Metal damper provided with restraining devices and stiffening ribs

A metal damper and restraint device technology, which is applied to building components, earthquake-proof and other directions, can solve problems such as the initial stiffness of buckling, and achieve the effects of preventing out-of-plane buckling, facilitating welding, and ensuring energy dissipation capacity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

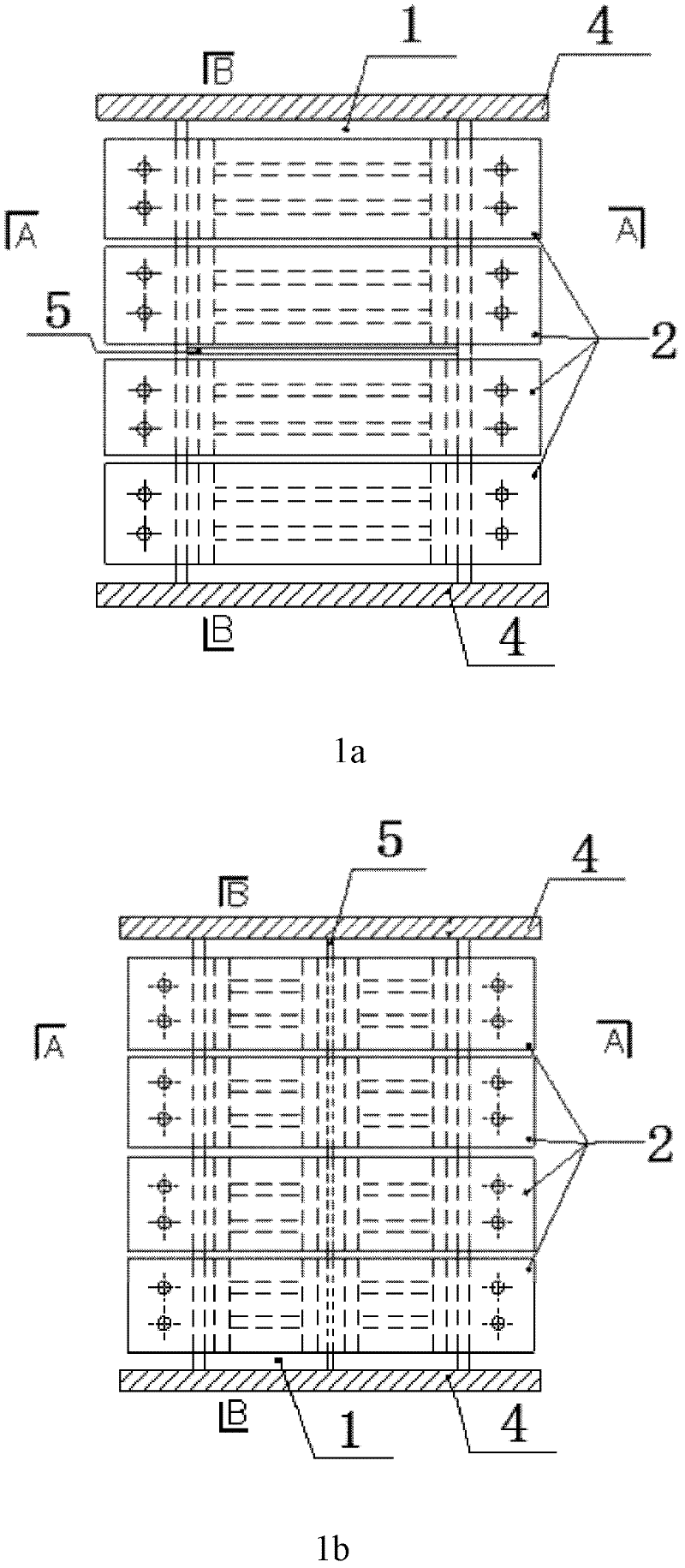

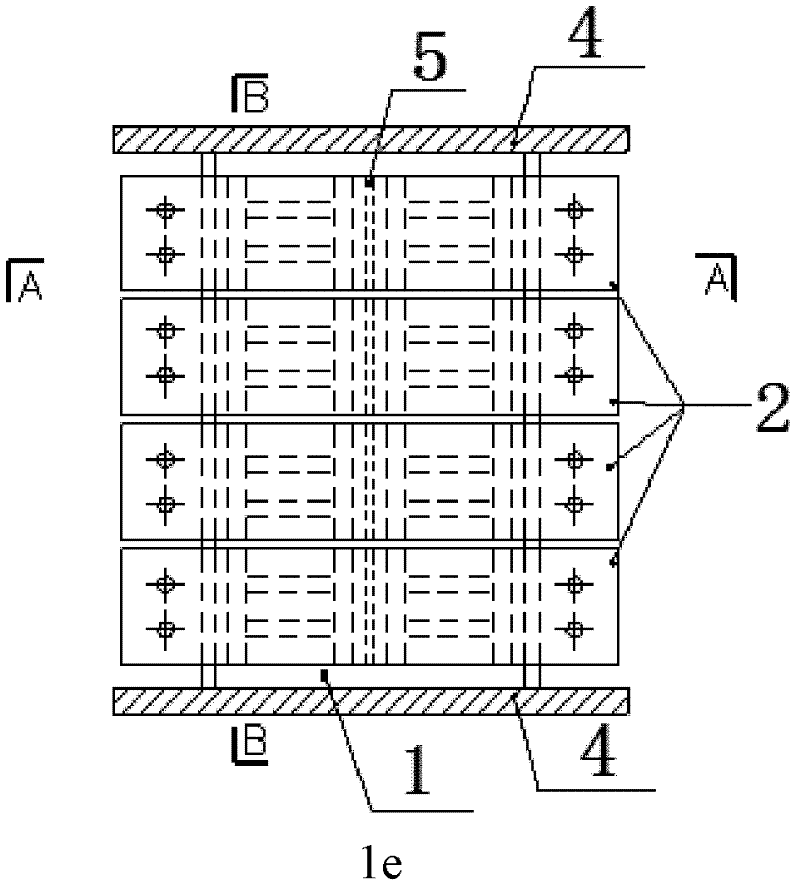

[0030] Such as figure 1 As shown in a, 2a and 3a, the figure includes the upper and lower horizontal connecting steel plates 4 arranged on the energy-dissipating steel plate 1, and the two sides of the energy-dissipating steel plate 1 are respectively provided with restraining devices 2, and the restraining device 2 and the energy-dissipating steel plate 1 are connected to each other Independently, the restraint devices 2 are horizontally arranged in pairs on both sides of the energy dissipation steel plate 1 without intersecting. A horizontal stiffener 5 is provided on one side of the energy dissipation steel plate 1 , and the stiffener 5 is welded horizontally on the energy dissipation steel plate 1 , parallel to and not in contact with the restraint device 2 . The left and right ends of the stiffener 5 are respectively welded to the flange plate. The restraint device 2 and the stiffener 5 constrain the energy-dissipating steel plate 1 to prevent out-of-plane buckling.

Embodiment 2

[0032] Such as figure 1 As shown in b, 2b and 3b, the figure includes the upper and lower horizontal connecting steel plates 4 arranged on the energy-dissipating steel plate 1, and the two sides of the energy-dissipating steel plate 1 are respectively provided with restraint devices 2, and the restraint device 2 and the energy-dissipating steel plate 1 are connected to each other. Independently, the restraint devices 2 are horizontally arranged in pairs on both sides of the energy dissipation steel plate 1 without intersecting. A vertical stiffener 5 is provided on one side of the energy-dissipating steel plate 1 , and the stiffening rib 5 is welded on the energy-dissipating steel plate 1 through its entire length, and is inside the restraint device 2 and does not connect with the restraint device 2 . The upper and lower ends of the stiffener 5 are respectively welded to the upper and lower horizontal connecting steel plates 4 . The restraint device 2 and the stiffener 5 cons...

