Method for transferring graphene

A graphene film and substrate technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of graphene doping, increase the surface roughness of the film, etc., achieve less transfer steps, improve Integrity and cleanliness, effect of reducing square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

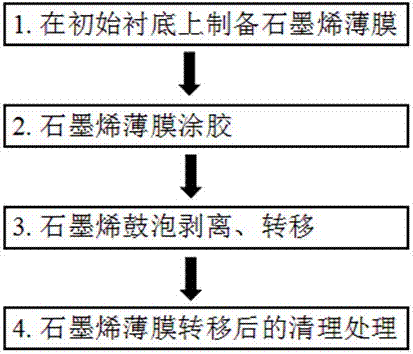

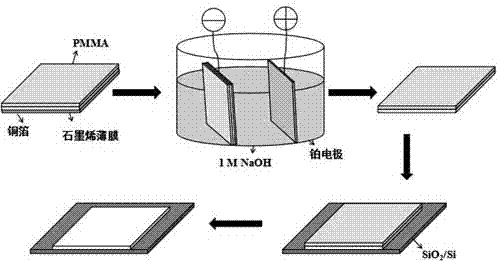

[0021] 1. Fabrication of graphene films on initial substrates. In this embodiment, copper Cu foil is used as the substrate with a thickness of 40 microns. By vapor deposition CVD method, using methane CH 4 and hydrogen H 2 As the reactive gas, a graphene film was prepared on copper foil.

[0022] 2. Spin-coat a layer of conductive adhesive on the prepared graphene film.

[0023] 3. Then bake at 100°C for 120 seconds to fully cure the conductive adhesive.

[0024] 4. The graphene film is peeled off from the initial substrate by electrochemical method, and transferred to the target substrate to complete the transfer of the graphene film. Specifically, first put the copper foil / graphene / conductive glue into the prepared electrolyte In the process, it is connected to the negative electrode, and the positive electrode is connected to the platinum electrode for electrochemical stripping. The electrolyte used was sodium hydroxide solution with a concentration of 5 M. The electr...

example 2

[0027] 1. Fabrication of graphene films on initial substrates. In this embodiment, copper Cu foil is used as the substrate with a thickness of 40 microns. By vapor deposition CVD method, using methane CH 4 and hydrogen H 2 As the reactive gas, a graphene film was prepared on copper foil.

[0028] 2. Spin-coat a layer of conductive adhesive on the prepared graphene film.

[0029] 3. Then bake at 100°C for 120 seconds to fully cure the conductive adhesive.

[0030] 4. The graphene film is peeled off from the initial substrate by electrochemical method, and transferred to the target substrate to complete the transfer of the graphene film. Specifically, first put the copper foil / graphene / conductive glue into the prepared electrolyte In the process, it is connected to the negative electrode, and the positive electrode is connected to the platinum electrode for electrochemical stripping. The electrolyte used was sodium hydroxide solution with a concentration of 5 M. The electr...

example 3

[0033] 1. Fabrication of graphene films on initial substrates. In this embodiment, copper Cu foil is used as the substrate with a thickness of 40 microns. By vapor deposition CVD method, using methane CH 4 and hydrogen H 2 As the reactive gas, a graphene film was prepared on copper foil.

[0034] 2. Spin-coat a layer of conductive adhesive on the prepared graphene film.

[0035] 3. Then bake at 100°C for 120 seconds to fully cure the conductive adhesive.

[0036] 4. The graphene film is peeled off from the initial substrate by electrochemical method, and transferred to the target substrate to complete the transfer of the graphene film. Specifically, first put the copper foil / graphene / conductive glue into the prepared electrolyte In the process, it is connected to the negative electrode, and the positive electrode is connected to the platinum electrode for electrochemical stripping. The electrolyte used was sodium hydroxide solution with a concentration of 5 M. The electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com