Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "There will be no bursting phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soybean protein casing colloid suitable for sausage coextrusion technology and preparation method thereof

The invention discloses soybean protein casing colloid suitable for the sausage coextrusion technology. The colloid comprises the following raw materials in parts by weight: 800-1200 parts of soybean protein colloid, 400-600 parts of collagen fiber colloid, 40-60 parts of high-strength long collagen fiber, 2-10 parts of crosslinking agent, 2-4 parts of transglutaminase and water, wherein the weight of water is 85%-95% of the weight of the final soybean protein casing colloid. After the casing colloid of the invention is extruded by a coextrusion system, the obtained casing has good elasticity and high compressive strength and packing strength, thus when the sausage with the obtained casing is cooked, the phenomenons that the casing shrinks excessively to burst and the casing fractures owning to high cooking temperature can not appear.

Owner:山东冠华蛋白肠衣有限公司

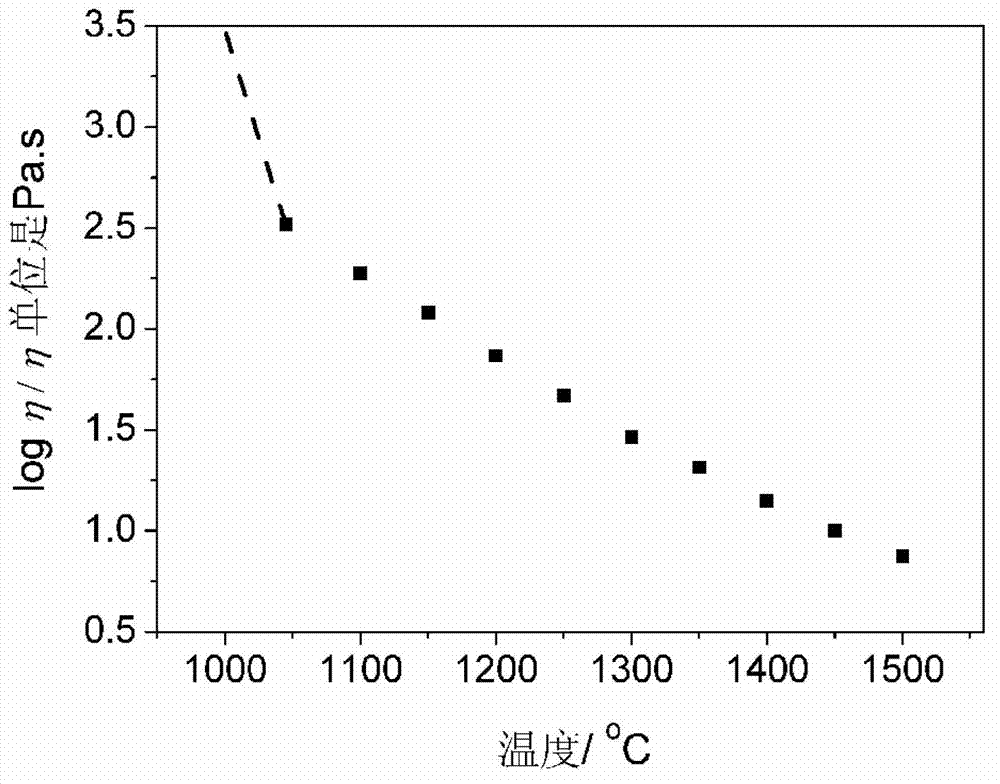

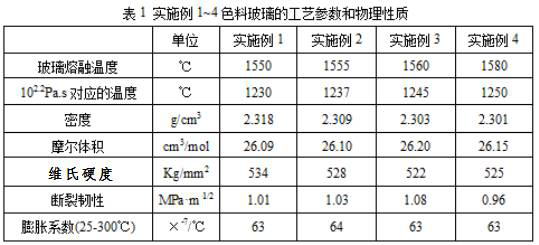

Manufacturing method for colored fluorine-free imitation ceramic glaze

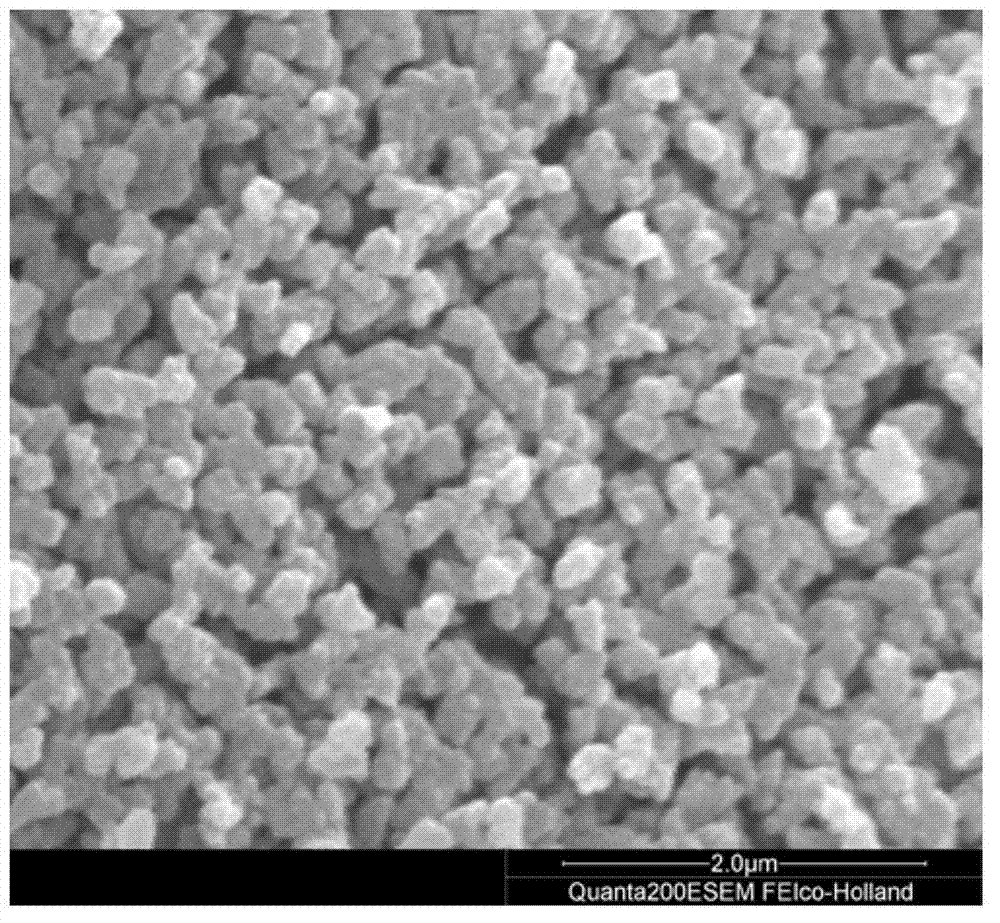

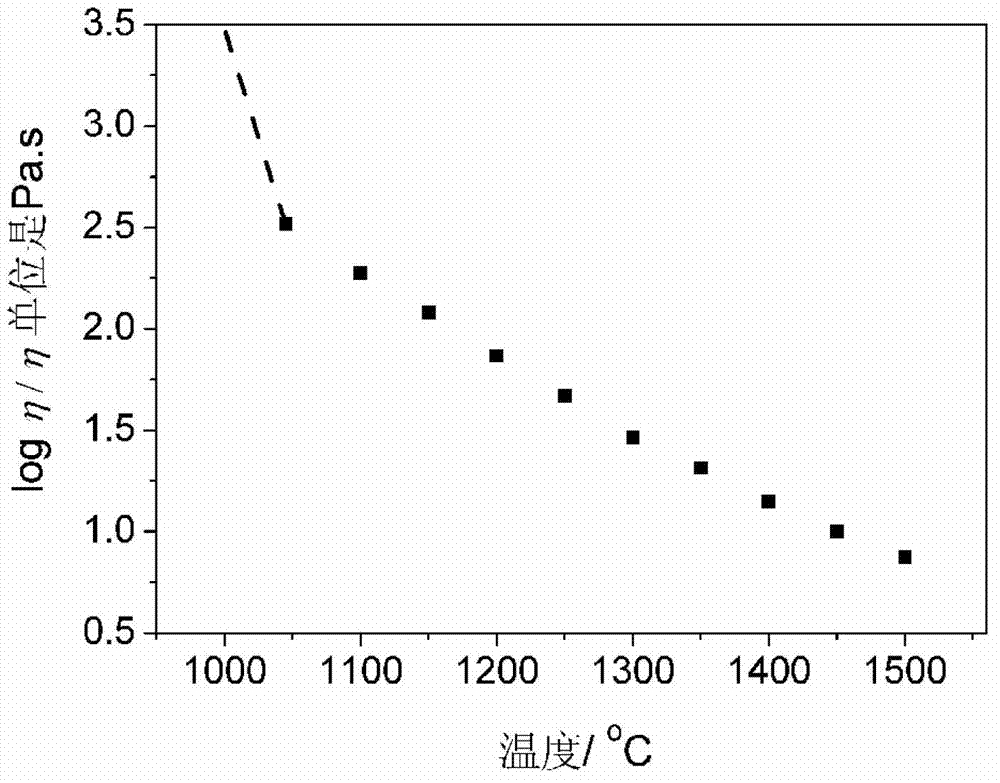

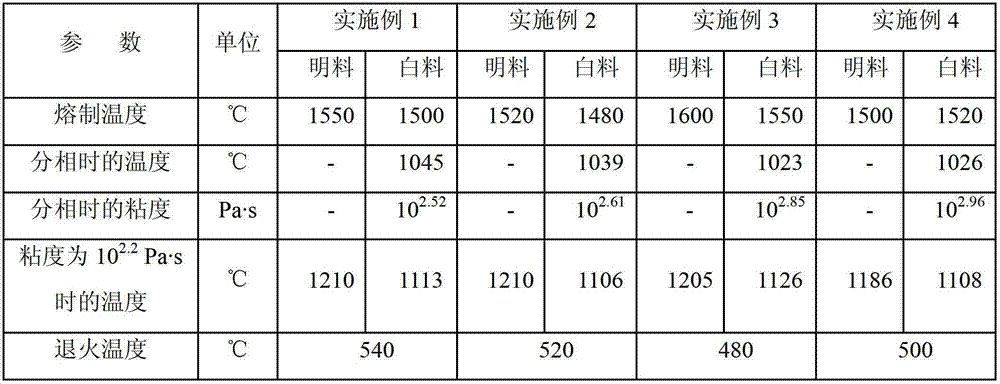

ActiveCN102786202AReduce cooling rateSlow coolingGlass blowing apparatusDevitrificationPhase splitting

A manufacturing method for colored fluorine-free imitation ceramic glaze belongs to the field of advanced glass materials. According to the manufacturing method, a melt jacking blowing method is adopted, and the five-layer colored fluorine-free imitation ceramic glaze is prepared by dip blowing according to the sequence of bright material, white material, bright material, pigment and bright material. The manufacturing method overcomes the defect that the traditional imitation ceramic glass production greatly depends on the initial temperature of glass melt phase-splitting or devitrification and the cooling speed during forming; and meanwhile, the manufacturing method realizes very good opacifying effect under the condition of lower phosphorous content, and the common defects of uneven opacifying degree, stripe and the like are not liable to occur.