Embodiment 3

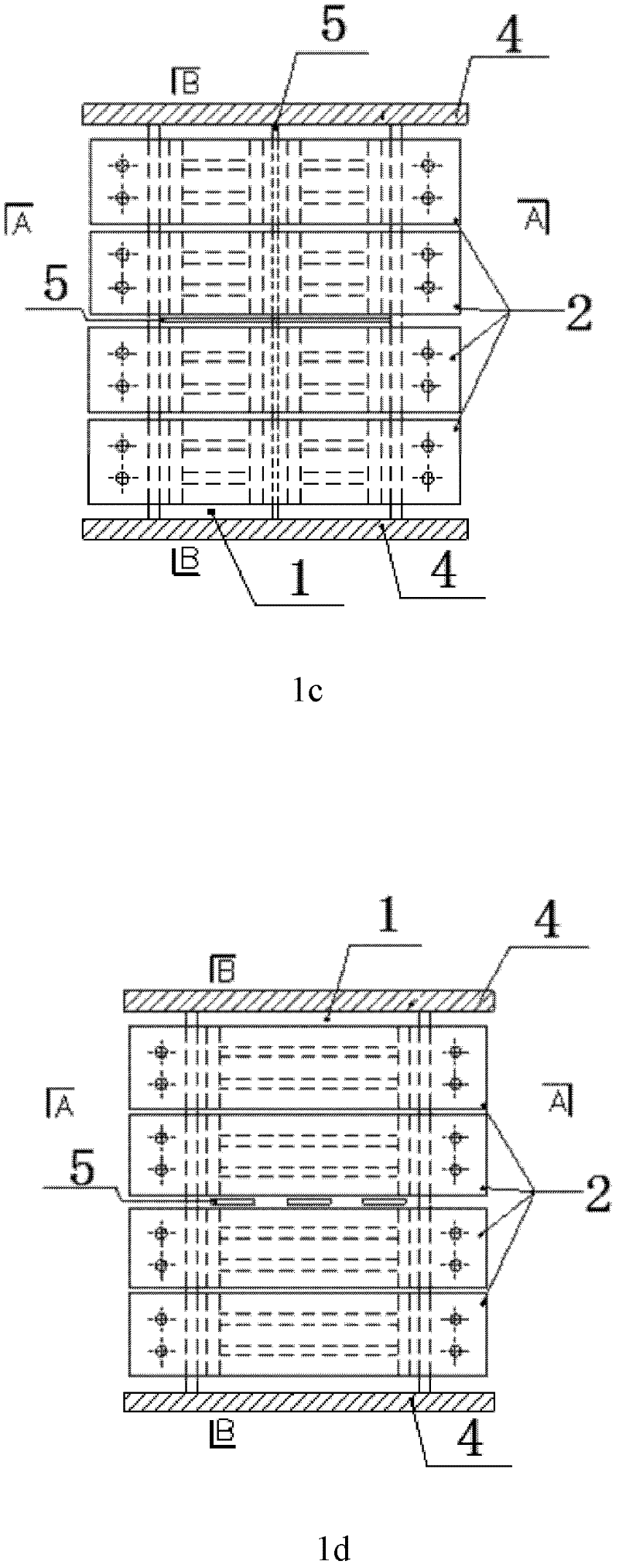

[0034] Such as figure 1 As shown in c, 2c and 3c, the figure includes the upper and lower horizontal connecting steel plates 4 arranged on the energy-dissipating steel plate 1, and the two sides of the energy-dissipating steel plate 1 are respectively provided with restraining devices 2, and the restraining device 2 and the energy-dissipating steel plate 1 are connected to each other. Independently, the restraint devices 2 are horizontally arranged in pairs on both sides of the energy dissipation steel plate 1 without intersecting.

[0035] A horizontal stiffener 5 is provided on one side of the energy-dissipating steel plate 1, and the stiffening rib 5 is welded on the energy-dissipating steel plate 1 throughout its length, parallel to and not connected to the restraint device 2, and the left and right ends of the stiffening rib 5 are welded respectively on the flange. A vertical stiffener 5 is provided on the other side of the energy-dissipating steel plate 1, and the stiff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com