Precision glass cutting-table tool bit assembly

A glass and table-cutting technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as easy existence of included angles, difficulty in keeping two vertical planes parallel, and edge bursting at the glass incision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by embodiment and accompanying drawing thereof:

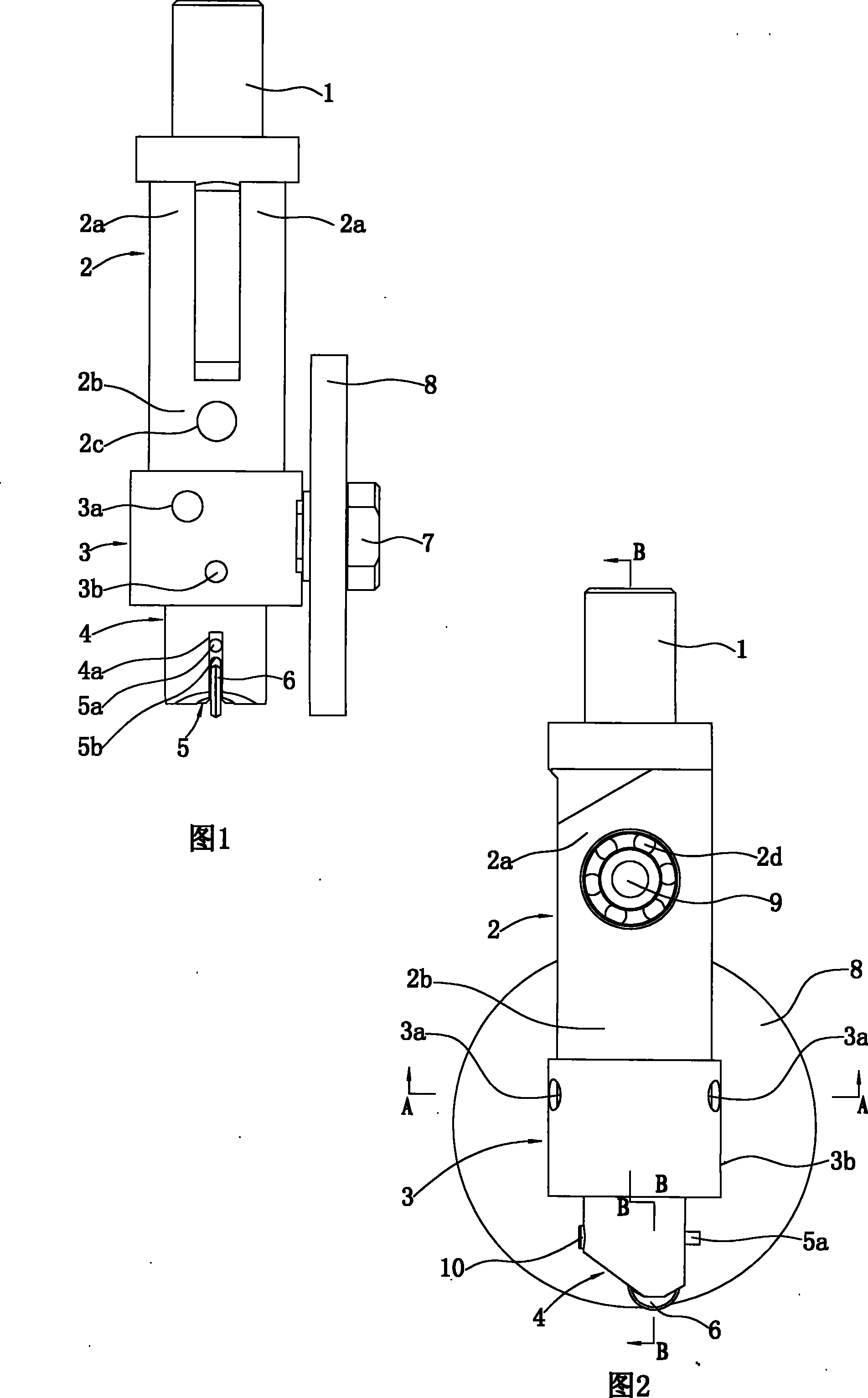

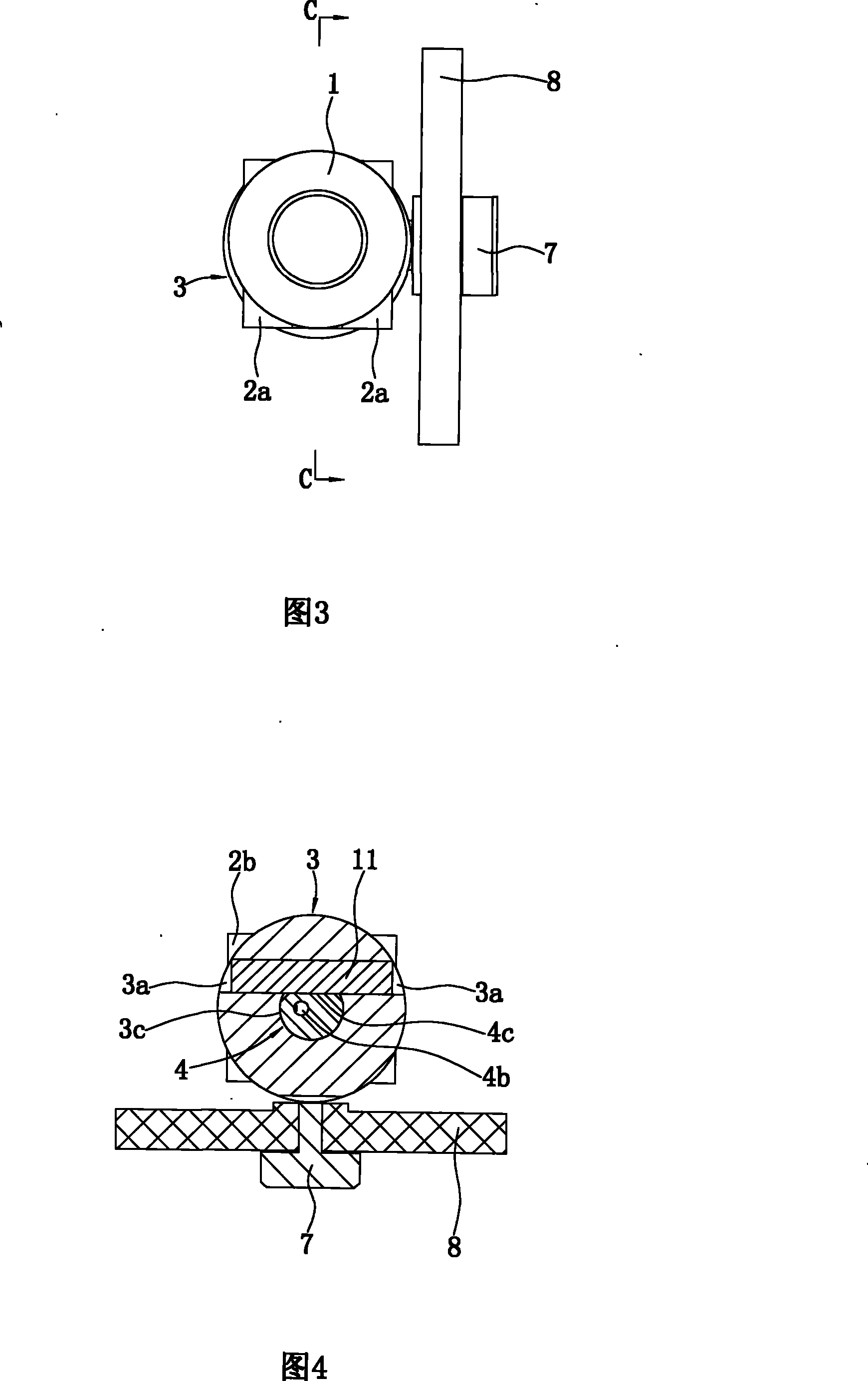

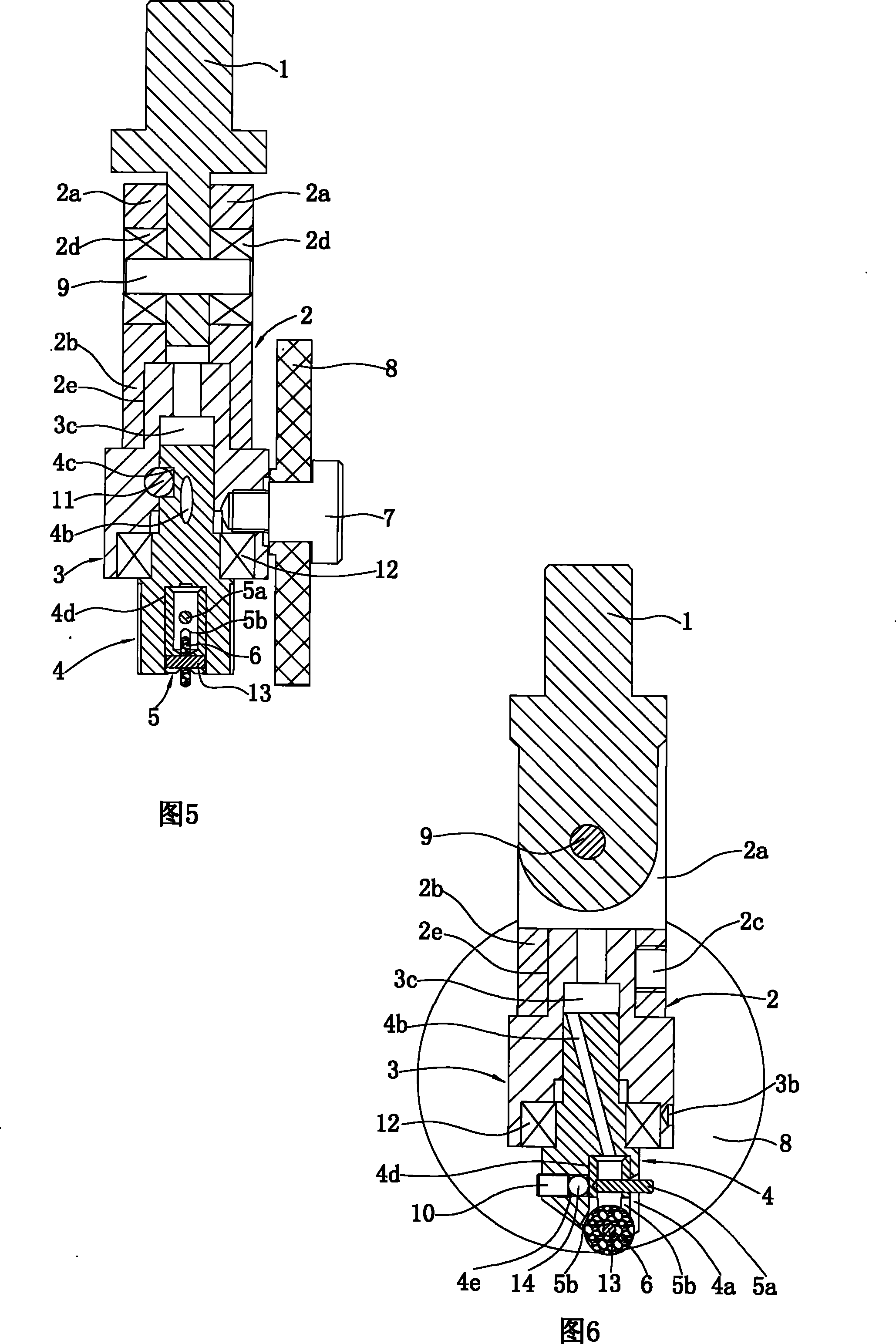

[0020] Referring to Fig. 1-Fig. 6, this precision glass cutting table cutter head assembly includes vertically arranged joint 1, pendulum block 2, fixed column 3, rotating column 4, nylon wheel 8, knife holder 5, knife wheel 6 and left and right horizontal The pin shaft 9, the screw 7, and the cutter wheel shaft 13 are arranged and the axes are parallel to each other.

[0021] The upper part of the pendulum block 2 is two left and right spaced and symmetrical ear plates 2a, and the lower part is a square block 2b. A vertically arranged bearing 2d is installed in each ear plate 2a. The center of the square block 2b has a vertical through-hole 2e. , The front side has a threaded hole 2c communicating with the light hole 2e.

[0022] There is a stepped hole 3c which runs up and down and has a circular cross-section in the fixed column 3. A bearing 12 is horizontally ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com