Owner:淄博市宝泉轻工制品有限公司

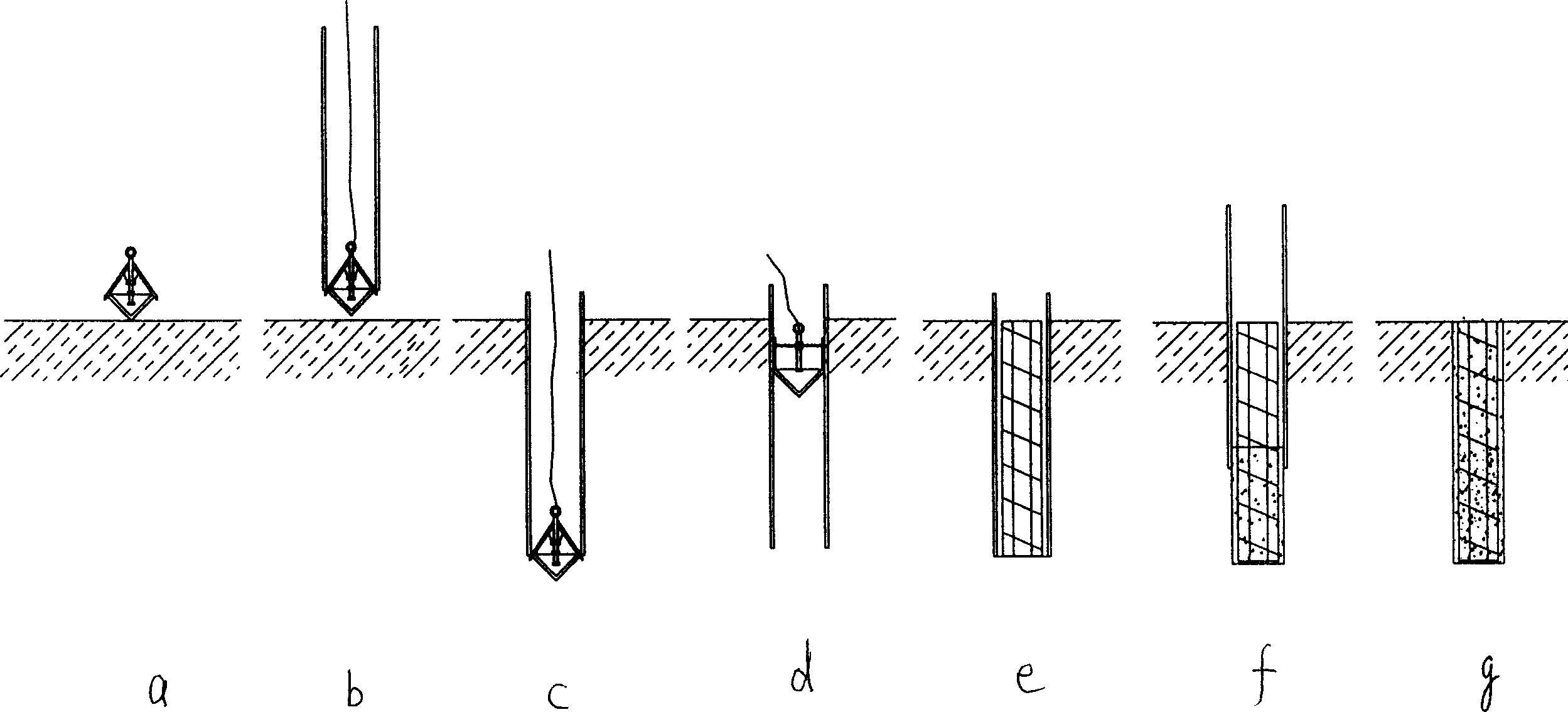

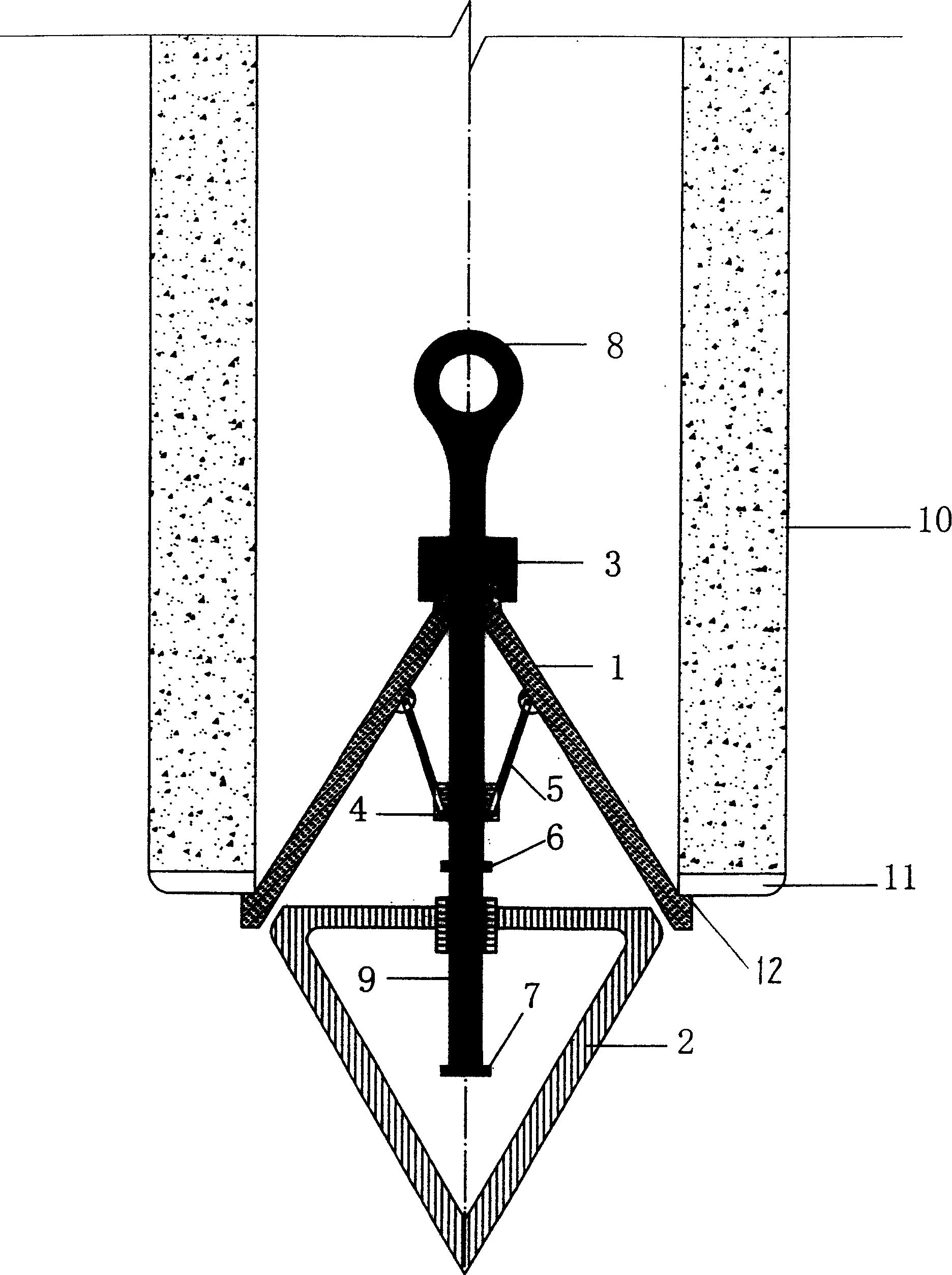

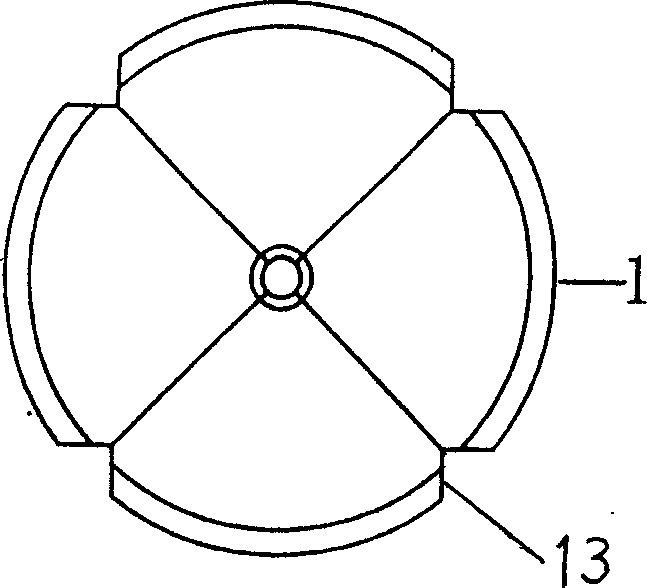

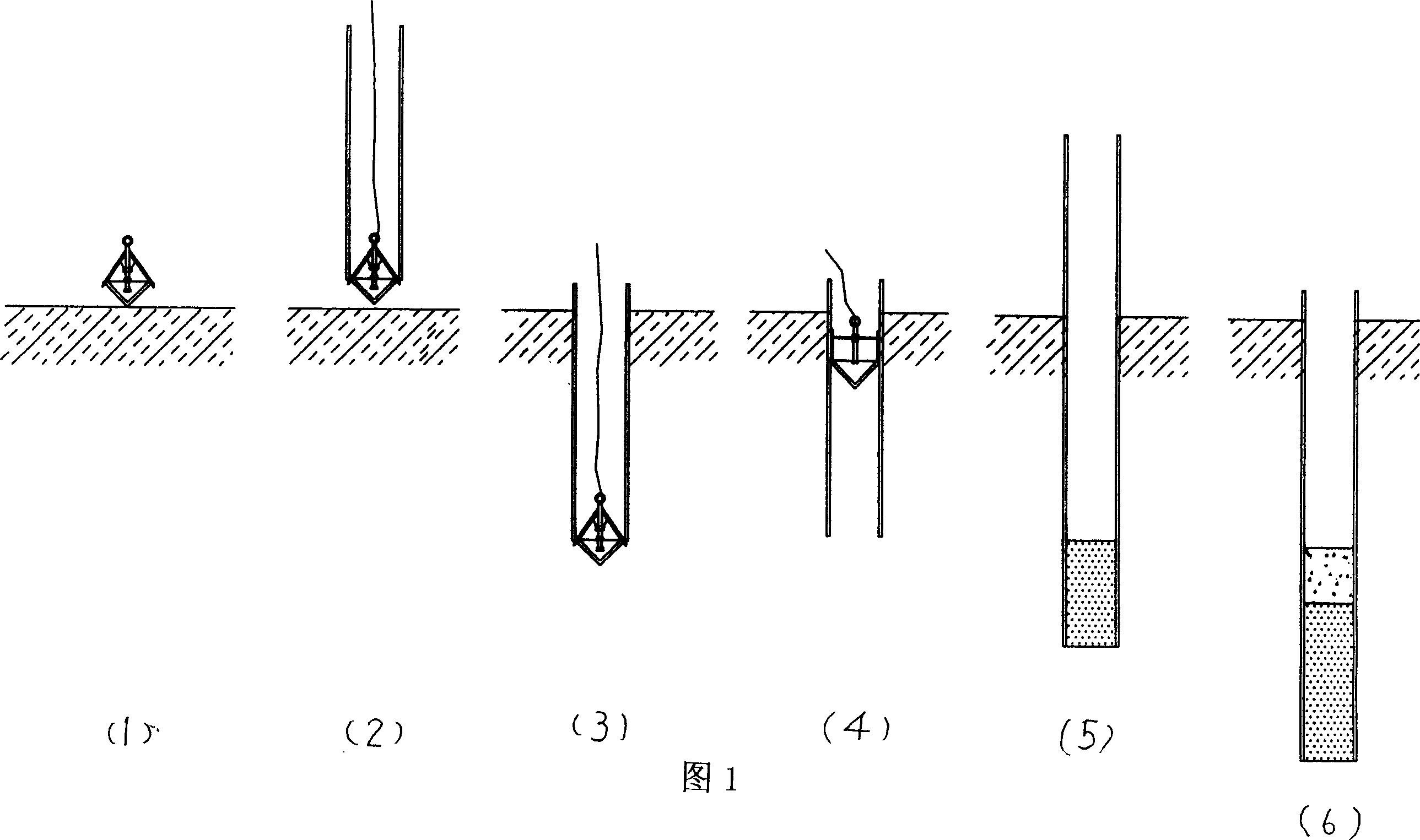

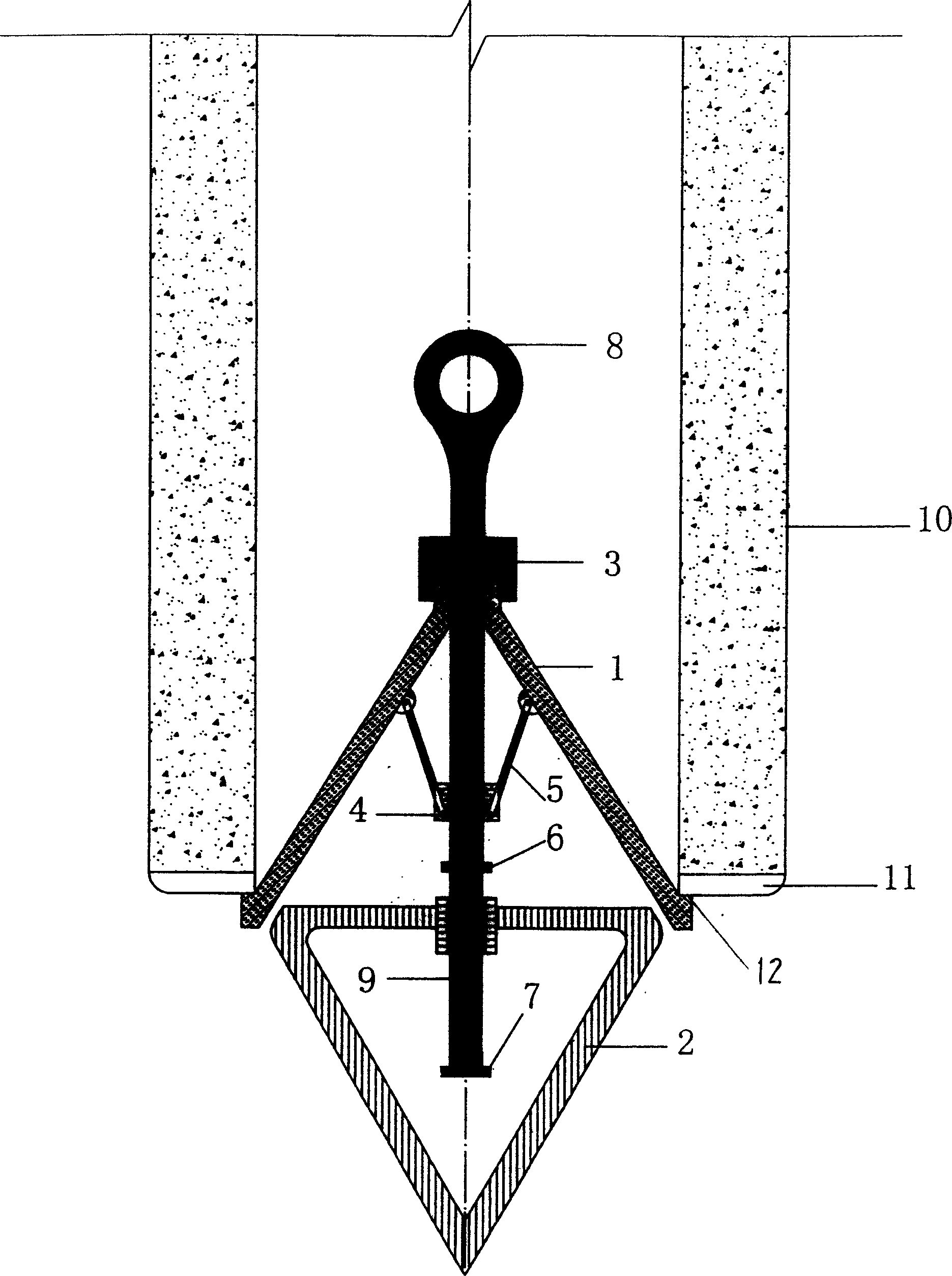

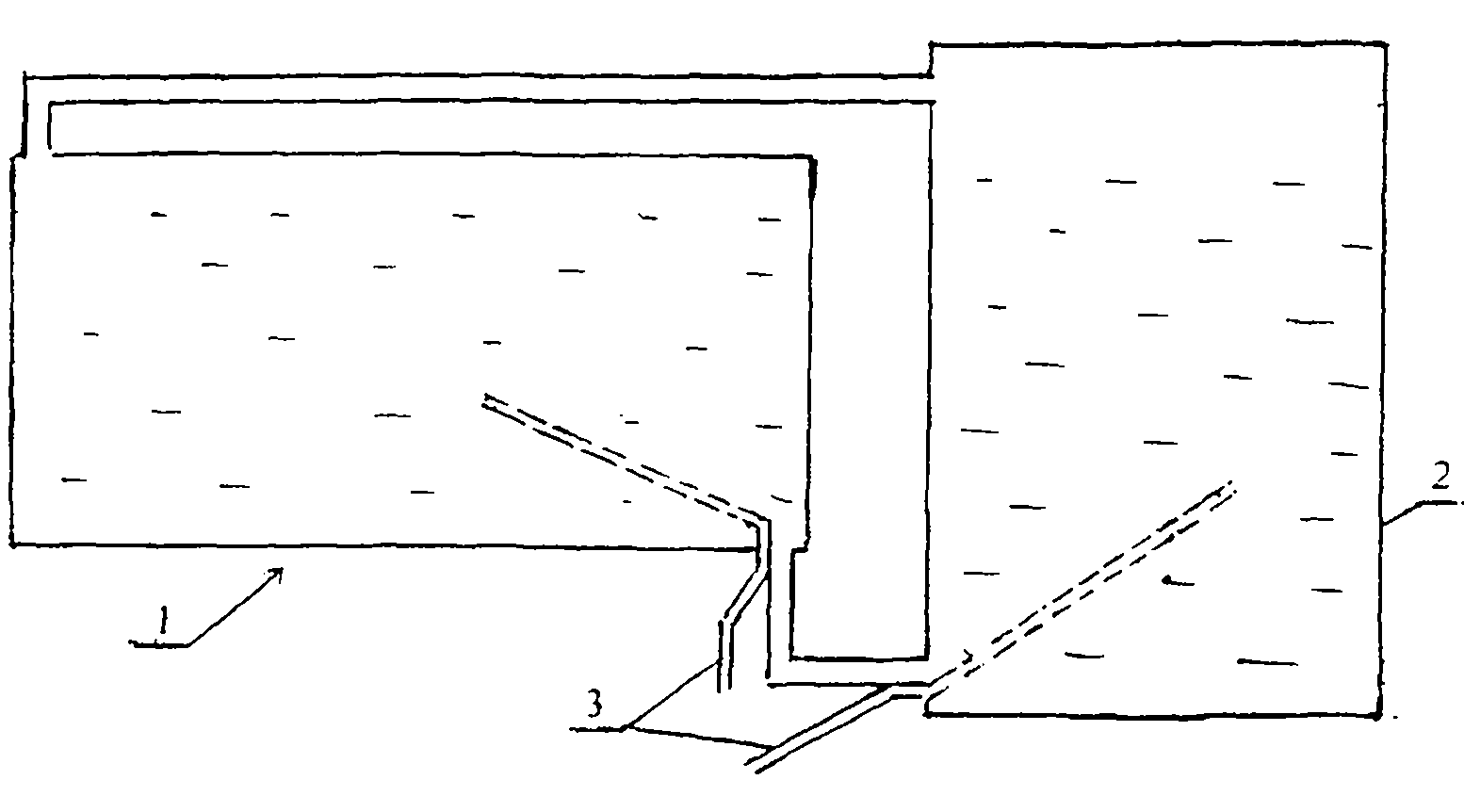

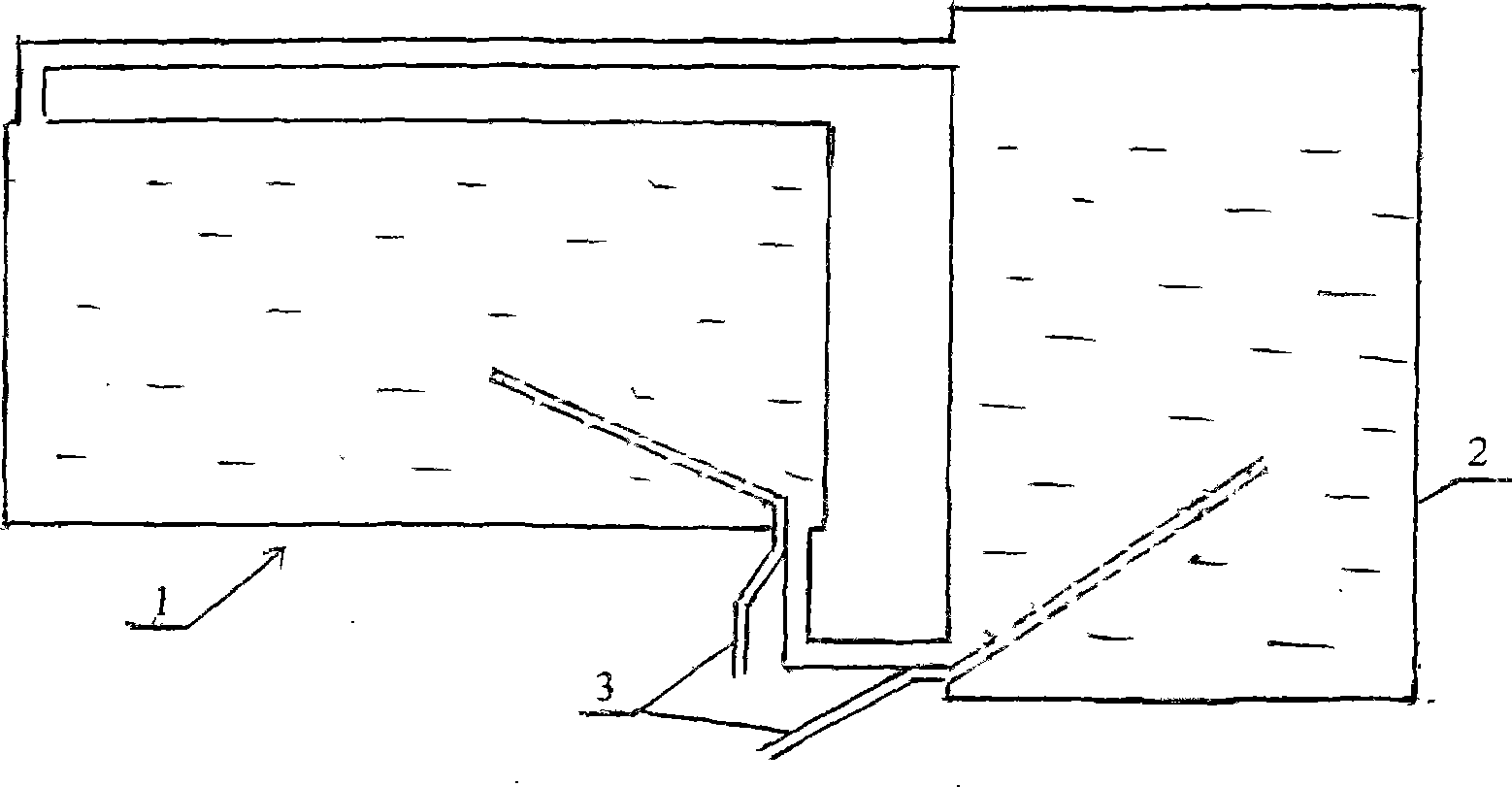

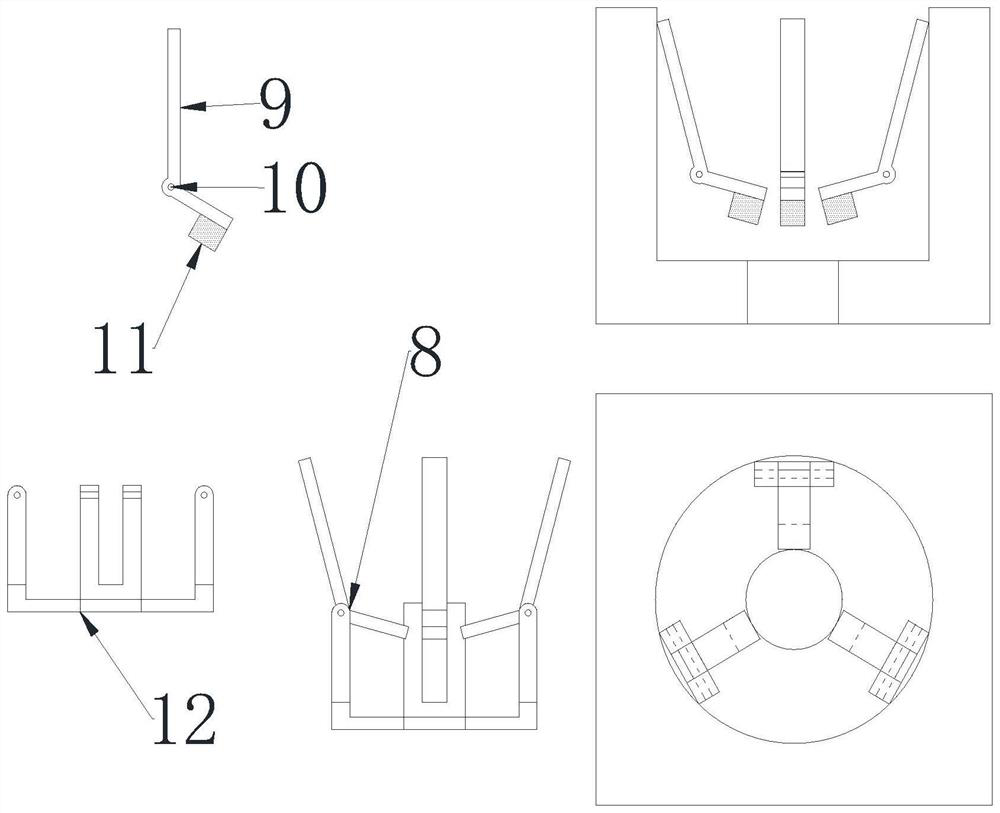

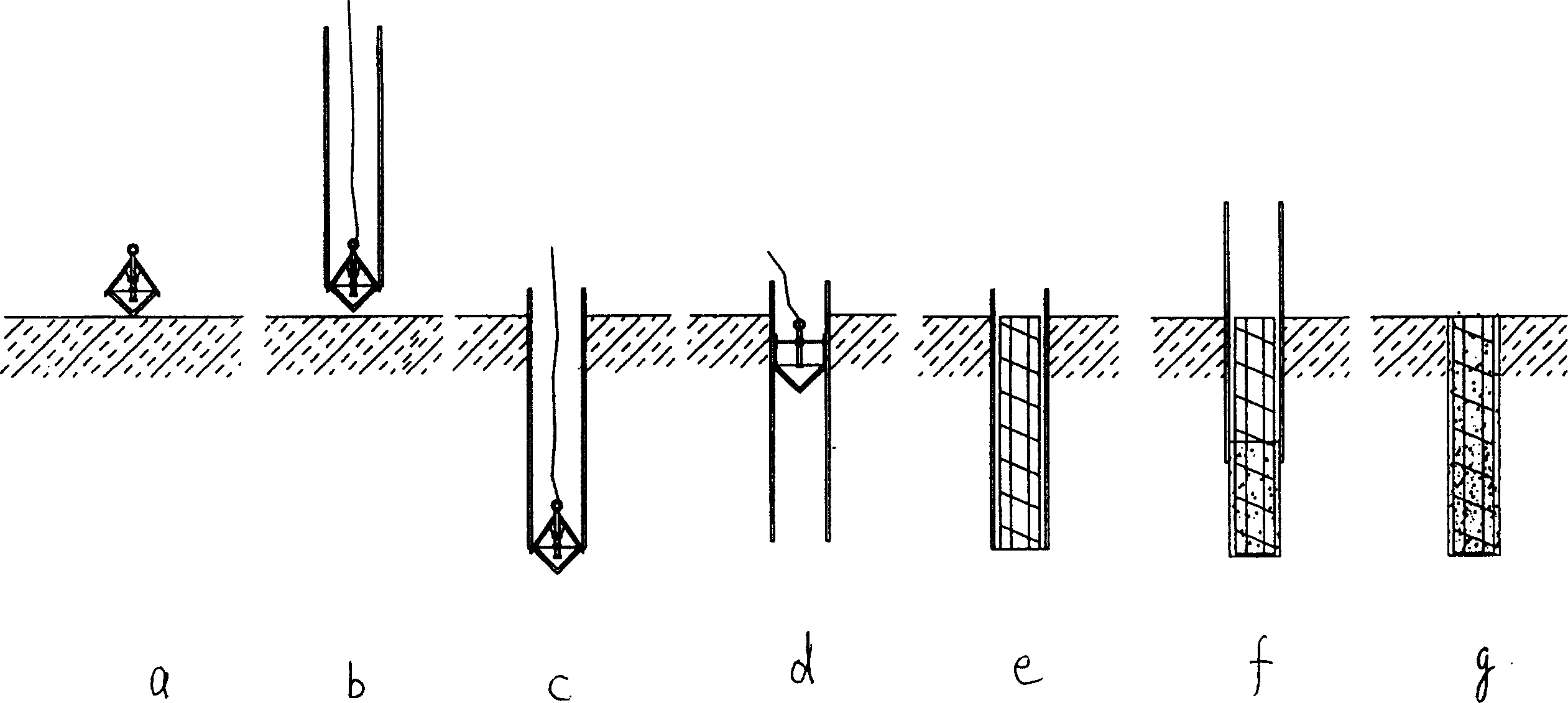

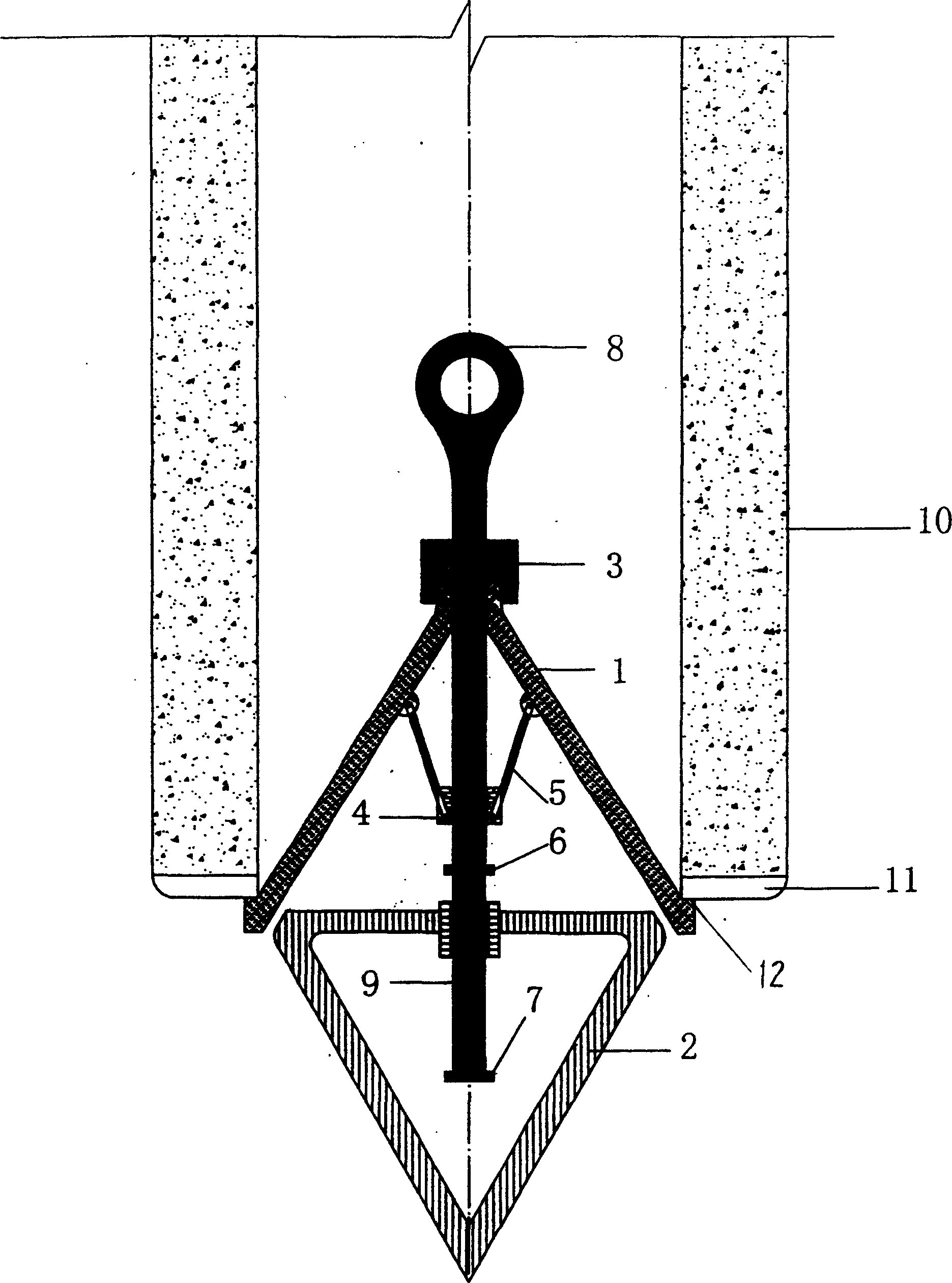

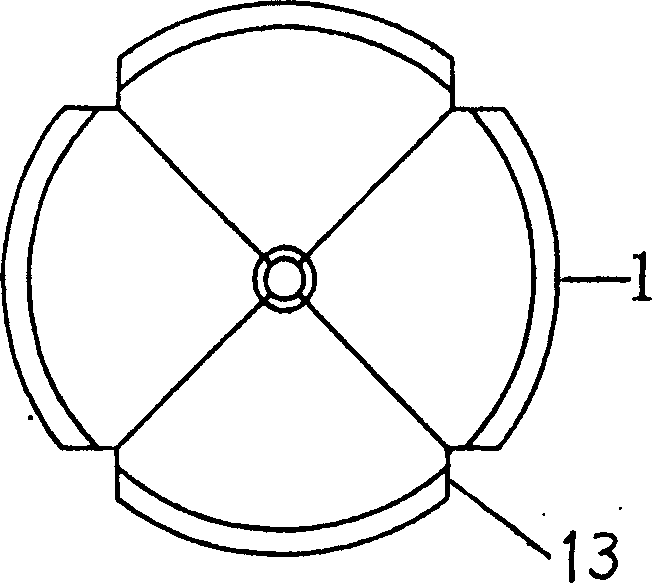

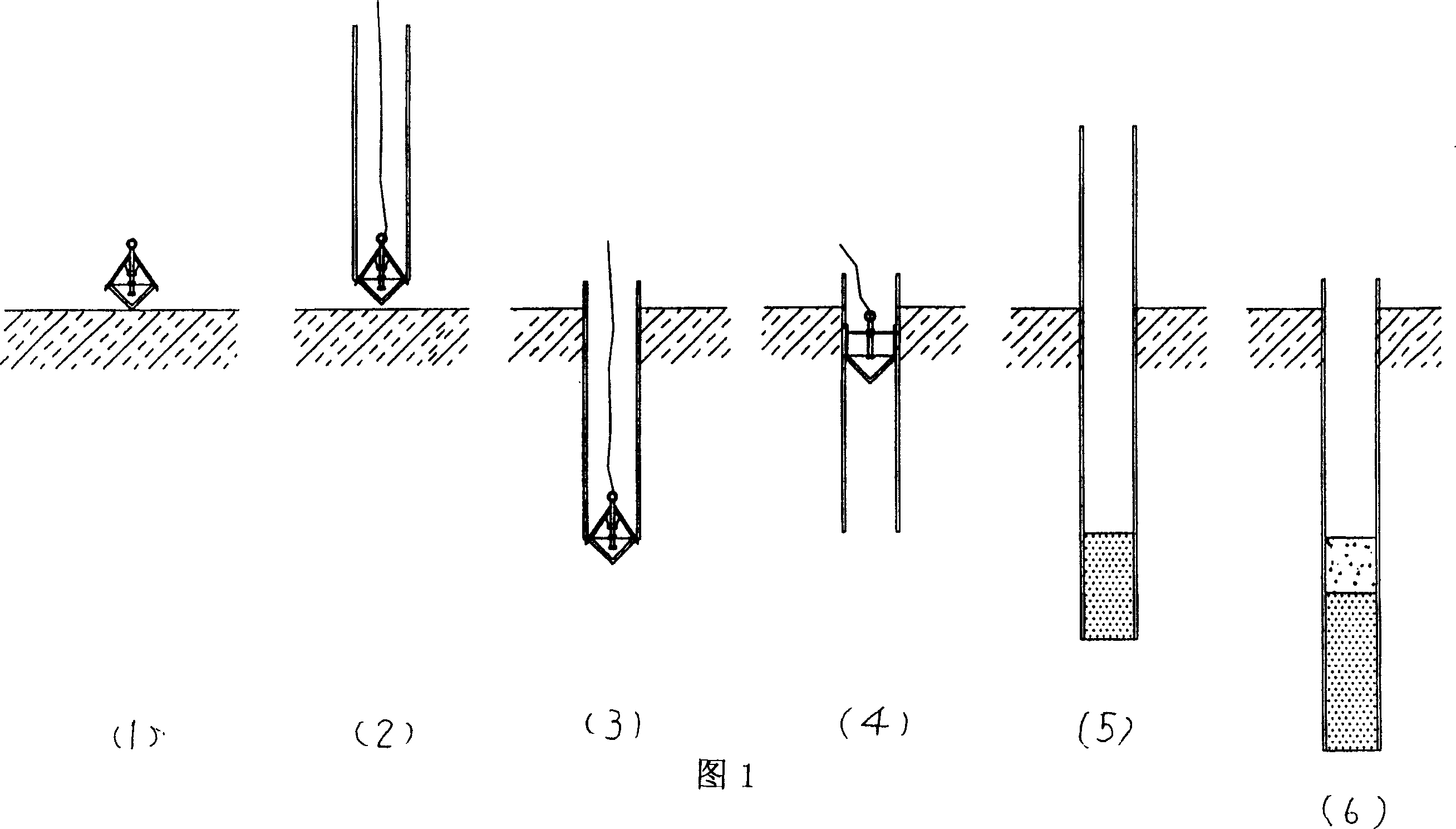

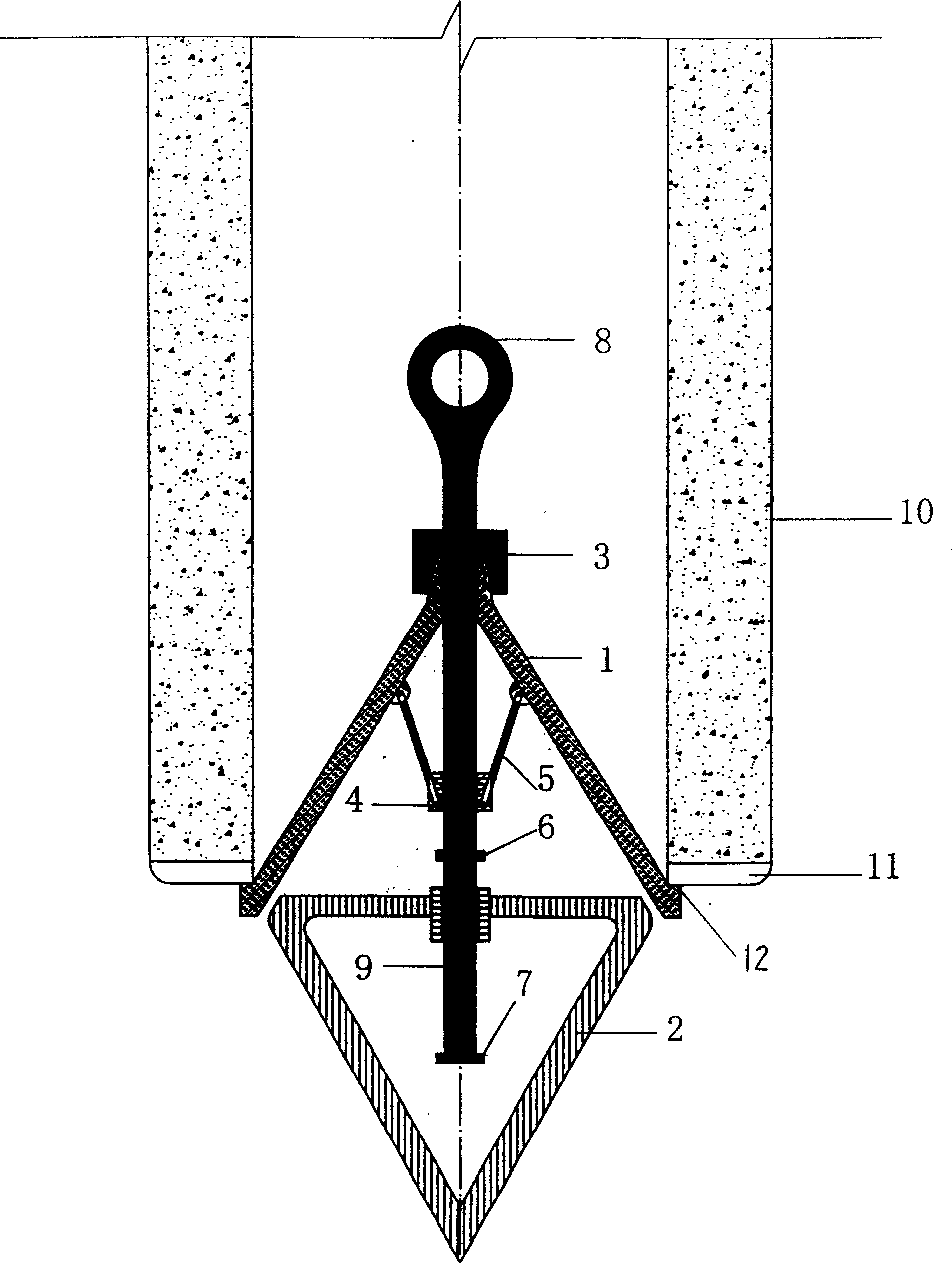

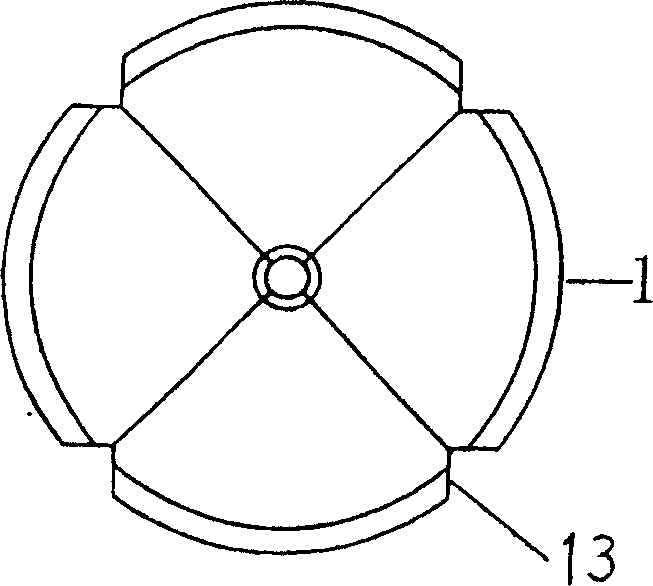

Immersed tube grout pile construction process and pile tip bearing capacity reinforcement equipment

The invention is a sinking tube pouring picket constructing technique and picket-end bearing capacity enhancer, placing the enhancer at positioning point of the picket base; the picket machine takes its place to align the end of the steel sleeve with the enhancer; starting sinking the tube to the calculated position; pulling the rope linked with the enhancer to drive axial umbrella rod, so that the top cap relieves the inclined support from restriction, the fixed stop block drives the annular slide block to make the supporting link rod push and spread the inclined support around so as to shrink into the steel sleeve, and the active stop block drives the picket boot to take out the enhancer. Placing bar reinforcement cage in the steel sleeve; vibrantly pulling the tube while pouring the concrete, and forming a picket. It can enhance the penetrating property of the steel sleeve, extrude picket end soil body closely, heighten picket-end bearing capacity, reduce deposition quantity, heighten picket forming quality and constructing efficiency, etc.

Owner:北京中技天昊工程技术有限公司

Colored fluoride-free ceramic imitation azure stone

ActiveCN102806727AReduce cooling rateIncrease the degree of phase separationGlass/slag layered productsSecondary layerColourant

The invention discloses a colored fluoride-free ceramic imitation azure stone, and belongs to the field of new materials of glass. The colored fluoride-free ceramic imitation azure stone is characterized by having a laminated structure and is divided into fiver layers from inside to outside, wherein a first layer is a first bright material layer; a second layer is a white material layer; a third layer is a second bright material layer; a fourth layer is a pigment layer; a fifth layer is a third bright material layer; the thickness of the white material layer is 0.7 to 0.95mm; and the thickness of the pigment layer is 0.6 to 0.85mm. According to the ceramic imitation azure stone, the defect of high dependence degree of the conventional ceramic imitation azure stone on the starting temperature of a glass melt in the phase-splitting or crystallizing process and the cooling speed of the temperature melt in the forming process is overcome; and simultaneously, common defects of non-uniform opacification degrees, stripes and the like are overcome through the ceramic imitation azure stone.

