Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Uniform sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

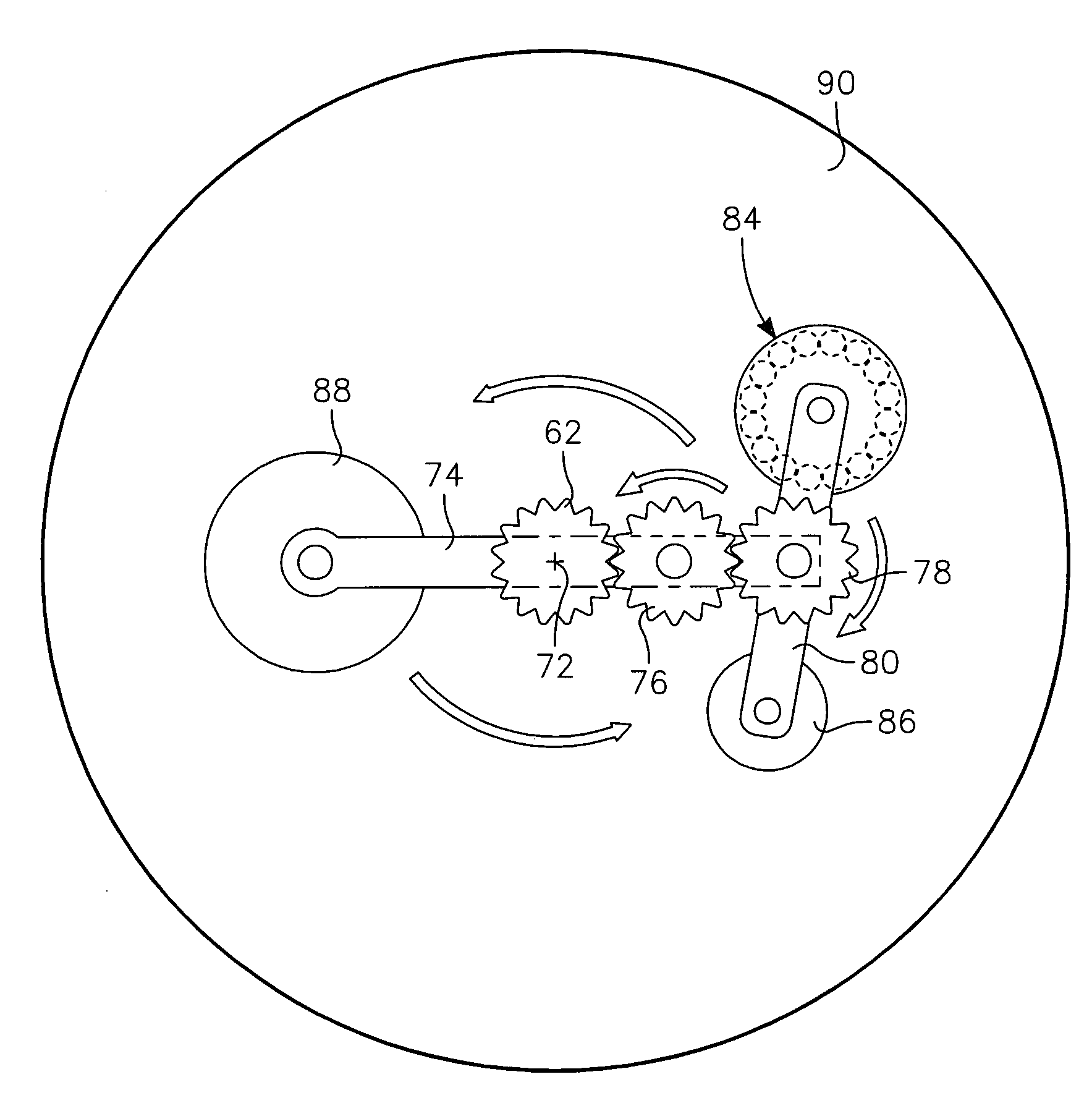

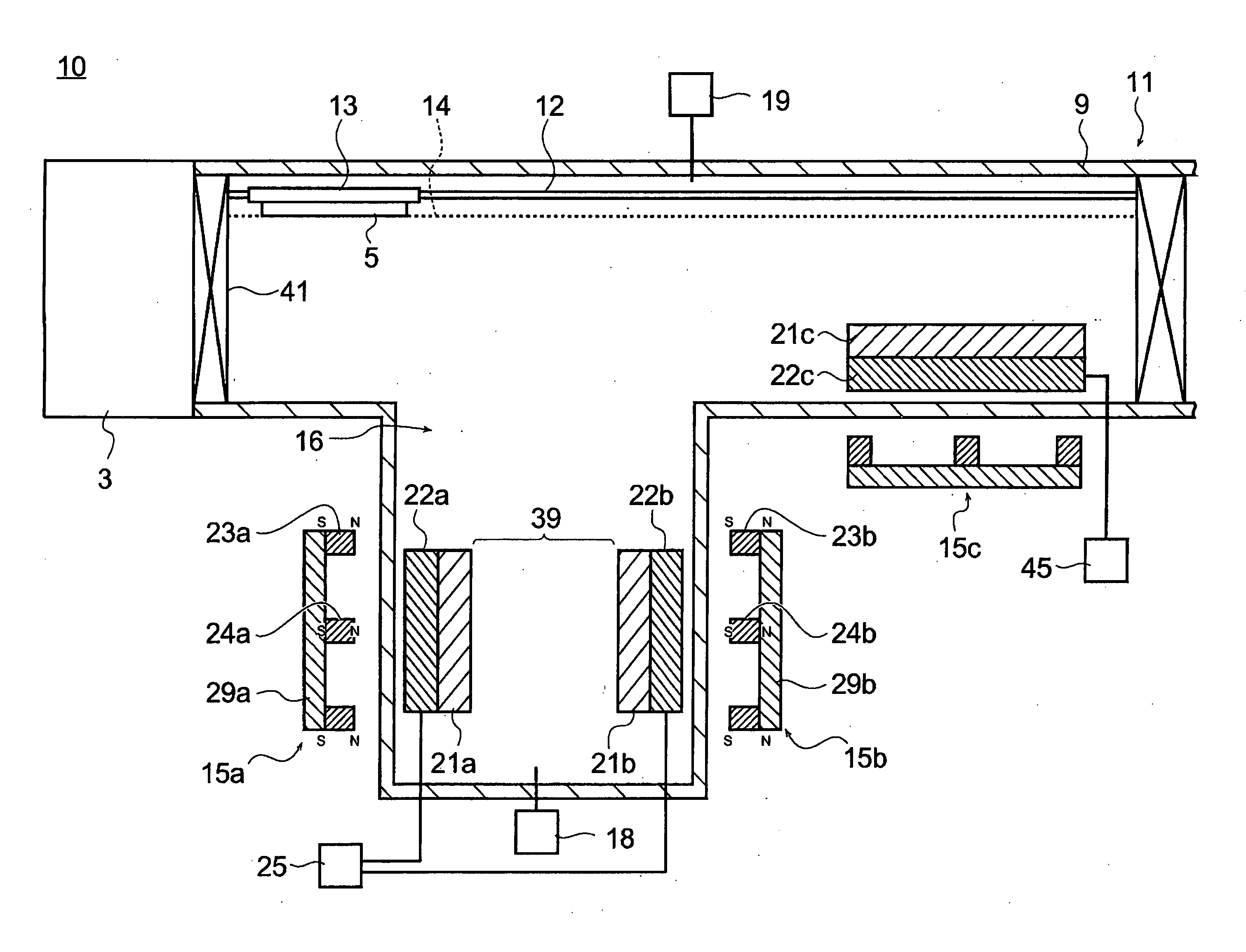

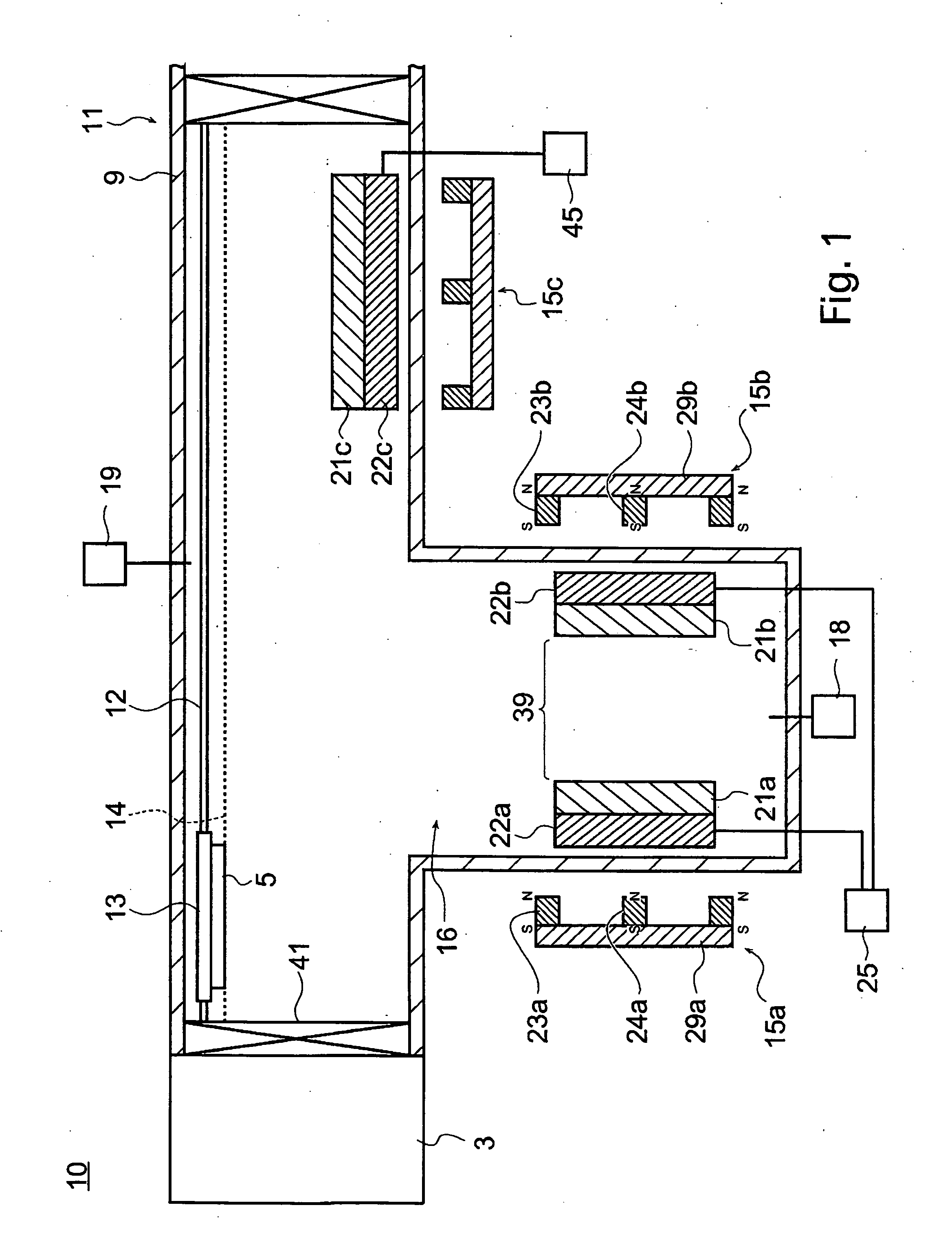

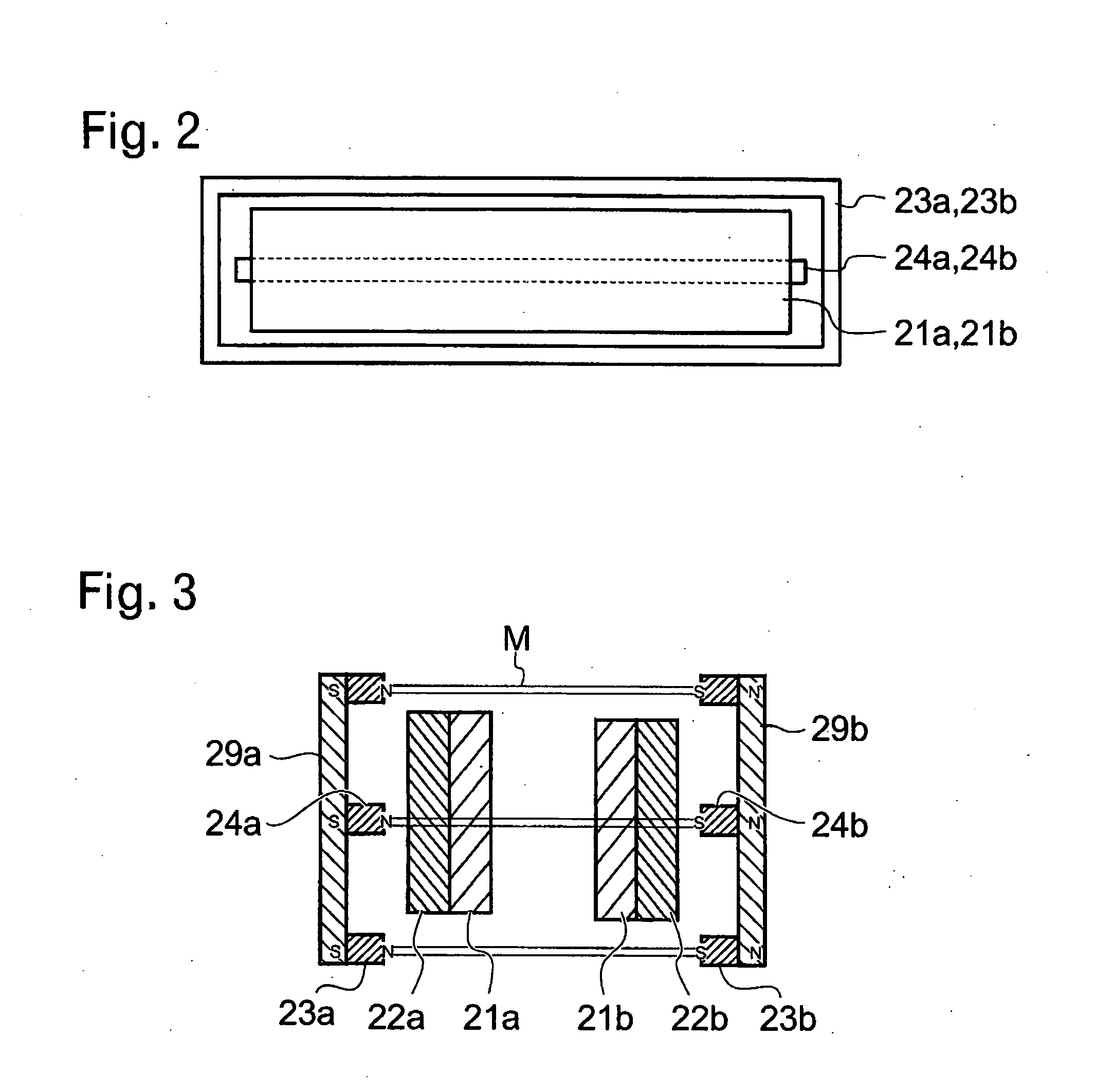

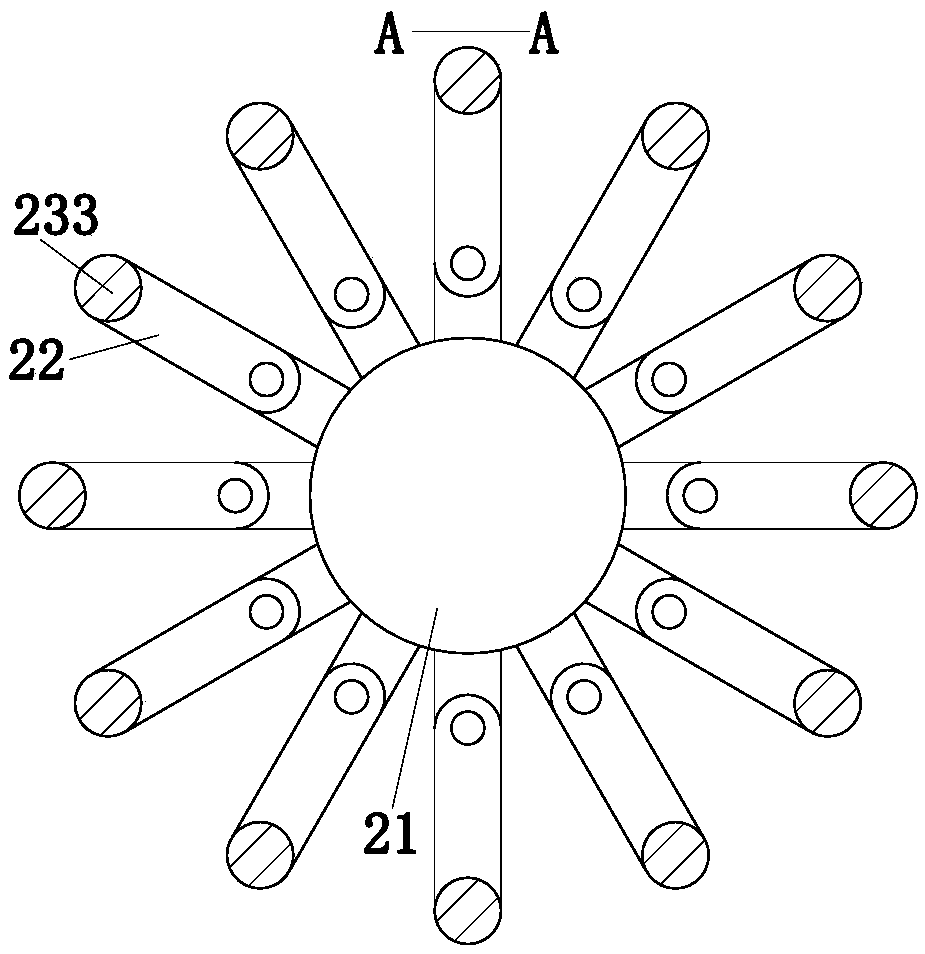

Small planetary magnetron

InactiveUS6841050B2Improve uniformityTarget utilizationCellsElectric discharge tubesIdler-wheelCantilever

