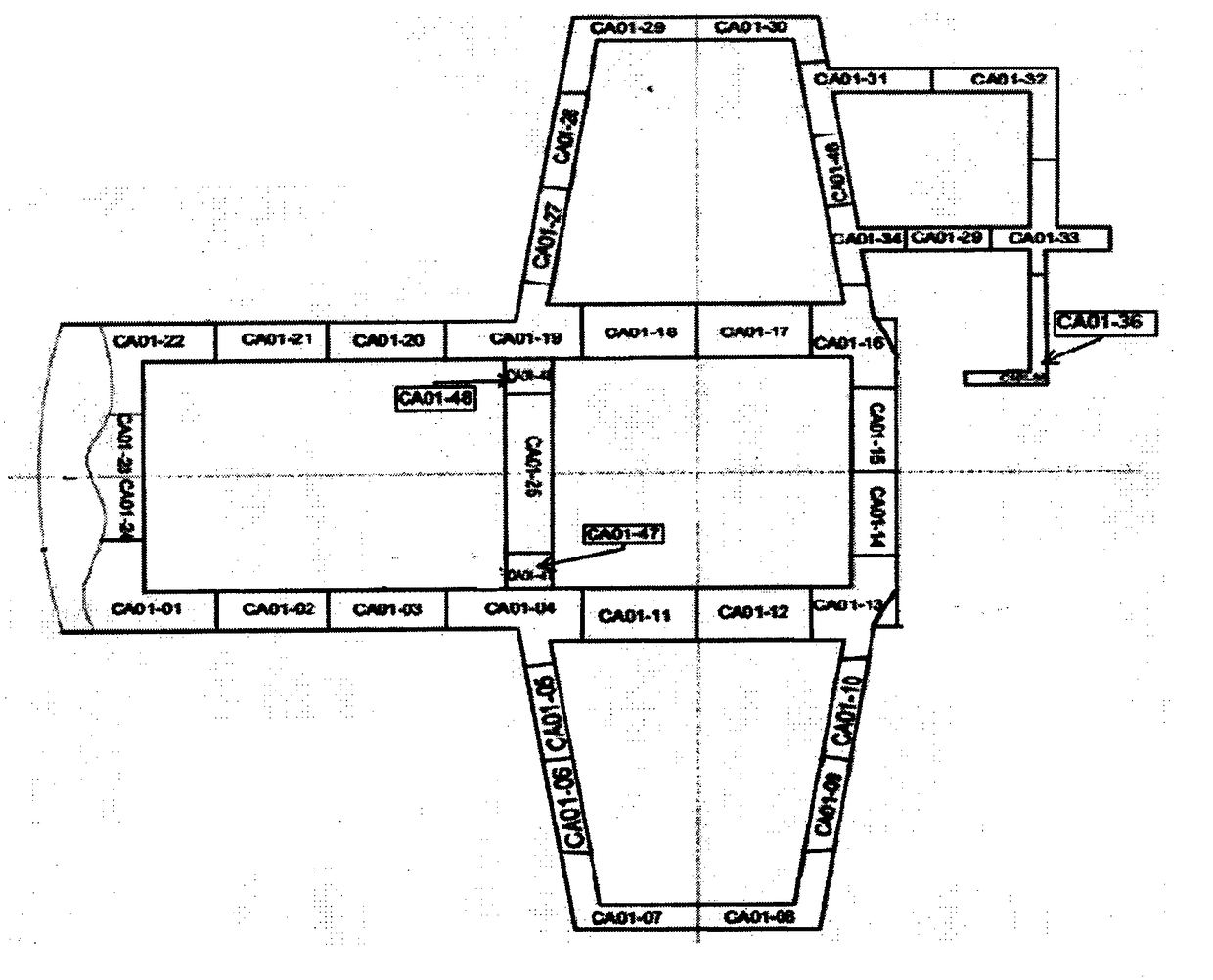

Vertical assembling method for structural modules of nuclear power plant

InactiveCN108442712AErrors do not accumulateImprove assembly accuracyBuilding material handlingNuclear powerComputer module

The invention provides a vertical assembling method for structural modules of a nuclear power plant. The vertical assembling method comprises the following steps that firstly, an assembly piece is disassembled with sub-modules as basic units, and the sub-modules are recombined and optimized, and the assembly sequence is determined; then, the placement position around an assembly platform of each sub-module in a site is determined according to the performance of a crane; the first two sub-modules are hoisted to the corresponding positions of the assembly platform; a scaffold is erected outsidethe sub-modules in place; the sub-modules in place are accurately measured and adjusted, the sub-modules are adjusted to the most ideal positions, and then assembling and welding-line welding are carried out; and similarly, the processes of hoisting of the next sub-module, erecting of a scaffold, accurate measuring and adjusting, assembling and welding-line welding are carried out, each follow-upsub-module is completed in sequence according to the assembly sequence, and the assembly advance route can generally be carried out symmetrically on both sides at the same time until all the sub-modules are assembled. The vertical assembling method greatly improves the assembling precision and quality of the structural modules of the nuclear power plant, the use of a large crane is avoid, and theeconomic performance is good.