Owner:淄博市宝泉轻工制品有限公司

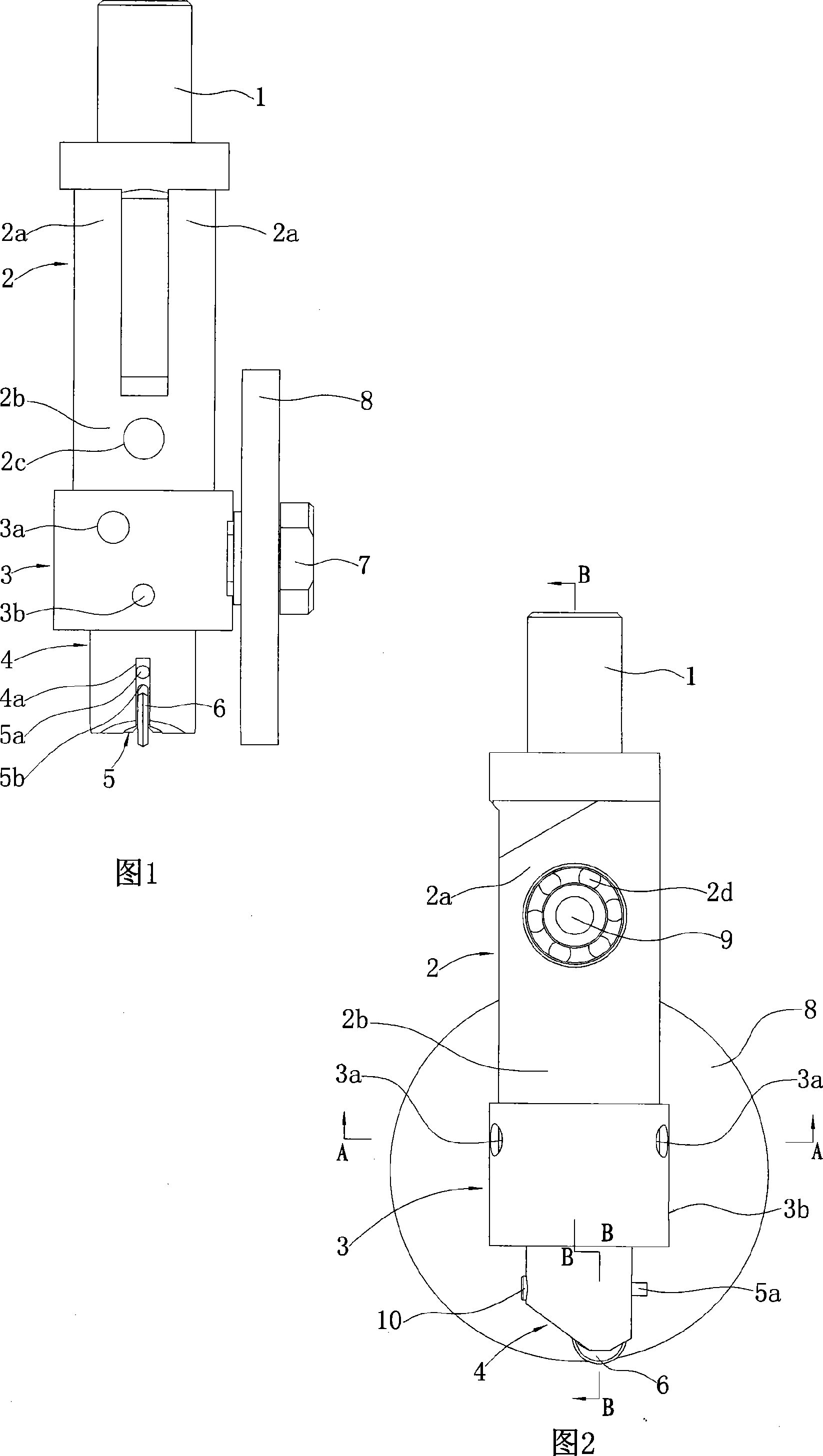

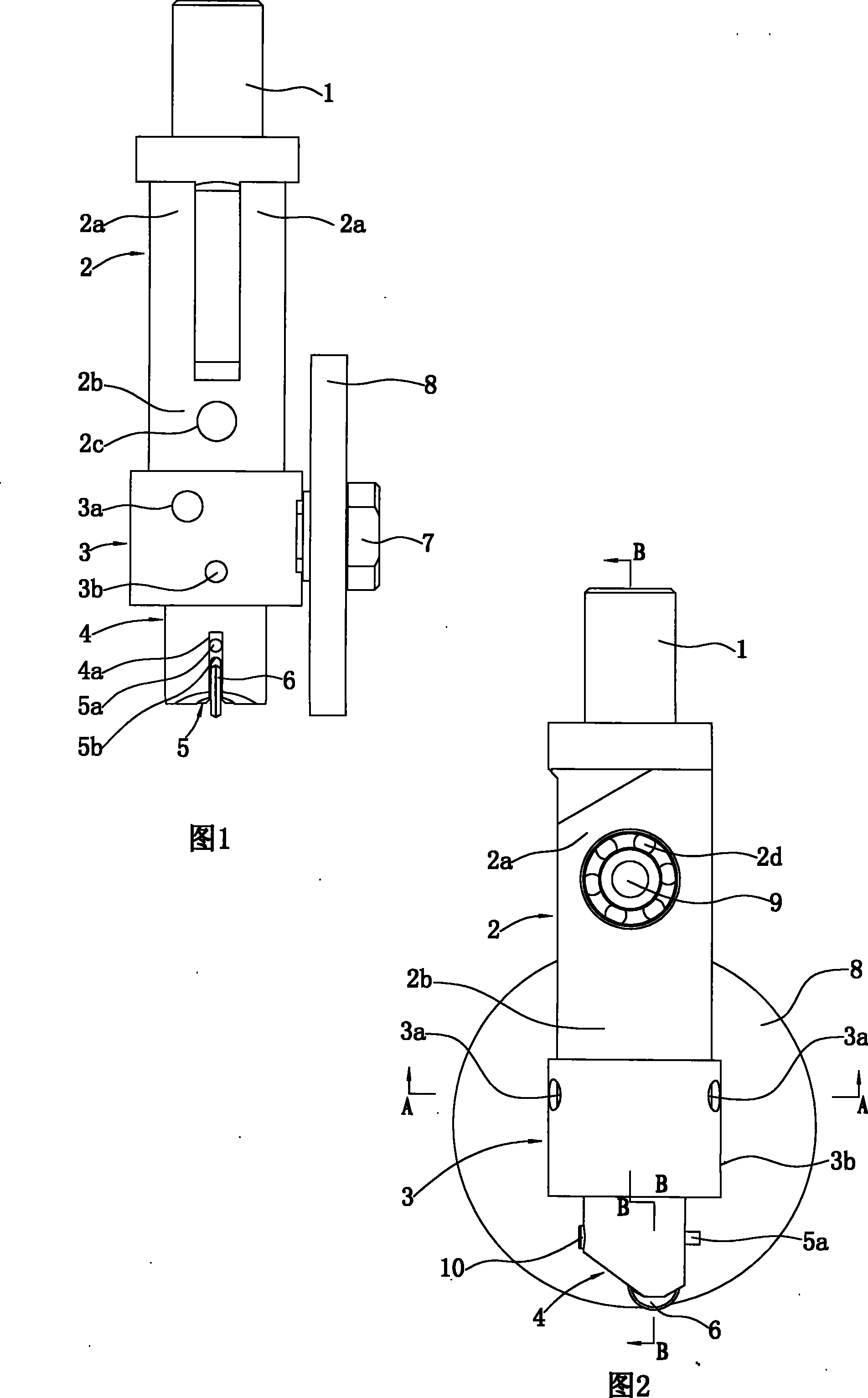

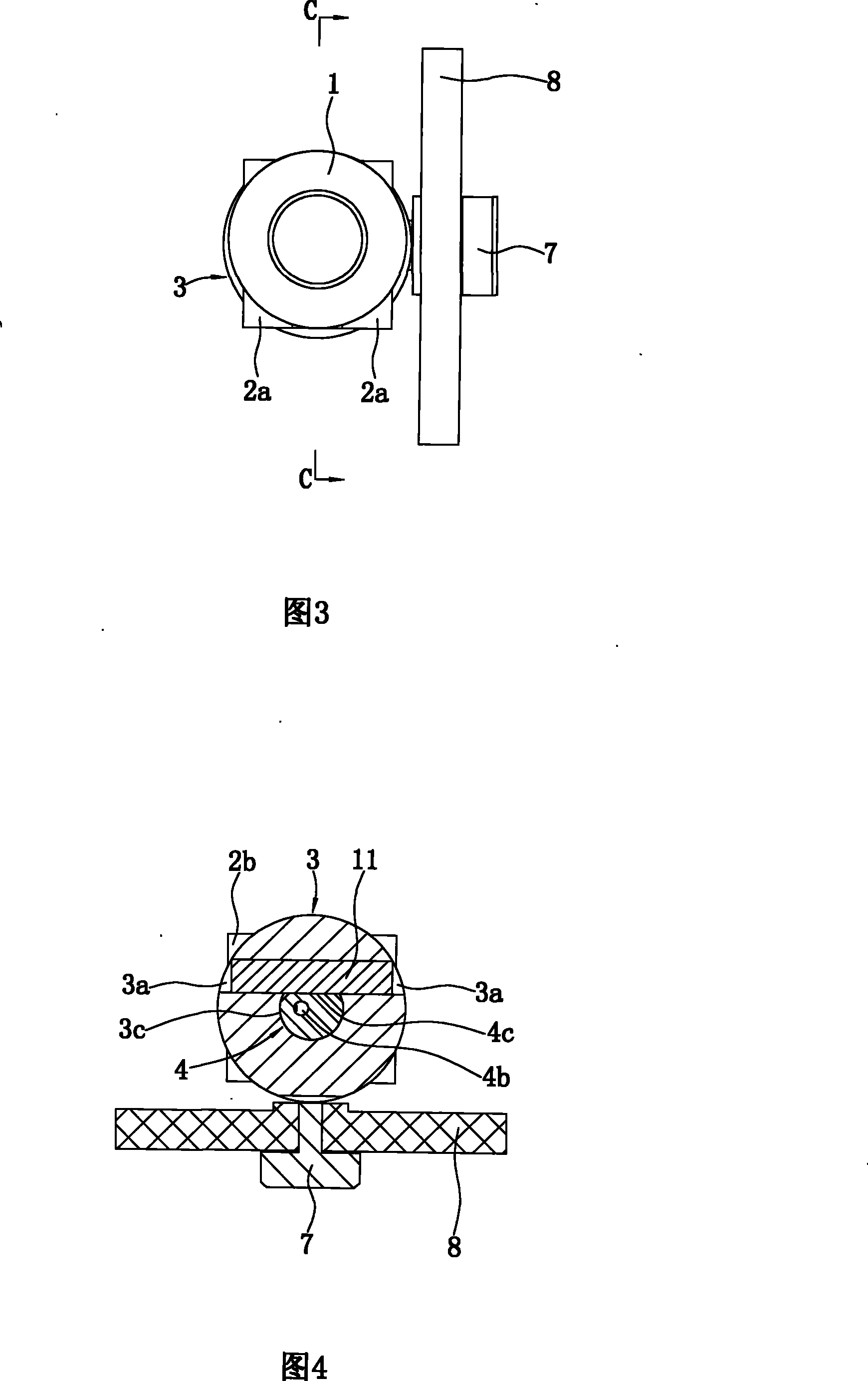

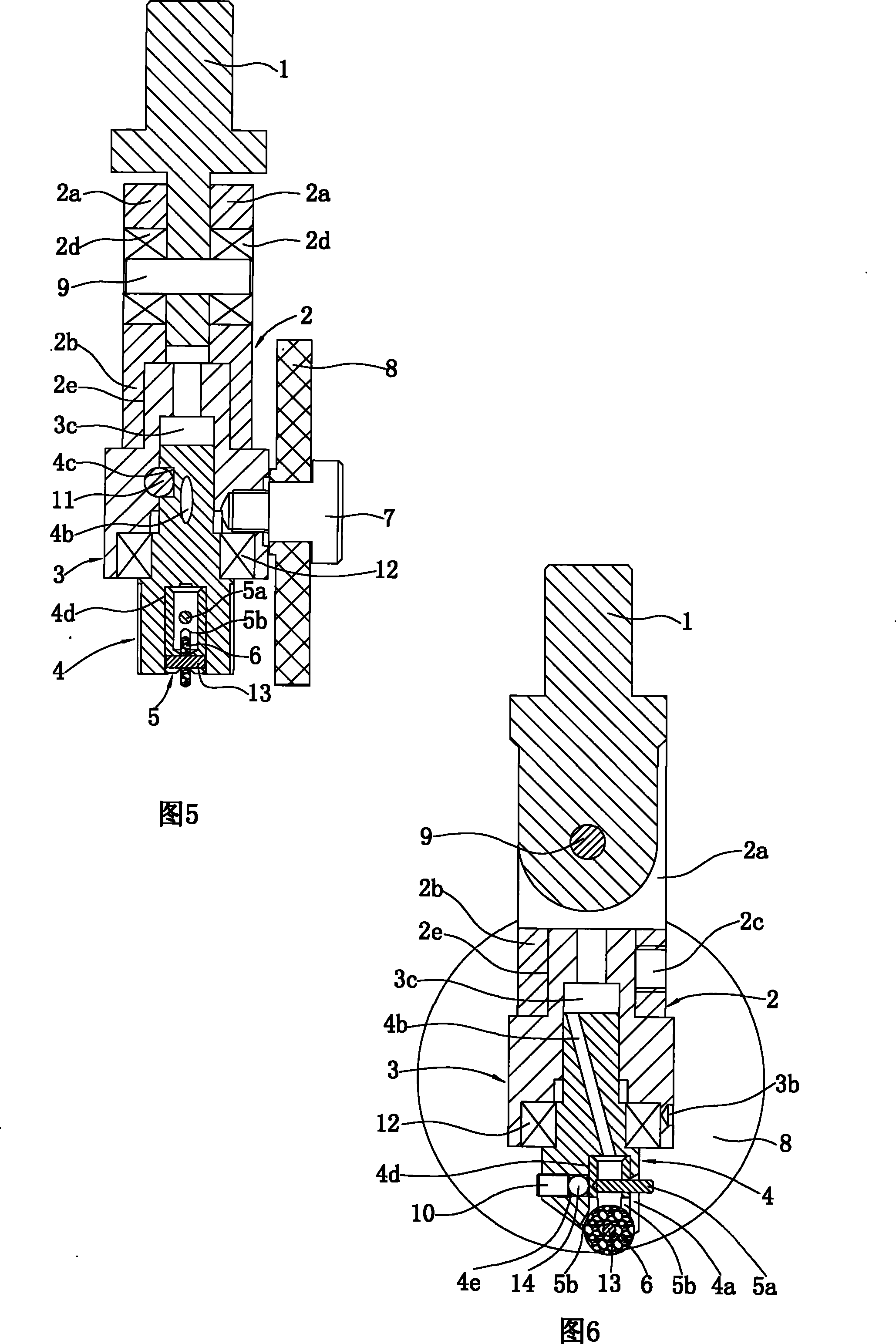

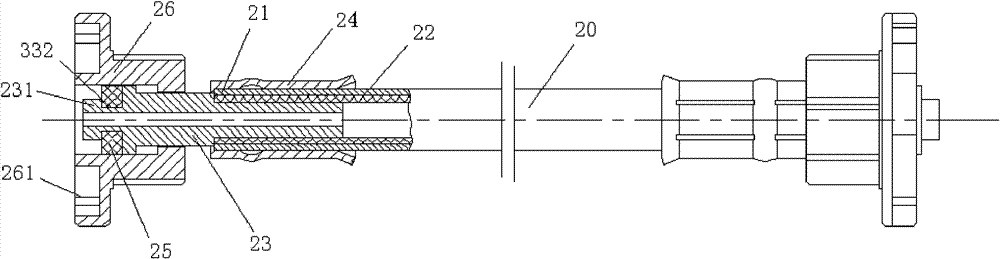

Precision glass cutting-table tool bit assembly

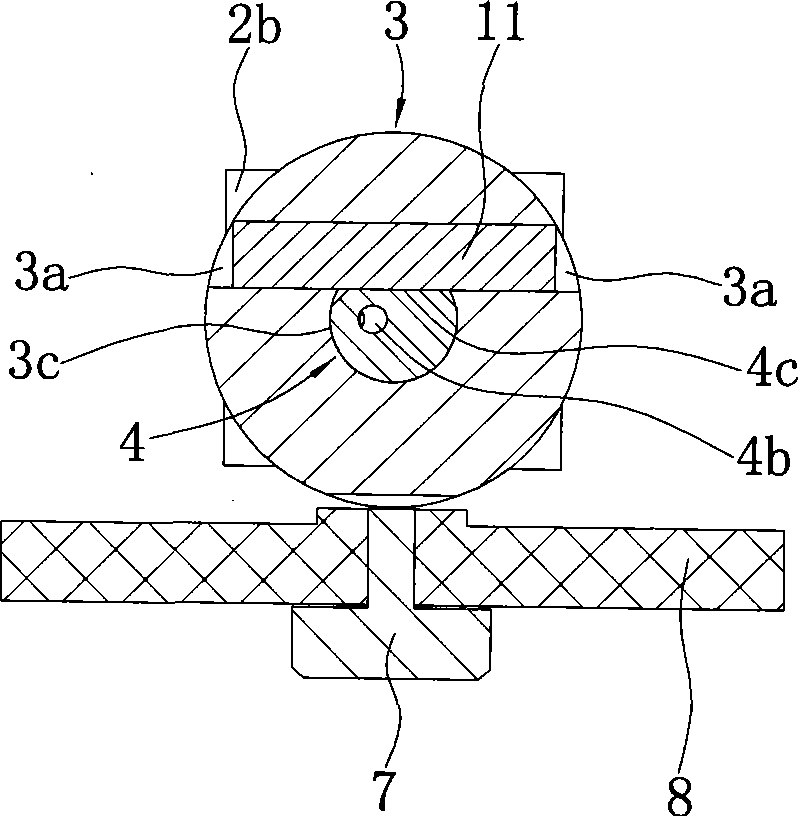

InactiveCN101423326AImprove slitting accuracyThere will be no bursting phenomenonGlass severing apparatusEngineeringScrew thread

The invention provides a precision glass cutting table cutter head assembly, wherein the lower part of a swinging block is fixedly connected with a fixing column, the inside of the fixing column is provided with a step hole, and the inside of an opening on the lower end of the step hole is provided with a bearing; the middle part of the fixing column is penetrated along the height direction, and is eccentrically provided with two horizontal pin holes which are symmetrical to each other, the shaft line of each pin hole is vertical to the axial line of the fixing column and the axial line of a pin shaft, an interval is arranged between the axial lines of the pin hole and the fixing column, the outer end of each pin hole is positioned on the outer column surface of the fixing column, and the inner end of each pin hole is communicated with the step hole; the upper part of a rotary column is communicated with a horizontal penetration square groove, the upper part of the rotary column is in rotary fit with the step hole, the middle part of the rotary column is connected with the fixing column through the bearing, and the lower part of the rotary column is provided with a cutter holder with a cutting wheel; a control pin orderly runs through one pin hole, a square groove and the other pin hole and then is arranged between the fixing column and the rotary column; and the middle part of the fixing column in the height direction is in screw-thread fit with a bolt passing through the center of a nylon wheel. When the assembly is used, the maximum clockwise or counterclockwise rotary angle of the cutting wheel is 15 degrees. A cutter box adopting the assembly has high slitting precision.

