Integral Lifting Construction Method of Long-span Steel Beam Pulling Rod

A technology of overall improvement and construction method, applied in the direction of construction, building structure, construction material processing, etc., can solve the problem of high cost, and achieve the effect of avoiding site requirements, ensuring welding quality, and avoiding high-altitude operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

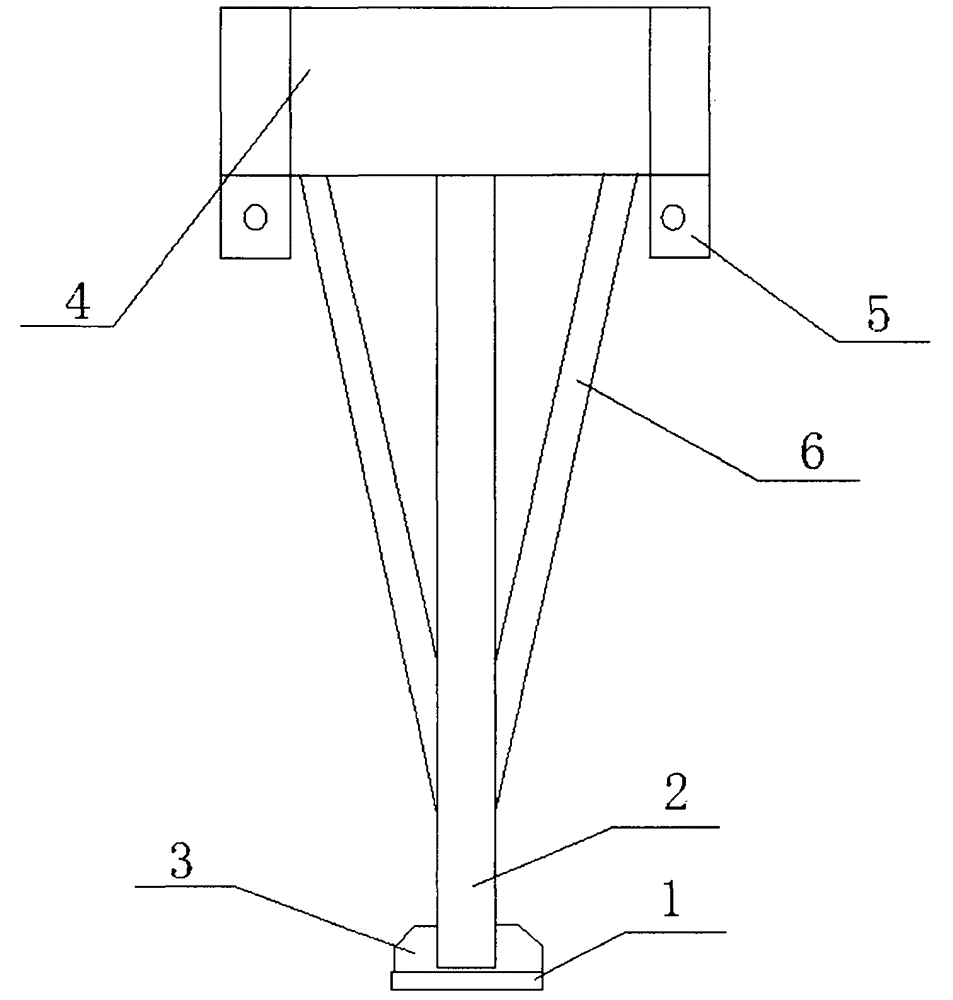

[0015] Such as figure 1 As shown, the present invention is a construction method for overall lifting of large-span steel girder pulling rods, comprising the following steps:

[0016] (1) To make a simple pole pulling device, first select a steel plate base 1, weld a vertical pole 2 longitudinally on the steel plate base 1, weld the rib plate 3 at the connection part of the steel plate base 1 and the vertical pole 2, and weld the top of the vertical pole 2 A beam 4, a lifting lug 5 is welded at both ends of the beam 4, and two diagonal braces 6 are welded between the vertical bar 2 and the beam 4; the beam 4 is made of 32a I-beam; the lifting lug 5 is made of 200×150×30mm It is made of steel plate with a hole in the center; the vertical rod is made of round steel pipe of 168×8mm; the diagonal brace 6 is made of round steel pipe of 76×4mm; (2) Set anchor bolts on the concrete beams or columns on both sides of the shaped steel beams, and install the simple pull-out rods on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com