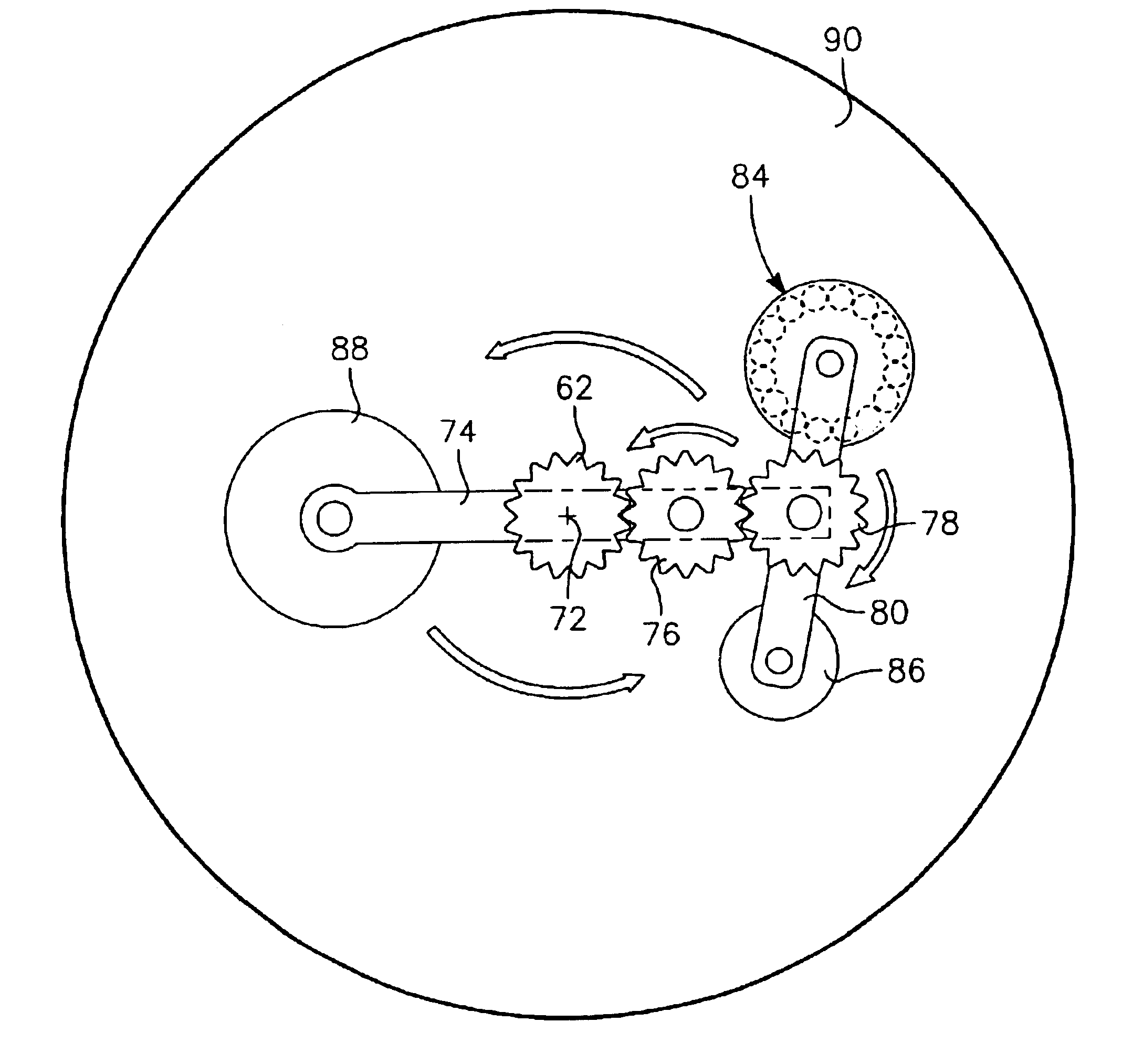

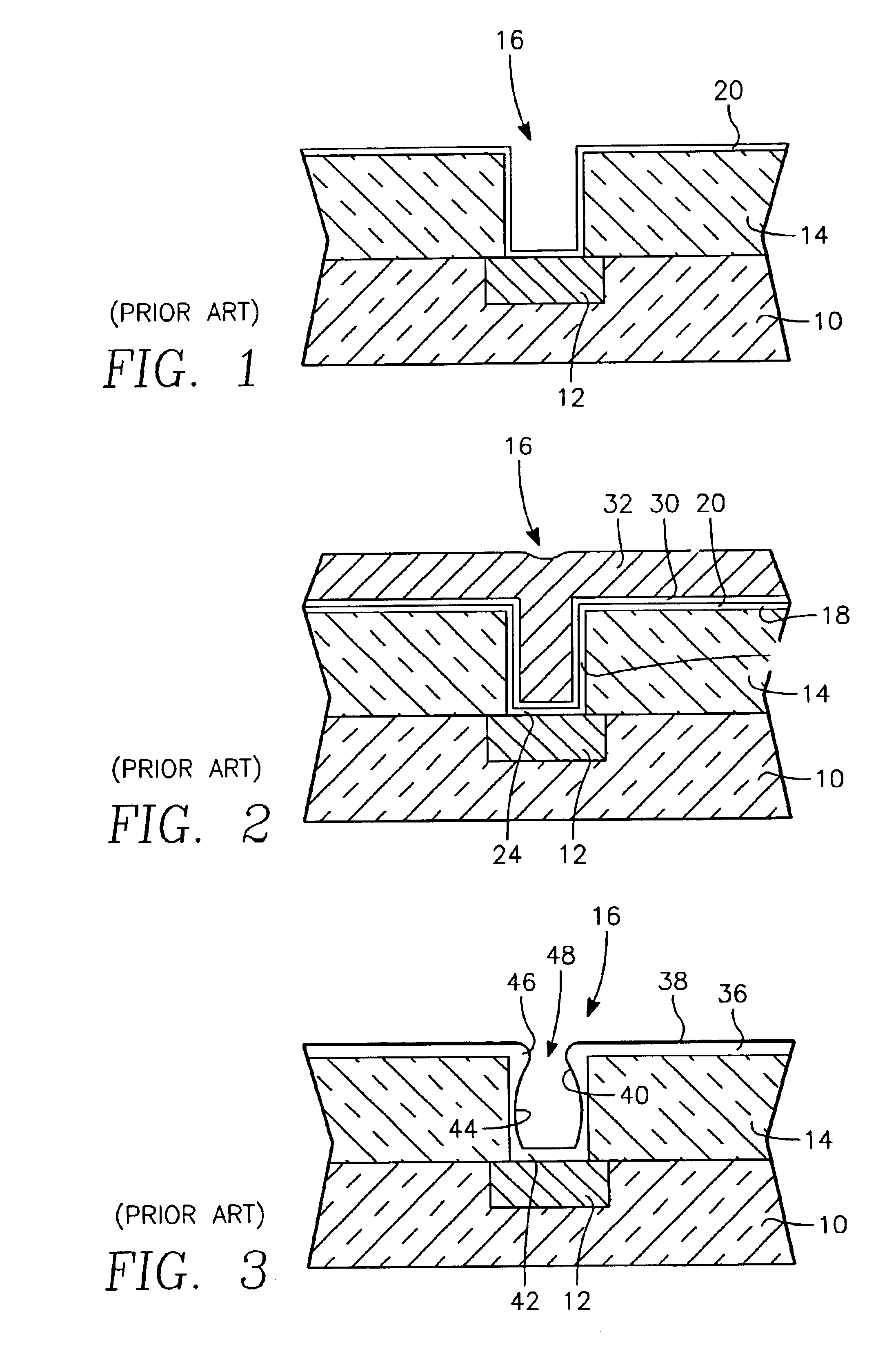

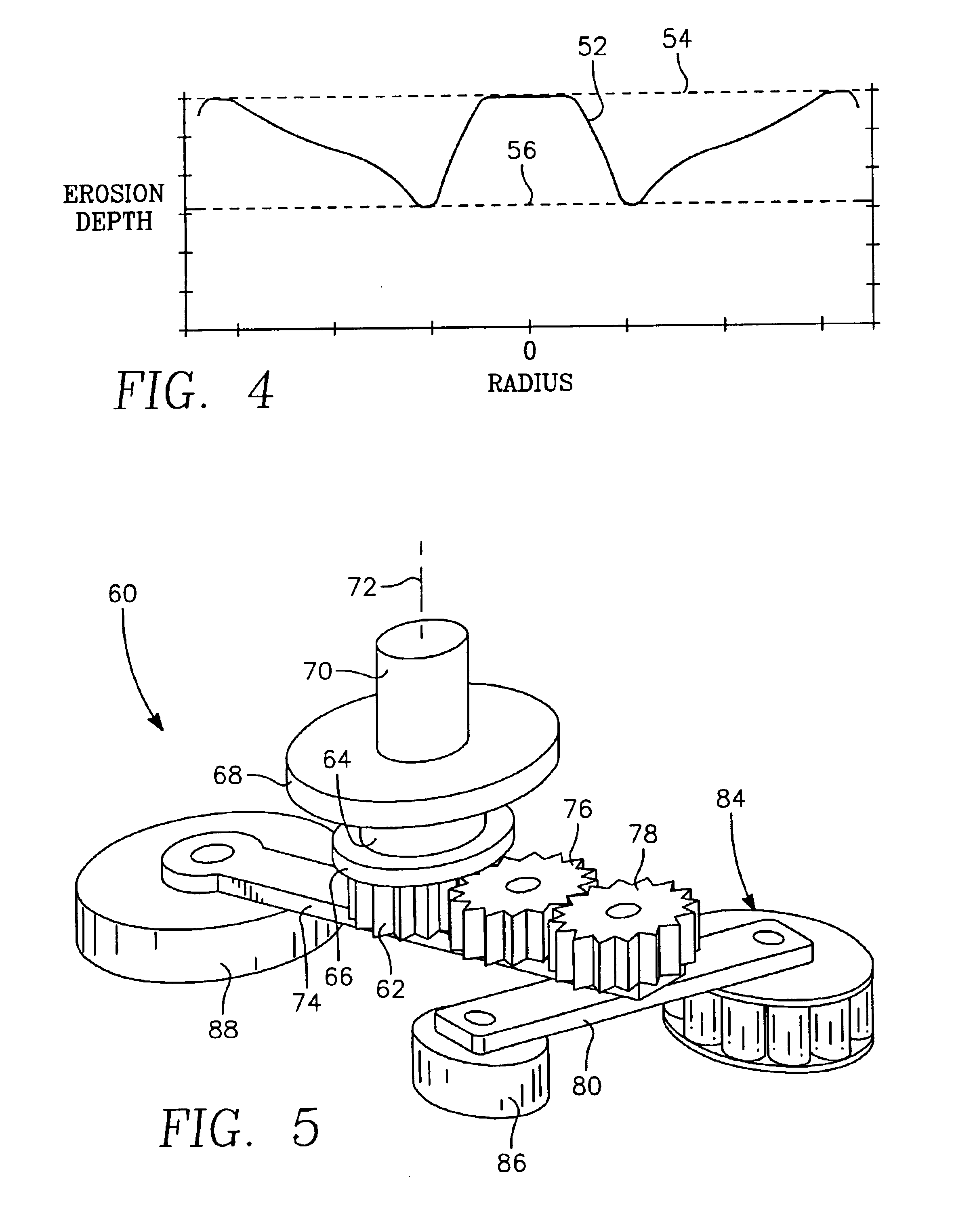

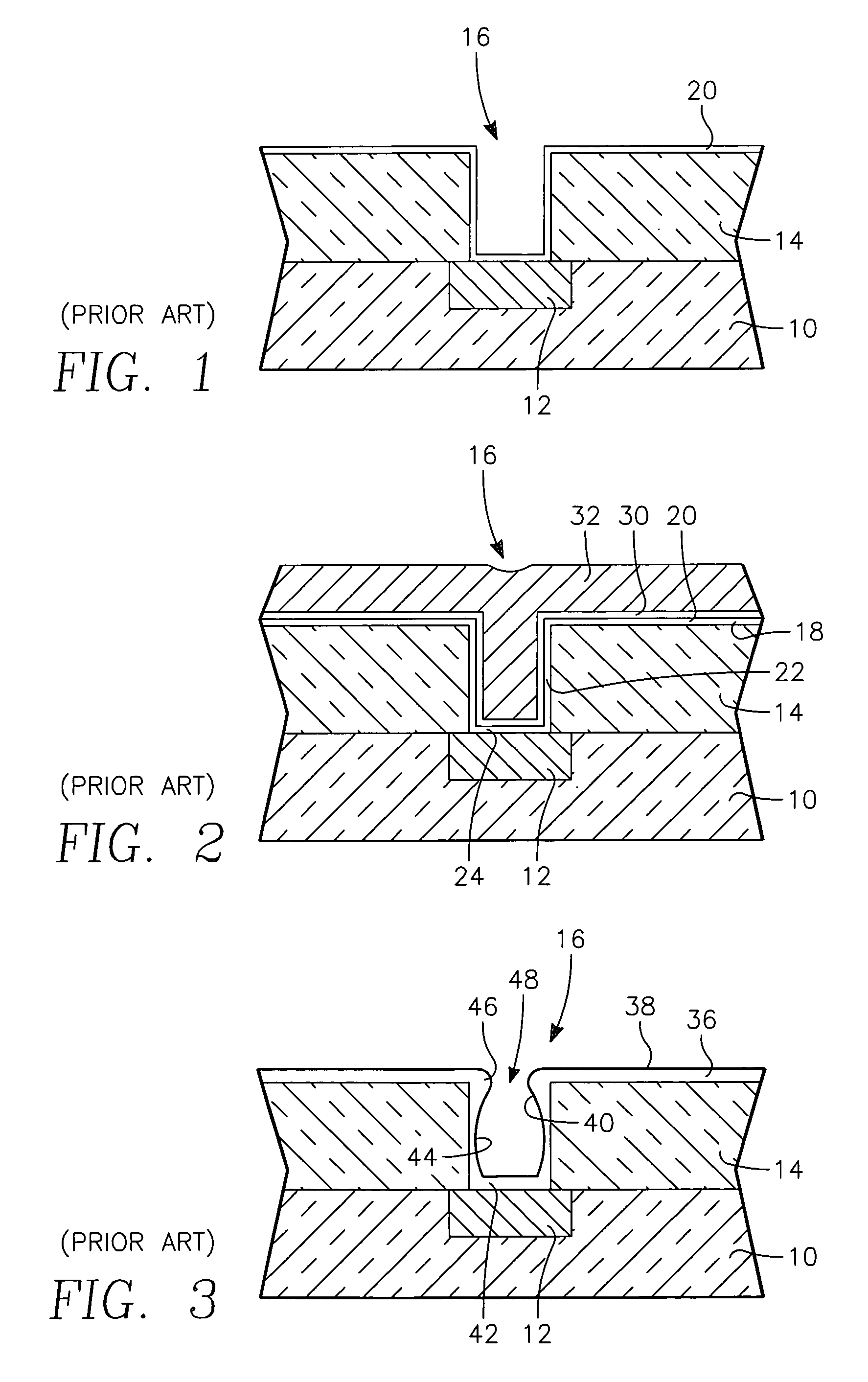

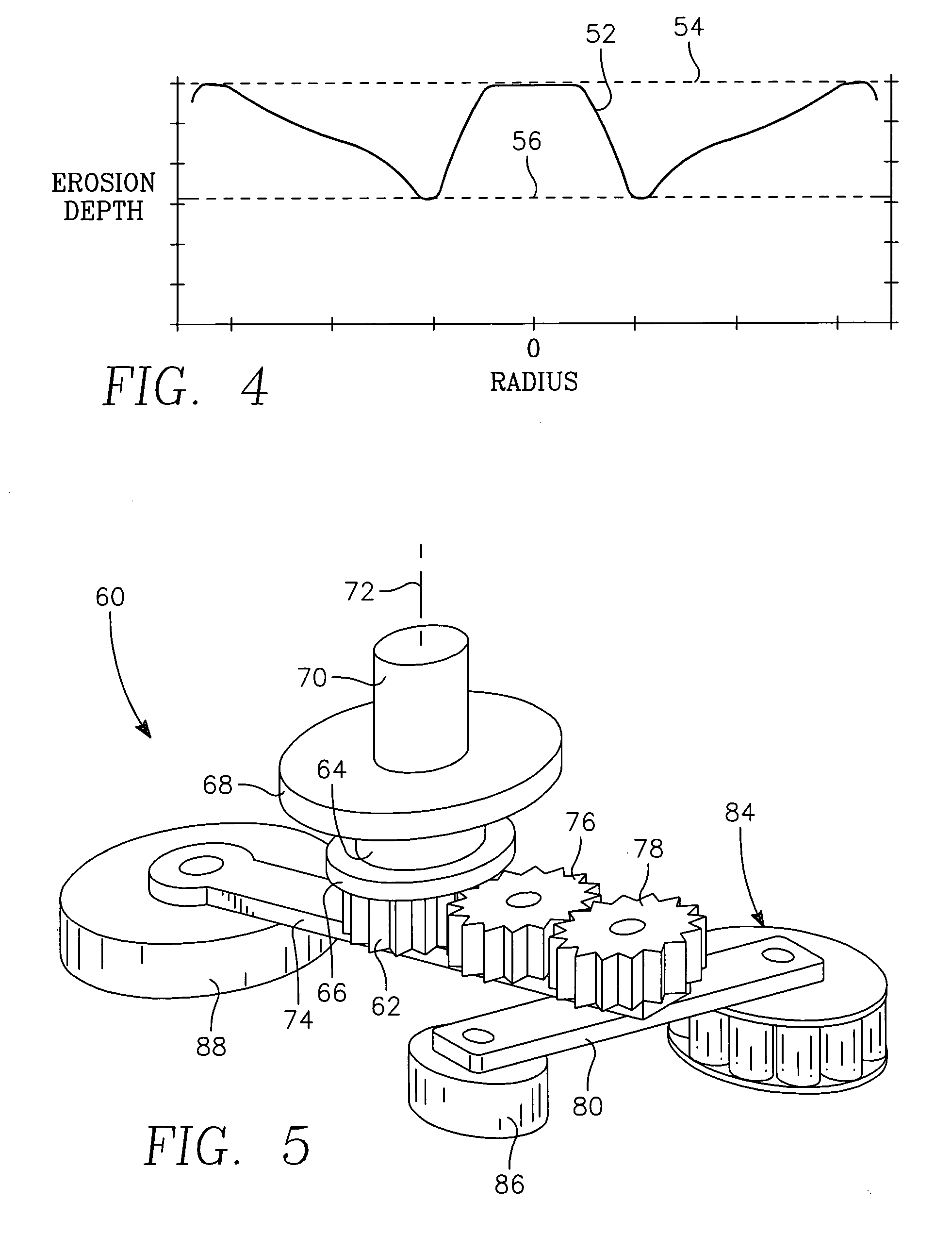

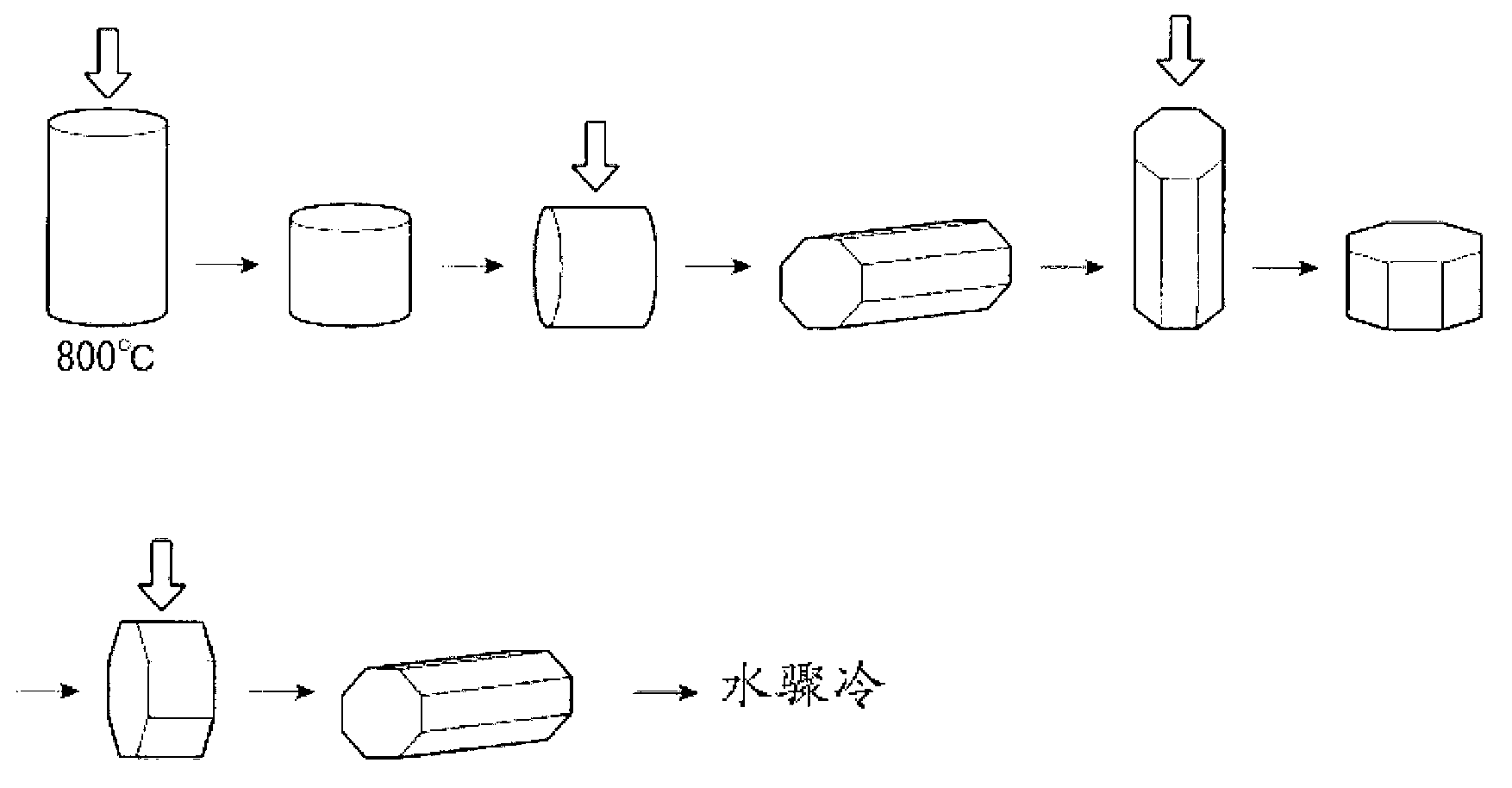

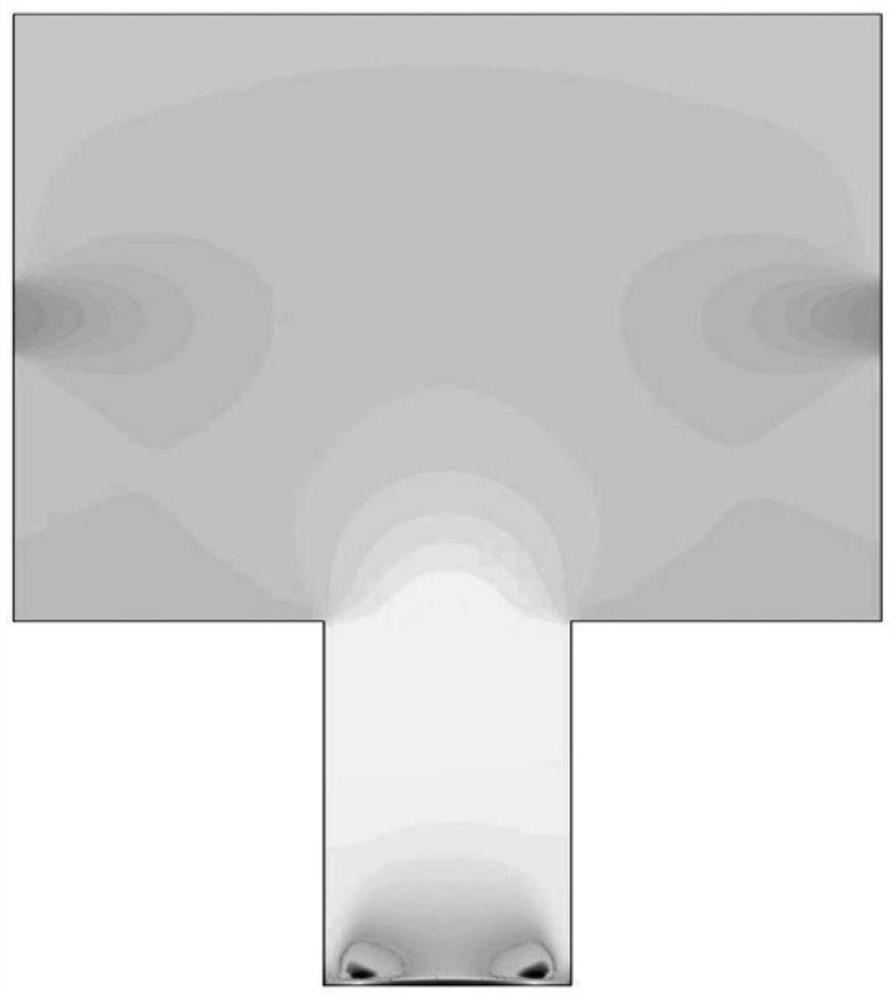

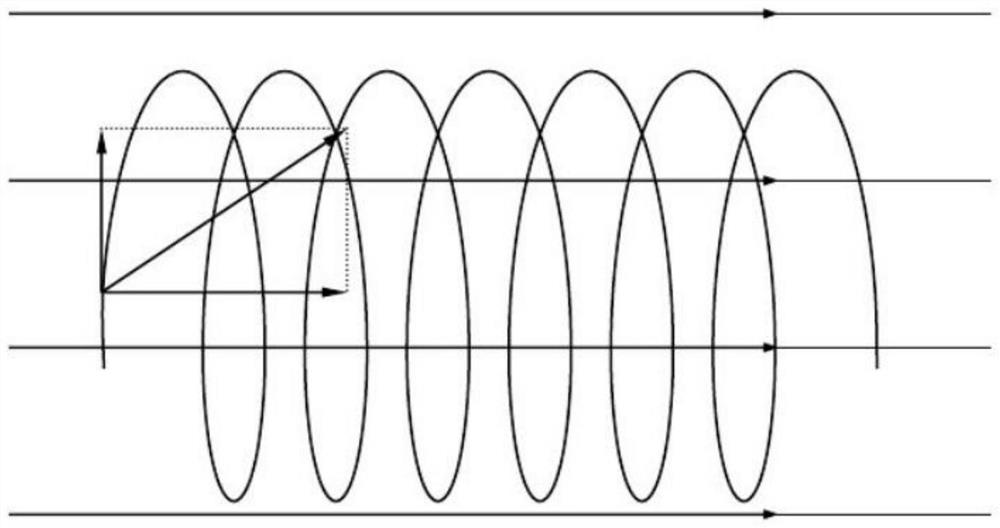

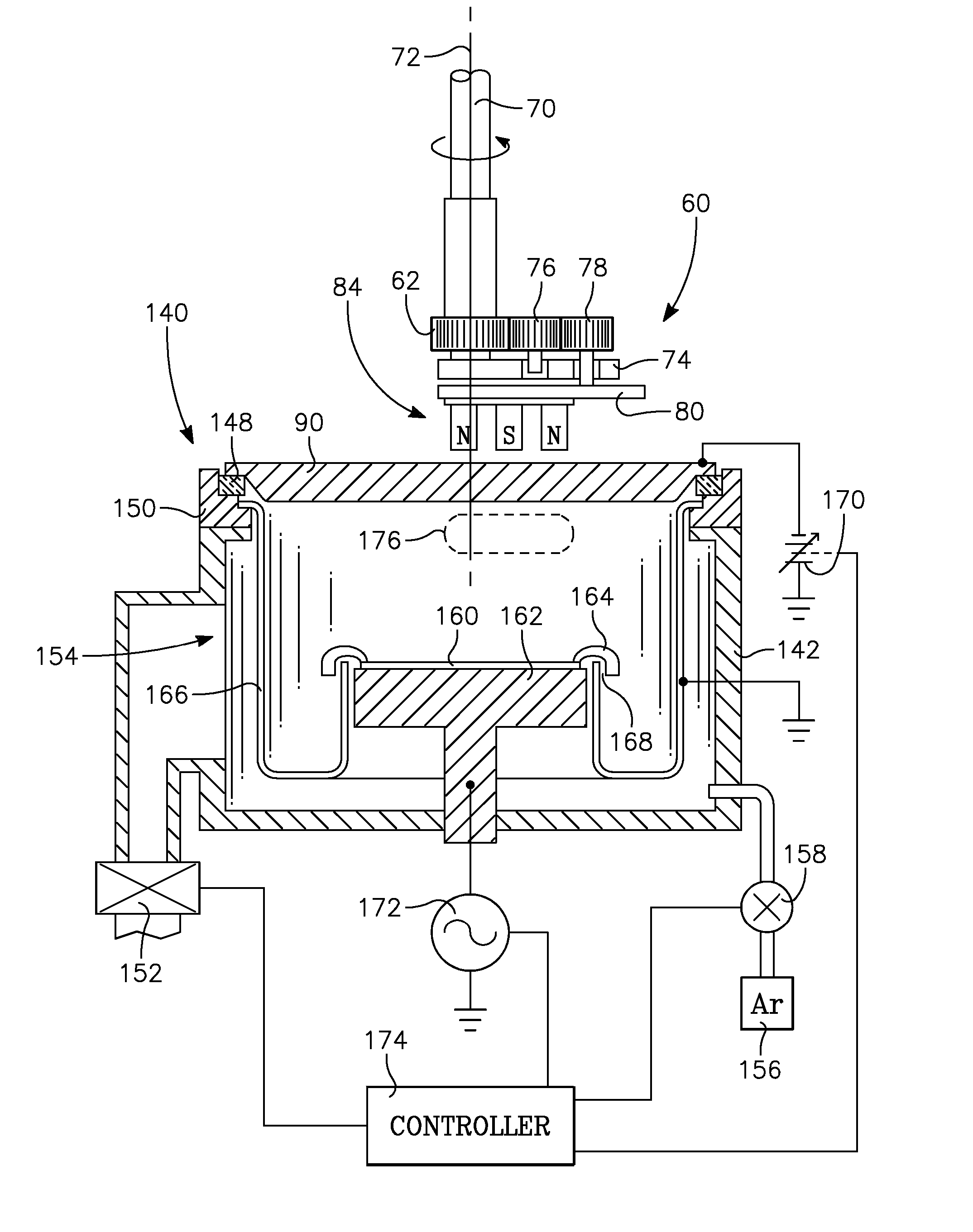

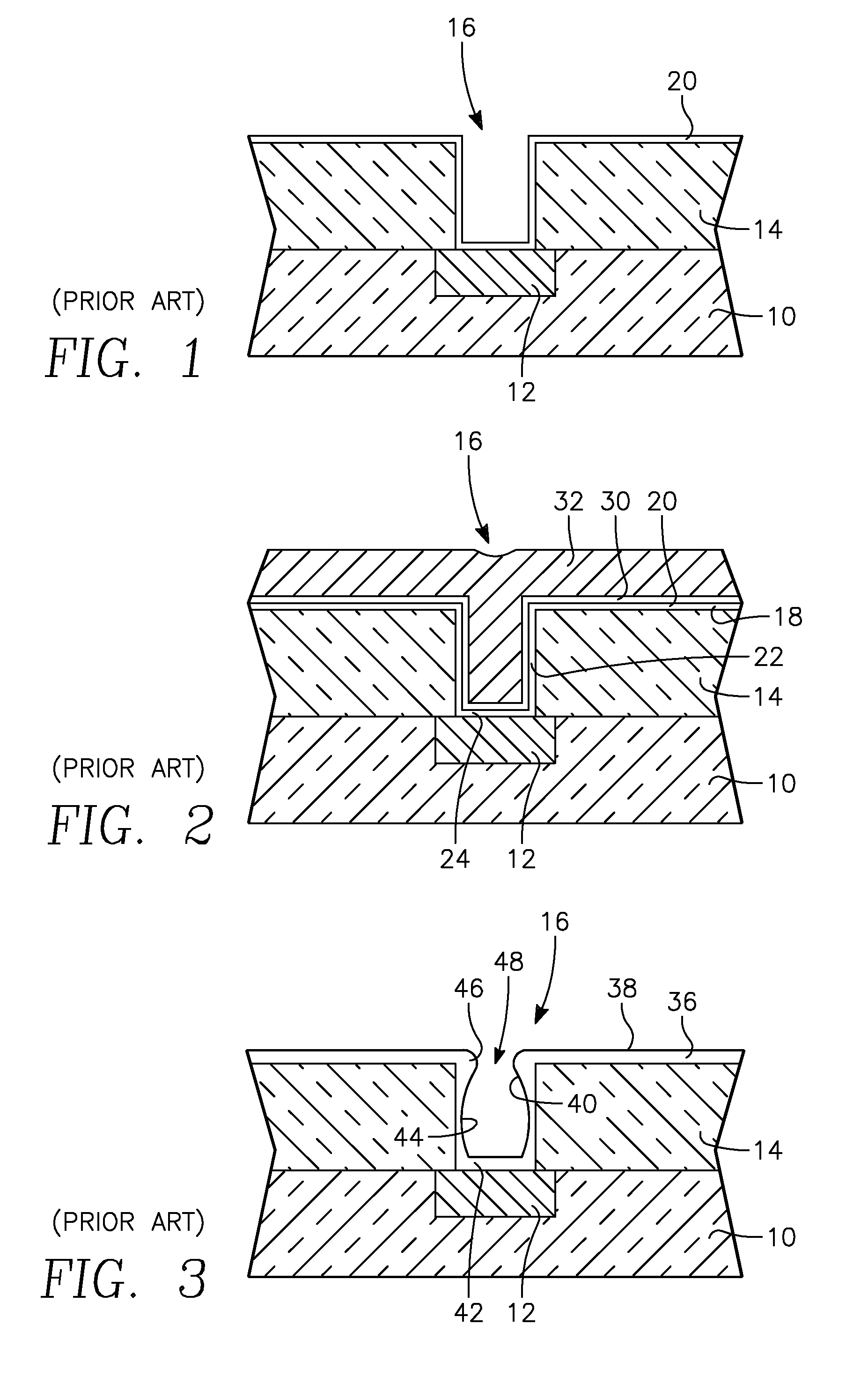

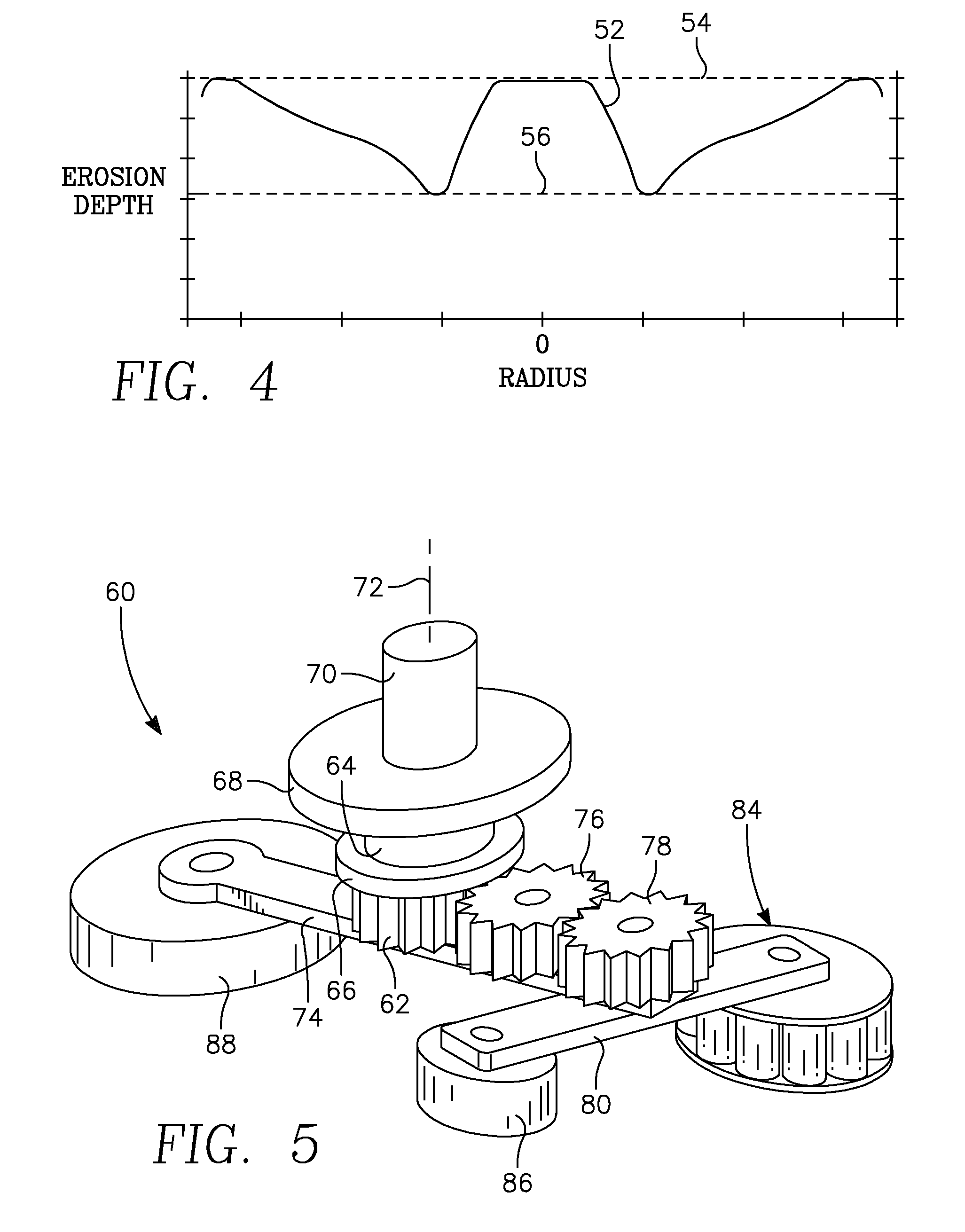

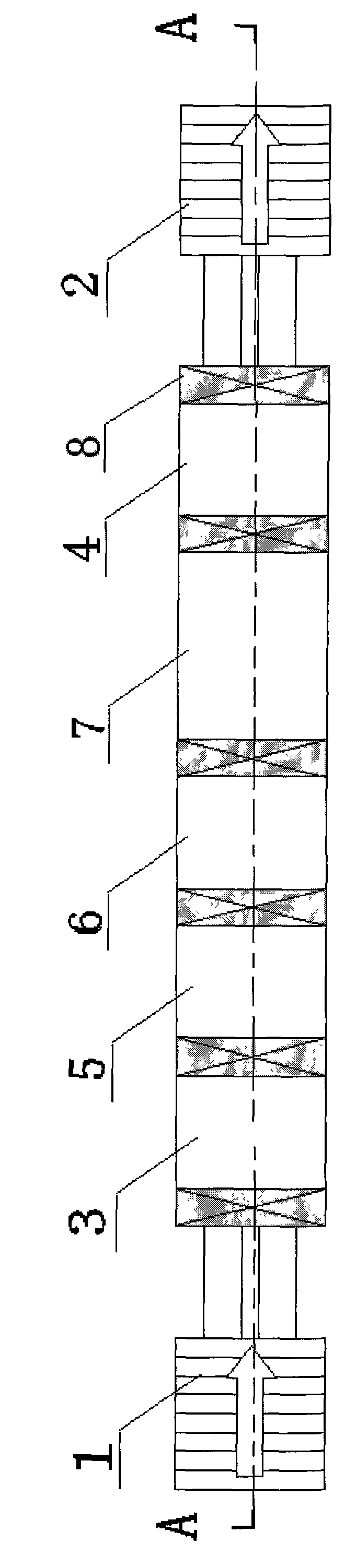

A small magnet assembly is scanned in a retrograde planetary or epicyclic path about the back of a target being plasma sputtered including an orbital rotation about the center axis of the target and a planetary rotation about another axis rotating about the target center axis. The magnet assembly passes through the target center, thus allowing full target coverage. A properly chosen ratio of the two rotations about respective axes produces a much slower magnet velocity near the target periphery than at the target center. A geared planetary mechanism includes a rotating drive plate, a fixed center gear, and an idler and a follower gear rotatably supported in the drive plane supporting a cantilevered magnet assembly on the side of the drive plate facing the target. A belted planetary mechanism includes a fixed center capstan, a follower pulley supporting the magnet assembly, and a belt wrapped around them.