Owner:ANHUI JINGLING GLASS MACHINERY

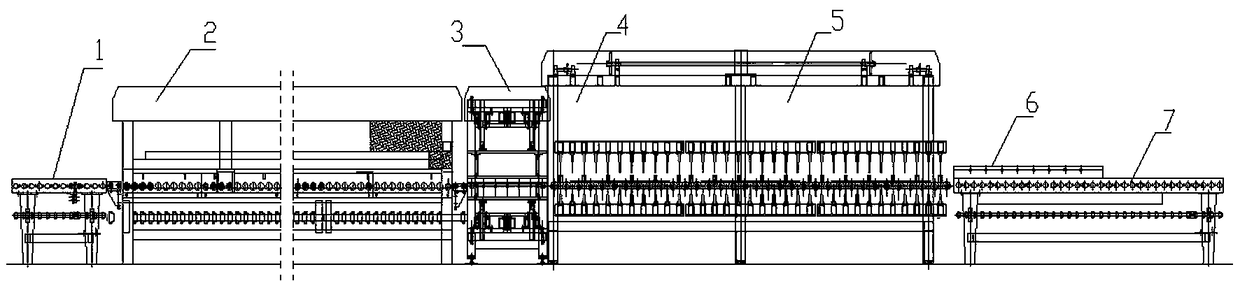

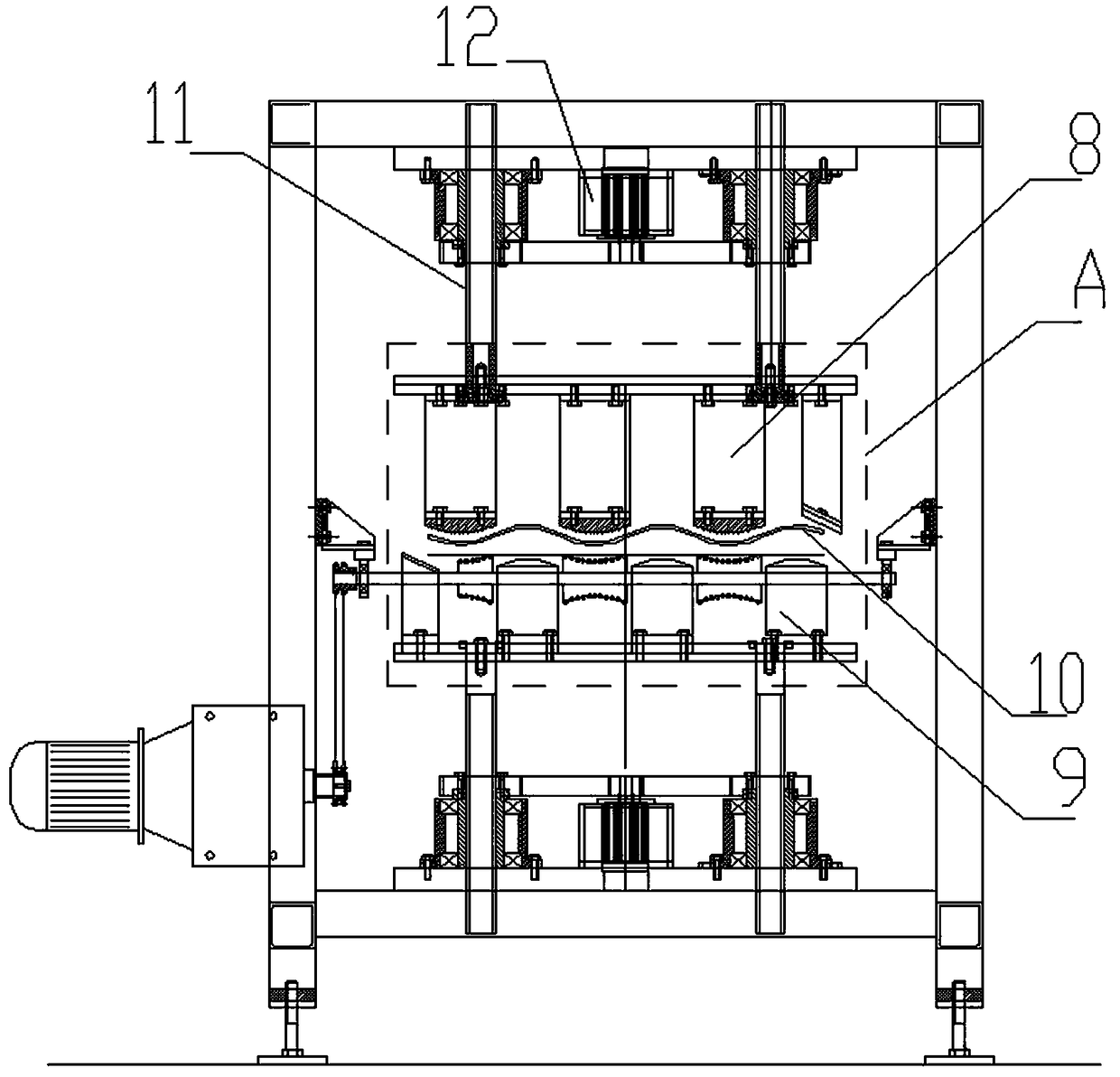

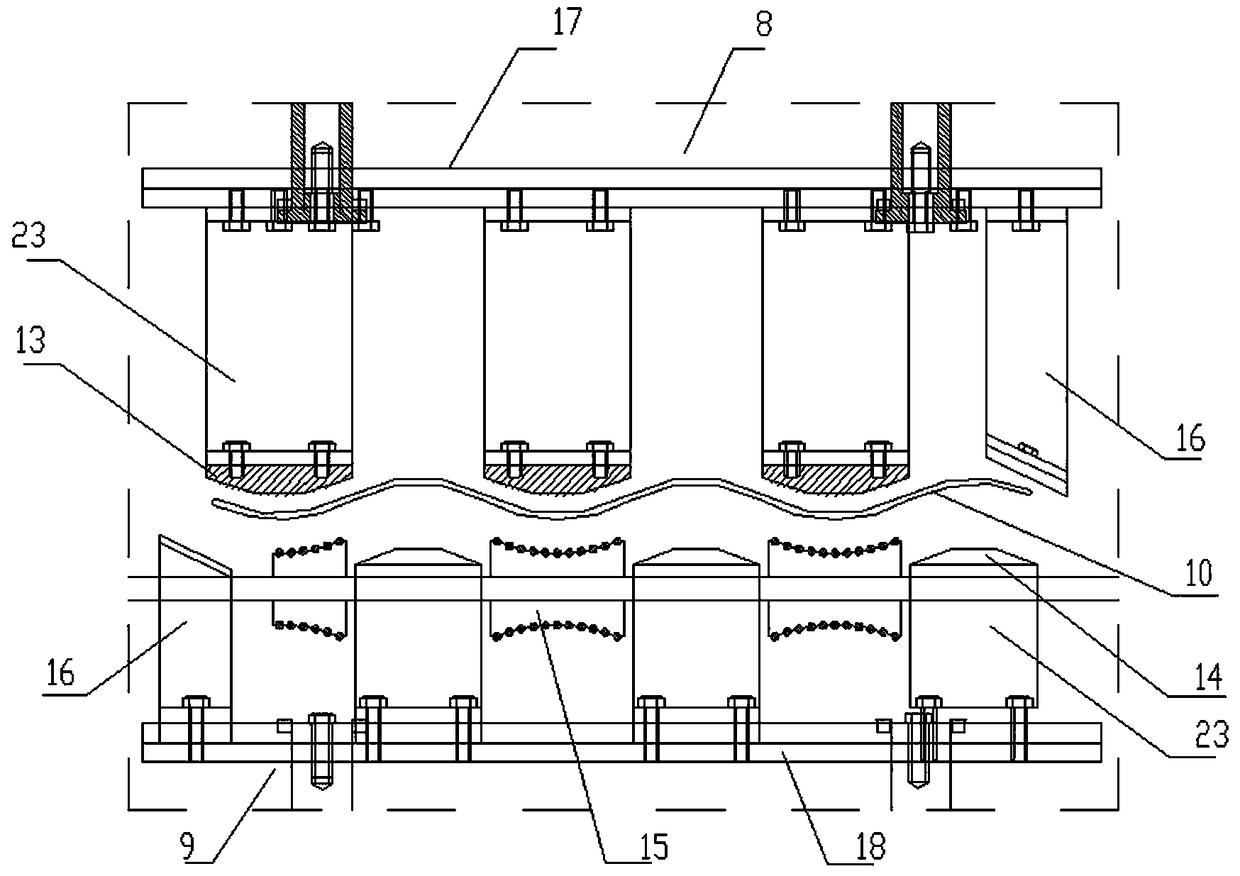

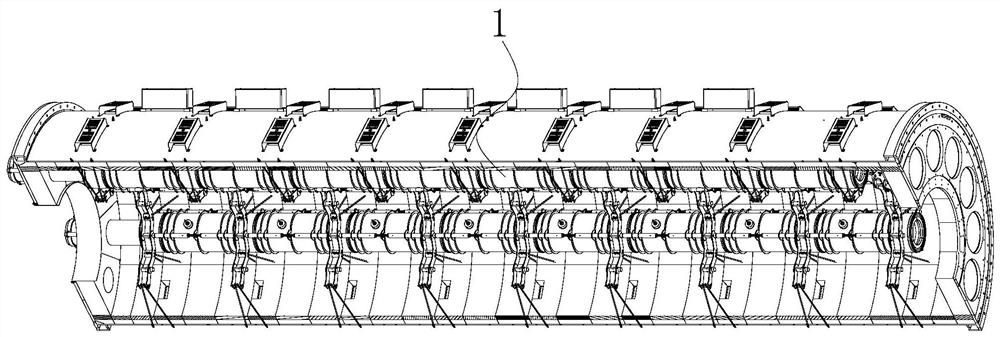

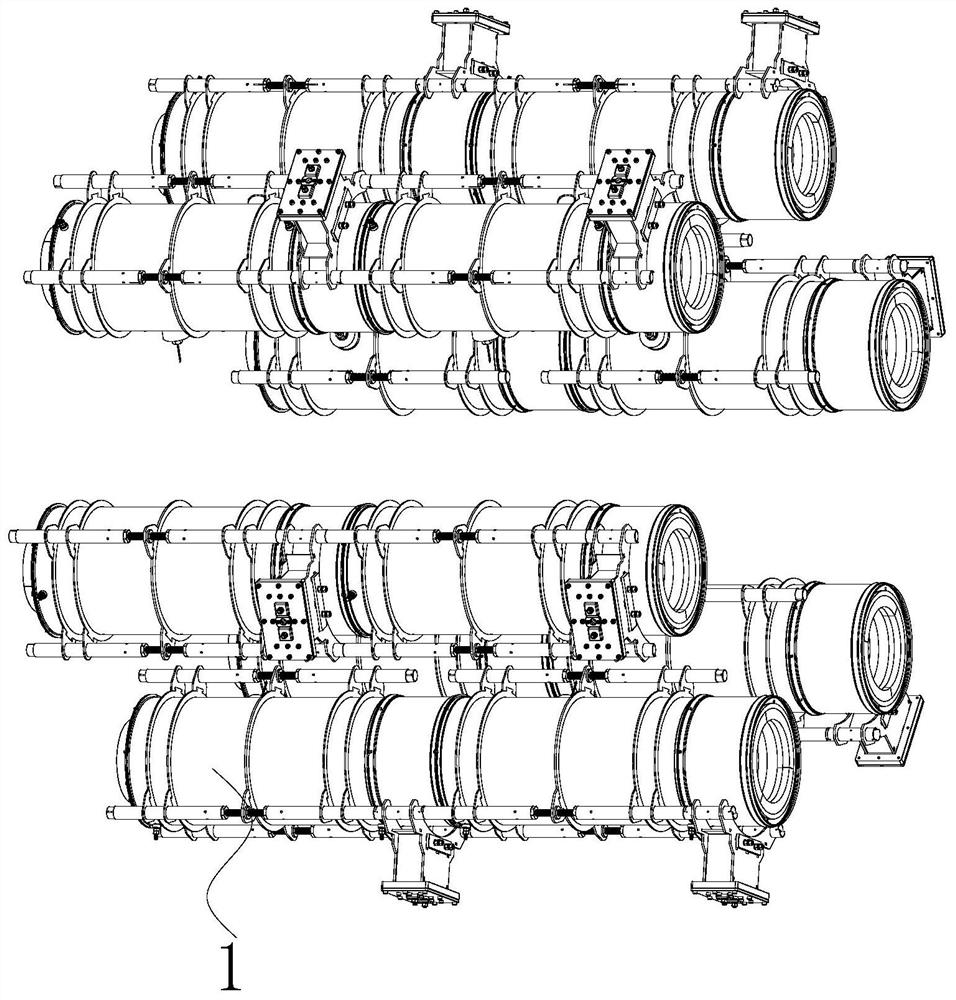

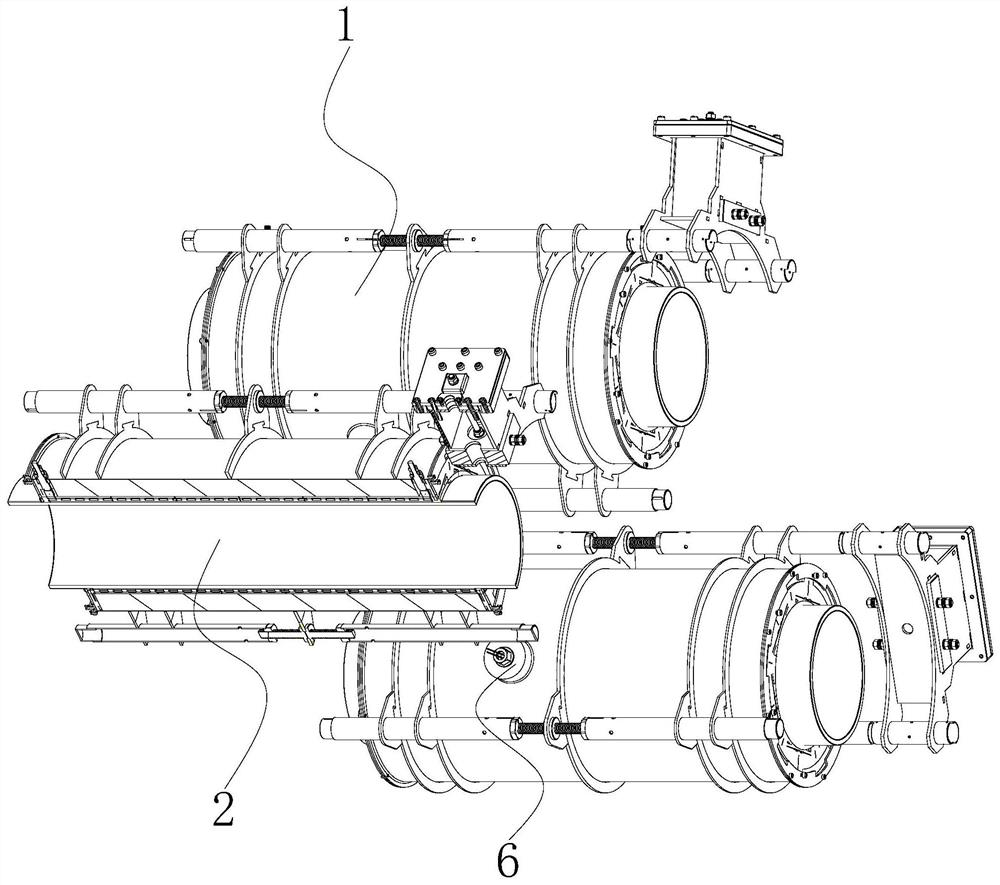

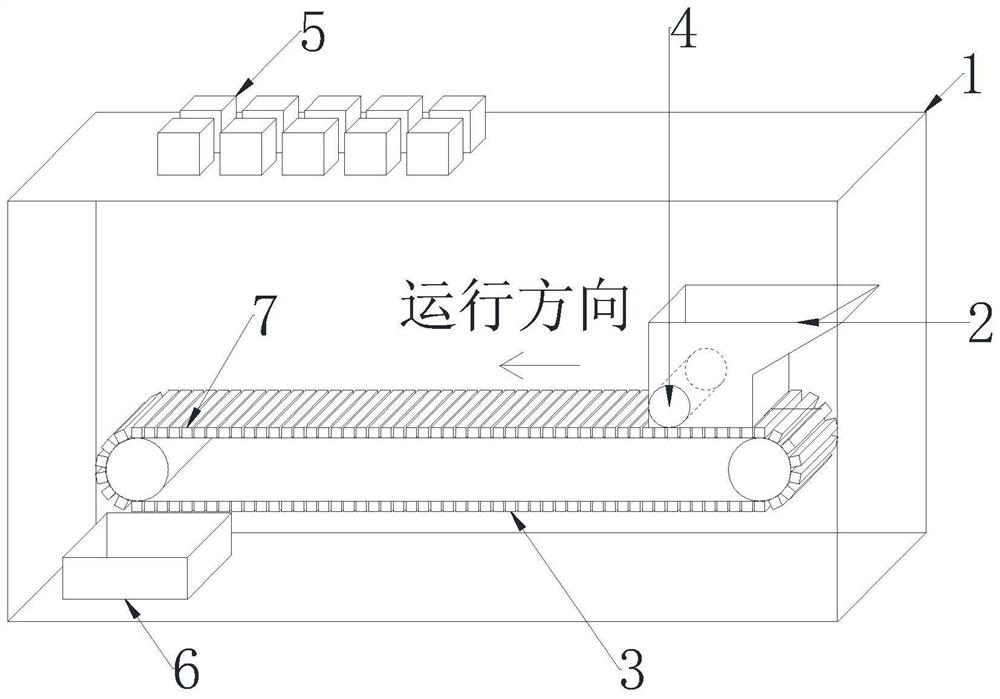

Production equipment of wave-shaped tempered glass

ActiveCN108328911ASolve bottlenecksIncrease power generation capacityGlass reforming apparatusGlass tempering apparatusWave shapeFusiform shape

The invention relates to production equipment of wave-shaped tempered glass. The production equipment comprises a sheet charging table, a heating furnace, a primary shaping section, a rolling pressingcorrection section, a tempering section and a sheet discharging table in sequential arrangement along the process progress direction, wherein the primary shaping section comprises an upper module, alower module and a plurality of rows of shaping rollers; the upper module and the lower module are in vertical arrangement; the shaping rollers are arranged in the glass conveying direction; a plurality of upper molds used for wave-shaped concave surface part shaping are arranged in the upper module; the upper molds and the shaping rollers are in vertical correspondence; a plurality of lower moldsused for wave-shaped glass convex surface part shaping are arranged in the lower module; the bus lines of the shaping rollers are anastomotic with the lower surface sectional line of the concave surface part after the glass shaping; the rolling pressing correction section is mainly formed by a roller way which are ranged in the glass conveying direction and is provided with a plurality of fusiform rollers; the bus lines of the fusiform rollers are anastomotic with the interface sectional lines of the wave-shaped glass in contact with the fusiform rollers. The equipment has the advantages thatthe production of the wave-shaped tempered glass becomes possible; the bottleneck problem of the wave-shaped curve surface photovoltaic solar panel production is solved.

Owner:洛阳格莱斯机械设备有限公司

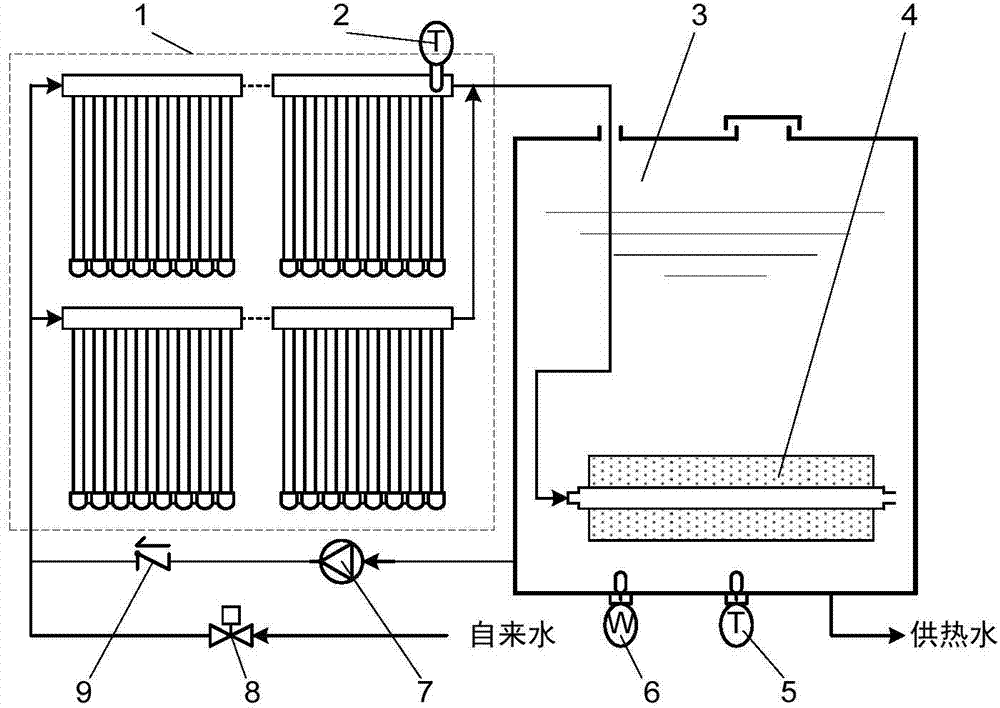

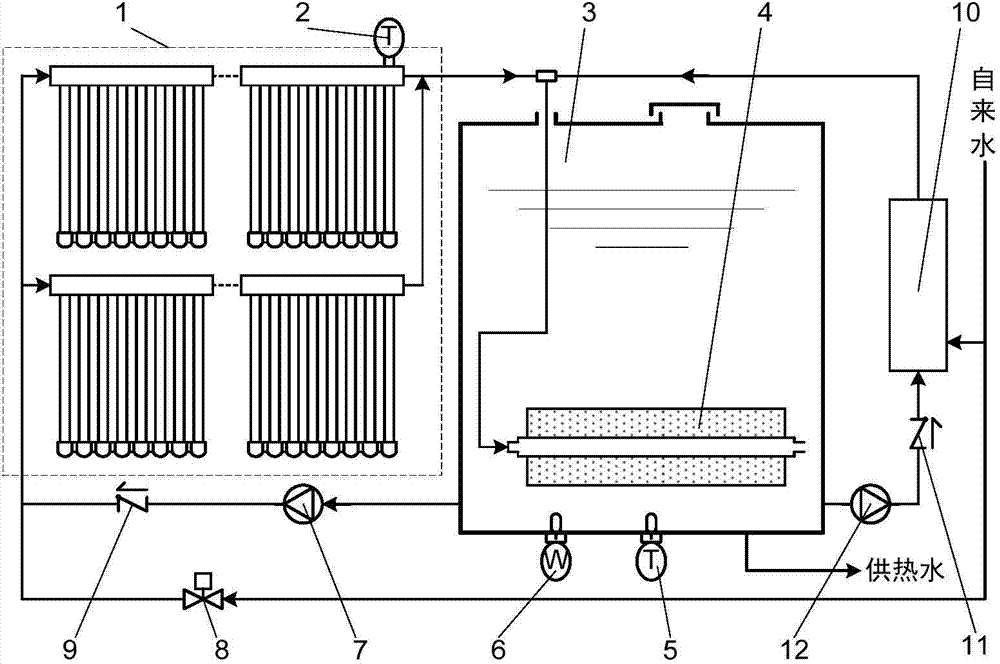

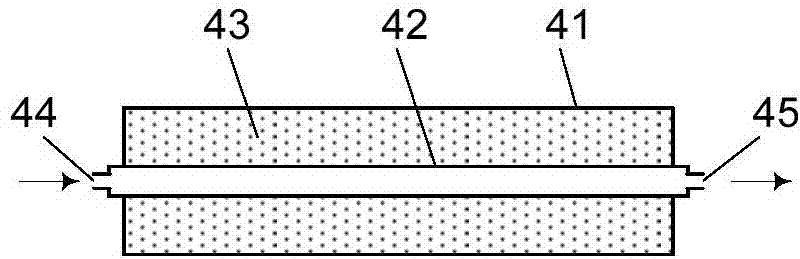

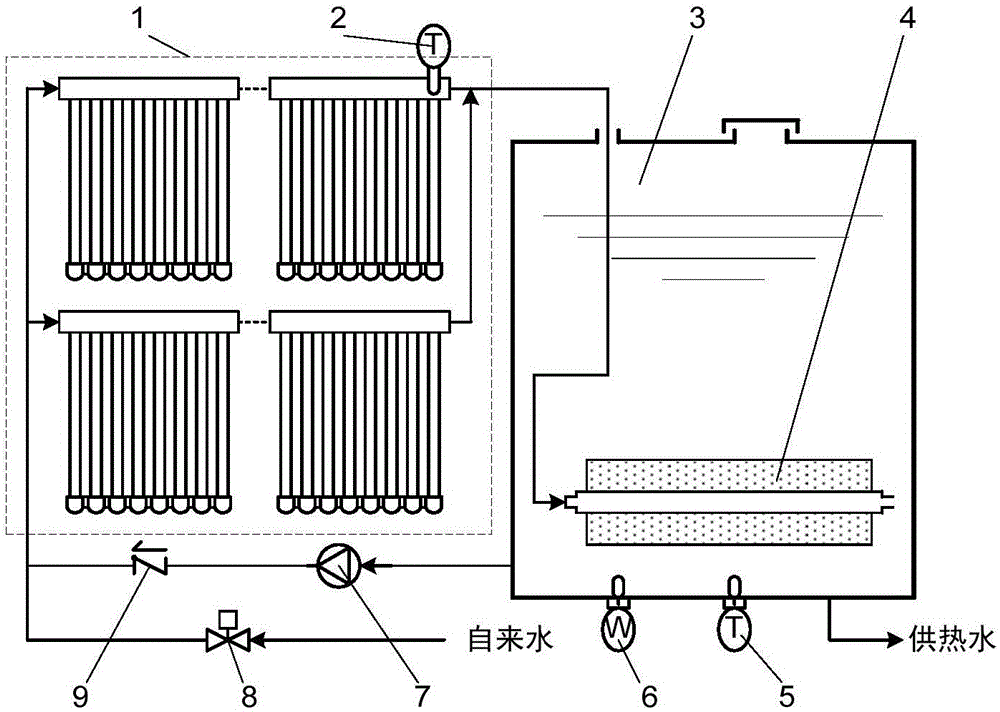

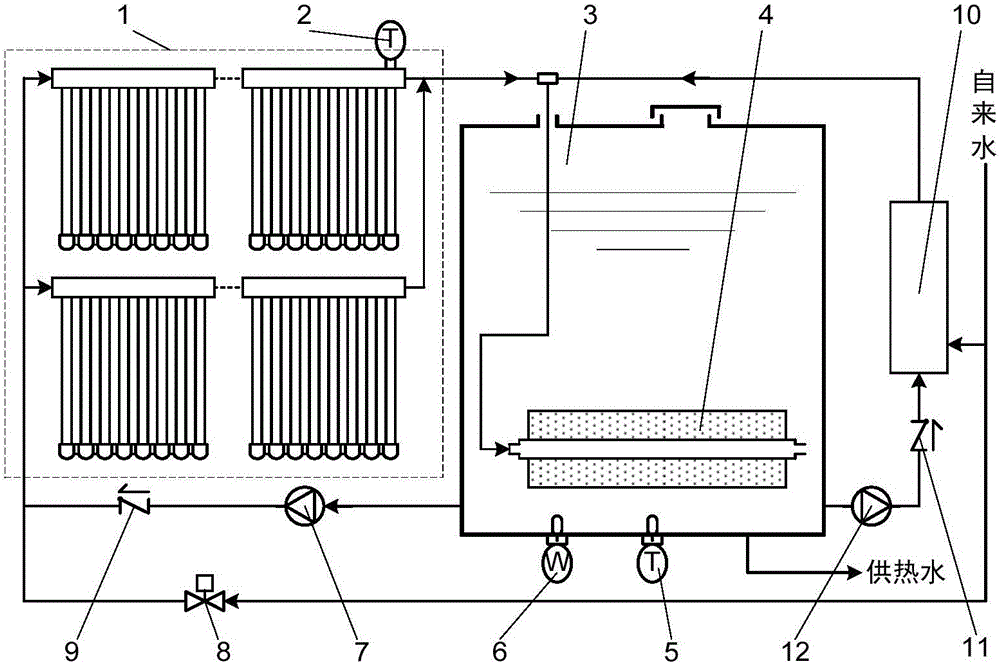

Solar central water heating system with heat accumulation function

ActiveCN103697607AReduce energy consumptionAchieve effective useSolar heat devicesSolar thermal energy generationSolar thermal collectorPhase change temperature

The invention discloses a solar central water heating system with a heat accumulation function, which comprises a solar thermal collector array, a water tank, a collector circulating pump, a check valve, an electromagnetic valve and other parts. A heat accumulator filled with phase-change heat accumulation medium is arranged on the bottom in the water tank, and the interior of a heat accumulator core tube is a water passage. A heat accumulator water passage inlet is connected with the outlet of the solar thermal collector array, a heat accumulator outlet is directly open in the hot water storage tank, and the inlet of the solar thermal collector array is connected with the bottom of the hot water storage tank sequentially through the check valve and the collector circulating pump and connected with a tap water supply pipeline through the water-lifting electromagnetic valve. Both hot water heated by the solar thermal collectors and cold water replenished into the water tank first flow through the heat accumulator core tube and exchange heat with the heat accumulator. When the water temperature in the water tank is higher or lower than the phase change temperature of the heat accumulation medium in the heat accumulator, heat is released to the heat accumulator or heat is absorbed from the heat accumulator. By means of the heat absorption and release of the heat accumulator, energy consumption can be reduced, and solar radiation energy can be effectively utilized by the way of peak load shifting.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

Method for repairing high Cr cast iron dredge pump impeller

InactiveCN106925943AReduce repair work timeImprove restoration qualityArc welding apparatusImpellerCast iron

The invention relates to a method for repairing a high Cr cast iron dredge pump impeller, and belongs to the technical field of engineering ship equipment. The method for repairing the high Cr cast iron dredge pump impeller is characterized in that bead welding is adopted to conduct recovery to the size of the position of a water sealing belt on the high Cr cast iron dredge pump impeller, it is guaranteed that an original gap between the water sealing belt and a lining board restores, and pump efficiency of the dredge pump is achieved. The method has the advantages that work efficiency of equipment is high, the working life and the replacement cycle of the equipment are long, and replace cost of spare parts is reduced; and the repairing method is convenient to operate, economical and practical, high in execution efficiency and pertinence, good in welding quality and the like.

Owner:CCCC TIANJIN DREDGING

Pipe pile construction method and pile tip bearing capacity reinforcement equipment

The invention is a tubular pile constructing method and pile-end bearing capacity enhancer, placing the enhancer at positioning point of the picket base; the pile machine takes its place to align the end of the pile end with the enhancer; starting sinking the pile, and when the pile passes through bad earth layer or enters in pile-end force-bearing layer, temporarily stopping stinking pile; pulling the rope to drive axial umbrella rod, so that the top cap relieves the inclined support from restriction, the fixed stop block drives the annular slide block to make the supporting link rod push and spread the inclined support around so as to shrink into the pile, and the active stop block drives the pile boot to take out the enhancer; sinking the pile to the designed depth and the pile end squeezes compact earth to gush into the pile to form an earth stopper; pouring concrete in the pile to form an earth stopper cap, thus forming a pile. It can enhance the penetrating property of the pile, extrude pile end earth closely, heighten pile-end bearing capacity, reduce deposition quantity, heighten pile forming quality and constructing efficiency, etc

Owner:北京中技天昊工程技术有限公司

Liquid heating vessel, heating tool and method for processing liquid heating vessel

PendingCN108577522AExtended service lifeSave location spaceCooking-vessel materialsWater-boiling vesselsHeating efficiencyEngineering

The invention discloses a liquid heating vessel. The liquid heating vessel comprises a vessel body and a heating body, the vessel body is used for containing liquid to be heated, the vessel body is made of non-metallic insulating materials, and the heating body is pre-buried at the bottom or / and in the side wall of the vessel body. When working, the heat generated by the heating body is directly transmitted to the vessel body, and the vessel body transfers the heat to the liquid to be heated. The invention further discloses a heating tool and a method for processing the liquid heating vessel.The liquid heating vessel is high in heat efficiency, simple in structure and convenient for mass processing.

Owner:陈梅

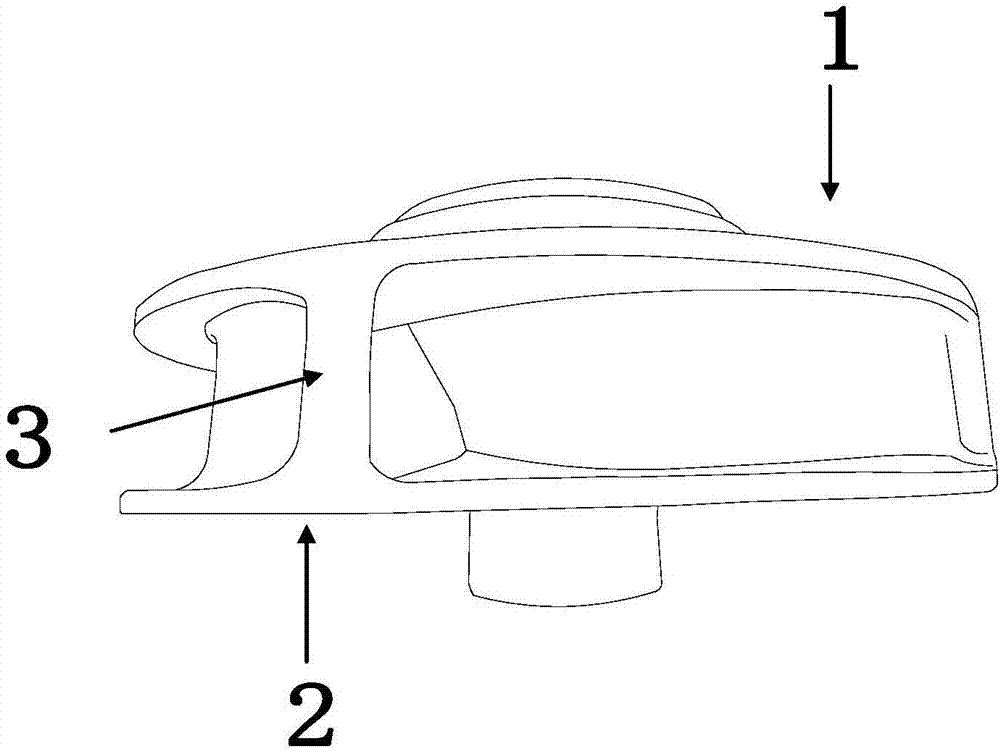

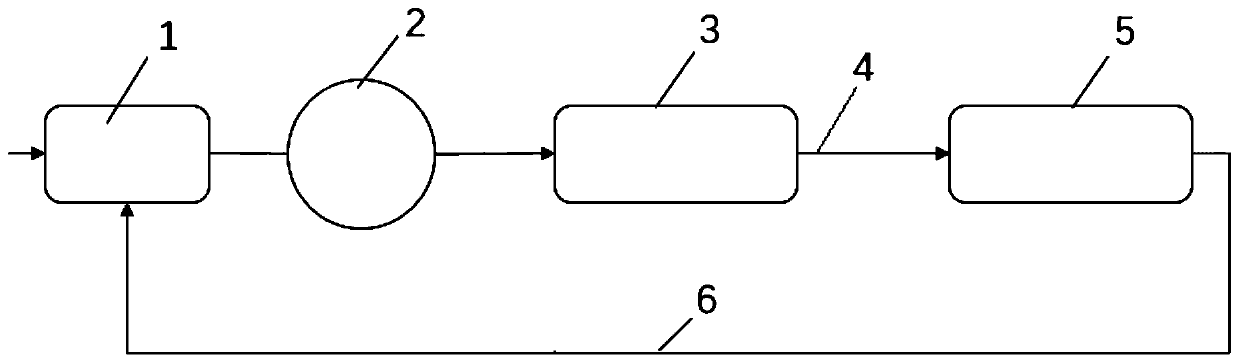

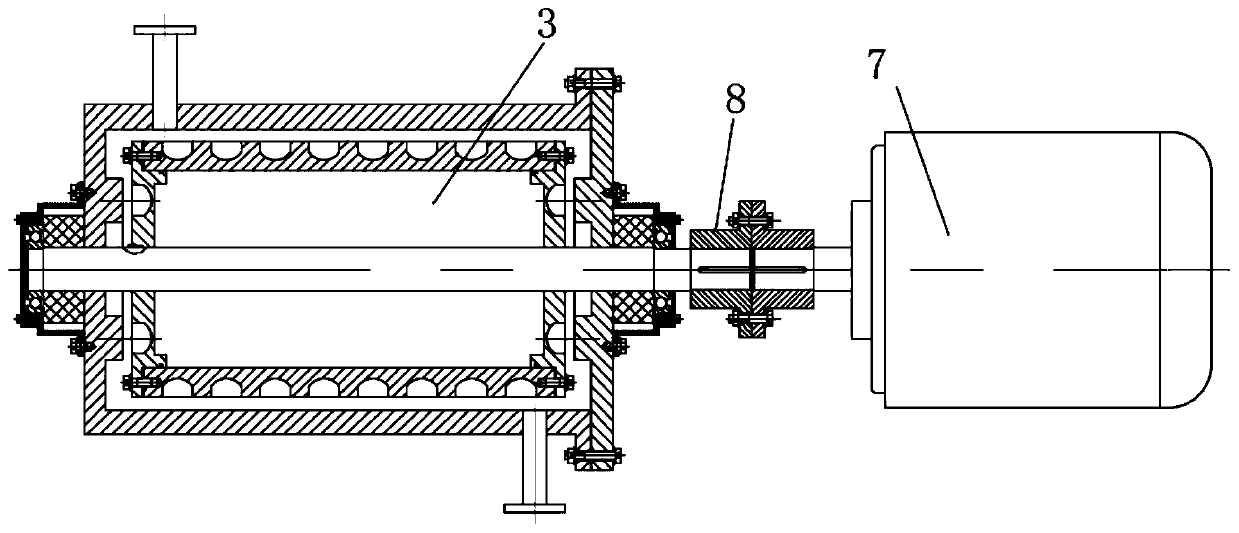

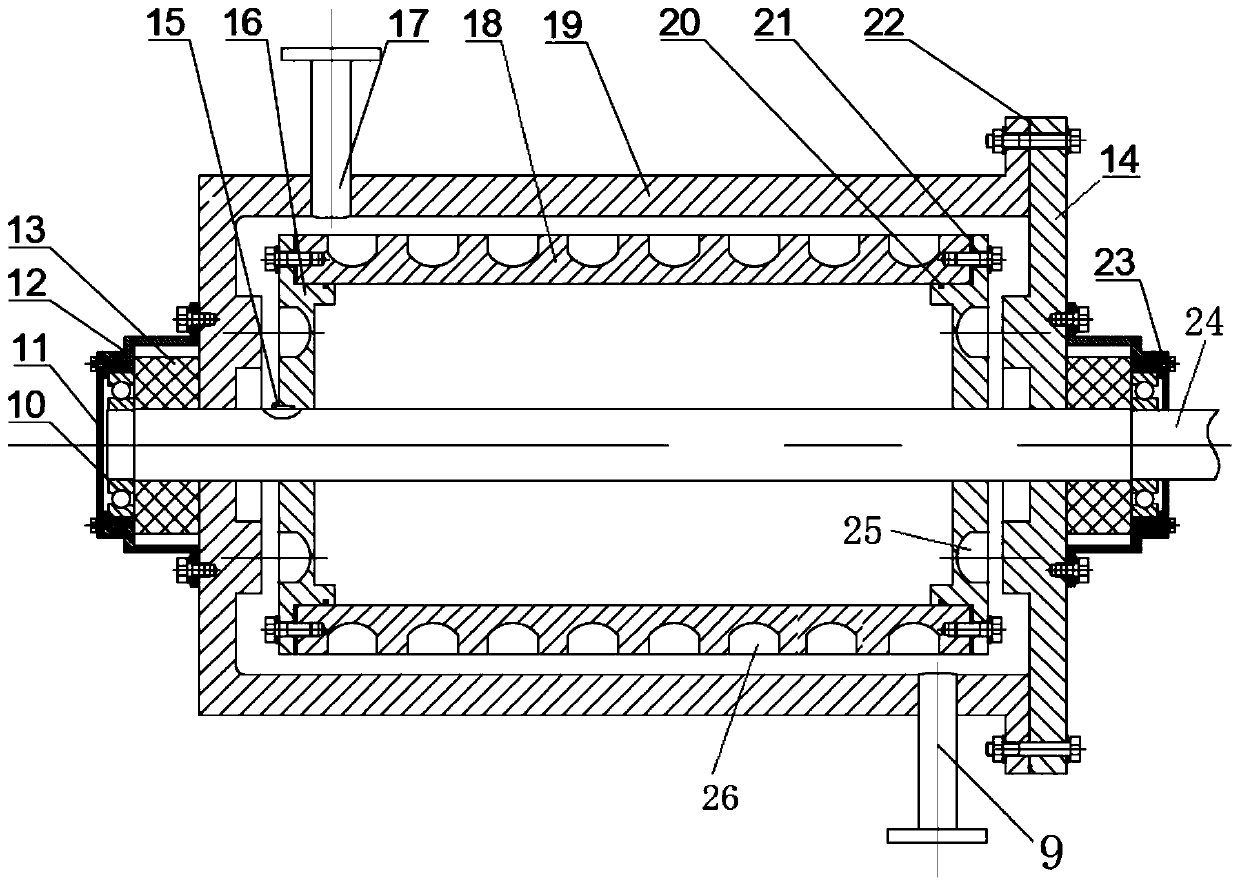

Hydrodynamic cavitation heating device

InactiveCN109855165AEnergy efficiencyImprove thermal performanceLighting and heating apparatusCentral heating systemCavitationWater flow