Owner:STATE NUCLEAR POWER ENG

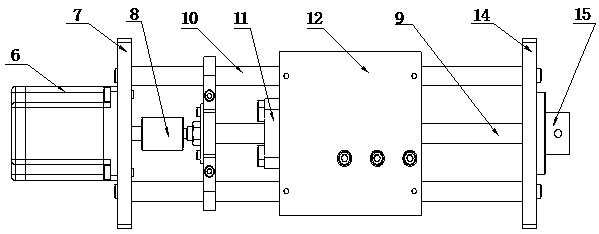

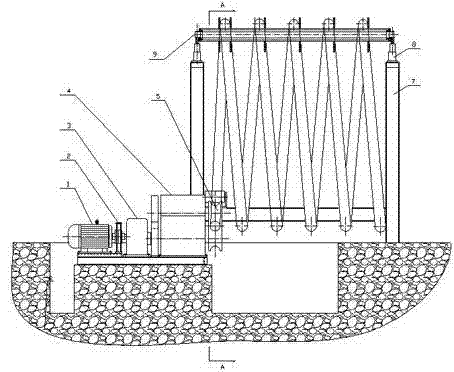

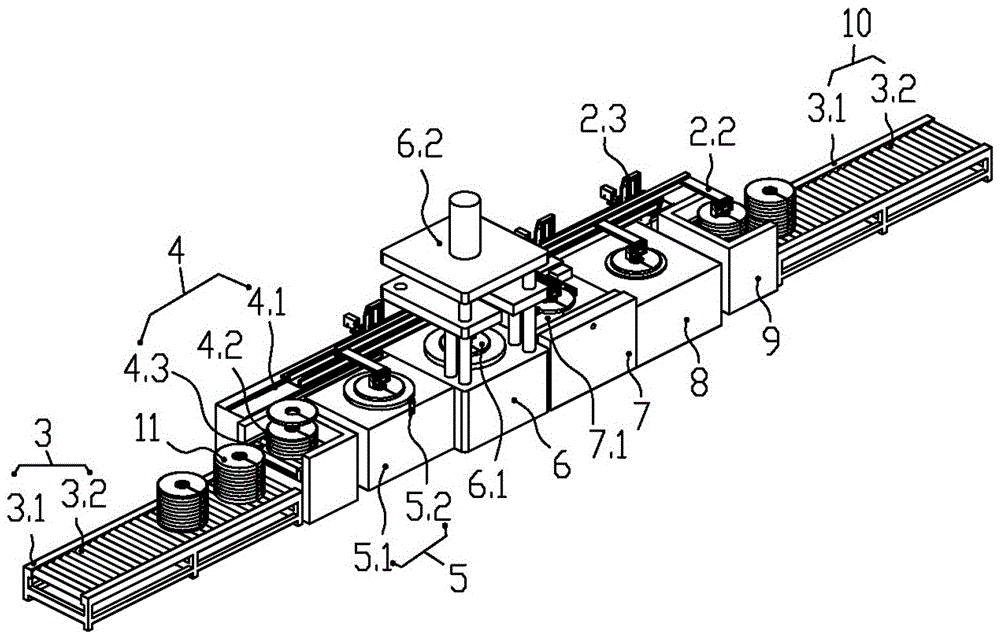

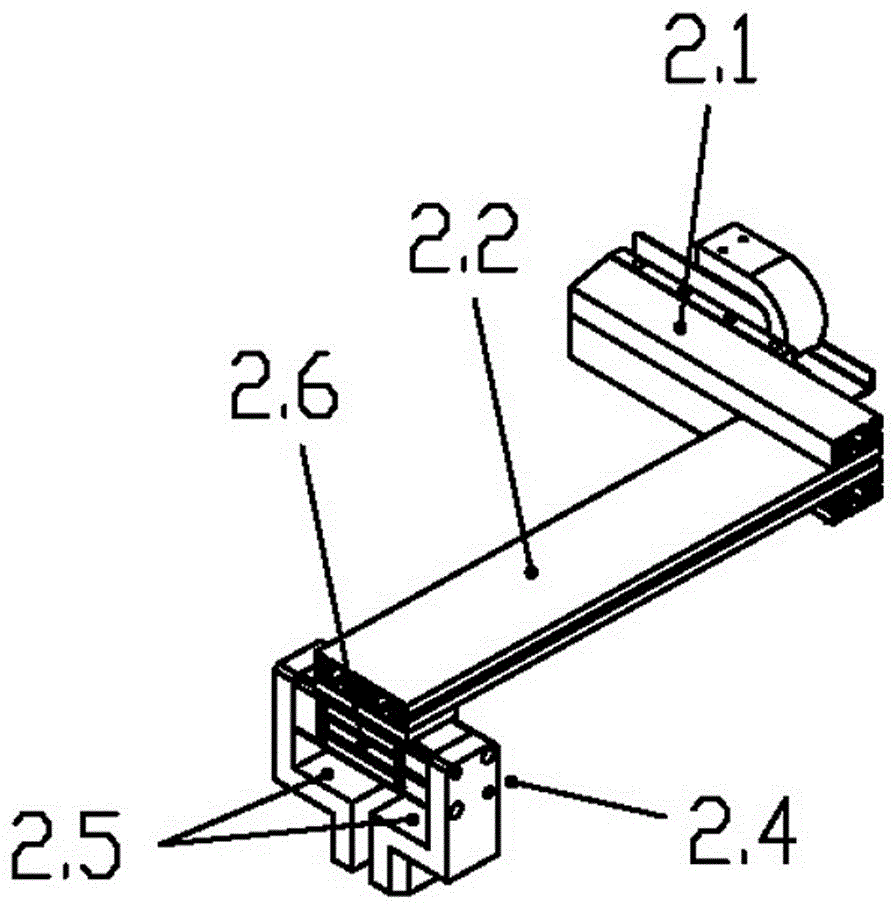

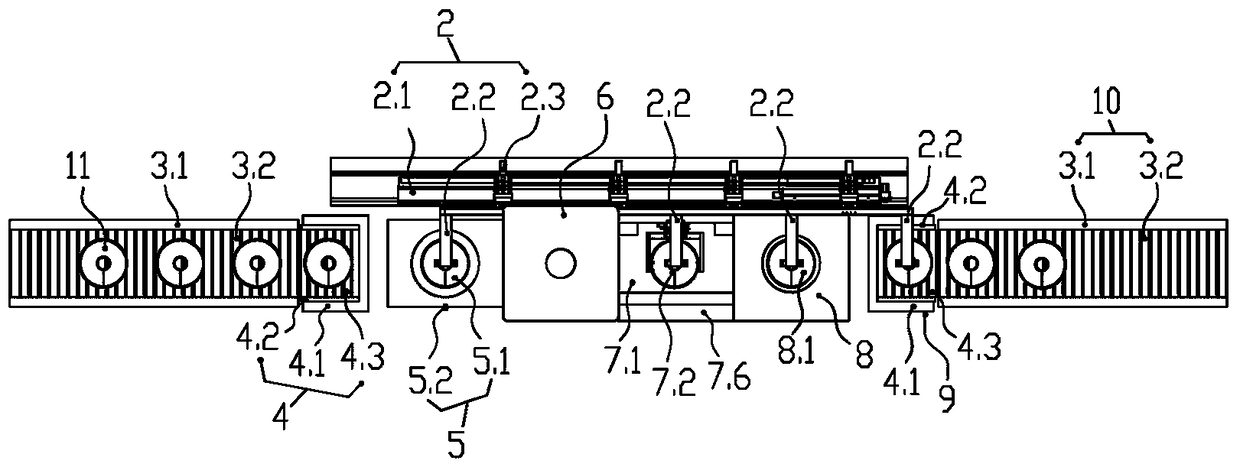

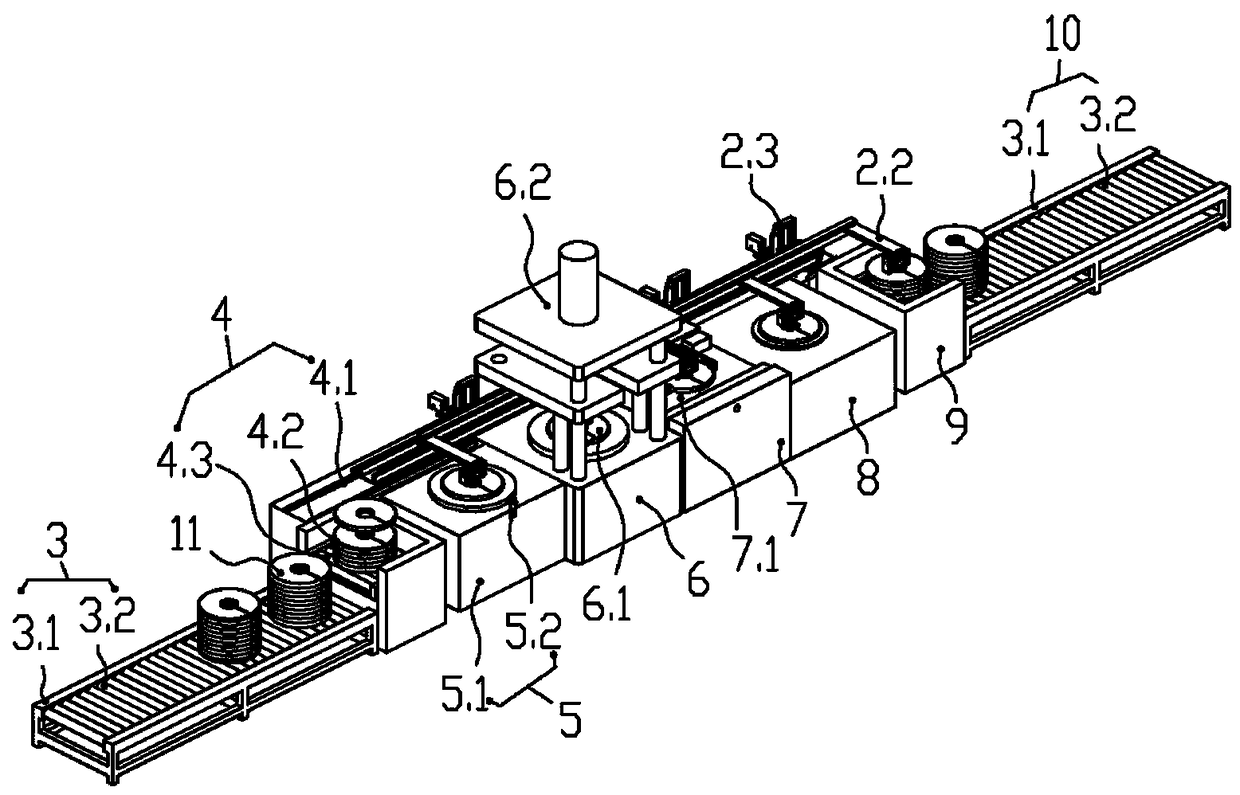

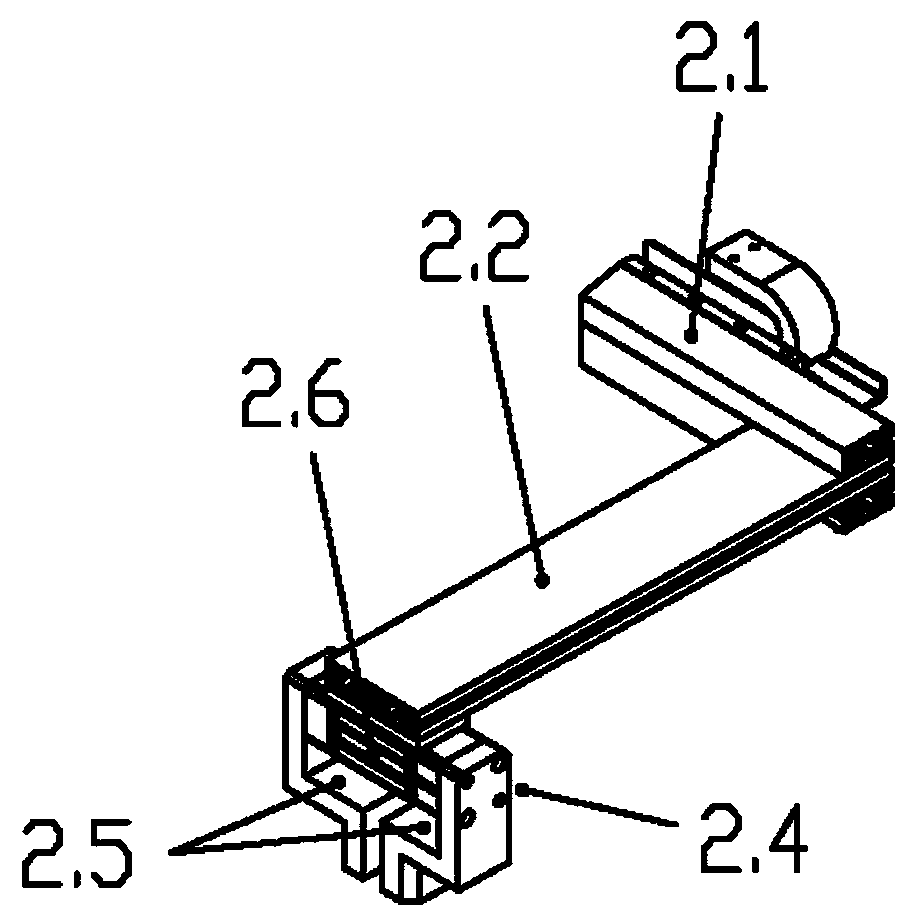

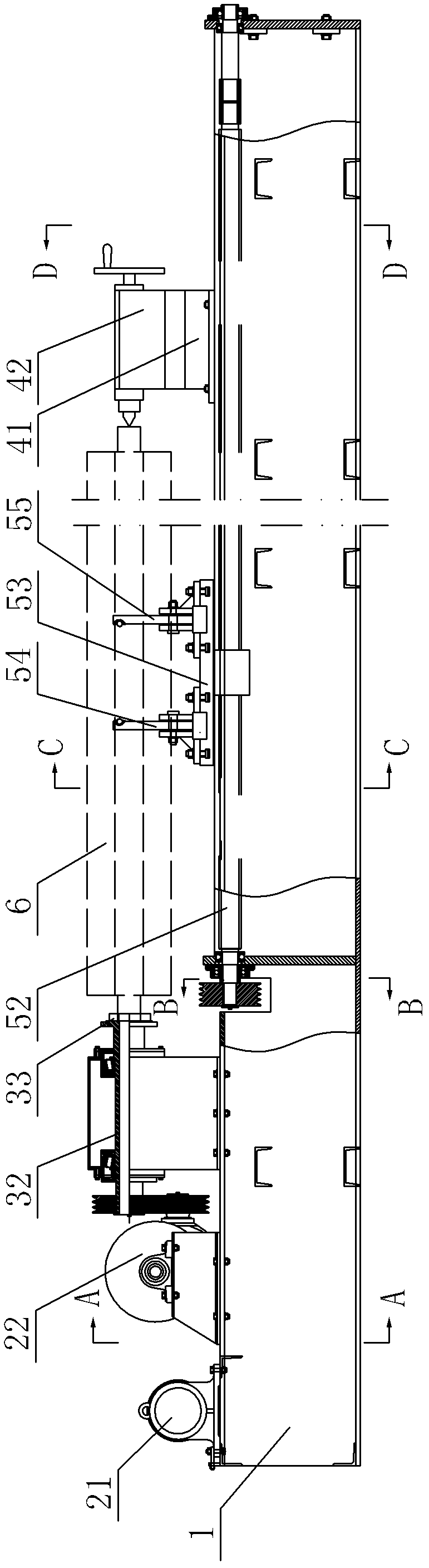

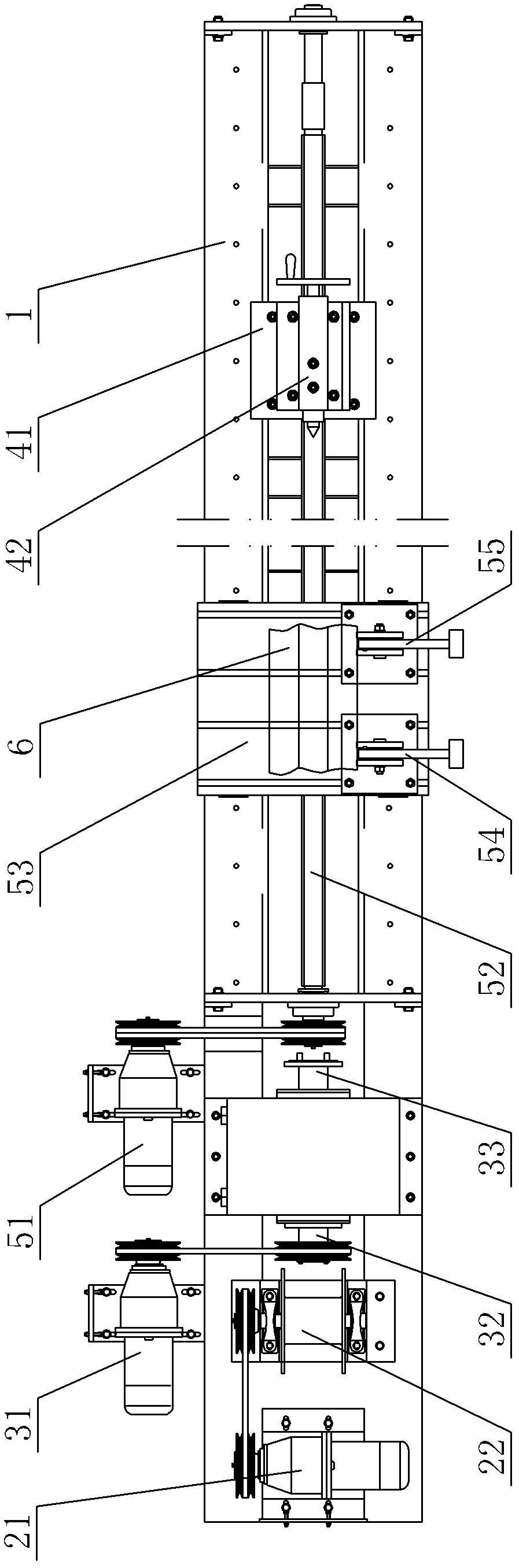

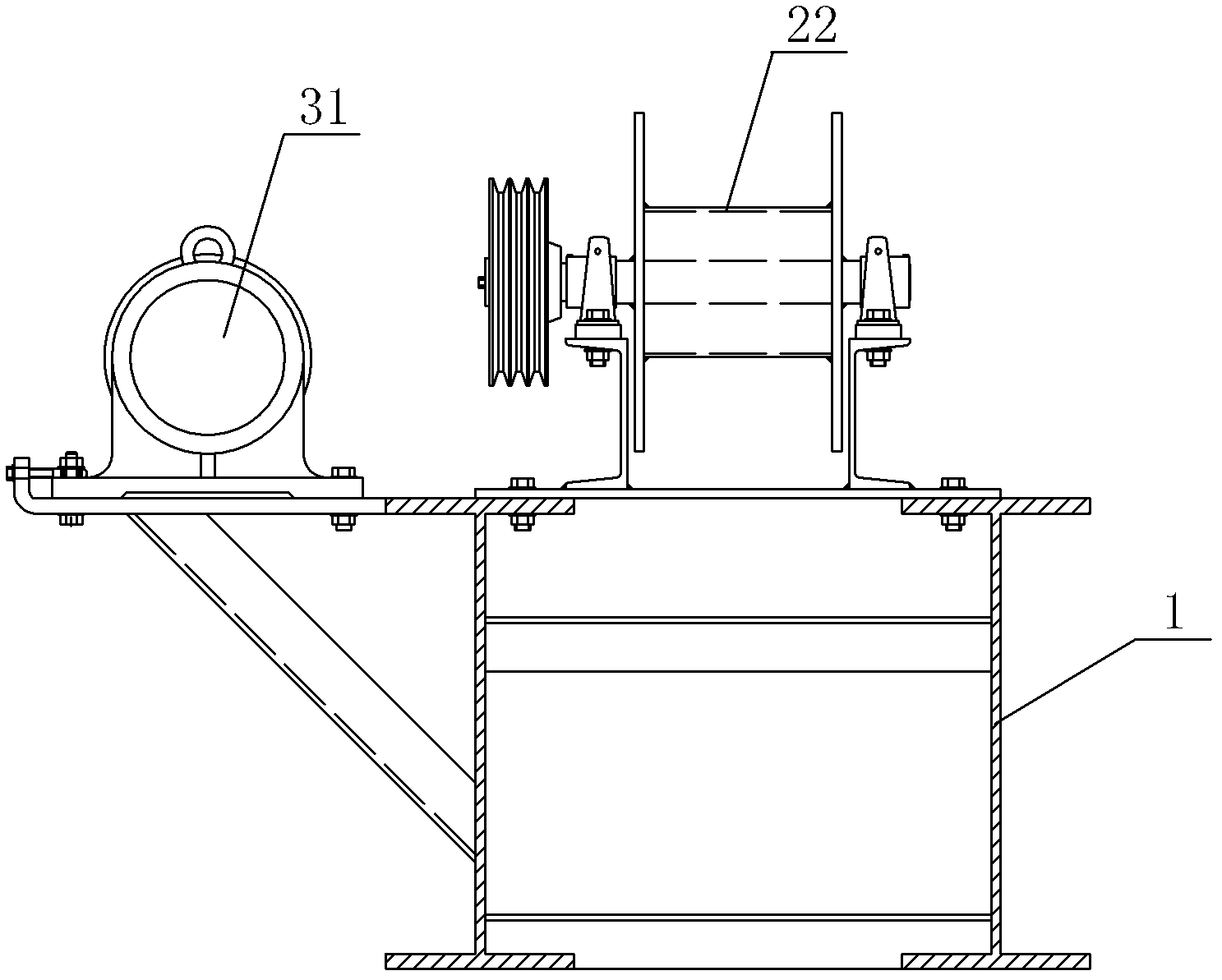

Tubular pile welding production line

InactiveCN106826018ASimple structure setupWelding quality is easy to guaranteeWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to the field of technologies for welding tubular piles, and particularly discloses a tubular pile welding production line which comprises welding devices. The tubular pile welding production line is characterized by further comprising a material translation manipulator for synchronously picking and shifting to-be-machined tubular piles; a tubular pile feeding rotary drum, a conveying lifting platform, a divisional straightening turntable, a flattening cabinet, a material turnover turntable, a welding positioning table, a discharging lifting table and a discharging rotary drum are sequentially arranged on a side of the material translation manipulator, the tubular piles can be upwardly hoisted by the conveying lifting table, required-to-be-welded connectors of the tubular piles can be correspondingly straightened by the divisional straightening turntable, the tubular piles can be flattened and welded by the flattening cabinet and can be turned over by the material turnover turntable, the turned tubular piles further can be welded by the welding positioning table, the welded tubular piles can be stacked by the discharging lifting table, the tubular piles can be delivered by the discharging rotary drum, and the welding devices are correspondingly arranged on a side of the flattening cabinet and a side of the welding positioning table. The tubular pile welding production line has the advantages that the tubular pile welding production line is simple and efficient in structural setting, tubular pile material welding working procedures are decomposed by the aid of the tubular pile welding production line, excessive manual participation basically can be omitted except for charging, the welding quality of products is easy to guarantee, and the production efficiency can be greatly enhanced.