Owner:APPLIED MATERIALS INC

Cr-Cr nanometer composite metal ceramic coating as well as preparation method and device thereof

ActiveCN104711515AReduce coating stressGood cushioning effectVacuum evaporation coatingSputtering coatingCorrosion resistantCermet

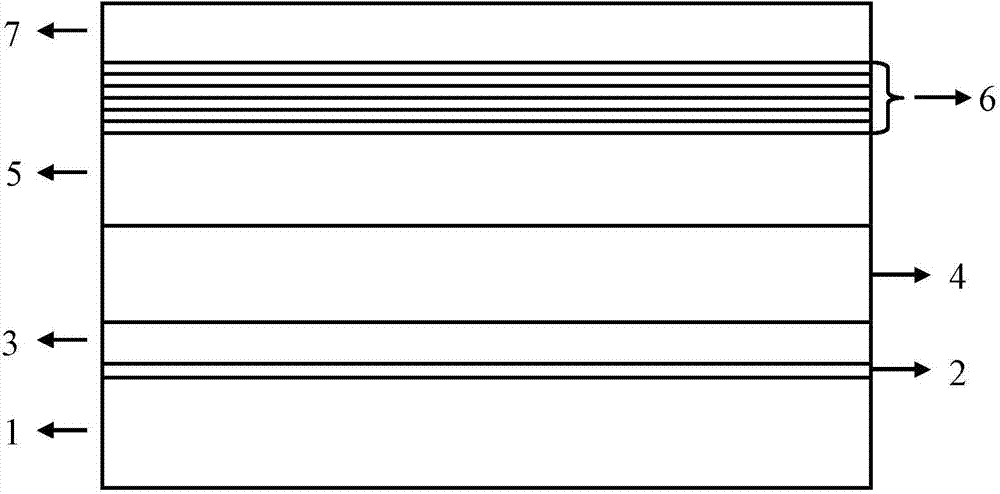

The invention provides a Cr-Cr nanometer composite metal ceramic coating as well as a preparation method and device thereof. The coating is provided with a Cr diffusion layer, a Cr bonding layer, a Cr transition layer, a CrNx supporting layer, a Cr / CrN corrosion-resistant layer and a Cr decoration layer, wherein the CrNx supporting layer satisfies 0<=x<1; the Cr / CrN corrosion-resistant layer is an alternating layer of Cr layers and CrN layers and provided with at least one layer of Cr layer and one CrN layer. The coating provided by the invention has gradual changes of structure and composition, good interlayer bonding and excellent corrosion resistance and comprehensive properties.

Owner:AEROSPACE PRECISION PROD INC LTD

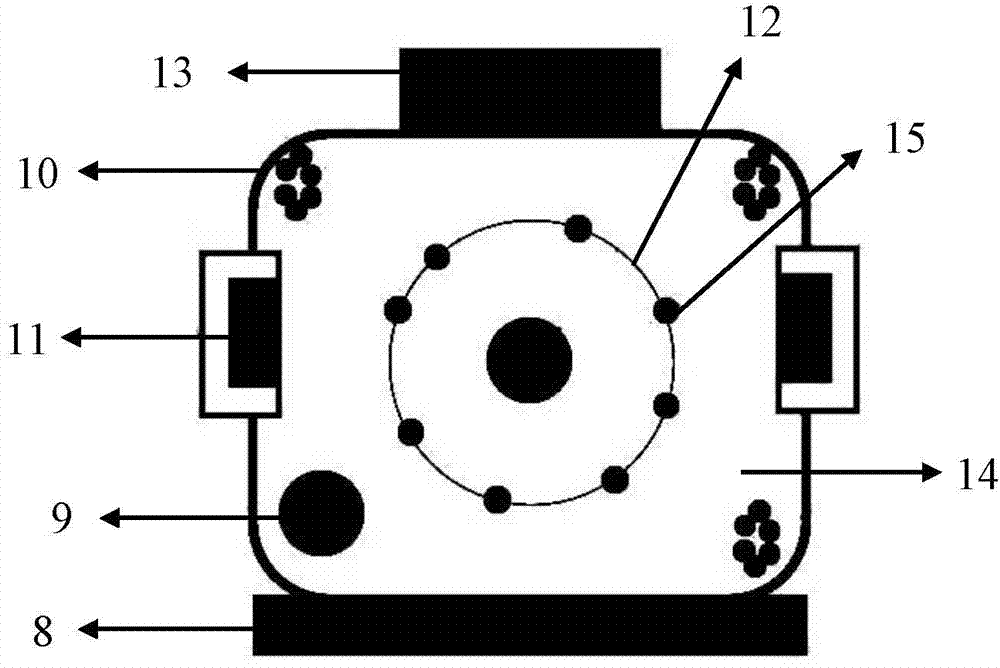

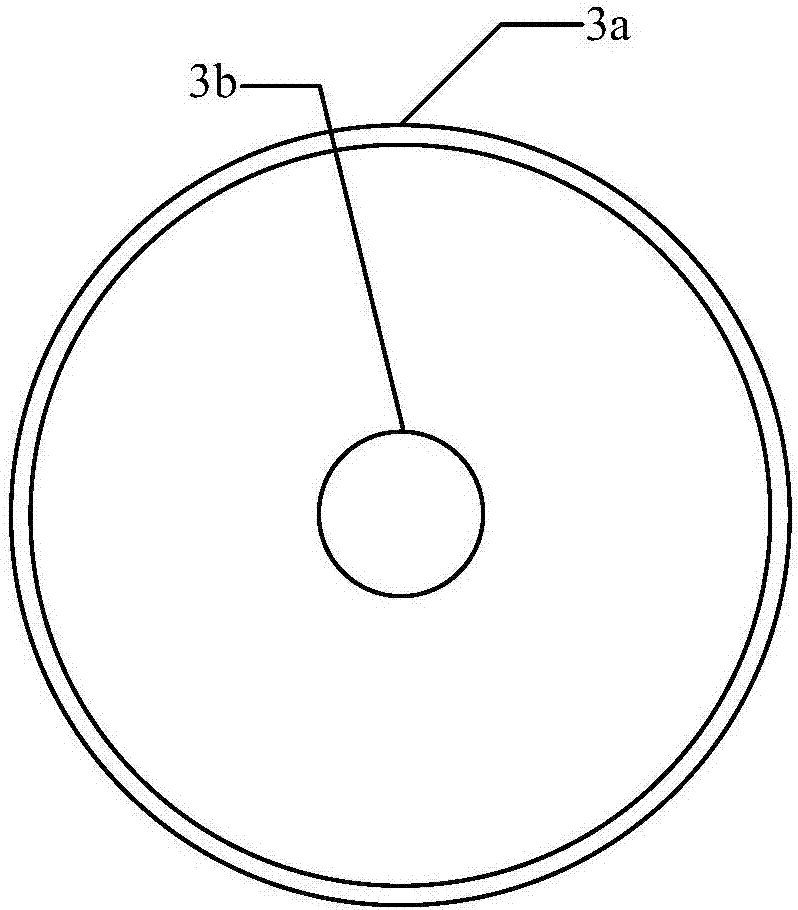

Novel plane magnetron sputtering cathode with high target material utilization rate

ActiveCN107083537AIncrease profitUniform sputteringVacuum evaporation coatingSputtering coatingPhysicsMagnet device

The invention provides a novel plane magnetron sputtering cathode. The plane magnetron sputtering cathode comprises a target material, a backboard, a magnet device and a magnetic conductive plate. The target material is arranged at one side of the backboard, and the magnetic conductive plate is arranged at the other side of the backboard. The magnet device is arranged between the backboard and the magnetic conductive plate. The magnet device comprises a middle magnet and an outer ring magnet surrounding the middle magnet. The middle magnet comprises at least two electromagnets. The polarities of magnetic poles, facing the target material, of the outer ring magnet and the middle magnet are opposite. The plane magnetron sputtering cathode further comprises an electromagnet power source. The electromagnet power source is connected with the at least two electromagnets and supplies power to the at least two electromagnets in sequence so that magnetic field distribution between the outer ring magnet and the middle magnet can be changed continuously. By implementing the novel plane magnetron sputtering cathode, the target material utilization rate can be effectively increased, pollution to the target material is prevented, and stability of the sputtering speed is improved. In addition, the plane magnetron sputtering cathode provided by the invention has the characteristics of being simple in structure, easy to control and high in reliability.

Owner:三河市衡岳真空设备有限公司

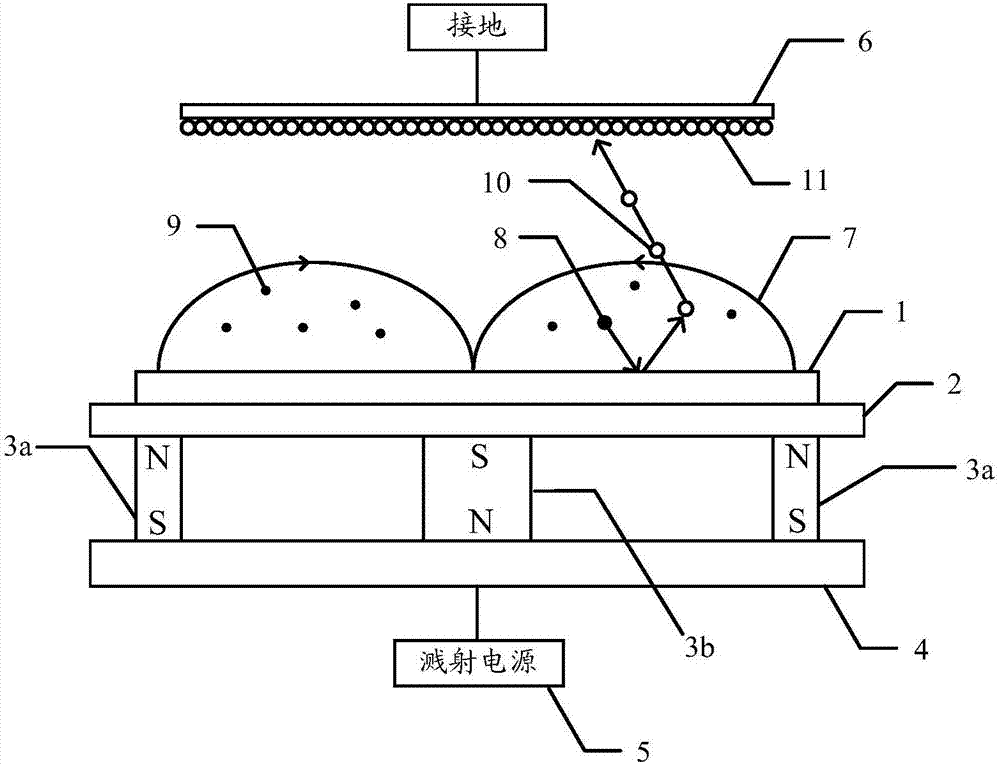

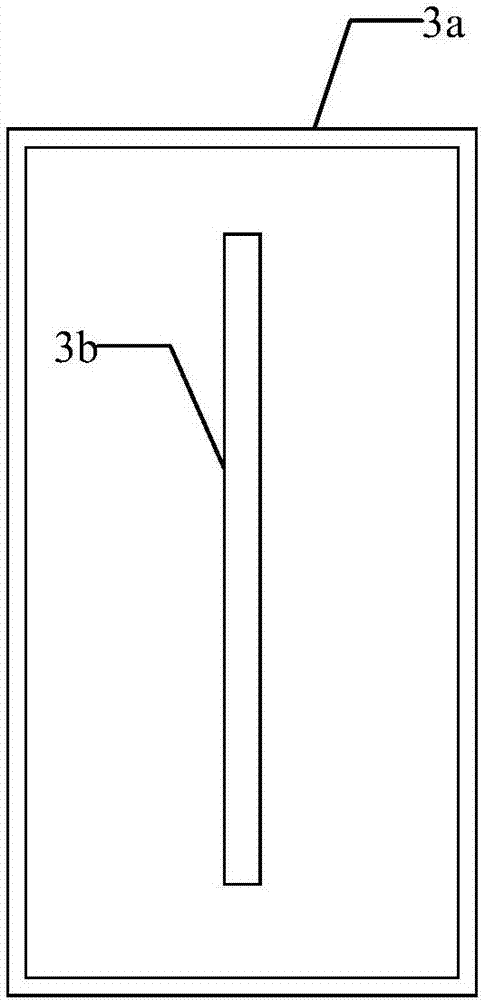

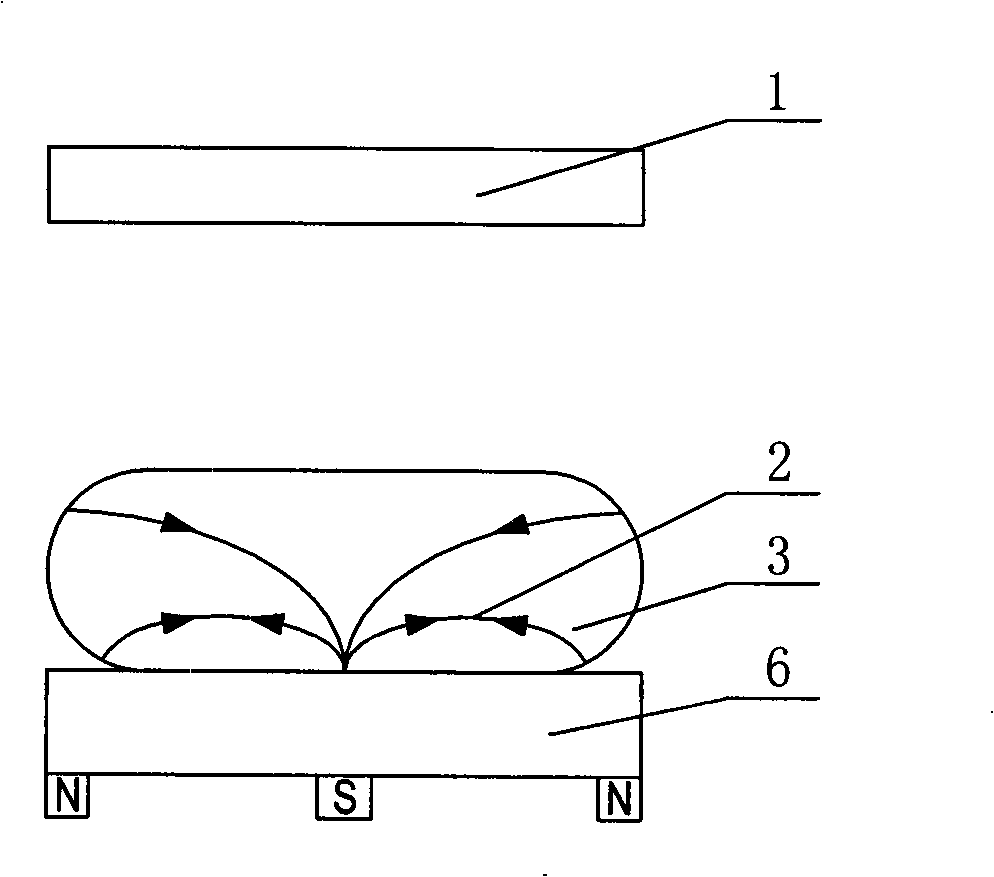

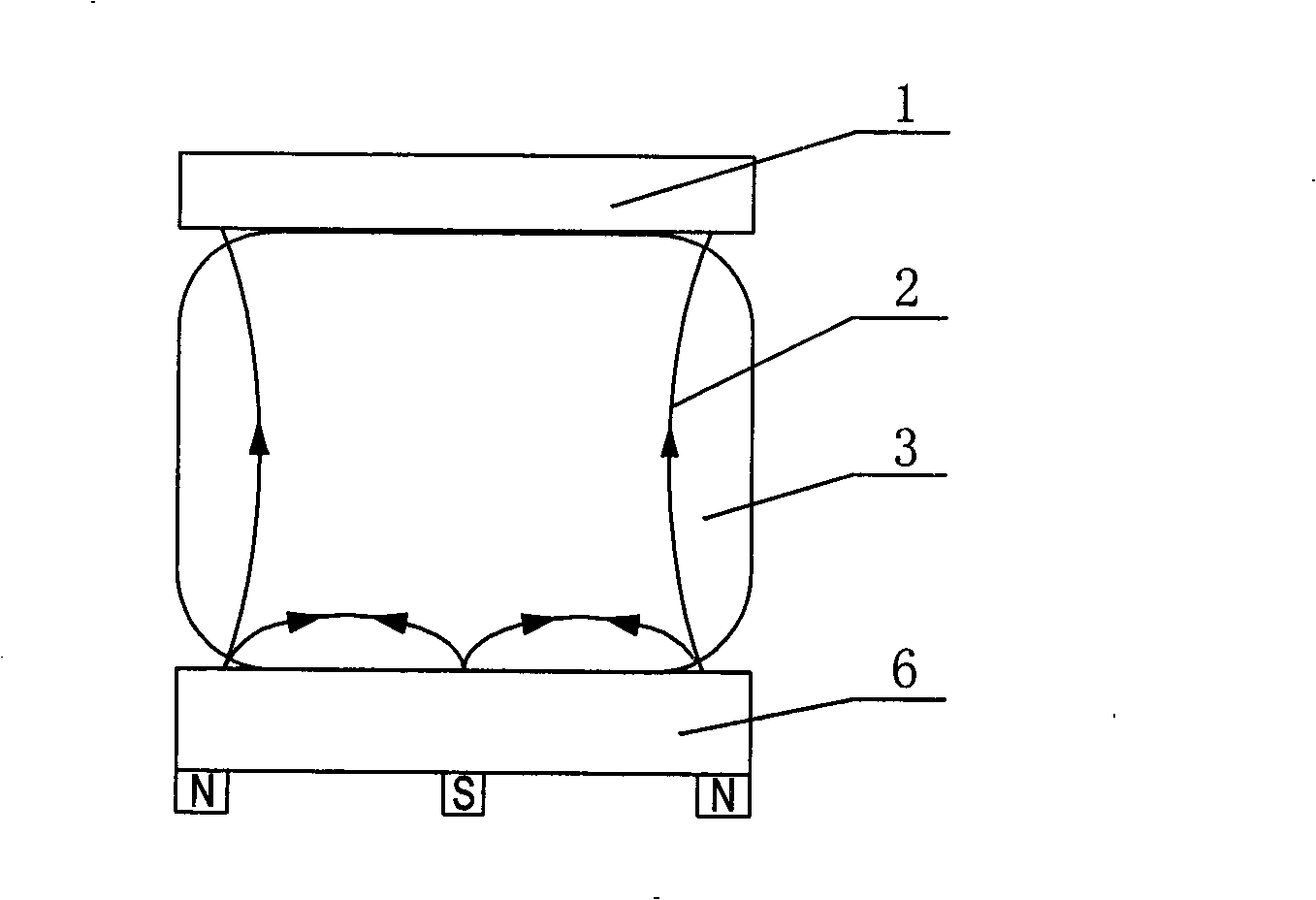

Magnetic confinement magnetron sputtering method and magnetron sputtering apparatus manufactured by the method

InactiveCN101348897AMake a leapReduce internal stressVacuum evaporation coatingSputtering coatingTarget surfaceMagnetic poles

The invention relates to a magnetic confinement magnetron sputtering method and a magnetron sputtering device prepared by use of the same. As the prior art adopts a balanced magnetron sputtering mode and an unbalanced magnetron sputtering mode, the target material utilization rate can only be raised to be between 20 and 35 percent even if permanent magnet movement or the transformation of a plurality of electromagnetic coil sets is adopted, and the prior art has the problems of complex structure and high processing cost. The magnetic confinement magnetron sputtering method forms a magnetic confinement magnetic field with the overall direction parallel to a target surface above the surface of a sputtering target. The magnetron sputtering device manufactured by use of the method comprises a magnet, a magnetic conductor, a substrate and the sputtering target, wherein contrary magnetic poles of the magnet are oppositely fixed on the sides of the sputtering target; the magnetic confinement magnetic field generated by the magnet is positioned between the substrate and the sputtering target, and a connecting line of the two magnetic poles is parallel to the target surface. The magnetron sputtering device can effectively overcome the problem that the prior art is low in target material utilization rate and deposition rate.

Owner:XIAN TECHNOLOGICAL UNIV

Magnetron executing planetary motion adjacent a sputtering target

InactiveUS7169271B2Improve uniformityMore target utilizationCellsElectric discharge tubesCantileverIdler-wheel

Owner:APPLIED MATERIALS INC

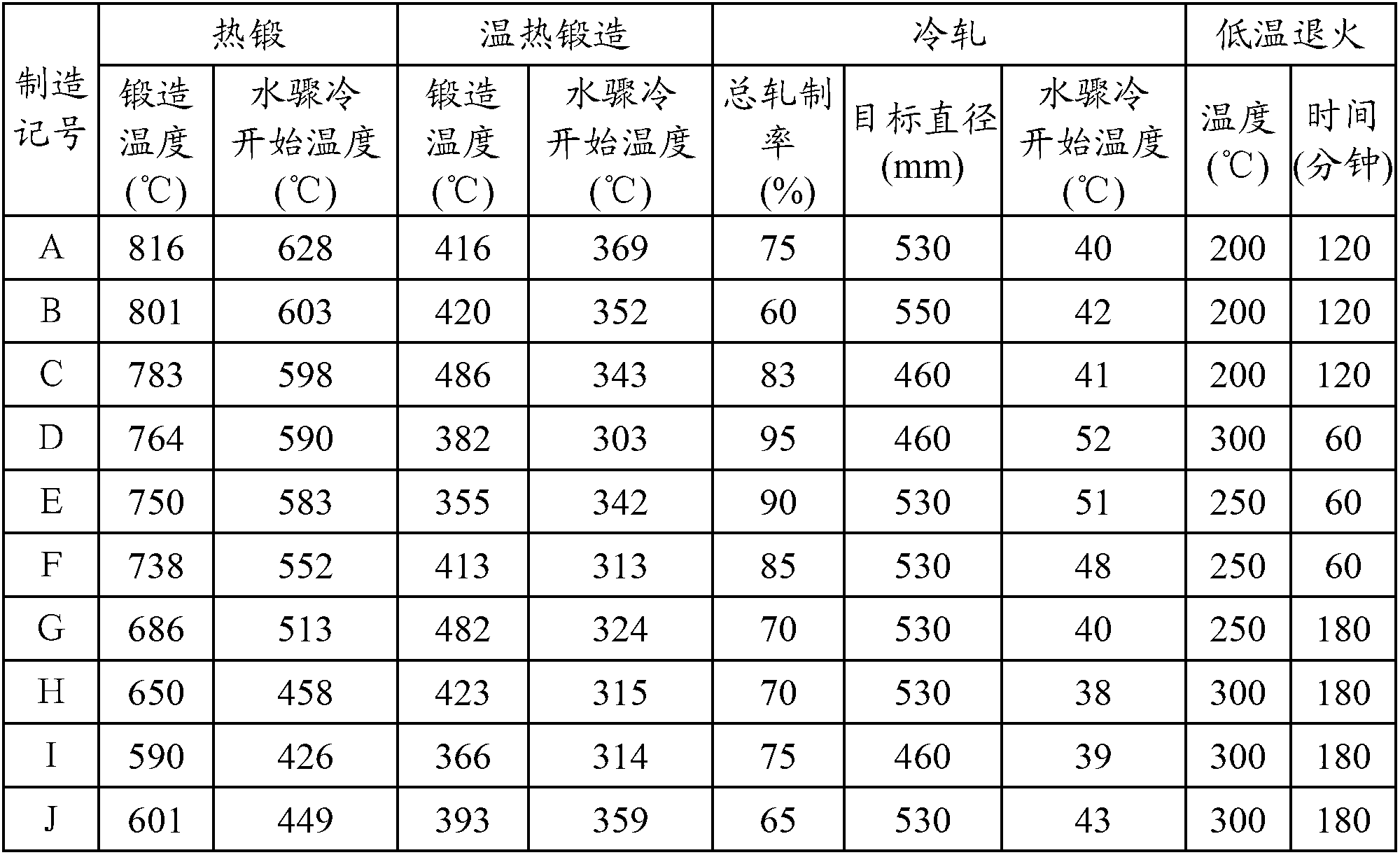

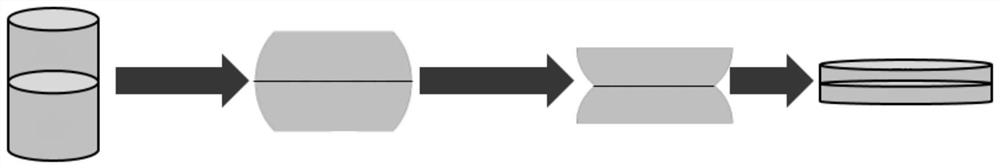

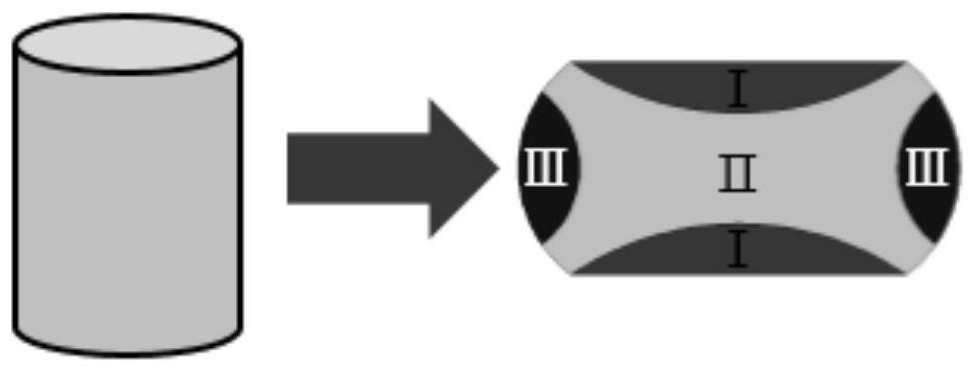

Processed high-purity copper material having uniform and fine crystalline structure, and process for production thereof

ActiveCN102762757AReduce defectsUniform sputteringVacuum evaporation coatingSputtering coatingStress reliefCopper

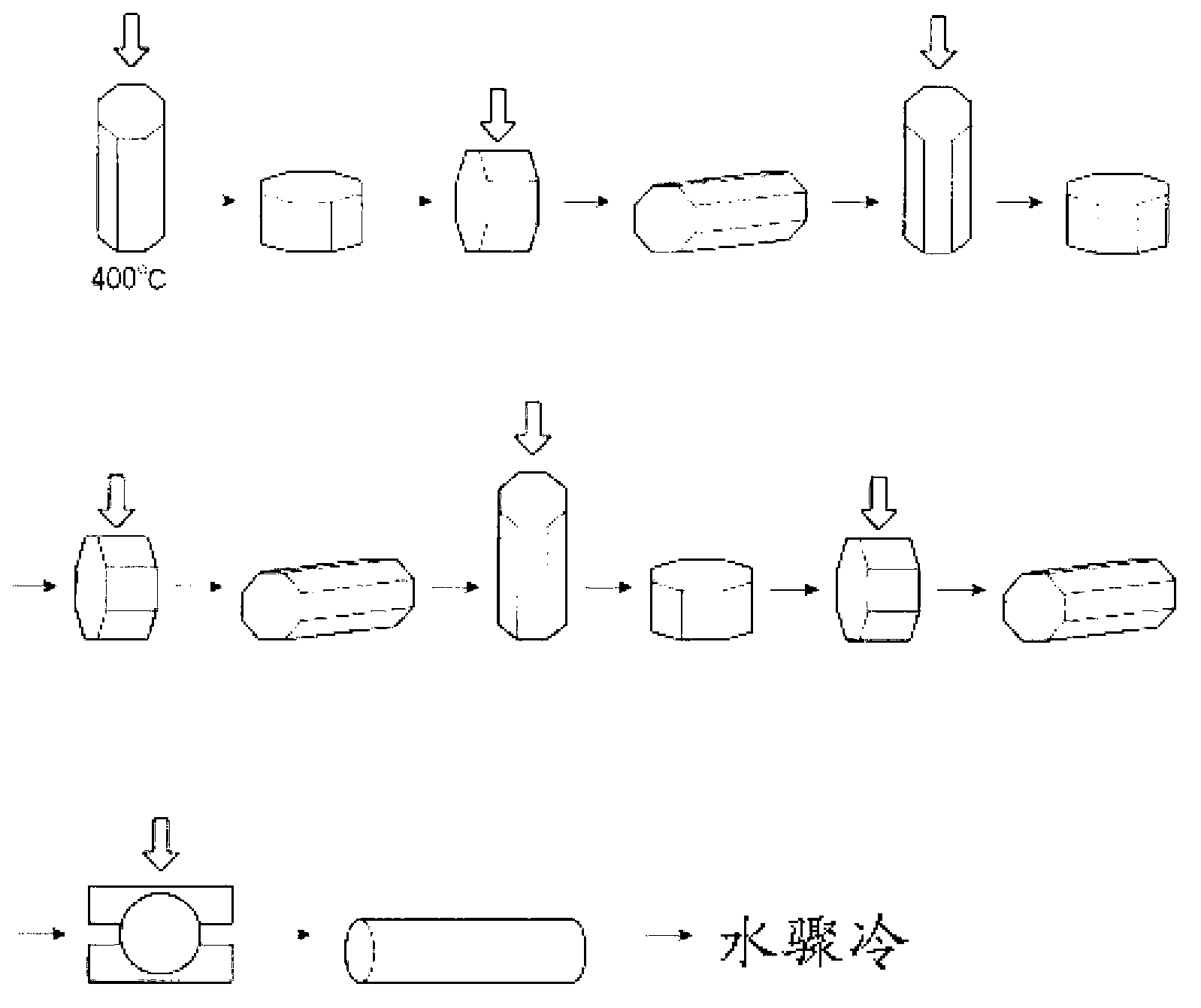

Disclosed is a processed high-purity copper material which comprises Cu having a purity of 99.9999 mass% or more and has an average crystal particle diameter of 20 [mu]m or less, wherein the ratio of an area occupied by crystal particles having particle diameters more than 2.5 times higher than the average crystal particle diameter is less than 10% of the total area occupied by all of the crystal particles in the particle size distribution of the crystal particles. Also disclosed is a process for producing the processed high-purity copper material, which comprises carrying out the hot forging of a mass of a cast comprising high-purity copper having a Cu purity of 99.9999 mass% or more at an initial temperature of 550 DEG C or higher, cooling the hot-forged product with water, carrying out the warm forging of the cooled product at an initial temperature of 350 DEG C or higher, cooling the warm-forged product with water, carrying out the cold cross-rolling of the cooled product at a total reduction of 50% or more, and carrying out the stress relief annealing of the rolled product at 200 DEG C or higher.

