ITO (indium tin oxide) thin film and preparation method thereof

A film and substrate technology, applied in the field of ITO film and its preparation, can solve the problem of failing to effectively ensure the uniformity of the square resistance of the film, and achieve the effects of easy control of the film thickness, good uniformity and low square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

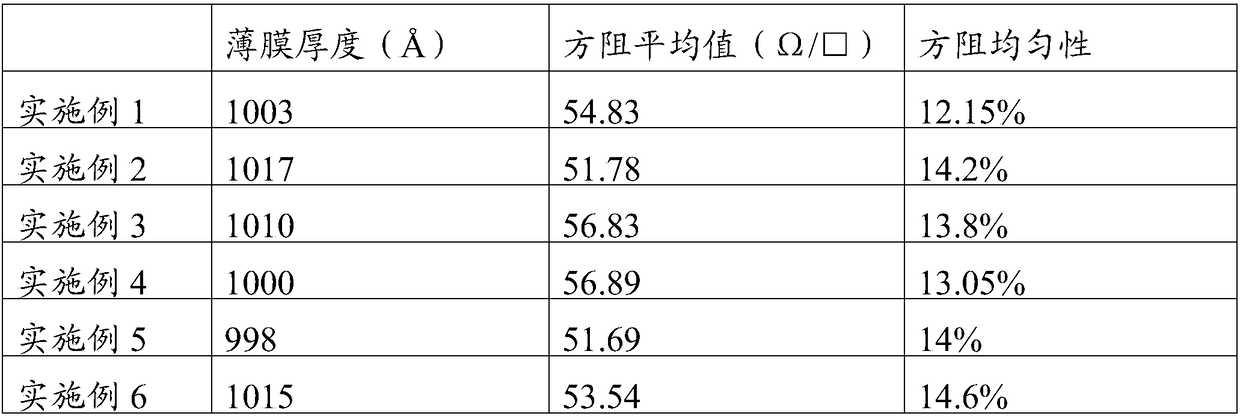

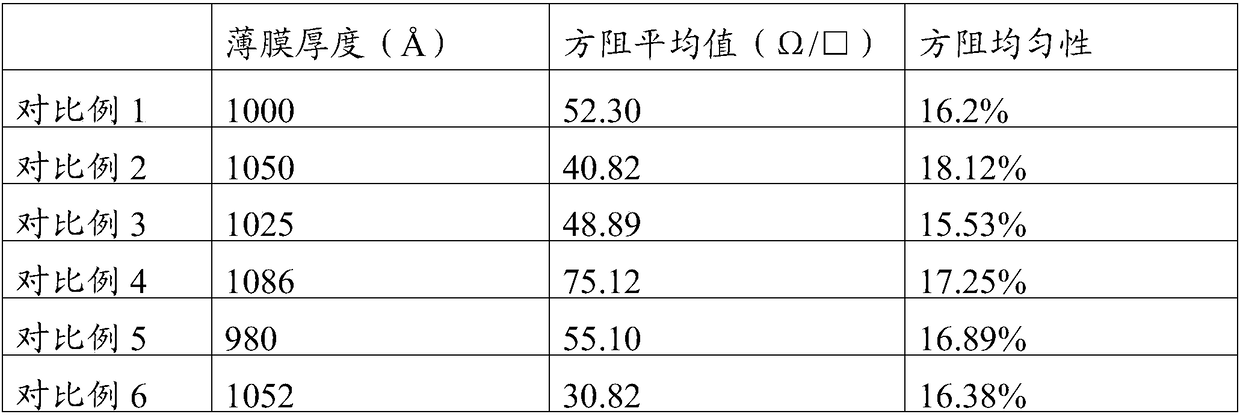

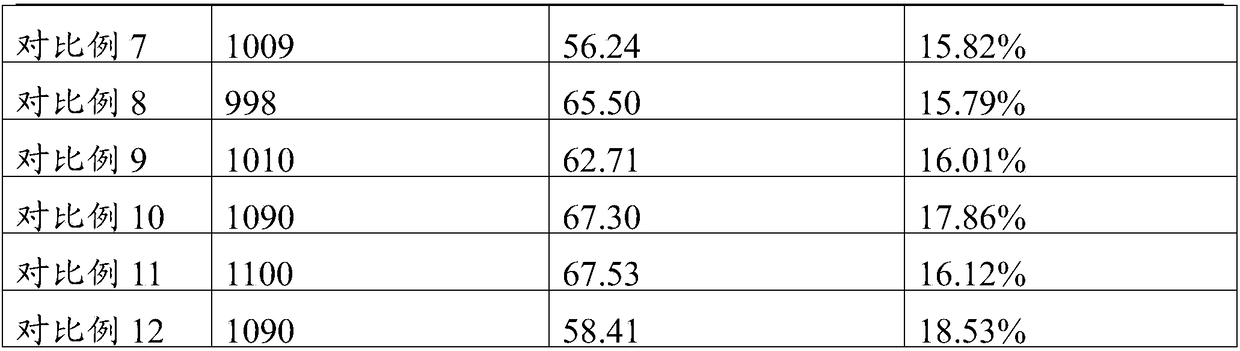

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of preparing ITO film, specifically comprises the following steps:

[0025] Step S1: placing the substrate in the chamber, and setting the distance between the target and the substrate to be 56 mm to 65 mm;

[0026] Step S2: vacuumizing and heating the chamber so that the temperature of the substrate is 285°C-328°C;

[0027] Step S3: Introduce argon gas into the chamber, adjust the vacuum degree of the chamber to 3.9mTorr-5.1mTorr, and set the sputtering power to 68W-82W;

[0028] Step S4: continue to feed oxygen into the chamber, and adjust the flow ratio of the argon to the oxygen to be 33:1-38:1;

[0029] Step S5: forming an ITO thin film on the surface of the substrate by magnetron sputtering.

[0030] The preparation method of the ITO thin film of the present invention can ensure that sputtered particles with sufficient energy are sputtered out by setting appropriate target base distance, vacuum degree, gas flow...

Embodiment 1

[0042] The 6-inch glass substrate is cleaned. The specific process of the cleaning treatment is: ultrasonic cleaning with acetone, water, ethanol, and water for 15 minutes in sequence. After the cleaning treatment is completed, it is dried with a spin dryer and dried in a nitrogen oven.

