Metal vacuum sputtering device and method

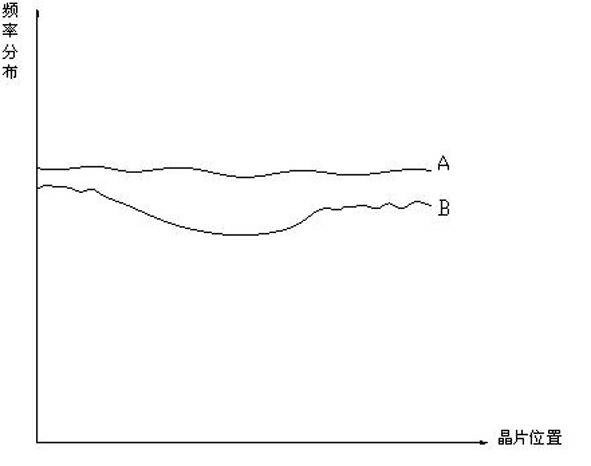

A vacuum sputtering and metal technology, applied in sputtering coating, vacuum evaporation coating, metal material coating process and other directions, can solve the problems of poor consistency of frequency characteristics, large frequency difference, large variation, etc., to achieve cost Inexpensive and simple to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

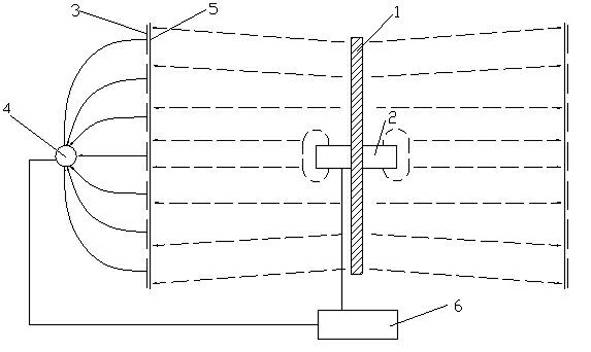

[0031] Below in conjunction with the accompanying drawings, the implementation of the present invention will be further described.

[0032] figure 1 As shown, the device for realizing the present invention includes a rod-shaped metal target 1, a balance coil 2, a wafer metal tooling 3, and a frequency detector 4. The rod-shaped metal target 1 is any metal (such as: silver, copper or chromium, etc.), and the wafer metal tooling 3 Located on both sides of the rod-shaped metal ion source, a wafer 5 is installed on the inner side of the wafer tooling 3, and the metal molecules produced by the rod-shaped metal target are sputtered onto the wafer 5 under the high-speed impact of argon ions that obtain strong electromagnetic field energy, forming electrode.

[0033] A balance coil 2 is installed in the middle of the rod-shaped metal target 1, and the balance coil 2 is formed by arranging and winding a metal wire according to a certain diameter (in other embodiments, the balance coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com