Owner:MITSUBISHI MATERIALS CORP

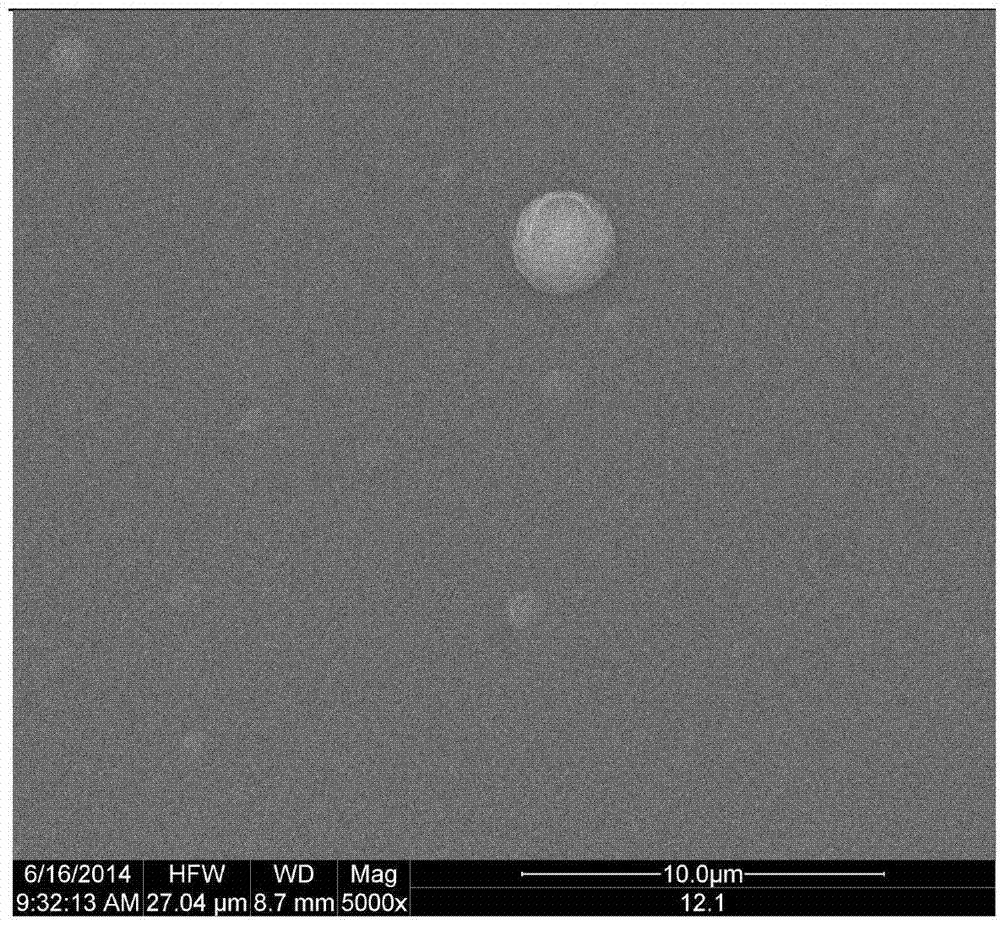

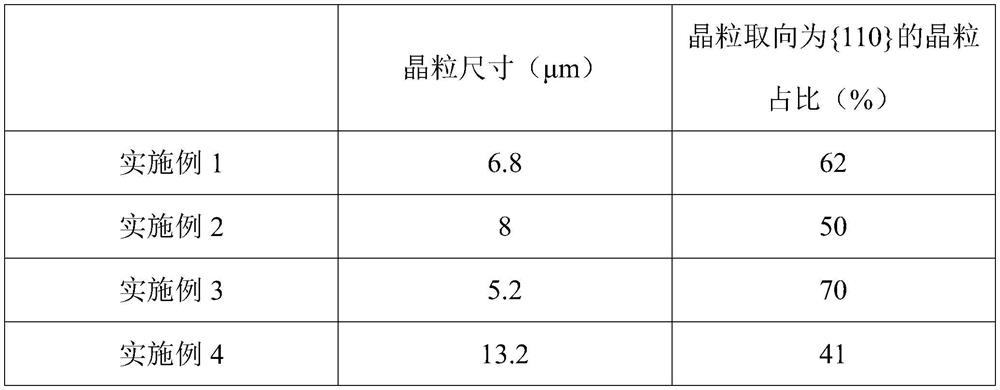

Copper target material as well as preparation method and application thereof

ActiveCN113046705ASmall sizeEvenly distributedVacuum evaporation coatingSputtering coatingThin membraneIngot

The invention provides a copper target material as well as a preparation method and application thereof. The grain size in the copper target material is smaller than or equal to 10 [mu] m, and the proportion of grains with the grain orientation being {110} in the copper target material is 50% -70%. The copper target material is applied to sputtering film forming of an integrated circuit, it can be guaranteed that the performance of the copper target material is stable in the sputtering process, a uniform thin film is formed on the integrated circuit, and the requirement for the sputtering performance below a 7 nm process node is met. The preparation method of the copper target material comprises the step of sequentially carrying out hot forging, first heat treatment, cold forging, second heat treatment, first static pressing, second static pressing and rolling on a copper cast ingot. The preparation method is simple and high in work efficiency.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

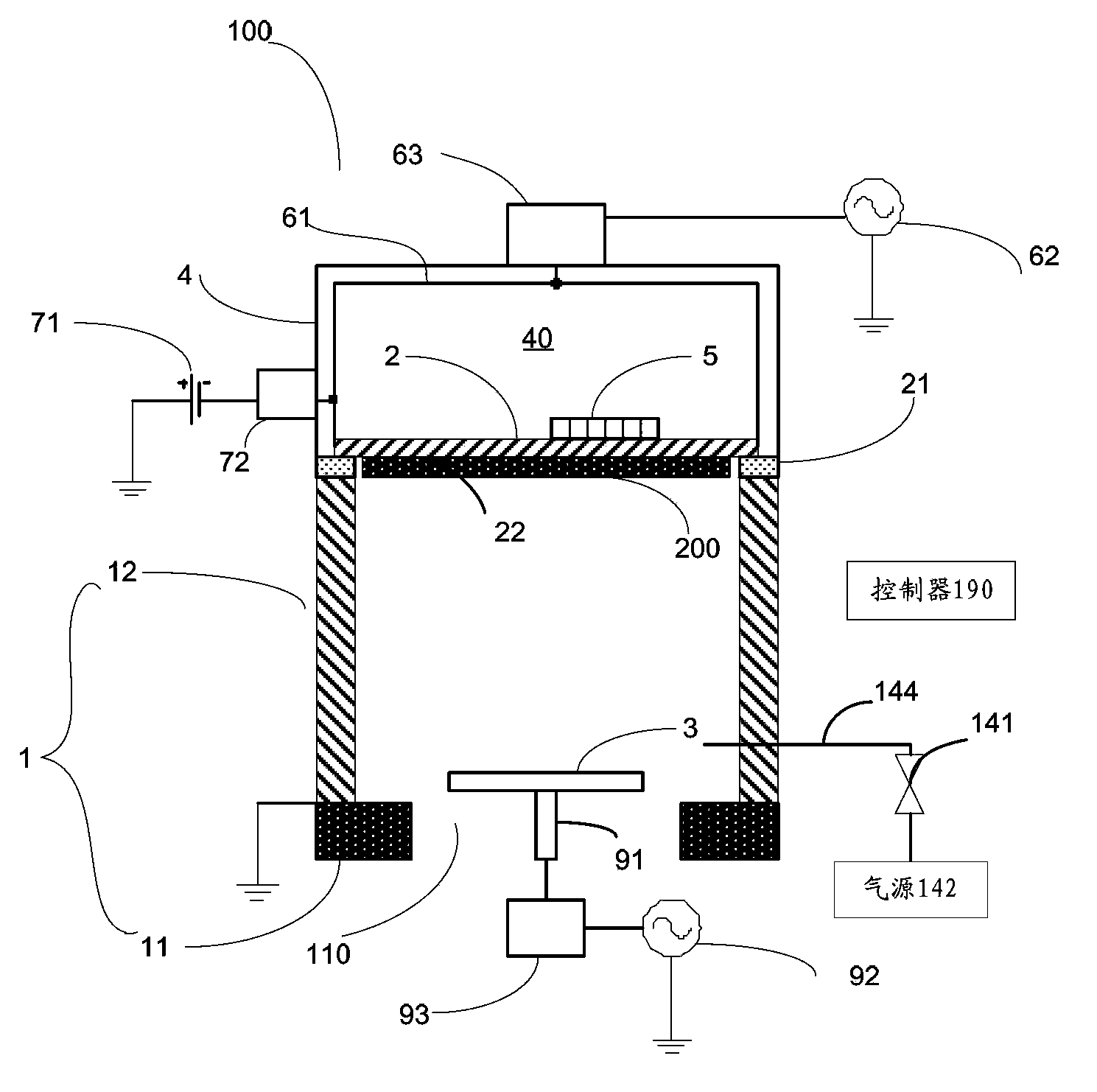

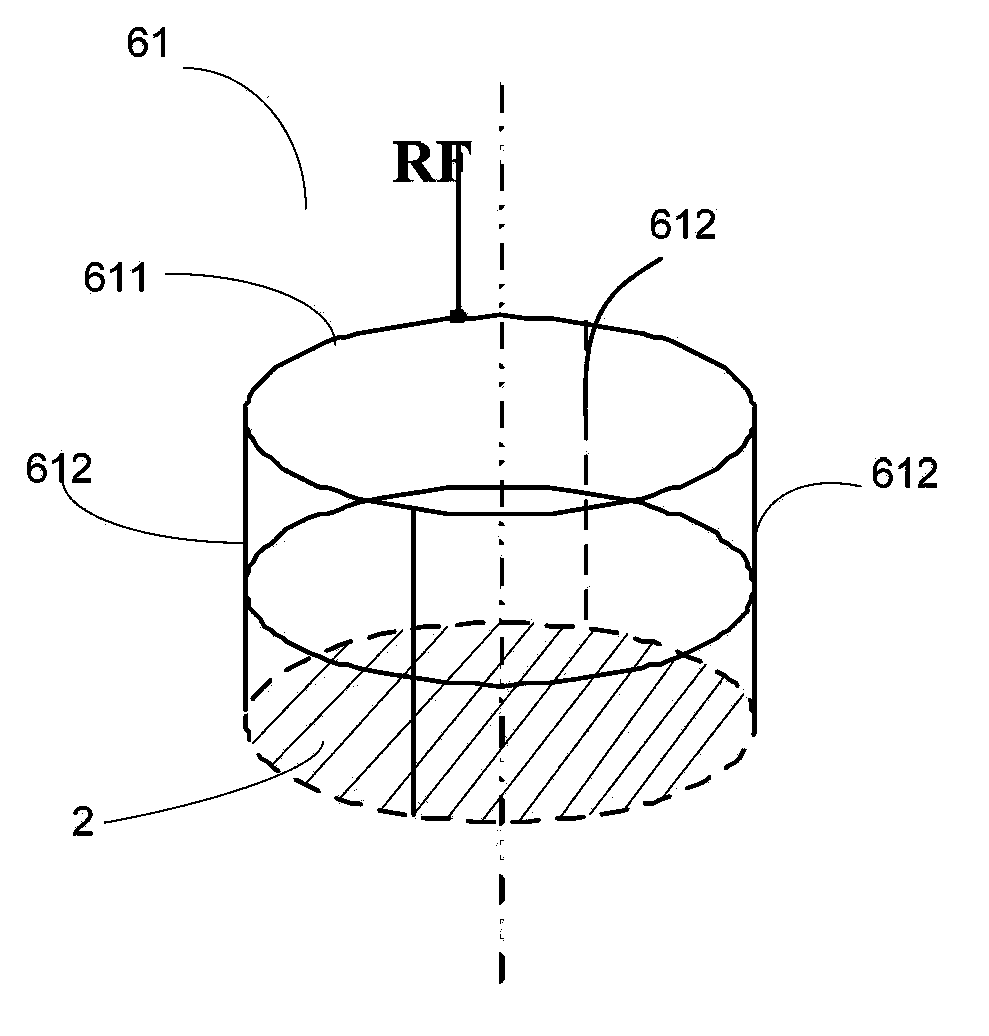

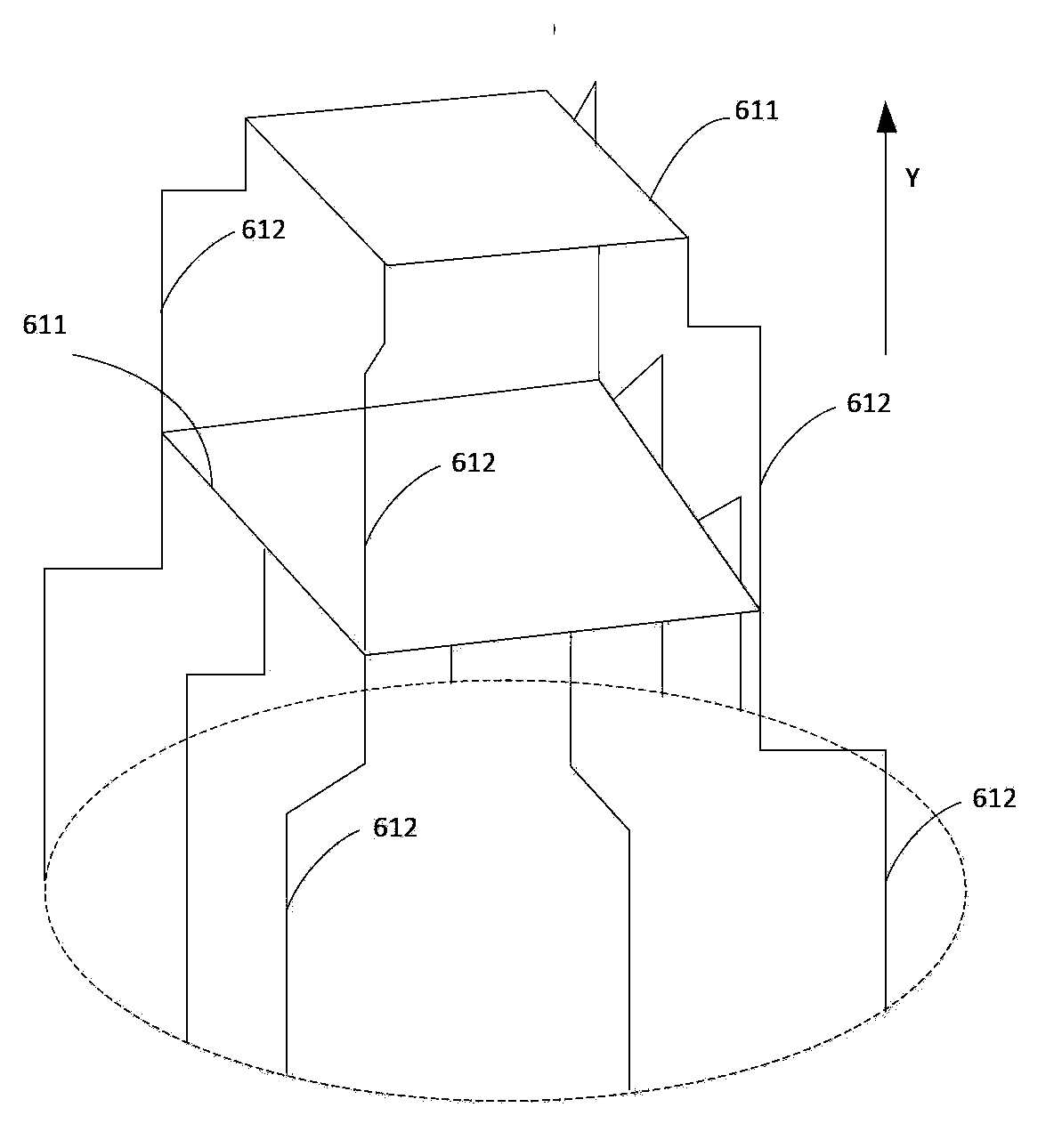

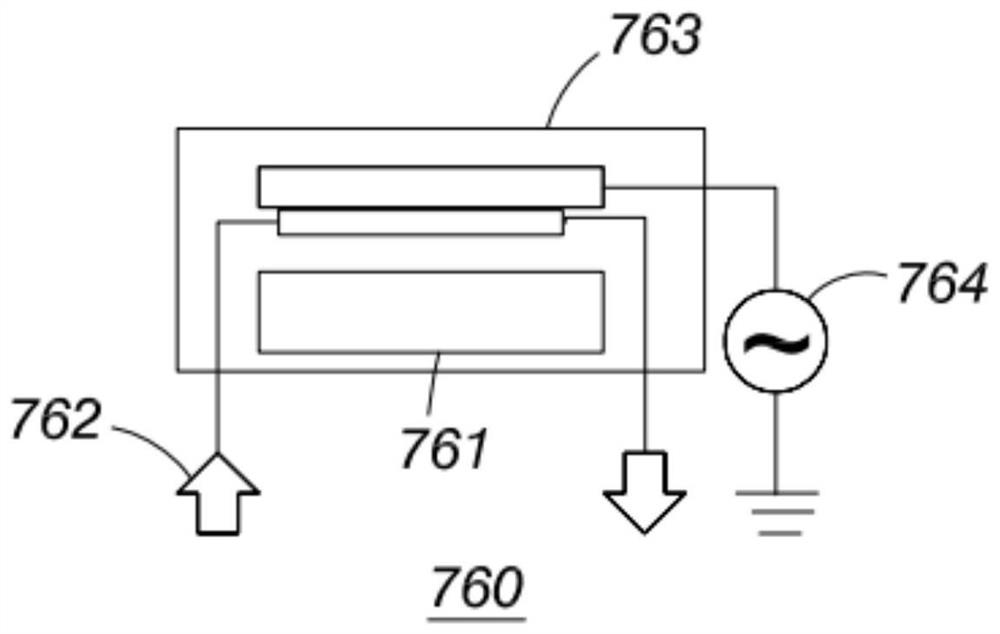

Physical vapor deposition apparatus

ActiveCN103849848AUniform sputteringElectric discharge tubesVacuum evaporation coatingGas phaseProcess efficiency

The present invention discloses a physical vapor deposition apparatus, which comprises: a reaction chamber; a substrate supporting member arranged on the bottom of the reaction chamber and opposite to a sputtering target; a direct current power supply coupled to the sputtering target; and a radio frequency power supply, wherein the radio frequency feed-in member is coupled to the sputtering target, and comprises a distribution ring and a plurality of distribution strips arranged along the circumference of the distribution ring at intervals, and the distribution ring is coupled to the radio frequency power supply and is coupled to the sputtering target through the distribution strip. According to the physical vapor deposition apparatus of the embodiments, the negative bias voltage produced on the target is reduced so as to reduce damage on the substrates or wafers, and the deposition rate is significantly improved so as to improve the process efficiency.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

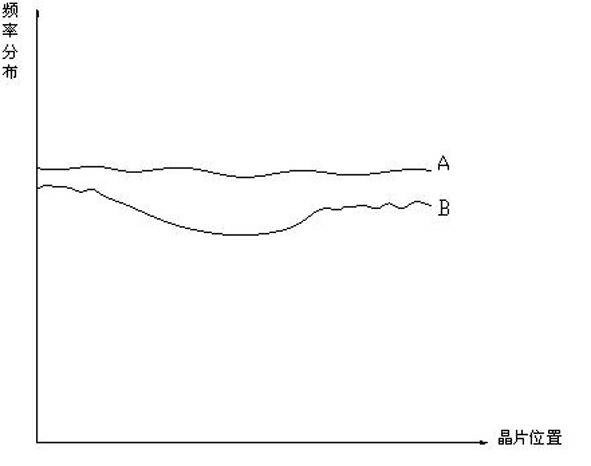

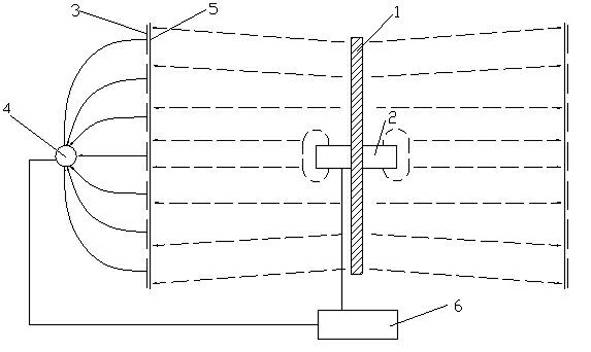

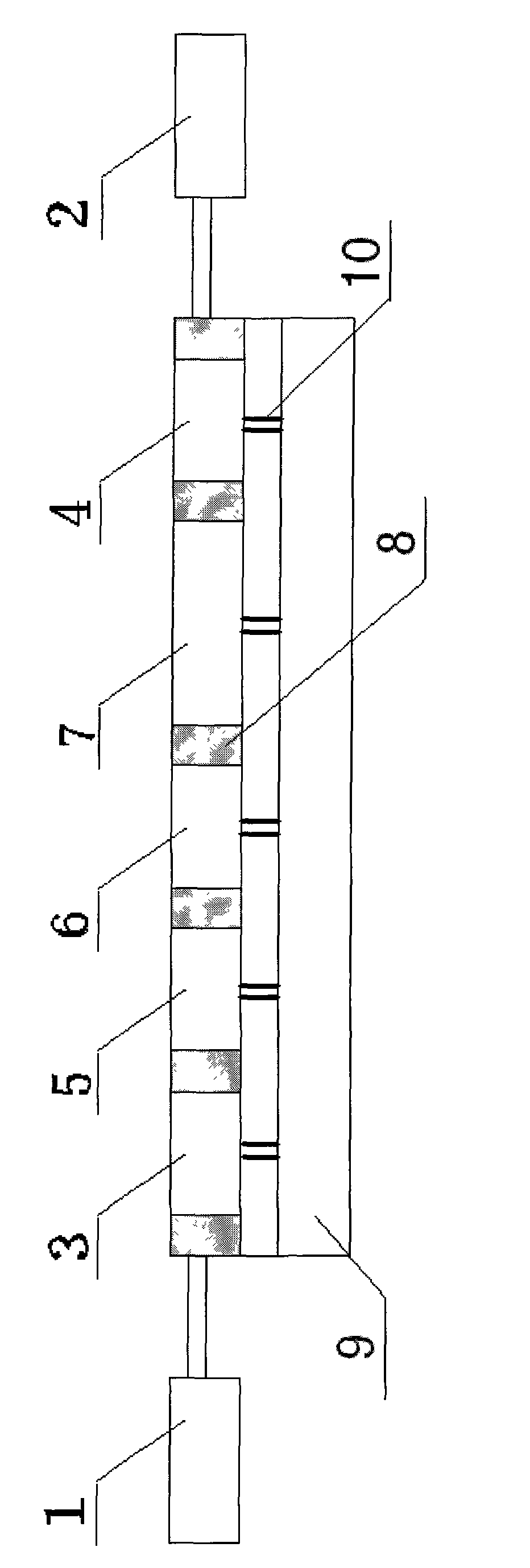

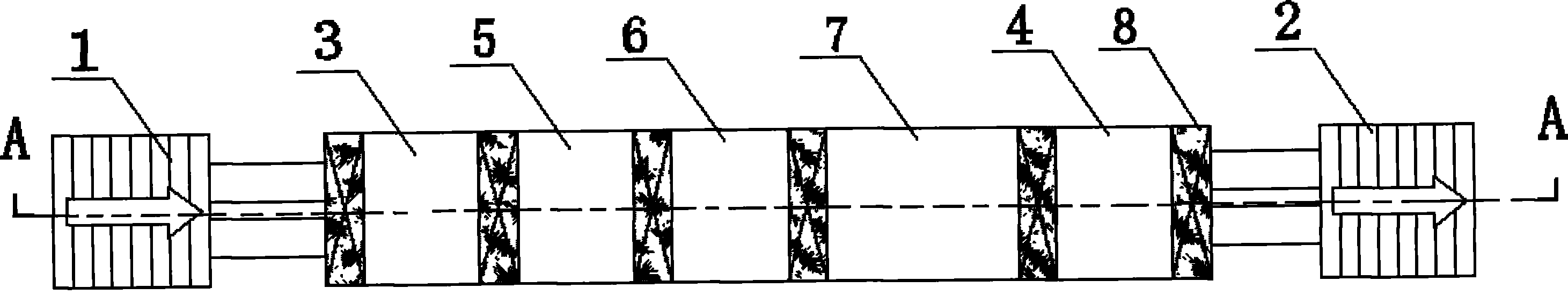

Metal vacuum sputtering device and method

ActiveCN102181841AUniform sputteringMeet production needsVacuum evaporation coatingSputtering coatingSputteringMetallurgy

The invention discloses a metal vacuum sputtering device and method. The device comprises a rod-shaped metal target and a wafer tool, wherein the middle position of the rod-shaped metal target is provided with a balance coil connected with a power source, the balance coil generates an additional electromagnetic field in the case of being energized, the total electromagnetic field in a metal vacuum sputtering system is influenced by the additional electromagnetic field so as to reduce the quantity of ions reaching the surfaces of wafers near the balance coil, and finally, the thickness shear resonant frequencies of the wafers are enhanced to result in consistent sputtering thickness of the wafers on the entire wafer tool, thereby ensuring excellent frequency consistency of the wafers of the sputtered metal electrode film.

Owner:INTERQUIP ELECTRONICS

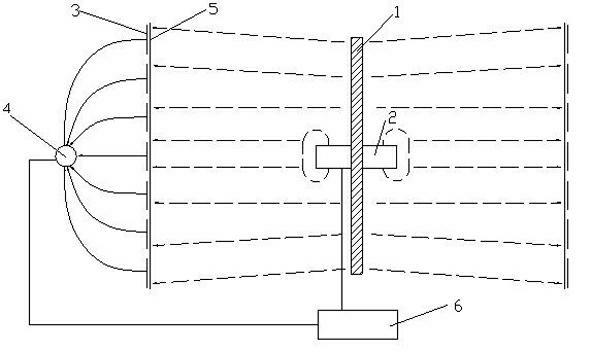

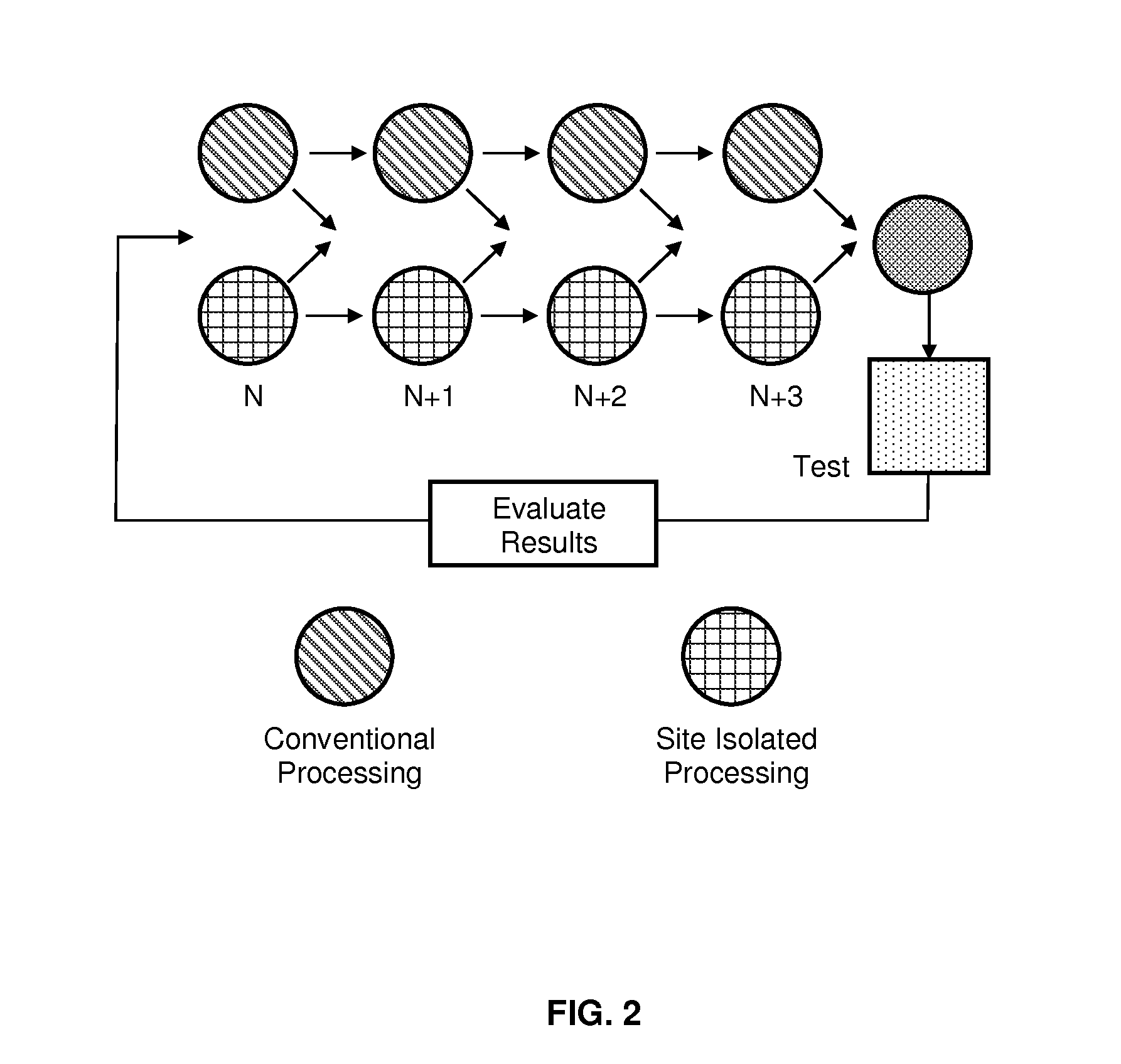

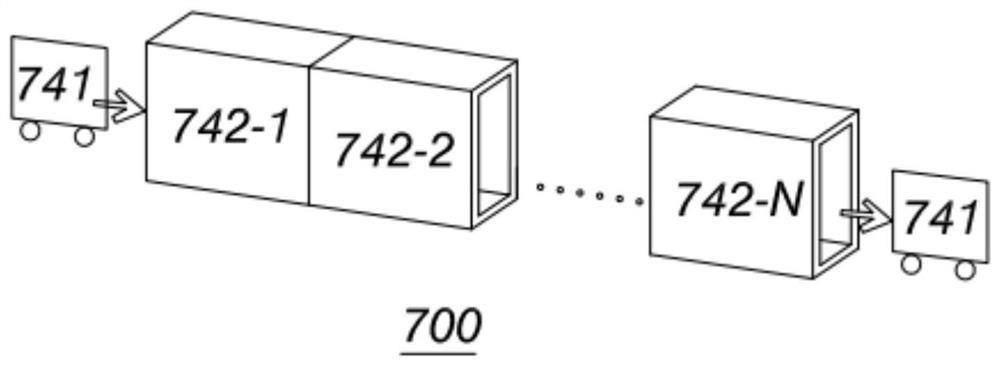

Combinatorial Processing Using High Deposition Rate Sputtering

InactiveUS20130167773A1Increase deposition rateGap minimizationVacuum evaporation coatingSputtering coatingSputteringTransport system

Apparatuses and methods for high-deposition-rate sputtering for depositing layers onto a substrate are disclosed. The apparatuses generally comprise a process chamber; one or more sputtering sources disposed within the process chamber, wherein each sputtering source comprises a sputtering target; a substrate support disposed within the process chamber; a shield positioned between the sputtering sources and the substrate, the shield comprising an aperture positioned under each sputtering source; and a transport system connected to the substrate support capable of positioning the substrate such that one of a plurality of site-isolated regions on the substrate can be exposed to sputtered material through the aperture positioned under each of the sputtering sources; wherein the spacing between the sputtering target and the substrate is less than 100 mm. The apparatus enables high deposition rate sputtering onto site-isolated regions on the substrate.

