Floor plate connected by zigzagging plates and preparation method thereof

A floor deck and slab connection technology, which is applied in the field of floor decks, can solve the problems of small unsupported length of reinforced truss floor decks, the inability to provide additional reinforcement flanges, and the large amount of steel used for truss reinforcement. It is easy to achieve welding quality Guarantee, great price advantage, and low project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

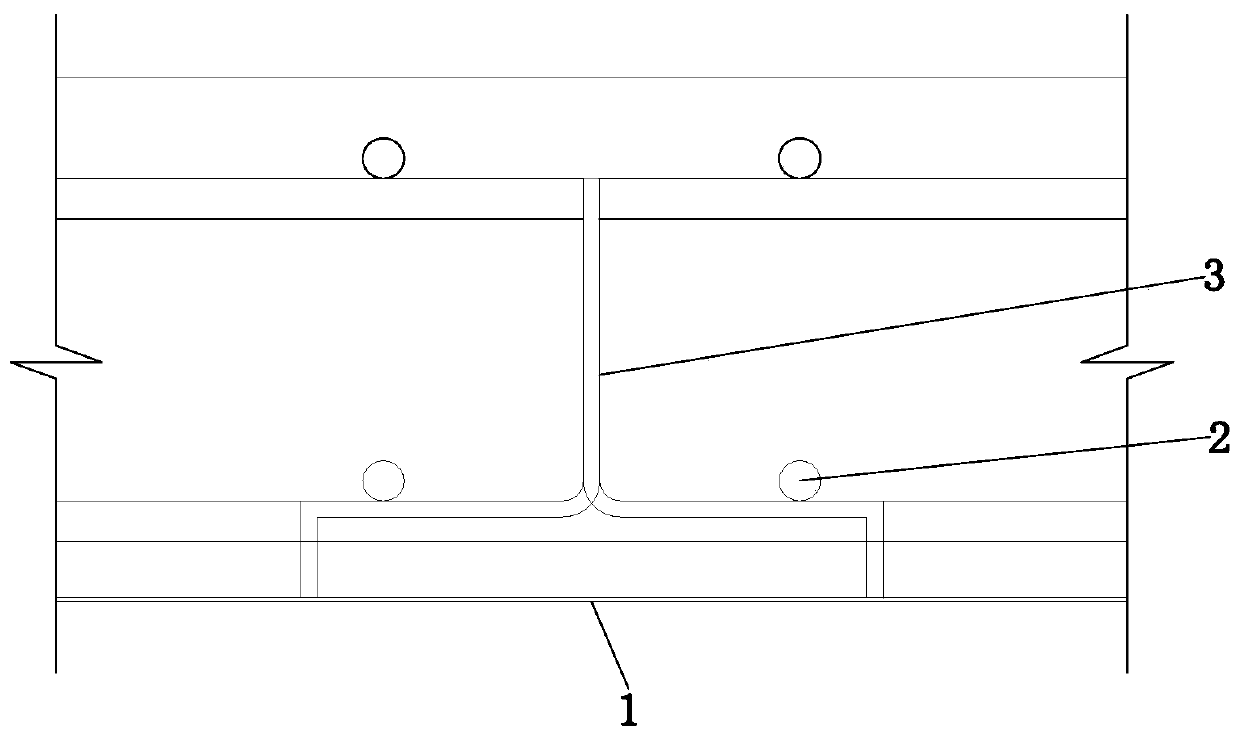

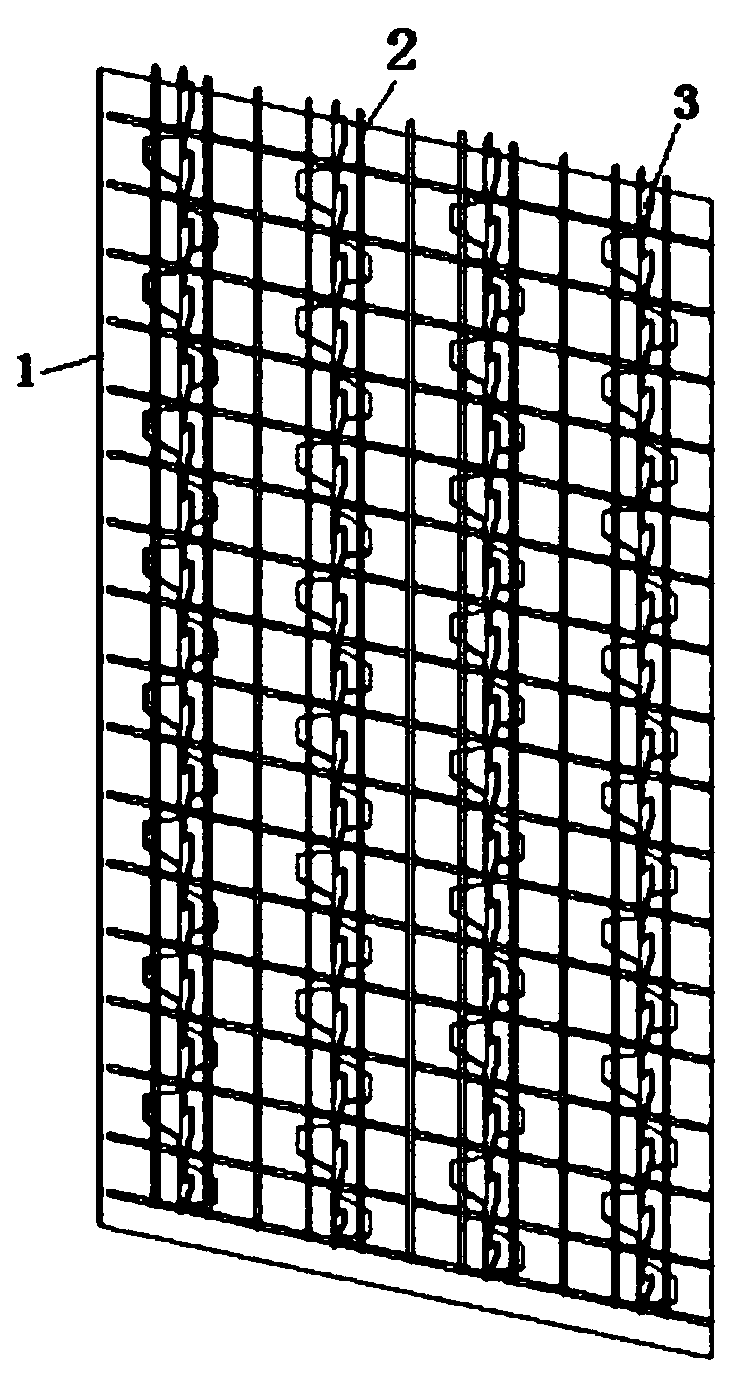

[0032] Example 1. A floor deck (open type) connected by a folded plate of this type, which is composed of figure 1 and figure 2 as well as Figure 7 to Figure 13 As shown, it includes a bottom plate 1, a shaped folded plate 3 is arranged above the bottom plate 1, and a steel bar layer 2 is also arranged under the shaped folded plate 3.

[0033] The bottom plate can be made of galvanized steel sheet and profiled steel sheet. The reinforcement layer and the folded plate can be connected by welding.

[0034] The above-mentioned foldable plate 3 includes a vertical plate 301, a set of vertical connecting plates 302 are arranged on the upper end of the vertical plate 301, a groove 303 is arranged between the adjacent vertical connecting plates 302, and both sides of the vertical plate 301 are provided with a set of vertical connecting plates 302. Horizontal mounting plate 304 .

[0035] The bottom plate 1 is a plane structure, and the end of the horizontal mounting plate 304 ...