[0043] The substrate is placed in the chamber, and the distance between the target and the substrate is set to 60 mm.

[0044] Vacuumize and heat the chamber so that the vacuum degree of the chamber is 5×10 -6 Torr, the temperature of the substrate is 300°C. During heating, the substrate was rotated at a speed of 6 r / min.

[0045] Introduce argon gas into the chamber, adjust the vacuum degree of the chamber to 4.1 mTorr, and keep it stable for 30 s, adjust the speed of the substrate to 6 r / min, and set the sputtering power to 80 W.

[0046] Continue to feed oxygen into the chamber, adjust the flow ratio of argon and oxygen to 34:1, and keep it stable for 15 seconds, then open the sputtering...

Embodiment 2

[0048] The 6-inch glass substrate is cleaned. The specific process of the cleaning treatment is: ultrasonic cleaning with acetone, water, ethanol, and water for 20 minutes in sequence. After the cleaning treatment is completed, it is dried with a spin dryer and dried in a nitrogen oven.

[0049] The substrate was placed in the chamber, and the distance between the target and the substrate was set at 56 mm.

[0050] Vacuumize and heat the chamber so that the vacuum degree of the chamber is 8×10 -6 Torr. The temperature of the substrate was 310°C. During heating, the substrate was rotated at a speed of 4 r / min.

[0051] Introduce argon gas into the chamber, and adjust the vacuum degree of the chamber to 5.1 mTorr, and keep it stable for 30 s. Adjust the speed of the substrate to 8r / min, and set the sputtering power to 70W.

[0052] Continue to feed oxygen into the chamber, adjust the flow ratio of argon and oxygen to 33:1, and keep it stable for 15 seconds, then open the spu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com