Owner:INTERMOLECULAR

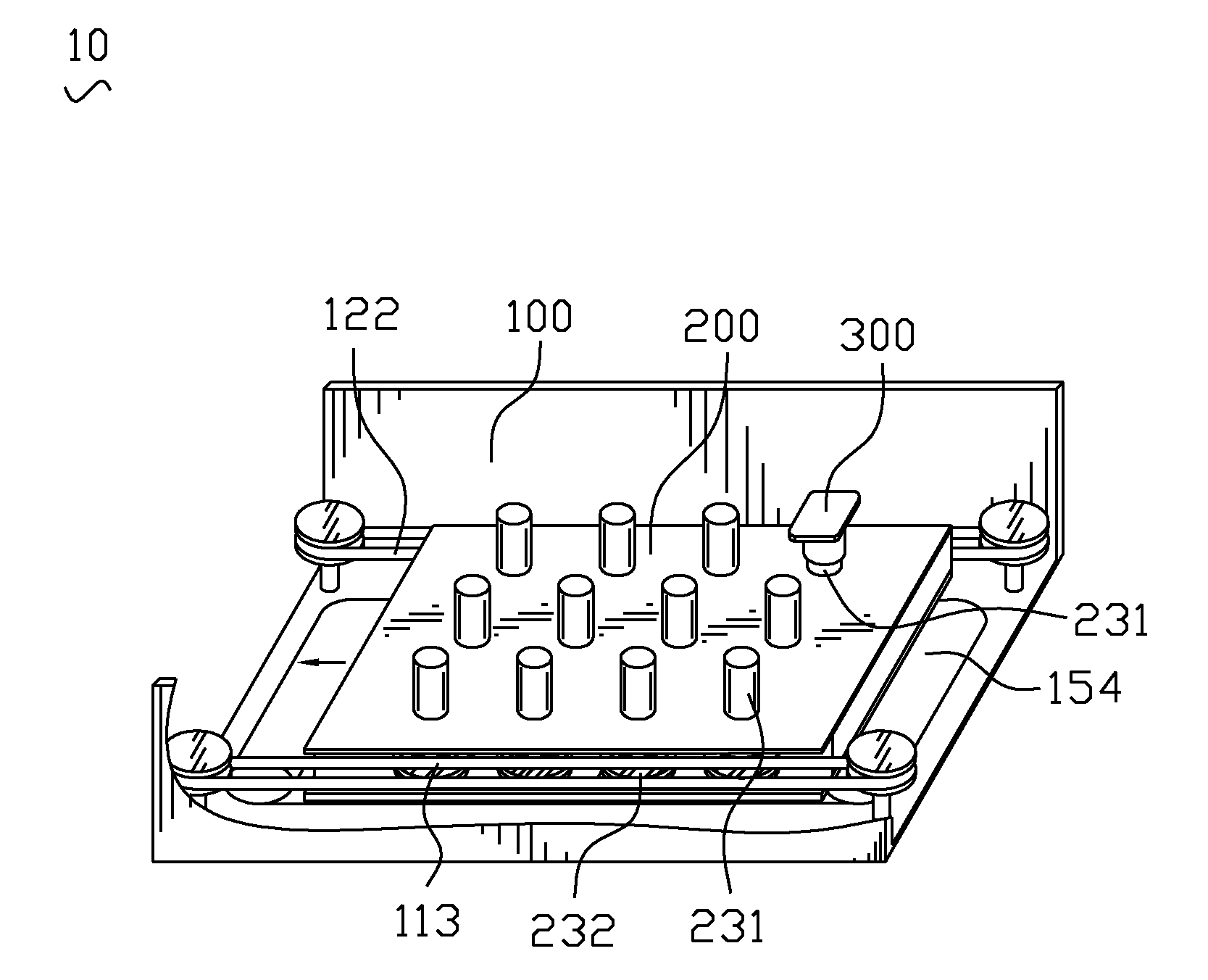

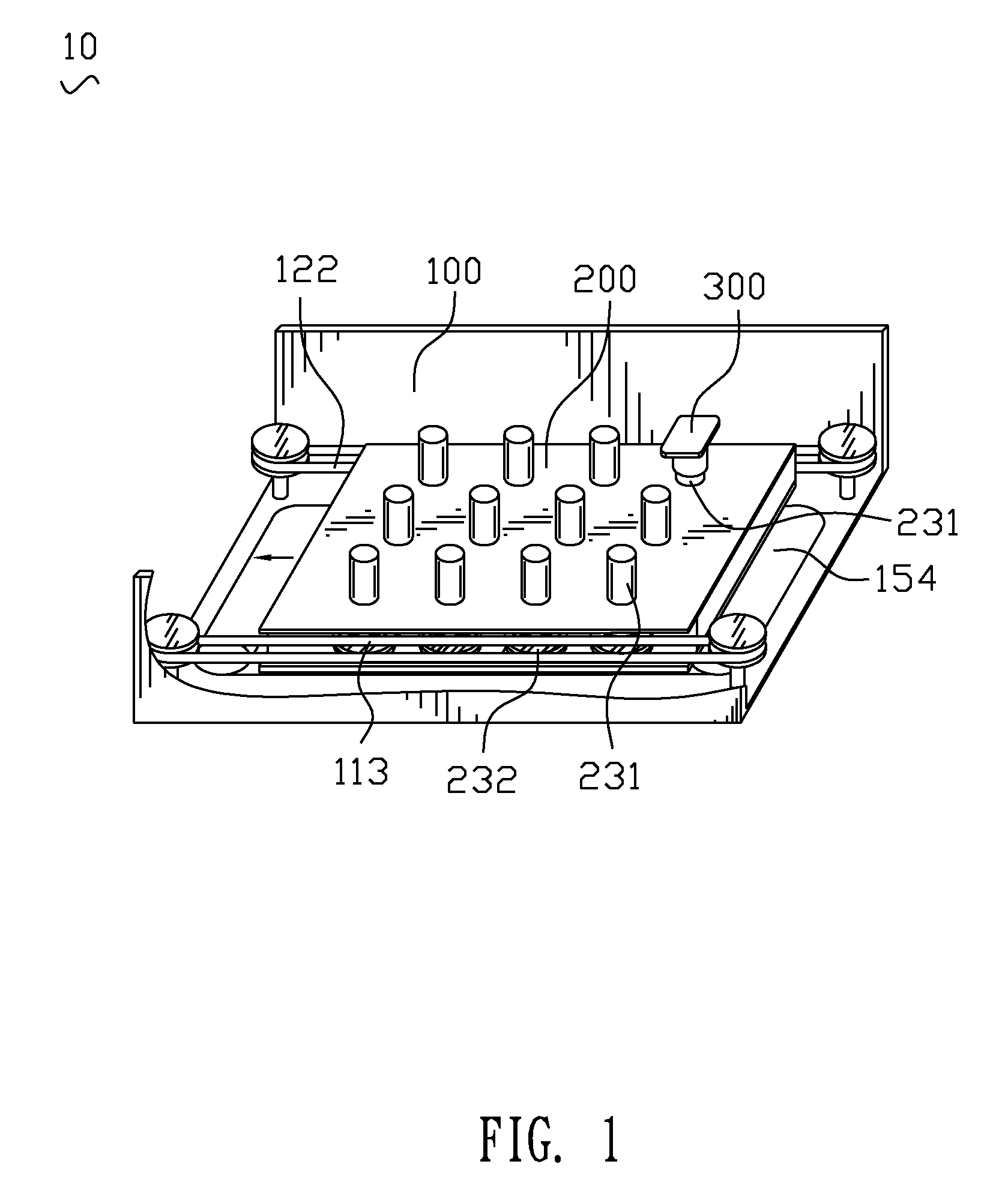

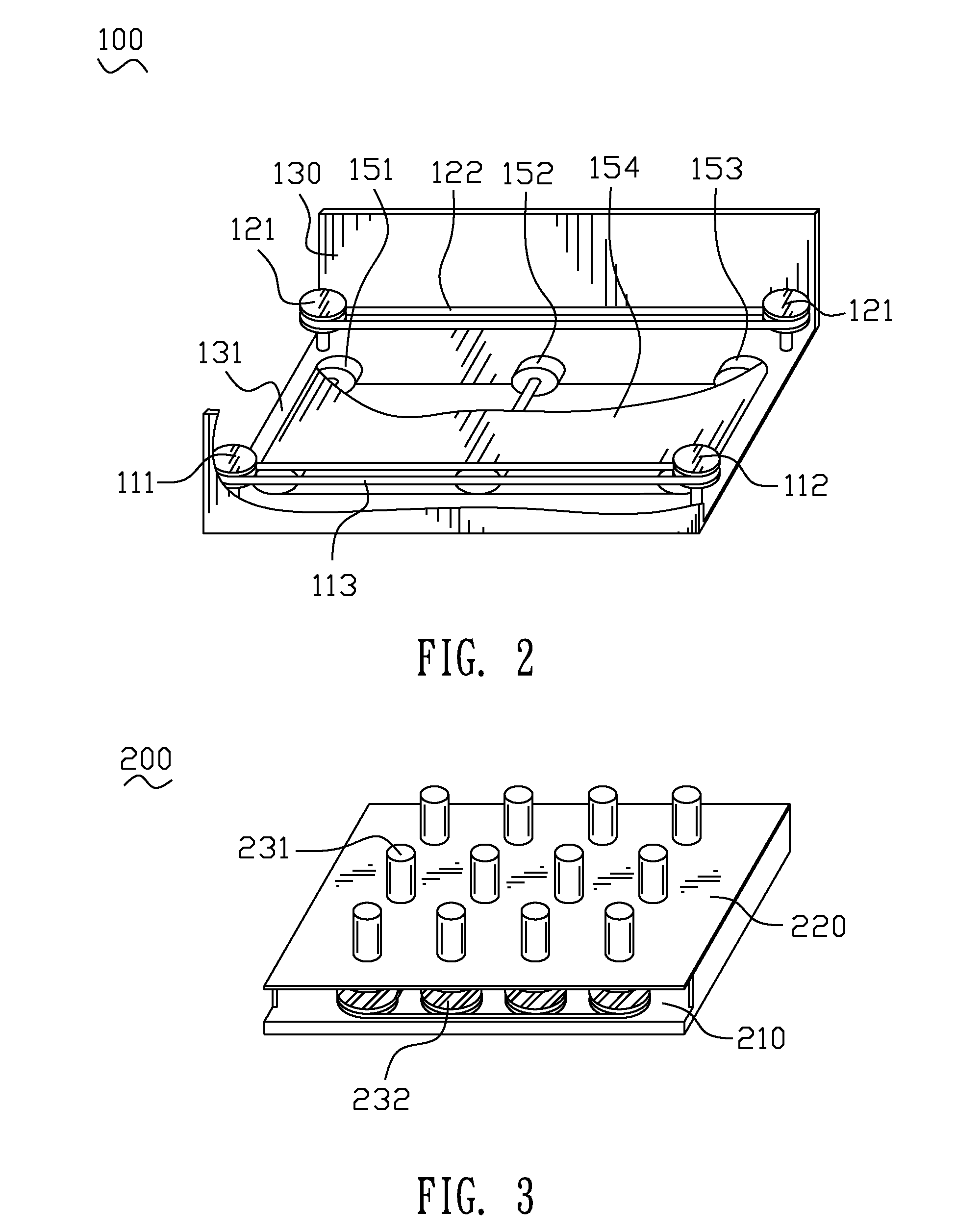

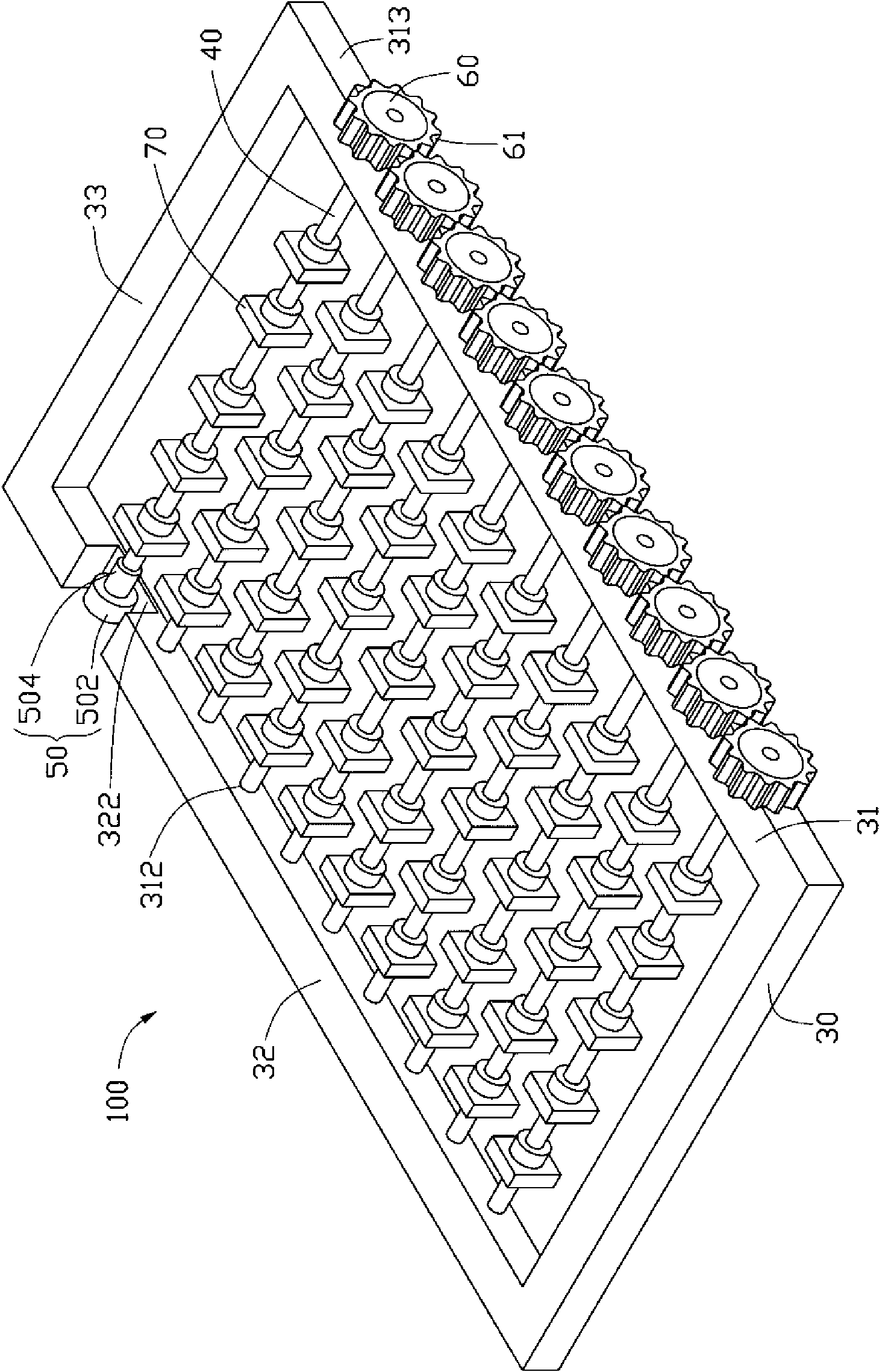

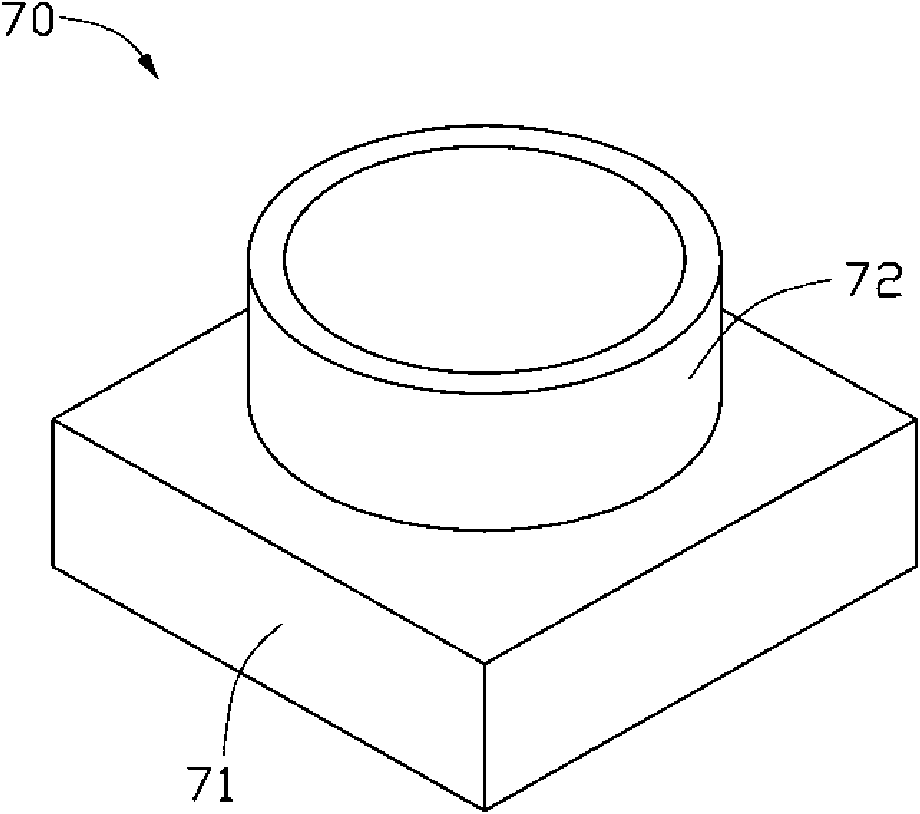

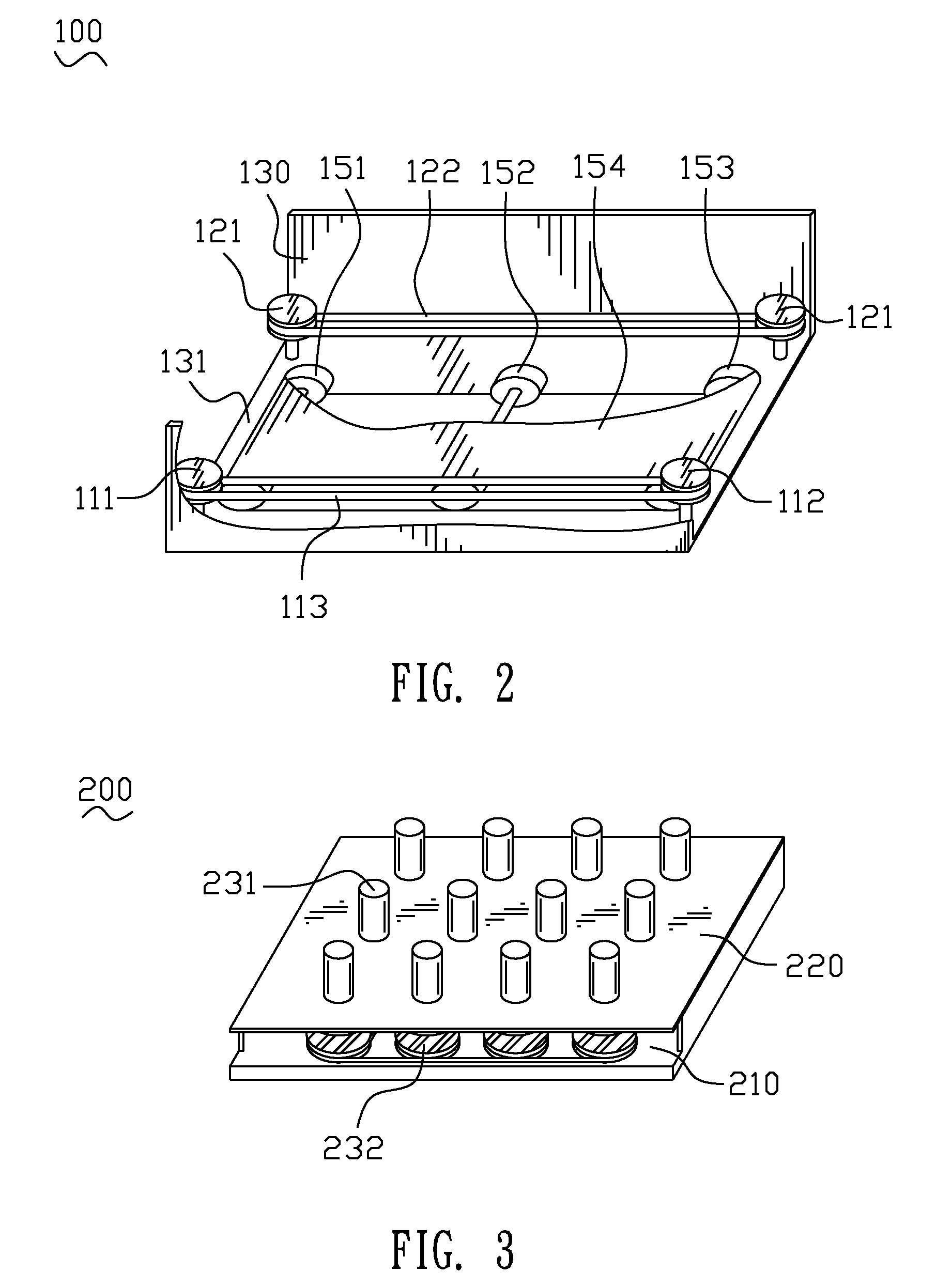

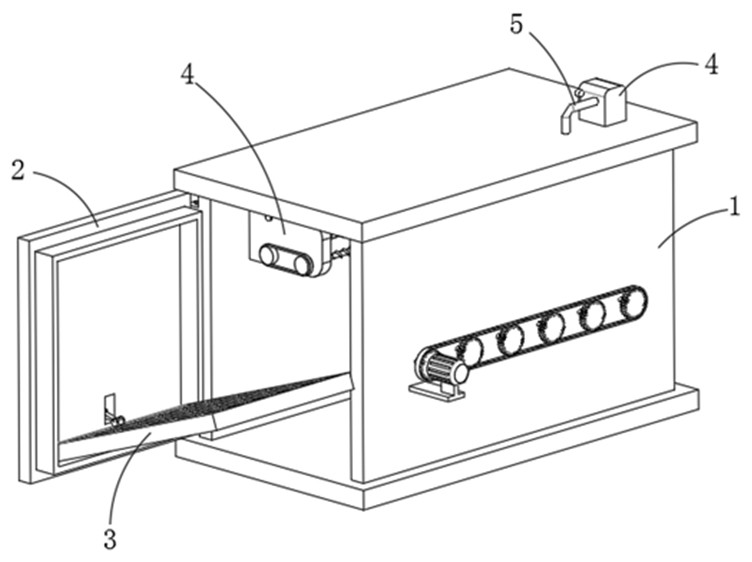

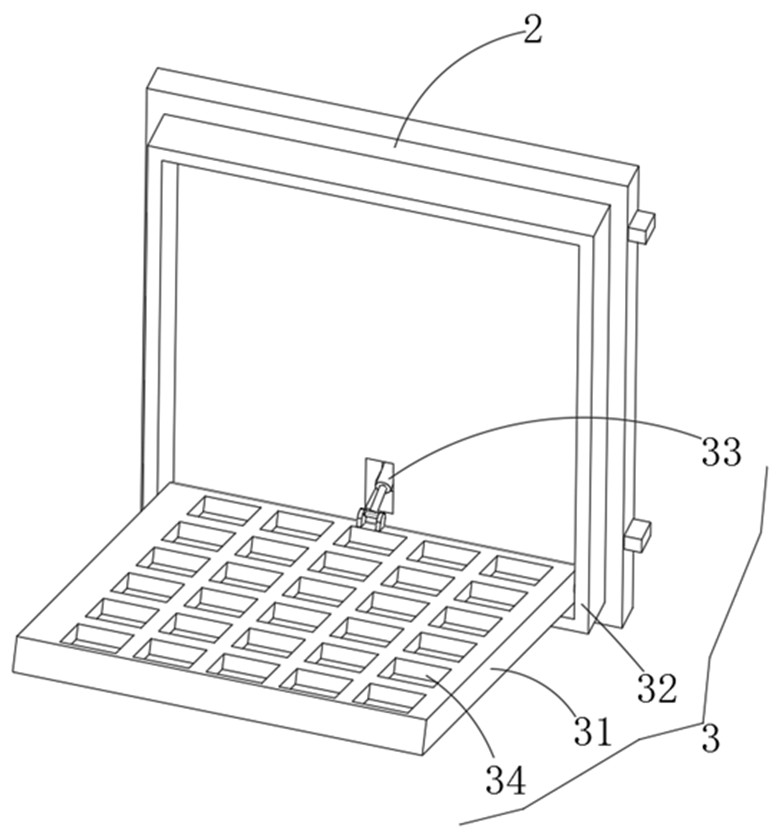

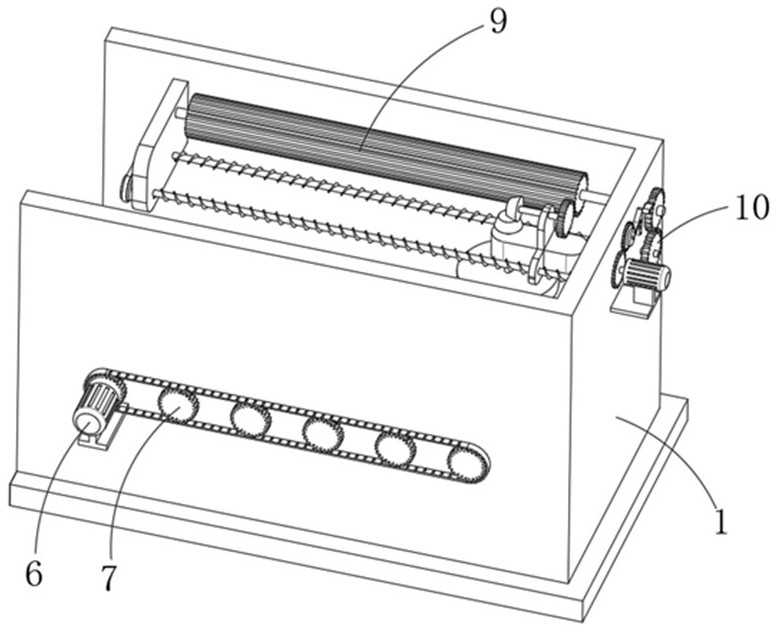

Workpiece-transporting arraratus of in-line sputtering machine

InactiveUS20090014933A1Uniform sputteringLiquid surface applicatorsVacuum evaporation coatingDrive wheelEngineering

A workpiece-transporting apparatus of in-line sputtering machine includes a conveyer unit and a carrying salver. The conveyer unit has a holder, and a transporting wheel group is arranged in the holder. A conveyer belt covers around the transporting wheel group. A driving wheel group is arranged in one side of the conveyer belt and located in the holder. The driving wheel group connects to a motor and surrounded by a connecting belt. The carrying salver is placed on the conveyer belt of the conveyer unit. The carrying salver has a base, a plurality of supporting shafts are assembled in the base and linked together for being driven together. A workpiece base is arranged on the supporting shafts. At least one of the supporting shafts is surrounded by a supporting wheel. The supporting wheel engages with the connecting belt for being driven by the connecting belt.