The invention provides a hydrodynamic cavitation heating device which comprises a stator, a rotor and a rotating shaft. A cavitation cavity is formed in the stator. A sealing cylinder body is adoptedas the rotor. The rotor is arranged in the cavitation cavity. The rotating shaft is installed in the stator and penetrates through the rotor in the stator. The rotor is fixedly connected with the rotating shaft. Cavitation holes are formed around the outer wall of the rotor and are blind holes. A water input pipeline is arranged at one end of the stator. A water output pipeline is arranged at theother end of the stator. According to the device, a motor drives the rotor to rotate at a high speed, the cavitation holes in the rotor and water move relatively, thus the cavitation phenomenon is caused, the purpose of heating water through the cavitation phenomenon is achieved, under the effect of a circulating water pump, hot water flows out of the hydrodynamic cavitation heating device and enters a heat exchanger through a water conveying pipeline, the hot water dissipates heat in the heat exchanger to achieve the heating effect, and the hot water flows back to a water storing tank througha circulating pipeline to prepare for heating circulation of the next time. The hydrodynamic cavitation heating device saves energy and is efficient, incrustation is not generated, pollution is avoided, energy consumption is low, and operation is safe and stable.

Owner:SHANDONG UNIV

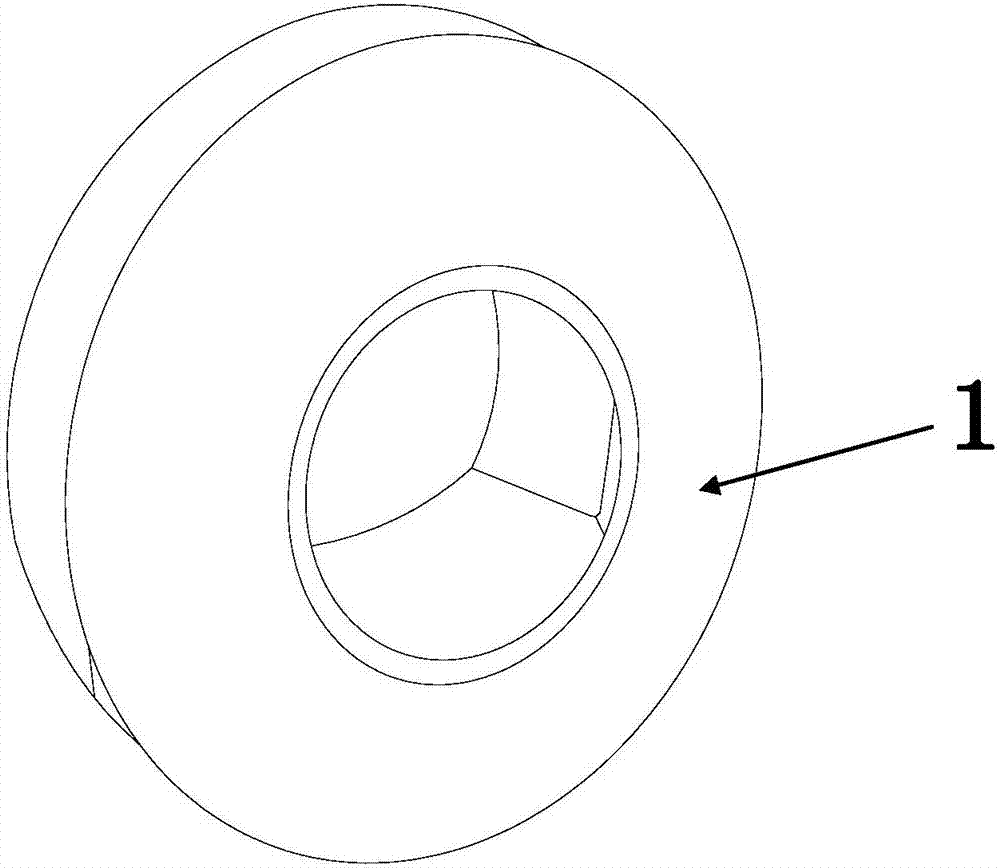

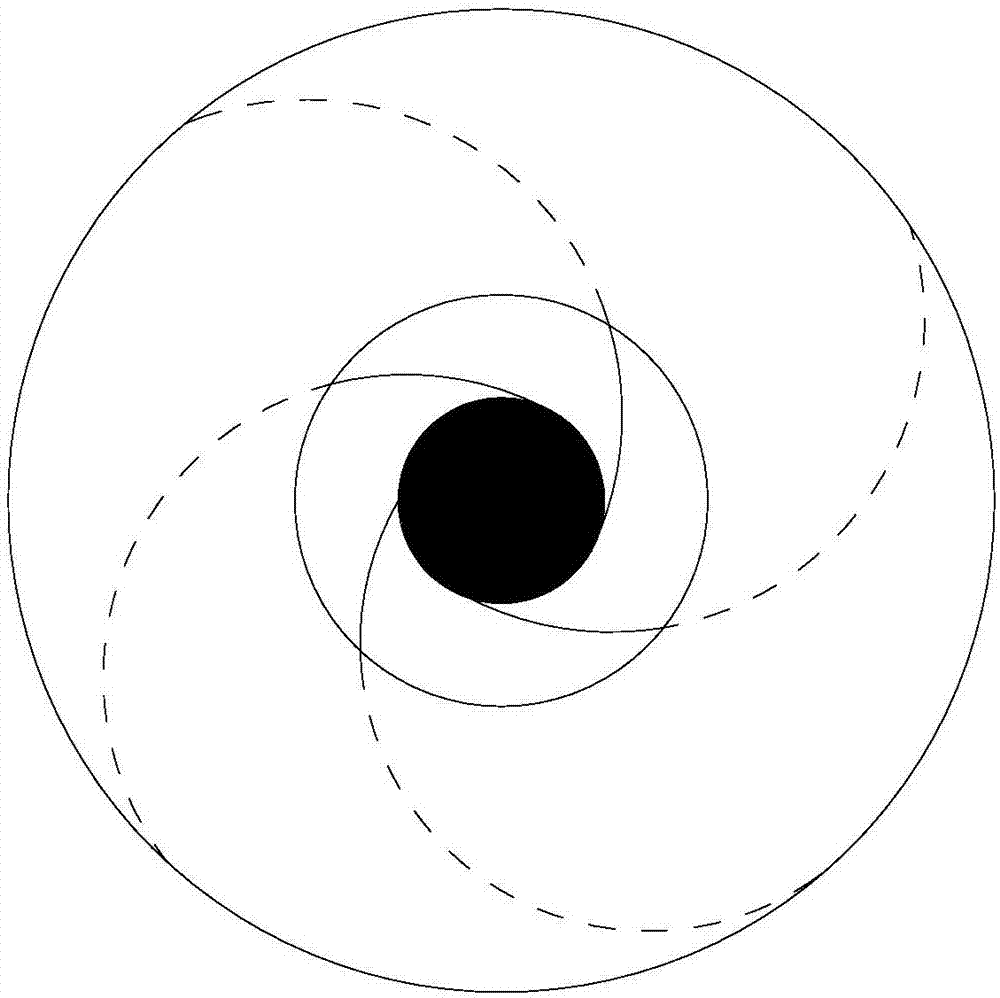

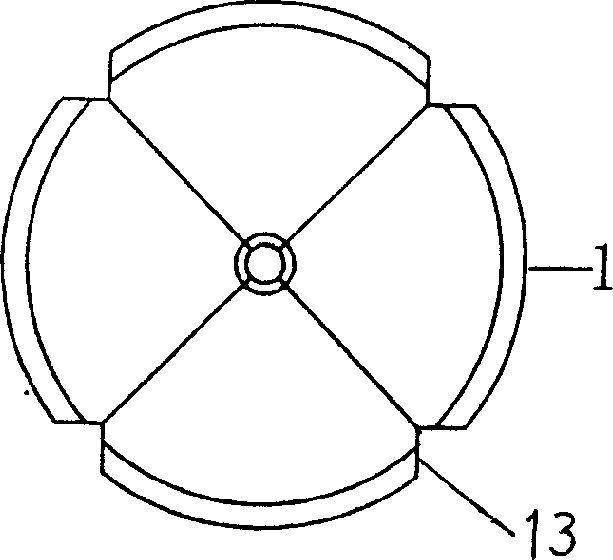

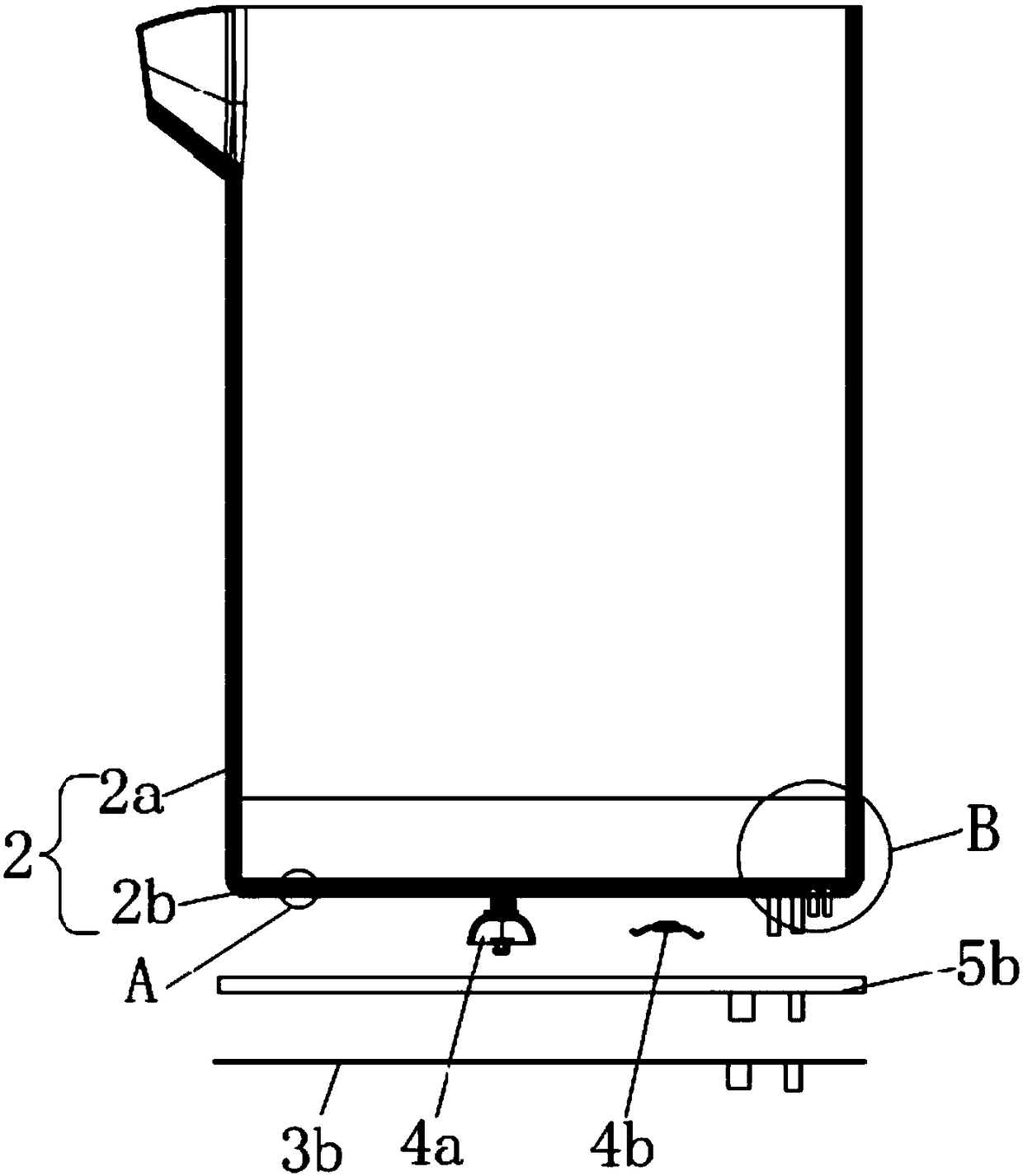

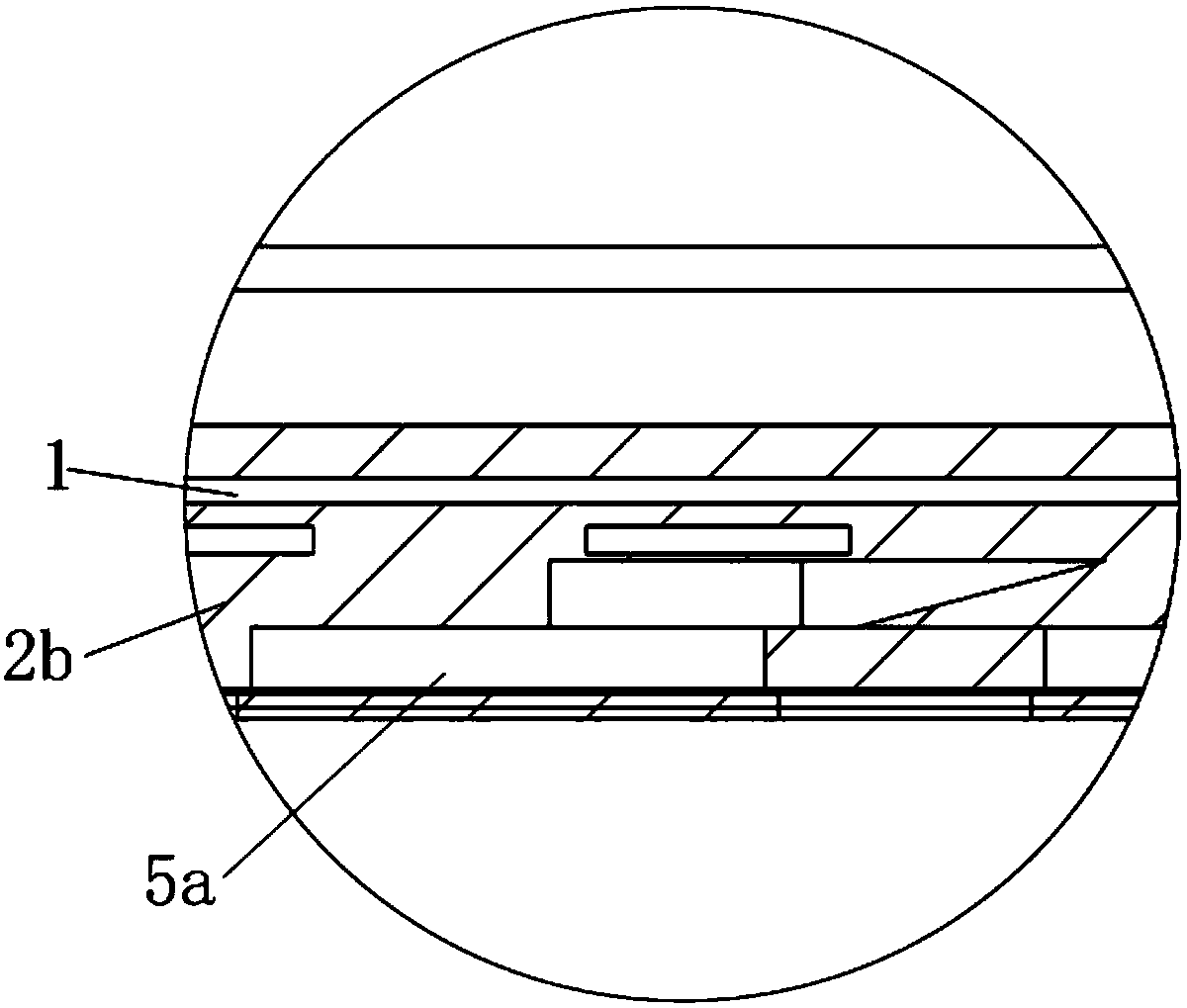

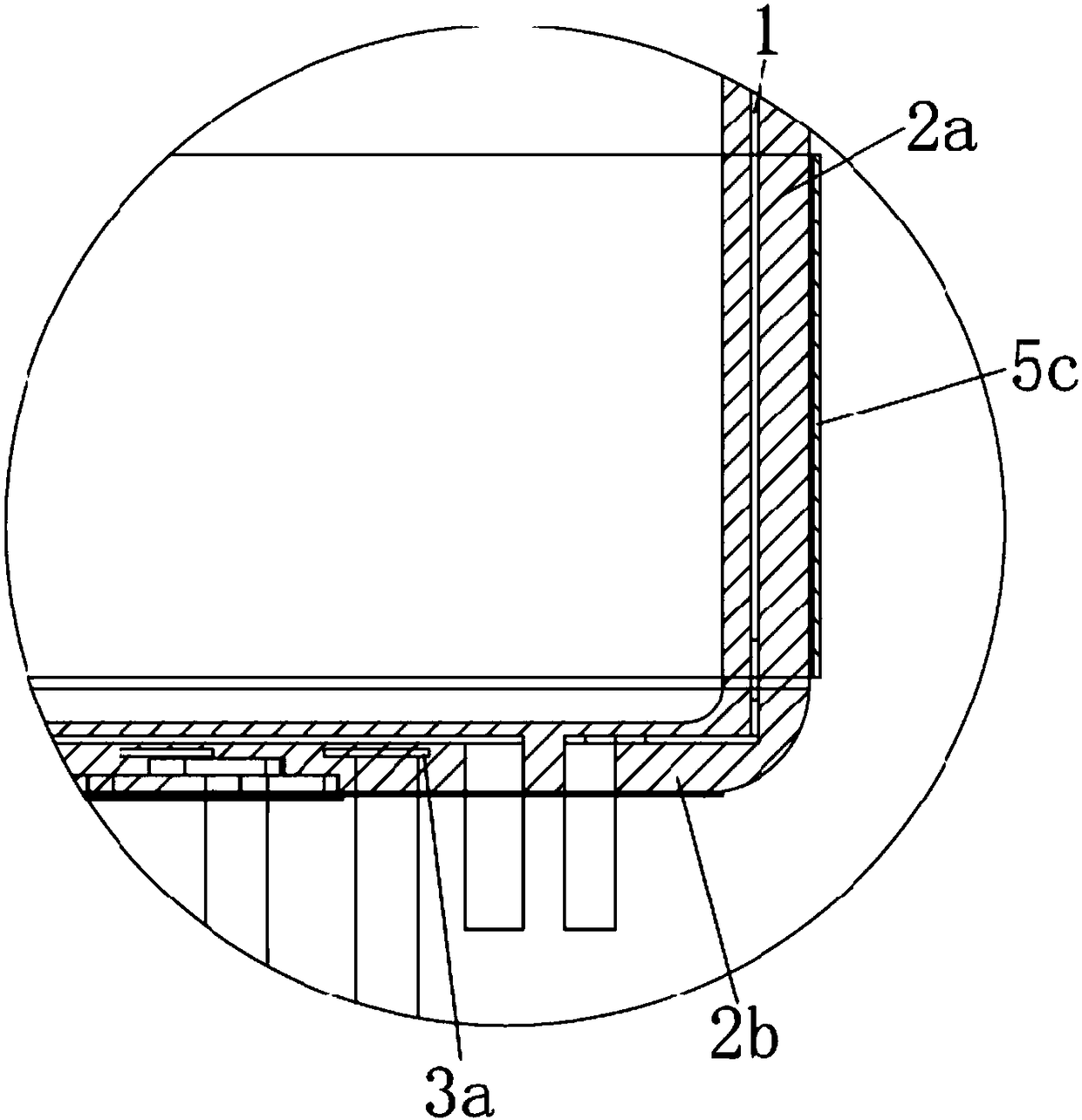

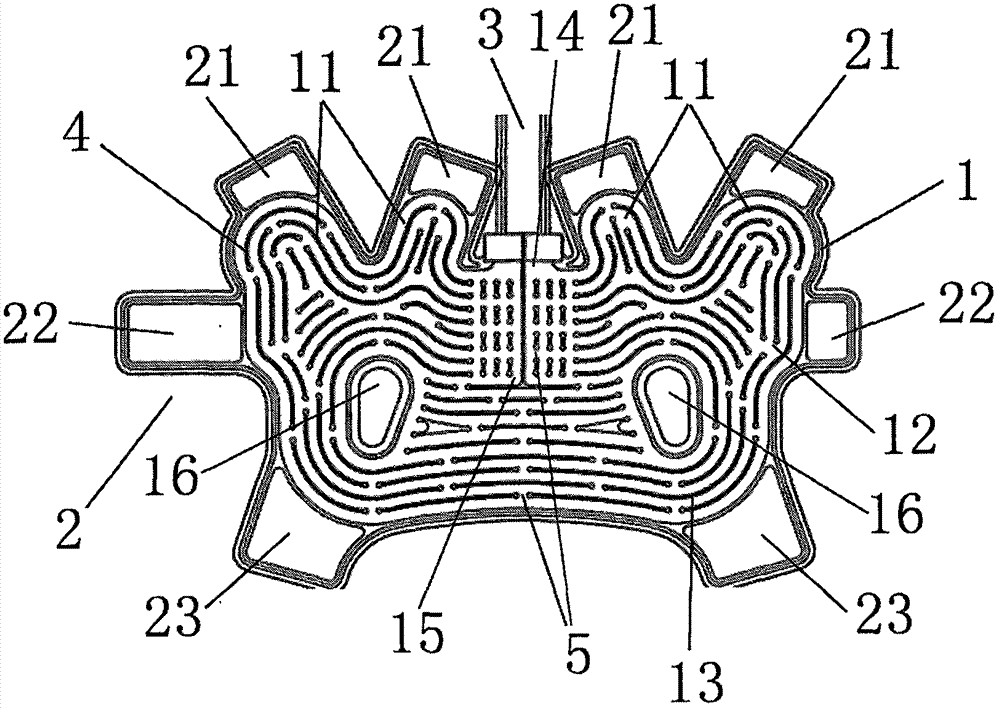

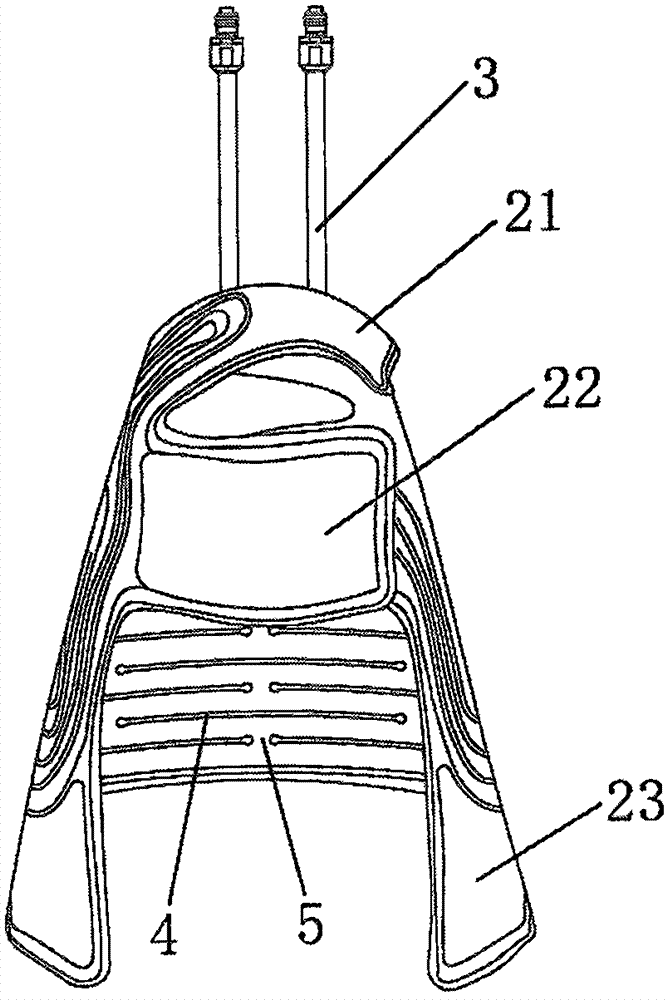

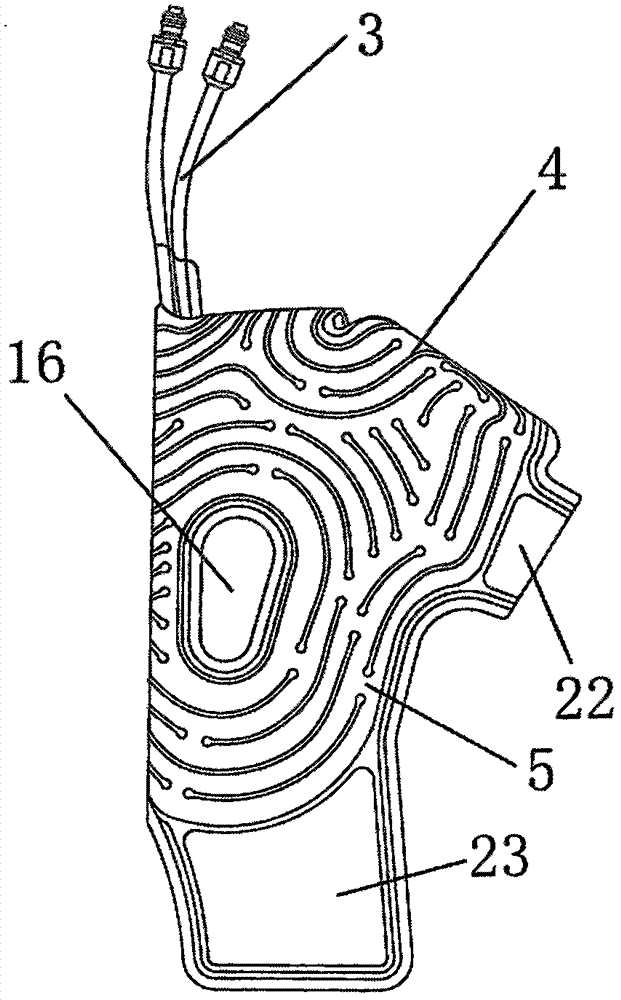

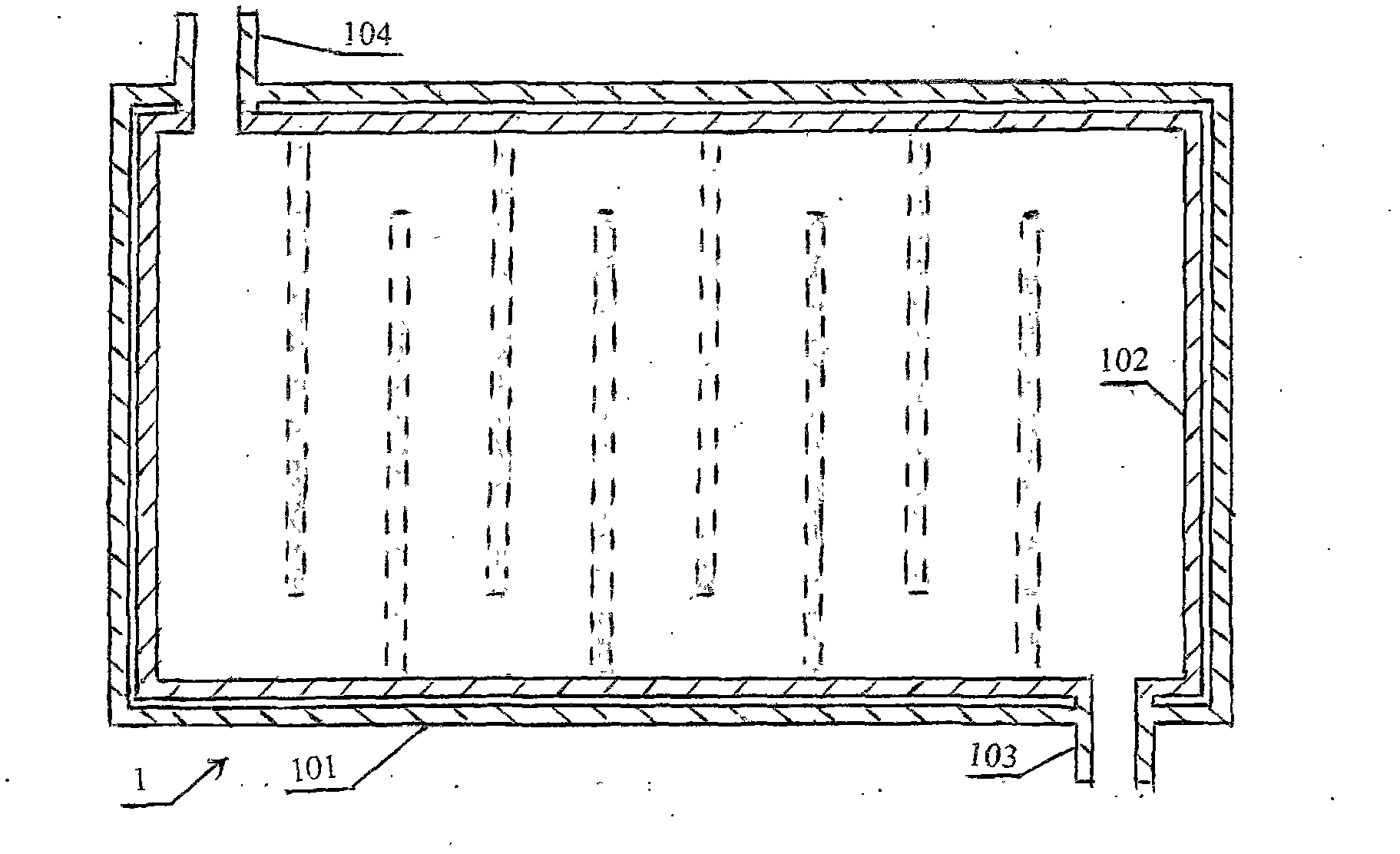

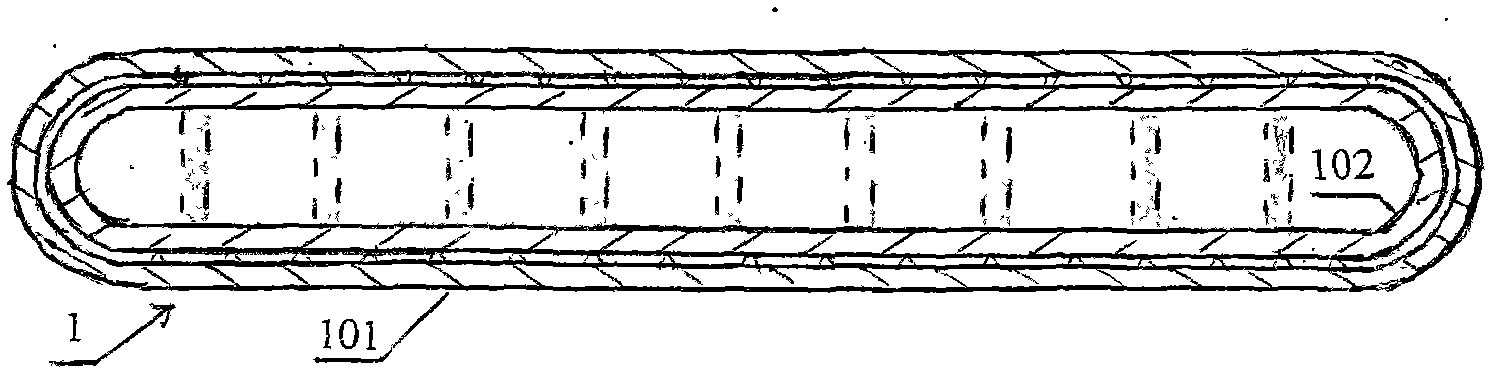

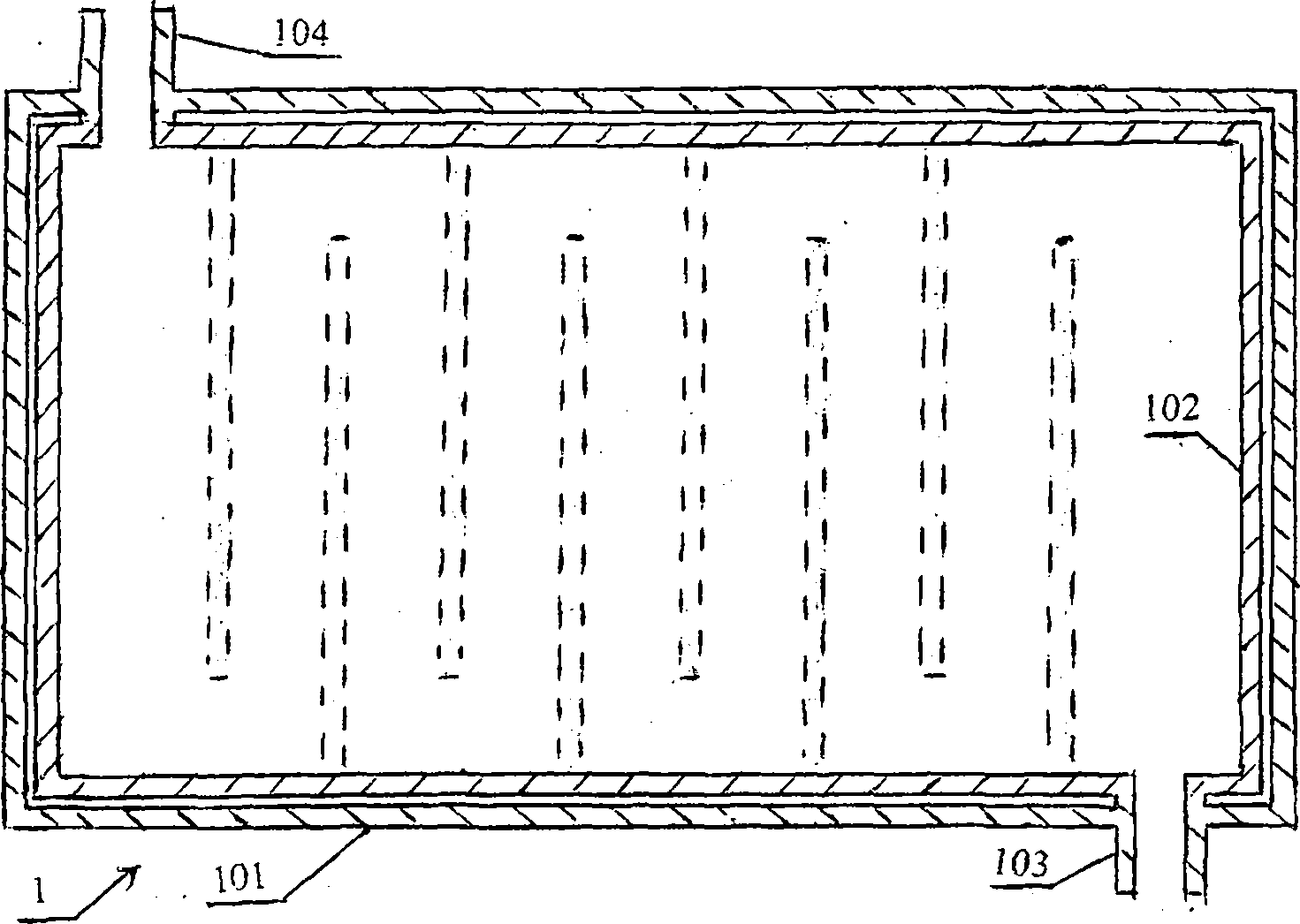

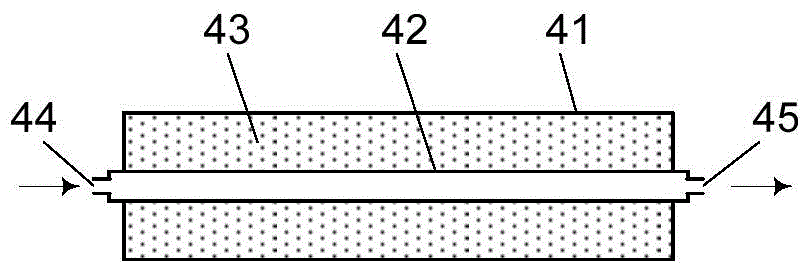

A kind of medical ice cap

ActiveCN105232212BThere will be no bursting phenomenonEasy to adjustTherapeutic coolingTherapeutic heatingWater channelWater flow

The invention discloses a medical ice cap, which comprises an ice cap body (1), a hasp (2) connected to the edge of the outer periphery of the ice cap body (1), and a communication hole formed on the ice cap body (1). The water inlet (14) of the inside of the ice cap body (1), the inside of the ice cap body (1) is provided with a plurality of circulating water channels (4), between the adjacent said circulating water channels (4) is formed a A plurality of water channel communication ports (5) for connecting the adjacent circulating water channels (4). By setting the water channel communication port between the circulating water channels, the adjacent circulating water channels can be connected to each other. If the circulating water channel is partially blocked, the water flow will flow into the adjacent circulating water channel through the water channel connecting port, directly bypassing the blockage. The inside of the ice cap body can continue to realize the cooling cycle, which not only avoids the situation that the cooling cannot be realized due to the blockage of the circulating water channel, but also avoids the phenomenon that the circulating water channel bursts due to excessive water pressure.

Owner:HENGBANGBEIJINGTECH DEV CO LTD

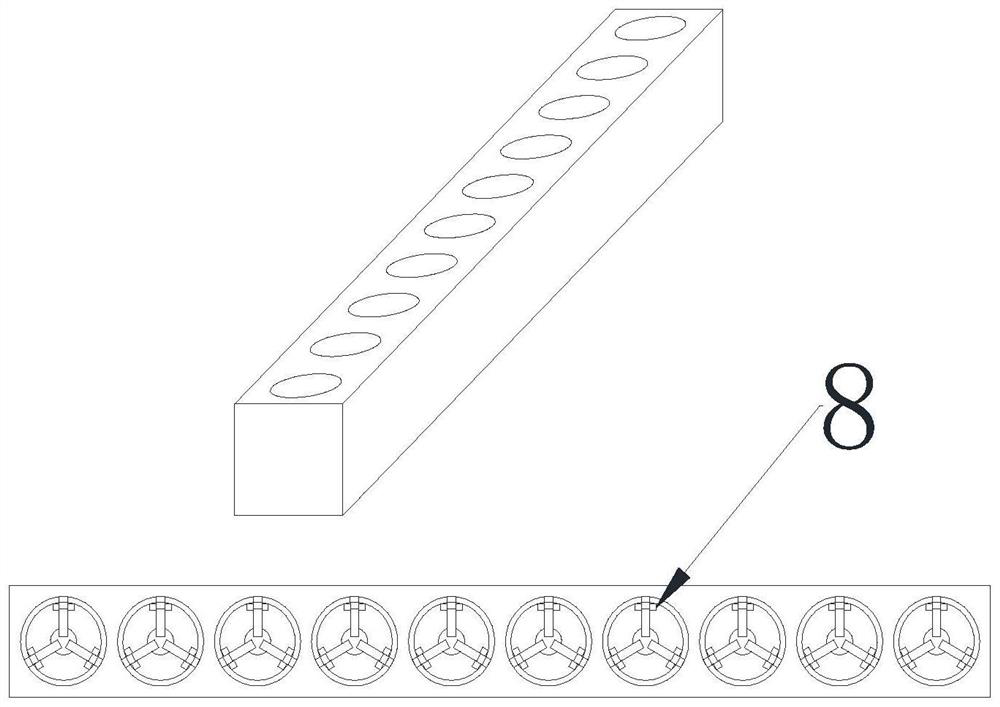

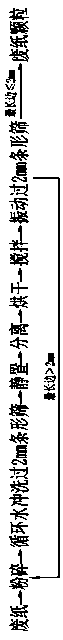

Moisture-proof high-quality filter rod making system and making method thereof