Owner:FOSHAN FODA HUAKANG TECH CO LTD

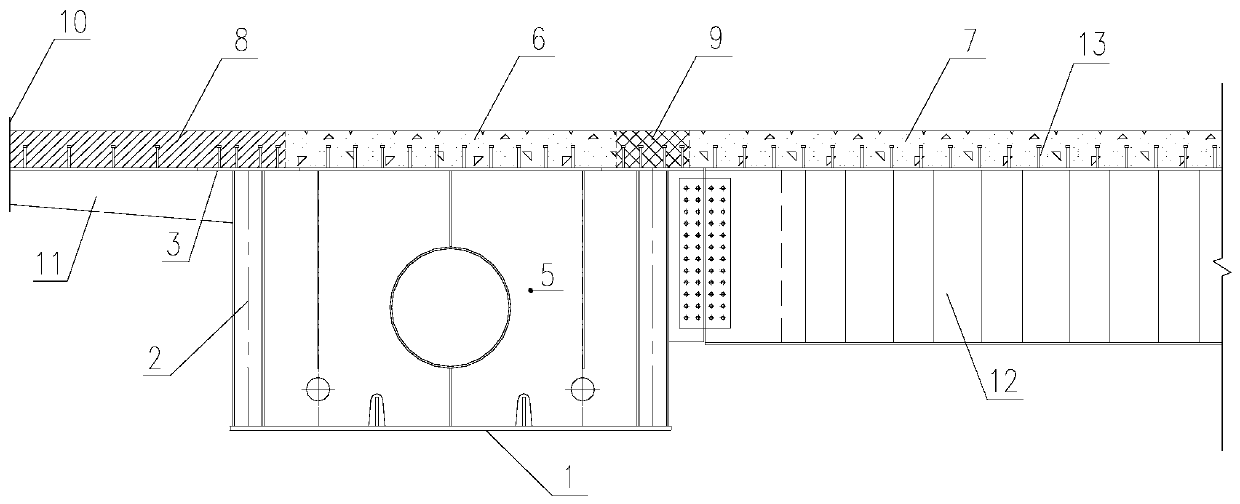

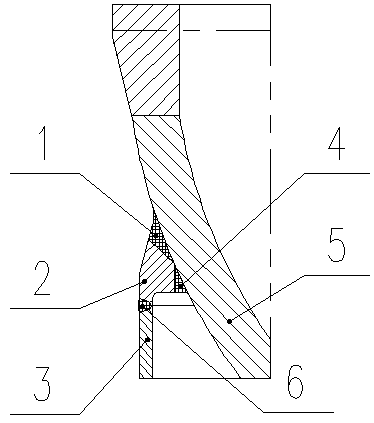

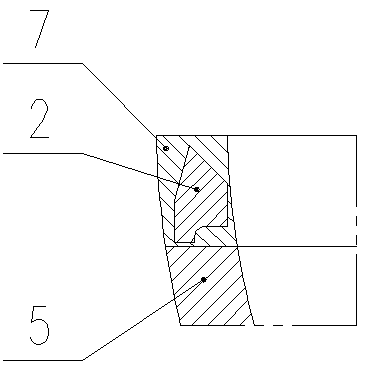

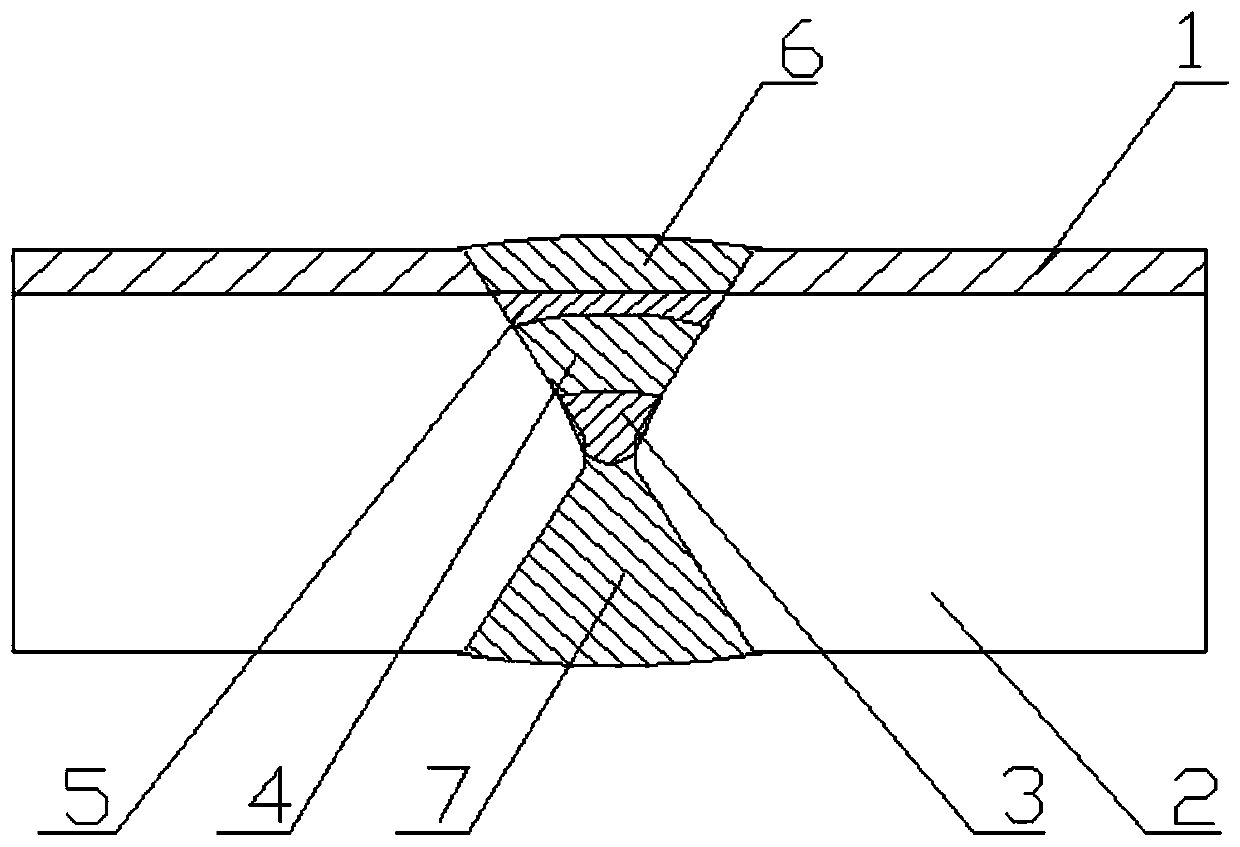

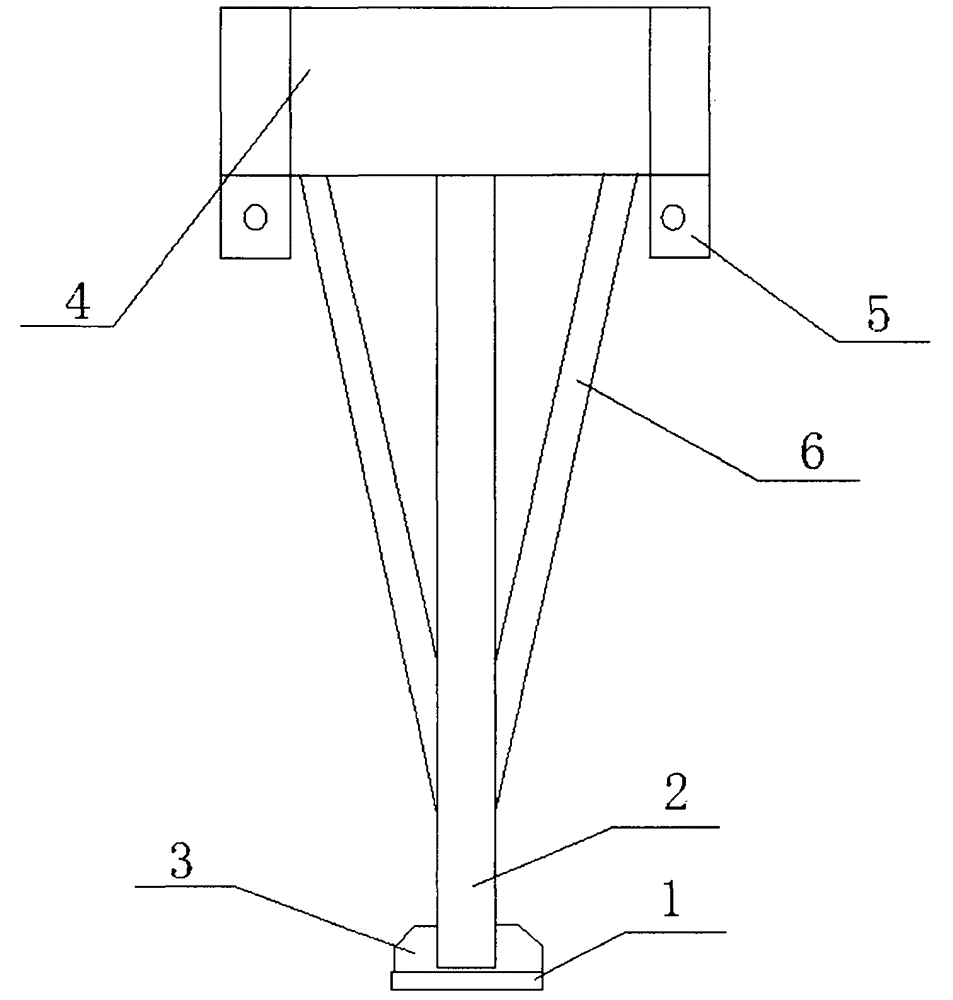

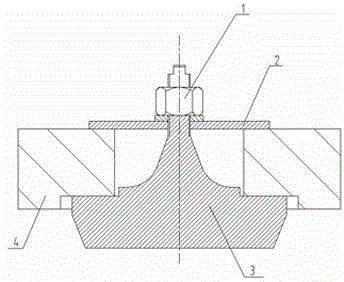

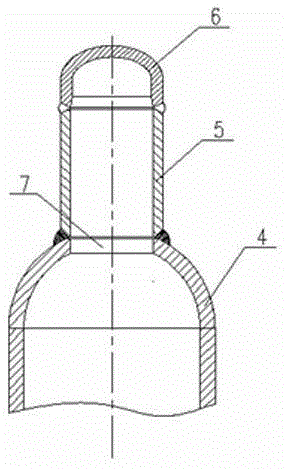

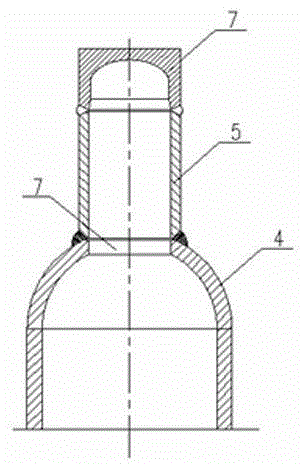

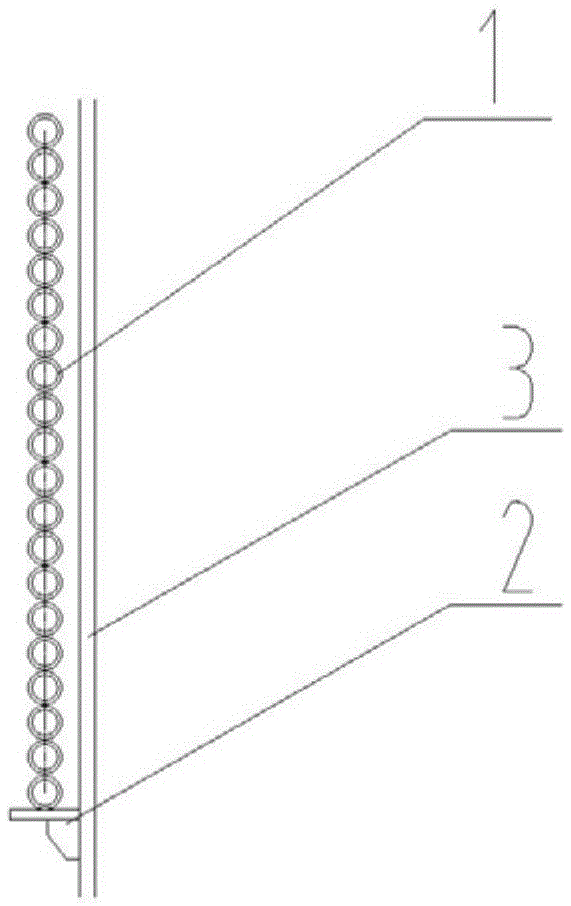

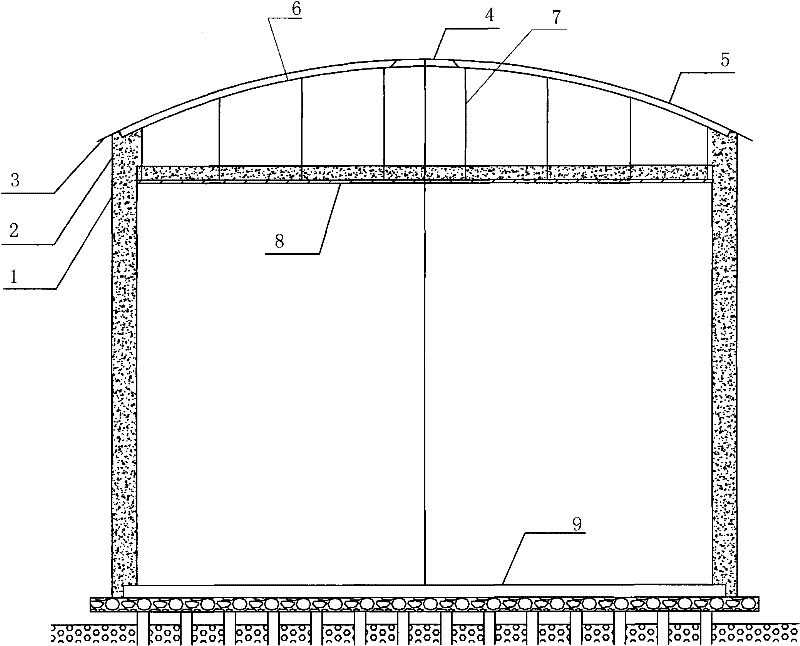

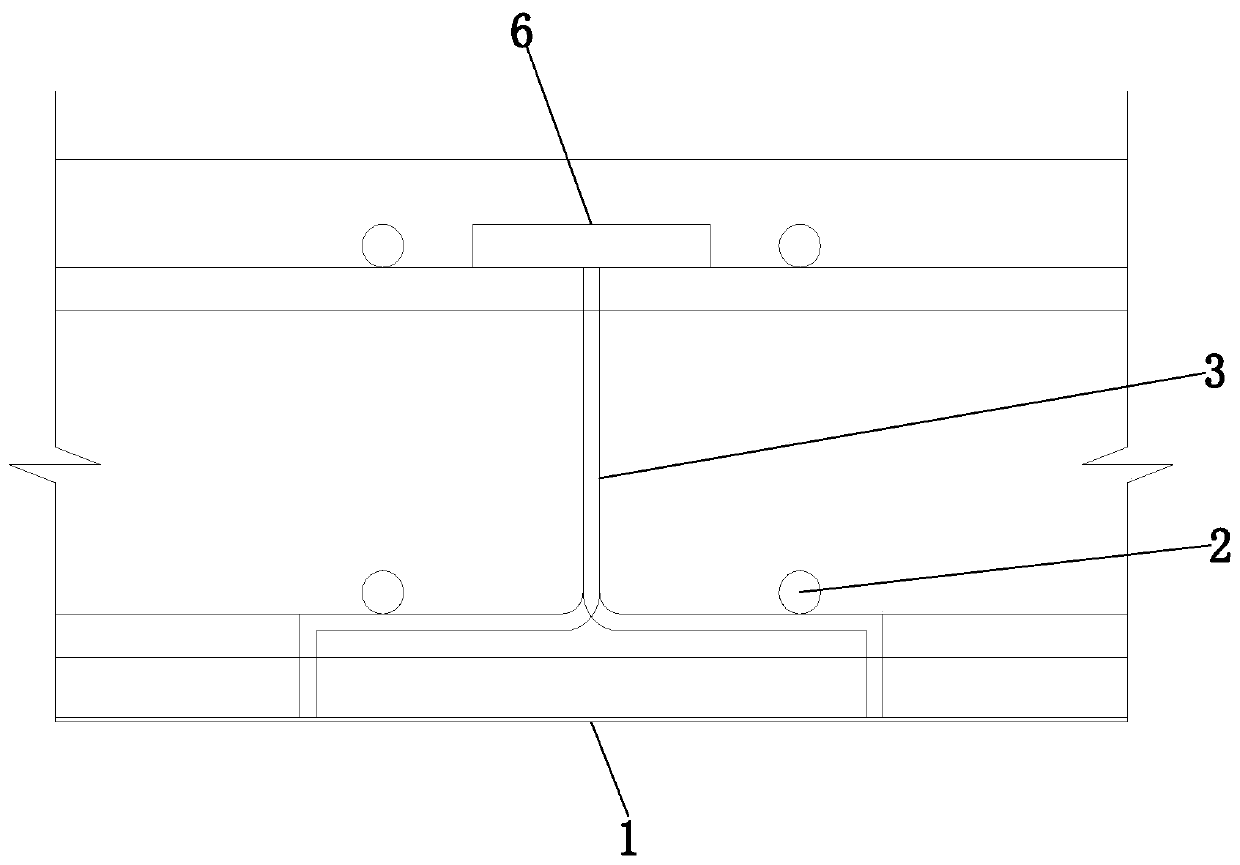

Connecting structure of skirt seat and bottom sealing head

InactiveCN109958877ASave welding consumablesSave manufacturing cyclePressure vesselsMaterial consumptionWeld seam

The invention relates to a connecting structure of a skirt seat and a bottom sealing head. The connecting structure of the skirt seat and the bottom sealing head comprises an upper welding seam (1), aconnecting member (2), a skirt seat cylinder / transition section (3), a lower welding seam (4), the sealing head (5), a circumferential welding seam (6) and sealing head end excess materials (7). Theconnecting structure is compact in structure and small in welding seam cross-section size, required weld metal is only about 30% of a traditional bead welding type, the manufacturing method is simpler, the manufacturing period is short, processing excess materials can be utilized, the cost is low, the quality is reliable, and compared with the prior art, the defects of complex manufacturing process, more welding materials consumption, large welding workload, long period, high cost and the like are overcome to a great extent.

Owner:HARBIN BOILER

Large-span variable-width corrugated web steel box-concrete continuous beam bridge and construction method thereof

PendingCN111206488AMeet the needs of different spansEasy to transportBridge structural detailsBridge erection/assemblyArchitectural engineeringContinuous beam

The invention relates to the technical field of bridges, in particular to a large-span variable-width corrugated web steel box-concrete continuous beam bridge and a construction method thereof. The continuous beam bridge comprises a plurality of corrugated web steel box beams and shear nails arranged on the corrugated web steel box beams, and further comprises corrugated web steel box beams arranged on a bridge deck slab, cantilever vertical plates welded to the corrugated web steel box beams and cantilever stiffening plates welded to the corrugated web steel box beams. The end cross beam concrete, middle fulcrum beam bottom concrete and middle fulcrum box girder concrete are poured into the corrugated web steel box beams, and an integrated body is formed by connecting with the corrugatedweb plate steel box beam through shear nails. The linear large-span variable-width corrugated web steel box-concrete combined continuous box beam bridge is convenient to design and construct, more reasonable in structural stress, less in steel consumption, capable of transporting and mounting steel box beam sections and convenient to construct.

Owner:甘肃省交通规划勘察设计院股份有限公司

Welding method of composite steel plates

