Lamp post and mounting method thereof

A light pole and connecting plate technology, applied in lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of expensive hoisting equipment rental fees, inconvenient installation, and high installation costs, and achieve simple structure, easy maintenance, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

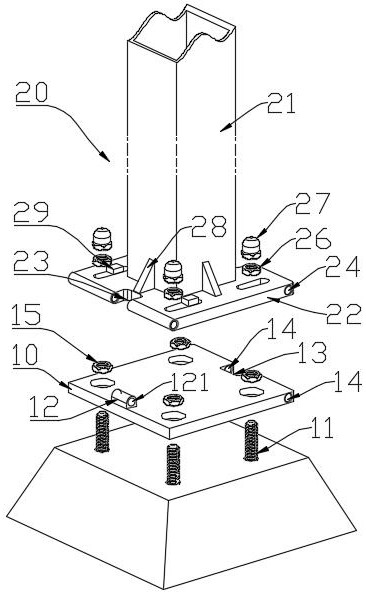

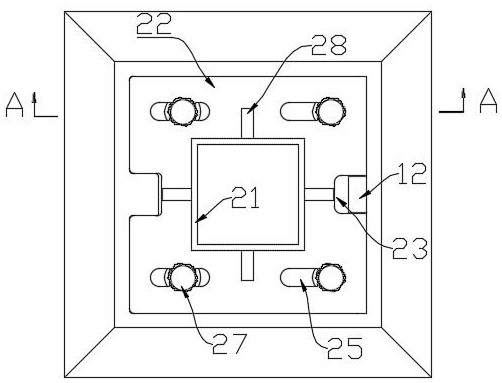

[0050] Such as Figure 1-3 As shown, a light pole includes: a connecting plate 10 and a column 21 .

[0051] Specifically, the connecting plate 10 is connected to the hard ground or platform through a plurality of anchor bolts 11. In this embodiment, there are four anchor bolts 11 arranged in a rectangular shape. One side of the connecting plate 10 is provided with a hinge support 12 , The hinge support 12 is processed with a hinge hole 121, the opposite side of the hinge support 12 is provided with a rectangular groove 13, and the side wall of the rectangular groove 13 is processed with a first socket 14.

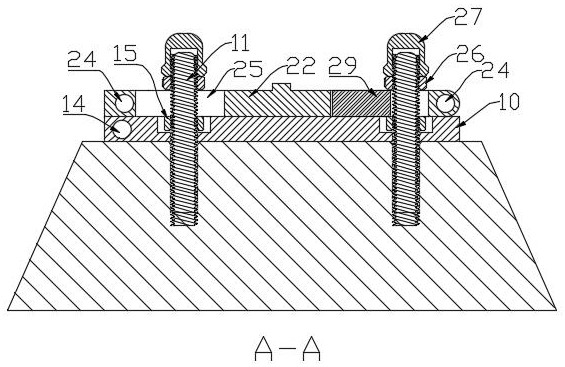

[0052] Specifically, a base plate 22 is provided at the bottom of the column 21, and the base plate 22 has a rectangular structure, wherein any opposite two sides are processed with a rectangular notch 23, and the side wall of the rectangular notch 23 is processed with a through hole 24, and the side where the through hole 24 and the rectangular notch 23 are located Paral...

Embodiment 2

[0060] Such as Figure 4-10 As shown, a method for installing the light pole described in Embodiment 1, the steps are as follows:

[0061] 1) Fix the anchor bolts 11 on a hard ground or platform. The commonly used methods for fixing the anchor bolts 11 are concrete fixing or welding. When fixing them, the connecting plate 10 needs to be used to position them, and the protrusion of the anchor bolts 11 The length needs to be calculated, and it needs to be greater than the thickness of the connecting plate 10 + the thickness of the bottom plate 22 + the thickness of the locking nut 26, and less than the thickness of the connecting plate 10 + the thickness of the bottom plate 22 + the thickness of the locking nut 26 + the inner hole of the threaded cap 27 depth;

[0062] 2) Install the connecting plate 10 on the anchor bolt 11, and lock it with the fastening nut 15;

[0063] 3) The column 21 is placed horizontally, so that the through hole 24 on either side is placed coaxially w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com