The invention provides a moisture-proof high-quality filter rod making system and a making method thereof. The moisture-proof high-quality filter rod making system comprises a bottom plate, a filter rod, a conveying device and a cutting device. The problems can be solved that a, when a whole filter rod is cut, cuts are coarse, fiber filaments fall off, and as a result the quality of cigarettes isaffected; b, when the filter rod is cut, the filter rod needs to be fixed and is severely extruded during fixation, as a result, the smoking resistance of the cigarettes is increased, and smoking is affected; c, during cutting, seam breaking easily occurs, the filter rod is wrinkled, and the usage of the filter rod is affected; the cuts are flush, and the function of the smoking resistance of thefilter rod is kept; the moisture-proof high-quality filter rod making system has the advantages that the cuts are free of filament burrs, during cutting, there is no seam breaking, during cutting, there is no falling and wrinkling of fiber filaments, and the cuts are flush.

Owner:FUYANG CIGARATE MATERIAL FACTORY

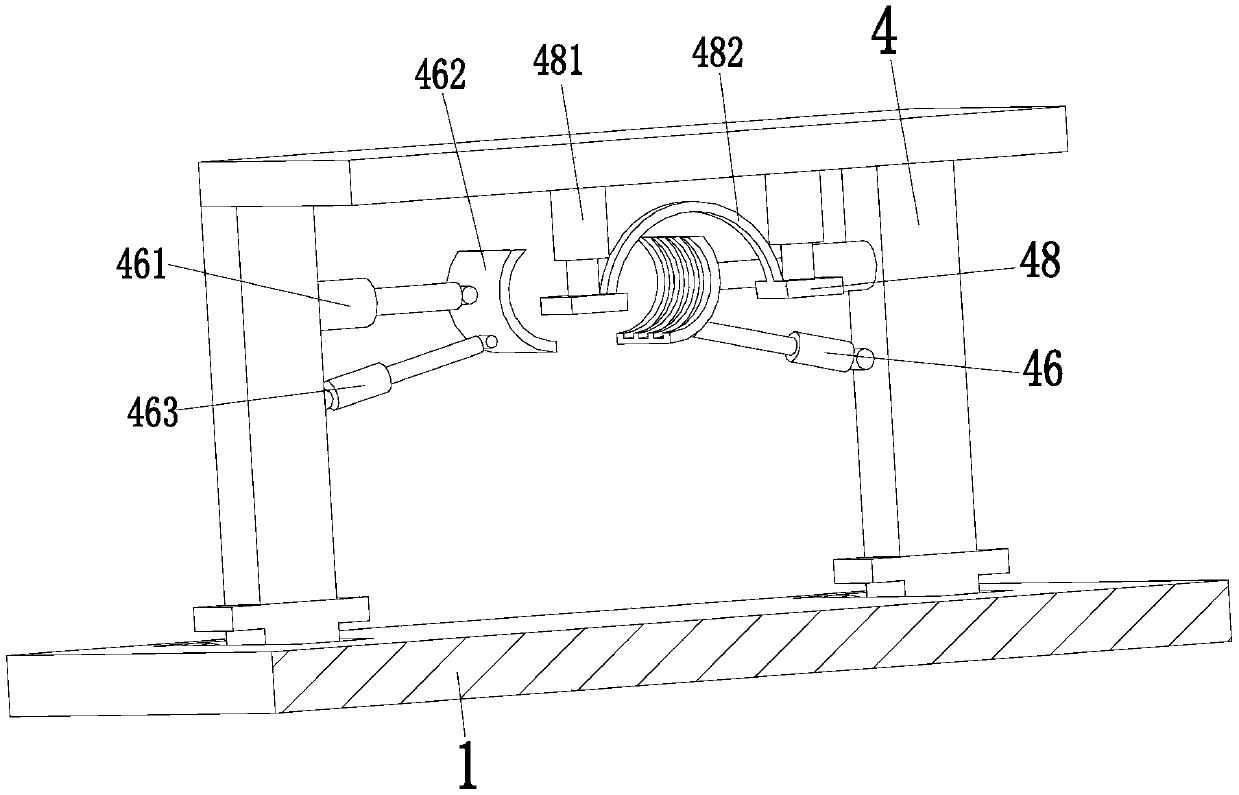

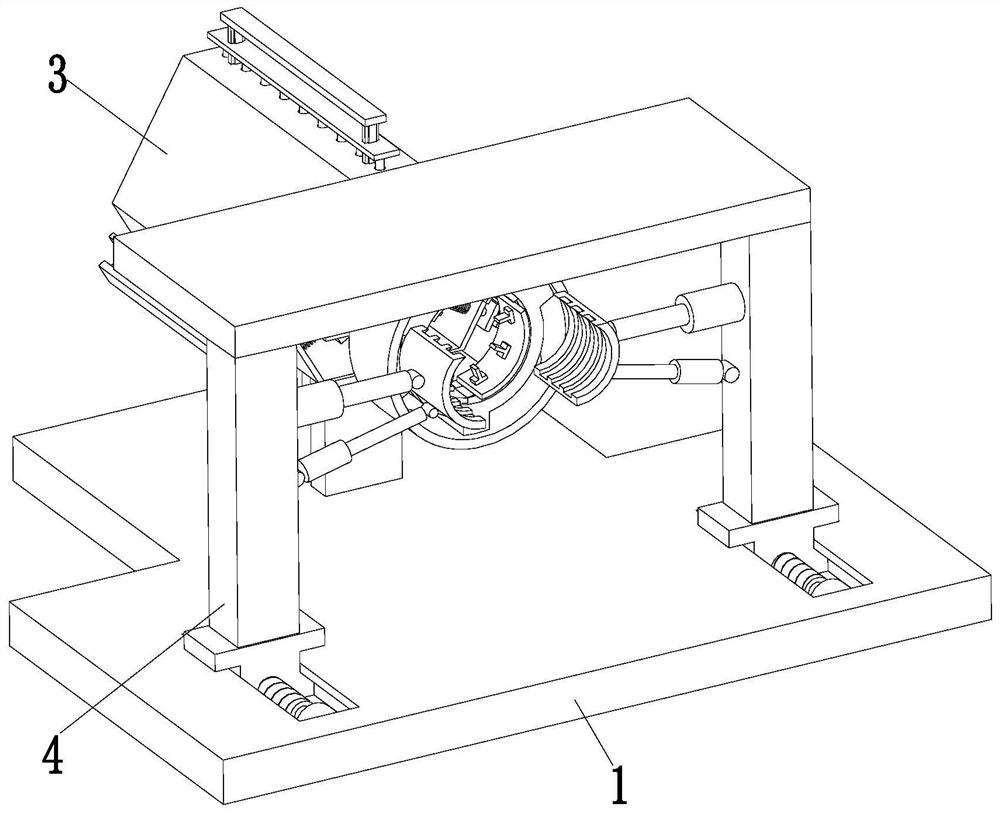

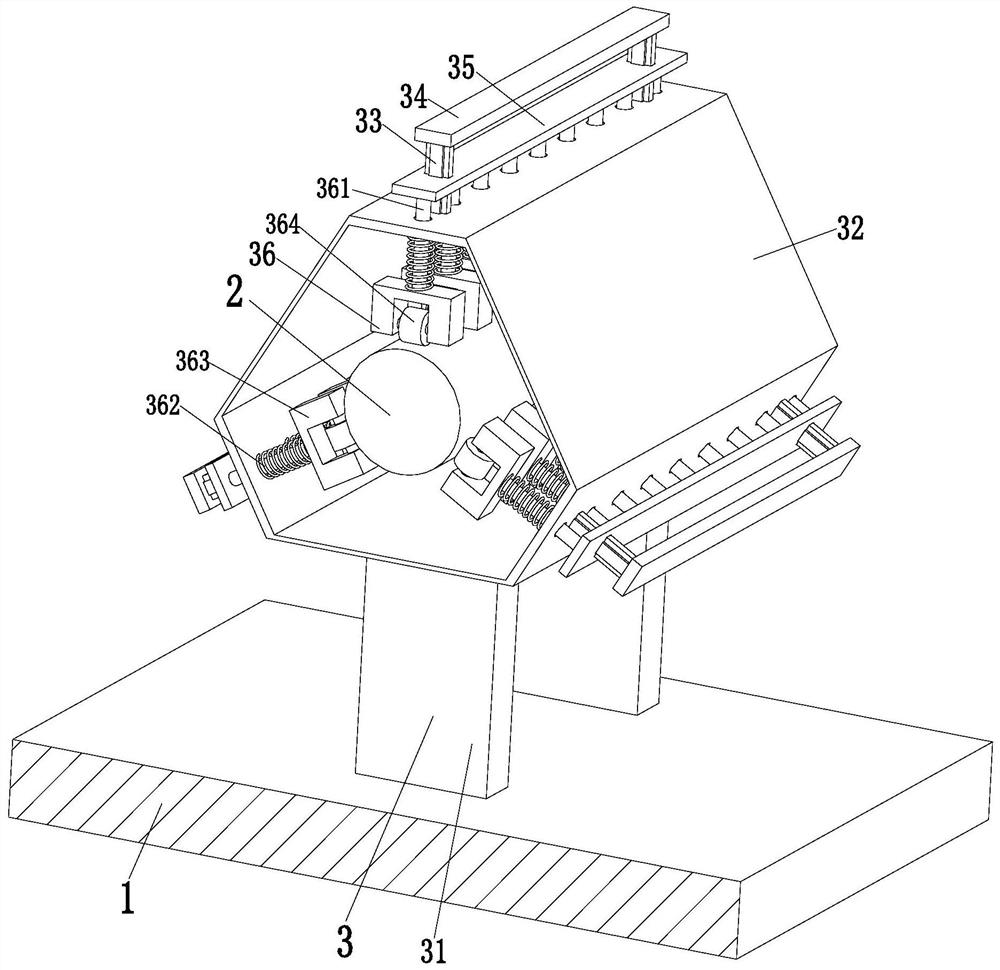

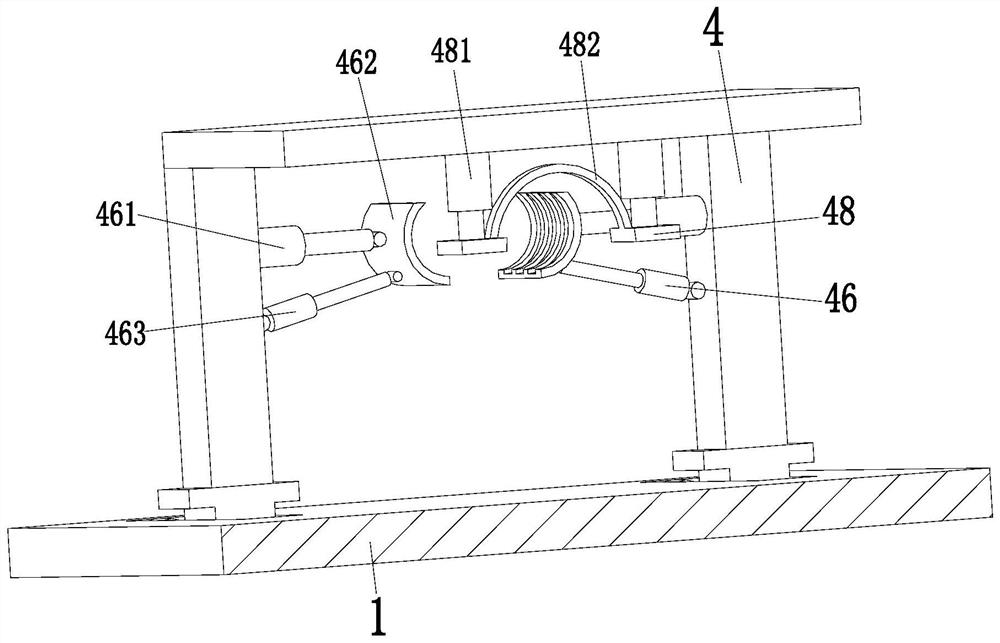

A moisture-proof high-quality filter rod production system and its production method

ActiveCN109619668BFunction to maintain suction resistanceSmooth cutTobacco smoke filtersFiberStructural engineering

The invention provides a moisture-proof high-quality filter rod making system and a making method thereof. The moisture-proof high-quality filter rod making system comprises a bottom plate, a filter rod, a conveying device and a cutting device. The problems can be solved that a, when a whole filter rod is cut, cuts are coarse, fiber filaments fall off, and as a result the quality of cigarettes isaffected; b, when the filter rod is cut, the filter rod needs to be fixed and is severely extruded during fixation, as a result, the smoking resistance of the cigarettes is increased, and smoking is affected; c, during cutting, seam breaking easily occurs, the filter rod is wrinkled, and the usage of the filter rod is affected; the cuts are flush, and the function of the smoking resistance of thefilter rod is kept; the moisture-proof high-quality filter rod making system has the advantages that the cuts are free of filament burrs, during cutting, there is no seam breaking, during cutting, there is no falling and wrinkling of fiber filaments, and the cuts are flush.

Owner:FUYANG CIGARATE MATERIAL FACTORY

Coated ceramic furnace tube leakage-proof device and detection method

PendingCN113028834ATemperature monitoringReal-time temperature detection and regulationFurnace typesElectric heating for furnacesTemperature monitoringThermocouple

The invention discloses a coated ceramic furnace tube leakage-proof device and a detection method. The device comprises a furnace body, a ceramic furnace tube is arranged in an inner cavity of the furnace body, an inner jacket plate is arranged on the surface of the ceramic furnace tube, a heating wire is arranged on the surface of the inner jacket plate, and an outer jacket plate is arranged on the surface of the heating wire. Through cooperative use of the furnace body, the ceramic furnace tube, the inner jacket plate, the heating wire, the outer jacket plate, a thermocouple and a conductive bolt, safety protection can be performed on the ceramic furnace tube, the temperature of the ceramic furnace tube can be detected and regulated in real time, and the problems that an existing ceramic furnace tube is generally used for heating and melting materials, but in the using process, the temperature of the ceramic furnace tube cannot be effectively monitored, the temperature of the ceramic furnace tube is too high to cause explosion, and meanwhile the protection effect is low are solved, and the coated ceramic furnace tube leakage-proof device and the detection method have the advantages of high safety and temperature monitoring and are worthy of popularization.