InactiveCN110695489AImprove welding efficiencyGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesSteel platesSS - Stainless steel

The invention relates to a welding method of composite steel plates, is used for the field of welding of composite stainless steel plates. The composite plates are explosion-welded composite plates, base materials of the composite plates are Q345R, and composite materials are 316L heat-resistant stainless steel. The method includes the steps of groove machining, groove cleaning and plate combination, base layer welding of composite layer sides, welding of transition layers, welding of composite layers as well as welding of back base layers. According to the composite stainless steel plates welded with the technology, appearance of fissile and fragile structures during welding of the composite plates is avoided, welding cracks are avoided, the welding quality of the composite plates is improved, and the welding efficiency of the composite plates is improved.

Owner:HUBEI POLYTECHNIC UNIV

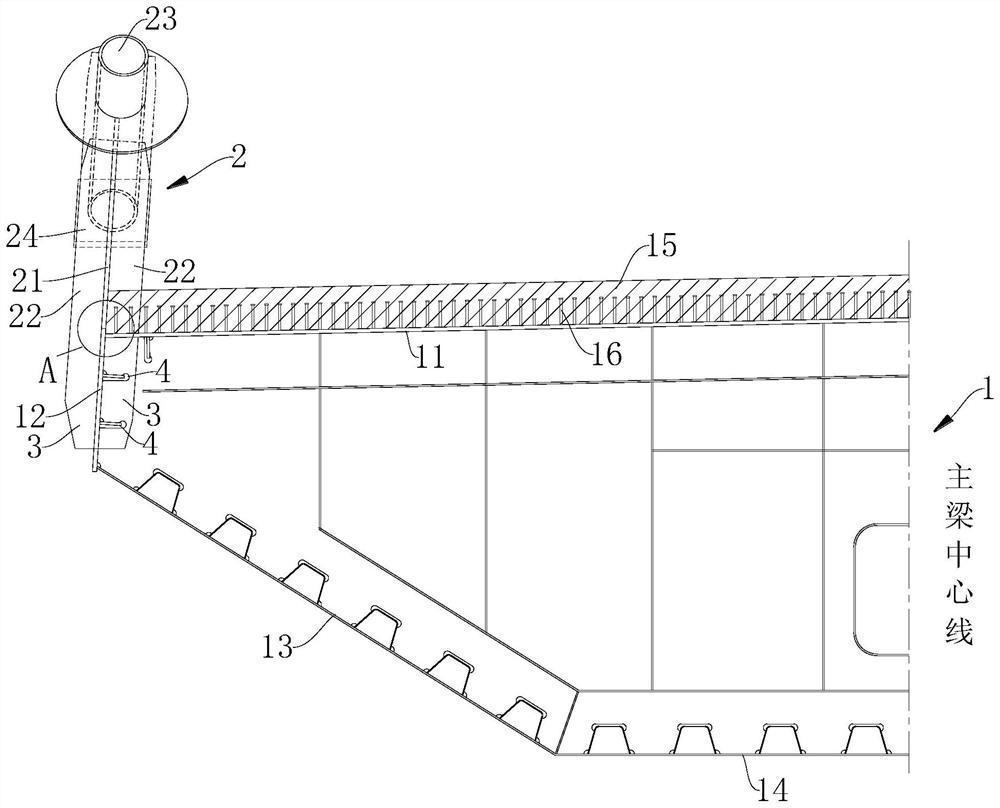

Cable-stayed bridge girder connected with anchor pulling plate

InactiveCN111851256AAvoid wastingGuaranteed forceSuspension bridgeBridge structural detailsButt weldingButt joint

The invention relates to the field of bridge structure buildings, and particularly relates to a cable-stayed bridge girder connected with an anchor pulling plate. The cable-stayed bridge girder comprises a steel-concrete composite beam and an anchor pulling plate assembly which are connected, the steel-concrete composite beam comprises a top plate and an upper web which are connected, the anchor pulling plate assembly comprises the anchor pulling plate, the upper web is vertically connected to the end of the top plate, and the upper web extends out of the top plate and is in butt joint with the anchor pulling plate. According to the cable-stayed bridge girder, the structural form, stress, wind resistance and the like of the anchoring plate and the steel-concrete composite beam are comprehensively considered; the section form of the main beam structure, the connection mode of the main beam structure and the anchor pulling plate and the like are optimally designed; therefore, the adverseconditions of material waste, large construction hoisting weight and the like can be avoided, meanwhile, under the condition that the wind resistance of the bridge is guaranteed, the steel consumption and the construction cost are saved, butt weld joints are adopted between the anchor pulling plates and the upper web of the main beam, and the advantages of being better in stress, easier to guarantee the welding quality and the like are achieved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Pipe pile welding production line

InactiveCN106826018BSimple structure setupWelding quality is easy to guaranteeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManipulator

Owner:FOSHAN FODA HUAKANG TECH CO LTD

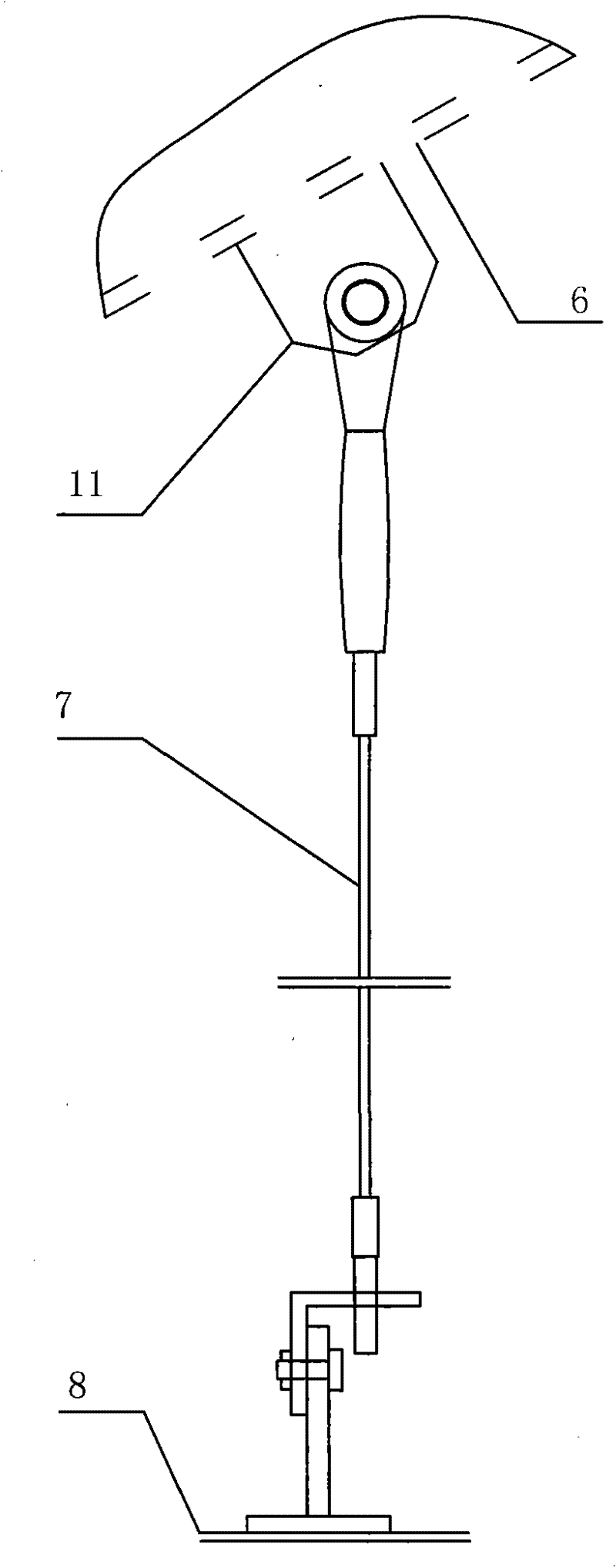

Helical blade forming machine

ActiveCN102303204ASimple and convenient welding forming operationGuaranteed forming qualityWelding/cutting auxillary devicesAuxillary welding devicesHelical bladeHelix

