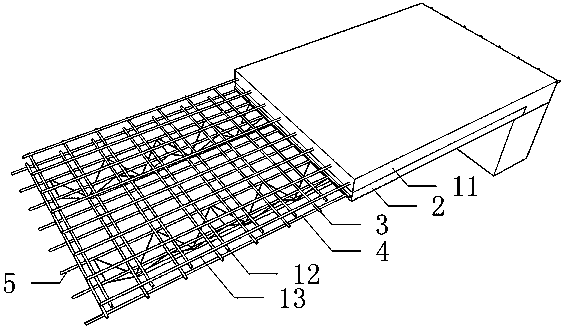

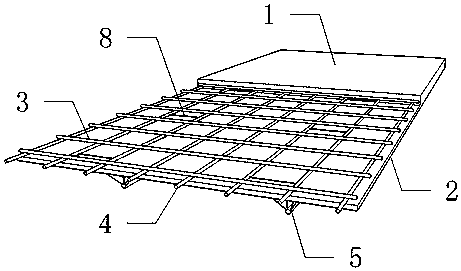

Inverted steel bar truss concrete laminated board and construction method thereof

A technology of reinforced concrete and steel trusses, which is applied to floors, building components, buildings, etc., can solve problems such as waste of steel bars, and achieve the effects of saving installation hours, steel materials, and high bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

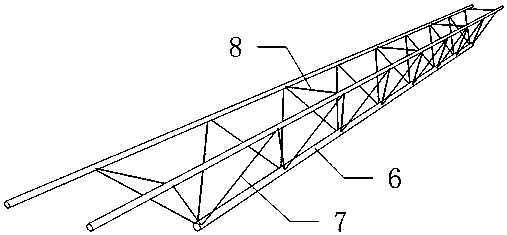

[0043] A construction method for an inverted reinforced truss concrete composite slab, comprising the following steps in sequence:

[0044] a. Manufacture of inverted steel truss: firstly, in the prefabrication factory, select the appropriate steel bar diameter according to the design and calculation results, and place the three straight bars at the three vertices of the inverted triangle through the limit device, and the size of the triangle is determined in advance according to the calculation. Bending the straight bars into wavy bars, all of which are automatically formed by machinery, and welding the two bars to the above three straight bars from the two sides of the inverted triangle respectively, and the welding points are located at the bending section of the bars At the point of contact with the straight bars, weld tie bars between the two upper straight bars at intervals. High-frequency resistance spot welding is used to ensure the welding quality of the welding proces...

Embodiment 2

[0050] A construction method for an inverted reinforced truss concrete composite slab, comprising the following steps in sequence:

[0051] a. Manufacture of inverted steel truss: firstly, in the prefabrication factory, select the appropriate steel bar diameter according to the design and calculation results, and place the three straight bars at the three vertices of the inverted triangle through the limit device, and the size of the triangle is determined in advance according to the calculation. Bending the straight bars into wavy bars, all of which are automatically formed by machinery, and welding the two bars to the above three straight bars from the two sides of the inverted triangle respectively, and the welding points are located at the bending section of the bars At the point of contact with the straight bars, weld tie bars between the two upper straight bars at intervals. High-frequency resistance spot welding is used to ensure the welding quality of the welding proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com