Helical blade forming machine

A technology of helical blade and forming machine, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large local stress of the helical blade, complicated and troublesome manufacturing process, and difficult to control the pitch size, and achieve the welding quality. Easy, easy to control the moving distance, simple and convenient operation of welding and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

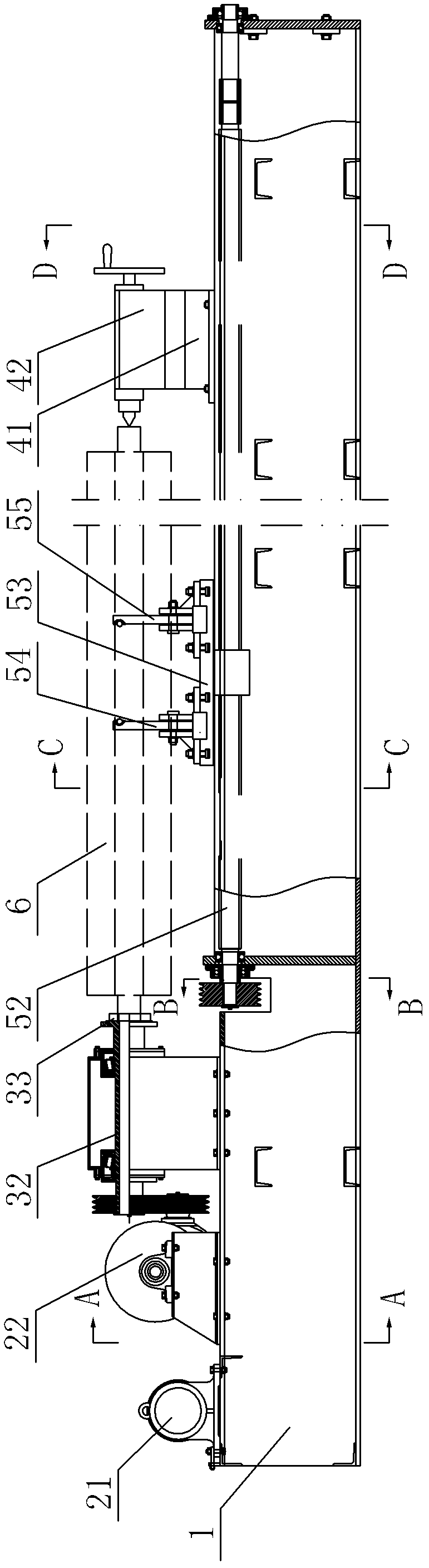

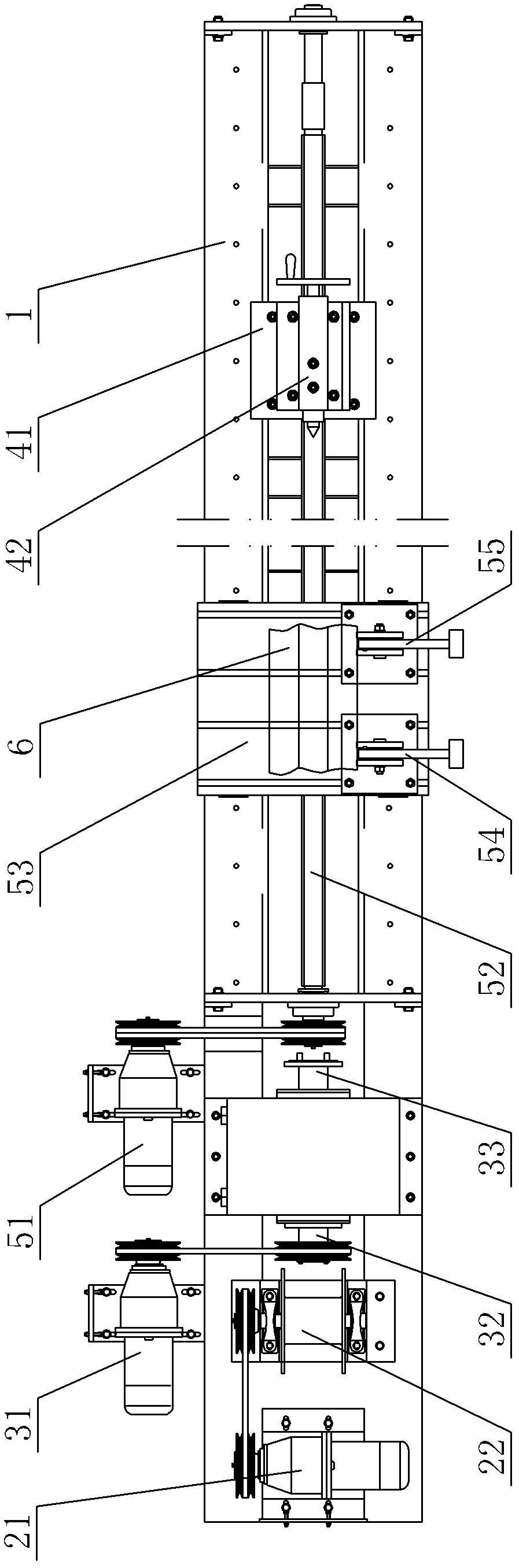

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

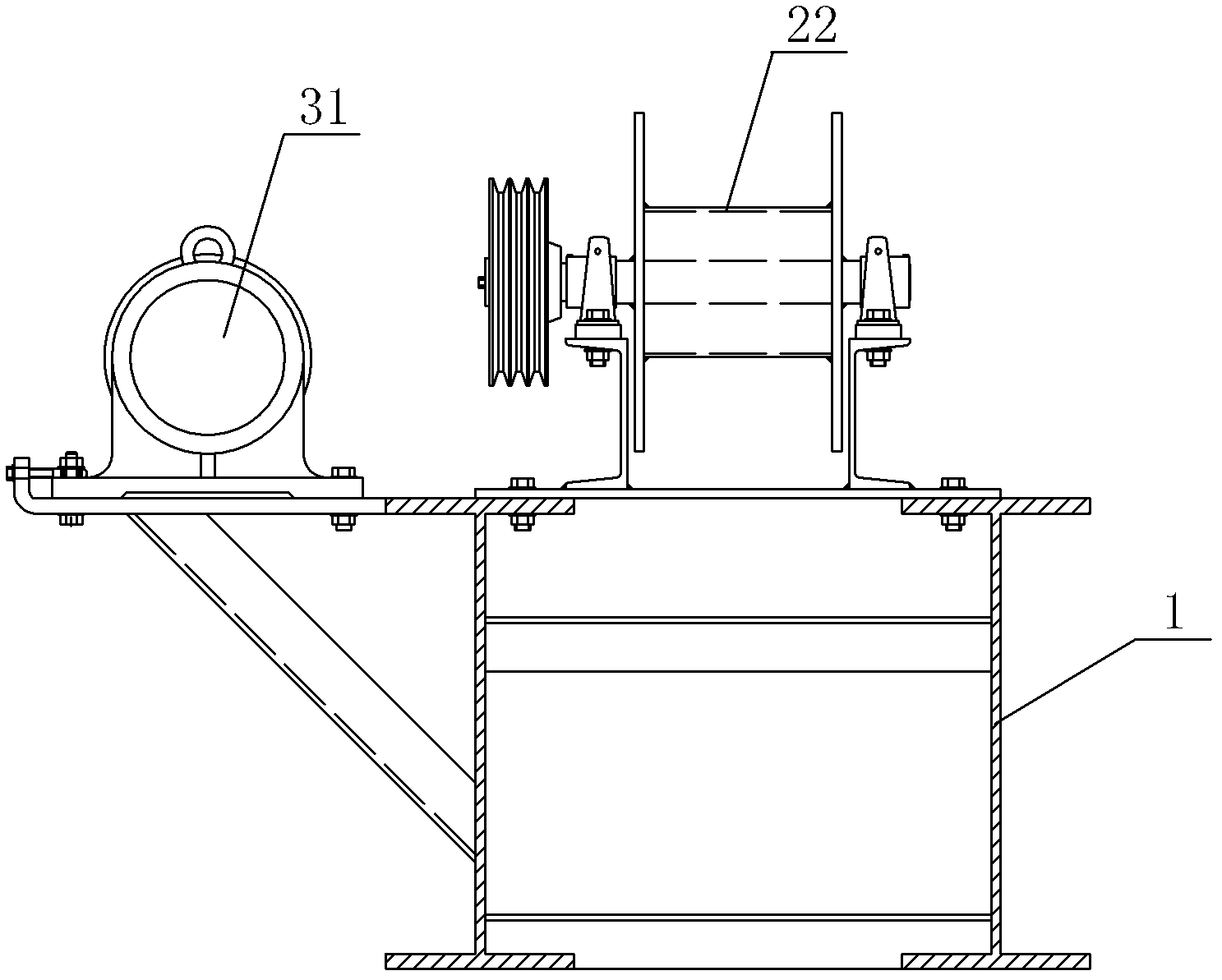

[0021] Such as Figure 1-8 Shown, the present invention comprises machine base 1, is provided with helical blade traction device and helical blade and shaft rotating device successively from left to right on the left upper part of machine base 1, is provided with helical blade on the right side upper part of machine base 1 The helical blade and the shaft supporting device matched with the shaft rotating device are provided with a helical blade pitch adjusting device on the base 1 between the helical blade and the shaft rotating device and the helical blade and the shaft supporting device.

[0022] The helical blade and shaft rotating device includes a rotating motor and a reducer 31, the rotating motor and the reducer 31 are connected to the left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com