Owner:南京利卡维智能科技有限公司

Precision glass cutting-table tool bit assembly

InactiveCN101423326BImprove slitting accuracyThere will be no bursting phenomenonGlass severing apparatusEngineeringScrew thread

Owner:ANHUI JINGLING GLASS MACHINERY

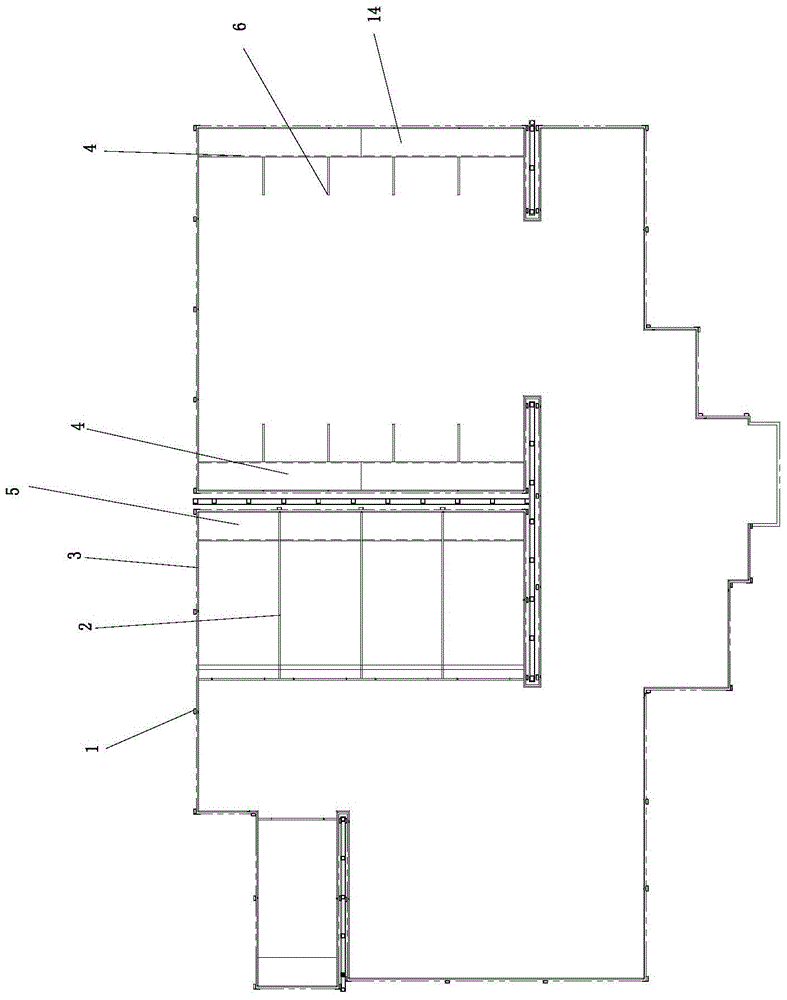

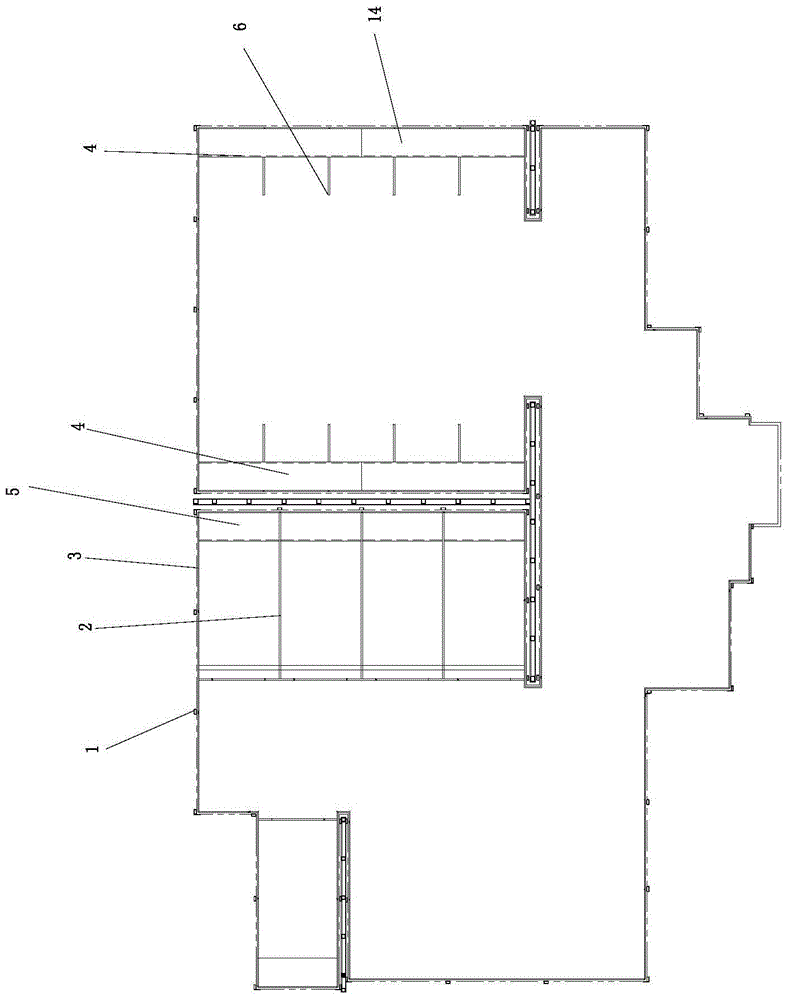

Novel industrial combined toilet

The invention belongs to a special building, and particularly relates to a novel industrial combined toilet which is arranged in a high-rise building. The novel industrial combined toilet comprises framework which is fixedly connected with a wall, and wallboards hung on the framework; the wallboards are connected with potty room partition plate units and urinal partition plate units; each potty room partition plate unit comprises a plurality of T-shaped partition plates which are vertically arranged on the ground; the lower ends of the T-shaped partition plates are fixed to the ground through brackets; the strip-shaped edges of the T-shaped partition plates are inserted into the wallboards; a mechanism for shielding and sealing a pedestal pan is arranged between every two adjacent T-shaped partition plates; each urinal partition plate unit comprises a connecting cross beam of which the two ends are fixed to a wall body; a baffle edge is hung on each connecting cross beam; the surface of each baffle edge extends outwards; a plurality of partition plates are uniformly distributed on the surface of each baffle edge; a urinal cover plate is arranged on the top of each baffle edge. The invention discloses the novel industrial combined toilet which facilitates industrial production and is conveniently assembled on the high-rise building; moreover, the novel industrial combined toilet is environment-friendly and attractive, and has high durability.

Owner:江苏丰顺新材料科技有限公司

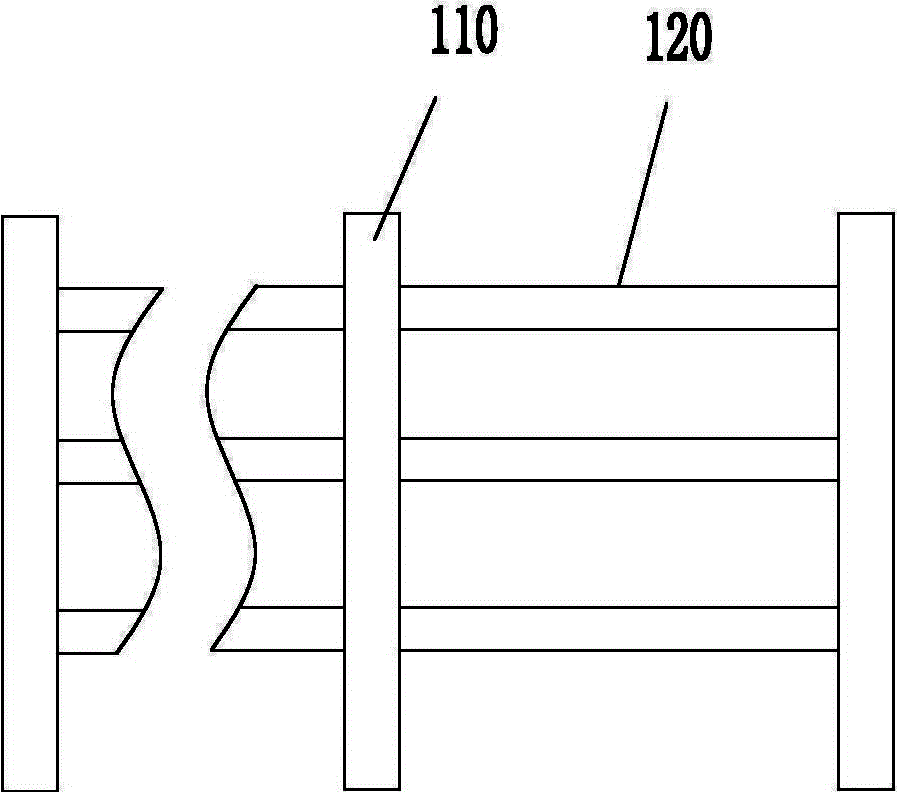

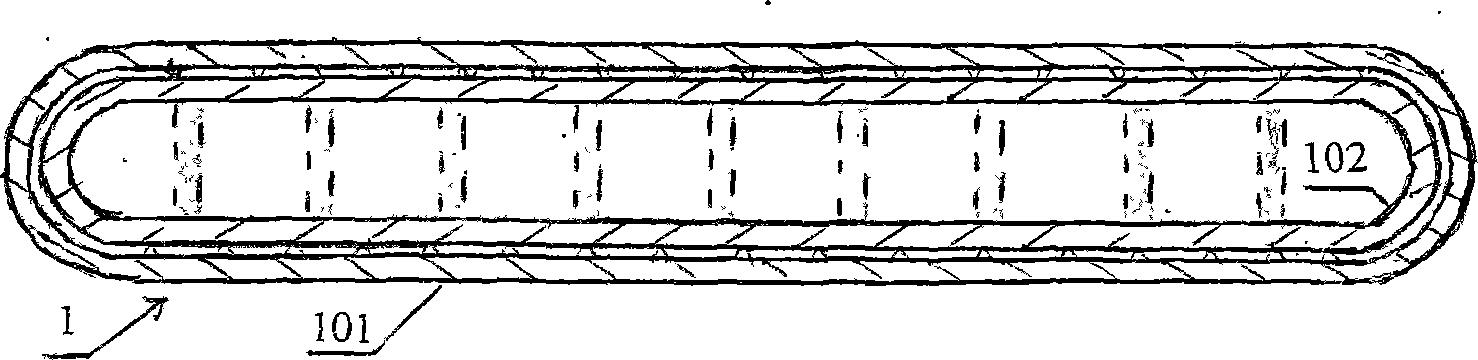

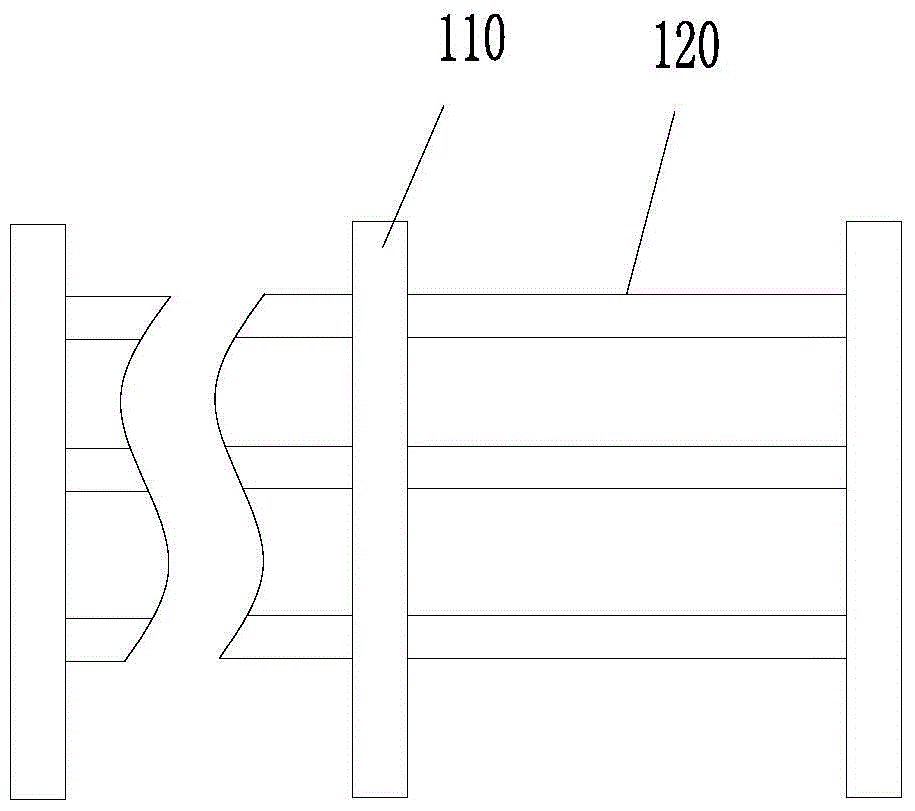

Wall-mounted solar water heater and manufacturing method of solar heat accumulator

ActiveCN102607192APrevent freezingThere will be no bursting phenomenonSolar heating energySolar heat devicesFlat glassSolar water

The invention discloses a wall-mounted solar water heater. The outer surface of an inner glass tank of a glass-panel solar heat accumulator is flat and smooth, many isometric conical projections are uniformly distributed on the front panel of an outer glass casing and the inner surface of a back panel to be used as supporting points, and the inner glass tank is surrounded inside the outer glass casing. A metal heat absorbing film is plated on the front panel of the inner glass tank of the glass-panel solar heat accumulator and the inner surface of the back panel, and the lateral side of the glass-panel solar heat accumulator is provided with a water inlet and a water outlet. After air in the outer glass casing and the inner glass tank is sucked out, the conical projections on the front panel of the outer glass casing and the inner surface of the back panel press on the outer surfaces of the front panel and the back panel of the inner glass tank respectively. The lateral sides of the inner glass tank and the outer glass casing are semi-arc glass plates and no supporting points are located between the inner glass tank and the outer glass casing, so that the inner glass tank has a displacement space. Further, the solar heat accumulator and a water tank can be protected from being damaged by expansion during freezing due to the fact that a safety valve or anti-explosion rubber pipe are mounted on the non-bearing heat accumulator and the water tank.

Owner:张英华

Wall-mounted solar water heater and manufacturing method of solar heat accumulator

ActiveCN102607192BPrevent freezingThere will be no bursting phenomenonSolar heating energySolar heat devicesFlat glassSolar water

The invention discloses a wall-mounted solar water heater. The outer surface of an inner glass tank of a glass-panel solar heat accumulator is flat and smooth, many isometric conical projections are uniformly distributed on the front panel of an outer glass casing and the inner surface of a back panel to be used as supporting points, and the inner glass tank is surrounded inside the outer glass casing. A metal heat absorbing film is plated on the front panel of the inner glass tank of the glass-panel solar heat accumulator and the inner surface of the back panel, and the lateral side of the glass-panel solar heat accumulator is provided with a water inlet and a water outlet. After air in the outer glass casing and the inner glass tank is sucked out, the conical projections on the front panel of the outer glass casing and the inner surface of the back panel press on the outer surfaces of the front panel and the back panel of the inner glass tank respectively. The lateral sides of the inner glass tank and the outer glass casing are semi-arc glass plates and no supporting points are located between the inner glass tank and the outer glass casing, so that the inner glass tank has a displacement space. Further, the solar heat accumulator and a water tank can be protected from being damaged by expansion during freezing due to the fact that a safety valve or anti-explosion rubber pipe are mounted on the non-bearing heat accumulator and the water tank.

Owner:张英华

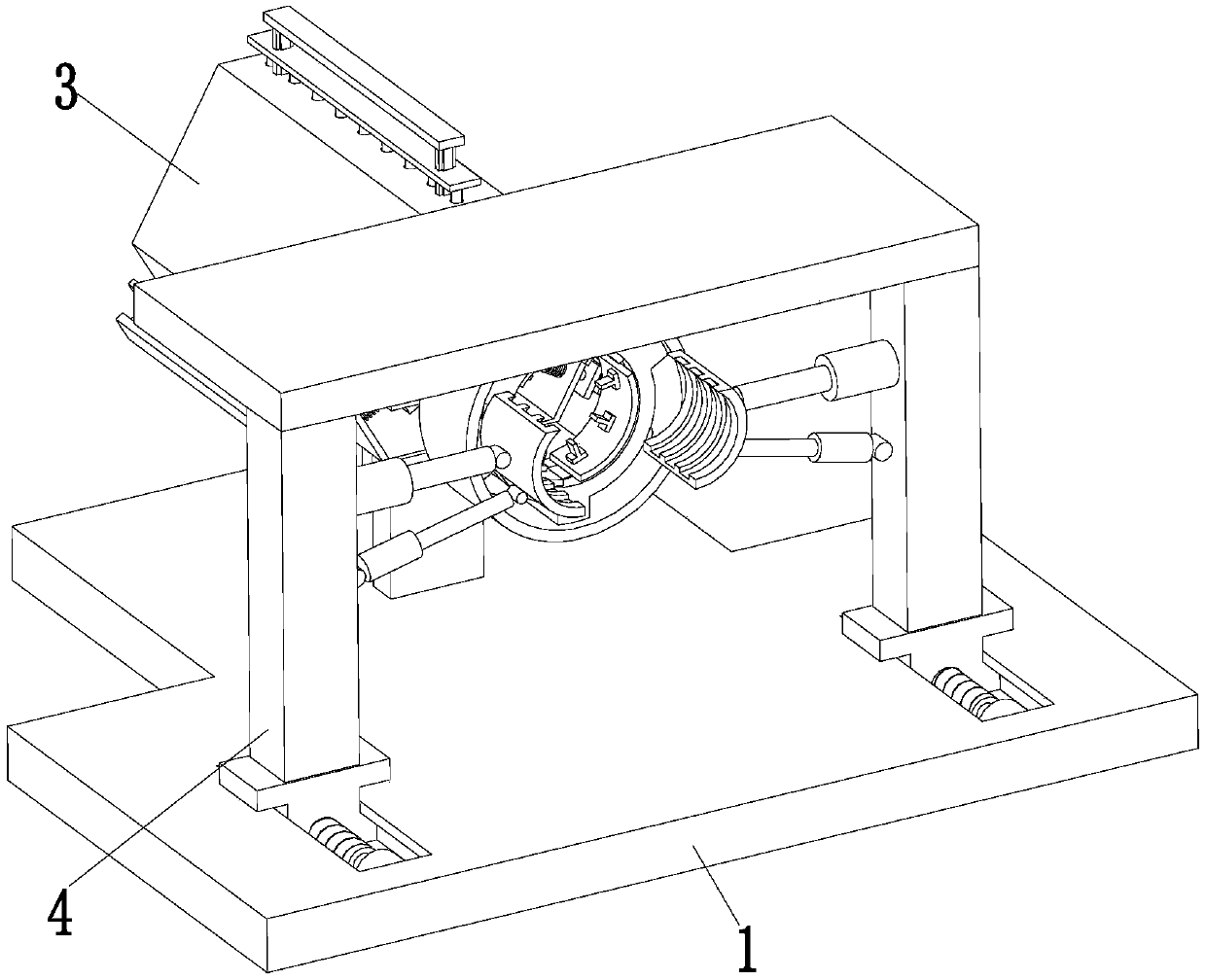

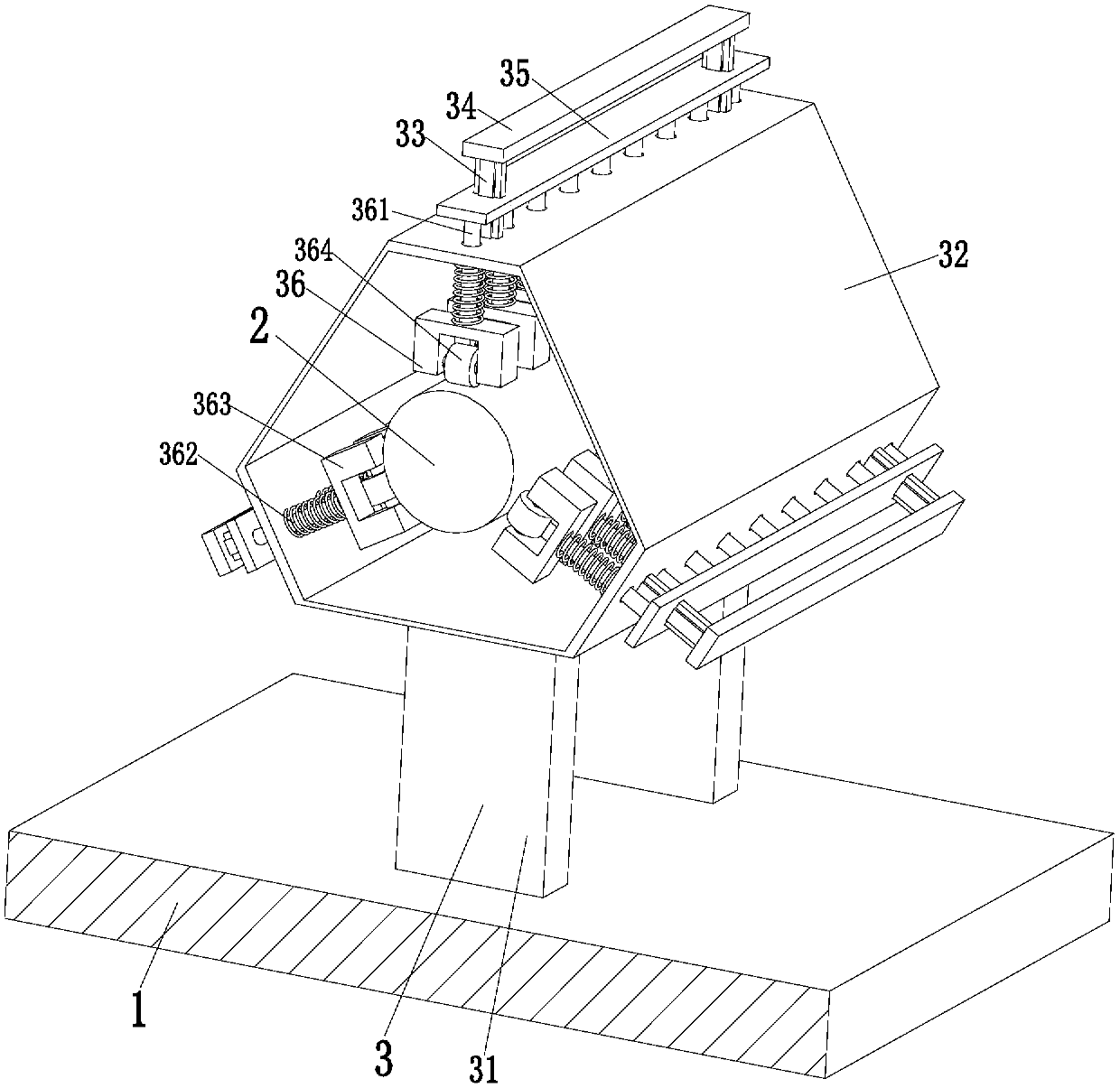

Punching method and equipment for scorched wild jujube

InactiveCN114868821AThere will be no bursting phenomenonLow technical requirementsTea substituesFood treatmentEngineeringMechanical engineering

The invention belongs to the technical field of food processing, and discloses a coked wild jujube punching method which comprises the following specific operation steps: S1, wild jujubes subjected to size screening are put into a hopper, and the bottommost layer of wild jujubes fall into a material carrying box in a material carrying chain plate structure; s2, when the wild jujube falls into a hole in a material carrying box, the magnetic balance of the material carrying box structure is broken, the upper half part structure of the fine adjustment support rod structure is influenced by gravity to centralize the wild jujube, so that the wild jujube and the center of a positioning hole are located at the coaxial position, and a gravity type position fine adjustment support rod is arranged in the positioning hole; and the horizontal position center of the wild jujube is adjusted to be coaxial with the vertical direction of the center of the positioning hole. Compared with the prior art, the perforated coked wild jujube does not burst in the drying and baking steps, the temperature rising speed does not need to be strictly controlled, the operation technical requirement is lowered, the drying time is shortened to 13 hours from original 37 hours, and a large amount of energy is saved.

Owner:张磊

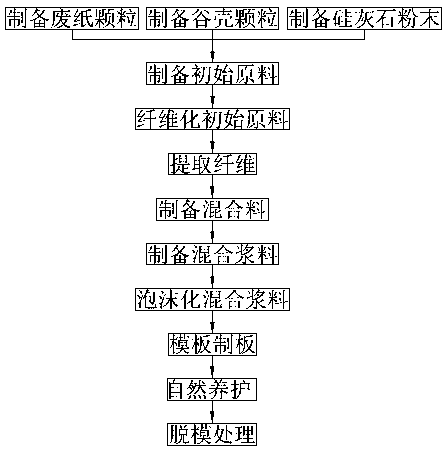

A kind of preparation method of foam board filler

The invention relates to preparation methods of materials used in the building field, in particular to a preparation method of foamed sheet filler. Waste paper and chaff are used as raw materials, short fibers in the waste paper and chaff and lignin in the chaff are extracted, and the obtained filler is light in mass, good in breathability and free of a rupture phenomenon. In addition, after wollastonite is added, the impact resistance, the anti-bending strength and abrasive resistance of prepared sheets can be greatly improved, and resources are saved. No environmental pollution can be caused after sheets made through the preparation method are abandoned. The preparation method has high practical value.

