Vacuum coating method for outer surface of mobile phone shell

A technology of vacuum coating and mobile phone shell, which is applied in the directions of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., which can solve the problem of uneven sputtering of coating layer thickness and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A vacuum coating method for the outer surface of a mobile phone case, comprising the following steps;

[0030] Step 1: The mobile phone case is made of metal material, and the back and edge of the mobile phone case are mirror polished;

[0031] Step 2: Clean and dedust the mobile phone case after step 1, and then dry the mobile phone case after cleaning and dedusting;

[0032] Step 3: Put the mobile phone case that has passed step 2 into the corresponding vacuum coating equipment, and take it out after a certain period of time to complete the coating.

[0033] The coating of the mobile phone shell is completed through polishing, cleaning and dust removal, drying and vacuum coating.

Embodiment 2

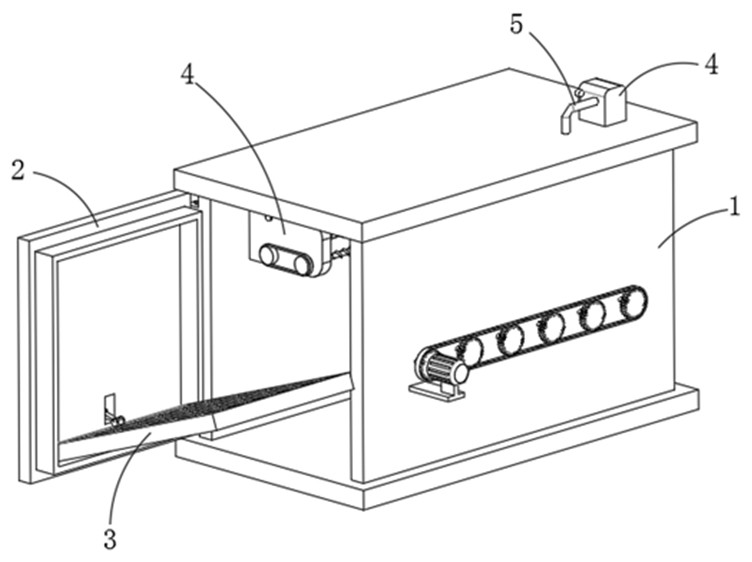

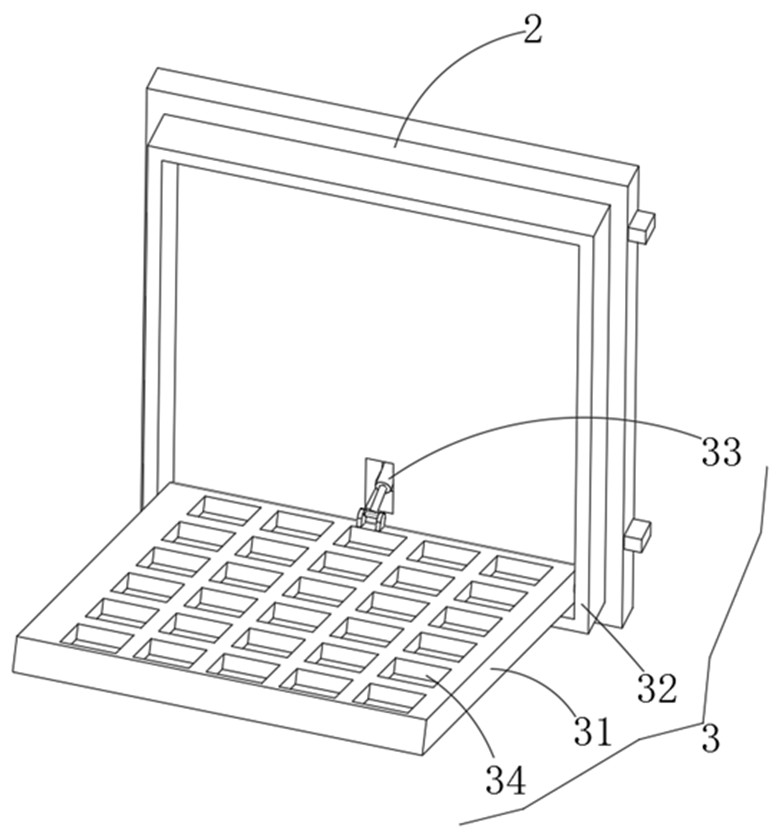

[0035] refer to Figure 1-6 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that in step 3, the vacuum coating equipment includes a box body 1, the outside of the box body 1 is hinged with a box door 2, and the inside of the box door 2 is installed with Placement mechanism 3, placement mechanism 3 comprises placement plate 31, and the inner side of box door 2 is fixedly installed with the accommodation frame 32 corresponding with placement plate 31, and one end of placement plate 31 is connected with accommodation frame 32 rotations, and the interior rotation installation of accommodation frame 32 There is a telescopic rod 33, the output end of the telescopic rod 33 is hinged with the placement plate 31, and the inner side of the placement plate 31 is provided with a plurality of placement slots 34, and the placement slots 34 are used to place the mobile phone casing;

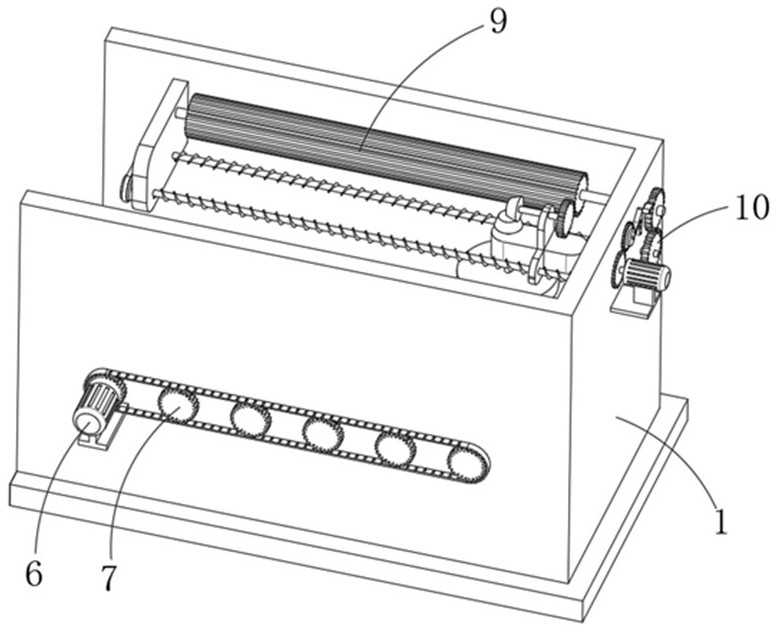

[0036] A coating mechanism 9 is installed in the box body 1,...

Embodiment 3

[0040] refer to Figure 1-6 , as another preferred embodiment of the present invention, the difference from Embodiment 1 or Embodiment 2 is that a drying mechanism 8 is installed on the inside of the box body 1, and the drying mechanism 8 includes an installation box 81, which is fixedly installed on Inside the box body 1, the inside of the installation box 81 is fixedly equipped with a heating pipe 82, and the inside of the installation box 81 is installed with a number of impellers 83, and the outside of the impeller 83 is coaxially fixed with a sprocket 7, and the sprockets 7 pass through The chain transmission connection, the outer side of the box body 1 is fixedly installed with the corresponding second motor 6, the output shaft of the second motor 6 is fixedly connected with the corresponding sprocket 7; the top of the box body 1 is fixedly installed with the corresponding vacuum pump 4, the vacuum pump 4 A conduit 5 is fixedly installed at the input end, and the conduit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com