Construction method for goblet-shaped support super-long multi-layer horseshoe-shaped curved surface space steel structure

A steel structure construction, horseshoe-shaped technology, applied in the direction of special structures, pillars, building components, etc., can solve the problems of truss core tube collision, corbel butt joint precision is difficult to control, etc., to enhance the bearing capacity of the board surface, facilitate local support reinforcement, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

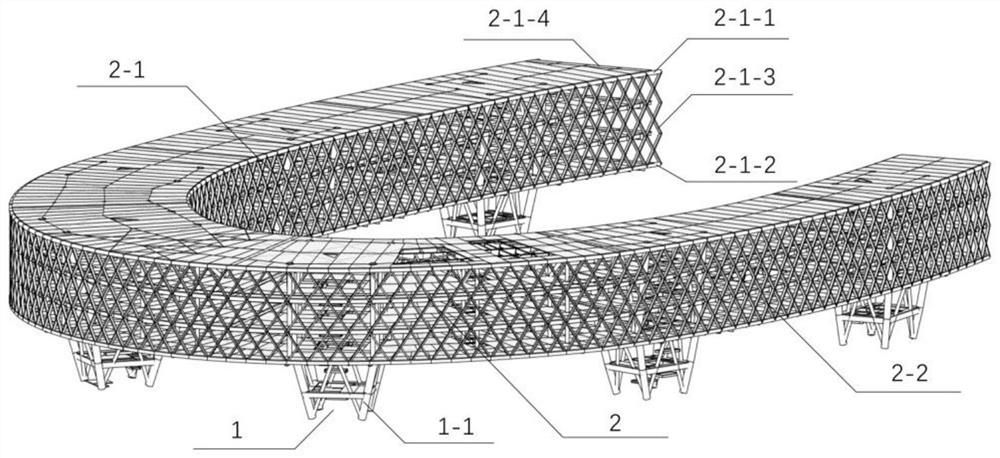

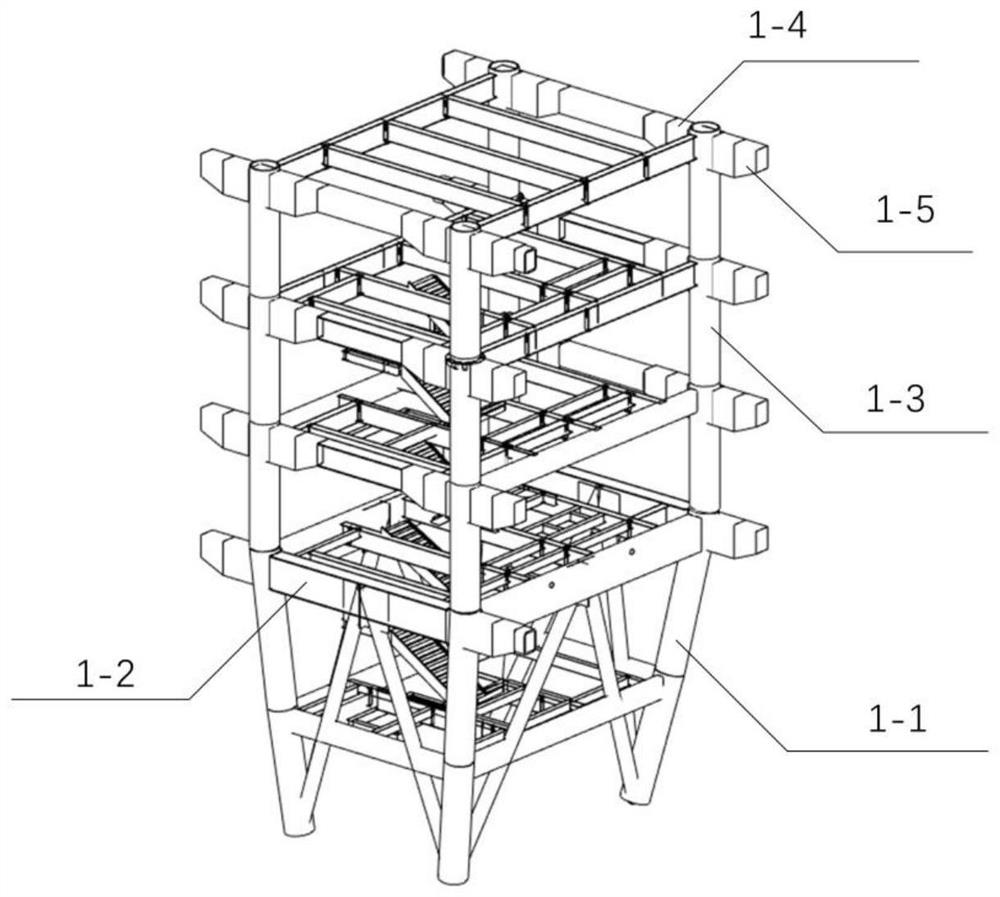

[0071] Please refer to the accompanying drawings, a construction method for a super-long multi-layered horseshoe-shaped curved space steel structure with bottle-shaped supports. The steel structure adopts a plurality of giant steel pipe column core tubes 1 that pass through the basement roof and have a large inclination angle to support a large-span asymmetrical horseshoe-shaped multi-layered truss 2. Each of the core tubes is provided with four giant steel pipe columns 1-1 with a large inclination angle. The cross truss is equipped with multi-layer webs 2-1-3 between the upper chord 2-1-1 and the lower chord 2-1-2, and the inner and outer ring oblique truss , The lower chord is connected by platform beam 2-1-4.

[0072] The construction met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com