Sputtering tool

A technology of sputtering and jigs, which is applied in the field of jigs, can solve the problems of unsatisfactory sputtering, uneven sputtering, and affecting product yield, so as to achieve the effect of ensuring sputtering and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

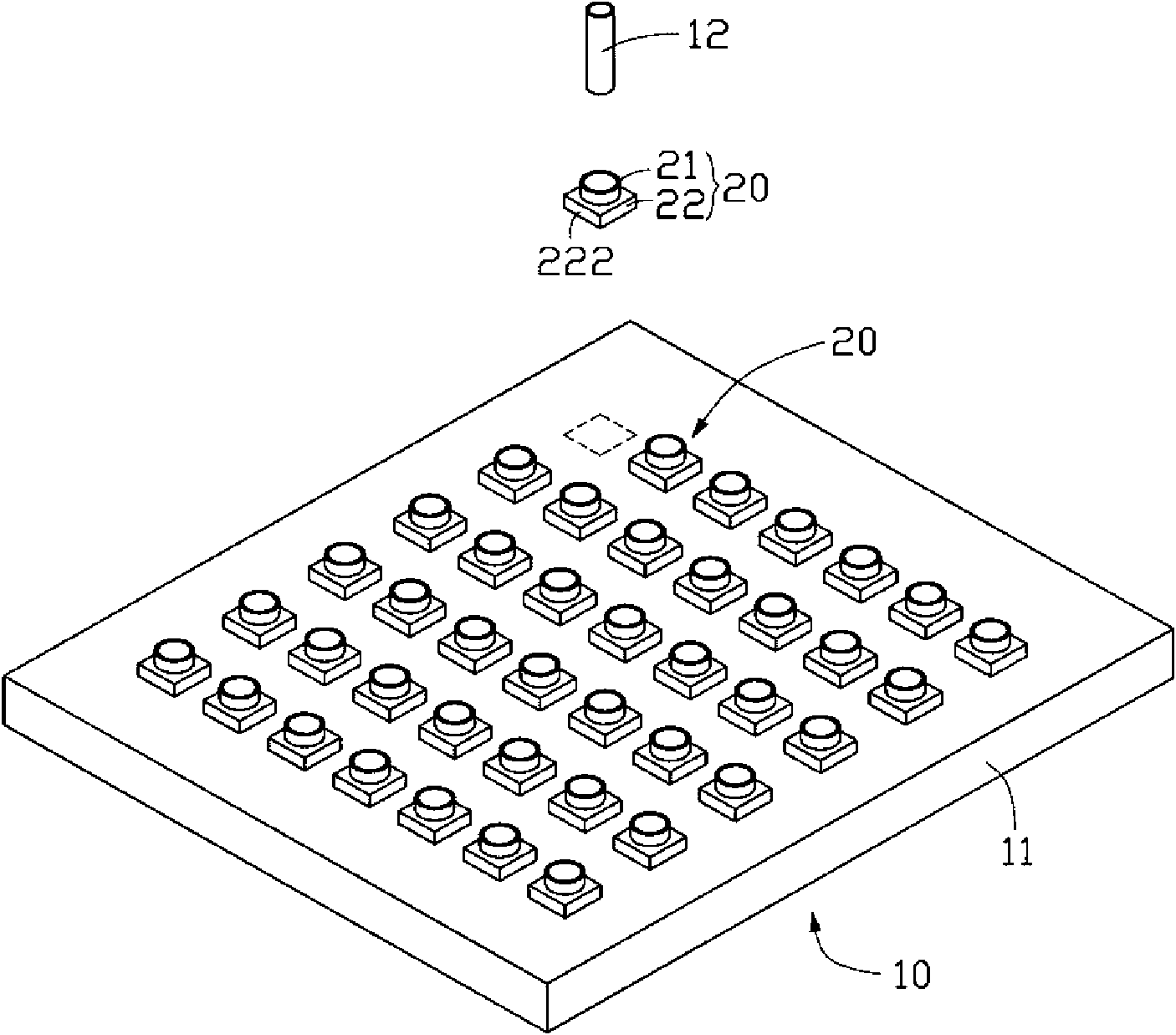

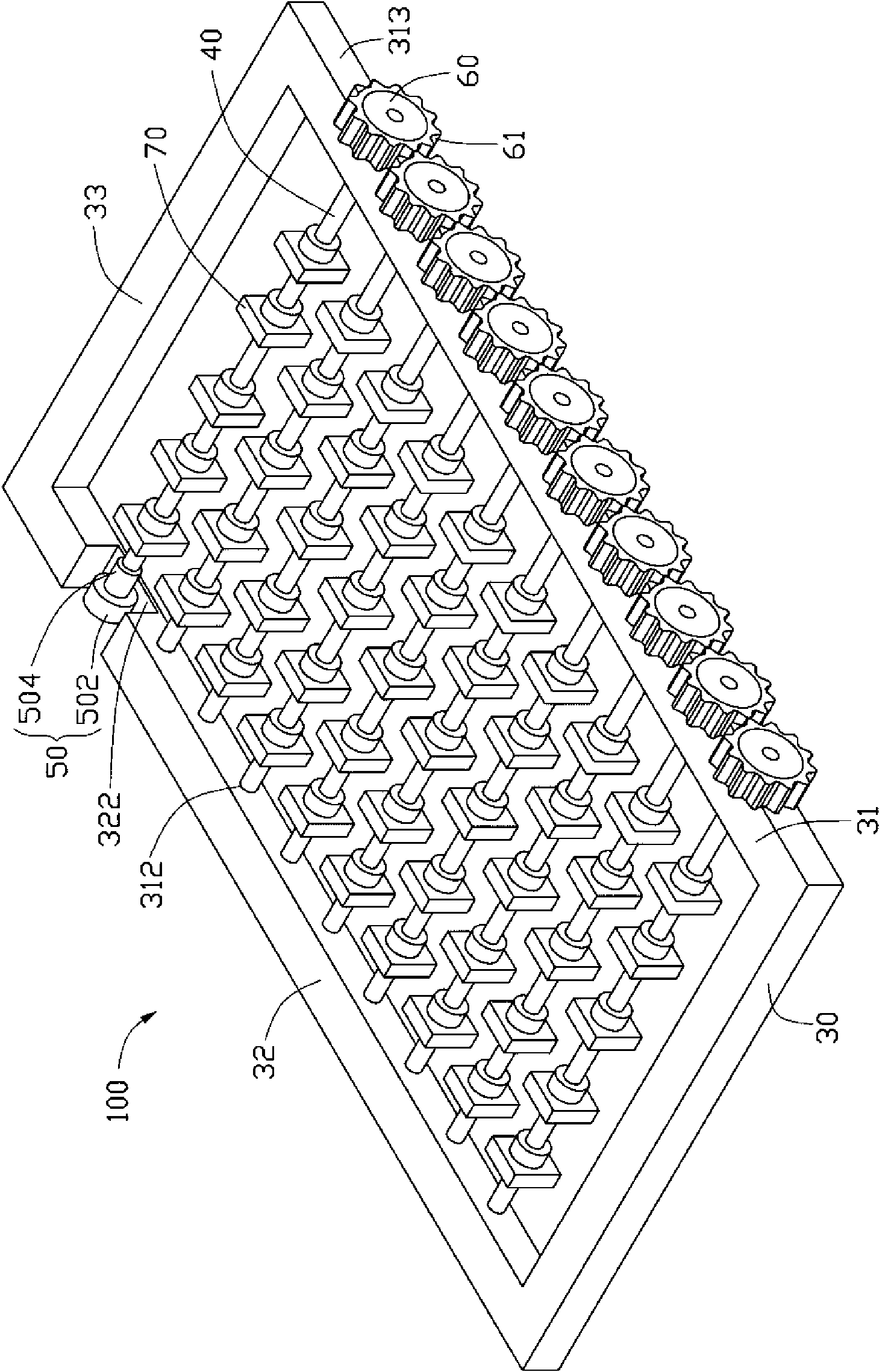

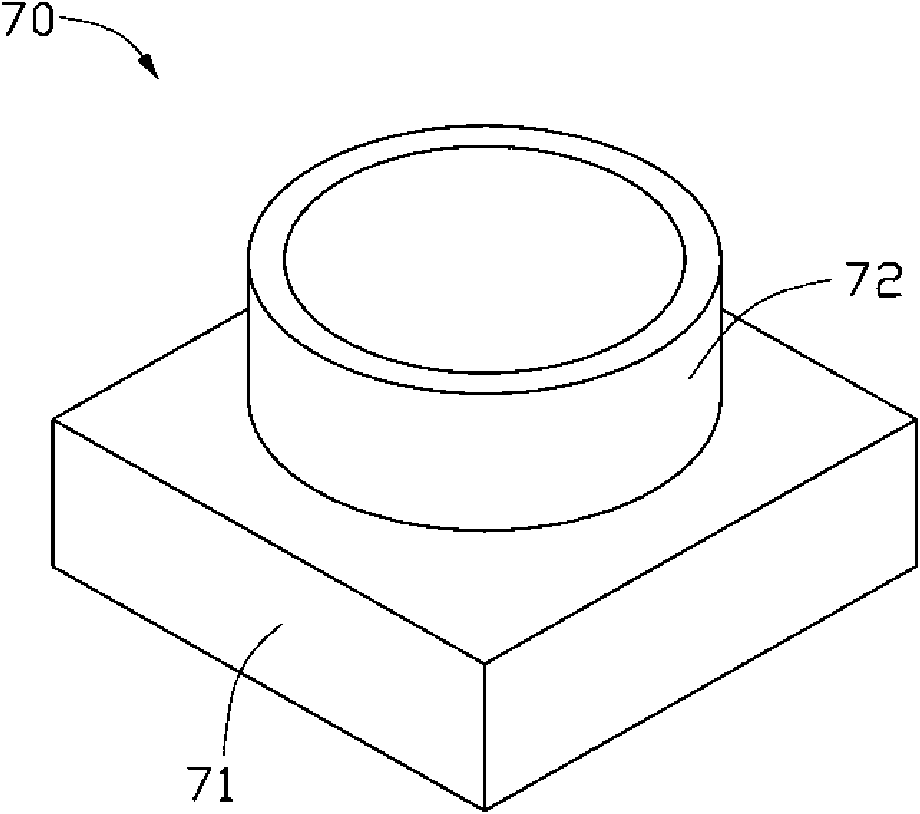

[0016] Please refer to Figure 2 to Figure 4 , is the sputtering fixture 100 of the first embodiment of the present invention, which is used for such as image 3 The shown mirror base 70 to be sputtered is sputtered with an anti-electromagnetic interference film layer. The mirror base 70 generally includes a base 71 and a cylindrical mirror base top 72 extending from the base 71 . The sputtering fixture 100 is used for sputtering the film material on the outer surface of the mirror holder 70 . The sputtering tool 100 includes a bracket 30, at least one rotating rod 40, a driving element 50 and at least two driven elements 60, and the at least two driven elements 60 are respectively arranged on one end of the rotating rod 40, so that The driving member 50 drives one of the rotating rods 40 to rotate with the driven member 60, and the other rotating rods 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com