Owner:CHENG UEI PRECISION IND CO LTD

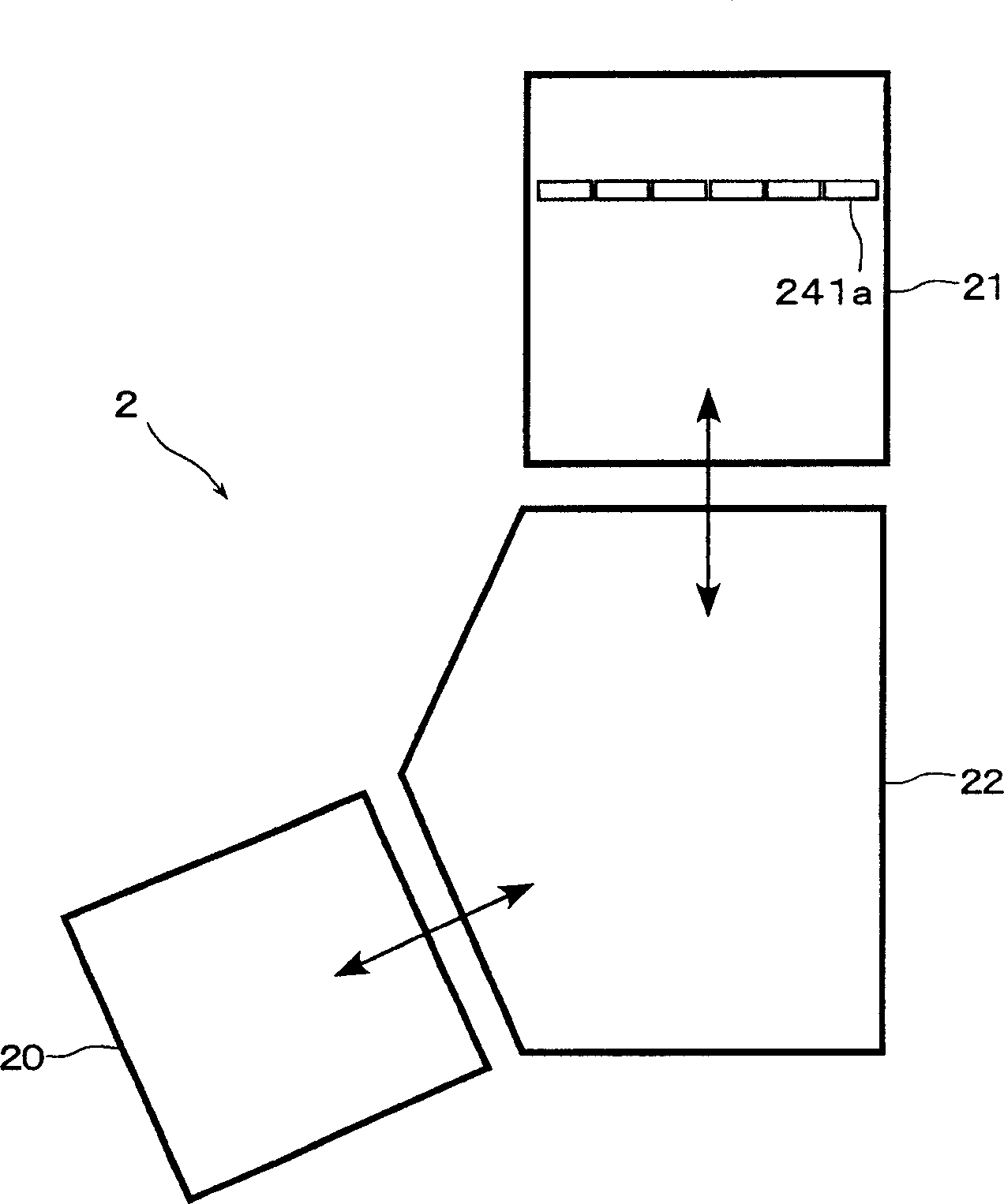

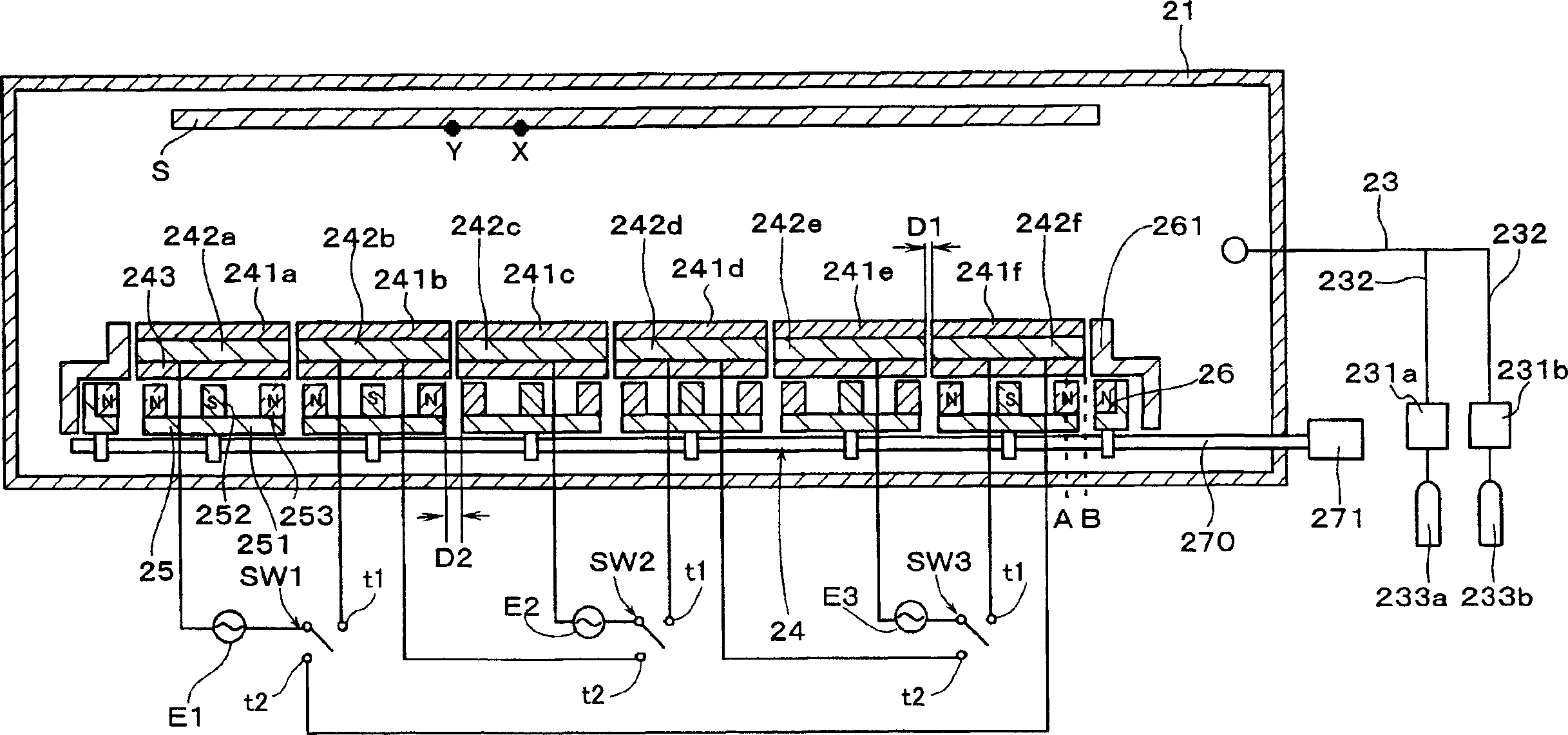

Sputtering device and sputtering method

ActiveCN1904133AUniform film qualityUniform sputteringVacuum evaporation coatingSputtering coatingNegative potentialEngineering

A sputtering apparatus which does not spoil the non-corrosive area on the target and gives uniform film during the reactive sputtering process is disclosed. The sputtering apparatus 2 comprises:(a) supplying a space to set more than three targets 241 in the vacuum chamber 21. (b)using alternating current power supply E1~E3 to alternatively charge each target 241 with negative potential and positive potential or with the ground potential, which is characterized by using at least one of branched outputs of the alternating current power supply E1~ E3 to connect more than two of targets 241, and placing the switches SW1~ SW3 which are the switches to control charging potential to targets from alternating current supply between targets 241 connected by branched outputs.

Owner:ULVAC INC

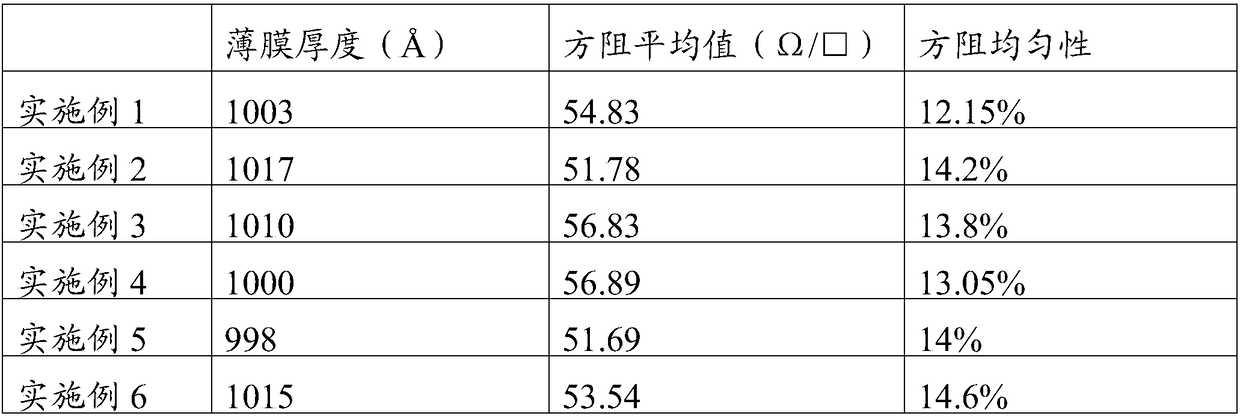

ITO (indium tin oxide) thin film and preparation method thereof

ActiveCN108374155AReduce square resistanceImprove uniformityVacuum evaporation coatingSputtering coatingIndium tin oxideFlow ratio

The invention relates to a preparation method of ITO (indium tin oxide) thin film. The method comprises the following steps: placing a substrate in a chamber, and setting a distance between a target and the substrate to be 56-65mm; carrying out vacuumizing treatment and heating treatment on the chamber to enable the temperature of the substrate to be 285-328 DEG C; introducing argon gas into the chamber, adjusting the vacuum degree of the chamber to be 3.9-5.1mTorr, and setting sputtering power to be 68-82W; continuing to introduce oxygen gas into the chamber, and adjusting the flow ratio of the argon gas to the oxygen gas to be (33 to 1)-(38 to 1); forming the ITO thin film on a surface of the substrate by using a magnetron sputtering method. According to the preparation method of the ITOthin film, the prepared ITO thin film has good film thickness uniformity through adjustment and cooperation of various process parameters at relatively low sputtering power.

Owner:TSINGHUA UNIV

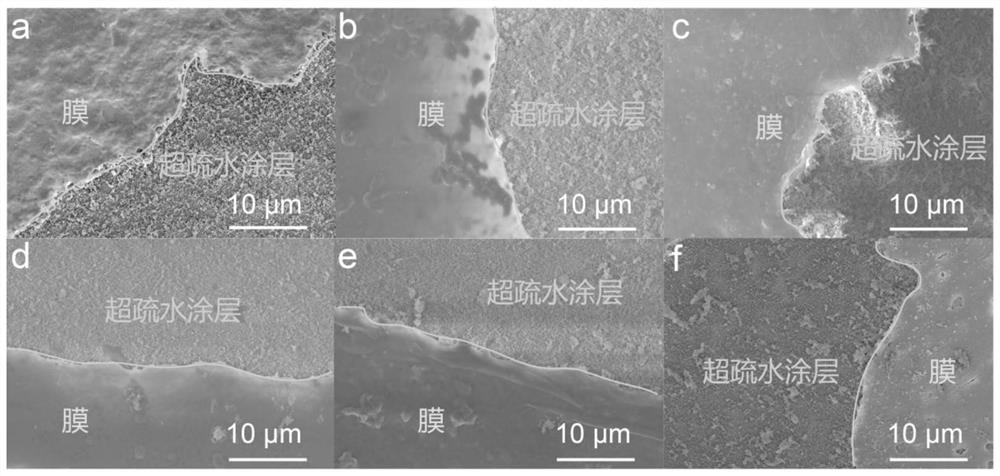

Protein product capable of fixing target object and being removed as required

ActiveCN111802385AEasy to prepareGood biocompatibilityCosmetic preparationsBiocideLactalbuminPancreatic hormone

The invention discloses a protein product capable of fixing a target object and being removed as required. The protein product comprises a protein (lysozyme, bovine serum albumin, whey albumin, insulin, alpha-lactalbumin, fibrinogen, ribonuclease A, cytochrome c, alpha-amylase, horse radish peroxidase, pepsase, myoglobin, collagen, keratin or the like), a protein modifier (a strong oxidant or a strong reducing agent), and a target fixture (a paint, a pesticide, a chemical fertilizer, a cosmetic, a medical drug or the like). According to the invention, a protein membrane generated by protein phase transformation is used for fixing the target fixture on a target surface, so the utilization rate of the target fixture is improved, and the problems of resource waste, environmental pollution andthe like caused by loss of the target fixture are reduced. In addition, as the protein membrane is decomposed, the target fixture can also be effectively removed. The main component, namely the protein is safe and environment-friendly, biocompatibility is high, a preparation method is simple, and the protein product has wide prospects in practical application.

Owner:西安清秀生态科技有限公司

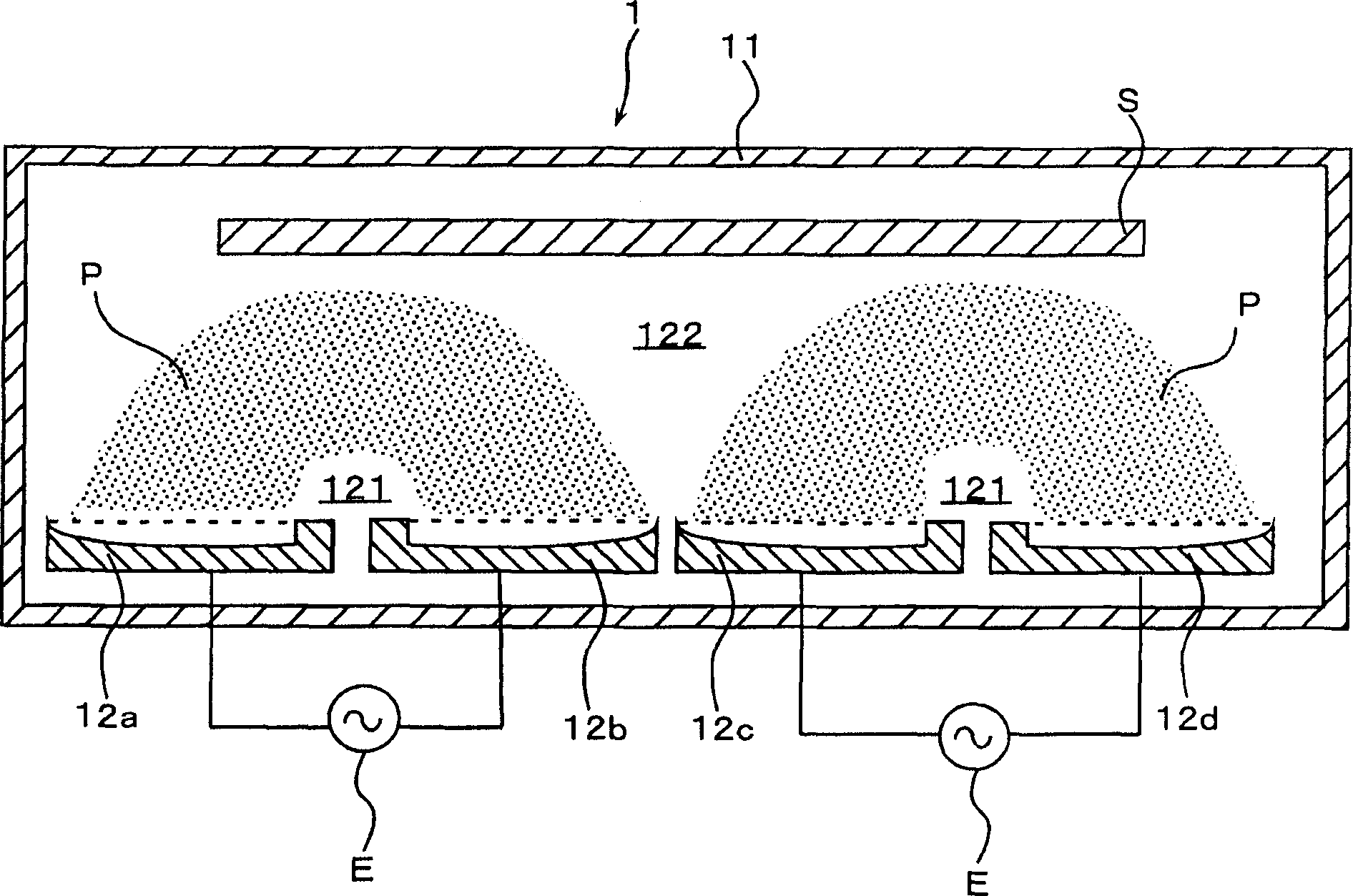

Sputtering apparatus

ActiveUS20080210556A1Improve efficiencySimple structureCellsElectric discharge tubesSputteringMagnetic tension force

A sputtering apparatus with high usage efficiency of a target is provided. A sputtering apparatus of the present invention includes first and second ring magnets, first and second magnet members arranged inside a ring of the first and second ring magnets, wherein in the first and second ring magnets and the first and second magnet members, magnetic poles with the same magnetism are faced toward the rear surface of a first and a second targets. Thus, in the rear surface of the first and second targets, the magnetic poles with the same polarity are adjacently arranged, and the absolute value of the strength of horizontal magnetic field components formed in the surfaces of the first and second targets becomes small and the strength distribution becomes narrow, and the strength of vertical magnetic field components becomes uniform; and consequently, a non-erosion portion is not produced in the first and second targets.

Owner:ULVAC INC

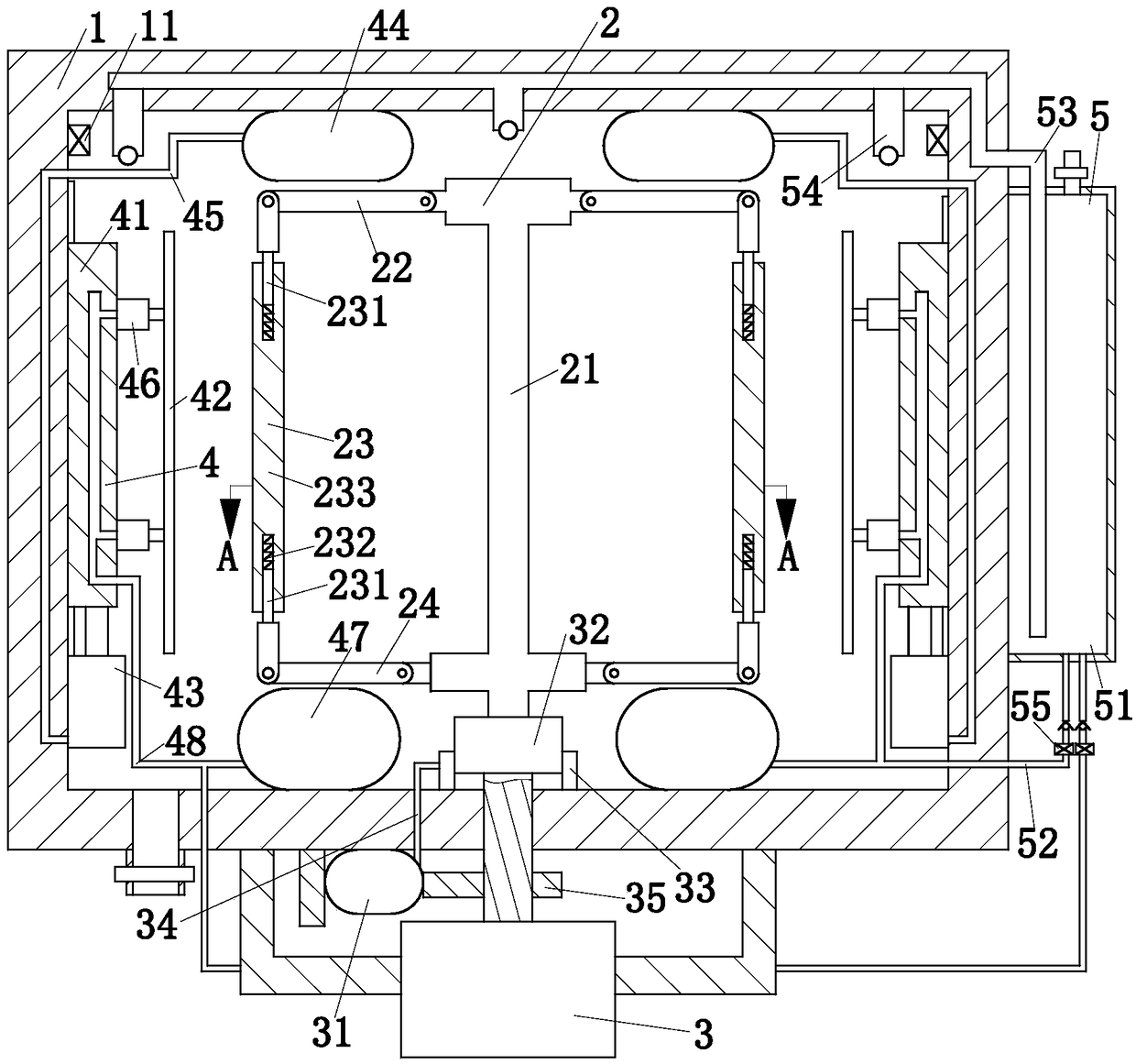

Film coating system for depositing metal on plastic substrate surface on basis of glow discharge principle

ActiveCN108950497AUniform sputteringImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention belongs to the technical field of film coating, and particularly relates to a film coating system for depositing metal on the plastic substrate surface on the basis of the glow dischargeprinciple. The film coating system comprises a box body, a motor and a bearing device; the bearing device is driven by the motor and comprises a lower supporting plate, a shear fork mechanism and anupper supporting plate, and the shear fork mechanism is composed of a group of material rods which are hinged to one another; one end of the bottom of the shear fork mechanism is hinged to the lower supporting plate, and a roller rotatably connected to the other end of the bottom of the shear fork mechanism can slide in a sliding groove formed in the lower supporting plate; the top of the shear fork mechanism is hinged to one end of the upper supporting plate, and the top of the shear fork mechanism is slidably connected with the other end of the upper supporting plate; each material rod comprises an upper material rod, a middle material rod and a lower material rod, and the middle material rods can relatively rotate; and a first air cylinder is used for pushing the roller to slide in thesliding groove. According to the film coating system for depositing the metal on the plastic substrate surface on the basis of the glow discharge principle, through cooperation of the shear fork mechanism and the material rods, a workpiece can rotate when sputtering coating is conducted, therefore, a coating film of the coated workpiece is uniform, and then the film coating effect of a sputteringcoating device is improved.

