Sputtering plating system for plastic and rubber pipe

A plastic tube and sputtering technology, which is applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of troublesome cleaning of sputtering device, limited uniformity of sputtering, and low efficiency, so as to improve efficiency , Improve cleaning efficiency and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

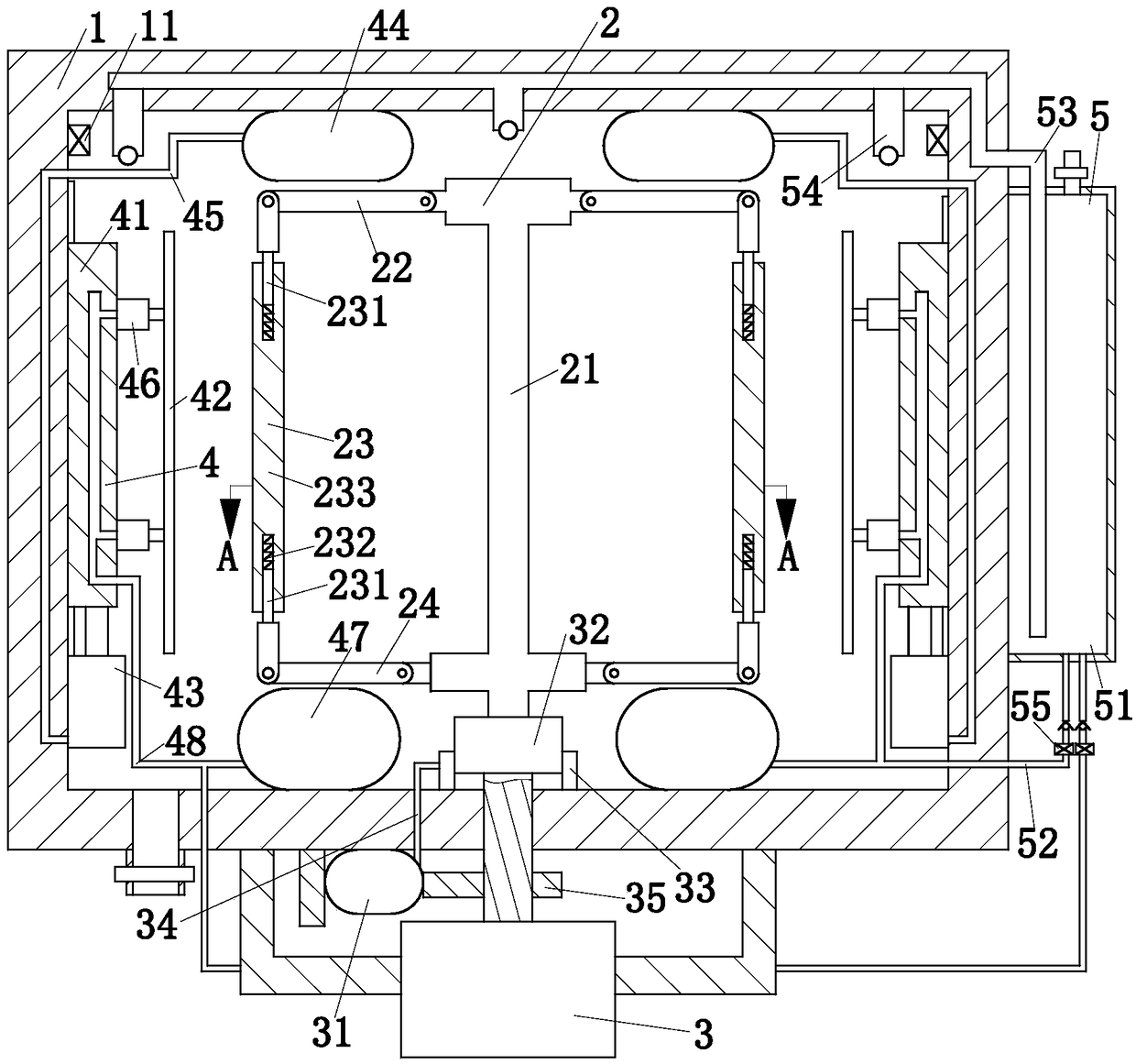

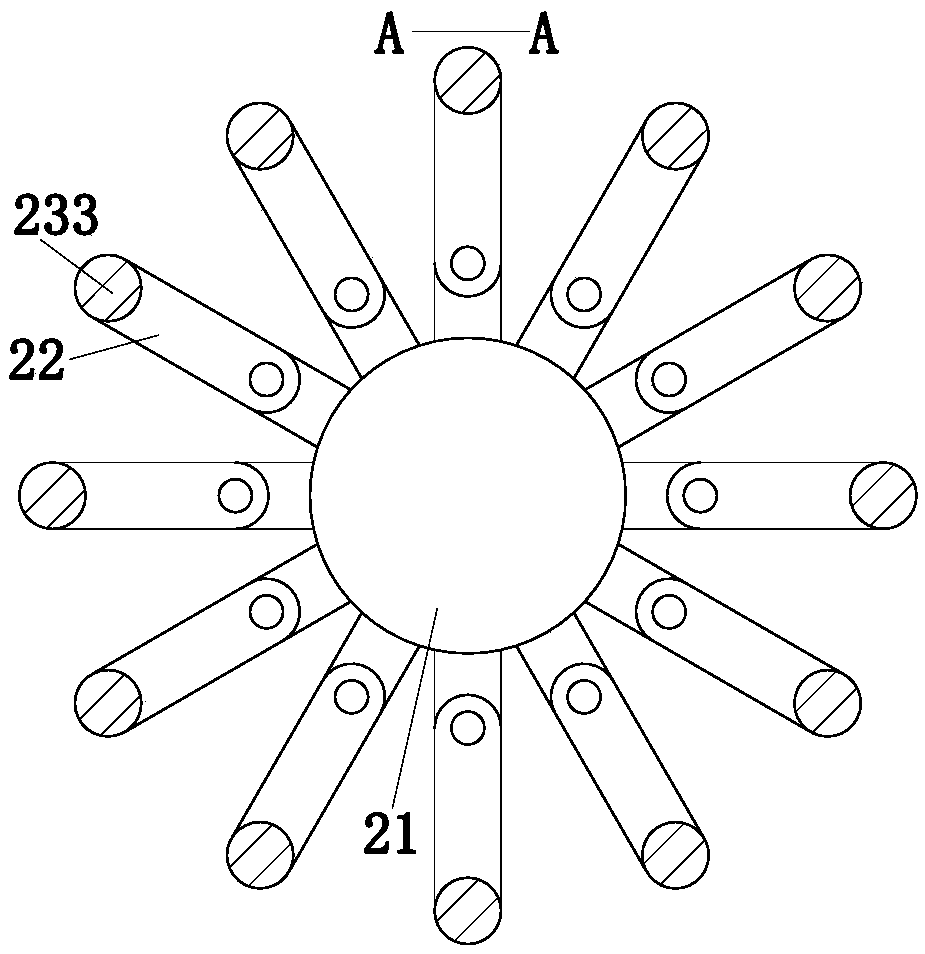

[0022] use Figure 1 to Figure 2 The plastic pipe sputtering system of the present invention will be described as follows.

[0023] Such as Figure 1 to Figure 2 As shown, a plastic pipe sputtering system according to the present invention includes a sputtering box 1, a workpiece holder 2, a motor 3, a target module 4, a heater 11, and an automatic cleaning module 5. The sputtering box 1 The bottom end is provided with a water outlet pipe and a water valve is provided on the outlet pipe; the motor 3 is fixed outside the sputtering box 1; the workpiece holder 2 is located in the center of the sputtering box 1, and the workpiece holder 2 is driven to rotate by the motor 3; The target module 4 is installed on the inner wall of the sputtering box 1. The target module 4 is adjacent to the workpiece holder 2, and the target module 4 can move up and down or laterally close to the workpiece holder 2. The main body of the automatic cleaning module 5 is fixed on the sputtering box. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com