The invention relates to a forming machine, and in particular relates to a helical blade forming machine which comprises a base, wherein the upper part of the left side of the base is sequentially provided with a helical blade draught device, a helical blade and shaft rotating device from left to right, the upper part of the right side of the base is provided with a helical blade and shaft supporting device matched with the helical blade and shaft rotating device, and a helical blade screw pitch regulating device is arranged on the base between the helical blade and shaft rotating device and the helical blade and shaft supporting device. The helical blade forming machine has a simple structure and a reasonable design, and is simple and convenient for welding and forming a helical blade, thereby labor intensity of workers is reduced, forming quality of the helical blade is ensured and production efficiency is increased.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Integral Lifting Construction Method of Long-span Steel Beam Pulling Rod

InactiveCN102116089BAvoid working at heightsAvoid site requirementsBuilding material handlingArchitectural engineeringMechanical equipment

The invention discloses a construction method for integrally lifting a large-span type steel beam pulling bar and particularly discloses a construction method for splicing and welding to manufacture a simple pulling bar in site by using a large-span type steel beam aiming at the characteristics of large span and complex modelling for integral lifting, aiming at overcoming the defects of wide required field, large-size mechanical equipment lifting and high cost of the traditional construction method. The invention provides a novel construction method for a project with a narrow field and a complex peripheral environment. When the construction of a large-span steel structure type steel beam is carried out by adopting the method, a profile steel beam is processed in segments as required in a factory, all segments are spliced and welded in site, therefore overhead working is prevented, welding quality is easy to ensure, site requirement for lifting by adopting multiple large-size mechanical equipment is prevented, project cost is reduced, and a construction period is shortened.

Owner:QINGDAO BOHAI CONSTR GROUP +1

Sealing device for hand holes of circulating fluidized bed boiler header

InactiveCN103557519AFew partsSimple structureFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention relates to a sealing device for hand holes of a circulating fluidized bed boiler header. The sealing device comprises a header body, wherein the hand holes are formed in the two ends of the header body. The sealing device is characterized in that a pipe connector and an end cover are connected in sequence outside the hand holes; one end of the pipe connector is hermetically connected with the peripheries of the hand holes; the pipe connector is hermetically connected with the periphery of an opening part of the end cover. The sealing device is simple in structure, low in manufacturing cost, good in sealing reliability, unlikely to leak and suitable for sealing the hand holes in the circulating fluidized bed boiler header.

Owner:WUXI DONGMA BOILER

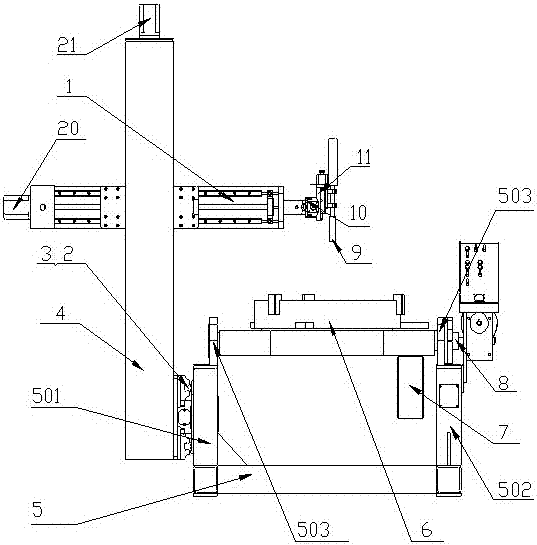

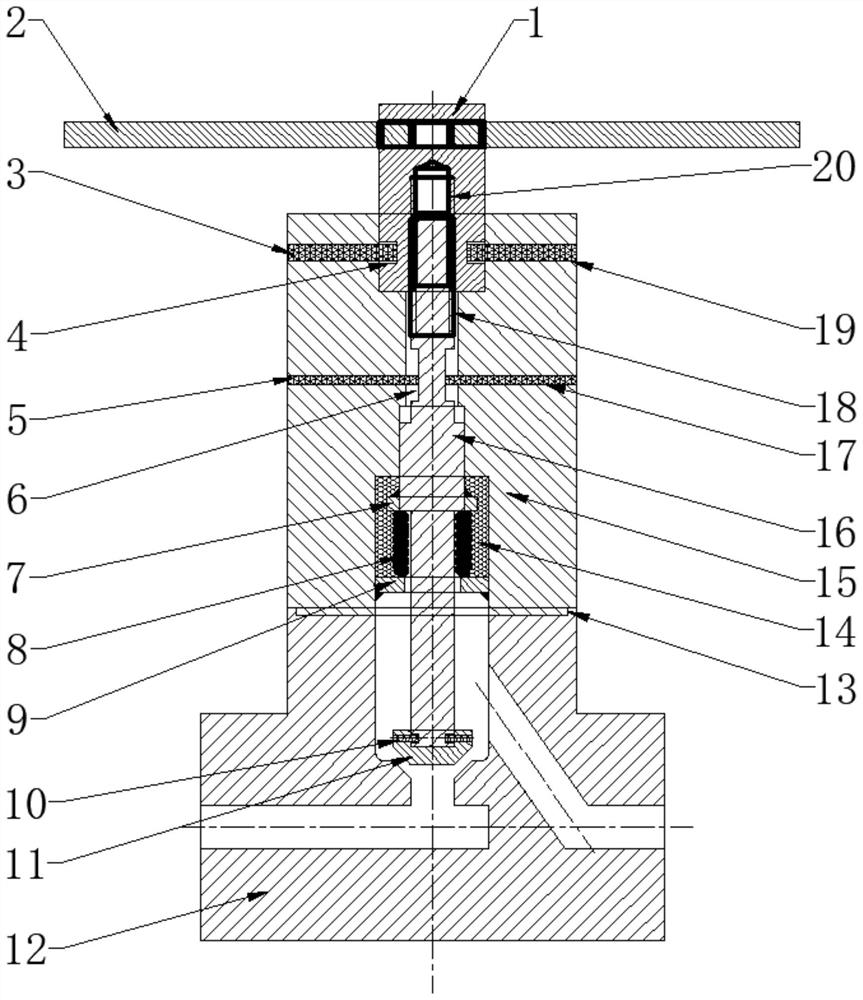

One-piece flange automatic welding equipment with central through hole

ActiveCN105269116BReduce labor intensityImprove welding efficiencyWelding/cutting auxillary devicesElectrode holder supportersAutomatic test equipmentClosed loop

The invention discloses an integral flange automatic welding device with a central through hole. The welding cross arm is slidably connected to the base of the positioner, and can move forward and backward relative to the base; the welding chuck is connected to the main motor through the rotary support fixed on the turning frame; the turning frame has a central through hole, and the workpiece can pass through the center through the hole The welding chuck can hold any part of the workpiece, so that the positioner, welding power supply and welding torch can be integrated structure, not only suitable for long pipe welding, but also when there are multiple welds on the workpiece, no need Repeatedly changing the relative position of the welding cross arm and the positioner can complete the welding of all welds on the workpiece. The welding cross arm is equipped with a welding oscillator and an arc length regulator. The welding torch is installed on the arc length regulator, which can automatically realize the swing and up and down adjustment, and is suitable for weldments with groove requirements and workpieces with obvious ellipticity. Welding, without human adjustment or intervention, realizes closed-loop control, and the welding quality is easy to guarantee.

Owner:JINAN JINLUDING WELDING TECH CO LTD

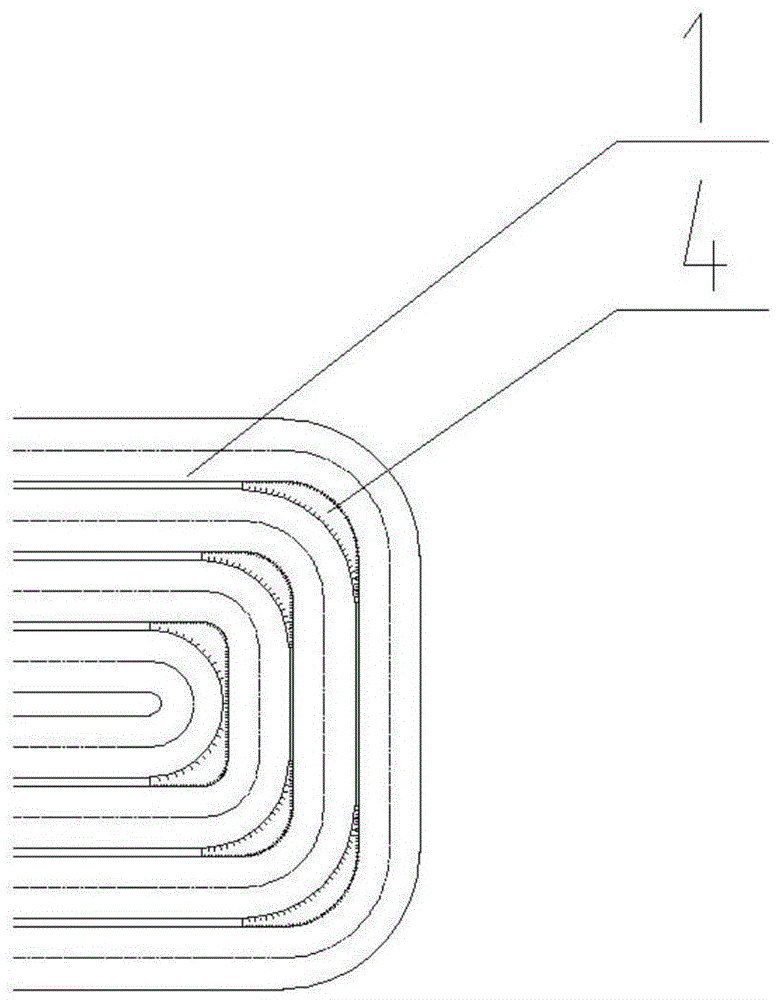

A processing technology for cooling and heating coils on large equipment

ActiveCN103753161BIncrease welding operation spaceConvenient welding operationButt weldingStress relieving

The invention relates to a machining process for novel cooling heating coils used on a large scale device. The process includes the following steps: 1) bending each group of cooling coils; 2) sequentially arranging the groups of bended cooling coils on the horizontal plane; 3) conducting pattern grading and cutting on connection plates between the cooling coils; 4) machining welding grooves of the cooling coils; 5) welding each bended cooling coil and a corresponding connection plate on the horizontal plane by group; 6) determining the circle rolling radius of each group of cooling coils and connection plates; 7) conducting circle rolling on each group of welded cooling coils and connection plates; 8) conducting stress removing setting on the cooling coils and the connection plates; 9) sequentially arranging the cooling coils and the connection plates subjected to circle rolling formation on a support piece; 10) conducting butt welding on the cooling coils and the connection plates sequentially and conducting flaw detection on welding gaps to ensure that the coils are qualified. The process has the advantages of being convenient to manufacture and operate and less in material consumption and not requiring additional manufacture of tools. The quality is easy to control.

