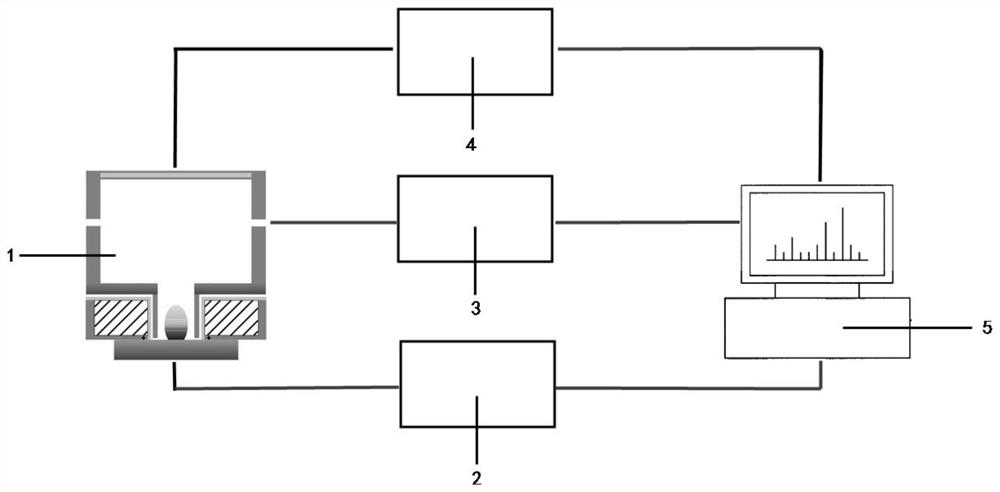

Device and method for preparing glow discharge sputtering sample for microscopic characterization of material

A glow discharge and sample preparation technology, applied in the preparation of test samples, electron/ion optical devices, discharge tubes, etc., can solve the problems of changing organizational structure, small area, high cost, etc., and achieve uniform sample sputtering and distribution Equalize, increase the effect of the motion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

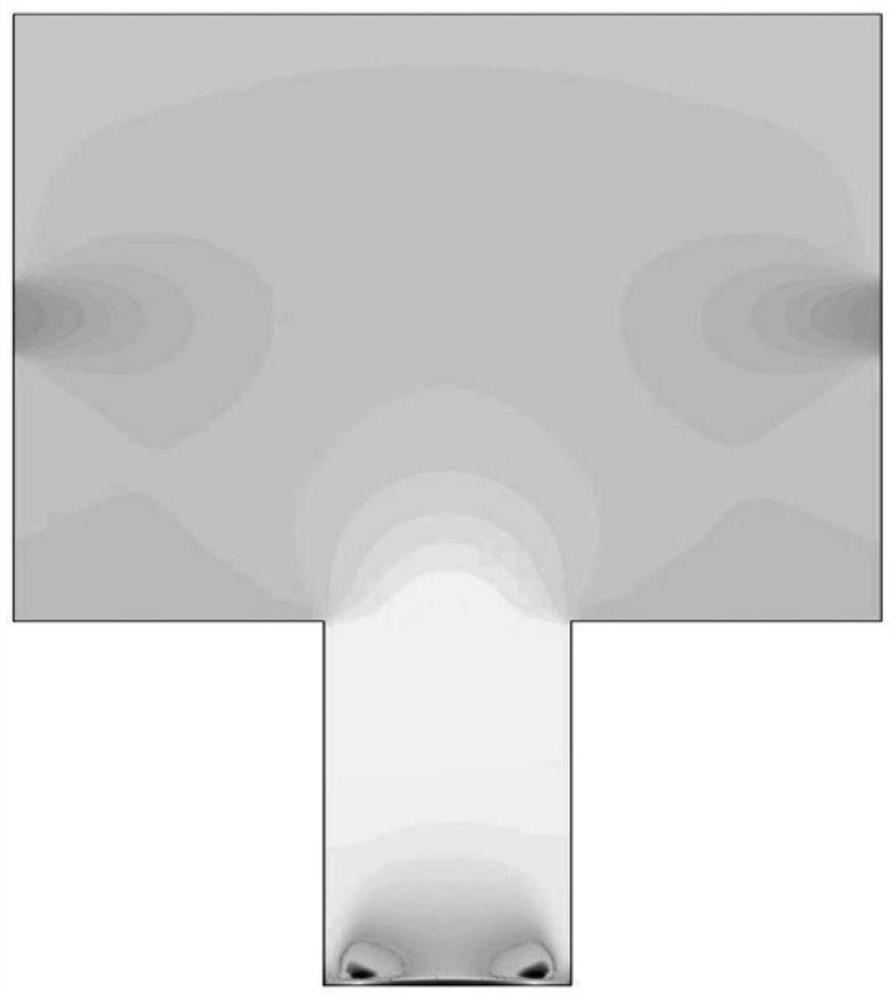

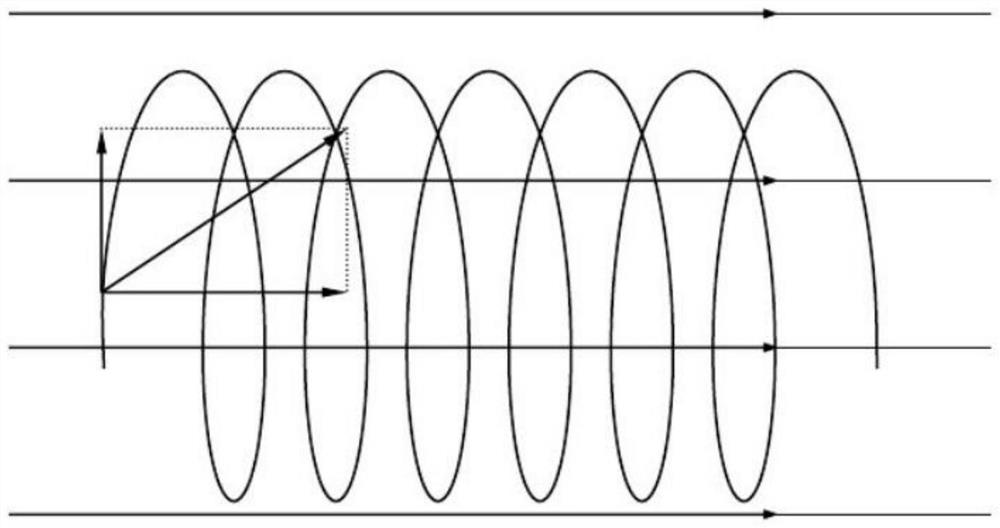

Method used

Image

Examples

Embodiment

[0090] The device for preparing samples by glow discharge sputtering for material microscopic characterization of the present invention is used to prepare large-scale samples of nickel-based single crystal superalloy samples. The operation steps are as follows:

[0091] Sample preparation: cut the sample into a size not less than 20mm, which can completely cover the anode cylinder of the glow discharge sputtering device and the sealing O-ring on the cathode disk. If the sample is too small, it needs to be hot-mounted with conductive resin to ensure that the sample It can be sputtered normally; the cut sample is ground and polished in sequence to obtain a flat and clean sample surface, which is ready for use.

[0092] The prepared sample can be marked with a microhardness tester, such as Figure 8 As shown, the width of the marking point is about 30 μm, and the coordinates of each marking point can be accurately obtained when the hardness point is punched by a microhardness te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com