Cable-stayed bridge girder connected with anchor pulling plate

An anchor pull plate and main beam technology, applied in bridges, bridge materials, bridge construction and other directions, can solve problems such as easy occurrence of diseases, increase in bridge width, and difficulty in repairing and maintaining bridge air nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

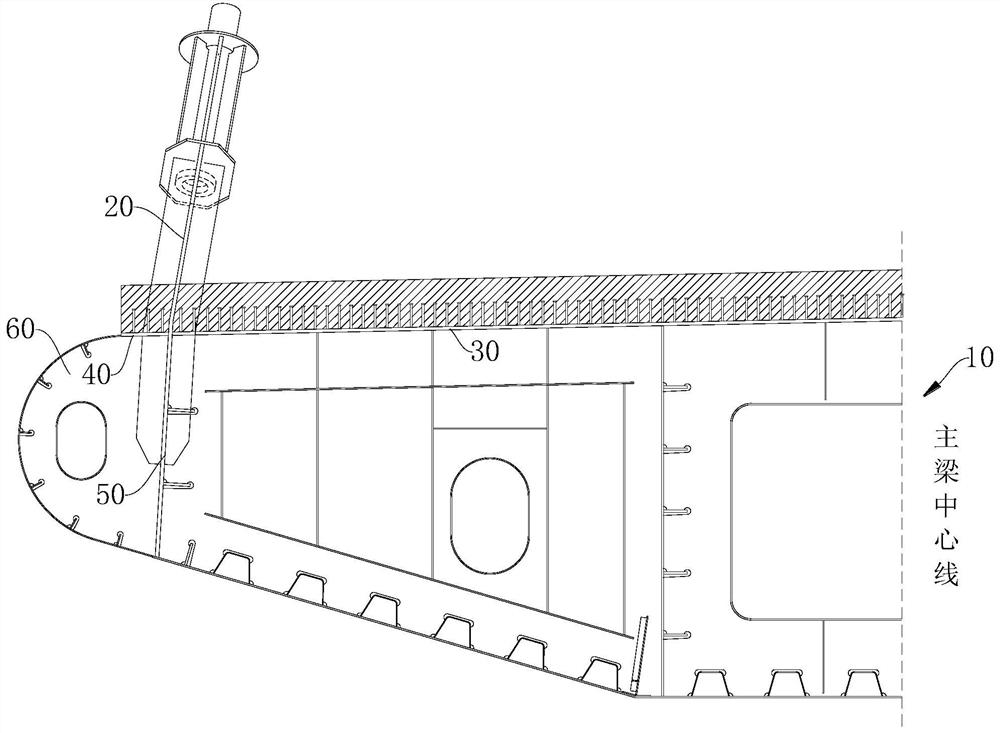

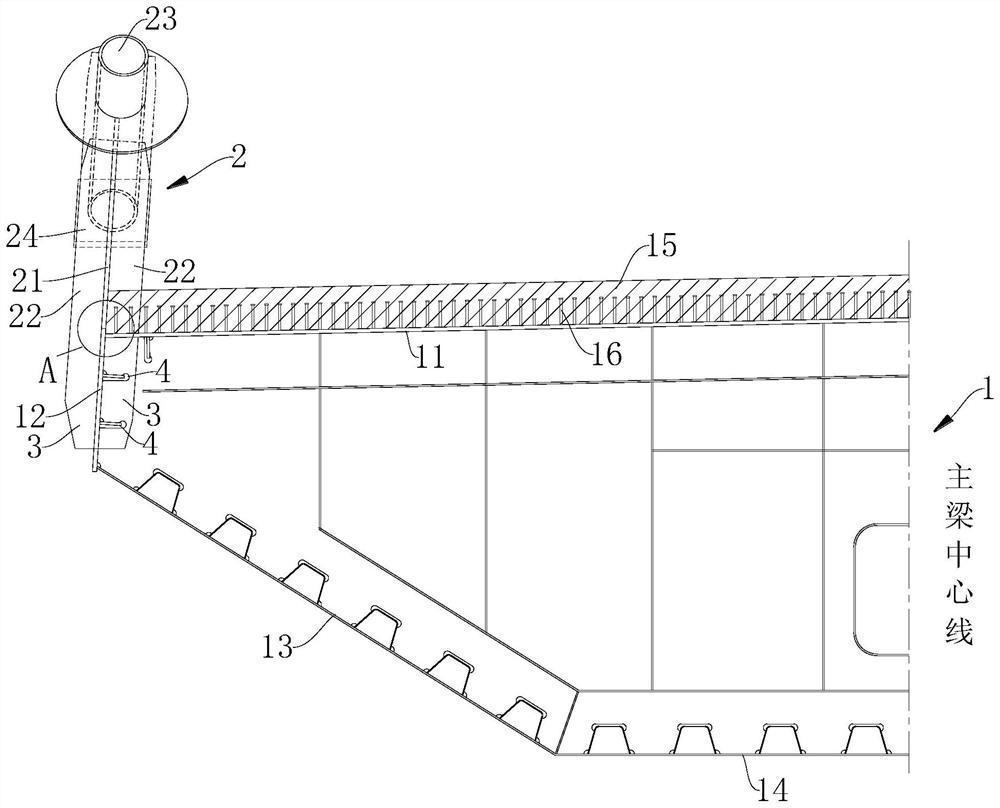

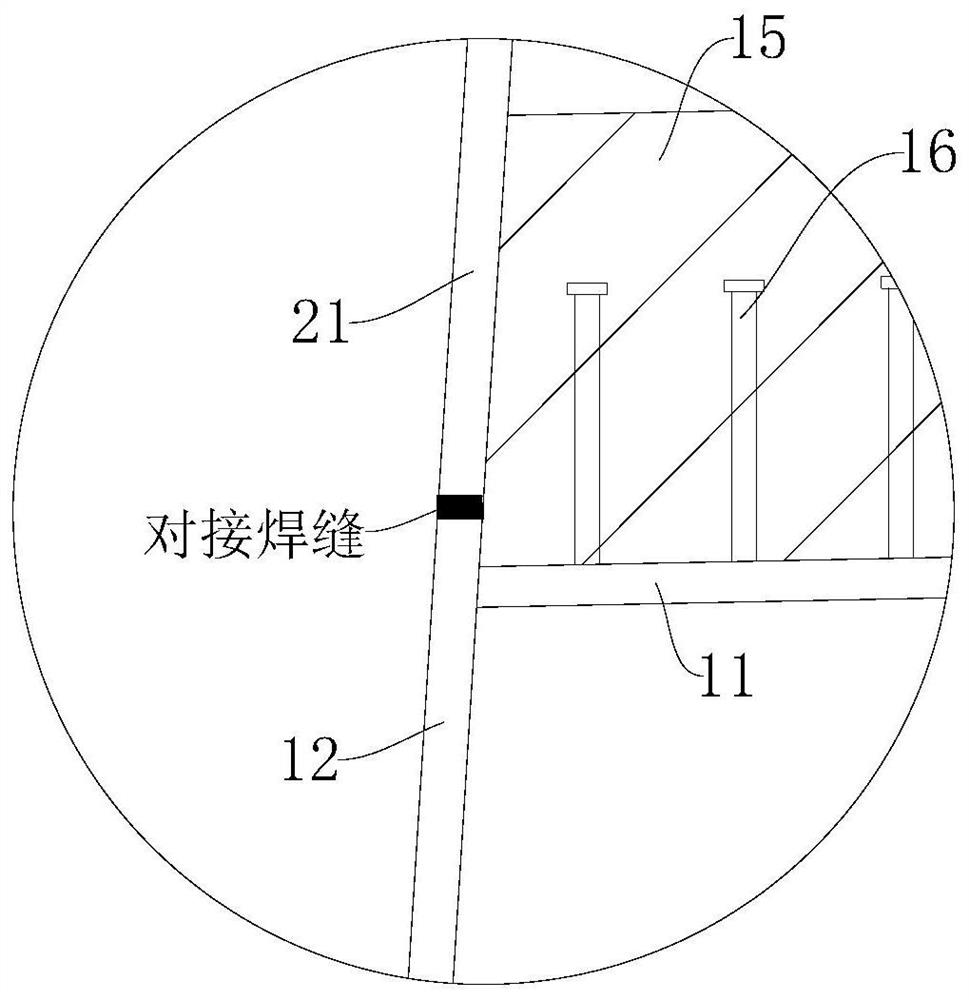

[0032] A main girder of a cable-stayed bridge connected with anchor slabs, such as Figure 2-4 As shown, it mainly includes steel-concrete composite beam 1 and anchor plate assembly 2:

[0033] Steel-concrete combined beam 1 is mainly composed of upper web 12, top plate 11, lower inclined web 13, bottom plate 14, and stiffeners on each plate. The plates are welded to each other to form a single-box single-chamber symmetrical structure, such as figure 2 . Both sides of the top plate 11 are respectively connected to the upper web 12 (only half of which is shown in the figure), and the upper web 12 is connected to the downward inclined web 13 in turn, and the downward inclined web 13 is arranged on both ends of the bottom plate 14, and the bottom plate 14 is opposite to the top plate 11; The combination of the web and the downward sloping web forms a streamlined section, which can reduce the wind resistance area and has good wind resistance. By adjusting the thickness of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com