Owner:中化学华谊装备科技(上海)有限公司

Tank top installing and welding process of single-coating double-wall low temperature storage tank

The invention relates to a tank top installing and welding process of a single-coating double-wall low temperature storage tank, which is characterized by comprising the following steps of: (1) installing temporary buttresses on an outer tank base plate and on an outer tank wall, installing and welding pressure bearing rods on the temporary buttresses, and building a full scaffold in the outer tank of the low temperature storage tank; (2) welding a net rack on the outer tank top; (3) welding top plate: welding each top plate on the net rack; (4) installing each suspension rod on each corresponding H-shaped steel, and removing the internal full scaffold; (5) installing and welding an inner tank suspended ceiling on the outer tank base plate; (6) lifting the welded inner tank suspended ceiling by using a leading chain, and connecting with each suspension rod; and (7) welding compression resisting rings: installing and welding the compression resisting rings at the junctions of the pressure bearing rods and the top plates of the outer tank top. Compared with the prior art, the process only requires building the full scaffold once and has the advantages of fewer temporary tooling quantity, low construction difficulty, simple construction procedures, capability of ensuring working safety, high construction quality and construction efficiency and low construction cost.

Owner:CHINA PETROLEUM & CHEM CORP +2

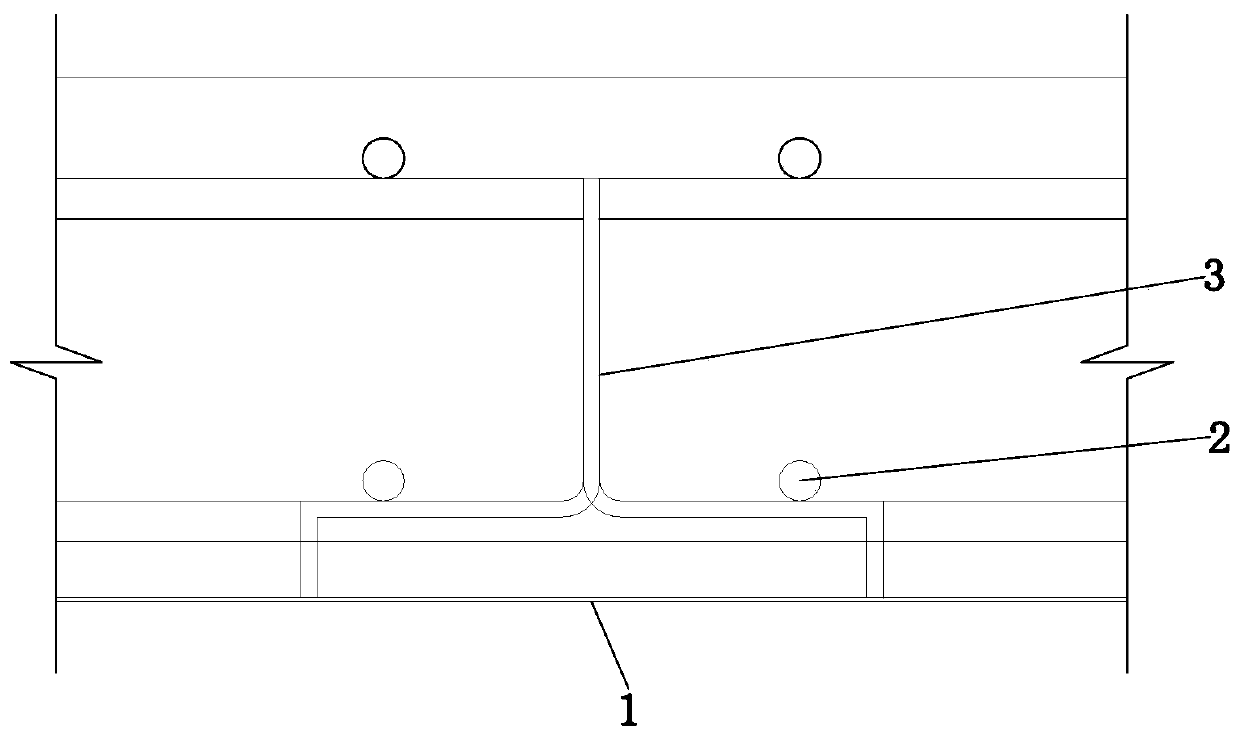

Floor plate connected by zigzagging plates and preparation method thereof

The invention discloses a floor plate connected by zigzagging plates and a preparation method thereof. The floor plate comprises a base plate (1) and the zigzagging plates (3) are above the base plate(1) and a steel layer (2) is under the zigzagging plates (3). The preparation method comprises the following steps: step 1, cutting and bending steel plates to form the zigzagging plates; step 2, strapping to obtain the steel layer and welding the steel layer in a corresponding position of the zigzagging plates to form a frame; and step 3, fixing the frame on the base plate to obtain the floor plate. The invention has the advantages of convenient manufacture, high welding quality, low engineering cost and wide application range.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