Owner:阜阳知麓信息科技有限公司

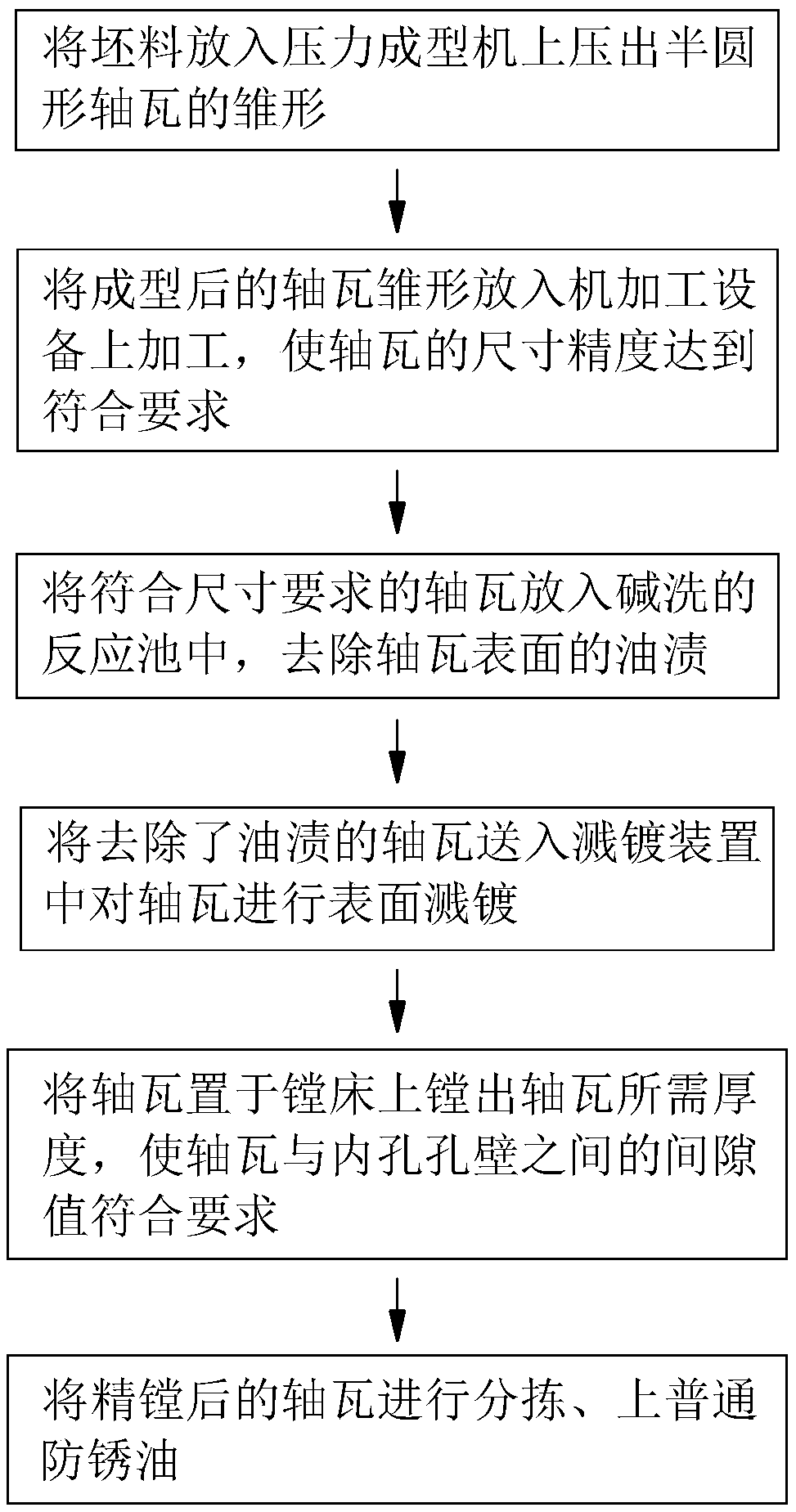

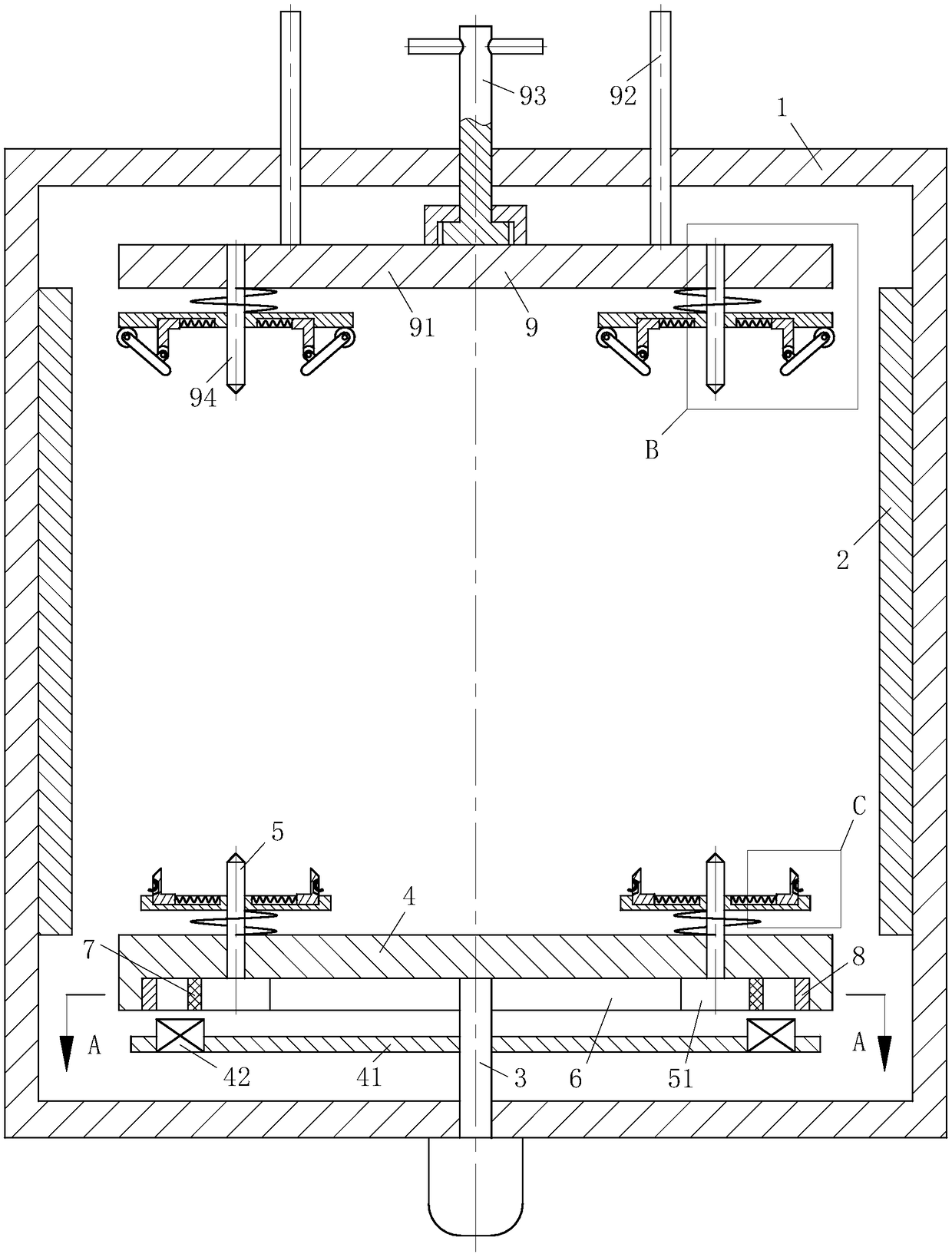

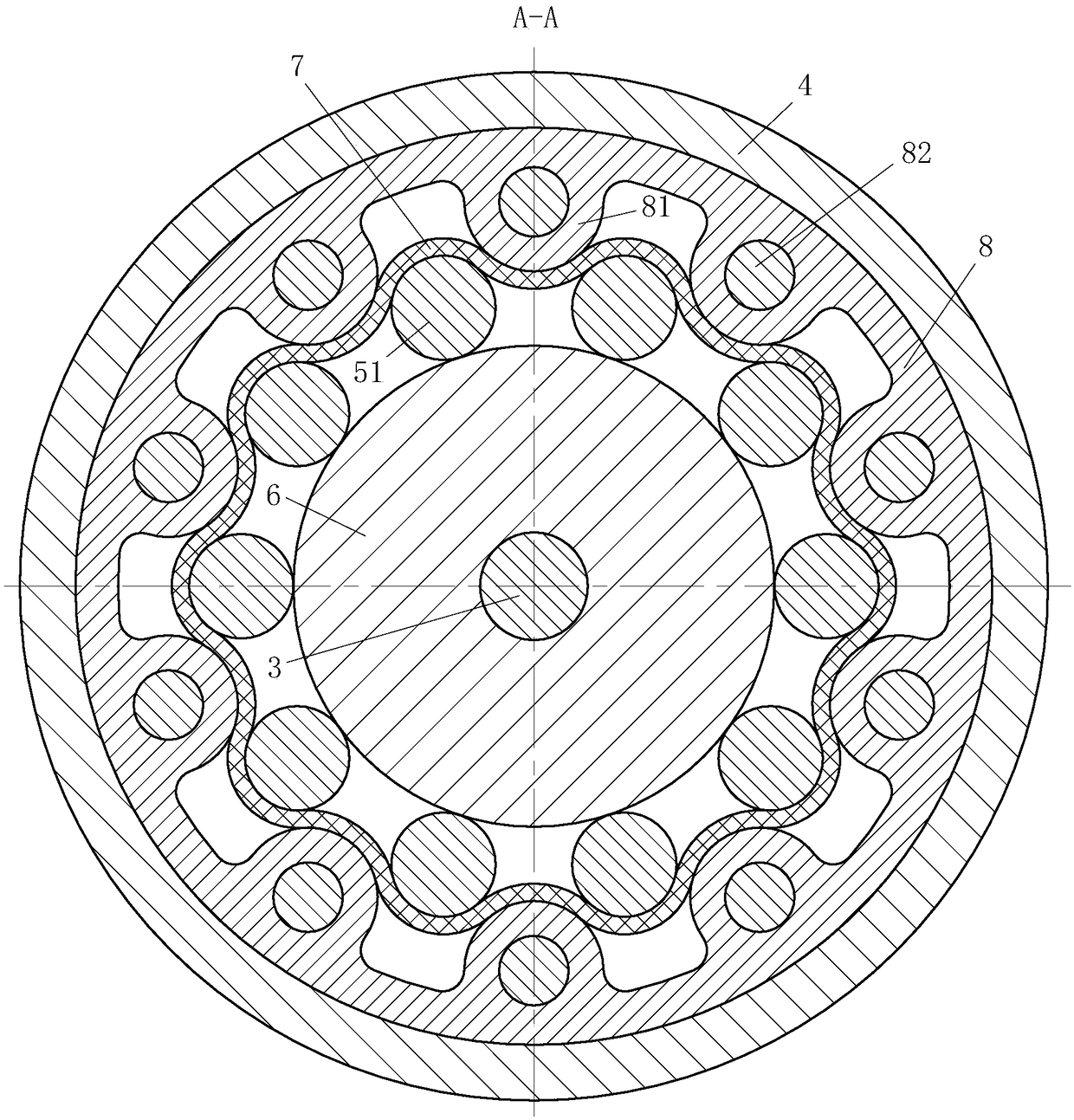

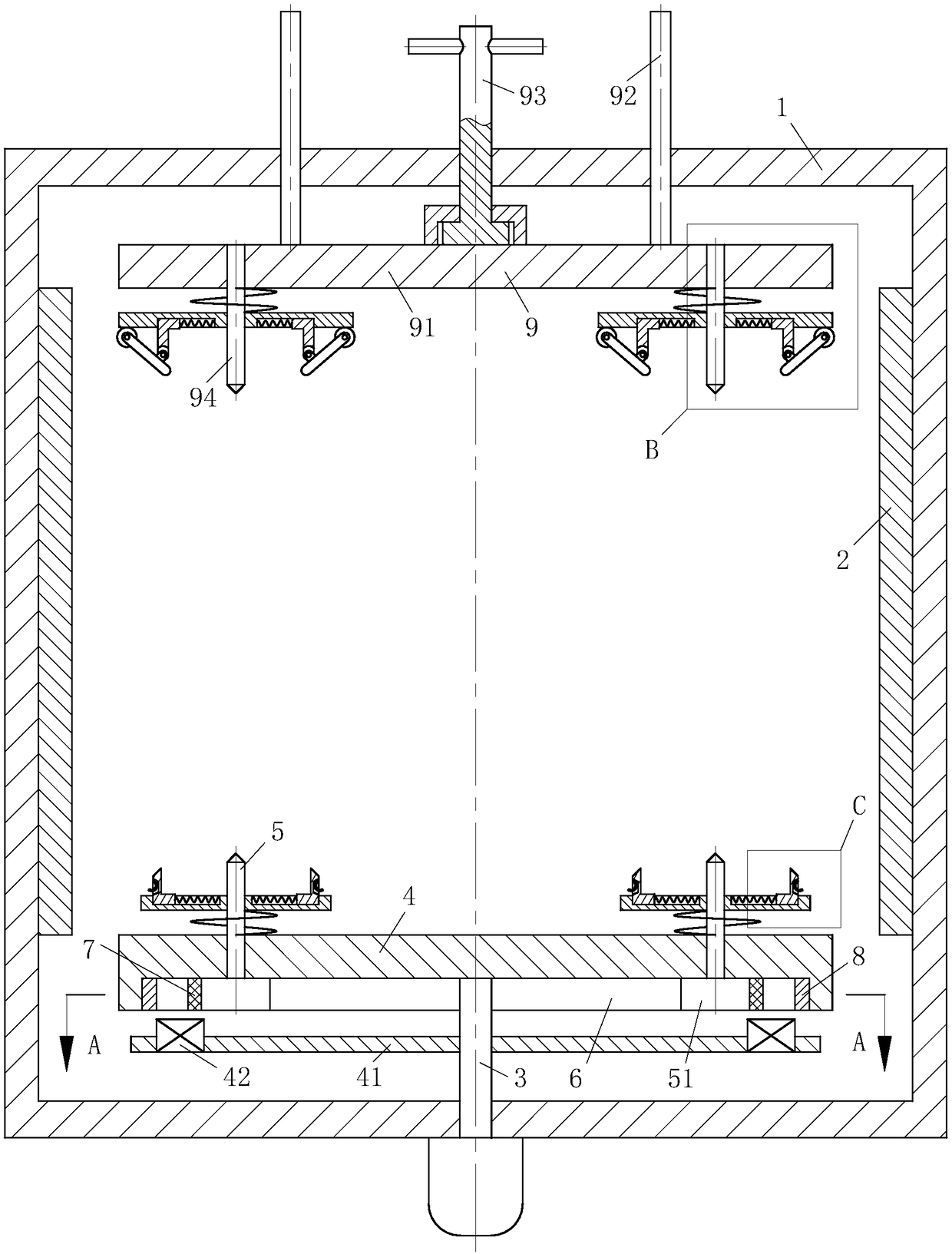

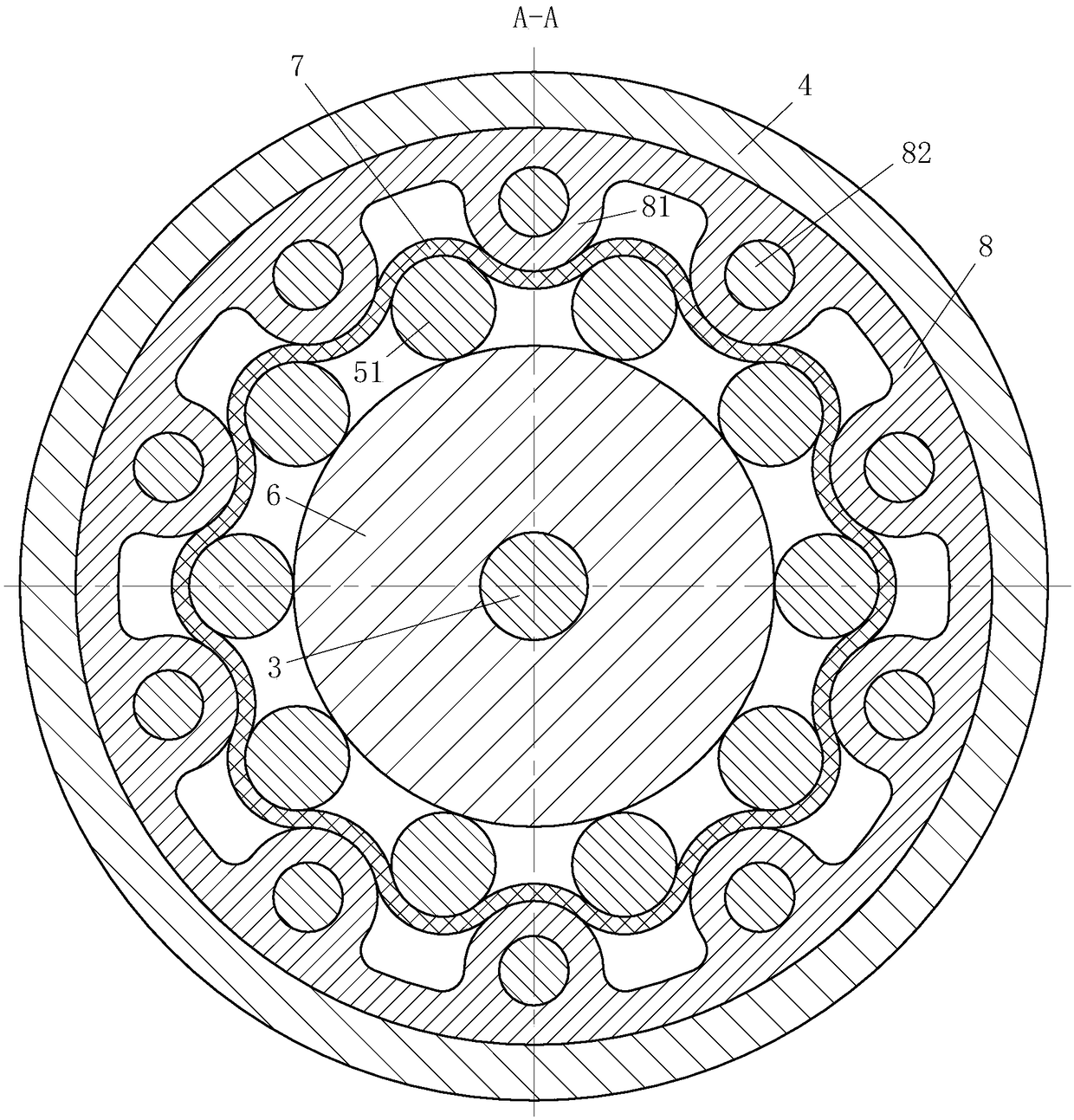

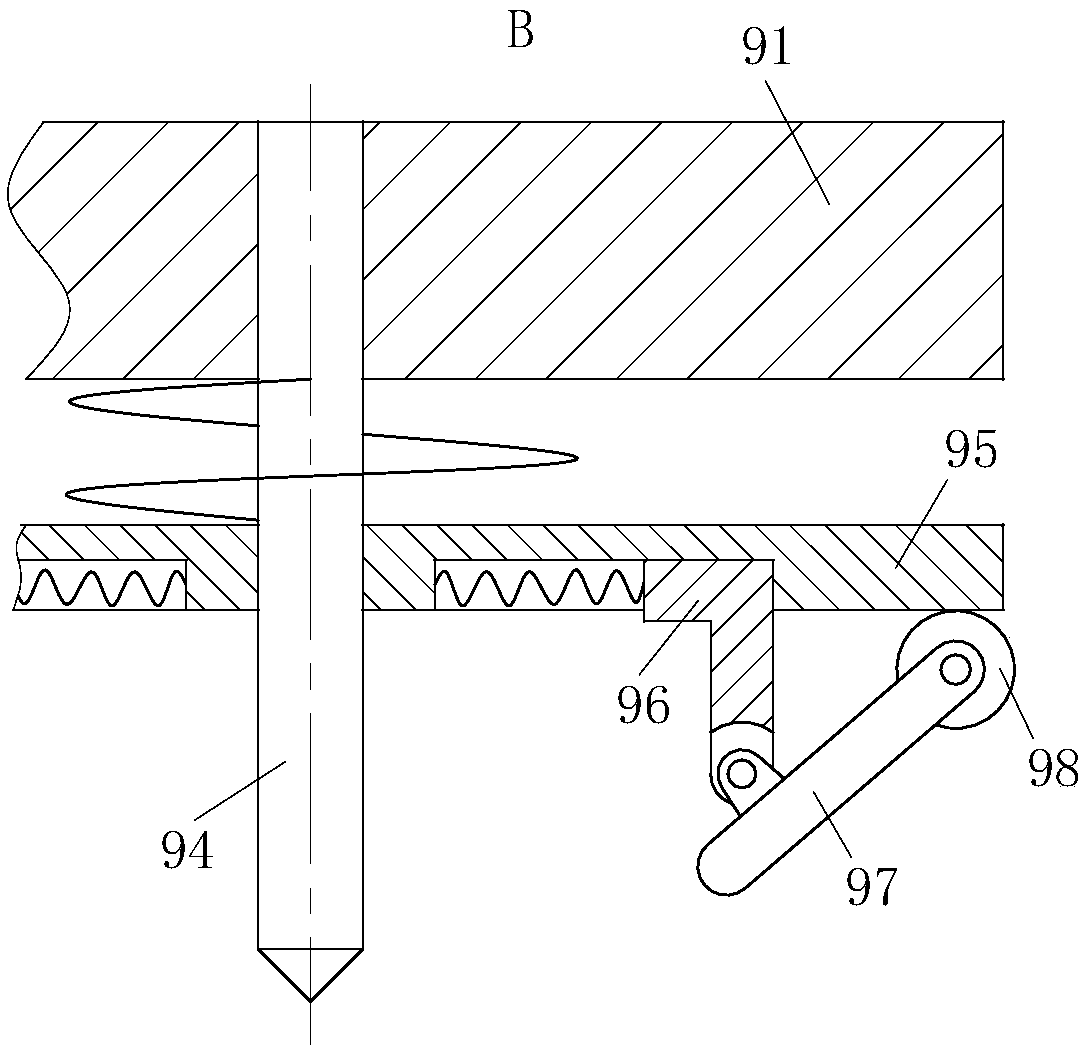

Production technology of engine bearing bush

The invention belongs to the technical field of bearing bushes, and particularly relates to a production technology of an engine bearing bush. A sputtering coating device used in the technology comprises a shell, a target material, a motor, a connection shaft, a lower supporting disc, a thimble, a friction wheel, a friction belt, an extrusion ring and a driven supporting module, wherein the friction wheel is fixedly connected with the upper end of the connection shaft; the lower supporting disc is arranged above the friction wheel; and the outer side surface of the extrusion ring is fixedly connected to the interior of a cylindrical groove in the lower supporting disc. The surface of a round disc at the lower end of the thimble is arranged to be in contact with the cylindrical surface of the friction wheel, a semispherical bulge on the extrusion ring and the round disc at the lower end of the thimble are alternately arranged, the friction belt is arranged between the extrusion ring andthe round disc at the lower end of the thimble, the driven supporting module is arranged at the upper end of the shell, the purpose that a to-be-plated workpiece above the lower supporting disc rotates around the connection shaft and self-rotates around the thimble is achieved, so that the surface of the to-be-plated workpiece can uniformly receive the ions impacted to the target material, and accordingly uniform sputtering and coating of the surface of a shaft part is achieved.

Owner:日照菁英传媒科技有限公司

Sputtering plating system for plastic and rubber pipe

ActiveCN108977784AImprove cleaning efficiencyImprove efficiencyHollow article cleaningVacuum evaporation coatingSputteringComputer module

The invention belongs to the technical field of film plating, in particular to a sputtering plating system for a plastic and rubber pipe. The sputtering plating system comprises a sputtering plating box, a workpiece frame, a motor, a target module, a heater and an automatic cleaning module, wherein the motor is fixedly arranged at the exterior of the sputtering plating box; the workpiece frame ispositioned at the center of the interior of the sputtering plating box, and is driven by the motor to rotate; the target module is arranged at the inner wall of the sputtering plating box, can be moved up and down, and be moved along the transverse direction to get close to the workpiece frame; the automatic cleaning module is used for cleaning the sputtering plating box before sputtering plating;the heater is positioned at the upper end of the inner wall of the sputtering plating box, and is used for drying the cleaned sputtering plating box. The sputtering plating system has the advantagesthat the automatic cleaning module is used for spraying water into the sputtering plating box to clean, so that the efficiency in the whole sputtering plating process of the plastic and rubber pipe isimproved; the motor is used for driving the workpiece frame to rotate, and the sputtering plating of the plastic and rubber pipe is uniform; the target module is moved up and down, or is moved alongthe transverse direction, so as to complete uniform sputtering plating of the plastic and rubber pipe, and improve the sputtering plating quality of the plastic and rubber pipe.

Owner:莘县鲁开综合服务有限公司

Active carbon mildewproof antimicrobial filter paper and manufacture method thereof

InactiveCN101559303AIncrease profitThoroughly exert the powerful antibacterial functionFiltration separationNon-woven fabricsPolyesterFiber

The invention relates to an active carbon mildewproof antimicrobial filter paper. The paper comprises the following compositions with the mass percentage of: 70 to 80 percent of active carbon and 20 to 30 percent of polyester spun-bonded fiber filament non-woven fabric which are heated and combined; nano silver ions are coated on the composite with coating area reaching over 95 percent. The filter paper can completely play the intensive sterilization function of the nano silver ions over 99.9 percent and the mildew resistance and deodorization function of the active carbon and the like.

