Automatic paperboard slitting device for carton processing

A cardboard and carton technology, which is applied to the field of automatic cardboard slitting devices for carton processing, can solve the problems of cardboard slitting damage, easy degradation of the sharpness of slitting blades, and increased cost consumption, so as to improve the slitting accuracy and reduce the scrap rate. , convenient grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

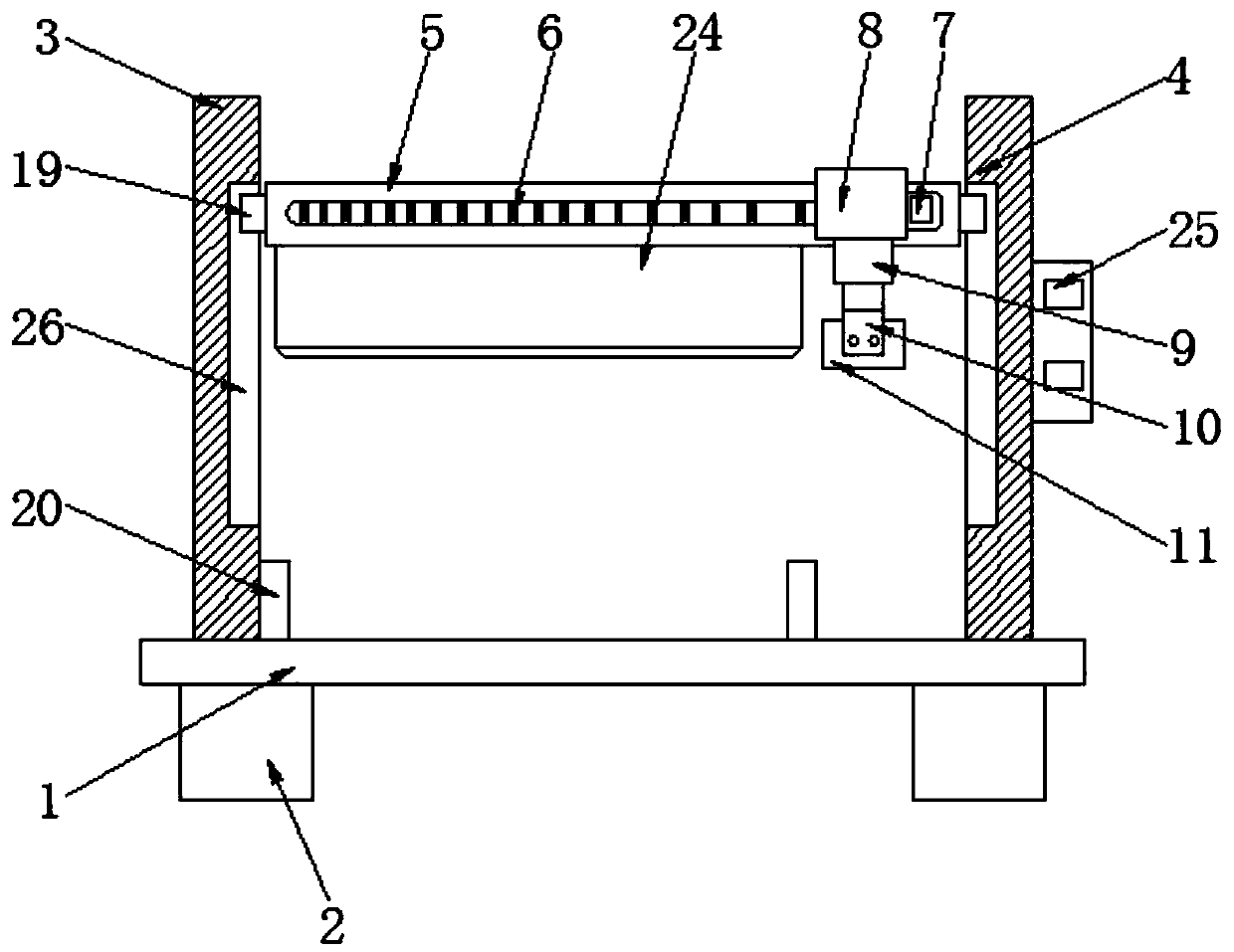

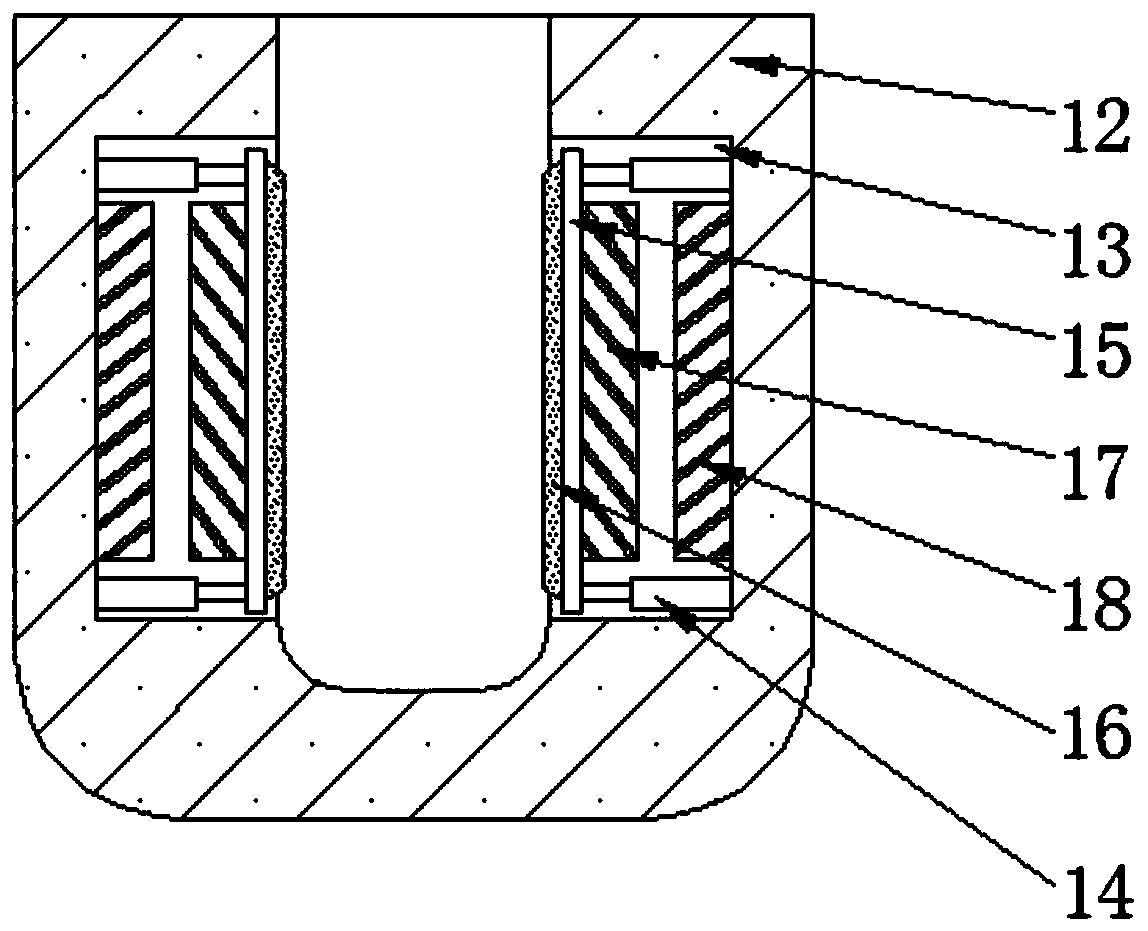

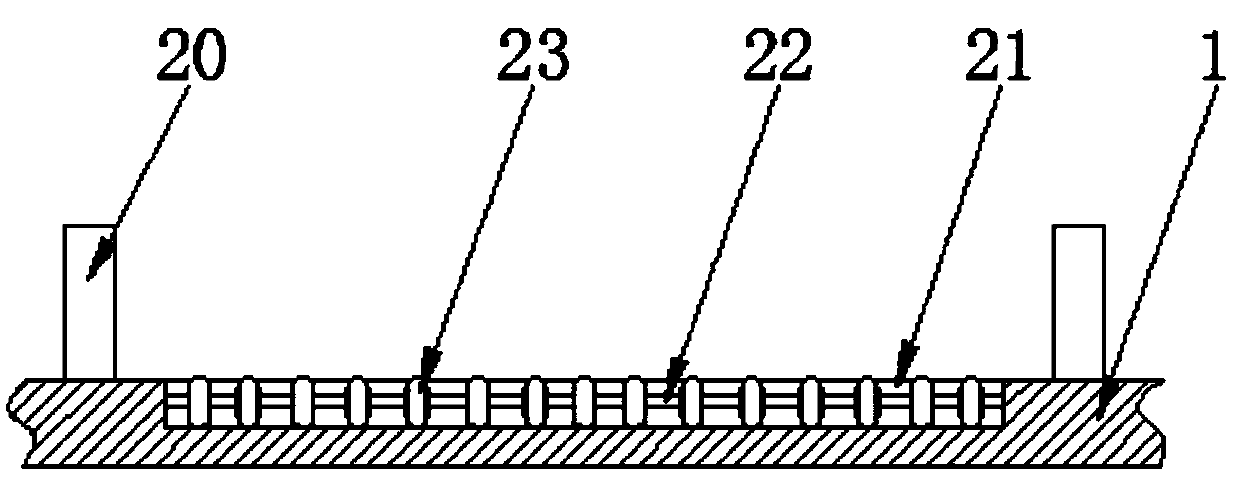

[0020] An automatic cardboard cutting device for carton processing, comprising a base 1 and supporting legs 2, both sides of the top of the base 1 are fixedly connected with limiting plates 20, the distance between the two limiting plates 20 is the width of the cardboard, the cardboard The two sides of the base 1 are in contact with the opposite sides of the two limiting plates 20, and the top of the base 1 is opened in the second chute 21, and the two sides of the second chute 21 are connected with a rotating rod 22 in rotation, and the surface of the rotating rod 22 A runner 23 is fixedly connected, the top of the runner 23 is 0.5cm higher than the top of the base 1, both sides of the bottom of the base 1 are fixedly connected with the top of the support leg 2, and the two sides of the top of the base 1 are respectively fixedly connected with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com