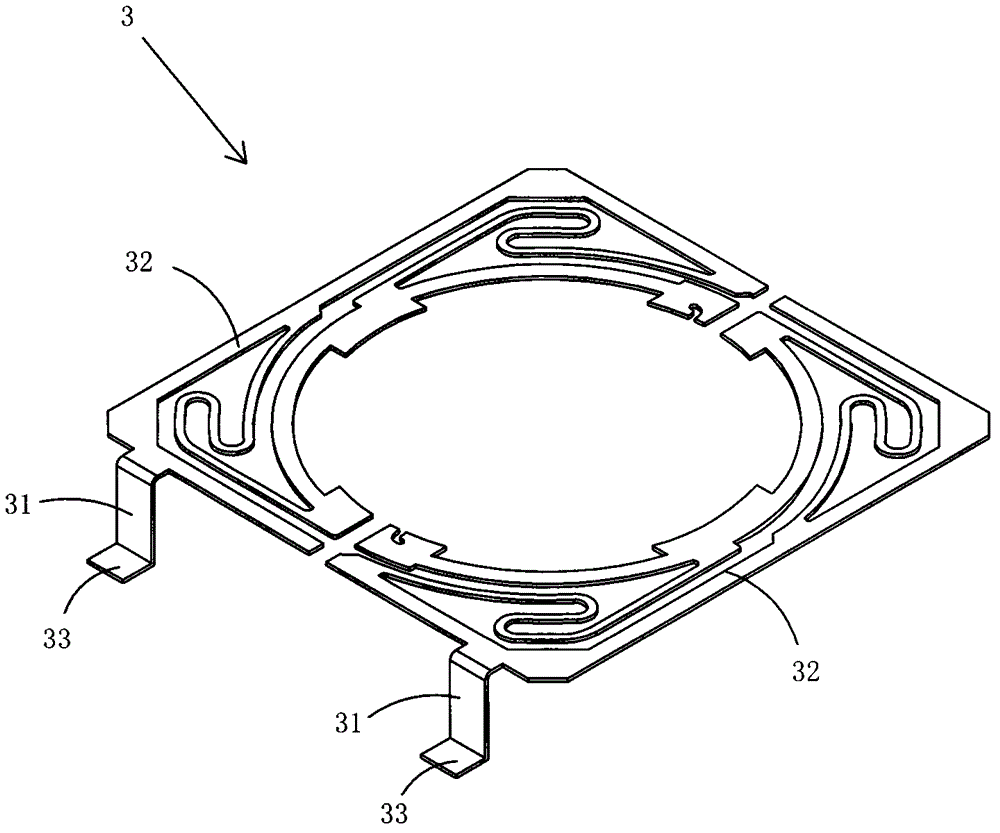

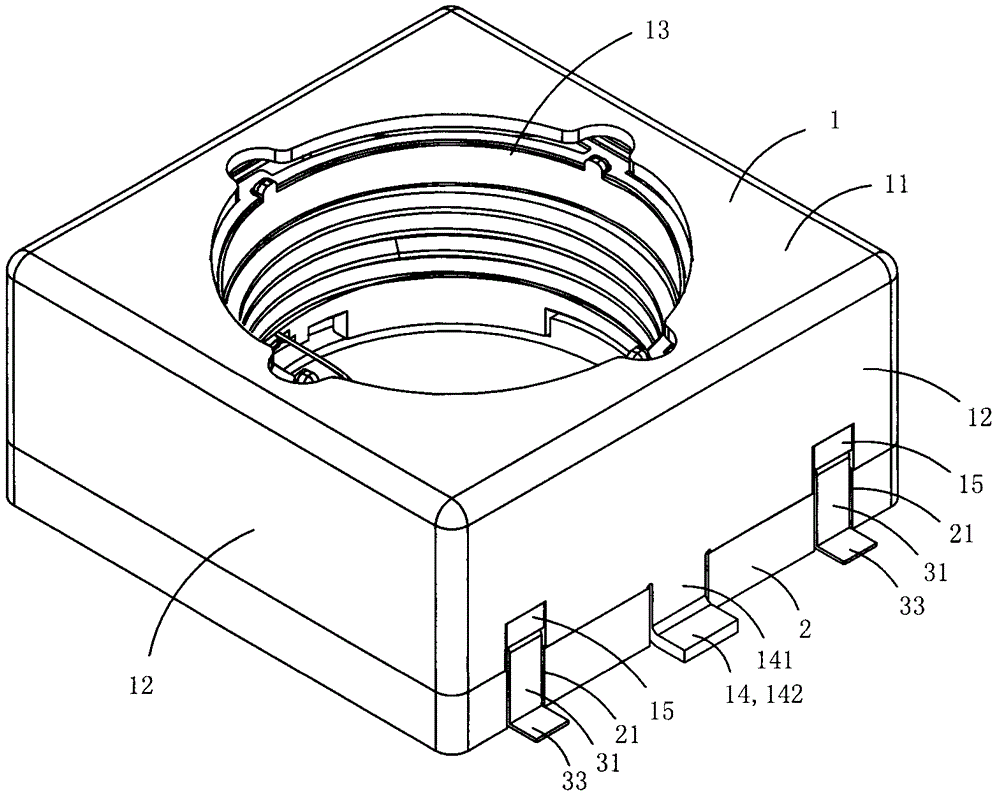

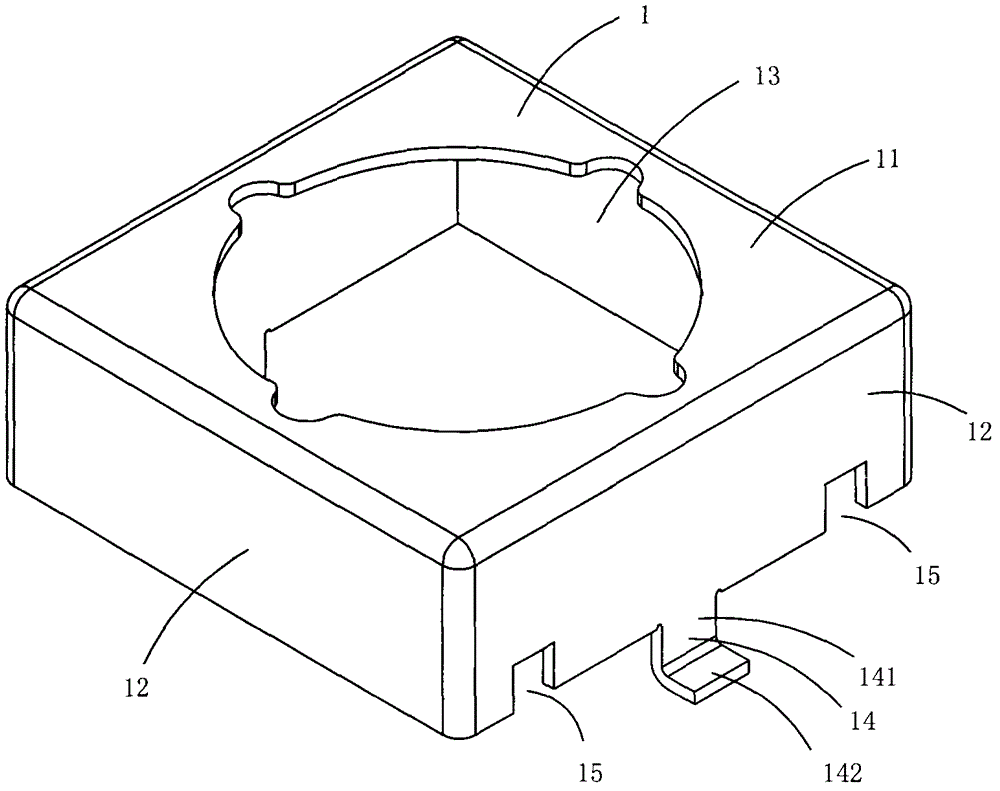

Micro-driving motor and lower spring for same

InactiveCN102723627BFast solderingWelding quality is easy to guaranteeFixed connectionsSupports/enclosures/casingsElastic componentEngineering

The invention discloses a micro-driving motor and a lower spring for the same. A lower elastic piece component comprises the lower spring for the micro-driving motor which comprises two mutually insulated elastic piece bodies and electrifying pins vertically extending down from one side of each elastic piece body. The bottom end of each electrifying pin protrudingly extends perpendicular to the corresponding electrifying pin and away from the lower elastic piece component to form a fixed pin. The micro-driving motor comprises a shell and the lower elastic piece component, wherein the shell consists of an upper cover and a base, and the lower elastic piece component is fixed into the shell. The micro-driving motor and the lower spring for the same have the advantages that the fixed pins of the lower elastic component are parallel and attached to a welding face of a circuit board, and welding can be quickly completed by a simple, reliable and efficient welding mode while welding quality is easy to guarantee.

Owner:深圳市光控数码光电有限公司

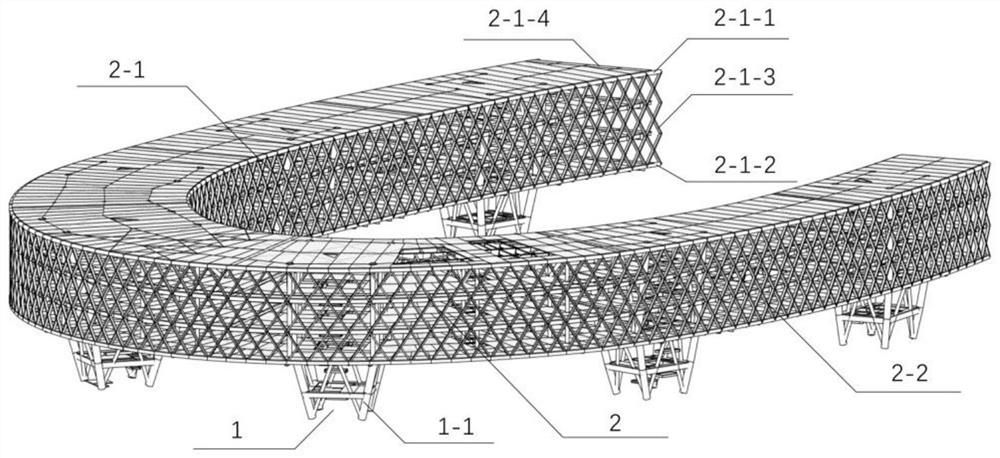

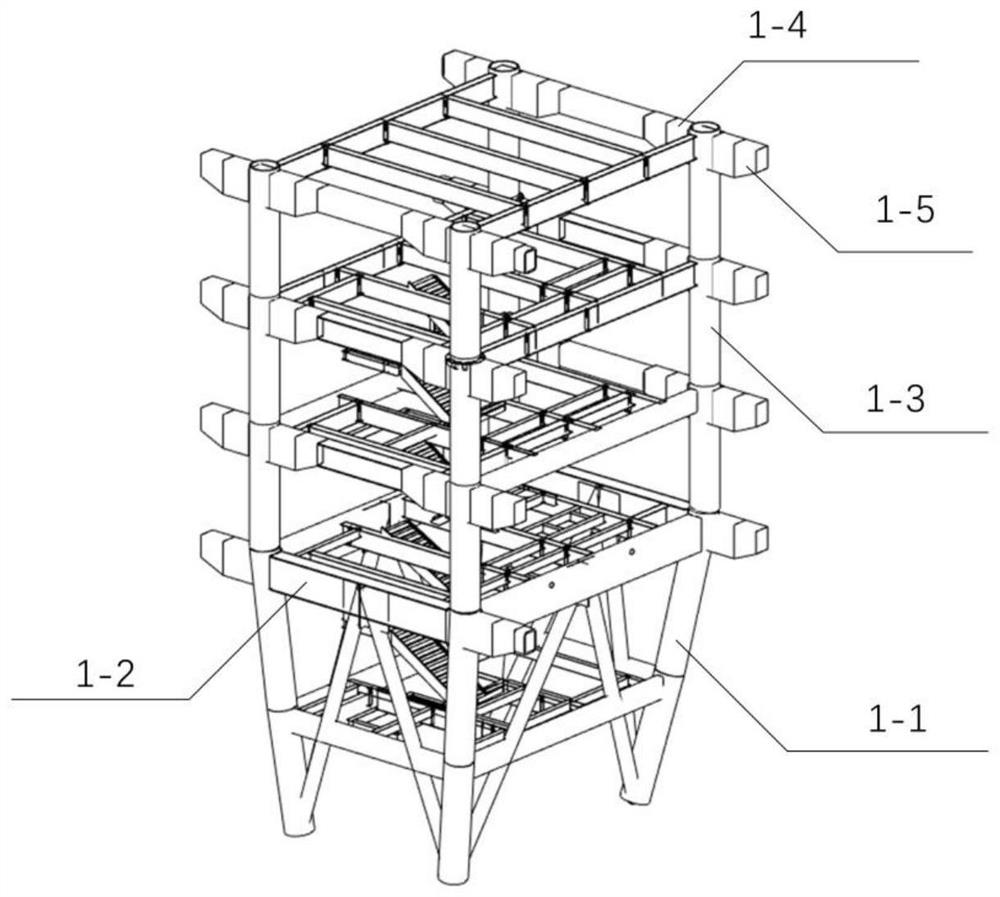

Construction method for goblet-shaped support super-long multi-layer horseshoe-shaped curved surface space steel structure

PendingCN113802693AAccurate spatial positioningImprove installation qualityStrutsExtraordinary structuresButt jointClassical mechanics

The invention discloses a construction method for a goblet-shaped support super-long multi-layer horseshoe-shaped curved surface space steel structure. The steel structure adopts a plurality of large-dip-angle giant steel pipe column core tubes penetrating through a top plate of a basement to support a large-span asymmetric horseshoe-shaped multilayer truss, and the construction method comprises the following steps: 1) mounting a core tube; pre-burying and fixing steel pipe column foundation bolts through a positioning frame; adopting multi-space accurate positioning on a spatial special-shaped circular tube inclined column of the steel pipe column; adopting multiple-space accurate positioning in positioning and mounting of a large-span overweight steel box girder, and reserving an operation hole in a cover plate, wherein welding is facilitated, and the field welding quality of a butt joint opening of the steel box girder is improved; and 2) mounting a truss: splicing the truss on the ground through a positioning jig frame, integrally lifting the truss through a plurality of lifters mounted on the top of a steel tube column of the core tube, and carrying out butt joint on pre-mounted inward-extending cantilever brackets and outward-extending cantilever brackets on the core tube. The method can meet the field mounting requirements of the goblet-shaped support super-long multi-layer horseshoe-shaped curved surface space steel structure.

Owner:中建六局第一建设有限公司 +1

A welding method for q500qe high-strength bridge steel corner joints

ActiveCN108817617BAvoid welding deformationGuaranteed verticalityArc welding apparatusWelding/cutting media/materialsThick plateClassical mechanics

Provided is a Q500qE high-strength bridge steel corner joint welding method. Two sides of a rib plate are provided with partially penetrated two-sided symmetrical grooves, groove angles are 48 degrees, and then the rib plate is vertically assembled and positioned on a base plate; during welding, an ER60Q solid wire and a CO2 gas shielded welding technology are firstly adopted to weld passes transversely, synchronously and symmetrically, and the rib plate is vertically fixed to the base plate; then, an H60Q submerged arc welding wire, an SJ105q submerged arc welding agent and an automatic submerged arc welding process are adopted to perform sequential filling of two sides of a ship's position and cover surface welding, and the angle of the ship's position is 45 degrees. According to the welding method integrating transverse gas shielded welding and ship's position submerged arc welding, preheating is not needed before welding, deformation correction is not needed after welding, formed welded appearance is attractive, and weld joints are internally reliable in performance, stable in quality, small in welding deformation and high in production efficiency. The Q500qE high-strength bridge steel corner joint welding method is suitable for welding of high-strength large and thick bridge steel plate units.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +2

Corrugated pipe filling valve structure

PendingCN114658918ASimple structureLess componentsSpindle sealingsOperating means/releasing devices for valvesStructural engineeringVALVE PORT

The invention discloses a corrugated pipe filling valve structure which comprises a driving handle, a driving nut, a valve rod, a valve cover and a valve body, the driving handle is connected with the driving nut, the driving nut is in threaded fit with the valve rod, a first pin hole is formed in the valve cover, and a first limiting pin penetrates through the first pin hole to be inserted into the driving nut; a second pin hole is further formed in the valve cover, and a second limiting pin penetrates through the second pin hole to limit rotation of the valve rod. The driving mechanism is composed of a driving nut, a driving handle and a limiting pin, the driving handle drives the driving nut to rotate, the limiting pin limits vertical movement of the driving nut, and the driving nut achieves vertical movement of the valve rod through threads. The driving mechanism is simple in structure, few in component parts, convenient to assemble and low in manufacturing cost.

Owner:济南新材料产业技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com