Embodiment 2

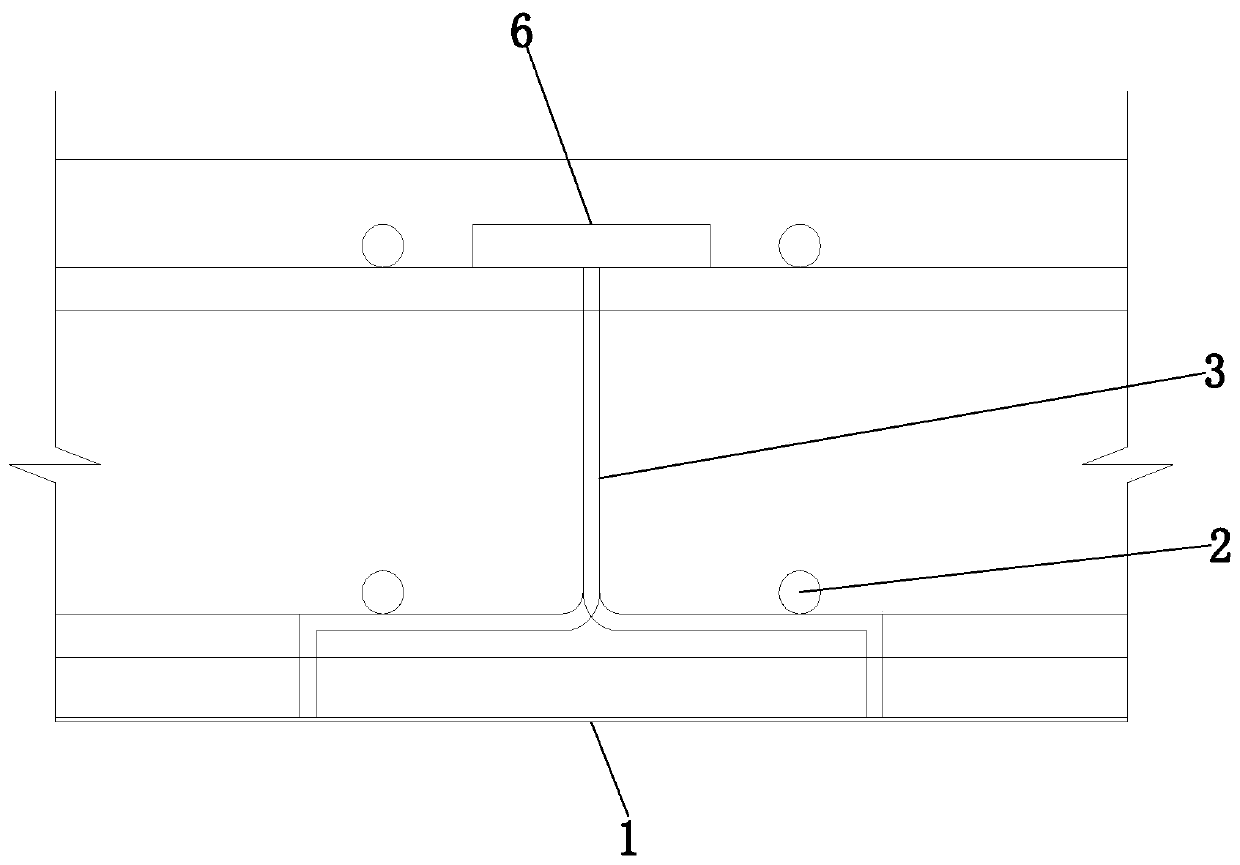

[0045] Example 2. A floor deck (closed-mouth type) connected by a folded plate, which is composed of Figure 3 to Figure 4 as well as Figure 7 to Figure 13 As shown, it includes a bottom plate 1, a shaped folded plate 3 is arranged above the bottom plate 1, and a steel bar layer 2 is also arranged under the shaped folded plate 3.

[0046] The bottom plate can be made of galvanized steel sheet and profiled steel sheet.

[0047]The above-mentioned foldable plate 3 includes a vertical plate 301, a set of vertical connecting plates 302 are arranged on the upper end of the vertical plate 301, a groove 303 is arranged between the adjacent vertical connecting plates 302, and both sides of the vertical plate 301 are provided with a set of vertical connecting plates 302. Horizontal mounting plate 304 .

[0048] A flange piece 6 is also provided on the upper end of the above-mentioned folded plate 3 .

[0049] The bottom plate 1 is a plane structure, and the end of the horizontal m...

Embodiment 3

[0061] Example 3. A floor deck (reinforced type) connected by a folded plate of this type, which is composed of Figure 5 to Figure 13 As shown, it includes a bottom plate 1, a shaped folded plate 3 is arranged above the bottom plate 1, and a steel bar layer 2 is also arranged under the shaped folded plate 3.

[0062] The bottom plate can be made of galvanized steel sheet and profiled steel sheet.

[0063] The above-mentioned foldable plate 3 includes a vertical plate 301, a set of vertical connecting plates 302 are arranged on the upper end of the vertical plate 301, a groove 303 is arranged between the adjacent vertical connecting plates 302, and both sides of the vertical plate 301 are provided with a set of vertical connecting plates 302. Horizontal mounting plate 304 .

[0064] The upper end of the folded plate 3 is provided with a connecting plate 7 , and the upper end of the connecting plate 7 is provided with a flange reinforcing member 8 , and the flange reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com