Sealing device for hand holes of circulating fluidized bed boiler header

A circulating fluidized bed and boiler header technology, applied in the field of mechanical seal mechanism, can solve problems such as poor performance, complex structure and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

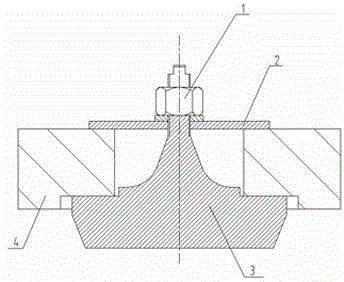

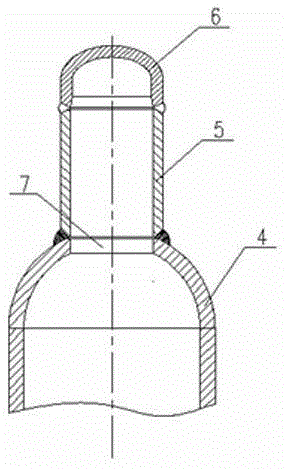

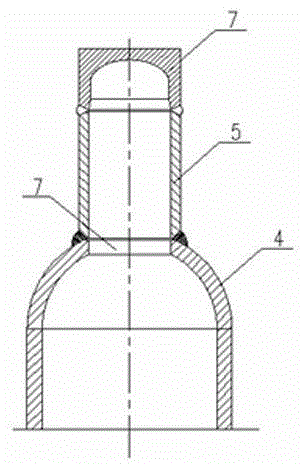

[0013] Such as figure 2 and image 3 As shown, the sealing device for the hand hole of the circulating fluidized bed boiler header of the present invention includes a header body 4, and both ends of the header body 4 are processed with hand holes 7 for maintenance. A pipe joint 5 and an end cap 6 are sequentially arranged outside the hand hole 7, and one end of the pipe joint 5 is welded together with the surroundings of the hand hole 7 and between the pipe joint 5 and the mouth of the end cap 6 in a sealed shape.

[0014] Wherein, the outer surface of the top of the end cover 6 can be spherical or flat. What shape to use depends on the need. In this embodiment, the outer surface of the top of the end cap 6 is spherical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com