Owner:DONGGUAN LUAO FILTER

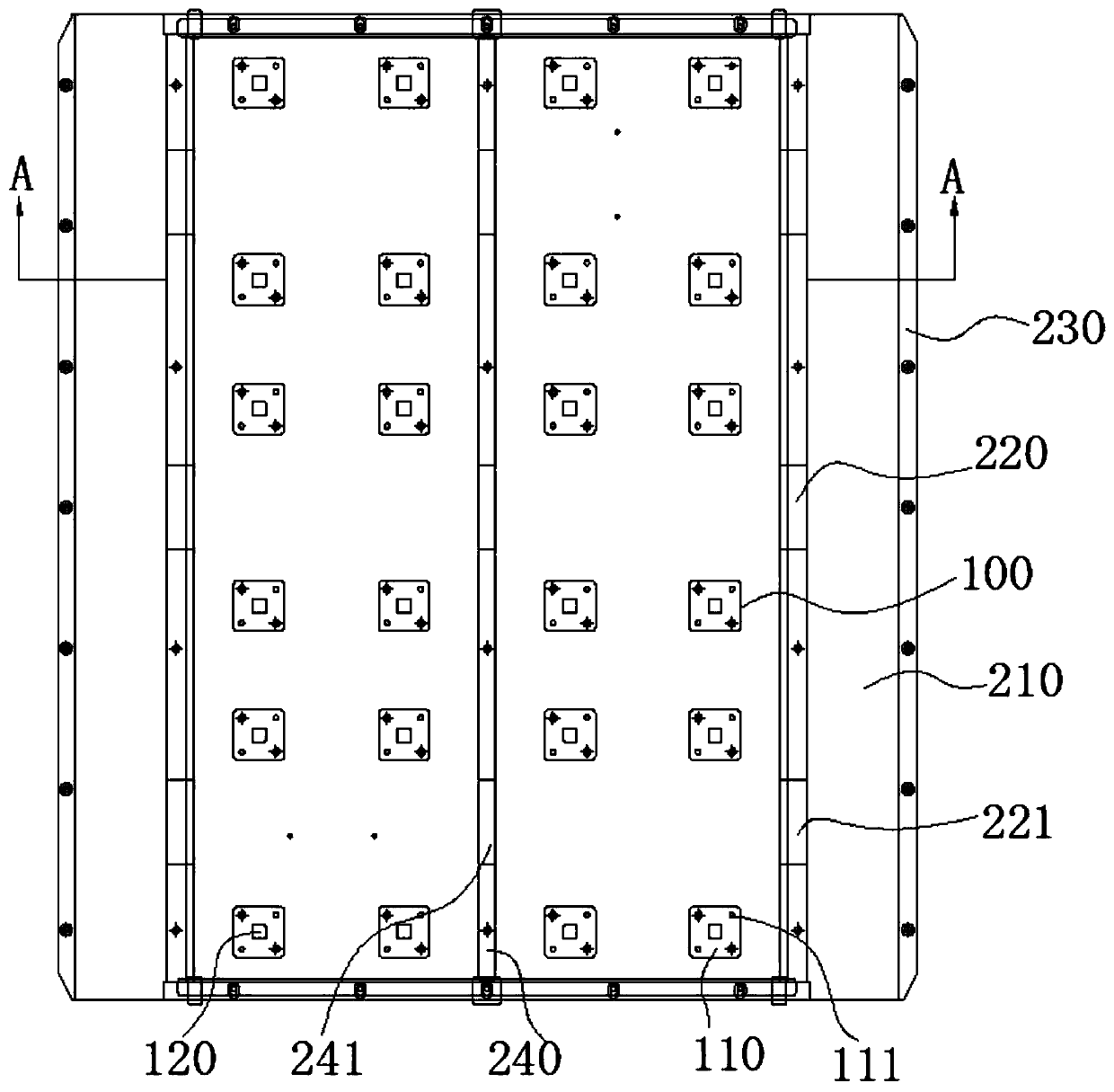

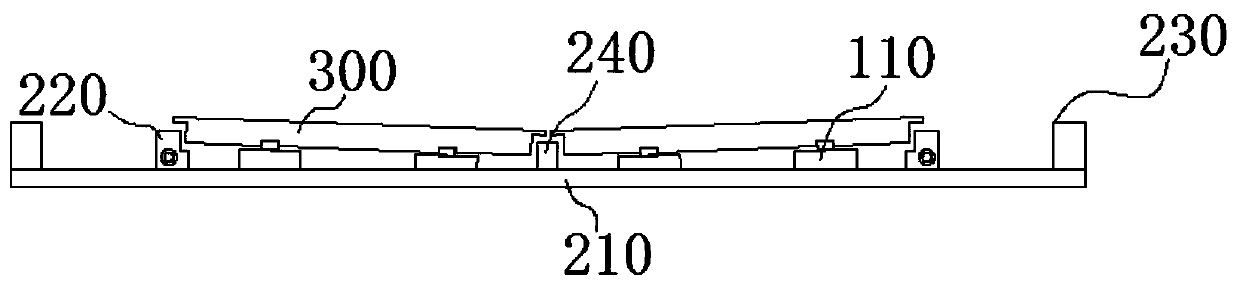

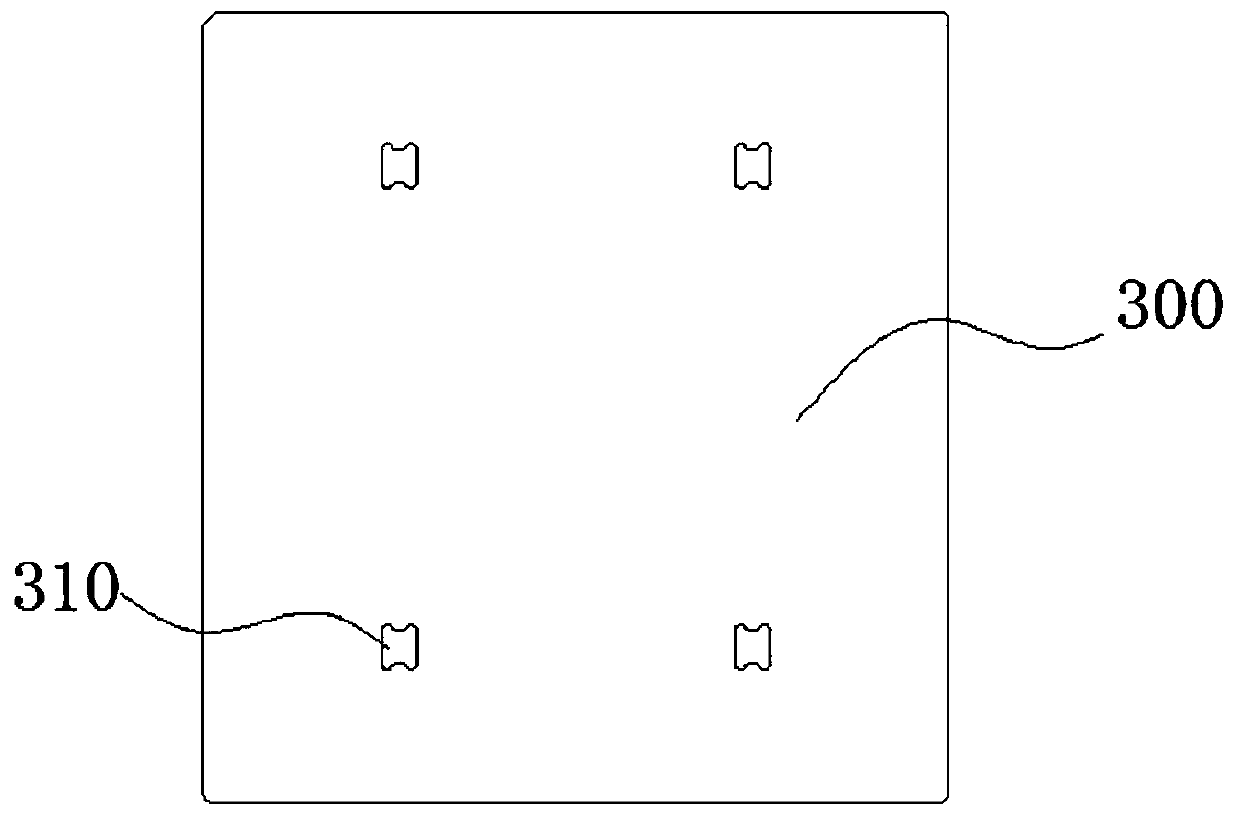

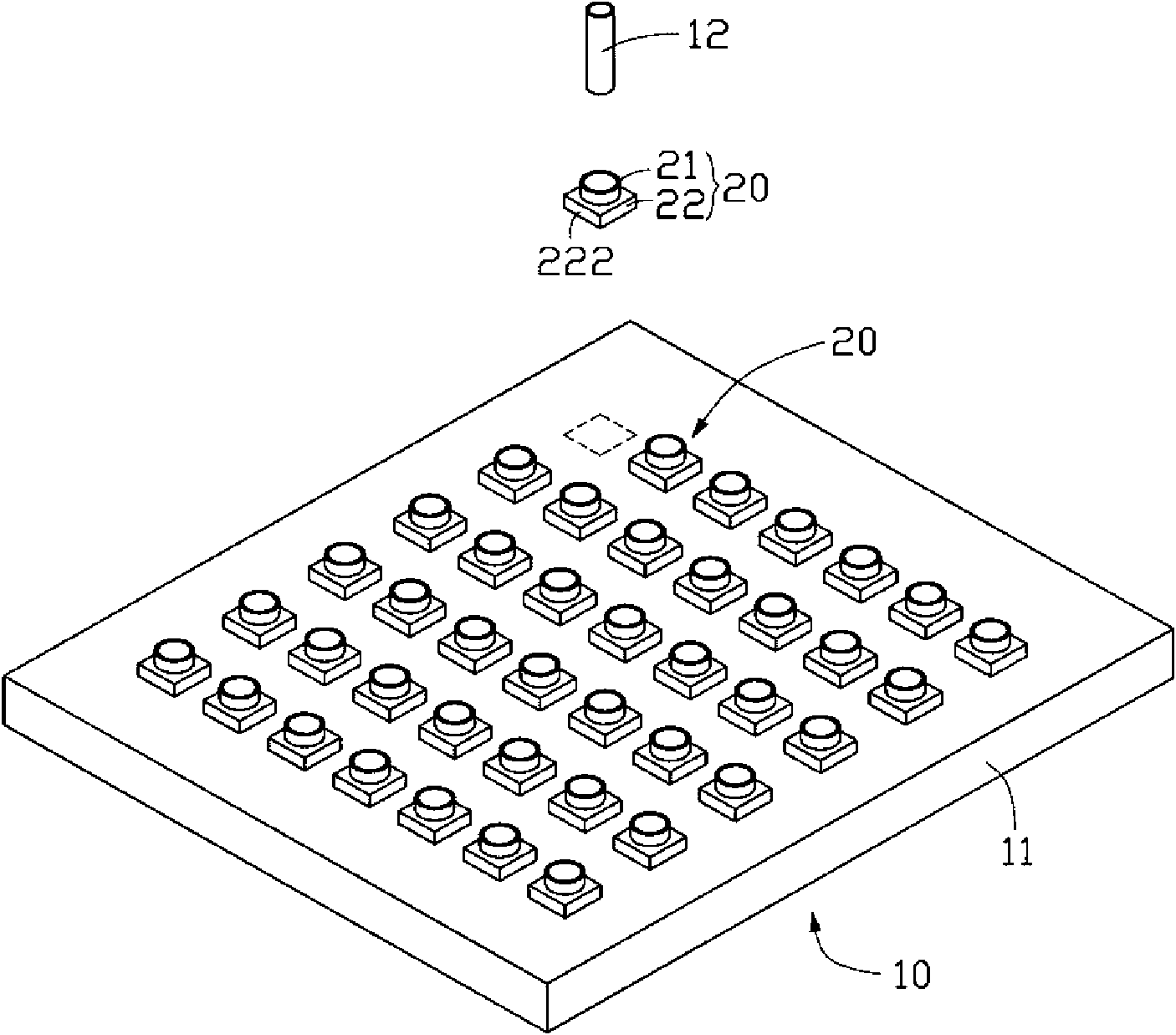

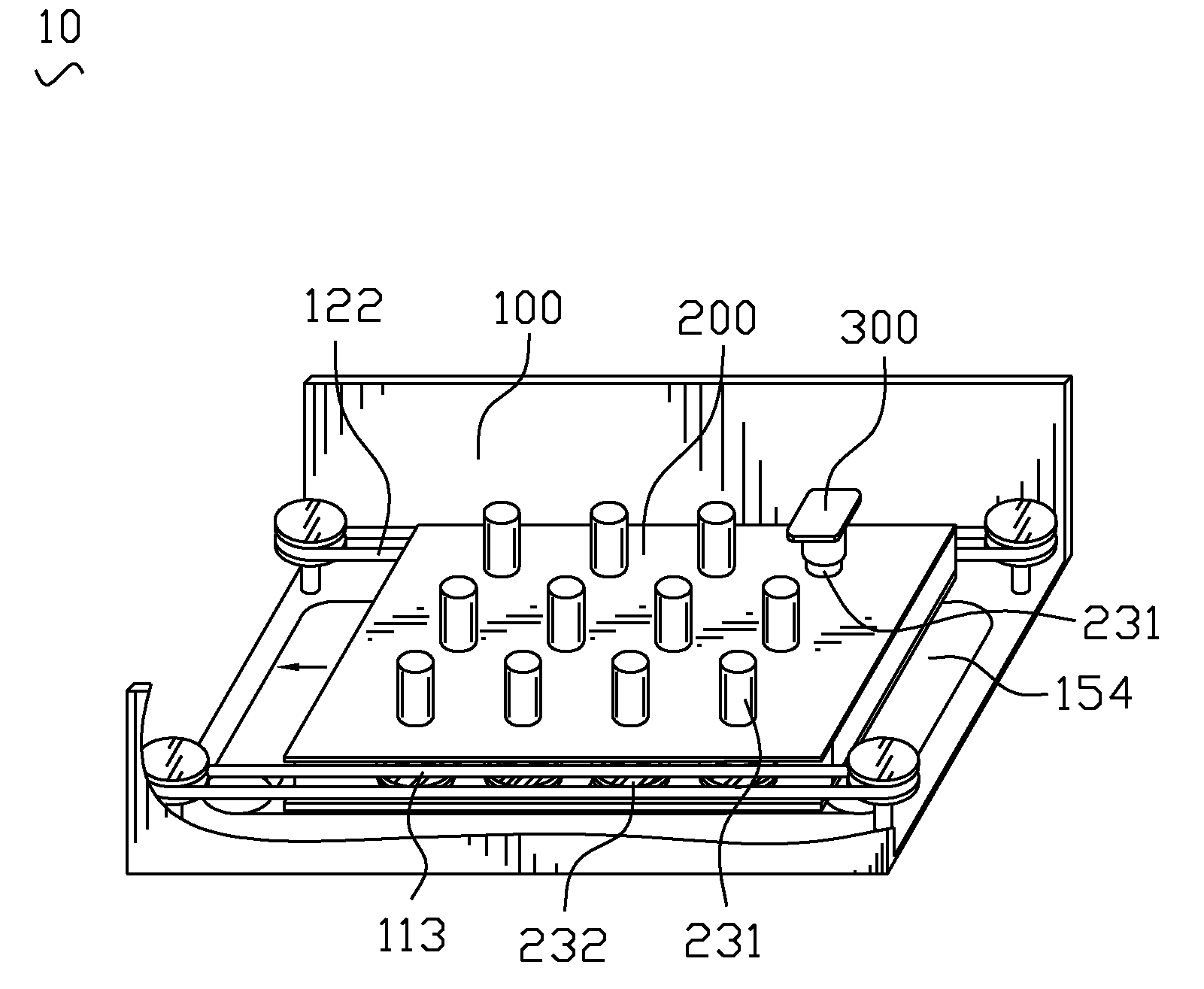

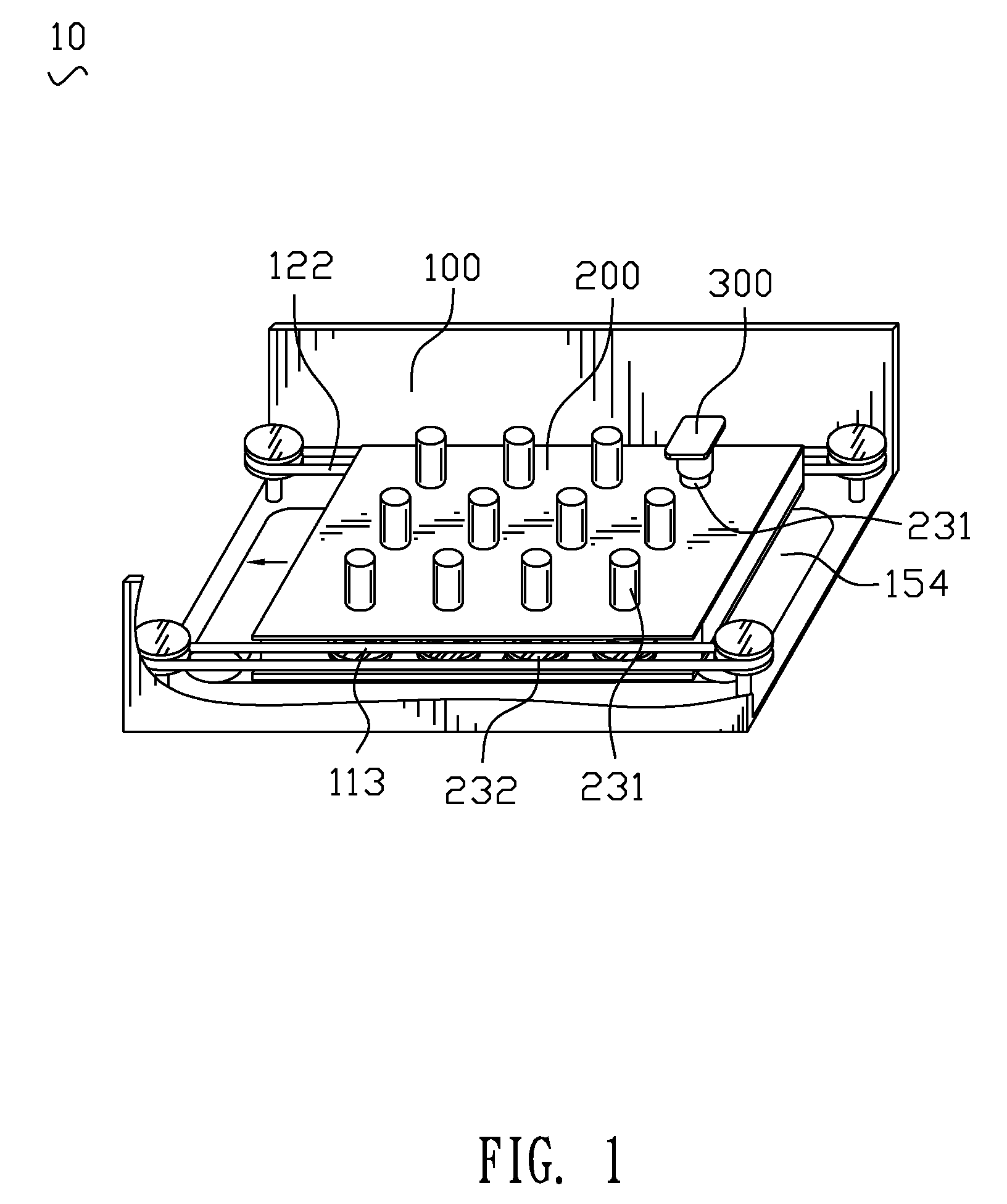

Sputtering tray and sputtering jigs

ActiveCN110724925AIncrease chance of contactUniform film thicknessVacuum evaporation coatingSputtering coatingMaterials scienceSupport surface

The invention provides a sputtering tray and sputtering jigs. The sputtering tray is positioned under target material in a sputtering chamber, and the jigs containing products to be sputtered are placed on the sputtering tray. The sputtering tray comprises a tray body and a plurality of supporting structures arranged on the tray body, wherein the supporting structures are provided with supportingsurfaces used for making the jigs placed on the supporting structures incline towards the central axis of the tray body, and the heights of the sides, away from the central axis, of the supporting surfaces are higher than the heights of the sides, close to the central axis, of the supporting surfaces, so that the contact probability of knocked target atoms with the side surfaces of the products, close to the edges of the tray body, on the jigs is increased, and the uniform film thicknesses of the sputtered products are ensured.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Sputtering system

ActiveCN112281123AUniform sputteringElectric discharge tubesVacuum evaporation coatingDrive shaftEngineering

The invention provides a sputtering system which is suitable for sputtering a surface to be sputtered with a plurality of sections. Each section has a projection height. The sputtering system comprises a support plate, a sputtering array and a controller. The sputtering array is arranged on the supporting plate and comprises a plurality of sputtering units, and each section at least corresponds toone of the sputtering units. Each sputtering coating unit is provided with a driving shaft and a target material. The target material faces the surface to be sputtered. The controller is electricallyconnected with the driving shaft. The driving shaft is linked with the target material and controls the target material to move relative to the surface to be sputtered, and the controller controls the distance from each sputtering unit in the sputtering units to a corresponding section in the sections in the direction of the projection height to meet a preset condition.

Owner:INTERFACE TECH CHENGDU CO LTD +2

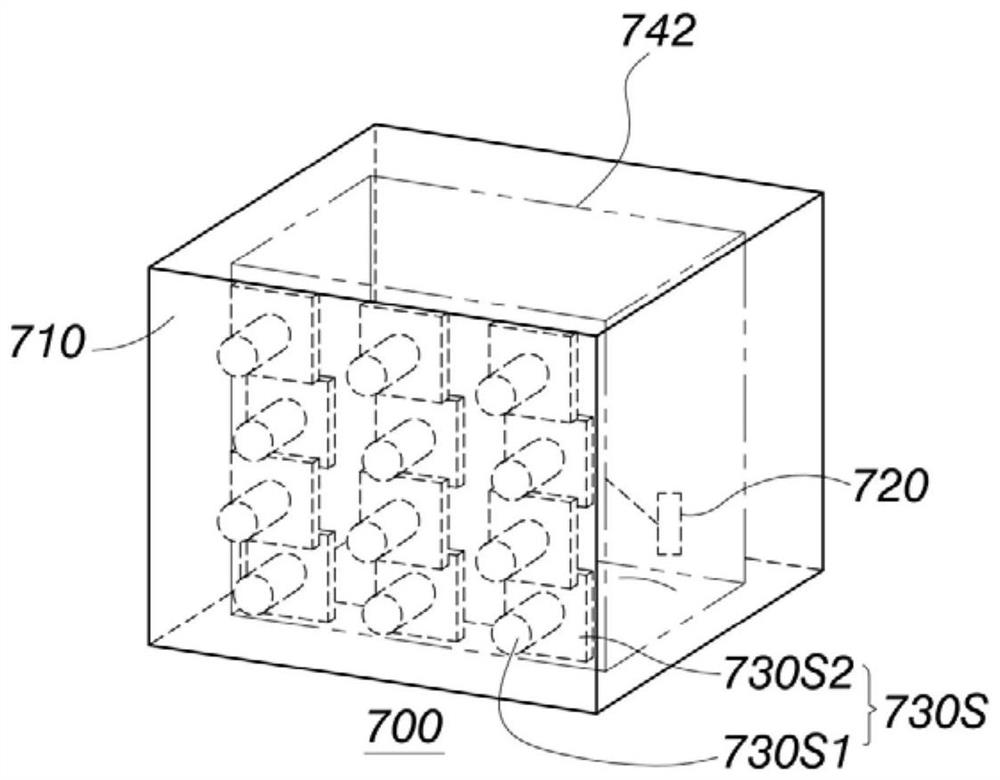

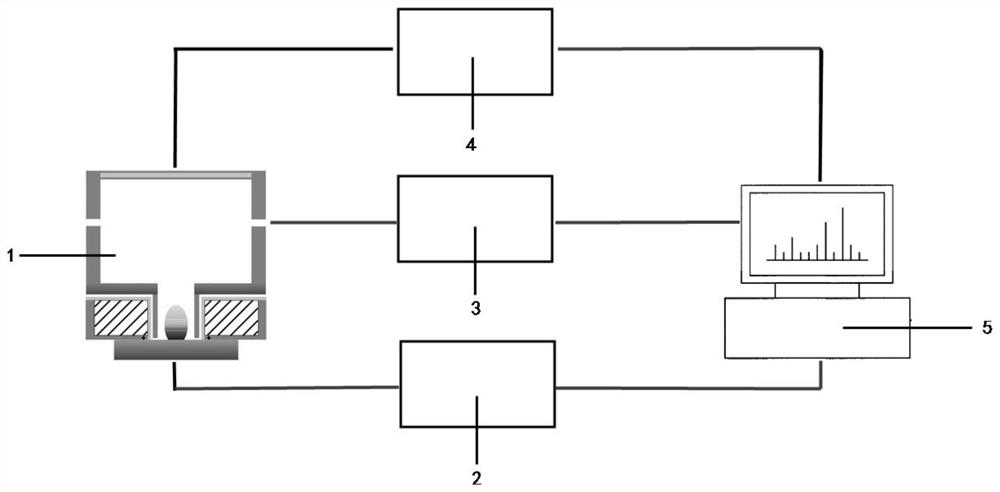

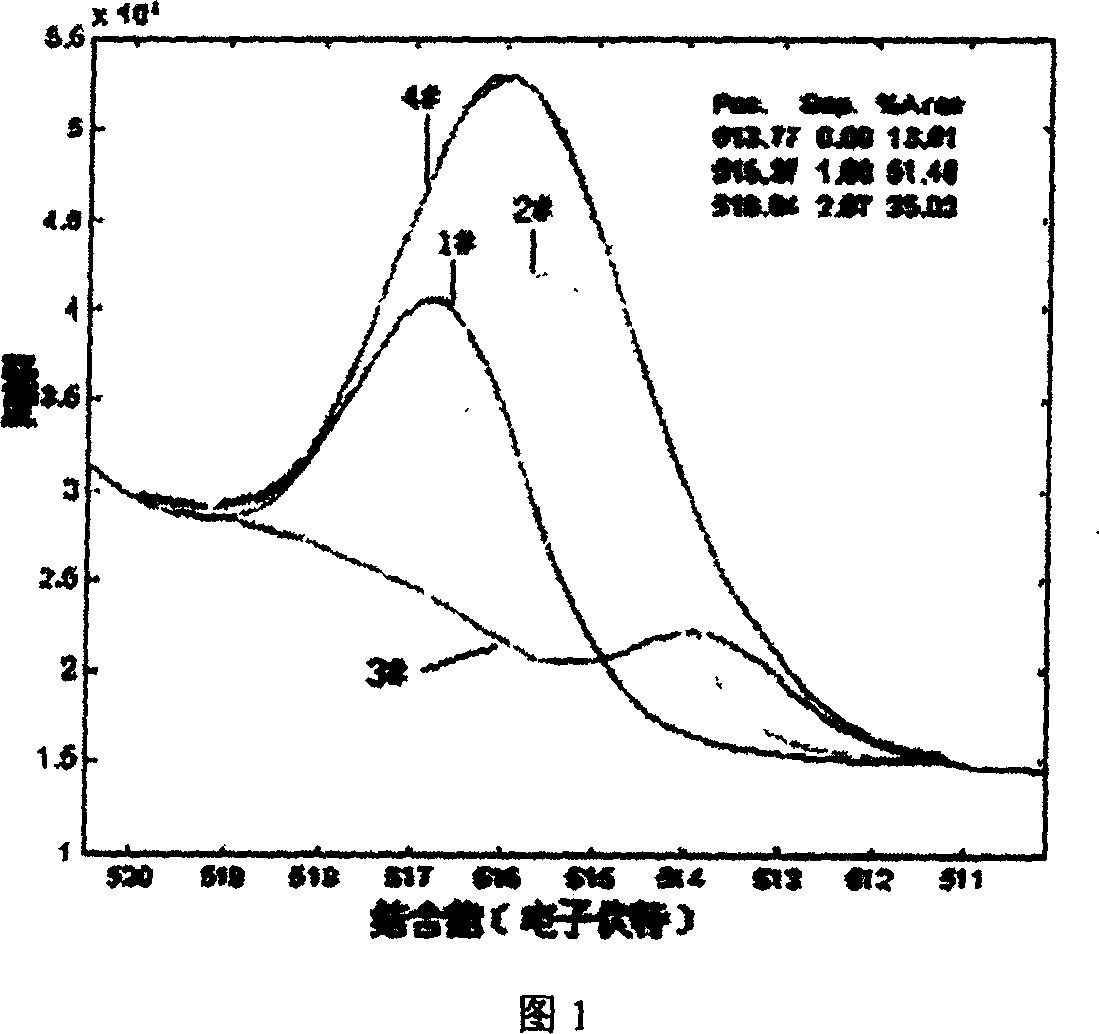

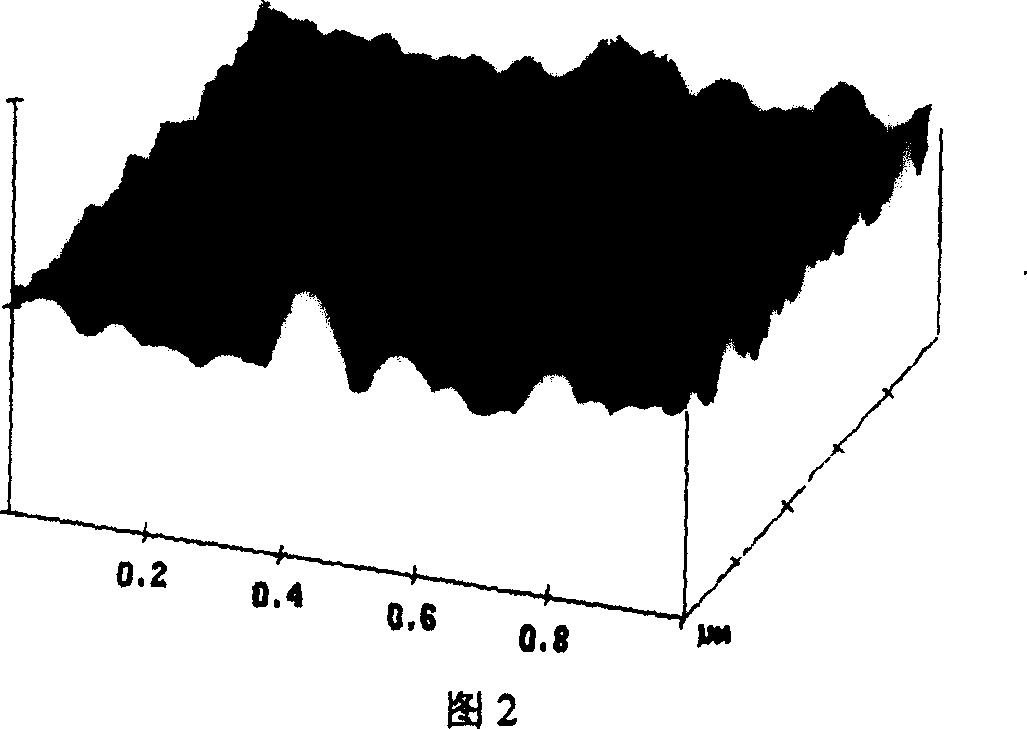

Device and method for preparing glow discharge sputtering sample for microscopic characterization of material

PendingCN112067391AUniform sputteringExtend the motion pathElectron/ion optical arrangementsPreparing sample for investigationOptical spectrometerAutomatic control

The invention relates to a device and a method for preparing a glow discharge sputtering sample for microscopic characterization of a material. The device comprises a glow discharge sputtering unit, aglow discharge energy supply source, an automatic gas circuit control unit, a spectrograph and a computer, wherein a glow discharge sputtering unit structure is more suitable for sample preparation through simulation optimization, and uniform sample sputtering on the surface of a sample in a large-size range is realized by applying a magnetic field to glow plasma; and the spectrograph is used formonitoring element spectral signals in the sputtering depth direction of the sample so as to realize accurate preparation of tissue structures of different layers. By combining the sample position mark and the acquisition of accurate space coordinate (x, y, z) information, the correspondence between the space coordinate of the sample preparation surface and the tissue structure is realized. Thus,large-size flat preparation of the sample at the millimeter-cm level can be achieved, no damage is caused to the material tissue structure, layer-by-layer preparation can be conducted in the depth direction of the surface of the sample, preparation is rapid, and the cost is low.

Owner:NCS TESTING TECH

Small Scanned Magentron

InactiveUS20070102284A1Improve uniformityMore target utilizationCellsElectric discharge tubesOrbitCantilever

A small magnet assembly having a magnet assembly of area less than 10% of the target area, is scanned in a retrograde planetary or epicyclic path about the back of a target being plasma sputtered including an orbital rotation about the center axis of the target and a planetary rotation about another axis rotating about the target center axis. The magnet assembly passes through the target center, thus allowing full target coverage. A properly chosen ratio of the two rotations about respective axes produces a much slower magnet velocity near the target periphery than at the target center. A geared planetary mechanism includes a rotating drive plate, a fixed center gear, and an idler and a follower gear rotatably supported in the drive plane supporting a cantilevered magnet assembly on the side of the drive plate facing the target.

Owner:APPLIED MATERIALS INC

Method for depositing back electrode in solar cell production

InactiveCN102102184AIncrease profitUniform sputteringVacuum evaporation coatingSputtering coatingEngineeringSolar cell

The invention relates to the field of production of solar cells, in particular to a method for depositing a back electrode in solar cell production. The method is implemented by special magnetron sputtering equipment for sputtering the back electrode on the back face of a solar cell by the following steps of: firstly, introducing two cell slices into a buffer cabin every time through a slice inlet platform under the driving action of a conveying guide rail on which a cell slice suspension box is hung, and making the cell slices continually move forward into two heating cabins in turn, wherein the heating temperature of one heating cabin into which the cell slices moves earlier is 35 DEG C, the heating temperature of the other second heating cabin into which the cell slices moves later is 50 DEG C, and the temperature is up to 50 DEG C after twice heating; and making the cell slices enter a sputtering cabin, uniformly sputtering an Al layer serving as the back electrode in the sputtering cabin by a magnetron sputtering principle, discharging the cell slices out of the cabin, and making the cell slices enter next equipment through a buffer cabin and a cell slice outlet platform, wherein a vacuum system connected to each cabin through a vacuum pipeline is used for controlling the vacuum value of each cabin, and a valve is used for partitioning each cabin into relatively independent spaces, so that the aim of sputtering the back electrode of the solar cell is fulfilled.

Owner:JILIN QINGDA NEW ENERGY ELECTRIC POWER

Opposite target reaction magnetocontrol sputtering method for preparing vanadium oxide film

InactiveCN100340699CIncrease profitFast sputtering rateVacuum evaporation coatingSputtering coatingSputteringElectrical resistance and conductance

A process for preparing the vanadium oxide film by magnetically controlled sputtering with the reaction between two opposite targets includes such steps as washing Si (or glass) substrate, depositing a silicon oxide film layer on the Si substrate by PECVD method, and magnetically controlled sputtering with two opposite targets to deposit vanadium oxide film. The technological condition for said sputtering is also disclosed. Said film features high electric resistance-temp coefficient and low electric resistance at ordinary temp.

Owner:TIANJIN UNIV

Sputtering tool

InactiveCN101643892AUniform sputteringImprove sputtering yieldVacuum evaporation coatingSputtering coatingEngineeringYield ratio

The invention relates to a sputtering tool which comprises a bracket and at least one rotating rod, wherein the bracket comprises a first lateral side and a second lateral side which are opposite arranged, and at least a group of corresponding shaft holes are respectively arranged on the first lateral side and the second lateral side; the rotating rod is arranged in the shaft hole in a penetratingway; the sputtering tool further comprises a driving component and at least two driven components; at least two driven components are respectively on one end of the corresponding rotating rod; the driving component drives one rotating rod and the driven component to rotate; and other rotating rods are driven by the driven components to rotate together, thereby driving a microscope stand to be sputtered on the rotating rod to rotate. The sputtering tool utilizes the matching of the driving component and the driven components to drive the microscope stand to be sputtered to rotate in the bracket, thereby not only ensuring the sputtering evenness, but also improving the sputtering yield ratio simultaneously.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Workpiece-transporting apparatus of in-line sputtering machine

InactiveUS7686155B2Uniform sputteringVacuum evaporation coatingSputtering coatingDrive wheelElectric motor

A workpiece-transporting apparatus of in-line sputtering machine includes a conveyer unit and a carrying salver. The conveyer unit has a holder, and a transporting wheel group is arranged in the holder. A conveyer belt covers around the transporting wheel group. A driving wheel group is arranged in one side of the conveyer belt and located in the holder. The driving wheel group connects to a motor and surrounded by a connecting belt. The carrying salver is placed on the conveyer belt of the conveyer unit. The carrying salver has a base, a plurality of supporting shafts are assembled in the base and linked together for being driven together. A workpiece base is arranged on the supporting shafts. At least one of the supporting shafts is surrounded by a supporting wheel. The supporting wheel engages with the connecting belt for being driven by the connecting belt.

Owner:CHENG UEI PRECISION IND CO LTD

Surface film coating device based on PVD technology

ActiveCN108998768AGuaranteed reliabilitySimple clamping processVacuum evaporation coatingSputtering coatingIonEngineering

The invention belongs to the technical field of film coating, and particularly relates to a surface film coating device based on a PVD technology. The surface film coating device comprises a shell, target materials, a motor, a connecting shaft, a lower supporting disc, ejector pins, a friction wheel, friction belts, an extrusion ring and a driven supporting module, wherein the friction wheel is fixedly connected to the upper end of the connecting shaft; a cylindrical groove in the lower supporting disc is internally and fixedly connected to the outer side surface of the extrusion ring; and a group of hemispherical protrusions are uniformly arranged on the inner side of the extrusion ring. According to the surface film coating device, surfaces of discs at the lower ends of the ejector pinsare in contact with a cylindrical surface of the friction wheel, the hemispherical protrusions on the extrusion ring and the discs at the lower ends of the ejector pins are arranged in a staggered mode, the friction belts are arranged between the extrusion ring and the discs at the lower ends of the ejector pins, the driven supporting module is arranged at the upper end of the shell, and thereforea to-be-coated workpiece on the lower supporting disc can rotate around the connecting shaft and auto-rotate around the ejector pins, so that the surface of the to-be-coated workpiece uniformly receives ions impacting from the target materials, and then the surface of a shaft part is uniformly sputtered.

Owner:深圳市锦瑞新材料股份有限公司

Microdrop ion sputtering technology and water turbine preparation method

ActiveCN107287567AIntegrity guaranteedUniform sputteringAdditive manufacturing apparatusVacuum evaporation coatingWater turbineIon sputtering

The invention relates to the technical field of microdrop ion sputtering in added material manufacturing, in particular to a microdrop ion sputtering technology and a water turbine preparation method. The process uses two sputtering heads for sputtering two opposite surfaces of a basal body to be sputtered at the same time to form a printing layer and a protecting layer, wherein the particle sizes of printing layer raw materials used for sputtering are 10-20 nanometers. The process can perform the printing layer raw material sputtering on relative areas of two opposite surfaces of the basal body to be sputtered at the same time, so that deformation caused by nonuniform heating is reduced, and such defects as cracks and bubbles of the basal body to be sputtered are solved.

Owner:CHENGDU TIANFU NEW AREA HECHUAN SCI & TECH CO LTD

Vacuum coating method for outer surface of mobile phone shell

ActiveCN112663004AUniform sputteringQuality improvementClimate change adaptationVacuum evaporation coatingEngineeringMechanical engineering

The invention relates to the technical field of mobile phone shell film coating, in particular to a vacuum film coating method for an outer surface of a mobile phone shell, which completes the film coating work of the mobile phone shell through polishing treatment, cleaning and dust removal, drying and vacuum film coating; and meanwhile, a sputtering target can uniformly sputter a coating layer on the mobile phone shell through corresponding vacuum coating equipment, so that the quality of the mobile phone shell is improved.

Owner:东莞铱诺科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com