Owner:四川明誉防水工程有限公司

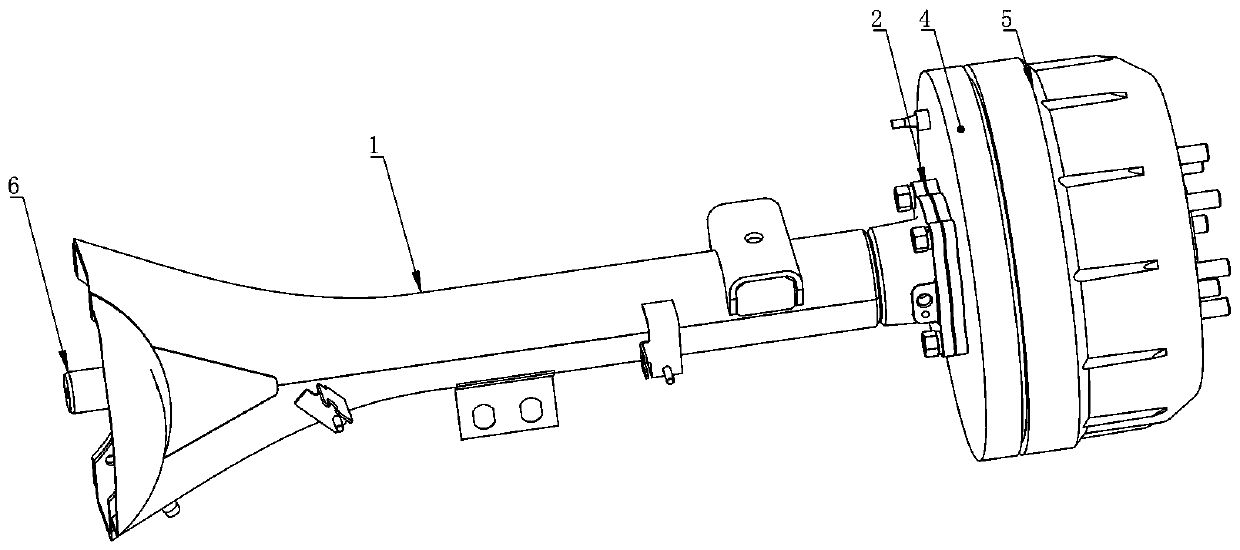

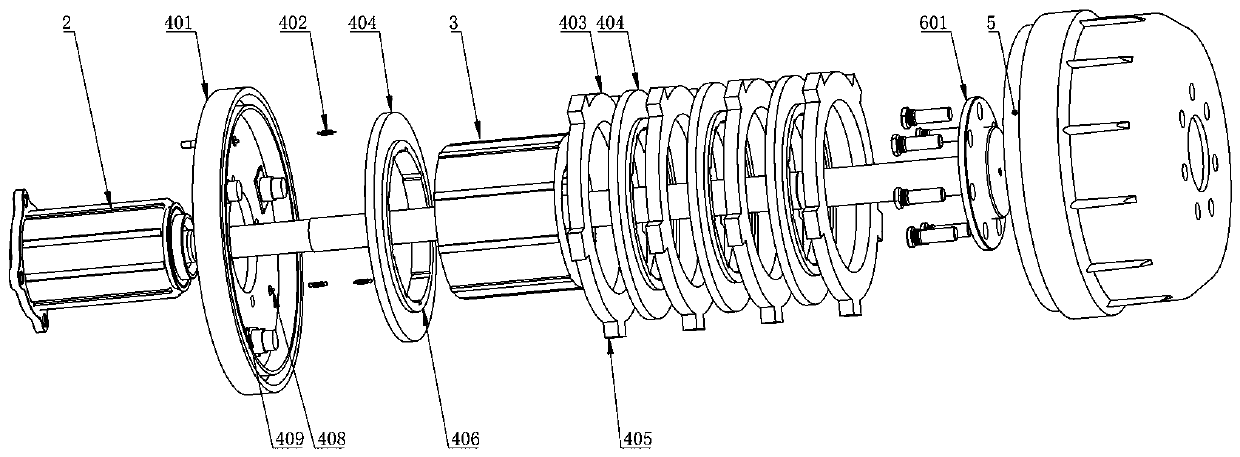

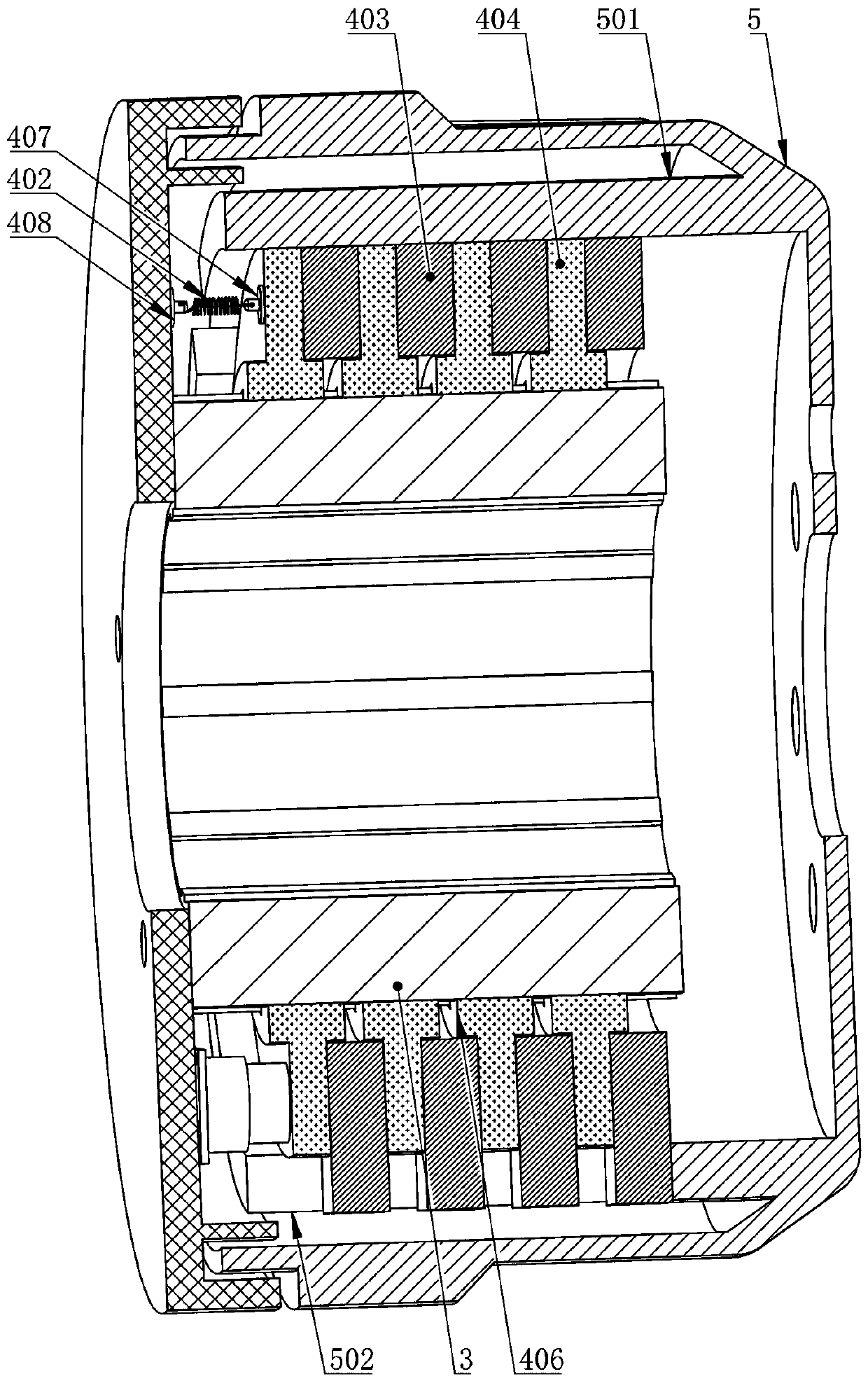

Automobile brake drum with heat resistance and wear resistance

InactiveCN109854644ASolve the problem of small heat dissipation area and poor heat dissipation effectLarge braking areaBraking drumsActuatorsHydraulic cylinderFriction effect

The invention relates to the technical field of brake drums, in particular to an automobile brake drum with heat resistance and wear resistance. The automobile brake drum comprises an axial multi-distance-piece brake device. In the braking process, a hydraulic cylinder pushes a brake pad at the left end to move towards the right side, therefore, multiple brake pads and arresters are pressed together, braking is achieved under the mutual friction effect of the brake pads and the arresters, friction force between each brake pad and the corresponding arrester can be used as brake resistance, thebrake area is large, the brake effect is good, and the problems that acting brake of the outer surface of a brake shoe and the inner surface of a brake drum of a traditional drum brake is small in brake area and not ideal in brake effect are solved. When the hydraulic cylinder is retracted, the brake pads and the arresters are separated under the effect of a reset tension spring, the brake state is removed, multi-face isolation heat dissipation is achieved by the brake pads and the arresters, the heat dissipation area is large, the heat dissipation effect is good, the problems that a traditional brake drum is small in heat dissipation area and poor in heat dissipation effect are solved, brake heat and brake wear are concentrated on the brake pads and the arresters, and the wear and cracking phenomena of the brake drum are avoided.

Owner:河北百龙汽车配件股份有限公司

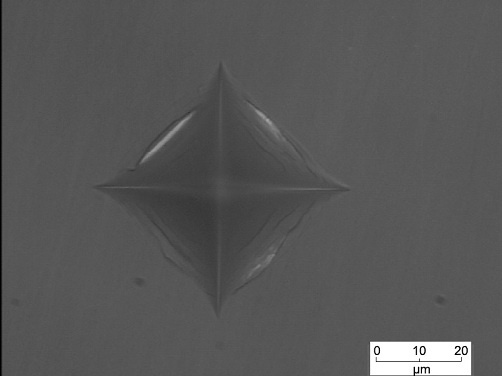

A kind of manufacturing method of glass for glaze carving porcelain

ActiveCN111186985BThere will be no bursting phenomenonRich layered engravingGlass blowing apparatusBlow moldingCrack resistance

The invention relates to the technical field of new glass materials, and in particular discloses a method for manufacturing colored glaze for glazed porcelain. The manufacturing method of colored glaze for glaze carving porcelain is to melt and homogenize bright material, white material and color material in a kiln respectively; flow to the working part through the forehearth, and cool down to make it suitable for blowing; Secondary material blow molding process, the formed colored glaze has three layers from the inside to the outside, of which the first layer is the clear material layer, the second layer is the white material layer, and the third layer is the color material layer; the obtained colored glaze products Put it into an annealing kiln for annealing, and then cool with the furnace to obtain the product. The present invention can obtain a larger molar volume by adjusting the composition and relative content of the glass, thereby improving its crack resistance, and at the same time, the hardness of the surface glass will not be significantly increased, that is, the difficulty of glaze carving will not be increased.

Owner:淄博市宝泉轻工制品有限公司 +1

A solar centralized hot water system with heat storage function

ActiveCN103697607BAchieve absorptionRealize comprehensive utilizationSolar heat devicesSolar thermal energy generationEngineeringCheck valve

The invention discloses a solar central water heating system with a heat accumulation function, which comprises a solar thermal collector array, a water tank, a collector circulating pump, a check valve, an electromagnetic valve and other parts. A heat accumulator filled with phase-change heat accumulation medium is arranged on the bottom in the water tank, and the interior of a heat accumulator core tube is a water passage. A heat accumulator water passage inlet is connected with the outlet of the solar thermal collector array, a heat accumulator outlet is directly open in the hot water storage tank, and the inlet of the solar thermal collector array is connected with the bottom of the hot water storage tank sequentially through the check valve and the collector circulating pump and connected with a tap water supply pipeline through the water-lifting electromagnetic valve. Both hot water heated by the solar thermal collectors and cold water replenished into the water tank first flow through the heat accumulator core tube and exchange heat with the heat accumulator. When the water temperature in the water tank is higher or lower than the phase change temperature of the heat accumulation medium in the heat accumulator, heat is released to the heat accumulator or heat is absorbed from the heat accumulator. By means of the heat absorption and release of the heat accumulator, energy consumption can be reduced, and solar radiation energy can be effectively utilized by the way of peak load shifting.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

Soybean protein casing colloid suitable for sausage coextrusion technology and preparation method thereof

Owner:山东冠华蛋白肠衣有限公司

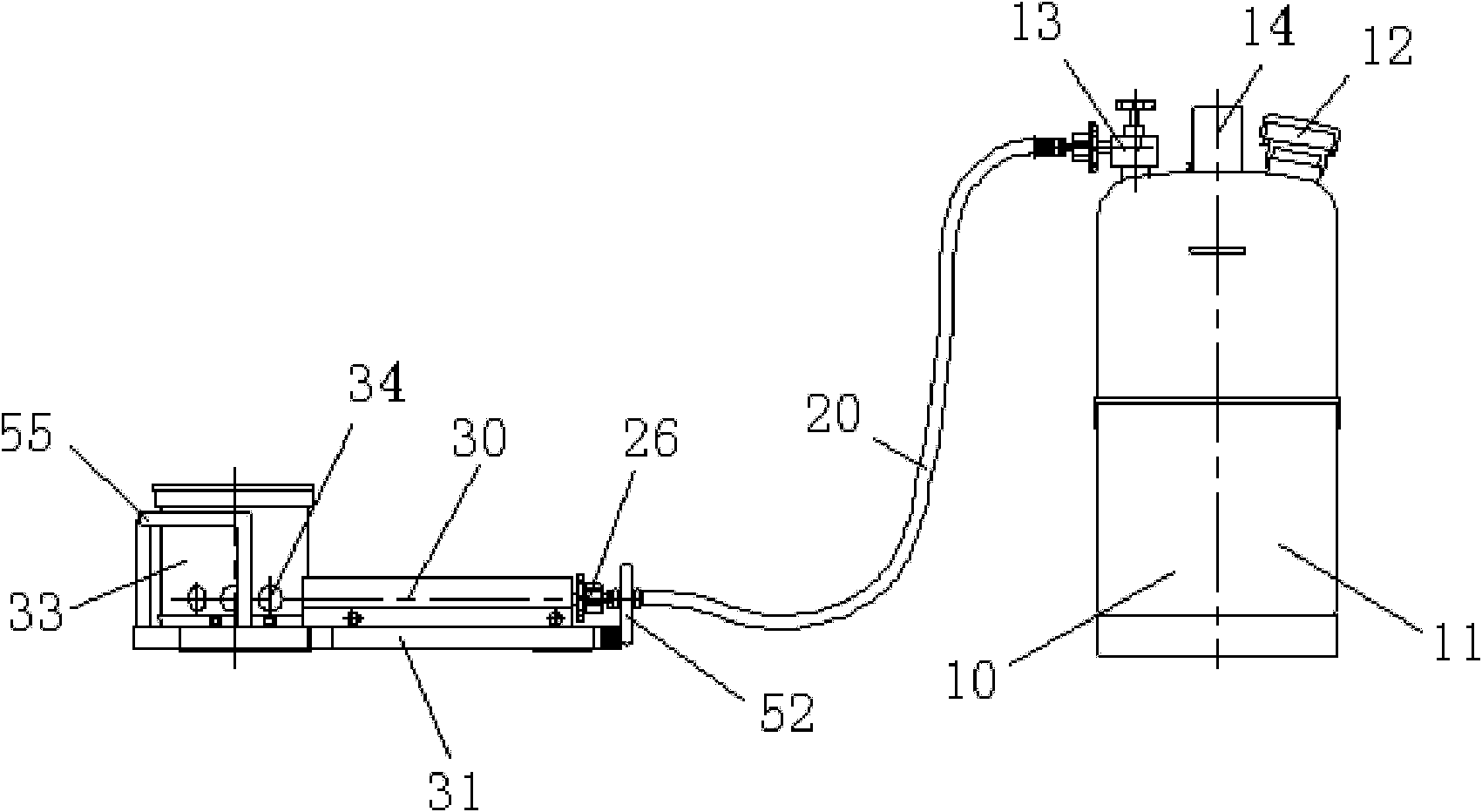

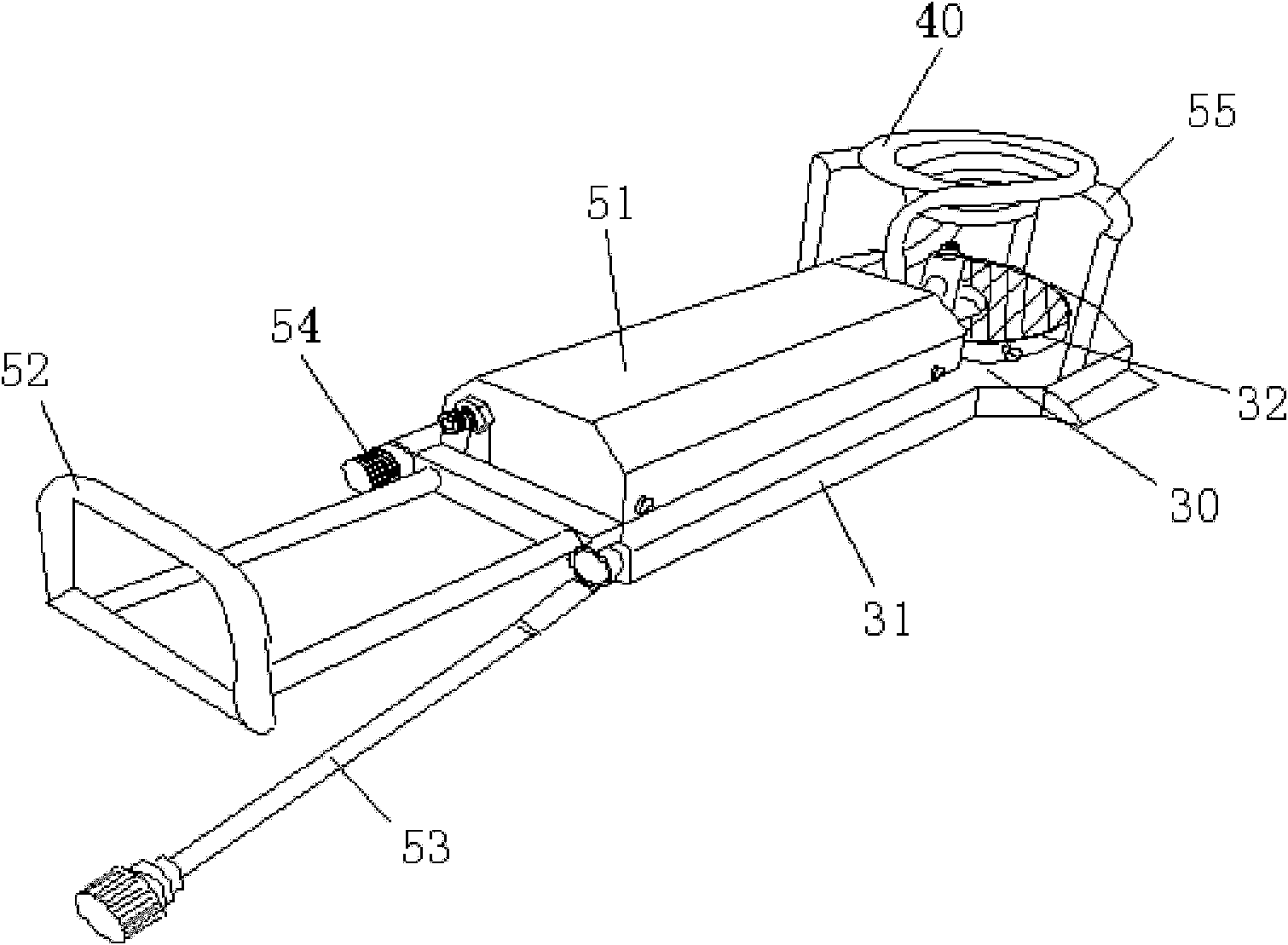

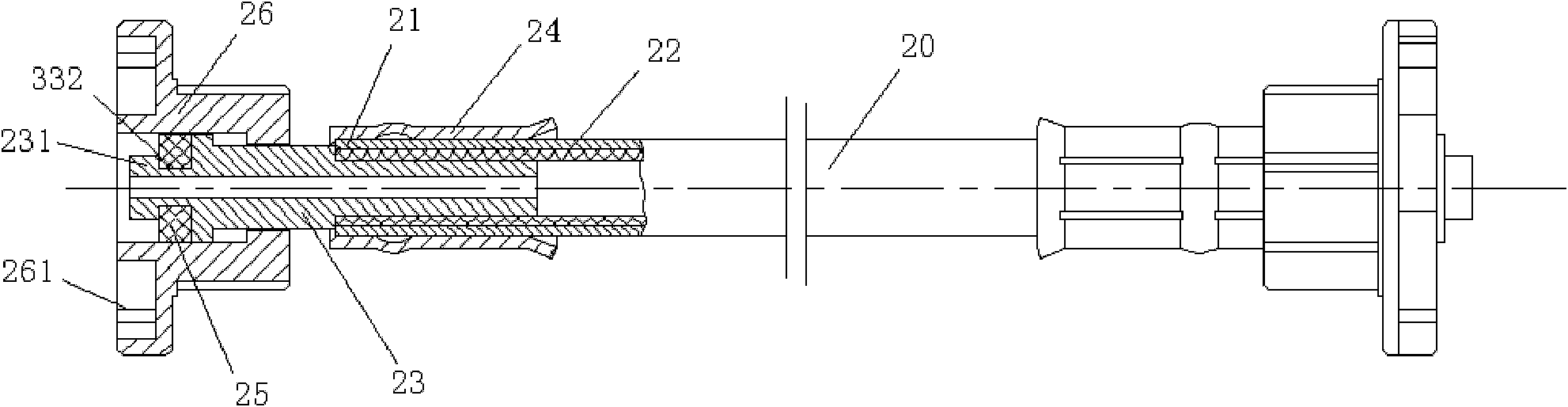

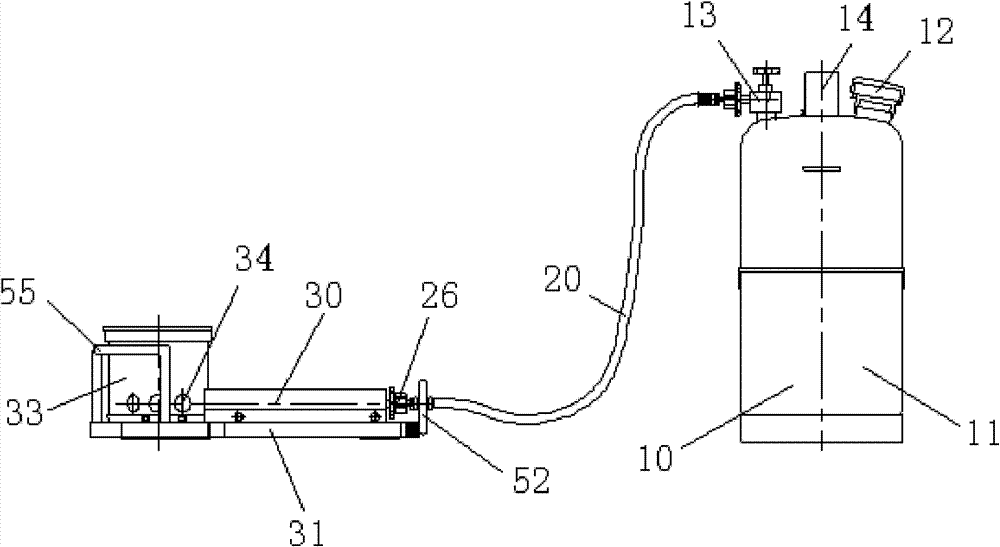

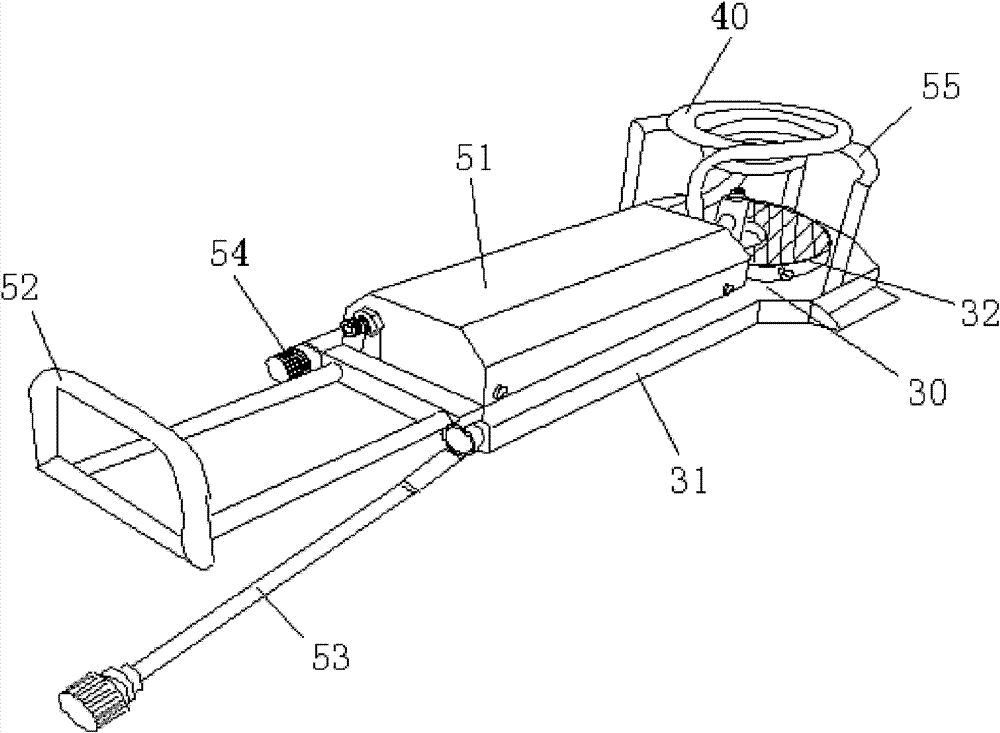

Field heat source generator

InactiveCN102109184AReduce pollutionBurn fullyDomestic stoves or rangesLiquid heating fuelVena contracta diameterNitrile rubber

The invention relates to a field heat source generator which is characterized in that an oil storage tank, an explosion proof oil pipeline, a heating furnace body, a preheating device and various accessories are included; the oil storage tank comprises an oil tank body, an oil inlet, an oil outlet valve and a gas-filling valve; the explosion proof oil pipeline comprises a nitrile rubber buna oil pipe, a stainless steel wire mesh pipe, a hoop, metal connecting sleeves and quick connect nuts, wherein one of the quick connect nuts is connected with the outlet valve of the oil storage tank; the heating furnace body comprises a metal base, an oil receiving plate, a fireproof hood, a disciform metal orifice plate and a fire distribution plate; the preheating device comprises a preheating pipe with the spiral rising body; and the inlet end of the preheating pipe is connected with the quick connect nut at the outlet end of the explosion proof oil pipeline; a valve body at the outlet end of the preheating pipe is connected with a spray nozzle through a connecting pipe; and the spray nozzle is arranged in the nozzle base and connected with the oil receiving plate. The field heat source generator has the advantages of simple structure, small volume, portability and convenience of use, and can be extensively used for various field cooking circumstances.

Owner:北京军适机械有限公司

Immersed tube grout pile construction process and pile tip bearing capacity reinforcement equipment

InactiveCN1240910CThere will be no bursting phenomenonProposed smoothlyBulkheads/pilesEngineeringImmersed tube

The invention is a sinking tube pouring picket constructing technique and picket-end bearing capacity enhancer, placing the enhancer at positioning point of the picket base; the picket machine takes its place to align the end of the steel sleeve with the enhancer; starting sinking the tube to the calculated position; pulling the rope linked with the enhancer to drive axial umbrella rod, so that the top cap relieves the inclined support from restriction, the fixed stop block drives the annular slide block to make the supporting link rod push and spread the inclined support around so as to shrink into the steel sleeve, and the active stop block drives the picket boot to take out the enhancer. Placing bar reinforcement cage in the steel sleeve; vibrantly pulling the tube while pouring the concrete, and forming a picket. It can enhance the penetrating property of the steel sleeve, extrude picket end soil body closely, heighten picket-end bearing capacity, reduce deposition quantity, heighten picket forming quality and constructing efficiency, etc.

Owner:北京中技天昊工程技术有限公司

Pipe pile construction method

The invention is a tubular pile constructing method and pile-end bearing capacity enhancer, placing the enhancer at positioning point of the picket base; the pile machine takes its place to align the end of the pile end with the enhancer; starting sinking the pile, and when the pile passes through bad earth layer or enters in pile-end force-bearing layer, temporarily stopping stinking pile; pulling the rope to drive axial umbrella rod, so that the top cap relieves the inclined support from restriction, the fixed stop block drives the annular slide block to make the supporting link rod push and spread the inclined support around so as to shrink into the pile, and the active stop block drives the pile boot to take out the enhancer; sinking the pile to the designed depth and the pile end squeezes compact earth to gush into the pile to form an earth stopper; pouring concrete in the pile to form an earth stopper cap, thus forming a pile. It can enhance the penetrating property of the pile, extrude pile end earth closely, heighten pile-end bearing capacity, reduce deposition quantity, heighten pile forming quality and constructing efficiency, etc

Owner:北京中技天昊工程技术有限公司

Industrial combined toilet

The invention belongs to a special building, and particularly relates to a novel industrial combined toilet which is arranged in a high-rise building. The novel industrial combined toilet comprises framework which is fixedly connected with a wall, and wallboards hung on the framework; the wallboards are connected with potty room partition plate units and urinal partition plate units; each potty room partition plate unit comprises a plurality of T-shaped partition plates which are vertically arranged on the ground; the lower ends of the T-shaped partition plates are fixed to the ground through brackets; the strip-shaped edges of the T-shaped partition plates are inserted into the wallboards; a mechanism for shielding and sealing a pedestal pan is arranged between every two adjacent T-shaped partition plates; each urinal partition plate unit comprises a connecting cross beam of which the two ends are fixed to a wall body; a baffle edge is hung on each connecting cross beam; the surface of each baffle edge extends outwards; a plurality of partition plates are uniformly distributed on the surface of each baffle edge; a urinal cover plate is arranged on the top of each baffle edge. The invention discloses the novel industrial combined toilet which facilitates industrial production and is conveniently assembled on the high-rise building; moreover, the novel industrial combined toilet is environment-friendly and attractive, and has high durability.

Owner:江苏丰顺新材料科技有限公司

Field heat source generator

InactiveCN102109184BReduce pollutionBurn fullyDomestic stoves or rangesLiquid heating fuelVena contracta diameterNitrile rubber

The invention relates to a field heat source generator which is characterized in that an oil storage tank, an explosion proof oil pipeline, a heating furnace body, a preheating device and various accessories are included; the oil storage tank comprises an oil tank body, an oil inlet, an oil outlet valve and a gas-filling valve; the explosion proof oil pipeline comprises a nitrile rubber buna oil pipe, a stainless steel wire mesh pipe, a hoop, metal connecting sleeves and quick connect nuts, wherein one of the quick connect nuts is connected with the outlet valve of the oil storage tank; the heating furnace body comprises a metal base, an oil receiving plate, a fireproof hood, a disciform metal orifice plate and a fire distribution plate; the preheating device comprises a preheating pipe with the spiral rising body; and the inlet end of the preheating pipe is connected with the quick connect nut at the outlet end of the explosion proof oil pipeline; a valve body at the outlet end of the preheating pipe is connected with a spray nozzle through a connecting pipe; and the spray nozzle is arranged in the nozzle base and connected with the oil receiving plate. The field heat source generator has the advantages of simple structure, small volume, portability and convenience of use, and can be extensively used for various field cooking circumstances.

Owner:北京军适机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com